Page 1

9.17, 917si Treadmill

Page 1

9.17, 9.17si Treadmill

Warning: This service manual is for use by Precor trained service providers only.

If you are not a Precor Trained Servicer, you must not attempt to service any Precor Product;

Call your dealer for service.

This document contains information required to perform the majority of troubleshooting, and

replacement procedures required to repair and maintain this product.

This document contains general product information, software diagnostic procedures (when

available), preventative maintenance procedures, inspection and adjustment procedures,

troubleshooting procedures, replacement procedures and electrical block and wiring diagrams.

To move directly to a procedure, click the appropriate procedure in the bookmark section to the

left of this page. You may “drag” the separator bar between this page and the bookmark section

to change the size of the page being viewed.

© 2003 Precor Incorporated

Unauthorized Reproduction and Distribution Prohibited By Law

.

Page 2

917, 917si Treadmillr

Page 2

Section One - Things You Should Know

About This Appendix

Section One, Things You Should Know. This section includes technical specifications and a

procedure matrix. Read this section, as well as the 917, 917si Treadmill Owner’s Manual, before

you perform the maintenance procedures in this manual.

Section Two, Software Features. Precor’s 917si Treadmill is programmed with several

diagnostic and setup features. This section contains the procedures you need to access the

diagnostic features on this treadmill.

Section Three, Checking Treadmill Operation. This section provides you with a quick way of

checking treadmill operation. Check treadmill operation at the end of a maintenance procedure

and when it is necessary to ensure that the treadmill is operating properly.

Section Four, Inspection and Adjustment Procedures. Perform inspection procedures when

a trouble symptom points to a particular problem and after removing and replacing major

components. Many maintenance problems can be fixed by adjusting various treadmill

components. This section also provides you with the step-by-step procedures required to make

these adjustments.

Section Five, Troubleshooting Procedures. The diagnostic and troubleshooting procedures

contained in this section should be performed when it is necessary to isolate a problem to a

particular component.

Section Six, Replacement Procedures. When a treadmill component must be replaced, go to

this section and follow the step-by-step procedures required to remove and replace the

component.

Section Seven, Wiring and Block Diagrams. This section includes wiring and block diagrams

for 917 and 917si Treadmill.

General Information

For the latest exploded view, part number and part pricing information, visit the Precor dealer

website at “www.precor.com/Dealer”.

Page 3

9.17, 917si Treadmill

Page 3

Technical Specifications

PHYSICAL SPECIFICATIONS

Length: 60 inches (152 cm)

Width: 28 inches (71 cm)

Height: 48 inches (122 cm)

Running surface: 18 X 54 inches (46 X 137 cm)

Motor: 2.0 hp continuous duty

Speed: 1.0 to 10 mph (1.6 to 16 kph)

10 mph is equivalent to a 6 minute mile

Incline: 0 to 10% grade

Power: 120 Vac, 50/60 Hz

240 Vac, 50/60 Hz

Weight: 150 lbs (68 kg)

Shipping weight: 160bs (75.6 kg)

ELECTRONIC SPECIFICATIONS

917 Programs:

Manual

917Si Programs:

Manual

Interval

Weight Loss

6 Pre-programmed courses (3 Walk, 3 Run)

2 Custom courses

Random

Heart Rate Course

Options

Polar Heart Rate System

Handrails

Page 4

917, 917si Treadmillr

Page 4

Procedure 2.1 - Accessing the Diagnostic Program

(917si only)

The keys on the display are hypothetically numbered for 1 to 7 from left to right. Therefore,

INCLINE

▲ would be key 1, INCLINE ▼ would be key 2, etc.

Placing the unit in the diagnostic mode causes the software to perform the following operations:

a. Test the LED’s mounted on the upper PCA;

b. Provide the option of calibrating the lift system;

c. Display the drive motor power bits;

d. Test the keyboard;

e. Display and test the heart rate function;

1. Plug the power cord into the wall outlet, then turn on the treadmill with the circuit breaker.

2. Press keys RESET,5,1,7,6,5,7,6,1, sequentially.

3. All of the LED’s on the display will light up. Any LED segment that is not lit is defective.

Press the SELECT key to continue.

4. After the LED test, the electronic console displays the potentiometer increment number.

5. Verify that the running bed inclines and declines as the INCLINE

▲ or INCLINE ▼ keys are

pressed.

6. When the potentiometer increment number is displayed on the electronic console, the

potentiometer increment number will track the incline as it is operated. Press the SELECT

key to continue.

7. The power bit number will be displayed.

Note:

When the running belt is started, the number of power bits will be displayed. Power bits represent

the amount of power applied to the drive motor. Power bits are the product of selected speed and

applied load.

8. Press the SPEED ▲ or SPEED ▼ key. Verify that the power bits number increments and

decrements as the SPEED keys are pressed. The Select key will toggle the display

between the power bit reading and a mile (or kilometer) per hour reading.

9. Press the STOP key to exit the power bits mode.

Page 5

9.17, 917si Treadmill

Page 5

10. A series of dots will appear on the display. Press each of the keys on the keyboard, the

appropriate dot will expand to indicate that the key is functioning. Press and hold the STOP

key to continue.

11. If the heart rate option has been installed, you may test the heart rate function using a chest

strap transmitter or test transmitter. Press the “SELECT to select U, F, or P heart rate mode.

U is unfiltered mode , F is filtered mode and P is Polar mode. The unfiltered mode will display

an unmodified heart rate directly from the heart rate transmitter, the filtered mode will

display the heart rate averaged over a short period of time and the Polar mode will utilize a

Polar filtering system.

12. Press the STOP key to exit the diagnostics program.

Diagram 2.1 - 917si Display

Key 1 Key 2 Key 3

RESET Key 5

Key 6 Key 7

Page 6

917, 917si Treadmillr

Page 6

Procedure 2.2 - Displaying the Odometer

(917si only)

The keys on the display are hypothetically numbered for 1 to 7 from left to right. Therefore,

INCLINE

▲ would be key 1, INCLINE ▼ would be key 2, etc.

This procedure allows you to display the number of miles or kilometers logged on the treadmill.

Procedure

1. Plug the power cord into the wall outlet, then turn on the treadmill with the circuit breaker

2. Press keys RESET,6,5, sequentially.

3. The console displays the number of miles or kilometers logged on the treadmill. Press the

STOP key to continue.

4. The total number of hours the treadmill drive motor has been operating will be displayed.

Press the STOP key to continue.

5. The software version will be displayed. Press the STOP key to continue.

6. The error code log will be displayed. There may be up to ten error codes logged. The error

code and the odometer reading when the error occurred will be displayed. Use either

▲ to

move forward through the error code log position. Use either

▼ to backward through the

error code log.

7. If you no longer require the contents of the error code log for troubleshooting and wish to

clear the error code log, press the STOP and QUICK START keys, simultaneously.

8. Press the STOP to exit.

Page 7

9.17, 917si Treadmill

Page 7

Procedure 2.3 - Selecting United States Standard or Metric

Units (917si only)

The keys on the display are hypothetically numbered for 1 to 7 from left to right. Therefore,

INCLINE

▲ would be key 1, INCLINE ▼ would be key 2, etc.

Selecting United States standard units causes information to be displayed in feet, miles and

pounds. Information is displayed in meters, kilometers and kilograms if metric units are selected.

After you have selected a measurement standard, the software compiles and records workout

information in the units of the measurement standard selected. Changing to the alternate

measurement standard after your workout has started will cause invalid data to be displayed. For

this reason, change the measurement standard only after turning ON the treadmill.

Procedure

1. Plug the power cord into the wall outlet, then turn on the treadmill with the circuit breaker.

2. With the Enter Your Weight banner scrolling, press keys RESET,5,6,7, sequentially.

3. The current setting, either U.S. Standard or Metric will be displayed.

4. Use the

▲ or ▼ keys to select the desired unit of measurement setting.

5. Press the STOP key to exit,

Page 8

917, 917si Treadmillr

Page 8

Procedure 2.4 - Documenting Software Problems

When a problem is found with either the PROM or upper or lower PCA’s, record the information

listed below. If you isolated the problem to either the PROM, upper PCA, or lower PCA, include

the information with the malfunctioning PROM or PCA when you ship it to Precor Customer

Service.

When a problem occurs, record the following information:

• Model and serial number.

• Software version number.

• User and program number running when the problem occurred.

• A description of:

a. What happened or failed to happen.

b. The action taken by the user just before the problem occurred.

c. Problem-related information (such as how far into the program the problem occurred,

the work level being used when the problem occurred, etc.)

• The frequency of occurrence.

Page 9

9.17, 917si Treadmill

Page 9

Section Three - Checking Treadmill Operation

This section provides you with a quick method of checking treadmill operation. Check treadmill

operation at the end of a maintenance procedure and when it is necessary to ensure that the

treadmill is operating properly.

Procedure

1. Plug the power cord into the wall outlet, then turn on the treadmill with the circuit breaker.

2. Adjust the speed of the running belt to 2–3 mph.

3. Operate the treadmill for at least 5 minutes.

a. Check the running belt alignment. If necessary, adjust the running belt tracking per

Procedure 4.3.

b. Concentrate on the feel of the running belt and the sound of the drive motor and rollers.

Be alert for running belt or drive belt slippage, unusual noises, smells, or vibrations.

c. Measure and log the AC input current under loaded and unloaded conditions.

4. Press the INCLINE ▲ key while viewing the electronic console. Confirm that the running

bed inclines and the incline display increments to 10 percent as the INCLINE ▲ key is

pressed.

5. Press the INCLINE ▼ key while viewing the electronic console. Confirm that the running bed

returns to a level position and the incline display decrements to zero percent as the

INCLINE ▼ key is pressed.

6. Check for targa looseness. The targa should not move back and forth with your body

weight. The targa should not creak or rattle as the treadmill is used.

7. Inspect the running deck trim strips for looseness. The running deck trim strips must be

securely snapped into place.

Turn off the treadmill with the circuit breaker, then unplug the treadmill from the wall outlet.

Page 10

917, 917si Treadmillr

Page 10

Procedure 4.1 - Calibrating the Lift (917 only)

WARNING

Always turn off the circuit breaker and unplug the treadmill before you remove the treadmill hood.

Procedure

1. Remove the top front and bottom front covers.

2. Lay the treadmill on it’s side and the unsnap lift platform wheel axle from the lift platform.

Remove the wheels and axle from the lift motor tube. See Diagram 4.1.

Diagram 4.1 - Lift Platform

3. Plug the AC line cord into an AC outlet and set the circuit breaker in the “on” position.

4. Connect a digital multimeter, set for DC volts, between terminals 5 (blue) and 6 (brown) of

the P7 lift motor connector on the lower PCA. Operate the lift until the voltmeter reading is

as close to 0.35 Vdc as possible. Set the circuit breaker in the “off” position. Allow about 5

seconds for the power supply voltage to bleed off, the green LED on the lower PCA will go

out.

Lift Platform

Wheel (4)

Lift Motor Tube

Lift Platform Axle

Page 11

9.17, 917si Treadmill

Page 11

5. Remove the P7 lift motor connector from the lower PCA. Thread the lift tube counterclockwise far enough so that you can comfortably grasp the lift motor drive screw. Set the

digital multimeter for ohms and leave it connected as in step 4. Turn the lift motor drive

screw, by hand, until the meter reads 98 ± 2Ω.

6. Thread the lift tube onto the lift drive screw until the distance between the top of t he lift tube

and the lift motor is 6-3/4 inches ± 1/8 inch. See Diagram 4.2 Be sure that the lift motor drive

screw does not turn as you turn the lift tube. If the drive screw turns the resistance re ading in

step 5 will change. The ohmmeter must reads 98Ω after the lift tube has been threaded into

position. Re-insert the P7 lift motor connector in the lower PCA.

Diagram 4.2 - Lift Motor

7. Slide the lift platform axle into the lift motor tube. Rotate the lift tube only enough to line up

with the lift platform. Slide two wheels onto each end of the lift platform axle. Align the

wheels with the wheel slots in the lift platform and snap the lift platform axle into the lift

platform.

8. Set the treadmill upright. Set the circuit breaker in the “on” position. Operate the lift between

0% and 10% several time to ensure that the lift is functioning normally.

6-3/4”

Page 12

917, 917si Treadmillr

Page 12

Procedure 4.2 - Calibrating the Lift (917si only)

WARNING

Always turn off the circuit breaker and unplug the treadmill before you remove the treadmill hood.

Procedure

1. Lay the treadmill on it’s side and unsnap the lift platform wheel axle from the lift platform.

Remove the wheels and axle from the lift motor tube. See Diagram 4.1.

2. Set the circuit breaker in “on” position. Access the diagnostics program, as in Procedure 2.1,

and proceed to the lift potentiometer increment number. Operate the lift until the lift

potentiometer increment number is 20.

3. Thread the lift tube onto the lift drive screw until the distance between the top of t he lift tube

and the lift motor is 6-3/4 inches ± 1/8 inch. See Diagram 4.2 Be sure that the lift motor drive

screw does not turn as you turn the lift tube. If the drive screw turns the potentiometer

increment number in step 3 will change. The potentiometer increment number must be 20

after the lift tube has been threaded into position.

4. Exit the diagnostic program and set the circuit breaker in the “off” position.

5. Slide the lift platform axle into the lift motor tube. Rotate the lift tube only enough to line up

with the lift platform. Slide two wheels onto each end of the lift platform axle. Align the

wheels with the wheel slots in the lift platform and snap the lift platform axle into the lift

platform.

6. Set the treadmill upright. Set the circuit breaker in the “on” position. Operate the lif t between

0% and 10% several time to ensure that the lift is functioning normally.

Page 13

9.17, 917si Treadmill

Page 13

Procedure 4.3 - Running Belt Tensioning and Tracking

WARNING

Always turn off the circuit breaker and unplug the treadmill before you remove the treadmill hood.

1. The basic running belt tensioning and tracking procedure described in the Residential

Treadmill service manual (part # 20081-101) may be used to tension and track the 917 or

917si treadmill with a few exceptions.

2. The drive roller on the 917 and 917si is a “fixed” mount. The drive roller is not moveable or

adjustable and does not play a part in the running belt tracking procedure.

3. The 917 and 917si treadmills use belt guides. The belt guides make the tracking procedure

easier in that the adjustment does not need to be as exacting without the belt guides.

4. The 917 and 917si running belt tension is 0.3%.

Page 14

917, 917si Treadmillr

Page 14

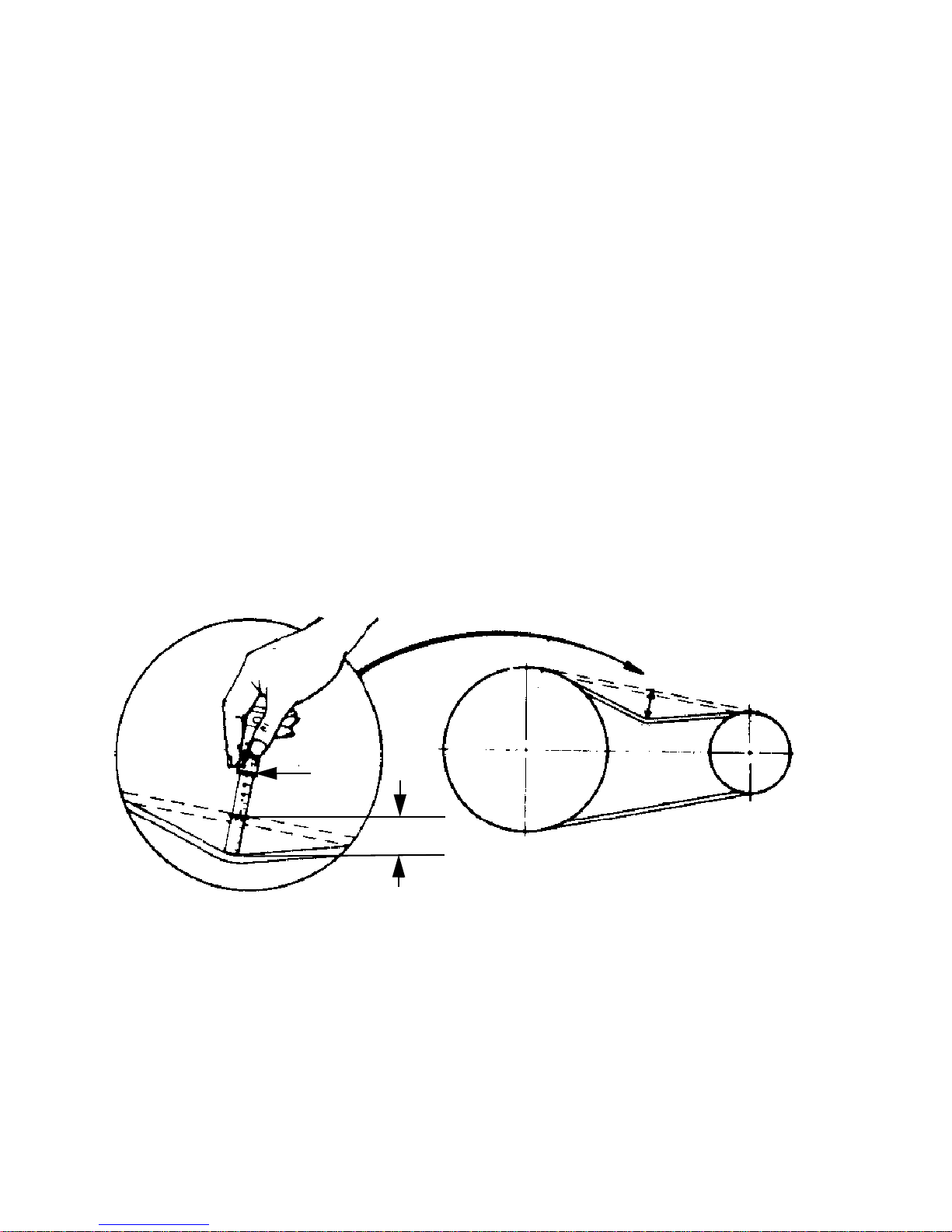

Procedure 4.4 - Drive Belt Tensioning

1. If the running bed is mounted in the treadmill, it may need to be moved slightly to gain

access to the upper surface of the drive belt. The drive belt tension test must be performed

in the center of the belt span between the drive roller pulley and the drive motor pulley.

2. If the running bed is mounted, running bed belt guides o n the bottom of th e running bed and

the screws that mount the running bed to the frame. Lift and slide the running bed just far

enough out of the right side of the running belt to expose the drive belt.

3. Place a belt gauge (Precor part # 20030-117 or equivalent) in the middle of the drive belt

and in the center of the belt span (see Diagram 5.3). Lay a straight e dge alon g the length of

the belt and beside the belt gauge. Slide one of the o-rings up against the shoulder of the

belt gauge. Press downward on the belt gauge, causing the belt to deflect. Read the

deflection on the belt gauge at the edge of the straight edge. Deflect the belt 1/2”. Read t he

tension across the top edge of the o-ring. If the belt is correctly tensioned the gauge will

read between 14 and 16 pounds. See Diagram 4.3.

Diagram 4.3 - Drive belt Tension Gauge

15 lbs

1/2”

Page 15

9.17, 917si Treadmill

Page 15

IF... THEN...

The belt tensioning gauge reads Turn the drive belt tension bolt

less than 14 pounds clockwise, until the belt tensioning

gauge reads 14-16 pounds @1/2” deflection.

The belt tensioning gauge reads Turn the drive belt tension bolt

more than 16 pounds counterclockwise, until the belt

tensioning gauge reads 14-16 pounds @ 1/2”

deflection.

4. When the belt tension is correctly set tighten the jam nut to lock the tension setting.

5. If necessary, slide the running bed back into place. Replace and tighten the running bed

mounting bolts. Replace both running belt guides.

Diagram 4.4 - Drive Belt Tensioner

Drive Belt

Tensioner

Adjustment

Bolt

Tension

Jam Nut

Page 16

917, 917si Treadmillr

Page 16

Procedure 5.1 - Troubleshooting Keypad Function (917 only)

If the function keys on the electronic console are unresponsive, the problem may be either the

upper PCA or keypad. This troubleshooting procedure gives you the information you need to

determine which of these components is malfunctioning.

Procedure

1. Set the circuit breaker in the “off” position.

WARNING

Before continuing with this procedure, review the Warning and Caution statements listed in

Section One of the Residential Treadmill Service Manual.

2. Remove the screws that secure the upper display assembly to the upper handrail. Carefully,

pull some excess interconnect cable out from the targa upright. Rotate the display housing,

so that the rear of the upper PCA is facing upward, and set the display housing on the upper

handrail.

3. Attach the wrist strap to your arm, then connect the ground lead of the wrist strap to the

treadmill frame.

Diagram 5.1 - 917 Upper PCA, Rear View

4. Set the voltmeter to a range that will conveniently read +6 Vdc.

5. Set the circuit breaker in the “on” position.

Connector

Keypad

Keypad

Cable

Interconnect

Cable

Pin # 1

Page 17

9.17, 917si Treadmill

Page 17

6. Use a DVM, set for DC volts, and read between pin 6 of J2 and the each of the pins in Table

5.1 (no keys pressed) and Table 5.2 (with the appropriate key pressed)...

Table 5.1. Voltage Test Points (Function Keys Not Pressed)

Place the positive lead of the The voltmeter should

voltmeter on... read...

Pin 3 of J2 5 Vdc ± 500 mVdc

Pin 4 of J2 5 Vdc ± 500 mVdc

Pin 5 of J2 5 Vdc ± 500 mVdc

Pin 7 of J2 5 Vdc ± 500 mVdc

Pin 8 of J2 5 Vdc ± 500 mVdc

Pin 9 of J2 5 Vdc ± 500 mVdc

Table 5.2. Voltage Test Points (Function Keys Pressed)

Place the positive At the electronic The voltmeter should

voltmeter lead on... console, press... read between...

Pin 3 of J2 SELECT/ENTER 0 Vdc and 500 mVdc

Pin 4 of J2 INCLINE

▼ 0 Vdc and 500 mVdc

Pin 5 of J2 INCLINE

▲ 0 Vdc and 500 mVdc

Pin 7 of J2 STOP 0 Vdc and 500 mVdc

Pin 8 of J 2 SPEED

▼ 0 Vdc and 500 mVdc

Pin 9 of J2 SPEED

▲ 0 Vdc and 500 mVdc

7. If the voltage readings match those listed in Tables 5.1 and 5.2 and one or more keys d o not

function, replace the upper PCA.

8. If the voltage readings in Table 5.1 are incorrect, disconnect the keypad cable from the key

pad connector and repeat the voltage measurements in 5.1. If the voltage readings are now

correct, replace the display housing (keypad). If the voltage readings are still incorrect,

replace the upper PCA.

9. If the voltage readings in Table 5.1 are correct and one or more voltage readings in Table

5.2 are incorrect, replace the display housing (keypad).

10. Set the circuit breaker in the “off” position.

11. If necessary, carefully re-connect the keypad cable to the keypad connector.

12. Remove the ground lead of the wrist strap from the treadmill frame, then remove the wrist

strap from your arm.

13. Position the display enclosure on the display plate. Install the screws that secure the display

enclosure to the display plate.

14. Check the operation of the treadmill as described in Section Three of this appendix.

Page 18

917, 917si Treadmillr

Page 18

Procedure 5.2 - Troubleshooting Keypad Function

(917si only)

If the function keys on the electronic console are unresponsive, the problem may be either the

upper PCA or keypad. This troubleshooting procedure gives you the information you need to

determine which of these components is malfunctioning.

Procedure

1. Set the circuit breaker in the “off” position.

WARNING

Before continuing with this procedure, review the Warning and Caution statements listed in

Section One of the Residential Treadmill Service Manual.

2. Remove the screws that secure the upper display assembly to the upper handrail. Carefully,

pull some excess interconnect cable out from the targa upright. Rotate the display housing,

so that the rear of the upper PCA is facing upward, and set the display housing on the upper

handrail.

3. Attach the wrist strap to your arm, then connect the ground lead of the wrist strap to the

treadmill frame.

Diagram 5.2 - 917si Upper PCA, Rear View

4. Set the voltmeter to a range that will conveniently read +6 Vdc.

Pin # 1

Keypad

Connector

Keypad

Cable

Interconnect

Cable

Page 19

9.17, 917si Treadmill

Page 19

5. Set the circuit breaker in the “on” position.

6. Use a DVM, set for DC volts, and read between pin 6 of J3 and the each of the pins in Table

5.1 (no keys pressed) and Table 5.2 (with the appropriate key pressed)...

Table 5.1. Voltage Test Points (Function Keys Not Pressed)

Place the positive lead of the The voltmeter should

voltmeter on... read...

Pin 3 of J3 5 Vdc ± 500 mVdc

Pin 4 of J3 5 Vdc ± 500 mVdc

Pin 5 of J3 5 Vdc ± 500 mVdc

Pin 7 of J3 5 Vdc ± 500 mVdc

Pin 8 of J3 5 Vdc ± 500 mVdc

Pin 9 of J3 5 Vdc ± 500 mVdc

Pin 10 of J3 5 Vdc ± 500 mVdc

Table 5.2. Voltage Test Points (Function Keys Pressed)

Place the positive At the electronic The voltmeter should

voltmeter lead on... console, press... read between...

Pin 3 of J3 SELECT/ENTER 0 Vdc and 500 mVdc

Pin 4 of J3 INCLINE

▼ 0 Vdc and 500 mVdc

Pin 5 of J3 INCLINE

▲ 0 Vdc and 500 mVdc

Pin 7 of J3 STOP 0 Vdc and 500 mVdc

Pin 8 of J3 SPEED

▼ 0 Vdc and 500 mVdc

Pin 9 of J3 SPEED

▲ 0 Vdc and 500 mVdc

Pin 10 of J3 QUICK START 0 Vdc and 500 mVdc

7. If the voltage readings match those listed in Tables 5.1 and 5.2 and one or more keys d o not

function, replace the upper PCA.

8. If the voltage readings in Table 5.1 are incorrect, disconnect the keypad cable from the key

pad connector and repeat the voltage measurements in 5.1. If the voltage readings are now

correct, replace the display housing (keypad). If the voltage readings are still incorrect,

replace the upper PCA.

9. If the voltage readings in Table 5.1 are correct and one or more voltage readings in Table

5.2 are incorrect, replace the display housing (keypad).

10. Set the circuit breaker in the “off” position.

11. If necessary, carefully re-connect the keypad cable to the keypad connector.

12. Remove the ground lead of the wrist strap from the treadmill frame, then remove the wrist

strap from your arm.

13. Position the display enclosure on the display plate. Install the screws that secure the display

enclosure to the display plate.

14. Check the operation of the treadmill as described in Section Three of this appendix.

Page 20

917, 917si Treadmillr

Page 20

Procedure 5.3 - Troubleshooting the Lift System

System Description

The lift system is powered by a 120 Vac lift motor that uses two independent motors windings,

one operates the motor in an upward direction and one operates the motor in a downward

direction. The motor contains a 1 KΩ potentiometer, driven by the motor, that indicates lift

position. AC power to operate the lift motor is provided by a pair of triacs. One triac provides

power to the “up” winding of the lift motor and the other triac provides power to the “down”

winding of the lift motor. The triacs are controlled either manually or by software control from the

upper PCA.

1. If the lift motor will not move skip to step 8. If the lift motor moves and an error occurs

continue with step 2.

2. For 917si treadmills, skip to step 3. For 917 treadmills, calibrate the lift per Procedure 4.1. If

the lift error still occurs, continue with step 4.

3. Access the diagnostics program per Procedure 2.1 and proceed to the lift calibration portion

of the diagnostics program. If the lift calibration number is 0 or 255 skip to step 4. Operate

the lift, if the lift calibration number does not increment as the lift moves, skip to step 4. If the

calibration number increments as the lift moves, re-calibrate the lift per Procedure 4.2. If recalibration does not correct the problem, continue with step 4.

4. Set the treadmill circuit breaker in the “off” position. Using an ohmmeter, measure between

terminal 4 (brown wire) and terminal 6 (orange wire) of the P7 connector on the lower PCA.

The measurement should be approximately 1 KΩ. If the measurement is open (∞) or

significantly high or low, replace the lift motor.

5. Using an ohmmeter, measure between terminals 4 and 5 of P7 and measure between 5 and

6 of P7 on the lower PCA. The two measurements should total approximately 1 KΩ. If the

measurement is open (∞) or significantly high or low, replace the lift motor.

6. If you have performed all of the above tests and an error still occurs when the lift motor

operates, there are three parts that could cause the problem. There are not any good tests

to check these parts other than substituting a known good part. They are lower PCA, ribbon

cable and upper PCA. Replace only one part at a time. If the new part does not correct the

problem replace the original part.

7. If you have performed all of the above tests and the lift system is still not functioning, call

Precor Technical Support.

8. Set the treadmill circuit breaker in the “off” position. Remove the F2 (2 amp slow blow) fuse

from the lower PCA. Measure the fuse with an ohmmeter. The measurement should be 1Ω

or less. If the fuse is good, re-insert the fuse and skip to step 10. If the fuse is open (∞)or

significantly high, replace the fuse. Before operating the lift motor it is necessary to perform

a continuity test on the lift motor.

Page 21

9.17, 917si Treadmill

Page 21

9. Remove the P7 connector from the lower board. Using an ohmmeter, measure between

terminals 1 and 3 of P7, between terminals 1 and 2 of P7 and between terminals 2 and 3 of

P7. The measurements should be approximately 49.5Ω, 47.5Ω and 97Ω, respectively. If any

of the measurements are significantly low or high, replace the lift motor.

10. Re-insert the P7 connector in the lower PCA. Set the treadmill circuit breaker in the “on”

position. Using an AC voltmeter, monitor the voltage between terminals 1 and 2 (red and

white wires) of the P7 connector. Enter the manual program and press the INCLINE

▲ key.

The measurement should be approximately 120 Vac (line voltage). If the voltage is present

and the lift motor moves normally, skip to step 10. The voltage will only be present until such

time as an error occurs. If line voltage is not present skip to step 11. If line voltage is

measured but the motor does not move, replace the lift motor.

11. Monitor terminals 1 and 3 (white and black wires) of P7. Enter the manual program and

press the INCLINE

▼ key. The measurement should be approximately 120 Vac (line

voltage). If the voltage is present and the lift motor moves normally skip to step 12. The

voltage will only be present until such time as an error occurs. If line voltage is measured but

the motor does not move, replace the lift motor.

12. If line voltage is not present in both steps 9 and 10, there are three parts that could cause

the problem. There are not any good tests to check these parts other than substituting a

known good part. They are lower PCA, ribbon cable and upper PCA. Replace only one part

at a time. If the new part does not correct the problem replace the original part.

13. If you have performed all of the above tests and the lift system is still not functioning, call

Precor Technical Support.

Page 22

917, 917si Treadmillr

Page 22

Procedure 5.4 - Troubleshooting the Speed Sensor

1. Remove the top front and bottom front covers.

2. Plug the line cord into an AC outlet and set the circuit breaker in the “on” position.

3. Use a digital voltmeter, set for DC volts, to measure the voltage between terminal 1 (green)

and terminal 2 (white) of the J1 connector on the lower PCA.

4. Slowly rotate the drive motor, the voltage should alternately switch from near 0 Vdc to near

5 Vdc as the target disk passes through the speed sensor.

Diagram 5.3 - Speed Sensor

5. If the voltage in step 4 switches between approximately 0 Vdc and 5 Vdc, the speed sensor

is functioning correc tly.

6. If the voltage in step 4 is incorrect, remove the J1 connector from the lower PCA. Measure

the voltage between terminals 1 an 4 of the J1 connector on the lower PCA. Terminals 1

and 4 are the terminals that mate with the green and red wires when the speed sensor

connector is inserted into the lower board. If the voltage does not measure approximately 5

Vdc, replace the lower PCA.

Drive Motor

Drive Belt

Target Disk

Tensioner

Speed Sensor

Motor Mounting

Bolts

Page 23

9.17, 917si Treadmill

Page 23

7. If the voltage in step 4 is incorrect and the voltage in step 6 is correct, either the speed

sensor or the lower PCA could be defective. Substitute a known good speed sensor and see

if that corrects the problem. If not, substitute a known good lower PCA.

8. If you have performed all of the above tests an d the speed sensor is still not functioning, call

Precor Technical Support.

Page 24

917, 917si Treadmillr

Page 24

Procedure 5.5 - Troubleshooting the External A.C. Power

Source

It is extremely important that any Precor treadmill be connected to and operated on a dedicated

20 amp A.C. circuit. A 20 amp dedicated circuit is defined as: a circuit fed by a 20 amp circuit

breaker that feeds a single load. A treadmill operating from a non-dedicated circuit or a circuit

breaker of less than 20 amps capacity will not have the necessary power available to operate

normally under higher load conditions. The lack of available power can cause any number of

symptoms ranging from numerous intermittent (seemingly inexplicable) error conditions, poor

speed control, or tripping the house circuit breaker.

If any of the above symptoms exist the external A.C. circuit must be checked and confirmed to be

a 20 amp dedicated circuit before

troubleshooting the treadmill.

In addition the A.C. voltage must be checked. Nominal A.C. operating voltage on 120 Vac circuits

is 105 Vac to 120 Vac. Nominal A.C. operating voltage on 240 Vac circuits is 208 Vac to 240

Vac.

For operator safety considerations and to minimize electrostatic discharge conditions the A.C.

frame ground continuity must also be verified to be a low resistance connection to the A.C.

distribution ground bar.

Important

If the A.C. circuit feeding a treadmill is found to be a non-dedicated circuit or a circuit equipped

with a circuit breaker with a capacity of less than 20 amps, the A.C. circuit must be corrected to

be a 20 amp dedicated circuit before

any reliable troubleshooting can be performed on the

treadmill. More importantly, a non-dedicated circuit may constitute a safety hazard to the

treadmill operator.

120 Vac Systems

120 Vac distribution systems utilize a single pole circuit breaker (hot lead) and a neutral lead

connected to a common neutral (ground) bar. The A.C. safety ground (green wire) is connected

to a separate ground bar in the distribution system.

The most common problems found are (1) the circuit is fed by a circuit breaker of less than 20

amp capacity, (2) the circuit breaker correctly feeds a single A.C. outlet but the neutral is

common between several A.C. outlets and (3) both the hot and neutral leads feed several A.C.

outlets. The appropriate correction action or actions (see below) must be followed if any of the

above conditions exist. Corrective actions should only be undertaken by a licensed

electrician.

1. The circuit breaker feeding the treadmill is not a 20 amp circuit breaker.

If the circuit breaker is greater than 20 amps, the circuit breaker should be replaced with a

20 amp circuit breaker. If the circuit breaker is less than 20 amps the circuit breaker must be

replaced with a 20 amp circuit breaker and the wiring from the A.C. distribution must be

capable of safely handing 20 amps. If the A.C. wiring is under sized, it must be replaced

with wire capable of safely handling 20 amps. Please, refer to local electrical codes when

determining the appropriate wire size for a 20 amp circuit.

Page 25

9.17, 917si Treadmill

Page 25

2. The circuit breaker correctly feeds a single A.C. outlet but the neutral is common

between several A.C. outlets.

The common neutral lead must be removed from treadmill’s A.C. outlet and a new neutral

lead from the treadmill’s A.C. outlet to the A.C. neutral distribution bar must be added.

3. Both the hot and neutral leads feed several A.C. outlets.

Both the common neutral and hot leads must be removed from treadmill’s A.C. outlet and a

new neutral lead and hot lead from the treadmill’s A.C. outlet to the A.C. neutra l distribution

bar and circuit breaker must be added.

240 Vac Systems

240 Vac distribution systems utilize a double pole circuit breaker (two hot leads) The A.C. safety

ground (green wire) is connected to a ground bar in the distribution system.

The most common problems found are (1) the circuit is fed by a circuit breaker of less than 20

amp capacity and (2) both the hot leads feed several A.C. outlets. The appropriate correction

action or actions (see below) must be followed if any of the above conditions exist. Corrective

actions should only be undertaken by a licensed electrician.

1. The circuit breaker feeding the treadmill is not a 20 amp circuit breaker.

If the circuit breaker is greater than 20 amps, the circuit breaker should be replaced with a

20 amp circuit breaker. If the circuit breaker is less than 20 amps the circuit breaker must be

replaced with a 20 amp circuit breaker and the wiring from the A.C. distribution must be

capable of safely handing 20 amps. If the A.C. wiring is under sized, it must be replaced

with wire capable of safely handling 20 amps. Please, refer to local electrical codes when

determining the appropriate wire size for a 20 amp circuit.

2. Both the hot leads feed several A.C. outlets.

Both hot leads must be removed from treadmill’s A.C. outlet and two new ho t leads from the

treadmill’s A.C. outlet to the circuit breaker must be added.

A licensed electrician may use the followings hints to determine if an A.C. service is dedicated.

1. If, on a 120 Vac system, the A.C. distribution panel contains more circuit breakers than

neutral leads, the system has shared neutral leads and is not dedicated.

2. If an A.C. outlet (120 or 240 Vac) has multiple hot and/or neutral leads, it is not a dedicated.

If either of the above conditions exist, the system is not dedicated. However, absence of the

above conditions does not necessarily mean that the system is dedicated. If any doubt exists

about A.C. systems dedication, point to point tracing of the A.C. wiring may be the only way to

prove system dedication.

Page 26

917, 917si Treadmillr

Page 26

Procedure 6.1 - Replacing the Running Bed

1. Set the circuit breaker in the “off” position and remove the line cord from the AC outlet.

2. Remove the four screws that retain the hood. Remove the hood by pulling the from the sid es

and back slightly.

3. Remove both endcaps and the take up roller.

4. Unsnap both of the running bed trim strips from the running bed.

5. Remove the screws that fasten the rear of the running bed to the treadmill frame.

6. Lift the running bed straight up and two inches to the rear, to clear the drive roller pulley.

Slide the running bed out of the running belt taking care not to scratch the treadmill frame

with the belt trackers that are fastened to the bottom front of the running bed.

Diagram 6.1 - Running Bed

7. Remove the belt trackers from the old running bed and mount them on the replacement

running bed. Set the replacement running bed in place in the treadmill, a gain taking care not

to scratch the treadmill frame as the running bed is slid into place.

8. Replace the running bed and partially tighten mounting screws removed in step 5. Center

the running bed between the treadmill frame rails and securely tighten the running bed

mounting screws.

9. Replace the take up roller and end caps.

End Cap

Running Belt

Trim Strip

Targa

Left Side Cover

Hood

Page 27

9.17, 917si Treadmill

Page 27

10. Center the running belt on the running bed, be sure that the running belt is centered

between the belt trackers. Using two running belt tension gauges, tension the running belt to

0.3%

11. Snap the trim strips onto the side rails and slide them back under the end caps. The

Timmerman clips (hood mounting clips) must be fully visible with at least a 1/4” of clearance

on all sides.

12. Replace the hood.

13. Check the running belt tracking per Procedure 4.3.

14. Check treadmill operation per procedure 3.

Page 28

917, 917si Treadmillr

Page 28

Procedure 6.2 - Replacing the Running Belt or Running Belt

and Running Bed

1. Set the circuit breaker in the “off” position and remove the line cord from the AC outlet.

2. Remove the four screws that retain the hood. Remove the hood by pulling the from the sid es

and back slightly.

3. Remove both endcaps and the take up roller.

4. Unsnap both of the running bed trim strips from the running bed.

5. Disconnect the interconnect cable from the lower PCA. Remove the six bolts that fasten the

targa to the treadmill frame and remove the targa. Care must be taken when removing the

targa to ensure that the interconnect cable is not damaged. See Diagram 6.1.

6. Turn the drive belt adjustment bolt counter-clockwise until all tension is removed from the

drive belt. Remove both drive roller mounting bolts. Slide the drive belt off of the drive roller

and remove the drive roller. See Diagram 6.2.

7. Remove the screws that fasten the rear of the running bed to the treadmill frame.

Diagram 6.2 - Drive Belt Tension Adjuster

Drive Belt

Tensioner

Jam Nut

Adjustment Bolt

Page 29

9.17, 917si Treadmill

Page 29

8. Lift the running belt and running bed straight up out of the treadmill frame.

9. Set the replacement running belt and running bed in place in the treadmill frame.

10. Set the drive roller in place, be sure that drive belt is around the drive roller. Replace the two

drive roller mounting bolts. Slide the drive belt onto the drive roller pulley and tension the

drive belt per Procedure 4.4.

11. Partially tighten the running bed mounting screws removed in step 7. Center the running

bed between the treadmill frame rails and securely tighten the running bed mounting

screws.

12. Replace the take up roller and end caps.

13. Center the running belt on the running bed, be sure that the running belt is centered

between the belt trackers. Using two running belt tension gauges, tension the running belt to

0.3%

14. Snap the trim strips onto the side rails and slide them back under the end caps. The

Timmerman clips (hood mounting clips) must be fully visible with at least a 1/4” of clearance

on all sides.

15. Replace the hood.

16. Check the running belt tracking per Procedure 4.3.

17. Check treadmill operation per procedure 3.

Page 30

917, 917si Treadmillr

Page 30

Procedure 6.3 - Replacing the Speed Sensor

1. The left side cover (See Diagram 6.1) must be removed during this procedure. It is possible

that the cover will be broken when it is removed. It is highly recommended that a left side

cover (Precor part number 38088-101) is available before performing this procedure.

1. Set the circuit breaker in the “off” position and unplug the line cord from the AC outlet.

2. Lay the treadmill on it’s right hand side. Protect the targa and plastic parts from scratching.

Remove the lower front cover.

3. Remove the shield that covers the lower PCA.

4. Carefully, pry the left side cover off of the treadmill frame. If the cover breaks or cracks it

must be replaced.

Diagram 6.3 - Speed Sensor

5. Cover the holes in the end of drive motor with paper or similar material. This will prevent

dropped objects, such as the speed sensor mounting screws from falling into the drive

motor.

6. Slowly rotate the drive motor to expose the speed sensor mounting screws between the

blades of the speed sensor target disk (See Diagram 6.3).

Drive Motor

Drive Belt

Target Disk

Tensioner

Speed Sensor

Page 31

9.17, 917si Treadmill

Page 31

7. Disconnect the speed sensor connector (J1) from the lower PCA. Remove the speed

sensor.

8. Set the replacement speed sensor in it’s mounting position, replace and tighten the speed

sensor mounting screws. Remove the paper or similar material that is covering the drive

motor holes.

9. Feed the speed sensor wire harness to the lower PCA. Cable tie the speed sensor wire

harness to the lift motor cable. Re-connect the speed sensor connector to the lower PCA.

10. Replace the shield that covers the lower PCA.

11. Check speed sensor operation per Procedure 5.4.

12. Carefully snap the left side cover onto the frame.

13. Replace the lower front cover.

Page 32

917, 917si Treadmillr

Page 32

Procedure 6.4 - Replacing the Lift Platform

1. Set the circuit breaker in the “off” position and remove the AC line cord from the AC outlet.

2. Lay the treadmill on it’s side.

3. The lift platform snaps onto the frame and the lift platform axle.

Diagram 6.4 - Lift Platform

4. Do not allow the lift motor tube to rotate during this procedure. If the lift motor tube is

allowed to rotate, the lift motor must be re-calibrated per Procedure 4.1 or 4.2.

5. Unsnap the lift platform from the frame and the lift platform axle.

6. Arrange the wheels on the lift platform axle so that they are aligned with the wheel slots in

the replacement lift platform and snap the replacement lift platform onto the lift platform axle.

7. Snap the lift platform onto the frame.

8. Set the treadmill in an upright position, and test the treadmill per Section 3.

Lift Platform

Wheel

Lift Motor Tube

Lift Platform Axle

Page 33

9.17, 917si Treadmill

Page 33

Procedure 6.5 - Replacing the Lift Motor

1. Set the circuit breaker in the “off” position and remove the AC line cord from the AC outlet.

2. Remove the lower front cover.

3. Lay the treadmill on it’s side. Remove the shield from the lower PCA.

Diagram 6.5 - 917, Bottom View

4. Remove the lift connector (J7) from the lower PCA. Remove the cable ties securing the lift

motor cable and feed the lift motor cable back toward the lift motor. Remove the lift motor

ground wire.

5. Unsnap the lift platform axle from the lift platform. Remove the lift platform axle and wheels

from the lift motor.

6. The lift motor is fastened to the treadmill by a clevis pin. Remove the hitch pin from the

clevis pin. Remove the clevis pin from the lift motor.

Page 34

917, 917si Treadmillr

Page 34

7. Set the replacement lift motor in it’s mounting position and secure it to the treadmill frame

with the clevis pin removed in step 6. Replace the hitch pin in the clevis pin.

8. Feed the lift motor cable to the lower PCA, and insert the lift motor connector into the lower

PCA. Replace the cable ties removed in step 4. Reconnect the lift motor ground wire.

9. Re-install the lower PCA shield. Reinstall the front lower cover.

10. If the treadmill is a 917, calibrate the lift and complete the installation per Procedure 4.1,

steps 3-8.

11. If the treadmill is a 917si, calibrate the lift and complete the installation per Procedure 4.2,

steps 3-7.

12. Set the treadmill in the upright position and test per Section 3.

Page 35

9.17, 917si Treadmill

Page 35

Procedure 6.6 - Replacing the Drive Motor/Flywheel

1. The flywheel on the 917 and 917si treadmills is balanced on the drive motor. Do do not

remove or reposition the flywheel on the drive motor.

2. Set the circuit breaker in the “off” position and remove the AC line cord from the AC outlet.

3. Remove the lower front and upper front covers (hood).

4. Remove the running bed trim strips. Turn the take up roller bolts counter-clockwise until all

tension has been removed from the running belt.

5. Turn the drive belt tension bolt counter-clockwise until all tension is removed from the drive

belt (See Diagram 6.2). Remove the drive belt from the drive motor pulley.

6. Remove the bolts that retain the drive roller and remove the drive roller.

7. Remove the bolts that fasten the rear of the running bed to the treadmill frame. Slide the

running bed 8 to 10 inches toward the rear of the treadmill.

8. Remove the shield from the lower PCA. Disconnect the AC input and drive motor wiring

from the lower PCA. Disconnect the interconnect cable, lift motor and speed sensor

connectors from the lower PCA.

Diagram 6.6 - Lower PCA

Interconnect

Cable

Speed

Sensor

Cable

Drive Motor

Wiring

AC Input

Wiring

Lift Motor

Cable

F2 Fuse

F1 Fuse

Page 36

917, 917si Treadmillr

Page 36

9. Remove the four bolts that retain the drive motor assembly. Remove the entire drive motor

assembly by lifting it out and upward.

10. Remove the three screws from the bottom of the motor bracket the retain the lower PCA to

the motor bracket. Remove the lower PCA.

11. Remove the two drive motor mounting bolts on the left side of the drive motor. See Diagram

5.3. Remove the drive motor mounting bolt on the bottom of the motor. Remove the drive

motor from the mounting bracket.

12. The flywheel on the 917 and 917si treadmills is balanced on the drive motor. Do do not

remove or reposition the flywheel on the drive motor.

13. Set the replacement drive motor in the motor bracket and replace the three screws removed

in step 11.

14. Set the lower PCA in place on the mounting bracket and replace the three screws removed

in step 10.

15. Set the drive motor assembly in place in the treadmill frame, be sure that the speed sensor

target is between the legs of the speed sensor. Replace the four bolts removed in step 9.

16. Re-connect the wiring removed in step 8 (see Diagram 6.6). Replace the shield on the lower

PCA.

17. Slide the running bed into place and replace the two running bed mounting screws.

18. Slide the drive roller into the running belt and remount the drive roller using the bolts

removed in step 6.

19. Slide the take up roller through the running belt and remount the take up roller using the

bolts removed in step 5. Re-tension the running belt per Procedure 4.3.

20. Replace the running bed trim strips, lower front and upper front covers.

21. Check treadmill operation per Section 3.

Page 37

9.17, 917si Treadmill

Page 37

Procedure 6.7 - Replacing the Drive Motor Brushes

1. Remove the drive motor per Procedure 6.6 steps, 1-10.

2. Remove both of the motor brush access covers.

3. Press downward on one of the brush retainers until the hook disengag es the bottom edge of

the brush holder. The spring will push the brush retainer out of the brush holder.

Diagram 6.7 - Drive Motor Brush Holder

4. Disconnect the brush connector from the tab on the brush holder and extract the brush from

the brush holder. Note the orientation of the brush as you remove it.

5. Observing the correct brush orientation, insert the replacement brush. If the brush is not

correctly oriented the brush will have a very small contact surface with the motor

commutator. Re-connect the brush connector on brush holder tab.

6. Carefully re-insert the brush retainer so that the hook on the retainer hooks under the

bottom edge of the brush holder. When the retainer is inserted the coil spring on the retainer

must be pressing downward on the top surface of the brush. If the spring does no t p ush the

brush toward the motor commutator the brush will make insufficient contact and the motor

will run poorly or not at all.

7. Replace the opposite motor brush in the same manner as above.

Brush

Retainer

Hook

Brush

Holder

Brush

Connector

Page 38

917, 917si Treadmillr

Page 38

8. Replace both motor brush access covers.

9. Re-install the drive motor per Procedure 6.6, steps 11-17

Page 39

9.17, 917si Treadmill

Page 39

Procedure 6.8 - Replacing the Drive Belt

1. Set the on/off switch in the “off” position. Remove the line cord from the AC outlet.

2. Remove the upper front cover (hood). Remove the shield from the lower PCA.

3. Disconnect the interconnect cable from the lower PCA. Remove the six bolts that fasten the

targa to the treadmill frame and remove the targa. Care must be taken when removing the

targa to ensure that the interconnect cable is not damaged. See Diagram 6.1.

4. Adjust the take up roller bolts counter-clockwise until all tension has been removed from the

running belt.

5. Turn the drive belt adjustment bolt counter-clockwise until all tension is removed from the

drive belt. Remove both drive roller mounting bolts. Slide the drive belt off of the drive roller

and remove the drive belt. See Diagram 6.2.

6. Slide the replacement drive belt onto the drive roller. Replace and tighten the drive roller

mounting bolts removed in step 4.

7. Re-tension the drive belt per Procedure 4.4.

8. Hold the targa near it’s mounting position and feed the interconnect cable through it’s

access hole in the frame. Set the targa in it’s mounting position, replace and tighten the six

targa mounting bolts removed in step 2. Re-connect the interconnect cable to the lower

PCA.

9. Replace the shield on the lower PCA. Replace the upper front cover (hood).

10. Tension and track the running belt per Procedure 4.3.

Page 40

917, 917si Treadmillr

Page 40

Procedure 6.9 - Replacing the PROM

Anti-static kits (part number 20024-101) can be ordered from Precor.

1. The PROM and the associated printed circuit assembly (PCA) are static sensitive. Antistatic devices must be used and all anti-static precautions must be followed during this

procedure.

2. Remove the printed circuit assembly per its associated procedure.

3. Currently we are using two styles of IC software packages. they are a 28 pin dual in line

package (DIP28) and a forty-four pin square package (PLCC44). Each of these packages

should be removed with a proper IC removal tool (see the illustrations below)

4. The IC’s may inserted into their socket by hand by carefully aligning the n otch on the IC with

the notch on the IC socket and carefully pressing the IC into its socket. See the illustrations

below for the alignment notches. Care must be taken that the IC legs on a DIP28 are all

aligned in the socket to prevent the legs from bending when inserted. The PLCC44 IC must

be carefully aligned squarely in its socket or it will not insert. Do not force the IC into its,

socket. If it does not insert easily, remove the it and re-align it in its socket.

DIP28 removal tool

PLCC44 removal tool

Notch

Notch

DIP28

Notch

Notch

PLCC44

Page 41

9.17, 917si Treadmill

Page 41

Wiring Diagram 7.1 - 917 and 917si (120 Vac)

Page 42

917, 917si Treadmillr

Page 42

Block Diagram 7.2 - 917 and 917si (120 Vac)

Page 43

9.17, 917si Treadmill

Page 43

Wiring Diagram 7.3 - 917 and 917si (240 Vac)

Line

Cord

Circuit

Breaker

Line

Filter

Stepdown

Transformer

BR

BR

BR

BR

BL

BL

BL

BL

Page 44

917, 917si Treadmillr

Page 44

Block Diagram 7.4 - 917 and 917si (240 Vac)

Loading...

Loading...