Page 1

PRO SubWoofers

PRO 104 PRO 124

Page 2

TABLE OF CONTENTS

Congratulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Caution

Specifications

Features

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Wiring Configurations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Enclosure Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Notes

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

2

Page 3

CONgrATuLATiONS

Thank you for choosing PrecisionPowerTM woofers. Designed and

engineered in the USA, this product combines innovative technology

with the finest materials to consistently deliver Absolutely State of

the Art™ performance, sound quality, reliability, and value. This

PrecisionPowerTM product reflects our commitment to offer you

unparalleled performance and quality for years of dependable

service and listening enjoyment.

Included in this manual are a number of different enclosure

suggestions. These are by no means the only enclosures to use,

but they provide a starting point. To determine the correct enclosure

for your needs many factors must be addressed (amount of

power, vehicle, placement, crossovers, etc.) Therefore, as always

PrecisionPowerTM recommends that your subwoofer be installed

by an authorized PrecisionPowerTM dealer

CAuTiON

Extended use of a high powered audio system may result in hearing

loss or damage. While PrecisionPowerTM systems are capable

of “Concert Level” volumes with incredible accuracy, they are also

designed for you to enjoy at more reasonable levels all of the sonic

subtleties created by musicians. Please observe all local sound

ordinances.

3

Page 4

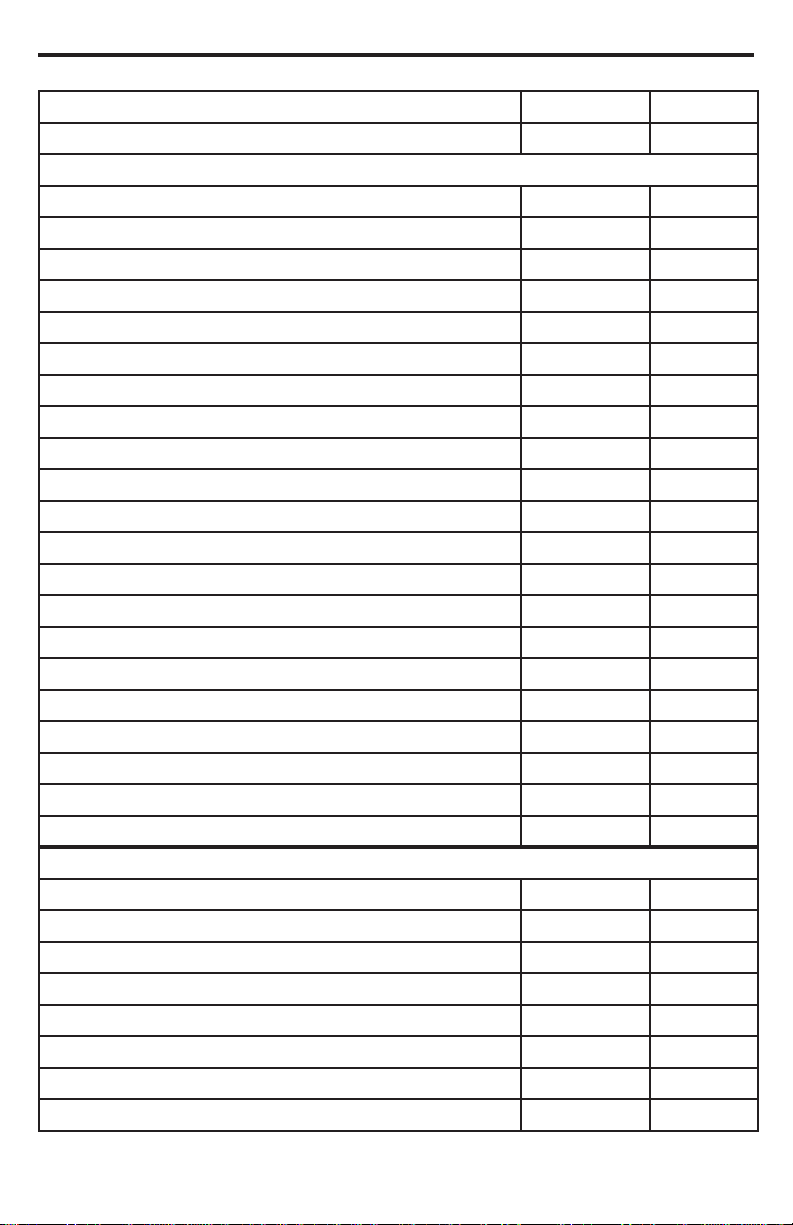

SpECiFiCATiONS

Directed Part Number 28206 28216

Model Number PRO104 PRO124

Thiele/Small parameters

Fs (free-air resonance, Hz) 44.51 42.26

Vas (equivalent compliance, cu. ft.) 0.319 0.656

Vas (equivalent compliance, liters) 9.03 18.58

Qms (Q, mechanical) 6.76 7.68

Qes (Q, electrical) 1.01 1.03

Qts (total driver Q) 0.88 0.91

Re (DC resistance, ohms) 5.8 5.8

Z (nominal impedance, ohms) 2 x 4 2 x 4

Le (inductance, mh) 1.46 1.47

Efficiency (1W @ 1M, dB) 80.87 83.23

Xmax (one way linear excursion, in.) 0.91 0.91

Xmax (one way linear excursion, mm) 26.5 26.5

Pe (continuous power handling, watts) 1000 1000

Peak power handling (music, watts) 2000 2000

Mms (total moving mass, grams) 218 260

Cms (mechanical compliance, mm/N) 0.059 0.055

Bl (motor strength, Tesla-M) 18.68 19.72

Sd (effective radiating area, sq. cm.) 330.06 491.03

Sd (effective radiating area, sq. in.) 51.18 76.11

Frequency range (Hz) 44-250 42-250

Energy Bandwidth Product (EBP) 44 41

Driver physical Dimension

Speaker Outer Diameter (inches) 10.71 12.44

Speaker Outer Diameter (mm) 272 316

Mounting hole diameter (inches) 9.29 11.06

Mounting hole diameter (mm) 236 281

Mounting depth (inches) 7.09 8.07

Mounting depth (mm) 180 205

Magnet Weight (Oz) 155 155

Basket diameter (inches) 10.71 12.44

4

Page 5

recommended Enclosures

Typical sealed enclosure (cu. ft.) 0.6 0.9

Enclosure Details

1. External dimensions calculated for 3/4” building material

2. Includes speaker displacement

3. Volumes given are net tuning volume

4. Enclosures include a minimal amount of damping material. Just enough ma

terial to line the inside of the enclosure is required.

Specifications subject to change without notice

5

Page 6

FEATurES

1 Woven Fiberglass over a Rohr cell foam center – flat panel.

2 Tall, wide, balanced, NBR Foam (high density expanded

polyester foam) surround for linear controlled long excursion

using a Tri Radius symmetrical edge design optimized on

non-linear FEA

3 Rubber wrap around two way mounting gasket.

4 Custom Cast Aluminum frame.

5 Aluminum flat panel to voice coil former attachment yoke.

6 Custom terminals and impedance jumpers.

7 Tinsel leads woven to single flat interlaced Conex spider.

8 Voice coil former vent holes. Part of enhanced voice coil

cooling system (forced convection).

9 10mm thick steel front gap plate. Part of Mmag dual gap

motor assembly.

10 Magnetic ring consisting of 12 donut style ceramic magnets

for front gap of dual gap motor. Part of Mmag dual gap

motor assembly. Total magnet weight of items 10 & 14 is 155

oz.

6

Page 7

11 10mm thick steel rear gap plate. Part of Mmag dual gap

motor assembly.

12 10mm thick steel rear plat / pole piece T yoke Part of Mmag

dual gap motor assembly.

13 1 inch flared Vent. Part of enhanced voice coil cooling system

(forced convection).

14 Two stack ceramic magnet for rear gap Part of Mmag dual

gap motor assembly. Total magnet weight of items 10 & 14 is

155 oz.

15 High temperature (Polyester Amide Amide Resin Coated)

Copper dual voice coil (2x4 ohm) wound on an).

16 Voice coil heat pick-up and heat sink assembly that also

serves as a control for flux and heat build up and control

in the dual gap motor. Part of enhanced voice coil cooling

system (forced convection – aluminum heat sinking –shorting

rings to reduce inductive heating).

17 Aluminum voice coil former (voice coil is a 3”).

18 Vented spider ring and terminal block assembly. Integrates

custom terminals and impedance jumper block. Venting in

spider ring is part of enhanced voice coil cooling system

(forced convection).

19 Vent holes in flat panel yoke assembly. Part of enhanced

voice coil cooling system (forced convection – aluminum heat

sinking –shorting rings to reduce inductive heating).

7

Page 8

WiriNg CONFigurATiONS

4 ohm

4 ohm

+ +

- -

+

-

The following illustrations provide guidelines on properly

connecting your PrecisionPowerTM woofer to a PrecisionPowerTM

amplifier for maximum power and performance using common

parallel, and series/parallel wiring configurations

Recommended Amplifier Power

Continuous Power (RMS) Peak Power (watts

1 woofer 500 to 1000 600 to 2000

2 woofers 1000 to 2000 1200 to 4000

3 woofers 1500 to 3000 1800 to 6000

4 woofers 2000 to 4000 2400 to 8000

Technical Brief:

How to properly wire a PPI woofer in parallel to a PPI amplifier for

maximum power and performance.

1. Wire the speaker parallel by connection the two + terminals

together and the two - terminals together.

8

Page 9

2. Wire the positive (+) terminals of the speakers to the positive (+)

4 ohm

4 ohm

+ +

- -

+

-

terminal on the amplifier. Wire the negative (-) terminals of the

woofers to the negative (-) terminal on the amplifier.

3. This wiring show the amplifier a 2 ohm load.

Technical Brief:

How to properly wire a PPI woofer in series to a PPI amplifier for

maximum power and performance.

1. Wire the woofer's coils together in series by wiring the positive of

one coil to ther negative of the other coil. This is series wiring.

2. Wire the two open terminals to the amplifier, positive terminal

to the amplifier positive and negative terminal to the amplifier

negative.

3. This wiring show the amplifier a 8 ohm load.

9

Page 10

Technical Brief:

4 ohm

4 ohm

+

+

- -

4 ohm

4 ohm

+

+

- -

+

-

How to properly wire a PPI woofer in parallel to a PPI amplifier for

maximum power and performance.

1. Wire the two speaker's voice coil parallel by connection the two

+ terminals together and the two - terminals together.

2. Wire the positive (+) terminals of the speakers to the positive (+)

terminal on the amplifier. Wire the negative (-) terminals of the

woofers to the negative (-) terminal on the amplifier.

3. This wiring show the amplifier a 1 ohm load.

10

Page 11

Technical Brief:

4 ohm

4 ohm

+

+

- -

4 ohm

4 ohm

+

+

- -

+

-

How to properly wire a PPI woofer in series/parallel to a PPI

amplifier for maximum power and performance.

1. Connect each woofer in series by connecting the negative (-) of

the first coil to the positive (+) terminal of the second coil.

2. Wire the positive (+) terminals of the first coil of each woofer to

the positive (+) terminal on the amplifier. Wire the negative (-)

terminal of the second coil of each woofer to the negative (-)

terminal on the amplifier.

3. This wiring show the amplifier a 4 ohm load.

11

Page 12

Technical Brief:

4 ohm

4 ohm

+

+

- -

4 ohm

4 ohm

+

+

- -

4 ohm

4 ohm

+

+

- -

+

-

How to properly wire a PPI woofer in parallel to a PPI amplifier for

maximum power and performance.

1. Connect each woofer in series by connecting the negative (-) of

the first coil to the positive (+) terminal of the second coil.

2. Wire the positive (+) terminals of the first coil of each woofer to

the positive (+) terminal on the amplifier. Wire the negative (-)

terminal of the second coil of each woofer to the negative (-)

terminal on the amplifier.

3. This wiring show the amplifier a 2.67 ohm load.

12

Page 13

Technical Brief:

4 ohm

4 ohm

4 ohm

4 ohm

4 ohm

4 ohm

4 ohm

4 ohm

+

-

+

+

- -

+

+

- -

+

+

- -

+

+

- -

How to properly wire a ppi woofer in seriesparallel to a PPI amplifier

for maximum power and performance.

1. Connect each woofer in series by connecting the negative (-) of

the first coil to the positive (+) terminal of the second coil.

2. Wire the positive (+) terminals of the first coil of each woofer

to the positive (+) terminal on the amplifier. Wire the negative

(-) terminal of the second coil of each woofer to the negative (-)

terminal on the amplifier.

3. This wiring show the amplifier a 2 ohm load.

13

Page 14

The Pro subs also can utilize jumper settings rather than wiring each

coil individually as the above diagrams show.

By default the jumpers come in the top two spots. This would keep

each of the coils separate just as a regular dual voice coil woofer

operates. All of the above diagrams would work fine when the

jumpers are in this position.

With the jumpers in the bottom two it would wire the coils in parallel,

giving you a two ohm final load. You would only need to use one set

of terminals when using the jumpers. The diagram would look like

this.

14

Page 15

Technical Brief:

How to properly wire a PPI woofer in parallel to a PPI amplifier for

maximum power and performance.

1. Using 1 set of terminals wire ther - to the - post of the amplifier

and the + to the + terminal of the amplifier.

2. This wiring show the amplifier a 2 ohm load.

With one jumper in the middle on the bottom row it wires the coils

in series.

The diagram would look like this

using the jumper block - both coils in series:

With the cone facing upward and the jumper block in front of you,

the positive terminal on the terminal block on the left side would

be positive and the negative terminal on the right side would be

negative. The negative on the left terminal and the positive on the

right terminal are shorted together and not used.

15

Page 16

Do not

use

Do not

use

+ -

To amplifier +

+ -

To amplifier -

Technical Brief:

How to properly wire a PPI woofer in parallel to a PPI amplifier for

maximum power and performance.

8 ohm

1. Use the + on one of ther terminals to the + of the amp and

the - of the opposite terminal to the negative on the amp. The

subwoofer would be wired in series.

2. This wiring show the amplifier a 8 ohm load.

Note if the sub doesn’t hit or sound right it is probably wired out of

phase, switch around the + and – wires.

16

Page 17

Enclosure Design

This manual will give the basic outline for a sealed enclosure.

Precision power woofers are designed for sealed enclosures. Sealed

are generally considered the most versatile for all music types and

are the easiest to build. They will also give a high power handling at

a wider range of frequencies. The enclosure must be absolutely air

tight. Use a high quality wood glue for all seams of the enclosure.

The enclosure should also be screwed together. We recommend to

use ¾” MDF for the following enclosures. MDF is a porous material

so it is best to seal the inside of the enclosure as well.

17

Page 18

Pro 104 Sealed Enclosure

c

b

—Box Parts—

Box Shape – Square Prism

1 Top, 1 Bottom

depth (c) = 11.5 in.

width (b) = 12 in.

thickness = 0.75 in.

1 Front, 1 Back

height (a) = 10.5 in.

width (d) = 10.5 in.

thickness = 0.75 in.

2 Sides

height (a) = 10.5 in.

depth (c) = 11.5 in.

thickness = 0.75 in.

—Driver Mounting—

Front

Top &

Bottom

a

d

Front &

Back

c

Sides

18

Page 19

Pro 124 Sealed Enclosure

A

B

C

—External Dimensions

—

A = 16 in.

B = 15 in.

C = 13.5 in.

—Internal Dimensions—

A = 14.5 in.

B = 13.5 in.

C = 11.75 in.

—Wall Thickness—

All Sides = 0.75 in.

c

b

—Box Parts—

Box Shape – Square Prism

1 Top, 1 Bottom

depth (c) = 13.25 in.

width (b) = 15 in.

thickness = 0.75 in.

1 Front, 1 Back

height (a) = 14.5 in.

width (d) = 13.5 in.

thickness = 0.75 in.

2 Sides

height (a) = 14.5 in.

depth (c) = 13.25 in.

thickness = 0.75 in.

—Driver Mounting—

Front

Top &

Bottom

a

d

Front &

Back

c

Sides

19

Page 20

Notes

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

_____________________________________________________

21

Page 21

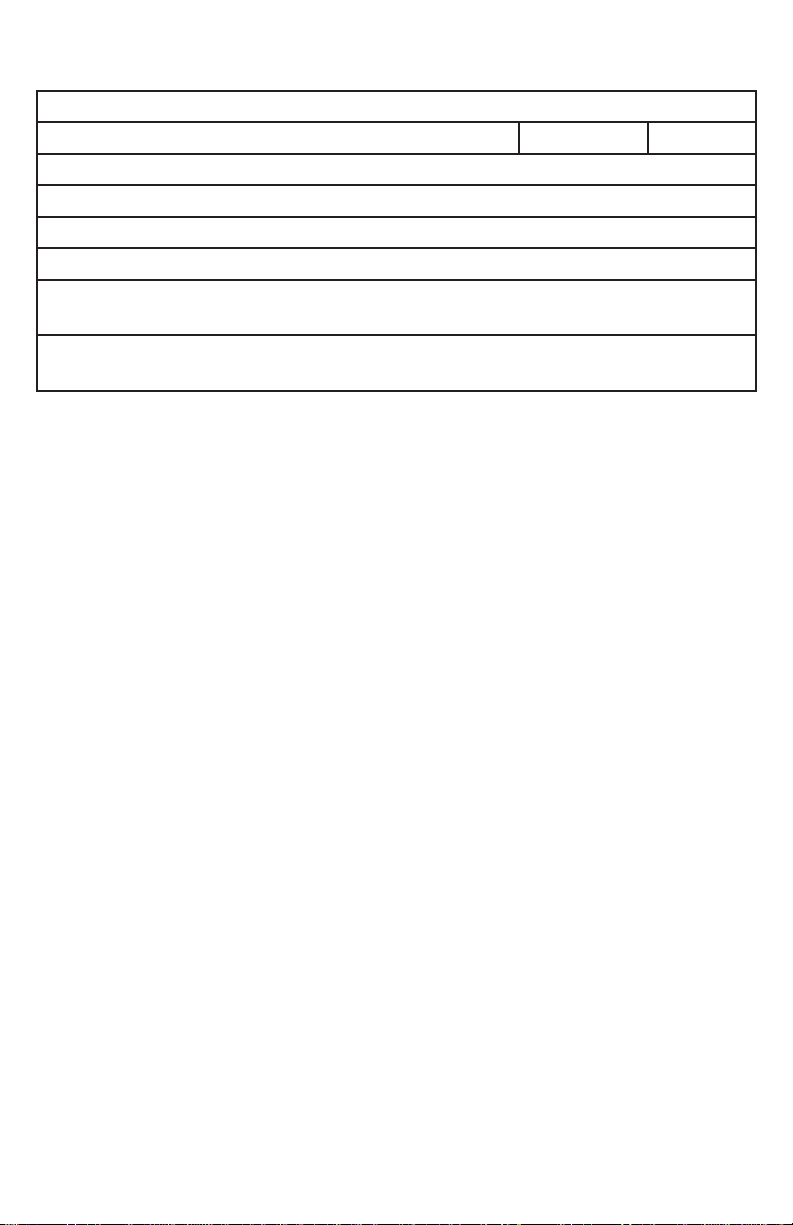

Warranty

LIMITED ONE-YEAR CONSUMER WARRANTY/

*LIMITED TWO-YEAR CONSUMER WARRANTY FOR AUTHORIZED DIRECTED DEALER

PURCHASE & INSTALLATION

Directed Electronics (herein “Directed”) promises to the original purchaser, to repair or replace with a

new or refurbished unit (at Directed’s sole and absolute discretion) this product should it prove to be

defective in workmanship or material under normal use, for a period of *two-years from the date of

purchase from the authorized Directed dealer PROVIDED the product was purchased and installed by

an authorized Directed dealer. During this *two-year period, there will be no charge for the repair or

replacement PROVIDED the unit is returned to Directed, shipping prepaid, along with the required proof

of installation, the bill of sale or other dated proof of purchase, and the consumer’s contact information.

If the unit is installed by anyone other than an authorized Directed dealer, the warranty period will be

one-year from the date of purchase. This warranty is non-transferable and does not apply to any unit

that has been modified or used in a manner contrary to its intended purpose, and does not cover damage

to the unit caused by installation or removal of the unit. During this one-year period, there will be no

charge for the repair or replacement PROVIDED the unit is returned to Directed, shipping pre-paid,

along with the bill of sale or other dated proof of purchase and the consumer’s contact information. This

warranty is void if the product has been damaged by accident or unreasonable use, neglect, improper

service or other causes not arising out of defects in materials or construction. This warranty does not

cover the elimination of externally generated static or noise, or the correction of antenna problems or

weak reception, damage to speakers, accessories, electrical systems, cosmetic damage or damage due

to negligence, misuse, failure to follow operating instructions, accidental spills or customer applied

cleaners, damage due to environmental causes such as floods, airborne fallout, chemicals, salt, hail,

lightning or extreme temperatures, damage due to accidents, road hazards, fire, theft, loss or vandalism,

damage due to improper connection to equipment of another manufacturer, modification of existing

equipment, or Product which has been opened or tampered for any reason. Units which are found to

be damaged by abuse resulting in thermally damaged voice coils are not covered by this warranty but

may be replaced at the absolute and sole discretion of Directed. Unit must be returned to Directed,

postage pre-paid, with bill of sale or other dated proof of purchase bearing the following information:

consumer's name, telephone number, and address, authorized dealer's name and address, and product

description. Unit must be returned to the following address: ATTN: WARRANTY DEPARTMENT, Directed

Electronics , 1 Viper Way, Vista, CA 92081. Note: This warranty does not cover labor costs for the removal

and reinstallation of the unit. IN ORDER FOR THE TWO-YEAR WARRANTY TO BE VALID, YOUR UNIT

MUST BE SHIPPED WITH PROOF OF INSTALLATION BY AN AUTHORIZED DIRECTED DEALER. ALL UNITS

RECEIVED BY DIRECTED FOR WARRANTY REPAIR WITHOUT PROOF OF DIRECTED DEALER INSTALLATION

AND PURCHASE WILL BE COVERED BY THE LIMITED 1 YEAR WARRANTY.

BY PURCHASING THIS PRODUCT, ALL WARRANTIES INCLUDING BUT NOT LIMITED TO EXPRESS

WARRANTY, IMPLIED WARRANTY, WARRANTY OF MERCHANTABILITY, FITNESS FOR PARTICULAR

PURPOSE, AND WARRANTY OF NON-INFRINGEMENT OF INTELLECTUAL PROPERTY ARE EXPRESSLY

EXCLUDED TO THE MAXIMUM EXTENT ALLOWED BY LAW, AND DIRECTED NEITHER ASSUMES NOR

AUTHORIZES ANY PERSON TO ASSUME FOR IT ANY LIABILITY IN CONNECTION WITH THE SALE OF

THE PRODUCT. DIRECTED HAS ABSOLUTELY NO LIABILITY FOR ANY AND ALL ACTS OF THIRD PARTIES

INCLUDING ITS AUTHORIZED DEALERS OR INSTALLERS. IN NO EVENT WILL DIRECTED BE LIABLE FOR ANY

INCIDENTAL, SPECIAL OR CONSEQUENTIAL DAMAGES (INCLUDING LOSS OF PROFITS). BY PURCHASING

THIS PRODUCT, THE CONSUMER AGREES AND CONSENTS THAT ALL DISPUTES BETWEEN THE CONSUMER

AND DIRECTED SHALL BE RESOLVED IN ACCORDANCE WITH CALIFORNIA LAWS IN SAN DIEGO COUNTY,

CALIFORNIA. This warranty is only valid for sale of Product within the United States of America. Product

sold outside of the United States of America is sold “AS-IS,” and shall have NO WARRANTY, express or

implied. Some states do not allow limitation on how long an implied warranty lasts. In such states, the

limitation or exclusions of this Limited Warranty may not apply. Some states do not allow the exclusion

or limitation of incidental or consequential damages. In such states, the exclusion or limitation of this

Limited Warrantymay not apply to you. This Limited Warranty gives you specific legal rights, and you may

have other rights which vary from state to state. 920-0033 Rev 02-07

© 2007 Directed Electronics. All rights reserved. G28206.16 01-07

Loading...

Loading...