USER MANUAL

CONTINUOUS &

CONTINUOUS INTERMITTENT

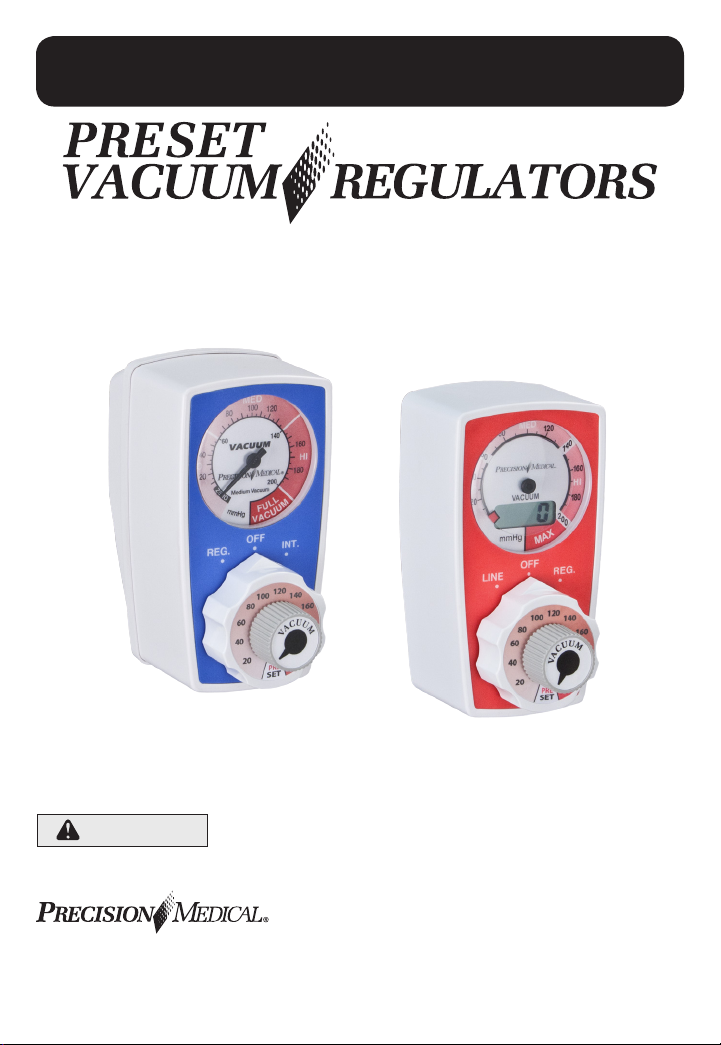

MODEL SERIES: PS3000 PS3400

PS3100 PS3500

PS3300 PS3600

Patent Pending

PS3300 (Shown)

PS3100 (Shown)

SAVE THESE INSTRUCTIONS

CAUTION

300 Held Drive Tel: (+001) 610-262-6090

Northampton, PA 18067 USA Fax: (+001) 610-262-6080

ISO 13485 Certied www.precisionmedical.com

Federal (USA) law restricts this device to sale by or

on the order of a physician.

CONTENTS

RECEIVING / INSPECTION .......................................................... 2

INTENDED USE ............................................................................ 2

READ ALL INSTRUCTIONS BEFORE USING .............................2

EXPLANATION OF ABBREVIATIONS ......................................... 2

SAFETY INFORMATION - WARNINGS AND CAUTIONS ............ 2

SPECIFICATIONS ........................................................................ 3

OPERATING INSTRUCTIONS ......................................................4

PARTS DESCRIPTION .................................................................5

REPAIR KITS ................................................................................6

DISASSEMBLY INSTRUCTIONS

DISASSEMBLY INSTRUCTIONS

for PS3000, PS3100, PS3500 & PS3600 Series

for PS3300 & PS3400 Series

.....................7

....7

ASSEMBLY INSTRUCTIONS .......................................................7

VACUUM REGULATOR CLEANING ILLUSTRATION ..................8

CLEANING / DECONTAMINATION ..............................................9

MAINTENANCE ............................................................................9

RETURNS .....................................................................................9

DISPOSAL INSTRUCTIONS .......................................................10

TROUBLESHOOTING ................................................................10

LIMITED WARRANTY ................................................................ 11

CONTINUOUS & CONTINUOUS INTERMITTENT

1

RECEIVING / INSPECTION

Remove the Precision Medical, Inc. Preset Vacuum Regulator from the

packaging and inspect for damage. If there is any damage, DO NOT USE

and contact your Provider.

INTENDED USE

The Preset Vacuum Regulator is intended to regulate and display the

amount of vacuum from a central vacuum system used in various medical

suctioning procedures.

READ ALL INSTRUCTIONS BEFORE USING

This manual instructs a Professional how to install and operate the Preset

Vacuum Regulator. This is provided for your safety and to prevent damage

to the Preset Vacuum Regulator. If you do not understand how to use the

Preset Vacuum Regulator, please contact your Provider.

EXPLANATION OF ABBREVIATIONS

l/min Liters Per Minute

mmHg Millimeters of Mercury

inHg Inches of Mercury (1 inHg = 25.4 mmHg)

SAFETY INFORMATION - WARNINGS AND CAUTIONS

WARNING

CAUTION

CAUTION

Indicates a potentially hazardous situation which, if

not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates a

potentially hazardous situation which, if not avoided,

may result in property damage.

CONSULT ACCOMPANYING DOCUMENTS

There are no components in this product made with

natural rubber latex.

WARNING

•

DO NOT use the Preset Vacuum Regulator for anything other than

its Intended Use. Personal injury and/or damage to Regulator may

result from misuse.

•

Only personnel instructed and trained in its use should operate the

Preset Vacuum Regulator.

2

CONTINUOUS & CONTINUOUS INTERMITTENT

SPECIFICATIONS

CALIBRATED RANGE

PS3000: 0 - 200 mmHg

PS3000HV: 0 - 300 mmHg

PS3100: 0 - 200 mmHg

GAUGE ACCURACY

Analog Gauge ± 5% of MAX calibrated range

Dual Analog/Digital Gauge

Digital Display ± 1% of Full Scale

Analog Gauge ± 5% of MAX calibrated range within ref. Indicator

INLET/OUTLET CONNECTIONS 1/8 NPT Female

MODES OF OPERATION

PS3000 Series

PS3500 Series

PS3100 Series

PS3600Series

OFF - No Vacuum

REG. -

OFF - No Vacuum

REG. LINE -

PS3300 Series

PS3400 series

OFF - No Vacuum

REG. INT. - Intermittent) Provides an adjustable vacuum level that cycles

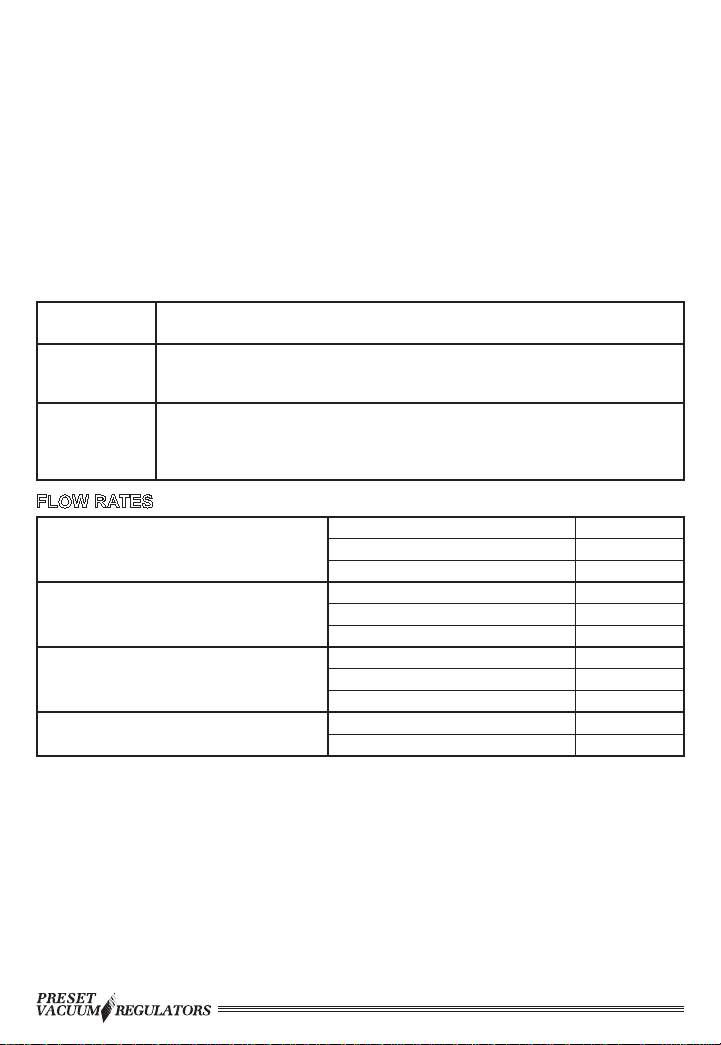

FLOW RATES

PS3000, PS3100 & PS3300

PS3000HV, PS3100HV & PS3300HV

PS3300 & PS3400

PS3600

FLOW RATES ARE OBTAINED WITH A VACUUM SOURCE OF 21” Hg

INTERMITTENT CYCLE TIME: Factory set at sixteen (16) seconds ON

Operating Environmental Limits: 0°F to 122°F (-18°C to 50°C)

Recommended Environmental Operating Limits:

Storage Environmental Limits

Temperature Range: -4°F to 140°F (-20°C to 60°C)

Humidity: Max 95% Noncondensing

Battery: 3 Volt Lithium, 1/2 AA (Digital Vacuum Gauge Models ONLY)

Specications are subject to change without prior notice.

PS3100HV: 0 - 300 mmHg

PS3300: 0 - 200 mmHg

PS3300HV: 0 - 300 mmHg

PS3400: 0 - 150 mmHg

PS3500: 0 - 150 mmHg

PS3600: 0 - 760 mmHg

(Regulated) Provides an adjustable, continuous vacuum level

(Regulated) Provides an adjustable, continuous vacuum level

Provides maximum, continuous vacuum from the vacuum source

(Regulated) Provides an adjustable, continuous vacuum level

between ON and OFF

REG MODE @ 200 mmHg 48 l/min

LINE MODE 55 l/min

INT. MODE (PS3300 Only) 10 l/min

REG MODE @ 300 mmHg 50 l/min

LINE MODE 55 l/min

INT. MODE (PS3300HV Only) 10 l/min

REG MODE @ 150 mmHg 50 l/min

INT. Mode (PS3300 only) 10 l/min

INT. MODE (PS3400 only) 3 l/min

REG MODE @ 635 mmHg 71 l/min

LINE MODE 82 l/min

and eight (8) seconds OFF (Reference only)

55°F to 85°F (13°C to 29°C)

CONTINUOUS & CONTINUOUS INTERMITTENT

3

OPERATING INSTRUCTIONS

CAUTION

Inspect the Preset Vacuum Regulator for visual damage before use, DO NOT USE if damaged.

NOTE: •

Overow protection should be used with the Vacuum Regulator.

(i.e. Filter, Vac Trap, Canister equipped with oat shutoff).

• The Digital / Analog Dual Gauges operate independently; if the digital gauge fails, the

1. Turn the Selector Knob to the “OFF” position.

2. Connect the Preset Vacuum Regulator to a vacuum source.

A. REG. MODE (Regulated Mode) ALL MODELS

B. LINE MODE (Full, unregulated vacuum) PS3100 & PS3600 Series ONLY

C. INT. MODE (Vacuum cycles ON and OFF.) PS3300 Series ONLY

3. Turn the Selector Knob to the “OFF” position to turn the Vacuum off.

analog gauge will still function and vice versa.

a. Turn the gray Preset Knob to desired vacuum range.

b. Block the bottom port of the Vacuum Regulator with your nger and turn the white Selector Knob

to the “REG.” position.

c. The preset vacuum range should correspond with the gauge readings along with the increase

and decrease in suction felt with the nger on blocked off bottom port.

d. Adjust vacuum as required.

To INCREASE vacuum - Turn gray Knob CLOCKWISE

To DECREASE vacuum - Turn gray Knob COUNTERCLOCKWISE

a. Block off bottom port of the Vacuum Regulator with your nger and turn the Selector Knob

to the “LINE” position. The gauge will indicate Max. vacuum and suction should be felt with

nger on blocked off bottom port. In this mode the vacuum level cannot be set and will be full

unregulated vacuum.

a. Turn the gray Preset Knob to desired vacuum range.

b. Block the bottom port of the Vacuum Regulator with your nger and turn the Selector Knob to

the “REG.” position.

c. The preset vacuum range should correspond with the gauge readings along with the suction felt

with the nger on blocked off bottom port.

d. Adjust vacuum as required.

To INCREASE vacuum - Turn gray Knob CLOCKWISE

To DECREASE vacuum - Turn gray Knob COUNTERCLOCKWISE

e. Turn the Selector Knob to the “INT.” position.

f. The intermittent cycle starts in the “OFF” phase. There will be approximately an 8 second

delay before the device cycles to the “ON” phase for approximately 16 seconds. During the

“ON” phase the gauge vacuum level should correspond with the preset vacuum level.

WARNING

•

When turning the Preset Vacuum Regulator to “REG.” from “LINE” or “OFF”, the vacuum level

will return to its previously regulated setting. Vacuum may be set at improper level for procedure.

•

PS3300 & PS3400 Series ONLY: When turning the Preset Vacuum Regulator to “REG.” or “INT.”

from any position, the vacuum level will return to its previously regulated setting.

Vacuum levels will remain the same when switching from one mode to the other.

•

ALWAYS conrm vacuum setting prior to performing procedure.

•

The vacuum CANNOT be regulated when the Selector Knob is set to the “LINE” position.

•

Full Line Vacuum is present between settings.

•

The desired vacuum mode (“REG”, “LINE”, “INT.”) and vacuum level should always be set and

conrmed before interface with patient to perform suctioning procedure.

CAUTION

DO NOT operate the Preset Vacuum Regulator when the collection canister is “full”. This

may cause loss of vacuum and damage to the Preset Vacuum Regulator. This will void the

warranty.

4

CONTINUOUS & CONTINUOUS INTERMITTENT

PARTS DESCRIPTION

CAUTION

Missing or illegible labels must be replaced, contact Precision Medical, Inc.

PS3000, PS3100, PS3500 & PS3600 Series

8

3-Digital

9

(0-200 mmHg)

507480

*507481

(0-300 mmHg)

10

These

components must

always be kept

together as a

matched set.

11

507730

(0-150

mmHg)

507731

(0-760

mmHg)

3-Analog

QTY - 6

PLACES

2

4

5

QTY - 4

PLACES

1

No. Description PS3000 PS3100 PS3500 PS3600

1 Housing Assembly 1561

2 Screw 503956

3 Analog Gauge (0-150 mmHg) - - 503826 -

Analog Gauge (0-200 mmHg) 503694 - -

Analog Gauge (HV) (0-300 mmHg) 504309 - -

Analog Gauge (0-760 mmHg) - - - 505937

Dual Analog /Digital Gauge (0-150 mmHg) - - 505391 -

Dual Analog /Digital Gauge (0-200 mmHg) 505244 - -

Dual Analog /Digital Gauge (HV) (0-300 mmHg) 505392 - -

Dual Analog /Digital Gauge (0-760 mmHg) - - - 505938

4 Snubber 1396

5 O-ring 1016

6 Selector Assembly 1563 1564 1563 505935

7 Selector Ring 502685

8 Wave Spring Washer 1614

9 Case Assembly 1565 1566 1565 1566

10 Regulator Module/Control Knob Assembly

11 Set Screw 1391

-- Battery for Dual Analog/Digital Gauge 8066

* HV Models ONLY (PS3000HV, PS3100HV & PS3300HV)

6

7

PARTS LIST

CONTINUOUS & CONTINUOUS INTERMITTENT

5

PS3300 SERIES

QTY - 6

2

PLACES

13

No. Description PS3300 PS3400

1 Housing Assembly 502102

2 Screw 503956

3 Analog Gauge (0-150 mmHg) - 503826

Analog Gauge (0-200 mmHg) 503694 -

Analog Gauge (HV) (0-300 mmHg) 504309 -

Dual Analog /Digital Gauge (0-150 mmHg) - 505391

Dual Analog /Digital Gauge (0-200 mmHg) 505244 -

Dual Analog /Digital Gauge (HV) (0-300 mmHg) 505392 -

4 Snubber 1396

5 O-ring 502231

6 Selector Assembly 1805

7 Index Ring 502685

8 Wave Spring Washer 1614

9 Case Assembly 1827

10 Regulator Module/ Control Knob Assembly

11 Set Screw 1391

12 Timing Module 502103

13 Back Case 1831

-- Battery for Dual Analog/Digital Gauge 8066

* HV Models ONLY (PS3300HV)

REPAIR KITS Analog Part# Digital Part#

PS3000 / PS3000D Vac Reg RKPS6000 RKPS6000D

PS3000HV / PS3000DHV Vac Reg RKPS6000HV RKPS6000DHV

PS3100 / PS3100D Vac Reg RKPS6100 RKPS6100D

PS3100HV / PS3100DHV Vac Reg RKPS6100HV RKPS6100DHV

PS3300/PS3300D Vac Reg RKPS6300 RKPS6300D

PS3300HV / PS3300DHV Vac Reg RKPS6300HV RK6300DHV

PS3400 / PS3400D Vac Reg RKPS6400 RKPS6400D

PS3500 / PS3500D Vac Reg RKPS6500 RKPS6500D

PS3600 / PS3600D Vac Reg RKPS6600 RKPS6600D

12

3-Analog

1

5

QTY - 4

PLACES

PARTS LIST

4

6 7

3-Digital

8

(0 - 200 mmHg)

(0 - 300 mmHg)

9

507480

*507481

components must

always be kept

together as a

matched set.

507730

(0-150 mmHg)

These

11

10

6

CONTINUOUS & CONTINUOUS INTERMITTENT

DISASSEMBLY INSTRUCTIONS for PS3000, PS3100, PS3500

& PS3600 Series

(Reference “PARTS DESCRIPTION”)

1. Loosen the Set Screw (Item# 11) in Selector Knob.

2. Pull the Regulator Module/Control Knob Assembly (Item # 12) away from case.

(The Regulator Module (Item # 10) is threaded onto the Control Knob Assembly.

Note: These components must always be kept together as a matched set.)

3. Remove the screws (Item# 2) from the back of the Regulator.

4. Separate the Case Assembly (Item# 9) by pulling it away from the Housing

Assembly (Item# 1).

5. Remove the Selector Assembly (Item# 6) by pulling it away from the Housing

Assembly (Item# 1).

6. Remove Gauge by pulling vertically out of socket (Item# 3).

DISASSEMBLY INSTRUCTIONS

(Reference “PARTS DESCRIPTION”)

1. Loosen the Set Screw (Item # 11) in Selector Knob.

2. Pull the Regulator Module/Control Knob Assembly (Item # 12) away from

case. (The Regulator Module (Item # 10) is threaded onto the Control Knob

Assembly. Note: These components must always be kept together as a

matched set.)

3. Remove the screws (Item # 2) from the back of the product.

4. Remove the Rear Case (Item # 14) by pulling away from product.

5. Remove screws (Item# 2) from the top of the Timing Module.

6. Remove the Timing Module (Item# 13) by pulling away from the Housing

Assembly (Item# 1).

7. Separate the Case Assembly (Item# 9) by pulling it away from the Housing

Assembly (Item# 1).

8. Remove the Selector Assembly (Item# 6) by pulling it away from the Housing

Assembly (Item# 1).

9. Remove Gauge by pulling vertically out of socket (Item# 3).

for PS3300 & PS3400 Series

ASSEMBLY INSTRUCTIONS

1. To assemble, perform the “DISASSEMBLY INSTRUCTIONS” in reverse order.

Note: • Ensure the tab on the Regulator Module is inserted into the internal

2. Lubricate all O-rings and cavities with Vacuum grease (part# 1775) supplied in

the Preset Vacuum Regulator Repair Kit.

3. Repeat steps 1 through 3 of “OPERATING INSTRUCTIONS”.

4. Prior to returning Preset Vacuum Regulator to service verify preset vacuum

level with gauge reading.

slot on the Selector Module at the 9 o’clock position.

• Ensure the tab on the Control Knob Assembly at the 12 o’clock

position is aligned with the outer circumference slot on the

Selector Module at the 12 o’clock position.

CONTINUOUS & CONTINUOUS INTERMITTENT

7

PRESET VACUUM REGULATOR CLEANING ILLUSTRATION

(Cleaning/Decontamination Instructions on page 9)

Preset Vacuum

Regulator

To Be Cleaned

Working

Vacuum

Regulator

Back (Inlet) Connection

Suction

Tubing

Suction

Tubing

Vacuum

Port

Cold

Disinfection/

Sterilization

Solution

Patient

Port

Suction

Collection

Canister

CAUTION

•

DO NOT autoclave or immerse in liquid. This will cause damage

to the Preset Vacuum Regulator and will void the warranty.

•

If Preset Vacuum Regulator becomes internally contaminated,

warranty is voided, DO NOT send back to Precision Medical, Inc. for

repair. Follow the contaminated equipment protocol at your facility.

•

Ensure all connections are tight and leak free.

•

The Preset Vacuum Regulator contains magnetic, ferrous

material that may affect the results of an MRI.

Tell us how we are doing!

Visit us at www.precisionmedical.com

8

CONTINUOUS & CONTINUOUS INTERMITTENT

CLEANING / DECONTAMINATION (As needed)

1. Attach a working Vacuum Regulator with a continuous regulated

mode to a minimum vacuum source of 15 inHg.

2. Mix cold disinfection/sterilization solution according to its

manufacturer’s directions.

3. Connect tubing as shown in Cleaning Illustration on previous page.

4.

Turn the working Vacuum Regulator on to a continuous regulated mode.

5. Adjust the vacuum to a minimum of 120 mmHg.

6. Set the “Preset” Vacuum Regulator to be cleaned to the “REG.”

mode, and set at 100 mmHg.

7. Allow cold disinfection/sterilization solution to pass through Preset

Vacuum Regulator and collect in Suction Canister. Procedure should

continue for time recommended by the manufacturer of the cold

disinfection/sterilization solution for the desired level of disinfection or

sterilization.

8. Turn the Preset Vacuum Regulator to be cleaned to the “LINE” mode

(if applicable).

9. Allow remaining cold disinfection/sterilization solution to pass through

and collect in Suction Canister.

10.

Set working Vacuum Regulator to its maximum vacuum setting.

11. Thoroughly dry the internal components by drawing maximum

vacuum through the cleaned Regulator for at least 30 seconds in

both “REG.” and “LINE” modes (if applicable).

NOTE: If it is not possible to pass cold disinfection/sterilization solution

through the Regulator, then the passageways are totally blocked

and DISASSEMBLY of the Regulator is required. Ensure to follow

the Biohazard protocol at your facility.

MAINTENANCE

Before each use, visually inspect Preset Vacuum Regulator for any sign

of damage. DO NOT USE if damaged.

RETURNS

Returned products require a Returned Goods Authorization (RGA) number,

contact Precision Medical, Inc. All returns must be packaged in sealed

containers to prevent damage. Precision Medical, Inc. will not be responsible

for goods damaged in transit. Refer to Precision Medical, Inc. Return Policy

available on the Internet, www.precisionmedical.com.

Note: Federal Law prohibits shipping of BioHazard materials Via U.S. mail.

Manuals available on our Website; www.precisionmedical.com

CONTINUOUS & CONTINUOUS INTERMITTENT

9

DISPOSAL INSTRUCTIONS

Dispose of the Preset Vacuum Regulator in accordance with local regulations.

Please Recycle

WARNING

Biohazardous devices should be disposed of properly.

TROUBLESHOOTING

If the Preset Vacuum Regulator fails to function, consult the Troubleshooting

Table below. If problem cannot be solved, consult your Provider.

Problem Probable Cause Remedy

No vacuum at bottom

port (gauge at zero)

No vacuum at bottom

port (gauge showing

vacuum)

Vacuum at bottom port

(No reading on gauge

when port is blocked)

Gauge will not return

to zero

Vacuum Regulation

erratic

Stiff movement of

white Selector Knob

No digital display Dead battery Replace battery

PS3300/PS3400 Series ONLY:

No Intermittent

(INT.) cycle

1. Regulator turned “OFF”

2. Loose connection

3.

No vacuum to Regulator

4. Clogged vacuum Port

Clogged Regulator Disassemble and clean

Defective Gauge Replace Gauge

1. Clogged Snubber

2. Damaged Regulator

Module

3. Defective Gauge

1. Dirty Regulator Module

2. Defective Regulator

Module

Dirty Selector Module

cavity or O-rings

1. Improper mode

selected

2.

Defective Timing Module

1. a. Turn white Selector

Knob to “REG.” mode

b.

Adjust gray Preset Knob

2. Tighten connection

3.

Connect to a known

working vacuum source

4. Disassemble and clean

1. Replace Snubber

2. Replace Regulator

Module

3. Replace Gauge

1. Disassemble, clean and

lubricate O-ring

2. Replace Module

Disassemble, clean casting

cavity and lubricate cavity

and O-rings

1. Turn Selector Knob to

“INT.” mode

2.

Replace Timing Module

10

CONTINUOUS & CONTINUOUS INTERMITTENT

LIMITED WARRANTY

AND

LIMITATION OF LIABILITY

Precision Medical, Inc. warrants that the Medical Preset Vacuum Regulator

(the Product) will be free of defects in workmanship and/or material for the

following period:

Ten (10) years from date of shipment.

Should any failure to conform to this warranty appear within the applicable

period, Precision Medical, Inc. shall, upon written notication thereof and

substantiation that the goods have been stored, installed, maintained and

operated in accordance with Precision Medical, Inc.’s instructions and standard

industry practice, and that no modications, substitutions, or alterations have

been made to the goods, correct such defect by suitable repair or replacement

at its own expense.

ORAL STATEMENTS DO NOT CONSTITUTE WARRANTIES.

Representative of Precision Medical, Inc. or any retailers are not authorized

to make oral warranties about the merchandise described in this contract, and

any such statements shall not be relied upon and are not part of the contract

for sale. Thus, this writing is a nal, complete and exclusive statement of the

terms of that contract.

THIS WARRANTY IS EXCLUSIVE AND IS IN LIEU OF ANY WARRANTY OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR OTHER

WARRANTY OF QUALITY, WHETHER EXPRESSED OR IMPLIED.

Precision Medical, Inc. shall not under any circumstances be liable for special,

incidental or consequential damages including but not limited to lost prots, lost

sales, or injury to person or property. Correction of non-conformities as provided

above shall constitute fulllment of all liabilities of Precision Medical, Inc. whether

based on contract, negligence, strict tort or otherwise. Precision Medical, Inc.

reserves the right to discontinue manufacture of any product or change product

materials, designs, or specications without notice.

Precision Medical, Inc. reserves the right to correct clerical or typographical

errors without penalty.

507440 Rev2 (?M) 8/14 Printed in USA

Loading...

Loading...