Page 1

Uninterruptible Power Supply

SOLA 4000

OPERATING MANUAL

JUE 401263

Page 2

Contents of JUE 401263

SOLA 4000 Operating Manual

The SOLA 4000 Operating Manual consists of the following documents:

SECTION 0: JUE 401263 INDEX AND SAFETY INSTRUCTIONS

SECTION 1: JUE 401264 GENERAL SYSTEM DESCRIPTION

SECTION 2: JUE 401265 INSTALLATION AND INITIAL START-UP

SECTION 3: JUE 401266 OPERATION

SECTION 4: JUE 401267 OPERATING PANEL

SECTION 5: JUE 401268 PCB DESCRIPTION

SECTION 6: JUE 401269 TECHNICAL DATA

We reserve the right to modify the contents of this document without notice. BEST POWER- BORRI ELETTRONICA INDUSTRIALE S.r.l Via 8 Marzo Soci, Bibbiena (AREZZO)

ISSUED

See Rev. Doc. JSE401440A

04.02.97

20.06.97

T. Boon

T. Boon

04.02.97M. Porpora

A4 31

JUE 401263

Page 3

3

SOLA 4000 - Operating Manual

Safety Instructions

SAFETY INSTRUCTIONS

The unit must be used as intended. Follow the instructions given in

the Operating Manual.

Dangerous voltages are present inside the unit.

Installation and use of this equipment must comply to all national

and local regulations and procedures.

To prevent overheating do not obstruct the flow of air for ventilation openings to the unit.

The components inside the unit are not repairable by the user. The

user must not open the UPS cabinet or auxiliary cabinets or remove any protective covers from inside the UPS cabinet.

This equipment must be installed and serviced by qualified personnel.

The unit contains Lead-Acid batteries which must be disposed of

correctly, in compliance with the local regulations.

To completely isolate the equipment, the switches IRP, IRE,

IBY,IUG and IB must be switched off, the input supply and the

battery supply must be isolated from the UPS and the output

isolated from other modules if the unit is part of a multi-module

system. For 10-30kVA units with an internal battery, intermediate

links must be removed in order to isolate the battery in sections of

a safe working voltage.

High leakage current: connect protective earth before power

supply cables.

JUE 401263

Page 4

4

SOLA 4000 - Operating Manual

Safety Instructions

Earth leakage protection: this device has a high leakage current

towards protective earthing. The maximum earth leakage current is

300 mA. When setting the threshold of the earth leakage circuit

breaker installed upstream from this equipment consider this

amount of current and that due to the loads.

All primary power switches installed downstream of the UPS must

be labelled as follows: "Isolate UPS (Uninterruptible Power Supply)

before working on this circuit.

The unit is provided with the E.P.O. (Emergency Power Off)

function. This function is activated by pressing simultaneously the

two push buttons on the bottom part of the Front Panel. This

function provides UPS disconnection from the load and from the

battery. Dangerous voltages will still be present inside the unit, if a

shunt-trip of the input supply switch is not provided for.

During electrolysis, batteries release hydrogen gas. There is a risk

of an explosion if the amount of hydrogen in the battery room

becomes too high. Ensure appropriate ventilation of the battery

room according to the standard EN50091-1, to prevent the risk of

an explosion.

JUE 401263

Page 5

Contents of JUE 401264

SOLA 4000 - General System Description

Chapters

1 UPS ASSEMBLY 2

1.1 Features 2

1.2 UPS System Structure 3

1.3 Rectifier/Battery Charger 3

1.4 Battery (Accumulator) 4

1.5 Inverter 4

1.6 Static Switches 4

1.7 Maintenance Bypass 6

1.8 Hot-Standby Systems 6

1.9 Parallel-Redundant Systems 7

1.10 Parallel Systems 7

2 OPERATING PANEL 8

2.1 Functional Description 8

Figures

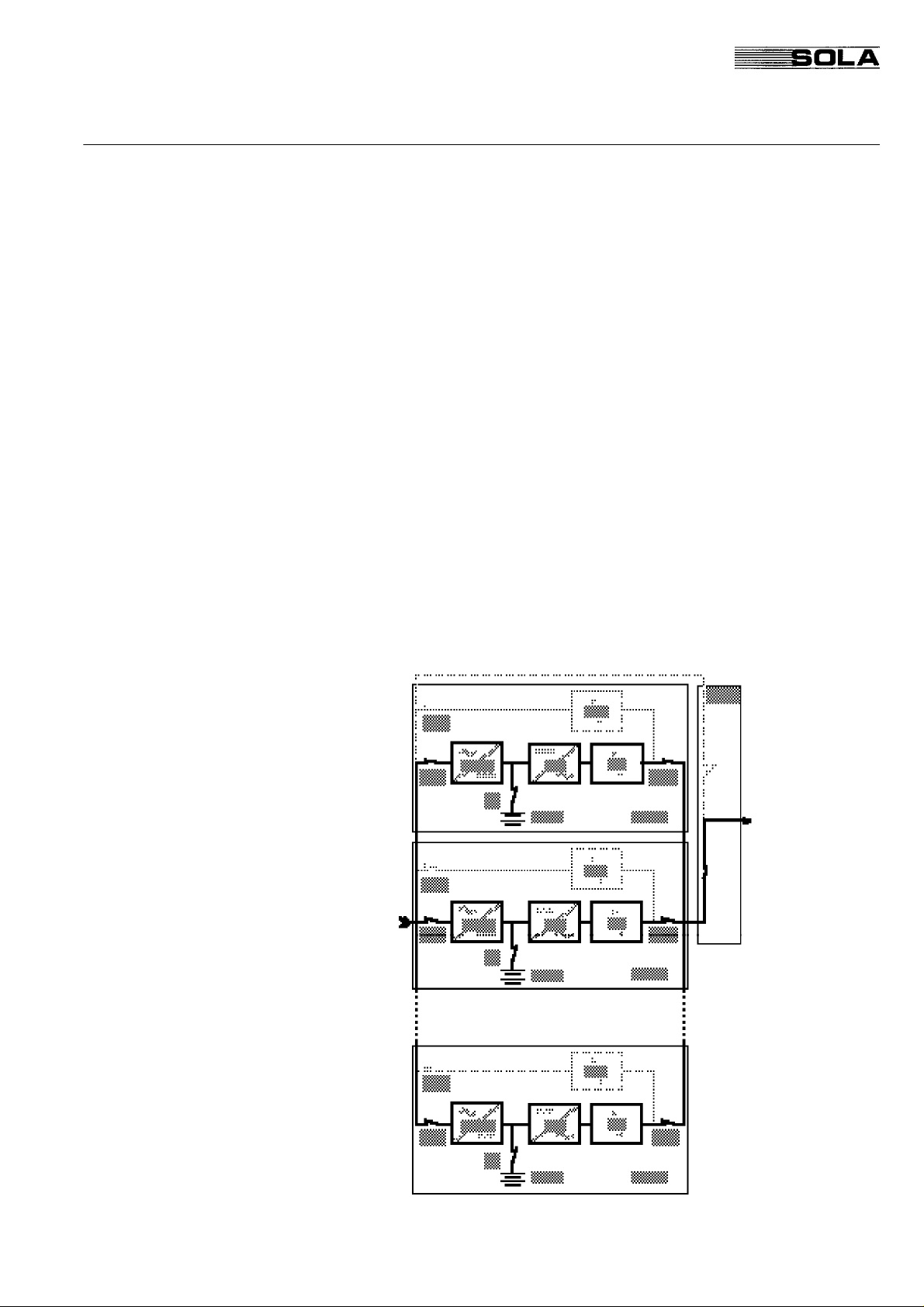

FIG. 1.1 UPS Block-Diagram 3

FIG. 1.2 Rectifier Block-Diagram 3

FIG. 1.3 12-Pulse Rectifier Block-Diagram 3

FIG. 1.4 Inverter Block-Diagram 4

FIG. 1.5 Static Switches Block-Diagram 4

FIG. 1.6 Maintenance Bypass Block-Diagram 6

FIG. 1.6.1 Wall-mounted Maintenance Bypass

Block-Diagram 6

FIG. 1.7 Hot-Standby Operation Block-Diagram

6

FIG. 1.8 Parallel Operation Block-Diagram 7

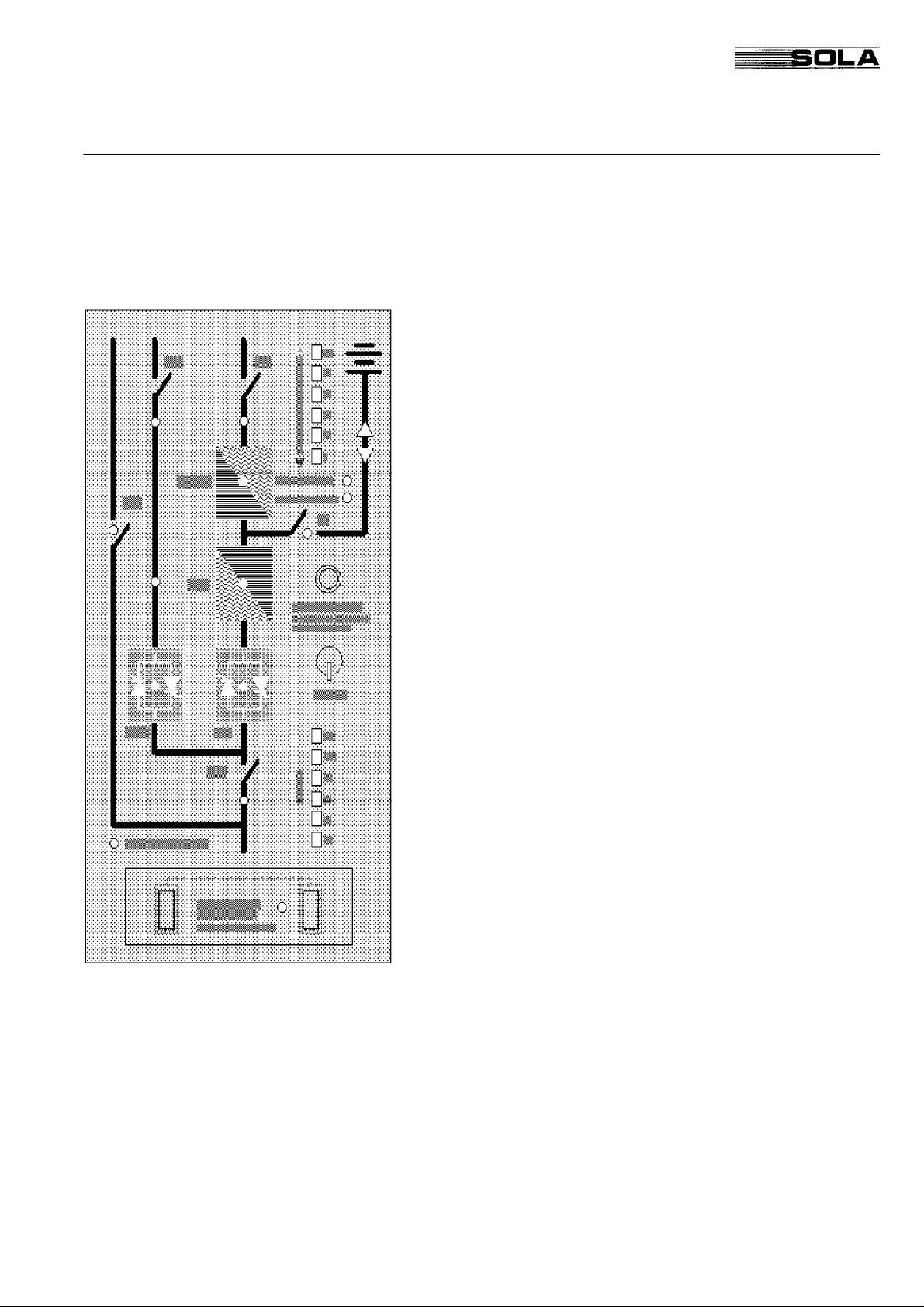

FIG. 2.1 SOLA 4000 Operating Panel 8

2.2 Remote Monitoring 8

2.3 Emergency Power Off 8

We reserve the right to modify the contents of this document without notice. BEST POWER- BORRI ELETTRONICA INDUSTRIALE S.r.l Via 8 Marzo Soci, Bibbiena (AREZZO)

ISSUED

See Rev. Doc. JSE401440A 20.06.97 T. Boon

04.02.97

T. Boon

04.02.97M. Porpora

A4 81

JUE 401264

Page 6

SOLA 4000 - General System Description

JUE 401264

1 UPS Assembly

1 UPS ASSEMBLY

1.1 Features

CE This equipment complies to the essential requirements of Euro-

pean Directives 89/336/EEC and 73/23/EEC, and complies to

EN50091-2 (1995) and EN50091-1 (1991) standards.

UPS Function The uninterruptible power supply (UPS) is connected between the

consumer's critical equipment (the load) and supply mains. Its

function is to guarantee a continuous and conditioned power supply

to the load. Even in the case of a total blackout it will supply the

load for a predetermined time (autonomy time). In addition, the

UPS provides the following advantages in comparison with conventional supply systems (mains, motor generator sets, etc.):

Better Output Power Characteristics The UPS output voltage control of frequency and amplitude guar-

antees consistent and stabilised output power. Mains voltage

fluctuations and frequency changes that are usually present in

electricity supply systems do not affect the UPS output voltage.

Uncoupling from Mains Distortion By using double energy conversion from ac to dc and back to ac

and using an isolation transformer in the inverter output, all mains

distortions are filtered out. Therefore, all loads connected to the

UPS system are protected against mains disturbances that can be

present in industrial electricity supply systems. This is especially

important for sensitive electronic devices, e.g. computer systems,

control systems, medical equipment.

Complete Protection against

Mains Failures

During long term or short term ac mains supply interruption, the

UPS system guarantees continuous supply to the connected loads

by means of a battery. The battery is connected to the rectifier

output and the inverter input of the UPS system. In normal operation the inverter (which feeds the load) is fed by the rectifier. In

case of a mains failure, the connected battery automatically feeds

the inverter. Thus the load is supplied without interruption. However, the load can only be supplied by the battery for a certain time

(autonomy time, see chapter 1.4 "Battery"). If longer autonomy

times are required, we recommend the use of a Diesel Generator

Set. In this case the battery autonomy time only has to be sufficient

for the time span between mains failure and full operating capacity

of the Diesel-Generator-Set.

This is a class A product.

In a domestic environment, this product may cause radio

interference, in which case, the user may be required to take

additional measures.

Page 7

SOLA 4000 - General System Description

JUE 401264

1 UPS Assembly

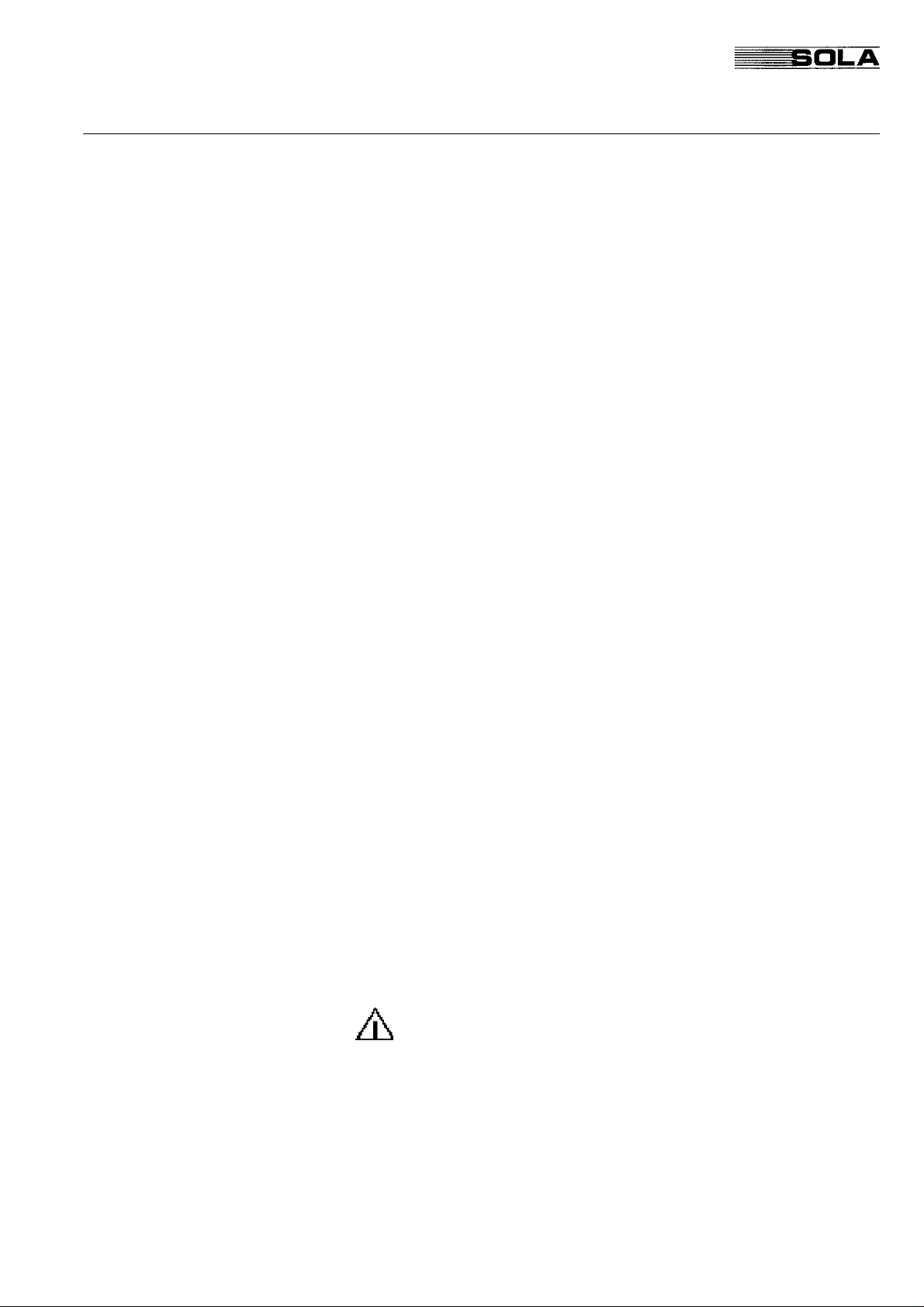

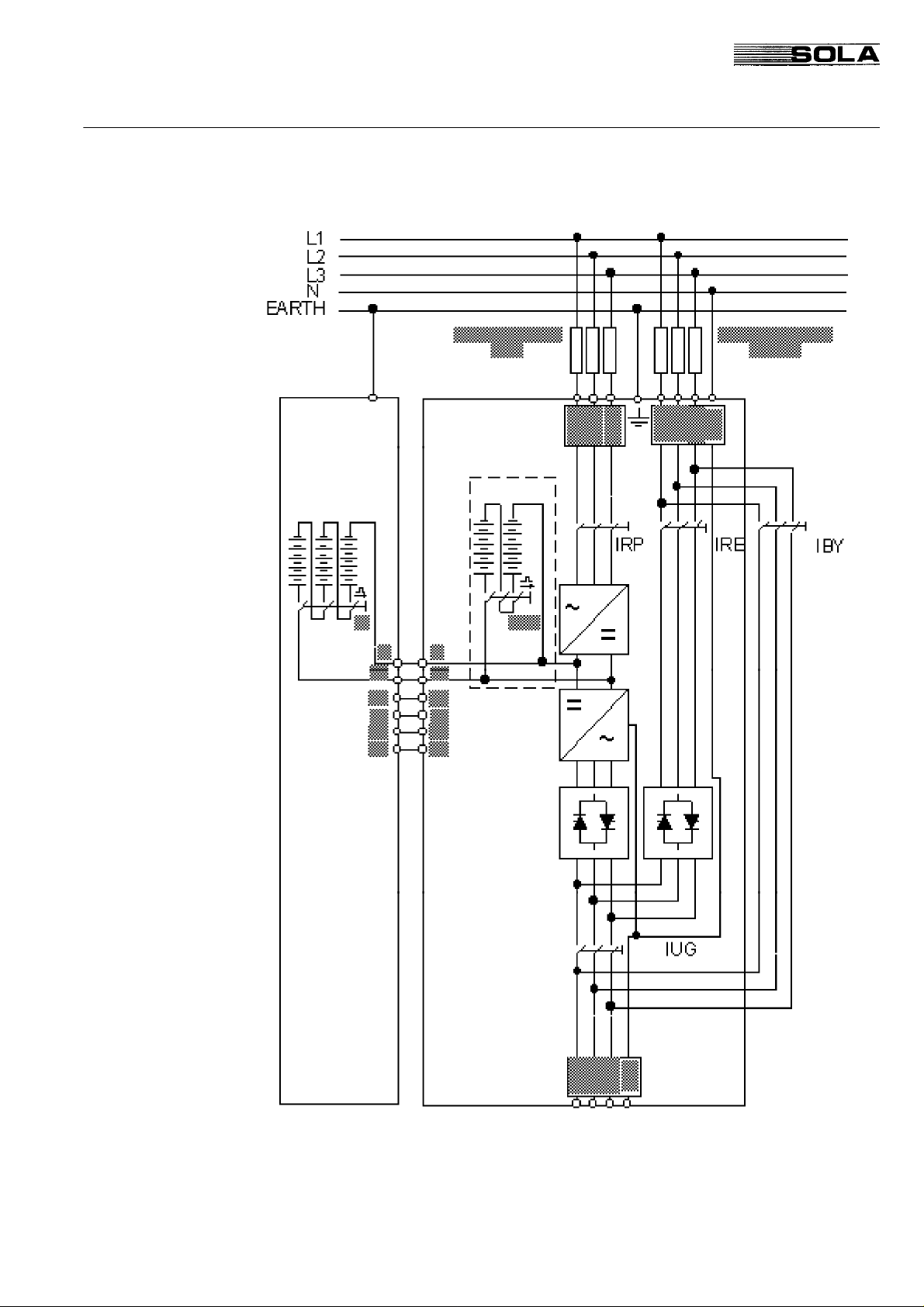

1.2 UPS System Structure

The basic SOLA 4000 power supply unit is an ac/dc/ac converter;

the block diagram: Figure 1.1 illustrates six essential functional

components:

• Rectifier/battery charger (6 pulse) (RECT.)

• Battery (BATT.)

• Inverter (INV.)

• Static inverter switch (SSI)

• Static bypass (SSB)

• Maintenance bypass (IBY)

All components are located in a single housing. They are explained

in detail on the following pages.The control electronics of the

rectifier, inverter and static bypass sections are completely independent of each other. i.e. a failure in any one section will not

cause a failure in another section.

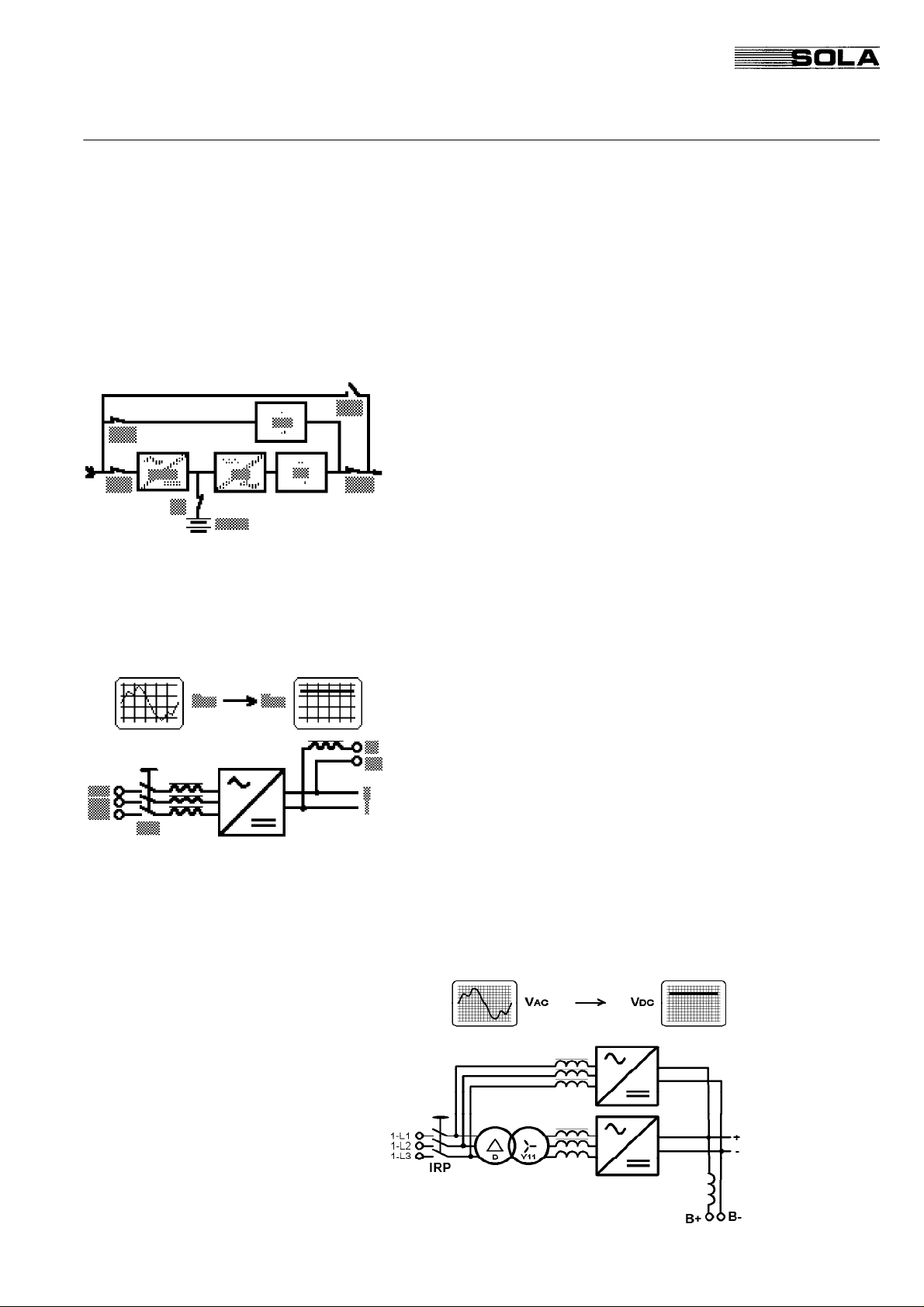

1.3 Rectifier/Battery Charger

In the standard configuration the charger is a three phase/6 pulse

rectifier that converts ac voltage to dc voltage. No isolation transformer is used and the rectifier is connected to the mains via the

commutation chokes which reduce the mains distortion created by

the rectifier. The dc output of the rectifier feeds the inverter and the

battery. The battery is connected to the rectifier through a saturation choke which reduces ac ripple current to the battery, thus

ensuring the maximum battery life-time.

The rectifier is designed to feed both the inverter at maximum load

conditions and simultaneously the battery with maximum charging

current. Normally, the battery voltage is constantly regulated at 432

V dc (floating charge, maintenance-free lead battery, 2.25 volts per

cell). The rectifier's recharge characteristic is of the I/U type. This

means that the recharging current limitation is accomplished by

reduction of the dc voltage, thus assuring that the batteries will not

be damaged by excessive charging currents.

A 12-pulse rectifier is optional and requires the addition of a second rectifier bridge inside the UPS cabinet and a phase shifting

transformer in a separate cabinet.

FIG. 1.3 - 12-pulse Rectifier Block-Diagram

Page 8

SOLA 4000 - General System Description

JUE 401264

1.4 Battery (Accumulator)

The battery supplies power in case of a short interruption or a total

breakdown of the ac mains supply. In case of a rectifier failure (no

dc voltage output), the load will be fed by the battery.

The battery is only capable of feeding the load for a certain time

(autonomy time), depending on battery capacity and actual load.

The number of cells within the battery depends on the battery type

and may also vary due to specific customer requirements. The

standard number is 192 cells for lead-acid batteries and 300 cells

for NiCd batteries. The battery capacity (Ah) depends on the UPS

output power and the required autonomy time. The battery of 1030kVA units is installed inside the UPS cabinet as standard. For

40-120kVA units (or 10-30kVA units with extended battery autonomy), batteries are installed in external battery cabinets.

1.5 Inverter

The inverter converts dc voltage supplied by the rectifier or battery

to ac voltage of a precisely stabilised amplitude and frequency that

is suitable for power supply to most sophisticated electrical equipment.

The inverter output voltage is generated by sinusoidal pulse width

modulation (PWM). The use of a high carrier frequency for the

PWM and a dedicated ac filter circuit consisting of the transformer

and capacitors, ensure a very low distortion of the output voltage

(THD<1% on linear loads).

Every phase voltage of the inverter output is controlled separately,

thus ensuring constant and equal UPS output voltages even with

highly unbalanced loads.

The inverter is designed specifically for the application of today's

loads i.e. The output harmonic distortion will be maintained at low

levels due to a unique adaptive correction technique, even with the

application of highly distorted loads.

The inverter control logic restricts the maximum output current to

150% of the nominal current in case of a short circuit. In case of

overload (up to 125% of the nominal current), the output voltage is

maintained constant. For higher currents the output voltage is

reduced, however, this will only occur if the bypass supply is not

available. Otherwise the UPS will switch to bypass operation for

currents higher than 110% of the nominal current.

The inverter IGBT transistors are fully protected from severe short

circuits by means of a desaturation monitor or "electronic fuse".

1 UPS Assembly

1.6 Static Switches

The block diagram illustrates the two static switch sections that use

thyristors as switching elements. During normal UPS operation,

SSI is closed and SSB is open, thus connecting the load to the

inverter output.

Page 9

SOLA 4000 - General System Description

JUE 401264

1 UPS Assembly

During overload or inverter failure conditions, SSI is switched off

and SSB is switched on, providing power supply from a backup

source (mains, output of another UPS system, diesel generator

set....). By always actuating both switches together for a short

period, an uninterrupted power supply during the switching is

ensured. This is an essential condition to reliably meet all power

supply requirements for connected sensitive equipment.

The control for each static switch (SSB and SSI) is performed

totally independently of each other, thus ensuring that a failure in

one static switch does not affect the other.

Switching Conditions, Inverter - Bypass

The voltage and frequency of the bypass line have to be within

set tolerance limits, and the inverters have to be synchronised

with the bypass line.

Under inverter failure conditions:

(i) the UPS switches to bypass operation, for a single unit. (SSB

switches on, and SSI off).

(ii) for hot-standby units, the load is commutated to the second

inverter, and will switch to bypass only when no inverter is ready to

take the load.

(iii) in parallel systems, all units switch to bypass operation together

only if the load is more than the rated value for the remaining on-line

units.

If the conditions above for the bypass line and synchronisation

are not met:

• the inverter will continue to operate with reduced output voltage

under overload conditions, or

• the inverter will stop if an inverter failure occurs.

In this second case, the system will:

(i) commutate to a second standby-inverter in the case of a hot-

standby system

(ii) the remaining inverters will take the load in the case of a

parallel-redundant system or,

(iii) the UPS will commutate to the bypass supply with a very short

interruption of 10msec if the supplies are not synchronised, for the

case of a single UPS unit.

Under overload conditions, all UPS modules present will

switch to the bypass supply, and remain in bypass until the

overload is removed.

Switching Conditions, Bypass - Inverter a) The UPS switches automatically back to inverter operation

when inverter voltage and frequency are within tolerance limits,

the overload has been removed and the inverter is synchronised with the bypass line (SSI switches on and SSB off).

b) If the UPS unsuccessfully attempts five times within 3 minutes

to switch to inverter operation, the UPS remains in bypass

operation and signals an alarm. After pressing the reset-button

once to reset the audible alarm, it should be pressed a second

time to automatically switch back to inverter operation.

c) If the UPS remains blocked on bypass operation and a mains

failure occurs, the UPS will switch automatically to inverter

operation if the inverter voltage and frequency are within

tolerance and the inverter is synchronised to the mains.

Page 10

SOLA 4000 - General System Description

JUE 401264

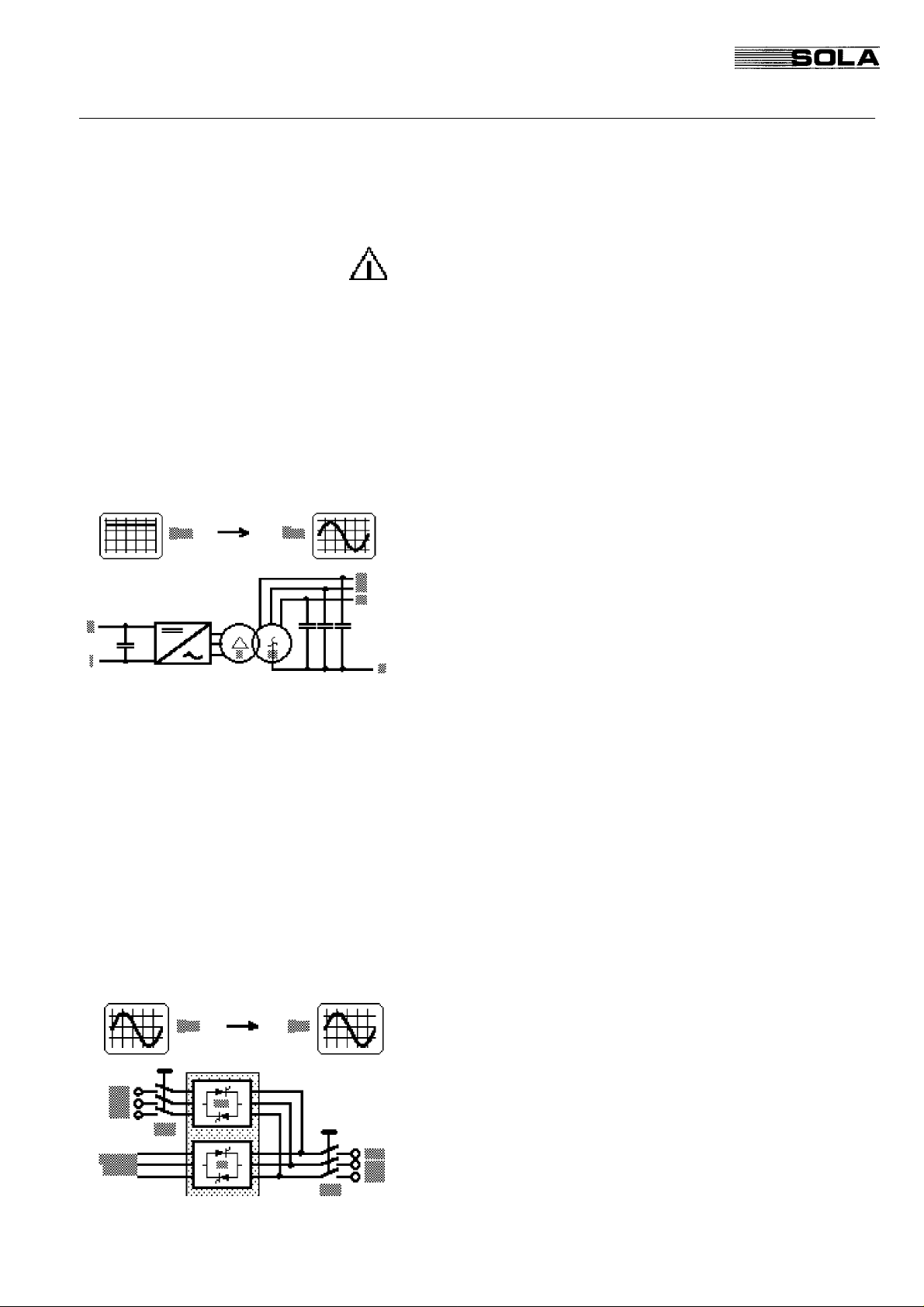

1.7 Maintenance Bypass

The maintenance bypass function is to supply power directly to the

connected load during UPS maintenance. The bypass consists

essentially of one switch IBY.

With SOLA 4000 series UPS systems, switching from different

operating modes to maintenance bypass can be performed without

interruption. With the maintenance bypass on, the UPS system

may be completely switched off, thus permitting maintenance work

to be carried out safely ( there will only be voltage at the input and

output terminals and their connections to the circuit-breakers).

In order to prevent erraneous switching of the maintenance bypass

switch IBY that could possibly cause parallel connection of the

bypass line and the inverter line, IBY is electronically interconnected with the static inverter switch SSI. Thus, during actuation of

IBY, switch SSB will be closed and switch SSI opened automatically, preventing parallel operation of the maintenance bypass

network and the inverter.

1 UPS Assembly

As an option, an external wall-mounted no-break maintenance

bypass switch (see FIG. 1.6.1) may be supplied by SOLA.This

switch provides simple one-step transfer to maintenance bypass

(version 1) without the possibility of erraneous switching and

without interruption to the load.For the version 2 type maintenance

bypass, an additional position is provided in order to completely

isolate the UPS with the one bypass switch.In this way, the UPS

may be isolated totally from all supply by switching off the input

supply to the UPS.

1.8 Hot-Standby Systems

A hot-standby UPS system basically consists of two (or more)

single UPS units which operate independently of each other. Any

one unit can be feeding the load at any time.

• All units are continuously in operation; but only one is supplying

the load, at any one time.

• In case of a failure in the unit currently supplying the load,

another unit is ready to takeover the load without an interruption on the output side. i.e. the load is still supplied with conditioned and stabilised power.

• The load is supplied by the static bypass, only if there is no

inverter ready in the system to takeover the load.

Page 11

SOLA 4000 - General System Description

JUE 401264

1 UPS Assembly

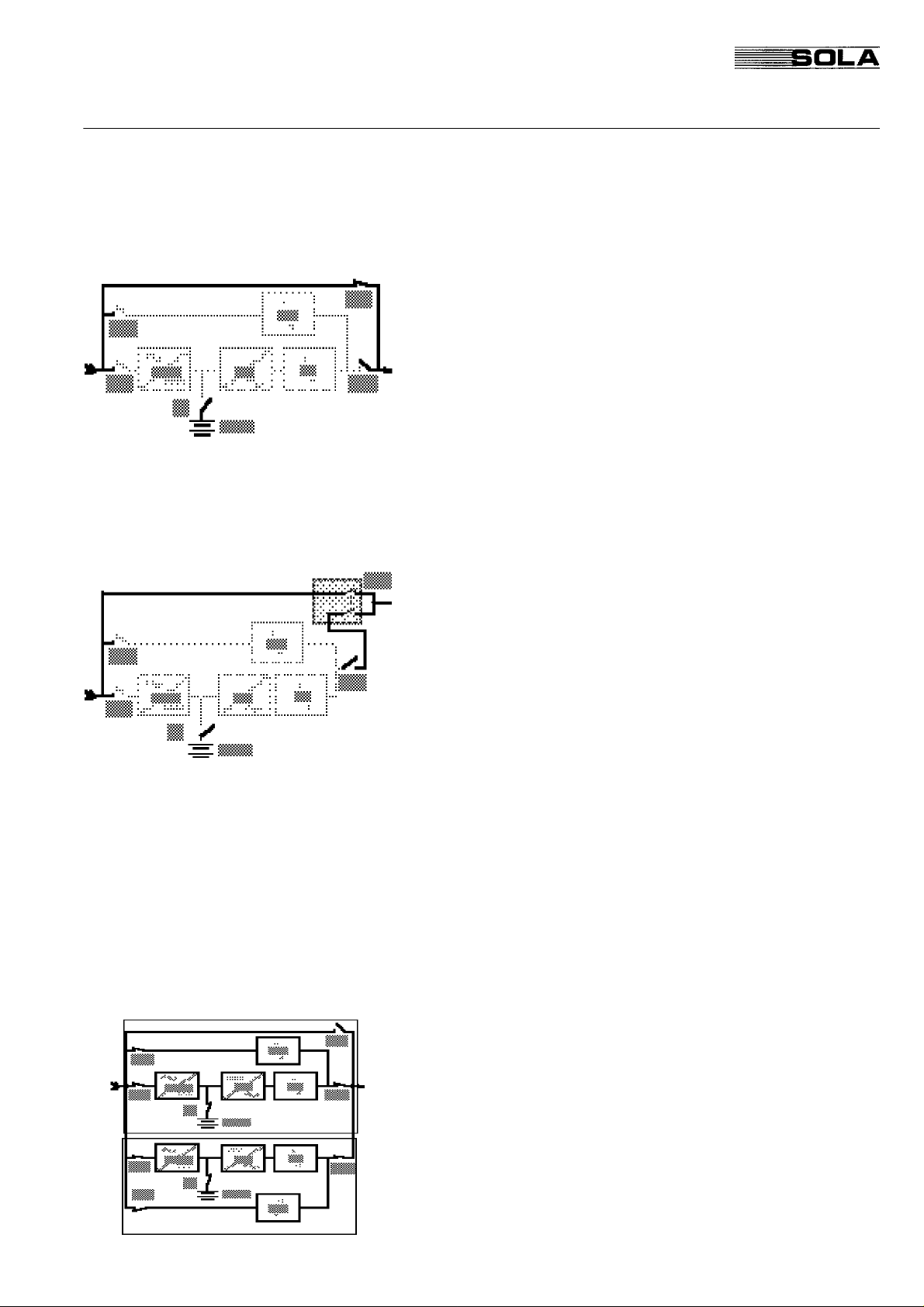

1.9 Parallel-Redundant Systems

A parallel UPS system consists of 2 to 8 single UPS units connected in parallel, sharing the load current equally. Each unit has an

individual static bypass, thus ensuring also redundancy of the static

bypasses in a redundant system, i.e. if one static bypass should fail,

the bypass system will still be available.

There is no common electronic device for the parallel system. Each

unit has its own parallel-operation electronics that controls all of its

functions, thus ensuring perfect redundancy.

1.10 Parallel Systems

This is identical to the configuration in section 1.9 except that the

rated load is normally equal to the rating of the UPS and there is

therefore no redundant unit. UPS units of different kVA ratings may

be connected in parallel in this configuration, proportionally sharing

the load.

Note that the parallel configuration is identical to the parallelredundant configuration if the load is reduced to a value such that

the system minus one (or more) units is capable of supplying the

reduced load. Therefore one (or more) units become redundant and

the control is identical.

FIG. 1.8 - Parallel Operation - Block Diagram

Page 12

SOLA 4000 - General System Description

JUE 401264

2 OPERATING PANEL

2.1 Functional Description

The operating panel is the user-interface of the UPS. It offers the

following functions:

• Indication of important data (actual load, battery charging

status, battery autonomy during the "BACK UP" phase)

• Protective functions ( Battery Running Down, Battery Test)

• Indication of the UPS operating mode

• Alarm signalling (audible and visual)

• Start push button

• Reset function after retransfer blocked condition

• Emergency-Power-Off function

The panel can be subdivided in four functional sections:

1. Block diagram with status LEDs

2. Battery autonomy and charging status

3. Percentage of load supplied

4. E.P.O. push-button

2 Operating Panel

2.2 Remote Monitoring

The operating panel provides an option to communicate with a

computer through RS232 and RS485 interfaces. The RS232 serial

interface communicates with a PC or mainframe computer, with a

SNMP protocol (SEC). With the RS485 interface it is possible to

transmit all necessary data up to a distance of 400m or to connect

a remote monitoring panel.

2.3 Emergency Power Off

In case of emergency it is possible to switch off the entire UPS

system. This is done by simultaneously pressing the "Emergency

Power Off" (E.P.O.) push-buttons located on the operating panel.

This function provides UPS disconnection from the load and the

battery, when a separate shunt-trip battery circuit breaker is installed.

In the case of parallel and hot-standby configurations, activating

E.P.O on one unit, automatically switches OFF the entire system

(when IUG is closed on that unit).

Page 13

Contents of JUE 401265

SOLA 4000 - Installation and Initial Start-Up

Chapters

1 INSTALLATION 3

1.1 Mechanical Installation 3

1.2 Electrical Installation 8

1.3 Install. of Additional Optional Cabinets 13

1.4 Installation of an External Maintenance

Bypass 16

1.5 CPNET Interface Card 18

1.6 Remote Emergency Power off 20

1.7 Diesel - Generator Operation 21

1.8 Common Alarm Contacts 22

1.9 Remote Reset 22

1.10 Installation of Hot-Standby Systems 23

1.10.1Installation of the Interconnection Cable 25

1.11 Installation of Parallel Systems 26

1.11.1Installation of the Interconnection Cable 29

1.12 Battery Installation 30

1.12.1Installation of the Internal Batteries SOLA

4000 10-30kVA 30

1.12.2Installation of External Batteries 32

Figures

FIG.1.1.1 Moving the UPS 10-60kVA units 3

FIG.1.1.2 10-60kVA UPS floor space 4

FIG.1.1.3 80-120kVA UPS floor space 4

FIG.1.1.4 AC001 transformer cabinet 4

FIG.1.1.5 AC002 transformer cabinet 4

FIG.1.1.6 10-60kVA UPS room size 5

FIG.1.1.7 80-120kVA UPS room size 6

FIG.1.1.8 80-120kVA UPS room size 7

FIG.1.2.1 UPS connection diagram, version 1 9

FIG.1.2.2 UPS connection diagram, version 2 11

FIG.1.3.1 UPS connection diagram, with input

and output transformers 13

FIG.1.3.2 UPS connection diagram, with bypass

input transformer 13

FIG.1.3.3 UPS connection diagram, with THD

filters 14

FIG.1.3.4 Installation of 12-pulse units without

galvanic isolation 15

FIG.1.3.5 Installation of 12-pulse units with

galvanic isolation 15

2 INITIAL START- UP 38

2.1 Start-Up Procedure 38

3 ADDITIONAL START- UP

PROCEDURE FOR MULTI-UNIT

SYSTEMS 42

3.1 Start-Up Procedure for

Hot-standby Systems 42

3.2 Start-Up Procedure

for Parallel Systems 43

We reserve the right to modify the contents of this document without notice. BEST POWER- BORRI ELETTRONICA INDUSTRIALE S.r.l Via 8 Marzo Soci, Bibbiena (AREZZO)

ISSUED

See Rev. Doc. JSE401479B08.08.97

See Rev. Doc. JSE401490

C

See Rev. Doc. JSE401547D23.09.97 T. Boon

04.02.97

01.09.97

M. Porpora

M. Porpora

FIG.1.4.1 External maintenance bypass switch,

version 1 16

FIG.1.4.2 External maintenance bypass switch,

version 2 17

FIG.1.6.1 Connection of remote EPO with N.C.

contact 20

FIG.1.6.2 Connection of remote EPO witn N.O.

contact 20

FIG.1.6.3 Connection of remote emergency

power off - input and battery circuit

breaker trip circuit 20

FIG.1.7.1 Connection for diesel generator

operation - syncronisation disable 21

FIG.1.7.2 Connection for diesel generator

operation - second level current

limitation 21

M. Porpora

T. Boon

04.02.97

A4 441

JUE 401265

Page 14

SOLA 4000 - Installation and Initial Start-Up

SOLA 4000 - Installation and Initial Start-Up

FIG.1.8.1 Connec. of remote common alarm 22

Figures

FIG.1.9.1 Connection of remote reset 22

FIG.1.10.1Interconnection of hot-standby units

with integrated maintenance bypasses

and separate bypass terminals 23

FIG.1.10.2Interconnection of hot-standby units

with external maintenance bypass and

separate bypass terminals. 24

FIG.1.10.3Interconnection of control BUS cable

for hot-standby units 25

FIG.1.11.1Interconnection of parallel units with

integrated maintenance bypasses and

separate bypass terminals. 27

FIG.1.11.2Interconnection of parallel units with

common maintenance bypass and

separate bypass terminals 28

FIG.1.11.3Location of connectors on the

IBYBP-CP pcb 29

FIG.1.11.4Interconnection of control BUS cables

between parallel units 29

FIG.1.12.1Internal battery connections 31

FIG.1.12.2B3/38: battery tray in the first level 32

FIG.1.12.3B3/38: batt. trays in the second and the

third level 32

FIG.1.12.4Battery cabinet B3/38 32

FIG.1.12.5B3/38:switch IB and terminals 33

FIG.1.12.6B3/38 internal electrical connec. 34

FIG.1.12.7Battery cabinet B3/65 35

FIG.1.12.8B3/65:switch IB and terminals 35

FIG.1.12.9B3/65 internal electrical connec. 36

FIG.1.12.10UPS with additional batt. cabinet 37

Page 15

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1 INSTALLATION

1.1 Mechanical Installation

Equipment Delivery and Storage After delivery, check equipment for any damage that may have

occurred during shipment. The shipper and your SOLA agency

must be notified in writing about damages due to shipment, including a detailed description of visual defects. If you do not wish to

install the equipment immediately, please observe the following

storage recommendations:

• Store equipment in a vertical position in a well conditioned

room, protected against humidity. Do not store the equipment

in close proximity to frequently used passageways and keep it

away from movable parts.

• If the UPS system is already unpacked, please ensure storage

in a clean environment protected from dust, away from heat

sources.

Handling the UPS System The UPS can be simply lifted and moved by means of a lifting

truck or a fork lifter for 80-120kVA units. For 10-60kVA units,

remove the front side and rear side base sheets and attach two

angle irons with 8MA bolts to the right front and rear side of the

UPS. The UPS can now be moved with a lifting fork. Remove the

angle irons when the UPS is set in the correct position.

Caution: Secure equipment against being knocked over

Setting Up The UPS system should be installed in a dry, clean and lockable

room. Provisions have to be made to remove heat created by the

system. Under all installation conditions, the unrestricted flow of

cooling air must be assured.

Page 16

SOLA 4000 - Installation and Initial Start-Up

Weight

1 Installation

Floor Space Required

Type

SOLA

4000

100 840 - 1219

120 870 - 1263

TAB. 1.1.1 UPS weight

Weight

without

Battery

[kg]

10 310 597 1277(*)

15 310 597 1277(*)

20 335 622 1330(*)

30 350 637 1362(*)

40 480 - 1026

60 520 - 1112

80 810 - 1176

Weight

with

Battery

[kg]

Static

Load

-

[kg/m²]

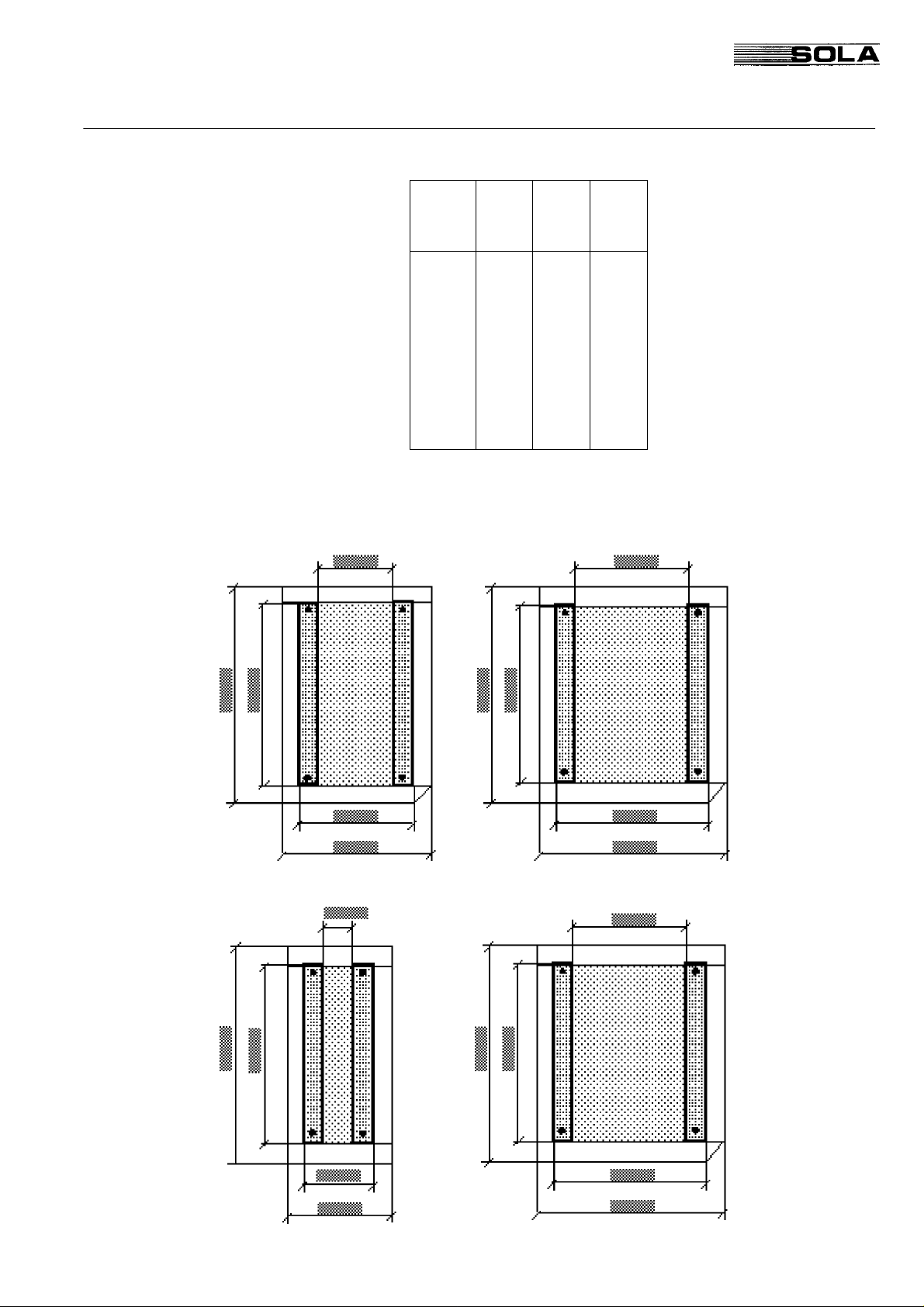

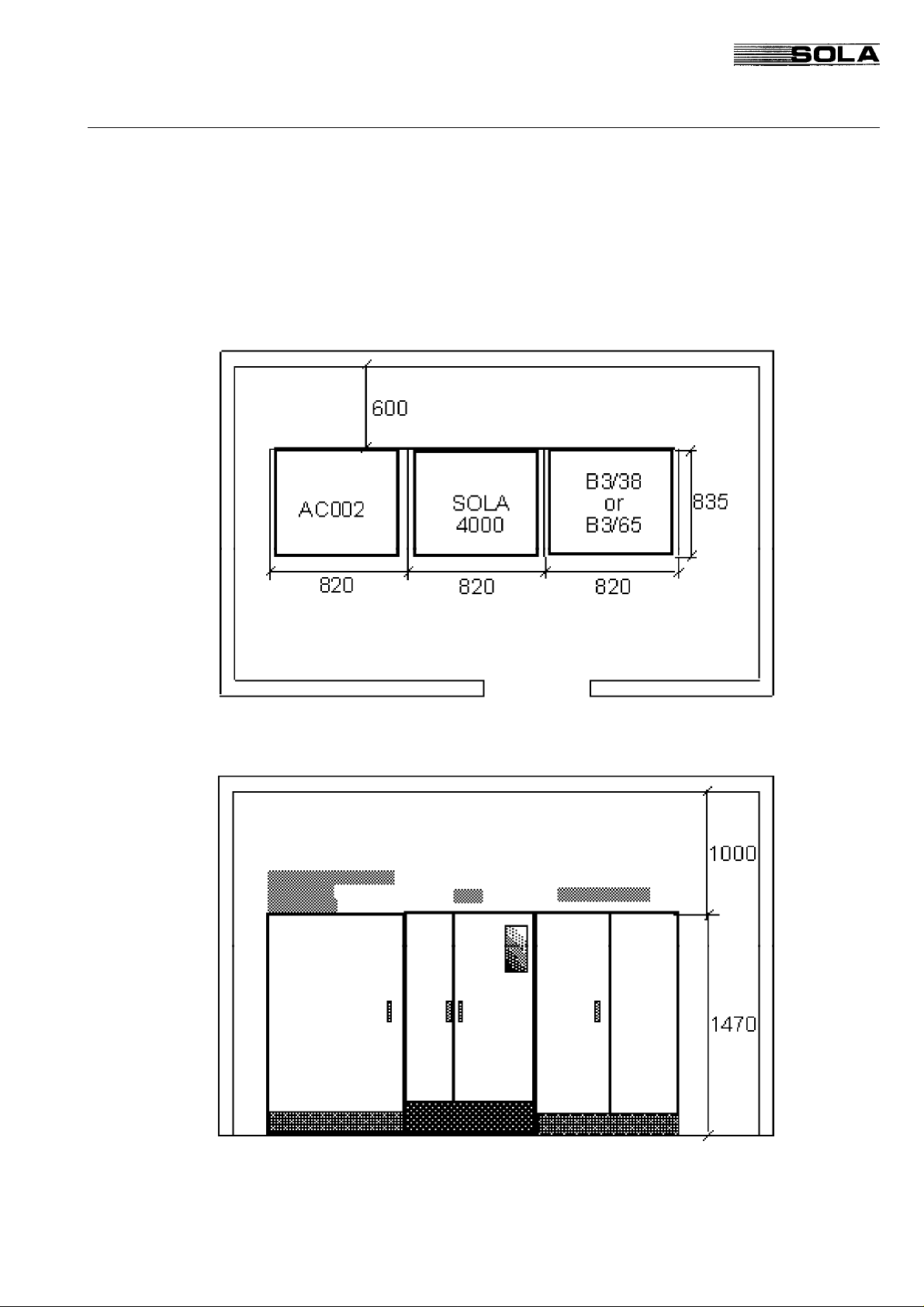

FIG. 1.1.2 10-60kVA UPS floor space FIG. 1.1.3 80-120kVA UPS floor space

Page 17

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Room Size for 10-60 kVA UPS

FIG. 1.1.6 UPS 10-60kVA room size

Page 18

SOLA 4000 - Installation and Initial Start-Up

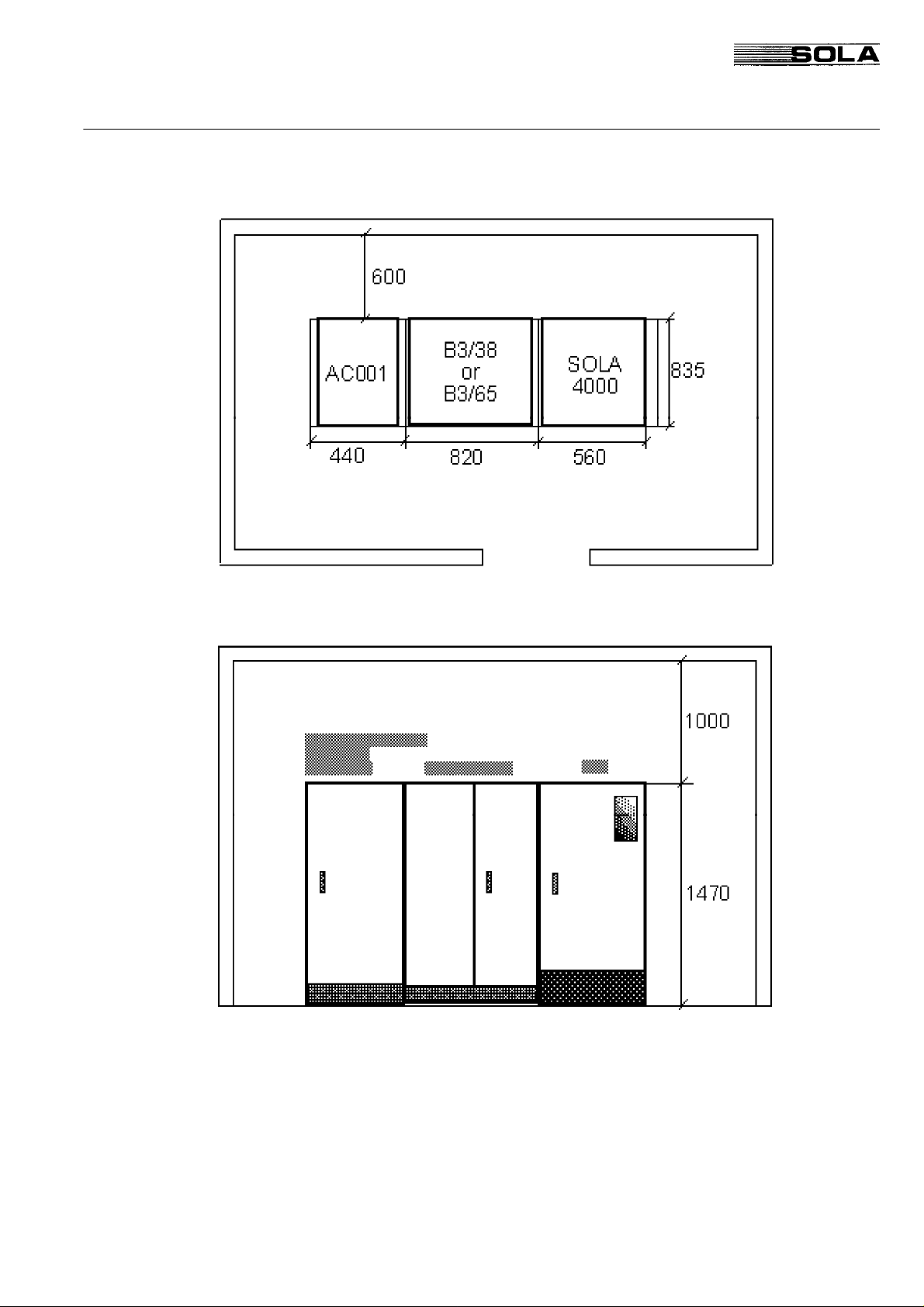

Room Size for 80-120 kVA UPS with

auxiliary AC001 cabinet

AC001 cabinets are used for SOLA 4000 units with 12 pulse

chargers without galvanic separation and with THD Filters.

1 Installation

FIG. 1.1.7 UPS 80-120kVA room size

Page 19

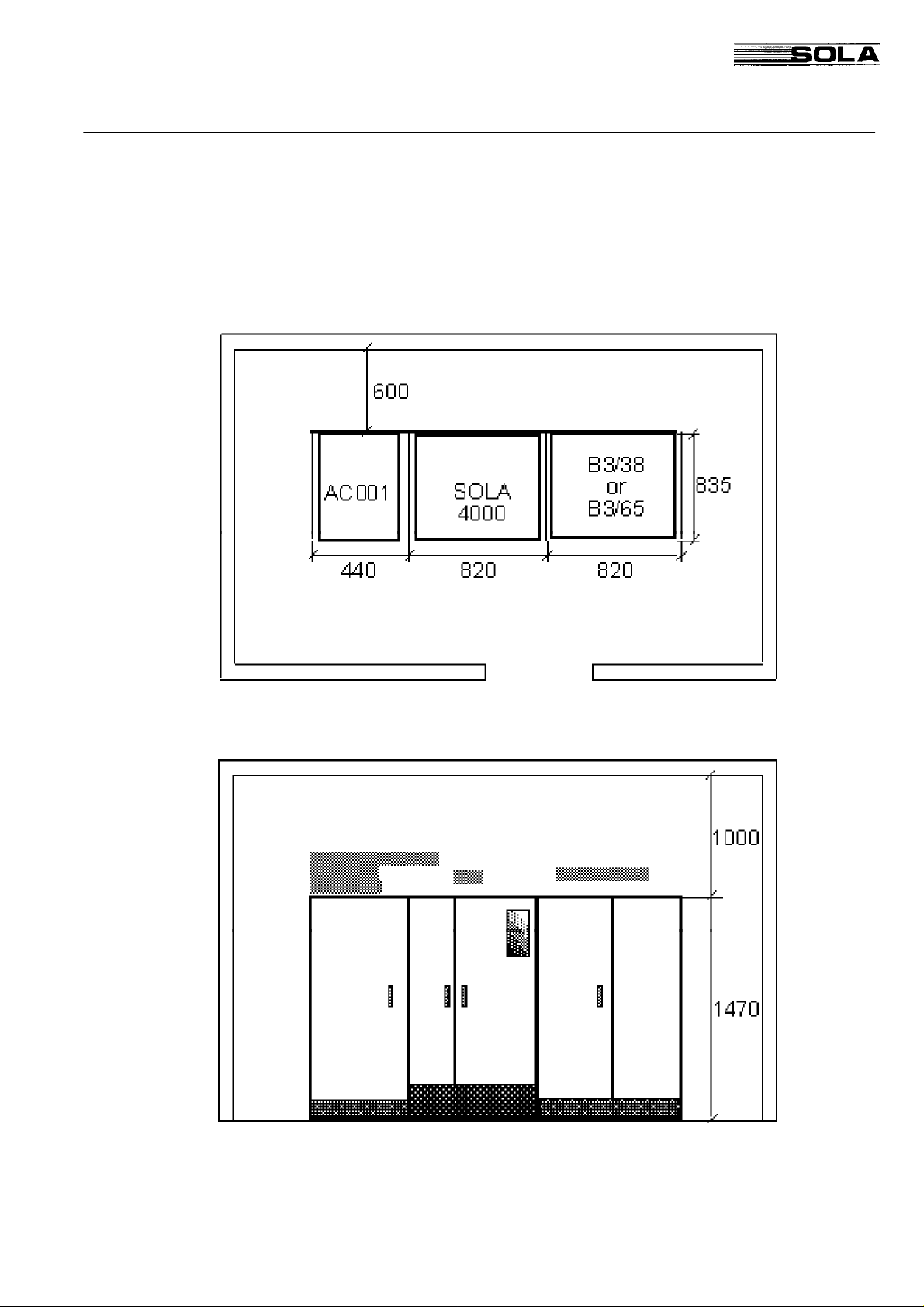

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Room Size for 80-120 kVA UPS with

auxiliary AC002 cabinet

AC002 cabinets are used for SOLA 4000 units with 12 pulse

chargers with galvanic separation and with auxiliary transformers.

FIG. 1.1.8 UPS 80-120kVA room size

Page 20

SOLA 4000 - Installation and Initial Start-Up

1.2 Electrical Installation

This equipment must be installed by qualified service personnel.

Switch off IRP, IRE, IB, IUG, IBY circuit breakers to completely

isolate the equipment.

Earth leakage protection: this device has high leakage current

towards protective earthing. Earth leakage circuit breakers

shouldn't be installed upstream from this equipment or a correct

threshold should be set.

High leakage current - it is essential to connect the protective

earth before connecting the power supply.

All primary power switches installed remotely from the UPS area

must be fitted with the following label: "Isolate uninterruptible

power supply (UPS) before working on this circuit".

1 Installation

General

All electrical connections must be made in accordance with local

standards and all input terminals (1-L1, 1-L2, 1-L3 and, if existing,

4-L1, 4-L2, 4-L3) must be protected by external fuses. The tables

give recommended values for fuse sizes and cable cross-sections.

These may vary, depending on local standards. They are valid for

voltages 380/220 V, 400/230 V and 415/240 V. Ensure clockwise

connection of conductors L1, L2 and L3 at input and output terminals.

If possible, install battery cables separately from other power

cables in order to avoid possible RF interference. Before wiring,

open all system switches (IRP, IRE, IBY, IUG) plus the battery

switch (IB).

Page 21

SOLA 4000 - Installation and Initial Start-Up

1 Installation

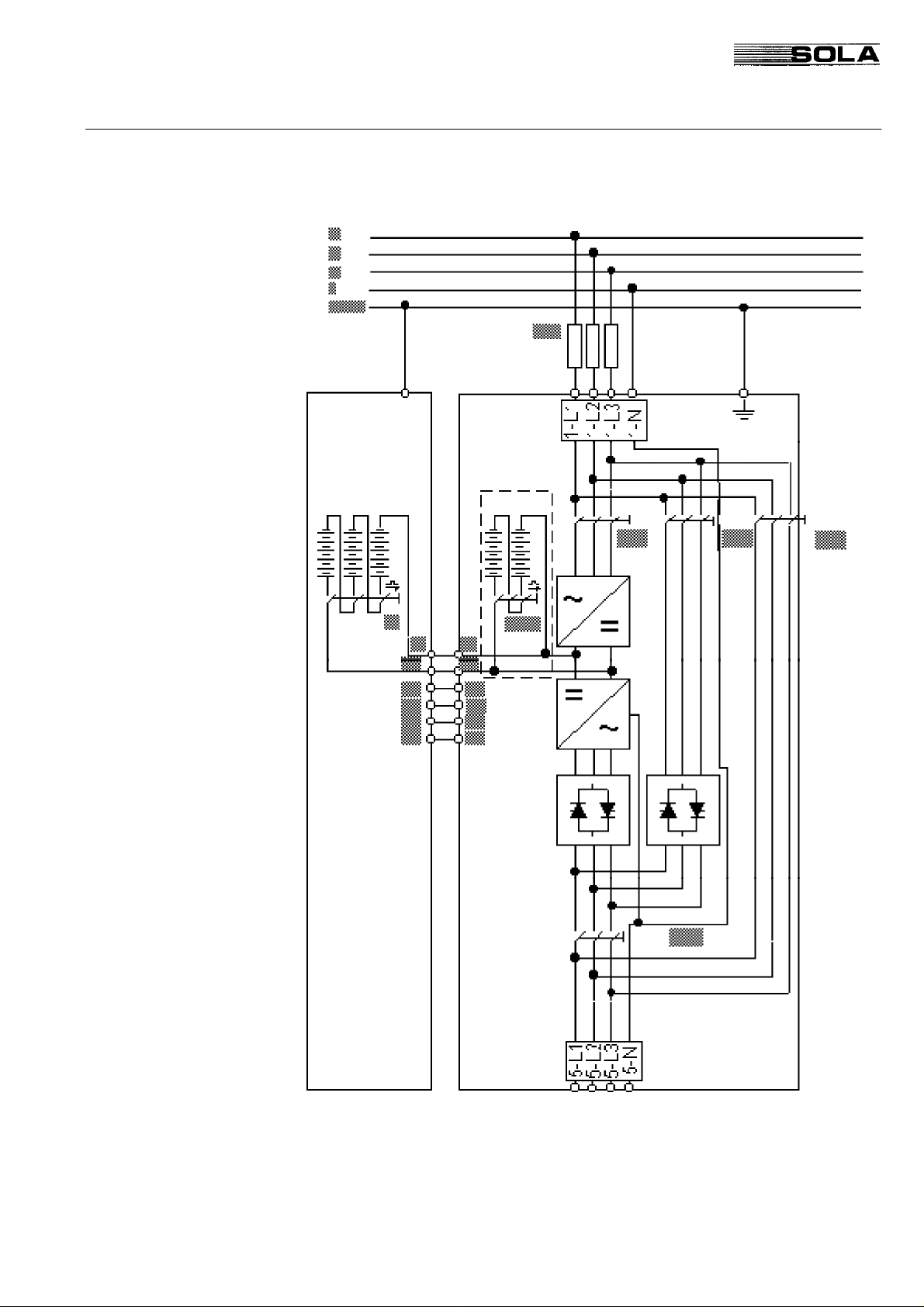

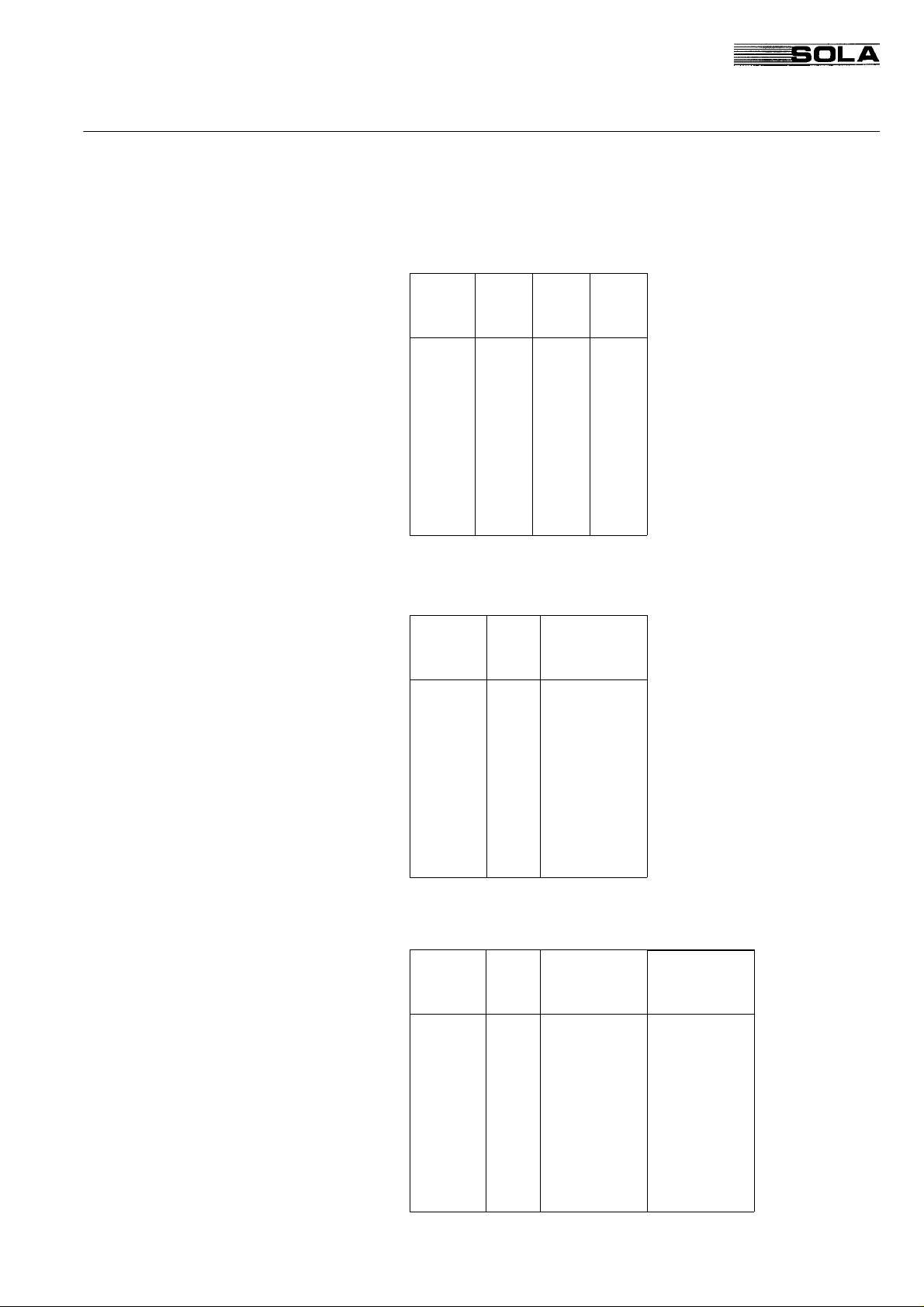

Version 1 SOLA 4000 with Common Input

for Rectifier and Bypass

FIG. 1.2.1 UPS connection diagram, version 1

(*) Note: Internal Battery only for 10-30kVA units

(**) Note: Customer supplied input fuses - see table 1.2.1

Page 22

SOLA 4000 - Installation and Initial Start-Up

Version 1 SOLA 4000 with Common Input for

Input Cables / Fuses

1 Installation

Rectifier and Bypass

Output / Battery Cables and Max. Cur-

rent Ratings for Battery Overcurr. pro-

tection

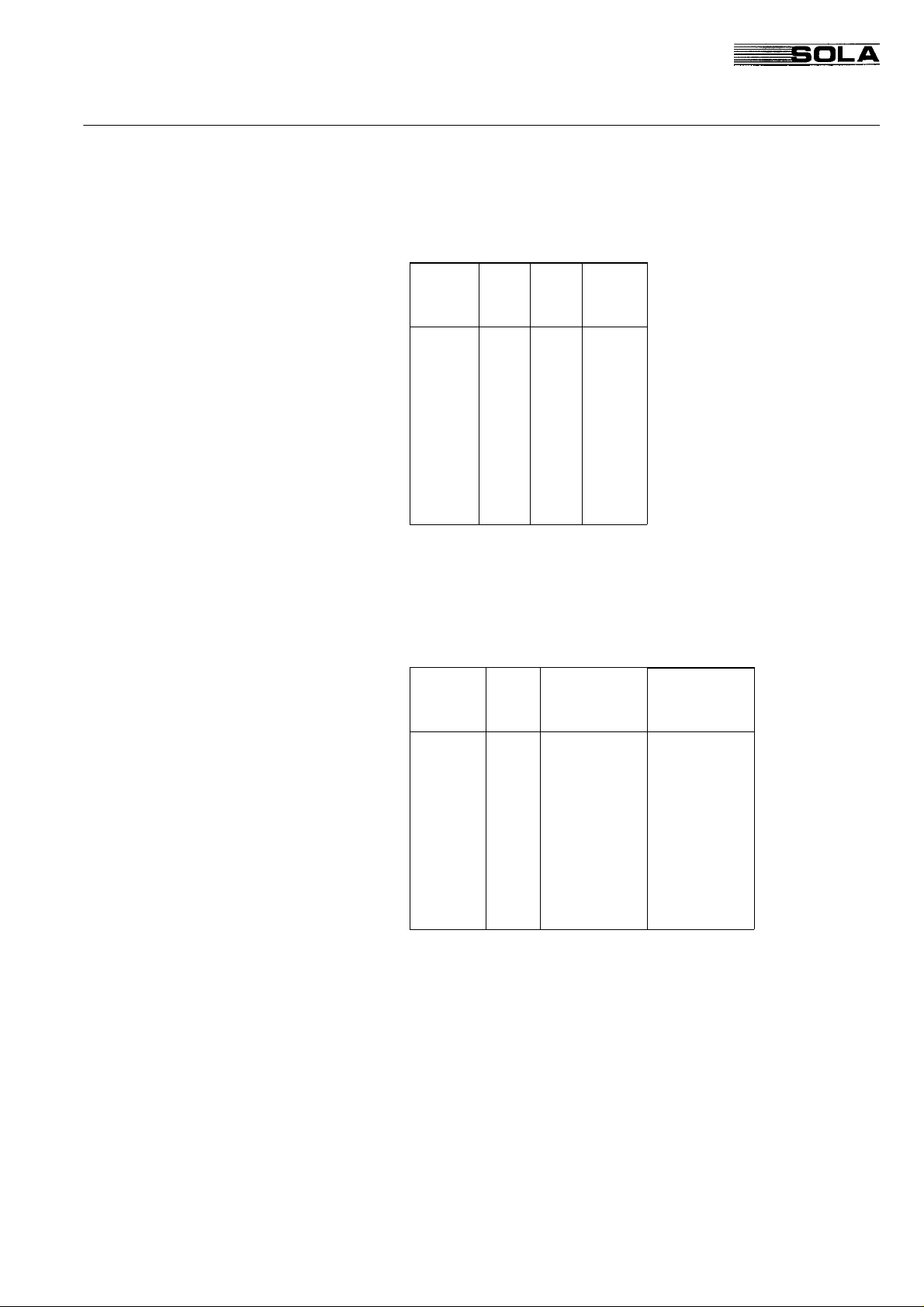

Type

SOLA

4000

10 4x10 25 16

15 4x10 35 16

20 4x16 50 16

30 4x25 63 25

40 4x35 100 25

60 4x35 125 25

80 4x70 160 50

100 4x70 200 50

120 4x120 250 70

TAB.1.2.1 UPS input cables

and fuses, version 1

Type

SOLA

4000

100 2x95 4x70 250

120 2x120 4 x120 300

Input

cables

[mm²]

Battery

cables

10 2x16 4x10 25

15 2x16 4x10 40

20 2x25 4x16 50

30 2x25 4x35 75

40 2x35 4x25 100

60 2x50 4x35 150

80 2x70 4x50 200

[mm²]

Input

fuses

[A]

Output cables

earth

cable

[mm²]

[mm²]

Max. inv. input

current

(Vdc=320V)

TAB.1.2.2 UPS output cables and fuses, version 1

Page 23

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Version 2 SOLA 4000 with Separate Inputs

for Rectifier and Bypass

FIG. 1.2.2 UPS connection diagram, version 2

(*) Note: Internal Battery only for 10-30kVA units

(**) Note: Customer supplied rectifier input fuses - see table 1.2.5

(***) Note: Customer supplied bypass input fuses - see table 1.2.5

Page 24

SOLA 4000 - Installation and Initial Start-Up

Version 2 SOLA 4000 with Separate Inputs

Input Cables

Type

SOLA

4000

10 3x10 4x10 16

15 3x10 4x10 16

20 3x16 4x16 16

30 3x25 4x25 25

40 3x25 4x25 25

60 3x35 4x35 25

80 3x50 4x50 50

100 3x70 4x70 50

120 3x120 4x120 70

Rect.

cables

[mm²]

1 Installation

for Rectifier and Bypass

Bypass

cables

[mm²]

earth

cable

[mm²]

Input Fuses

Output / Battery Cables

TAB. 1.2.3 UPS input cables, version 2

Type

SOLA

Rect.

Fuses

4000

10 25 25

15 35 35

20 50 50

30 63 63

40 100 100

60 100 125

80 125 160

100 160 200

120 200 250

TAB. 1.2.4 UPS input fuses, version 2

Type

SOLA

4000

10 2x16 4x10 25

15 2x16 4x10 40

20 2x25 4x16 50

30 2x25 4x35 75

40 2x35 4x25 100

60 2x50 4x35 150

80 2x70 4x50 200

100 2x95 4x70 250

120 2x120 4 x120 300

Battery

cables

[mm²]

Bypass Fuses

[A]

[A]

Output cables

[mm²]

Max. inv. input

current

(Vdc=320V)

TAB. 1.2.5 UPS output cables and fuses, version 2

Page 25

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1.3 Installation of additional optional cabinets

SOLA 4000 with input and output transformers for voltage adaption

FIG. 1.3.1 UPS connection diagram, with input and output transformers to adapt the

UPS to the on-site voltage.

SOLA 4000 with isolation transformer of the bypass supply

FIG. 1.3.2 UPS connection diagram, with bypass input transformer to isolate the

neutral line (** 4-N may be connected to the supply neutral or earth or left disconnected.)

(*) Note: Internal Battery only for 10-30kVA units

Page 26

SOLA 4000 - Installation and Initial Start-Up

SOLA 4000 with THD filters

1 Installation

FIG. 1.3.3 UPS connection diagram, with THD filters

(*) Note: Internal Battery only for 10-30kVA units

Page 27

SOLA 4000 - Installation and Initial Start-Up

1 Installation

SOLA 4000 with 12-pulse charger / rectifier

FIG. 1.3.4 Installation of 12-pulse units without galvanic isolation

SOLA 4000 with 12-pulse charger / rectifier and galvanic isolation of the input supply.

FIG. 1.3.5 Installation of 12-pulse units with galvanic isolation

(*) Note: Internal Battery only for 10-30kVA units

Page 28

SOLA 4000 - Installation and Initial Start-Up

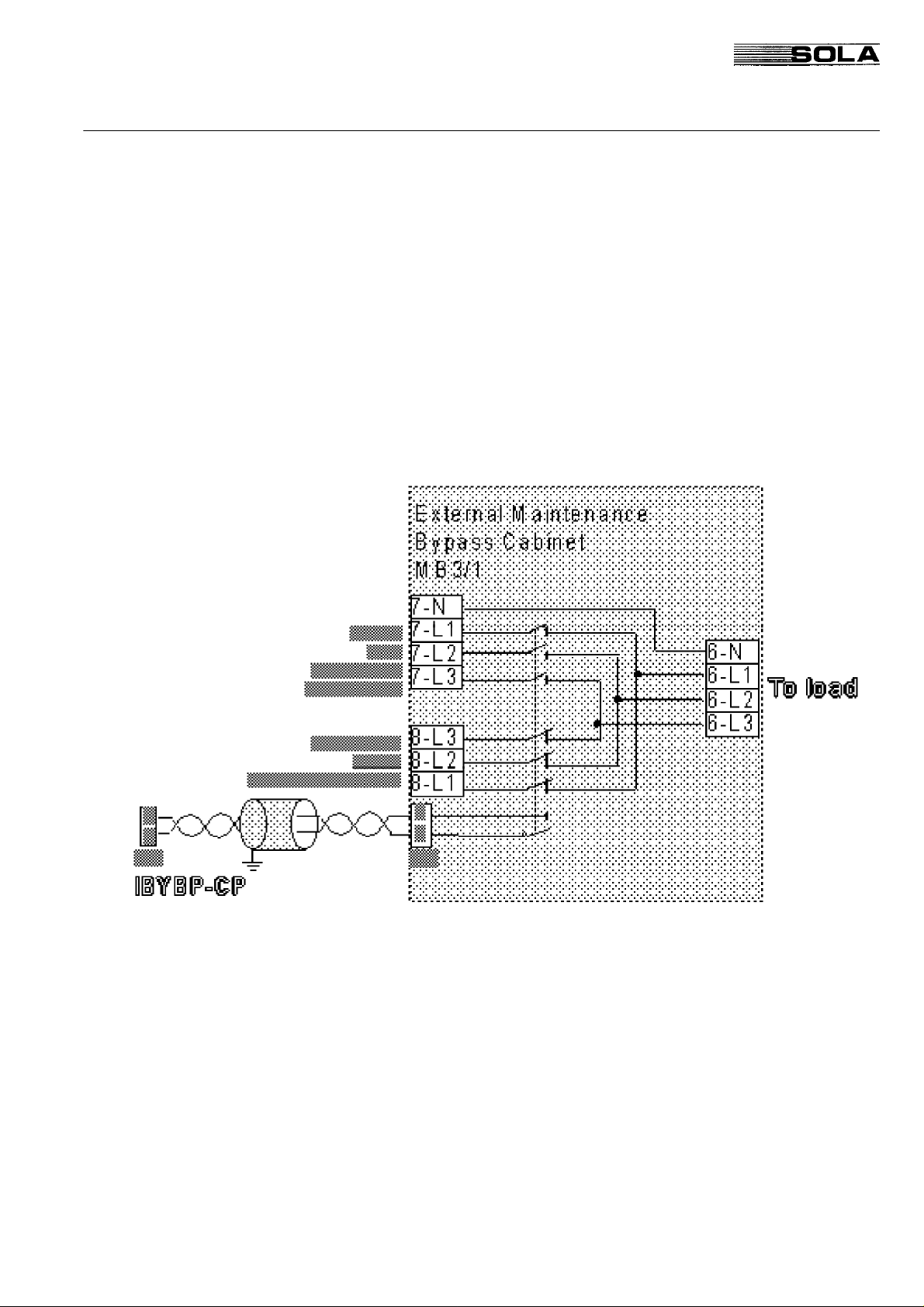

1.4 Installation of an External Maintenance

Bypass

When an external maintenance bypass is installed, a normally

open, voltage free contact must be available. This contact must be

connected to the connector M4, Pin1 and Pin 2 at the top left hand

corner of the mother board for the inverter/bypass electronics

(IBYBP-CP see figure 1.10.3).

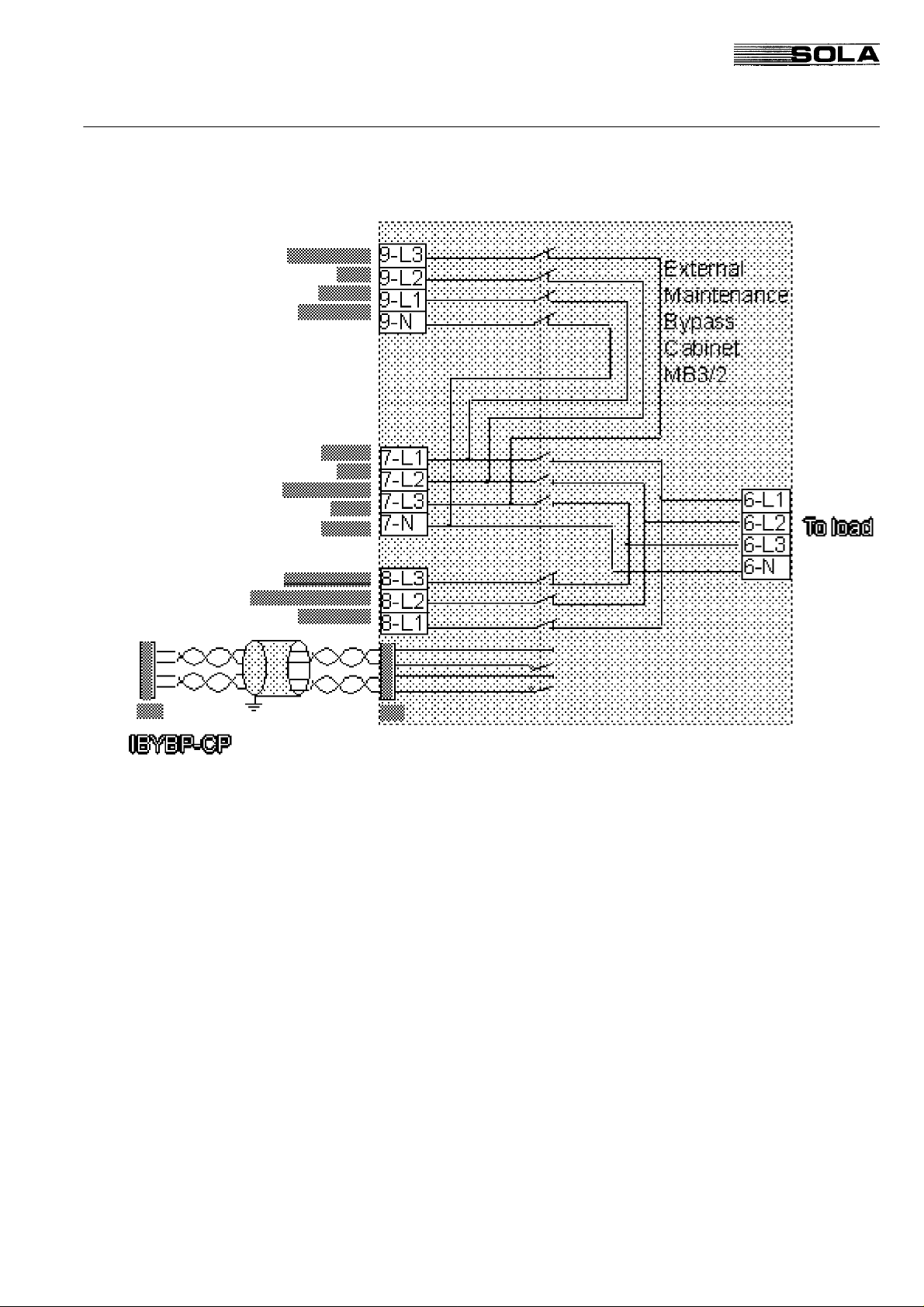

If the standard SOLA no-break wall-mounted maintenance bypass

switch is used (optional) in the MB3 cabinet, a normally open

contact is provided.For the version 2 maintenance bypass (3

position), an additional contact is provided which automatically

isolates the UPS system (EPO) when switched to the "UPS ISOLATED" position (see FIG 1.4.2).

1 Installation

FIG.1.4.1 External Maintenance Bypass Switch Version 1 (2 position)

Page 29

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG.1.4.2 External Maintenance Bypass Switch Version 2 (3 position)

Note1: For Hot-Standby or parallel systems, it is sufficient to

feed one contact into one unit only, however they may be

connected in parallel at M4 (of IBYBP-CP) Pin1 and Pin 2 for

all units. In this case separate terminals may be provided

within the MB3 cabinet (see FIG. 1.9.2 and 1.10.2)

Note2: The cable used must be twisted pair, with a total shield.

This shield must be grounded at one end (the cabinet of the

UPS may be used).

Page 30

SOLA 4000 - Installation and Initial Start-Up

1.5 CPNET Interface Card

The CPNET interface card is used for remote signalling of four

standard alarm conditions by means of voltage-free contacts in

programmable configurations.

1.5.1 Installation

The CPNET interface card is a small pcb that is installed directly

underneath the CPU/NCP pcb, inside the front door of the UPS

cabinet.

It is connected to the UPS via the connector CN1 on the CPNET

pcb to CN10 on the CPU/NCP pcb.

It can be connected to remote devices via two different connectors:

• CN2, a 9 pin sub-D connector for standard computer connection. The following interface cables are available (see also

JUE 300 599):

- IBM AS-400

- Novell

- 3-COM

- Banyan Vines

• M1, a terminal block for individual configurations.

1 Installation

1.5.2 Functions

Contacts for the following alarm conditions are available:

Inverter Operation (N) (CN1, pin 6)

Bypass Operation (B) (CN1, pin 8)

Mains Failure (MF) (CN1, pin 5)

Battery Low (BL) (CN1, pin 7)

By means of the DIP switch SW1, the single relays and output pins

can be configured for each requirement.

SW1

1 2 3 4 5 6 7 8

0 0 0 1 0 1 1 0 IBM-AS400

0 0 0 0 - - 0 1 NOVEL

0 0 1 0 - - - - 3-COM

0 0 0 0 - - - - BANYAN-VINES

0 1 1 0 - - 0 1 BORRI VIKING

0 0 1 0 - - 0 1 BORRI SIDEKICK

0 0 1 0 - - 0 1 AMERICAN POWER

INTERFACE

TAB. 1.5.2.1 Programming of the CP-NET pcb

Note: Maximum rating of relay contacts: 250Vac, 6A (only when using

connector M1)

Page 31

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Pin

Pin

CN2

1 1 Not Used

2 2 N - MF* - MF* MF* MF*

3 3 MF MF MF MF MF MF MF

4 4 Common

5 5 BL BL BL BL BL BL BL

6 6 B MOK - - MOK MOK MOK

7 7 BOK BOK BOK BOK BOK BOK BOK

8 8 - - - - BL* - 9 9 0 V

AS400 NOVEL 3-COM BANYAN-VINES

M1

10 Not Used

BORRI

VIKING

BORRI

SIDEKICK

AMERICAN

POWER

TAB. 1.5.2.2 Allocation of the pins for the output connectors CN1 and M1 for the various programming

configurations of TAB. 1.5.2.1

Key to table 1.5.2.2 (when contact is closed with respect to pin 4).

N: Inverter Operation

B: Bypass Operation

MF: Mains Failure

BL: Battery Low

MF*: 0V when mains failure, -12V when mains OK

BL*: -12V when battery low, otherwise +12V

MOK: Mains OK

BOK: Battery not low

Page 32

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1.6 Remote Emergency Power off

A Remote Emergency Power Off may be connected to the system.

The connection terminals are M4 Pin 5 and Pin 6, using a normally-open, voltage-free contact as a pushbutton.(See FIG. 1.6.1.

and FIG 1.6.2.)

FIG. 1.6.1 Connection of Remote EPO with N.C. contact FIG. 1.6.2 Connection of Remote EPO with N.O. contact

Note 1: The cable used must be twisted pair, with a total shield. This

shield must be grounded at one end (the cabinet of the UPS may

be used).

Note 2: For Hot-Standby or parallel systems, it is sufficient to feed

one contact into one unit only, however they may be connected in

parallel at M4 (of IBYBP-CP) Pin5 and Pin 6 for all units (N/O) only

or series for (N/C).

Note 3: To completely isolate the UPS system from all voltage with

the emergency power off (EPO), it is necessary to install trippable

circuit breaker on the input supply (to terminals 1-L1, 1-L2, 1-L3

and 4-L1, 4-L2, 4-L3 and 4-N if installed).

The trip coil is then connected to the terminal M1 on the CPU/NCP

pcb located inside the front door of the cabinet. A normally open or

normally closed voltage-free contact is available.

Note 4: The N.C. contact can only be used for IBYBP-CP

motherboards in rev. 0A and following.

FIG. 1.6.3 Connection of Remote Emergency Power Off - Input and battery circuit

breaker trip circuit.

Nominal Rating of Contacts

125 V

30 V

TAB. 1.6.1 Nominal Rating of contacts for the input breaker trip circuit.

0,5 A 60 W

≅

≅

2 A 60 W

Page 33

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1.7 Diesel - Generator Operation

During diesel generator operation, if the frequency of the dieselgenerator, with UPS and load connected, is unstable, it is advisable

to disconnect the synchronisation of the inverter. This is achieved

with a normally-open, voltage-free contact (which closes during

diesel-generator operation) and is connected to the connector M4

Pin 7 and Pin 8 as follows:

FIG. 1.7.1 Connection for Diesel Generator Operation (connector M4) - synchronisation disable.

Note1: For Hot-Standby or parallel systems, it is sufficient to feed

one contact into one unit only, however they may be connected in

parallel at M4 Pin7 and Pin 8 for all units

If it is necessary to reduce the current supplied by the dieselgenerator, then a second voltage-free contact (again normally

open) is required and must to be connected to the connector M8,

Pin 1 and Pin 2 on the rectifier electronic mother board (RBPHC16)

see FIG.1.7.2

FIG. 1.7.2 Connection for Diesel Generator Operation (connector M8) - second level

current limitation.

Note 1: The cable used in both cases must be twisted pair, with a

total shield.This shield must be grounded at one end (the cabinet

of theUPS may be used).

Note 2: The cable for current limitation must be connected to all units

for parallel or hot-standby units, using separate voltage-free

contacts.

Page 34

SOLA 4000 - Installation and Initial Start-Up

1.8 Common Alarm Contacts

As a standard feature, contacts are provided for a remote common

alarm.The connector is located on the control p.c.b for the front

operating panel (CPU/NCP), located inside the front door of the

UPS.

FIG. 1.8.1 Connection of Remote Common Alarm

Nominal Rating of Contacts

1 Installation

125 V

30 V

TAB. 1.8.1 Nominal Rating of contacts for the common alarm.

Note 1: As an option a pcb CP-NET is available, providing more

contacts, compatible with most common configurations (eg AS400,

Novell etc.)

A Remote panel may also be purchased with identical functions to

the front operating panel.

Note 2: To achieve a single common alarm for parallel or hot-

standby units, the contacts of each unit may be interconnected in

parallel (normally - open) or series (normally - closed).

0,5 A 60 W

≅

≅

2 A 60 W

1.9 Remote Reset

The UPS system may be reset remotely with the connection of

contacts ( a push-button) to the terminal M4 as shown:

FIG.1.9.1 Connection of Remote Reset

Note: The cable used must be twisted pair, with a total shield.

This shield must be grounded at one end (the cabinet of the

UPS may be used).

Page 35

SOLA 4000 - Installation and Initial Start-Up

1 Installation

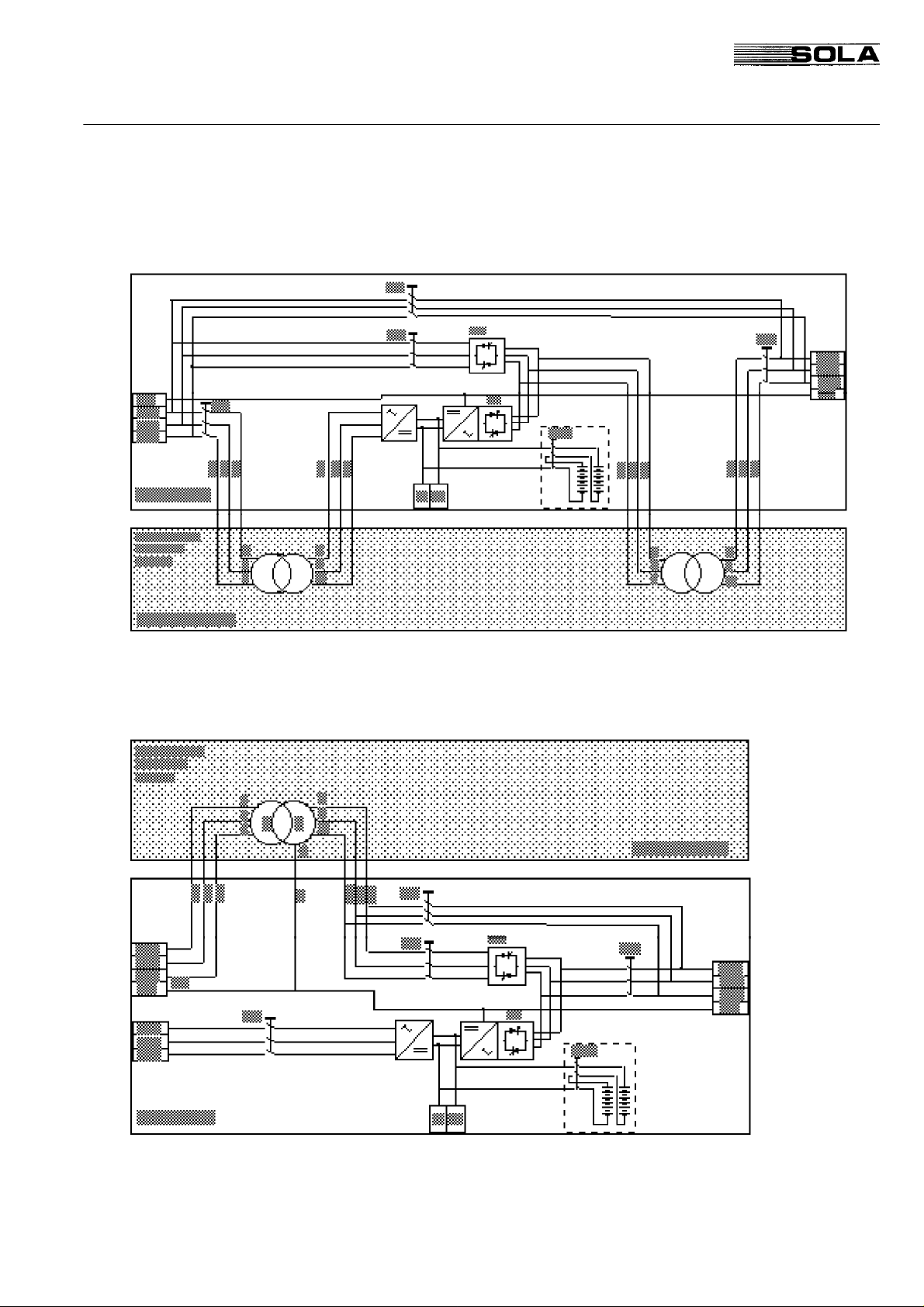

1.10 Installation of Hot-Standby Systems

For hot-standby systems the units must be connected together as

shown in the FIG. 1.10.1 or FIG. 1.10.2

Note: The installation for each unit must be performed in accordance

to the installation of single units as described in the previous

sections. Additionally to this, the outputs must be connected in

parallel as shown in FIG. 1.10.1 or in FIG.1.10.2

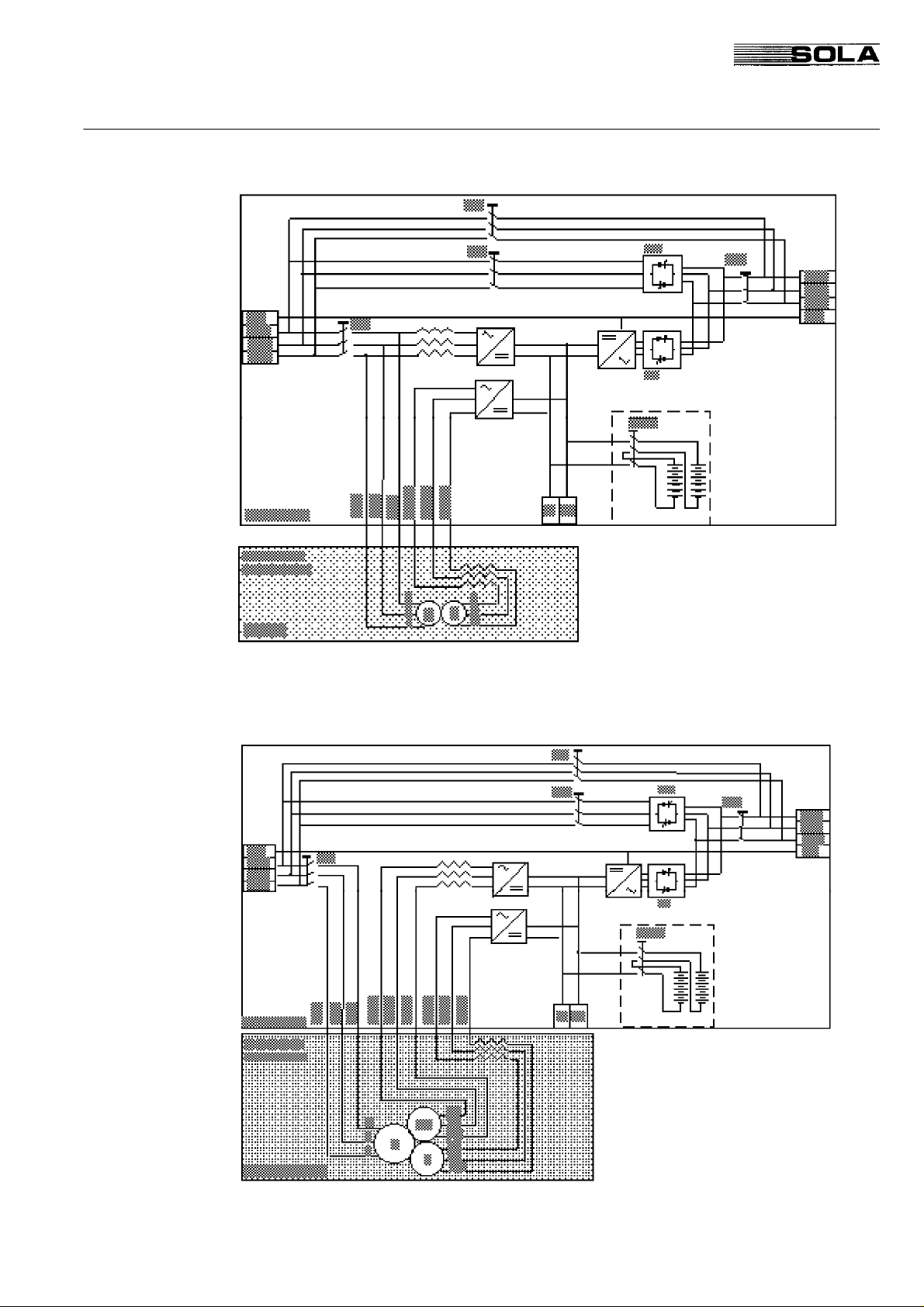

FIG. 1.10.1 Interconnection of hot-standby units with integrated

maintenance bypasses and separate bypass terminals.

(*) Note: Internal Battery only for 10-30kVA units

Page 36

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG. 1.10.2 Interconnection of hot-standby units with external maintenance bypass and

separate bypass terminals.

(*) Note: The internal maintenance bypass (IBY) may or may not be installed in this con-

figuration.

(**) Note: This cable must be twisted pair, total shield (refer. to section 1.4)

(***) Note: Internal Battery only for 10-30kVA units

Page 37

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1.10.1 Installation of the Interconnection Cable

The supplied cable must be connected between the units within the

system. This must be connected at either of the connectors CN12

or CN13 on the mother-board of the Inverter/Bypass electronics

(IBYBP-CP) and the other end of the cable is connected to either

CN12 or CN13 on the mother-board of the Inverter/Bypass electronics (IBYBP-CP) of the other unit(s).

Note: If the unit is to be added to one already installed stand-alone

unit which has not been previously tested in a hot-standby configuration, the supports and mounting screws to mount the cable to the

p.c.b are supplied with the cable. They must be mounted at both

sides of the selected connector in order to fix the cable securely to

the connector with the supplied screws.

FIG. 1.10.3 Interconnection of control BUS cable for hot-standby units

Page 38

SOLA 4000 - Installation and Initial Start-Up

1.11 Installation of Parallel Systems

Up to a total of 8 units may be installed together in the one parallel

system.

Note: The installation for each unit must be performed in accordance to the installation of single units as described in the previous

sections. Additionally to this, the outputs must be connected in

parallel as shown in FIG. 1.11.1 or in FIG.1.11.2

Care must be taken with the installation of the bypass line and in

particular, that the cables from the point of common coupling of the

input supply to the terminals 1-L1, 1-L2, 1-L3 (or 4-L1, 4-L2, 4-L3,

4-N if an optional separate bypass input is installed), are of equal

length. Likewise, the output cables from the output terminals (5-L1,

5-L2, 5-L3, 5-N) to the point of common coupling on the load side

must be of equal length.

1 Installation

Page 39

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG. 1.11.1 Interconnection of parallel units with integrated maintenance bypasses and separate bypass

terminals.

(*) Note: Internal Battery only for 10-30kVA units

Page 40

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG. 1.11.2 Interconnection of parallel units with common maintenance bypass and separate bypass

terminals.

(*) Note: The internal maintenance bypass may or may not be installed in this configuration.

(**) Note: This cable must be twisted pair, total shield (refer to section 1.4)

(***) Note: Internal Battery only for 10-30kVA units

Page 41

SOLA 4000 - Installation and Initial Start-Up

1 Installation

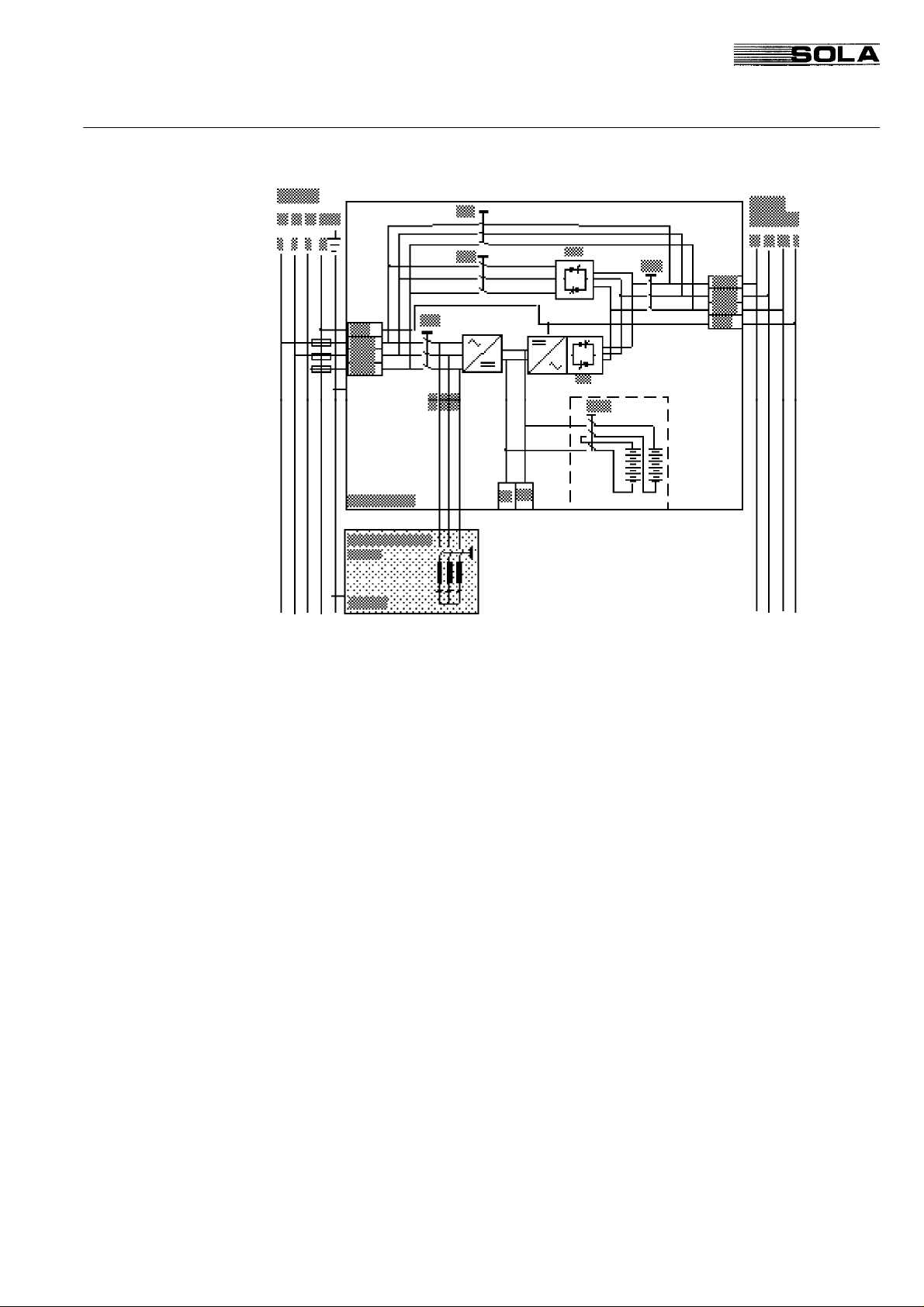

1.11.1 Installation of the Interconnection Cables

There are two interconnection cables supplied with the units for

each additional unit to the first unit. These cables must be connected between the units as shown in FIG. 1.11.4 One cable is

connected to either CN12 or CN13 (the other end being connected

to the corresponding connector of another unit), and the other

cable is connected to either of CN10 or CN11, again with the other

end connected to the corresponding connector of another unit. In

this way, all units will be interconnected by two cables in a BUSCommunication system (Daisy-chain connection).

Note: If the unit is to be added to one already installed stand-alone

unit which has not been previously tested in a parallel configuration, the supports and mounting screws to mount the cable to the

p.c.b are supplied with the cables. They must be mounted at both

sides of the selected connectors in order to fix the cables securely

to the connectors with the supplied screws.

FIG. 1.11.3 Location of connectors on the IBYBP-CP pcb.

FIG. 1.11.4 Interconnection of control BUS cables between parallel units

Page 42

SOLA 4000 - Installation and Initial Start-Up

1.12 Battery Installation

Battery Installation must be in accordance with local safety

standards.

General The batteries are charged. The installation should only be made by

appropriately qualified personnel. The screw connections between

the batteries should be tightened with a torque wrench (max. 7

Nm).

1.12.1 Installation of Internal batteries

SOLA 4000 (10-30kVA)

Internal Battery (24Ah) Installation

• Place five battery blocks on the trays of the first level.

• Place nine battery blocks on the trays of the second, third and

fourth level.

• Interconnect the blocks in series (see FIG.1.12.1)

1 Installation

1° LEVEL

2° LEVEL

3° LEVEL

Warning: after assembly there is a voltage of 67,5 V on the first

level, and 121,5 V on the second, third and fourth levels.

4° LEVEL

Page 43

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Internal Electrical Connections

Cable (1) n° 3; L = 280 mm; diameter 16 mm

Cable (2) n° 8; L = 420 mm; diameter 16 mm

Cable (3) n° 4; L = 490 mm; diameter 16 mm

Cable (4) n° 2; L = 650 mm; diameter 16 mm

Support (CA1) n° 4; See Fig. CA1

Support (CA2) n° 9; See Fig. CA2

2

2

2

2

FIG. 1.12.1 Internal Battery connections.

Copper bars for battery connection Two copper plates diam. 0,5 mm. are used.

CA1

CA2

Page 44

SOLA 4000 - Installation and Initial Start-Up

1 Installation

1.12.2 Installation of External Batteries

External Battery (38 Ah) Installation 38 Ah external batteries are installed in a B3/38 battery cabinet. To

assemble the battery cabinet:

• Place four battery blocks on the trays of the first level (see FIG.

1.12.2).

• Place six battery blocks on the trays of the second and third

levels (see FIG. 1.12.3).

• Interconnect the blocks in series (block 1 / negative pole ==>

block 2 / positive pole,....)

Warning: after assembly there is a voltage of 48 V on the first

level, and 72 V on the second and third levels.

• If necessary secure with strapping (against vibrations).

• Insert the trays into the battery cabinet as shown in FIG. 1.12.4

FIG. 1.12.3 B3/38: battery trays in the

second and the third level

FIG. 1.12.4 Battery cabinet B3/38

Page 45

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Important: Open battery switch IB before connecting the cables.

• Place the trays with the

batteries on the corresponding levels in the UPS.

• Connect the battery blocks

of the various levels to the

battery switch IB, and IB to

the terminals, as shown in

FIG. 1.12.5 and FIG. 1.12.6

Ensure appropriate ventilation of the battery room according to the

standard EN50091-1, to prevent the risk of an explosion.

Page 46

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG. 1.12.6 B3/38 internal electrical connections

Page 47

SOLA 4000 - Installation and Initial Start-Up

1 Installation

External Battery (65 Ah) Installation 65 Ah external batteries are installed in a B3/65 battery cabinet. To

assemble the battery cabinet:

• Remove the battery switch IB and the terminals.

• Insert the battery blocks from the front and rear sides.

Warning: after assembly there is a voltage of 192 V at the front

and rear side.

• Remount the battery switch IB and the terminals.

Important: Open battery switch IB before connecting the cables.

• Connect the battery blocks on the various levels to the battery

switch IB, and IB to the terminals, as shown in FIG. 1.12.8 and

FIG. 1.12.9

FIG. 1.12.7 Battery cabinet B3/65

FIG. 1.12.8 B3/65: switch IB and terminals

Page 48

SOLA 4000 - Installation and Initial Start-Up

1 Installation

FIG. 1.12.9 B3/65 internal electrical connections

Page 49

SOLA 4000 - Installation and Initial Start-Up

1 Installation

Connection Between UPS and Additional

Battery Cabinets

Important: Open all battery switches IB before connecting the

cables. Observe the indicated wiring polarity.

• For UPS systems with external batteries: connect the external

batteries as shown in FIG. 1.12.10

• After wiring, check that the external battery is connected with

correct polarity.

Connection of Auxiliary Contacts

FIG. 1.12.10 UPS with additional battery cabinet

For the standard battery cabinet, the terminals C1, C2, C3 and C4

are connected to the corresponding terminals in the UPS cabinet

as in FIG. 1.12.10.

If a battery is installed without standard cabinet(s), then a voltagefree auxiliary contact (normally closed) should be provided, along

with a dc shunt trip circuit, for the battery circuit breaker / fuse

switch. The auxiliary contact is connected to the terminals C1 and

C2. The shunt trip circuit is connected in series with C3 and C4 and

the appropriate number of batteries in order to achieve the rated

shunt trip coil voltage.

Page 50

SOLA 4000 - Installation and Initial Start-Up

2 INITIAL START-UP

2.1 Start-Up Procedure

2 Initial Start-Up

General

Preparation

A: Rectifier Power Supply Check • Switch on the external mains supply to the UPS.

With the Start-Up procedure the correct installation of the UPS

according to the previous section is checked. It must be carried out

by specialised personnel.

Safety precautions according to the appropriate local safety standards must be applied.

Should problems arise during the Start-Up Procedure, call for

service assistance.

For carrying out the Start-Up Procedure you need a 3 1/2 digit

voltmeter with 1% accuracy, an AC/DC clip-on ammeter and a

small screwdriver for potentiometers (only when necessary).

The installation of the UPS must have been carried out according

to the previous section.

• Check that the ventilation system of the UPS room is ready to

operate.

• Check that all switches IRP, IRE, IUG, IBY, IB are open and

the load is off.

• Check that the supply voltage at terminals 1-L1, 1-L2, 1-L3 is

within ±10% of the UPS rated voltage.

• Close IRP.

Does the display on the CPHC16 -R pcb for the rectifier give the

?

indication "P"?

yes The phase rotation at the input is incorrect.

• Open IRP, switch off the external mains supply and exchange

any two of the cables at input terminals 1-L1, 1-L2, 1-L3.

• Return to A.

no The rectifier supply voltage is o.k. and the rectifier will automati-

cally start to operate.

• Wait until the Data Monitor Panel / NCP is illuminated

• Press the START push-button on the front of panel (or the push

button PB2 on the top of ICP card) the inverter will start and

after approximately 10s the green led L16 will be permanently

lit.

• Press the push-button PB3 on the bottom of ICP card:

after few seconds the three green leds on SS/FY card will be lit.

One led is flashing:

- green LED 3 flashing: "Battery switch open". Note that when

using the external battery cabinet this function is desabled.

NOTE: If the battery switch indication is not blinking then the connections to C1

and C2 in the battery cabinet are not correct. Refer to the section "Installation".

Page 51

SOLA 4000 - Installation and Initial Start-Up

2 Initial Start-Up

B: Inverter Voltage Adjustment • On the SS/FY pcb, measure the voltage at the screws Inverter

R, Inverter S, Inverter T with respect to the neutral terminal 5N.

Does this voltage correspond to the desired voltage?

?

no • Adjust the voltage to the desired value individually for each

phase using P3, P4 and P5 on the ICT-2 pcb.

NOTE: If the inverter output voltage is changed, the value at

TP1 (adjusted with P1) on the ICP pcb should be checked. (6V

corresponds to nominal voltage). Note also that for parallel

systems, if the voltage is changed here, the current sharing will

also be affected. Therefore, change voltage settings ONLY IF

ABSOLUTELY NECESSARY. Small variations of the voltage will not

affect system performance. The UPS is already pre-calibrated

in the factory with nominal load.

yes • Continue with C

C: Inverter free-run frequency check • Insert a pin d=2mm in the red test point S1 on the ICP pcb. The

red LED LD3 on the ICP pcb must be permanently lit. The

inverter frequency is now free-running without the internal

oscillator.

• On the SS/FY pcb, measure the inverter frequency on the

screws Inverter R, S or T with respect to neutral.

• Check that the frequency is set at the required value (50/60 Hz

+/- 0,1 Hz). It can be adjusted with P1 on the ICT-2 pcb. Remove the pin from S1. The inverter now synchronises with the

internal oscillator.

• Make sure that the batteries have been installed according to

the instructions for installation.

With an external battery cabinet B3/38:

• Measure the battery voltage in the battery cabinet at the battery

switch between cables:

- -290 (-) and -1 (+)

- +1 (-) and +4 (+)

With an external battery cabinet B3/65:

• Measure the battery voltage in the battery cabinet at the battery

switch between cables:

- -290 (-) and -1 (+)

- +1 (-) and +2 (+)

Does this voltage have positive polarity?

?

no • Open IRP, wait for 5-10 minutes, and then reconnect the

battery cables at the terminals which lead to the switch(es)

where the wrong polarity was detected.

• Return to D.

yes • Check the voltage between the battery terminals B+ and B-.

The value of this voltage should be already set according to the

amount of batteries installed.

• Close battery switch IB.

The alarm "battery switch open" stops.

Page 52

SOLA 4000 - Installation and Initial Start-Up

• If your unit has separate supplies for the rectifier and bypass

(terminals 4-L1, 4-L2, 4-L3, 4-N), switch on the external supply

for the bypass. Check that the bypass supply voltage at terminals 4-L1, 4-L2, 4-L3, 4-N is within ±10% of the nominal input

voltage.

If there are no separate input terminals then the bypass input is

the same as that checked previously for the rectifier input.

• Close IUG.

• Close IRE.

Does the display on the CPHC16 -S pcb for the bypass give the

?

indication "P"?

yes • Open IRE and exchange any two of the cables at the bypass

input terminals 4-L1, 4-L2, 4-L3.

• Return to E.

2 Initial Start-Up

no • Are the status LEDs (green) 1, 2, 3, 14, 16, 17, 19, 26, on the

yes:

F: Synchronisation Check

operating panel continuously on?

no: Check that the mains frequency is in tolerance.

OK?

yes: Is the pcb CPHC16 -S for the bypass

correctly functioning? The display should be

rotating clockwise.

no: Call for service assistance.

yes: Check again the input supply. Check

that it is in accordance with the UPS

rating label.

no: The mains frequency must be within

tolerance in order for the bypass to be

availabe

Continue with F.

• Check that the green LED LD1 on the ICT-2 pcb is permanently

lit and there is no "S" indication on the bypass electronics.

• On the SS/FY pcb, measure the voltage between the screws

Bypass R and Inverter R. Then repeat for the other two phases.

Are the voltages < 25Vac?

?

no • If the voltage is continuously fluctuating from 0 to 400V there is

a synchronisation problem. Switch off IRE and call for service

assistance.

If the voltage is slightly higher but relatively constant and the

default values have been re-entered using the serial interface

on the CPHC16 -S p.c.b., then the synchronisation may need to

be re-adjusted. This can be easily confirmed by comparing the

two sinewaves for a possible phase difference.

Are the two waveforms phase-shifted?

yes: The synchronisation must be re-adjusted using the serial

interface of the CPHC16 -S pcb and the PSRS232 and a

portable computer.

Page 53

SOLA 4000 - Installation and Initial Start-Up

2 Initial Start-Up

no: The difference is probably due to distortion of the mains

voltage (the inverter voltage is an almost perfect

sinewave)

Continue with G

yes: Continue with G

G: Static Switch Commutation Check

H: Battery Charging Current Limitation

Check • Connect the load and open IRP.

no The rectifier is not yet in battery current limitation. In order to check

• COMMUTATION TO THE BYPASS

Press the pushbutton on the CPHC16-S pcb for the bypass.

The static switch SSB will switch on and SSI will switch off, as

indicated on the front panel and on the SS/FY pcb (red LEDs).

• COMMUTATION TO INVERTER

Press the pushbutton PB3 at the bottom of the ICP pcb. The

static switch SSI will switch on and SSB will switch off, as

indicated on the front panel and the SS/FY pcb (green LEDs).

The load is now supplied only by the batteries.

• Discharge the batteries for about 2 minutes at nominal UPS

load or longer if the connected load is smaller than nominal

UPS load

• Close IRP again.

• After 30 seconds, measure the battery voltage.

Is the battery voltage lower than the set floating charge voltage?

?

the battery current limitation you must discharge the batteries for a

longer period.

• Return to H.

yes The battery current limitation can now be checked according to the

battery installed. Standard setting is 10% of the battery capacity.

• Measure the battery recharging current with a dc clip-on ammeter.

Is this approximately 10% of the battery Ah capacity?

?

no Check the settings of the dipswitch S1 on the CPHC16 -R pcb for

the rectifier according to JUE400899 programming of PCBs (V2.0

or later). Otherwise, the battery charging current may need to be

adjusted using the RS232 connector on the CPHC16-R pcb and a

portable computer. This must be performed by first discharging the

battery by switching off IRP, connecting the PC and adjusting the

charging current. The battery must remain connected through-

out the procedure.

• Return to H.

yes THE START-UP PROCEDURE HAS BEEN SUCCESSFULLY COMPLETED NOW.

Page 54

SOLA 4000 - Installation and Initial Start-Up

3 Additional Start-Up Proced. for Multi-Unit Systems

3 ADDITIONAL START-UP PROCED. FOR

MULTI-UNIT SYSTEMS

3.1 Start-Up Procedure for Hot -standby Systems

Repeat the procedure of section 2 for the second unit in the system

(with the first unit off).

Ensure that the interconnecting BUS cable is connected according

to section 1.9.1 and FIG 1.9.3.

J • Switch off the inverter at the second unit with PB2 at the top of

the ICP pcb. The unit will transfer to the bypass supply.

• Switch on IRP of the first unit.

• Ensure that the switch IUG of this unit is off.

• Switch on IRE of the first unit.

After approx. 10 seconds the display will flash with a "U" indica-

tion and static bypass switch SSB will be closed.

• Measure across the output switch IUG from input to output of

each phase.

Is this voltage less than 2V a.c for all three phases?

?

no The output power interconnections are incorrect and must be

reconnected correctly. Switch off both units and the mains

supply and recheck the connections.Return to J

yes Continue

• Close IUG of the first unit. The two static bypasses (SSB) are

now connected in parallel.

• Close the battery switch of the first unit.

• Start the unit by pressing "START" on the front operating panel.

when the inverter is synchronised, the unit will transfer the

inverter to the output (SSI closes and both SSB switches switch

off).

• Press "START" on the operating panel of the second unit.

The inverter will start and become ready (check that the green LED

LD6 on the ICP pcb is illuminated) but the static switch SSI will not

close.

• Check the commutation of the inverters by pressing PB2 at the

top of the ICP pcb on the unit currently with SSI closed.

• Restart the inverters (with PB2 on ICP or with "START").

THE SYSTEM IS NOW IN NORMAL OPERATION AND THE HOT-STANDBY START-UP

HAS BEEN SUCCESSFULLY COMPLETED.

Page 55

SOLA 4000 - Installation and Initial Start-Up

3 Additional Start-Up Proced. for Multi-Unit Systems

3.2 Start-Up Procedure for Parallel Systems

Repeat the procedure of section 2 individually for all units in the

system, with the the other units off.

Ensure that the interconnecting BUS cables are connected according to section 1.10.1 and FIG 1.10.3.

• Open IRP, IRE, IB and IUG of the last unit checked with the

procedure in section 2.

K • Ensure that no load is connected to the system output.

• Ensure that all IUG switches are open.

• Switch on the IRE switches of all units. Wait until all units give

a flashing "U" indication on the display of the CPHC16-S pcb.

• Close IUG on one unit only.

• At each unit in turn:

Measure across the output switch IUG from input to output of each

phase.

Is this voltage less than 2V.a.c for all three phases for every unit?

?

no

yes Continue.

The output power interconnections are incorrect and must be

reconnected correctly. Switch off all units and the mains supply

and recheck the connections.

Return to K

• Close the IUG switches on all units. The static bypasses (SSB)

will now be connected in parallel for all units.

• Close IRP of all units.

• When the front operating panel is initialised on all units (after 3

beeps), close the battery switches of the respective units.

•Press the "START" pushbutton on any one unit. The inverter

will start and when synchronised to the bypass supply, transfer

to the system output and all static bypass switches (SSB) will

open.

• Press the "START" pushbutton on each successive unit in the

system, each time checking that the SSI closes on the unit and

that the system operates in parallel operation.

• Commutations to the bypass/inverter supplies may be checked

by pressing the pushbutton on the CPH16 -S pcb and PB3 at

the bottom of the ICP pcb.

• Apply a load to the UPS system and check for correct sharing

of the load currents on each phase. If stand-alone units have

been converted for parallel operation, the current sharing needs

to be checked and is best performed with a load as close as

possible

Page 56

SOLA 4000 - Installation and Initial Start-Up

3 Additional Start-Up Proced. for Multi-Unit Systems

to the nominal load. Measure the currents at the output of each

module on phase T. If this current varies by more than ± 1% for

this module, fine adjustment can be made with P1 on the IPR

pcb.

Check the currents at the output of each module on phase S.

These currents must be balanced to within ± 1% by finely

adjusting the inverter voltage of phase S (P4 on ICT-2). i.e. If

the module is supplying more current than the system average,

the inverter voltage of this module must be reduced slightly.

Repeat for phase R currents by finely adjusting the R phase

inverter voltage of this module with P3 on the ICT-2 pcb until

the currents on the phase R of all modules are equal to within

± 1%.

• THE SYSTEM START-UP HAS NOW BEEN SUCCESSFULLY COMPLETED.

Page 57

Contents of JUE 401266

SOLA 4000 - Operation

Chapters

1 OPERATING MODES 2

1.1 General 2

1.2 Led Indication 3

2 OPERATING MODES STAND-

ALONE UNIT 4

2.1 Normal Operation 4

2.2 Battery Operation 4

2.3 Bypass Operation 5

2.4 Maintenance Bypass Operation 5

2.5 Standby Operation 5

3 OPERATING MODES HOT-

STANDBY OPERATION 6

3.1 Normal Operation 6

3.2 Operation with an Inverter Failure 6

5 OPERATING INSTRUCTIONS 11

5.1 Switching On the UPS System/from

Maintenance Bypass 11

5.2 Switching Off the UPS System/to

Maintenance Bypass 13

5.3 Switching On any one unit within a

System (Parallel and Hot-standby Systems) 14

5.4 Switching Off any one unit within a

System (Parallel and Hot-standby Systems) 15

5.5 Emergency Power Off 16

Figures

FIG. 2.1 Normal Operation 4

FIG. 2.2 Battery Operation 4

3.3 Battery Operation 6

3.4 Bypass Operation 7

3.5 Maintenance Bypass Operation 7

4 OPERATING MODES PARALLEL

AND PARALLEL/REDUNDANT

OPERATION 8

4.1 Normal Operation 8

4.2 Partial Load Operation 8

4.3 Battery Operation 9

4.4 Operation with an Inverter Failure 9

4.5 Bypass Operation 10

4.6 Maintenance Bypass Operation 10

We reserve the right to modify the contents of this document without notice. BEST POWER- BORRI ELETTRONICA INDUSTRIALE S.r.l Via 8 Marzo Soci, Bibbiena (AREZZO)

FIG. 2.3 Bypass Operation 5

FIG. 2.4 Maintenance Bypass Operation 5

FIG. 2.5 Standby Operation 5

FIG. 3.1 Normal Operation 6

FIG. 3.2 Operation with an Inverter failure 6

FIG. 3.3 Battery Operation 6

FIG. 3.4 Bypass Operation 7

FIG. 3.5 Maintenance Bypass Operation 7

FIG. 4.1 Normal Operation 8

FIG. 4.2 Partial Load Operation 8

FIG. 4.3 Battery Operation 9

FIG. 4.4 Operation with an Inverter Failure 9

FIG. 4.5 Bypass Operation 10

FIG. 4.6 Maintenance Bypass Operation 10

ISSUED

A

See Rev. Doc. JSE 401440

See Rev. Doc. JSE 401547B

04.02.97

20.06.97 T. Boon

23.09.97

T. Boon

T. Boon

04.02.97M. Porpora

A4 161

JUE 401266

Page 58

SOLA 4000 - Operation

1 Operating Modes

1 OPERATING MODES

1.1 General

There are four different operating modes of the standard standalone on-line UPS-system (5 for hot-standby and 6 for parallel

systems), ensuring uninterrupted power supply of the load under all

conditions. Transitions between these operating modes are performed without interruption of the power supply to the load.

Security concept

• In "Normal Operation" any failure, internal or external, will

transfer the UPS system either to "battery operation", to "bypass operation" for a stand-alone UPS or to "operation with an

inverter failure" for parallel and hot-standby systems.

• In "Battery Operation" or "Bypass Operation", with a standalone UPS system, an additional failure may interrupt the

power supply to the load, depending on the kind of failure. In

both operating modes the UPS signals a failure condition

(audible and visual alarm) to indicate that any additional failure

bears the risk of interrupting the power supply to the load.

• As additional security, a second UPS unit may be added and

connected in parallel with the original unit, in a hot-standby

configuration. Therefore, in the case of a failure of one inverter,

the second inverter will take over the load. This system requires the occurrence of 3 or 4 simultaneous failures (the

bypass can be also redundant) before the load is interrupted.

Any number of units can be connected together in this way, the

addition of each unit providing the addition of 1 or 2 additional

security factors. The interconnection of the SOLA 4000 in this

way requires a special cable available from your local distributor.

• Parallel Operation is used to provide redundancy in the same

way as for hot-standby units above and / or an increased

capacity to supply the load, the parallel units exactly sharing

the load requirement.

• "Maintenance Bypass Operation" is used to supply the load

directly from mains during maintenance or repair work.

Warning: Even in case of a total blackout, the UPS will continue to

supply power to the load, therefore all necessary precautions

against direct and indirect accidental contact as specified in national and local safety standards must be followed.

JUE 401266

58

Page 59

SOLA 4000 - Operation

1 Operating Modes

LED 1 MAINS PRESENT

LED 2 RECTIFIER

LED 3 BATTERY SWITCH

LED 4 BATTERY DISCHARGING

LED 5 BATTERY CHARGING

LED 14 BYPASS POWER SUPPLY

LED 15 MAINTENANCE BYPASS SWITCH

LED 16 INVERTER

LED 17 LOAD FED by INVERTER

LED 18 LOAD FED by BYPASS

POWER SUPPLY

LED 19 LOAD IS SUPPLIED

LED 27 BATTERY TEST

LED 28 E.P.O.

LED 26 BYPASS AVAILABLE

LED 29 COMMON ALARM

LED 30 BOOST CHARGE

1.2 LED Indication

The block diagram of the UPS, with integrated LEDs, allows a

quick check of the UPS operating status.

JUE 401266

59

Page 60

SOLA 4000 - Operation

2 Operating Modes Stand-alone Unit

2 OPERATING MODES STAND-ALONE

UNIT

2.1 Normal Operation

"Normal Operation" is the standard operating mode of the UPS

• Mains power is present.

• The rectifier converts ac power to dc power which charges the

batteries and feeds the inverter.

• The inverter converts this dc power to ac power used to feed

the connected load.

2.2 Battery Operation

The "Battery Operation" mode is activated by a mains failure or

rectifier failure

• The rectifier supplies no power.

• The battery supplies the required dc power to the inverter.

• The inverter supplies ac power to the load as described above.

• Power will only be supplied to the load for a certain period of

time depending on the battery capacity and the amount of load

applied.

JUE 401266

60

Page 61

SOLA 4000 - Operation

2 Operating Modes Stand-alone Unit

2.3 Bypass Operation

The "Bypass Operation" mode is activated by an inverter failure or

an overload

• The rectifier supplies dc power only to the battery.

• The static inverter switch SSI opens automatically after the

static bypass switch SSB is closed.

• The load is supplied directly from the mains through the static

bypass line.

2.4 Maintenance Bypass Operation

The "Maintenance Bypass Operation" mode is used to supply the

load directly from the mains during maintenance or repair work.

• In this mode, the individual functional components are completely separated from the load.

• Power for the load is supplied directly from the mains through

the switch IBY.

2.5 Standby Operation

If an appropriately programmmed IPR pcb is inserted in the control

electronic of the stand-alone unit, as an option, this mode of

operation is possible.

• If the load is completely switched off, the inverter and the

inverter static switch SSI, switch off and the UPS commutates

to the bypass supply (SSB closes), thus saving power when the

UPS is not needed.

• When the load is again switched on, the inverter automatically

switches on and the inverter static switch SSI will commutate

the load to the protected inverter supply.

JUE 401266

61

Page 62

SOLA 4000 - Operation

3 Operating Modes Hot-Standby Operation

3 OPERATING MODES HOT-STANDBY

OPERATION

3.1 Normal Operation

"Normal Operation" is the standard operating mode of the hotstandby system.

• Mains power is present.

• The rectifiers of all units convert ac power to dc power which

charges the batteries and feeds the inverters.

• The inverters convert this dc power to ac power.

• The inverter of one unit feeds the connected load.

• The inverter of the other unit(s) is working in standby mode,

ready to takeover the load if there is a failure in the unit supplying the load.

• All units in the system are identical and operate completely

independently of each other.

3.2 Operation with an Inverter Failure

"Operation with an Inverter Failure" is the operating mode of the

hot-standby system after a failure has occurred in one unit.

• Mains power is present.

• The static inverter switch of the failed unit opens automatically