Page 1

Online UPS

owerWalker VFI 10000TCP 3/1

P

PowerWalker VFI 10000TP 3/1

PowerWalker VFI 20000TP 3/1

Manual

EN/DE

Uninterruptible Power Supply System

Page 2

CONTENT:

1. Safety ........................................................................................................... 1

1.1 Installation............................................................................................... 1

1.2 Operation ................................................................................................ 2

1.3 Maintenance, Servicing and Faults ........................................................ 3

1.4 Transport ................................................................................................ 4

1.5 Storage ................................................................................................... 4

1.6 Standards ............................................................................................... 5

2. Description of Commonly Used Symbols ................................................ 6

3. Introduction ................................................................................................. 7

3.1 System and Model Description ............................................................... 7

3.2 Product Specification and Performance ............................................... 10

4. Installation ................................................................................................. 13

4.1 Unpacking and Inspection .................................................................... 13

4.2 Input and Output Power Cords and Protective Earth Ground

Installation ................................................................................................... 16

4.3 Operating Procedure for Connecting with The External Battery .......... 21

5. Operation ................................................................................................... 23

5.1 Display Panel ........................................................................................ 23

5.2 Operating Mode .................................................................................... 27

5.3 Turning On and Turning Off UPS ......................................................... 29

5.4 LCD Operation ...................................................................................... 31

6. Special function ........................................................................................ 40

6.1 HE Function .......................................................................................... 40

Page 3

6.2 Converter Function ............................................................................... 40

6.3 Parallel Function ................................................................................... 41

6.4 PowerWalker VFI 10000TCP 3/1 Optional Design of Charger Current 47

6.5 Backfeed Protection ............................................................................. 48

7. Trouble Shooting ...................................................................................... 51

7.1 Trouble Shooting According To Warning Indication .............................. 51

7.2 Trouble Shooting According To Fault Indication ................................... 53

7.3 Trouble Shooting In Else Cases ........................................................... 54

8. Battery Maintenance, Replacement and Disposal ................................. 56

8.1 Maintenance ......................................................................................... 56

8.2 Replacement and Disposal of Batteries ............................................... 57

9. Communication Port................................................................................. 60

9.1 RS232&USB Interface .......................................................................... 60

9.2 Intelligent Slot ....................................................................................... 60

9.3 AS400 Interface (Option) ...................................................................... 60

10. Software Installation ..................................... Error! Bookmark not defined.

Page 4

1. Safety

Please read carefully the following user manual and the safety

instructions before installing the unit or using the unit!

1.1 Installation

★ Condensation may occur if the UPS is moved directly from a

cold to a warm environment. The UPS must be absolutely dry

before being installed. Please allow an acclimatization time of

at least two hours.

★ Do not install the UPS near water or in damp environment.

★ Do not install the UPS where it would be exposed to direct

sunlight or near heat.

★ Do not block ventilation openings in the UPS’s housing.

★ Do not connect appliances or items of e quipment w hi ch would

overload the UPS (e.g. laser printers, etc) to the UPS output.

★ Place cables in such a way that no one can step on or trip over

them.

★ UPS has provided earthed terminal, in the final installed

system configuration, equipotential earth bonding to the

external UPS battery cabinets.

★ An integral single emergency switching device which prevents

further supply to the load by the UPS in any mode of operation

should be provided in the building wiring installation.

1

Page 5

★ An appropriate disconnect device as short-circuit backup

protection should be provided in the building wiring

installation.

★ For thre e-phase equipmen t connection to an IT power syste m,

a four-pole device which disconnect all phase conductors and

the neutral conductor should be provided in the buil ding wiring

installation.

★ This is permanently connected equipment, it must be installed

by qualified maintenance personnel.

★ Earth connection essential before connecting to the building

wiring terminal.

1.2 Operation

★ Do not disconnect the ea rth con ductor ca ble on the UPS or the

building wiring terminals in any time since this would cancel

the protective earthing of the UPS system and of all connected

loads.

★ The UPS output terminal block ma y be electrically liv ed eve n if

the UPS system is not connected to the building wiring

terminal.

★ In order to fully disconnect the UPS, turn the M1/M2/N input

breaker in the “OFF” position (for PowerWalker VFI

10000-20000 TP 3/1), turn the R/S/T/N input switch in the

“OFF” position (for PowerWalker VFI 10000TCP 3/1), then

disconnect the mains lead.

2

Page 6

★ Ensure that no liquid or other foreign objects can enter the

UPS.

1.3 Maintenance, servicing and faults

★ The UPS operates with hazardous voltages. Repairs should be

carried out only by qualified maintenance personnel.

★ Caution - risk of electric shock. Even after the unit is

disconnected from the mains power supply (building wiring

terminal), components inside the UPS are still c onnected to the

battery which are potentially dangerous.

★ Before carrying out any kind of service and/or maintenance,

please disconnect the batteries. Verify that no current is

present and no hazardous voltage exists in the capacitor or

BUS capacitor terminals.

★ Batteries must be replaced only by qualified personnel.

★ Caution - risk of electric shock. The battery circuit is not

isolated from the in put v oltage. Hazardous v oltages may occu r

between the battery terminals and the ground. Verify that no

voltage is present before servicing!

★ Batteri es have a high shor t-circuit current and pose a risk of

shock. Take all precautionary measures specified below and

any other measures necessary when working with batteries:

- remove all jewellery, wristwatches, rings and other metal

objects

3

Page 7

- use only tools with insulated grips and handles.

★ When changing batteries, replace with the same quantity and

the same type of batteries.

★ Do not attempt to dispose of batteries by burning them. It

could cause explosion.

★ Do not open or destroy batteries. Effluent electrolyte can cause

injury to the skin and eyes. It may be toxic.

★ Please replace the fuse only by a fuse of the same type and of

the same amperage in order to avoid fire hazards.

★ Do not dismantle the UPS, except the qualified maintenance

personnel.

1.4 Transport

★ Please transport the UPS only in the original packaging (to

protect against shock and impact).

1.5 Storage

★ The UPS m ust be stockpiled in the room w here it is ventilated

and dry.

4

Page 8

* Safety

IEC/EN 62040-1

*EMS

ESD........................................:IEC/EN 61000-4-2

Level 3

RS..........................................:IEC/EN 61000-4-3

Level 3

EFT.........................................:IEC/EN 61000-4-4

Level 4

SURGE....................................:IEC/EN 61000-4-5

Level 4

Low Frequency Signals .............:IEC/EN 61000-2-2

1.6 Standards

* EMI

Conducted Em i ss i on .. ...............:IEC/EN 62040-2 Category C3

Radiated Emission...................:IEC/EN 62040-2 Category C3

Warning: This is a product for c om mer cial and industrial application

in the second environment-installation restrictions or additional

measures may be needed to prevent disturbances.

5

Page 9

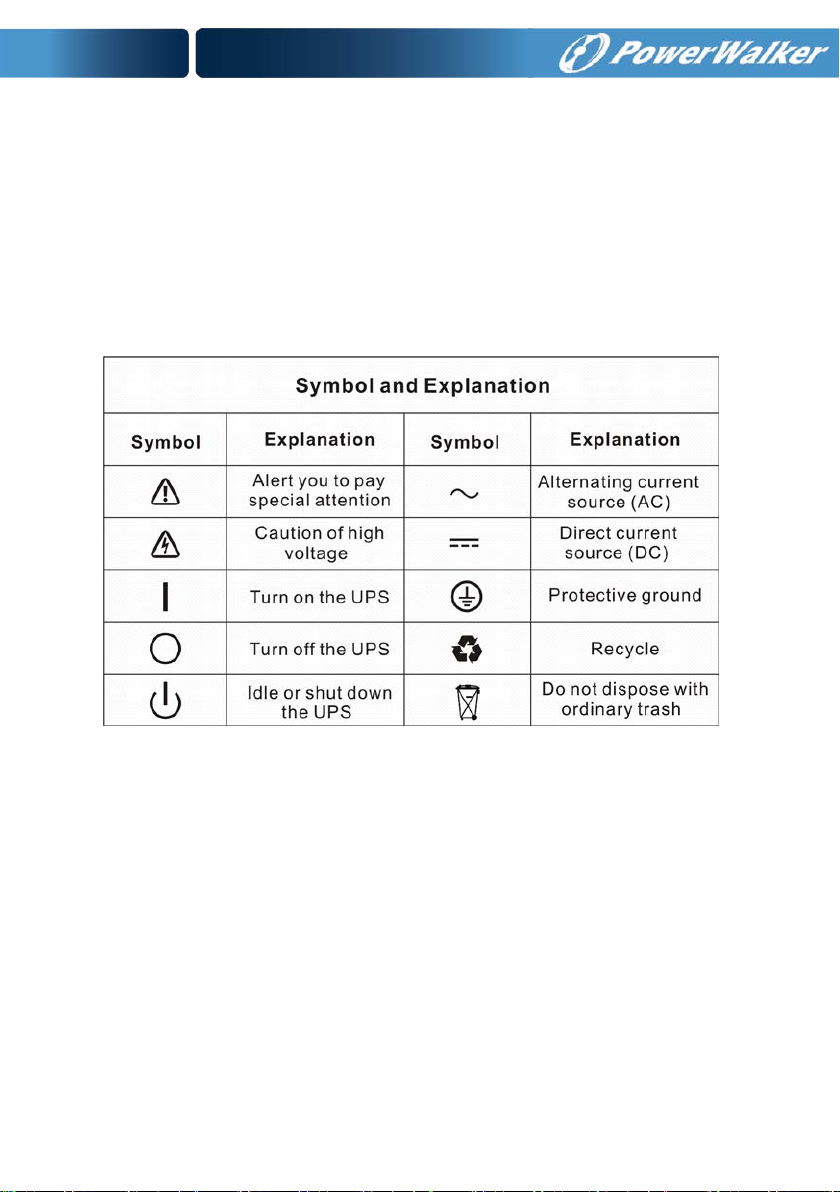

2. Description of Commonly Used Symbols

Some or all of the following symbols may be used in this manual. It is

advisable to familiarize yourself with them and understand their

meaning:

6

Page 10

3. Introduction

3.1 System and model description

This Online Series is an uninterruptible power supply incorporating

double-conversion technology. It provides perfect protection

specifically for computer equipment, communication systems to

computerized instruments.

Its true online double-conversion design eliminates all mains power

disturbances. A rectifier converts the alternating current from the

utility power to direct current. This direct current powers the inverte r.

On the basis of this DC voltage, the inverter generates a pure

sinusoidal AC voltage, which is constantly powering the loads.

Computers and Peripherals are thus powered entirely by the UPS. In

the event of power failure, the maintenance-free batteries power the

inverter.

This manual is applicable to the PowerWalker VFI 10000-20000 TP

3/1 models and PowerWalker VFI 10000T CP 3/1 model.

The tower 3-phase series UPS providing outstanding performance

and reliability, the UPS’s unique benefits include:

Online UPS design with pure sine wave output.

True online d ouble-conv ersion te chnolog y with hi gh power densit y,

utility frequency independence, and generator compatibility.

Overall high efficiency > 93%, saving the operating cost.

True three-phase power factor correction and high input power

factor (PF>0.99). Save the installation cost and reduce the

pollution back feed into upstream power system.

7

Page 11

High output power factor (0.9), to adapt more type load.

Intelligent Battery Management technology that uses advanced

battery management to increase battery service life, optimize

recharge time.

Selectable High Efficiency mode (ECO mode) or CVCF mode

operation.

Combo input (single phase or three phase) auto detection

Back-feed protection

Start-on-battery capability for powering up the UPS even if utility

power is not available.

Standard communication options: one RS-232 communication port,

one USB communi cation port.

Optional connectivity cards with enhanced communication

capabilities.

Remote shutdown control through the Remote Power-off (RPO)

port.

For tower PowerWalker VF I 10000-20000 TP 3/1, Maintenances are

simplified by allowing the safe replacement of batteries without

powering down the UPS. But PowerWalker VFI 10000TCP 3/1 model

have no this function.

N+X parallel redundancy to increase the reliability and flexibility.

The max p ar a llel numb er is 4.

User-friendly LCD display and LED indicators.

For tower PowerWalker VFI 10000-20000 TP 3/1, easily battery

exchange or extension and ava ilable to exten d the ba ckup time. But

PowerWalker VFI 10000TCP 3/1 model have no this function.

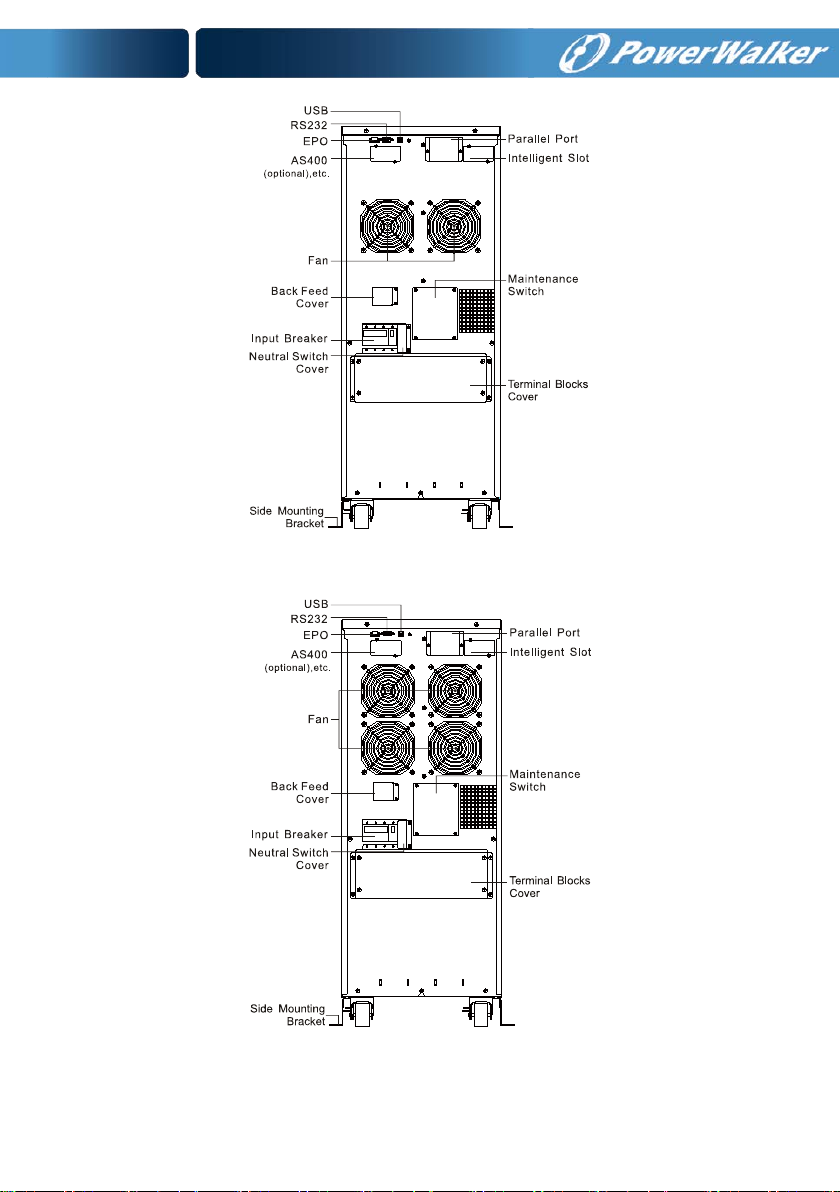

The appearance of tower 3-phase series

Refers to Fig. 3-1

8

Page 12

PowerW a lk er VFI 10000 TP 3/1 REAR VIEW

PowerWalker VFI 20000 TP 3/1 REAR VIEW

9

Page 13

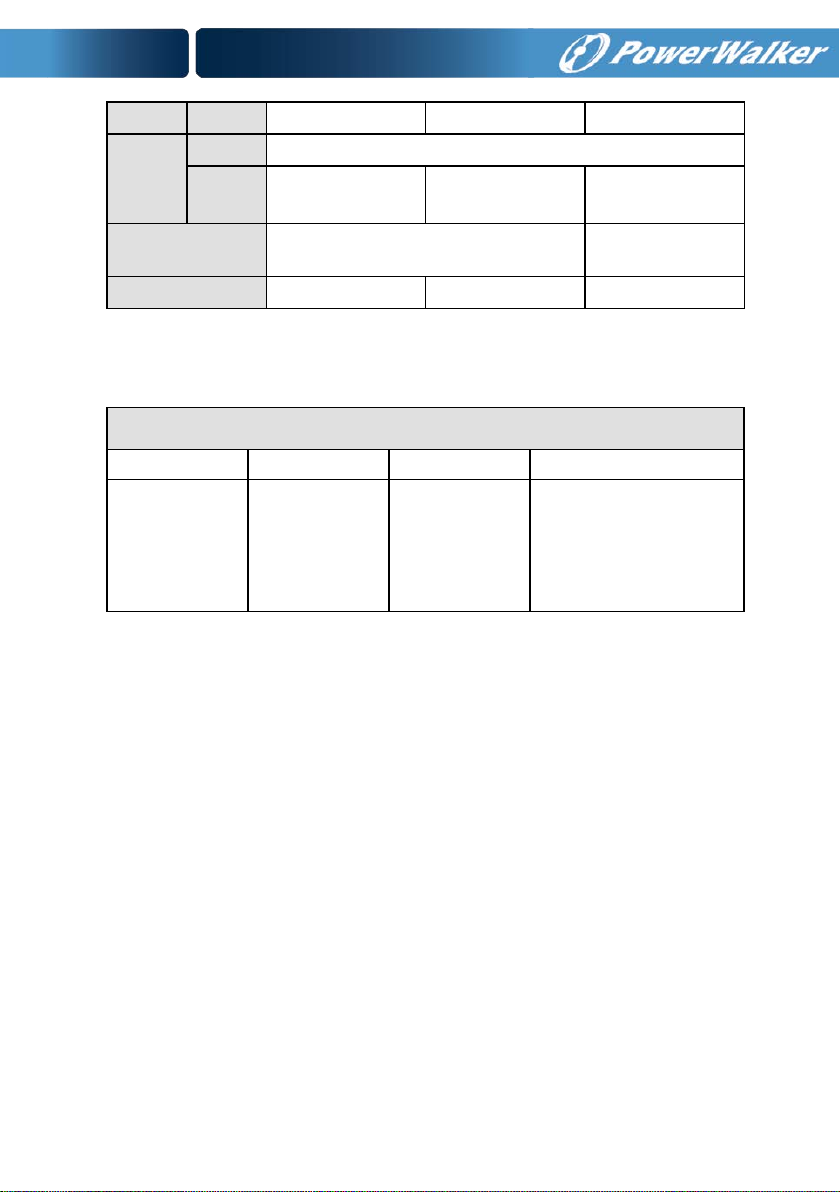

10000TP 3/1

20000TP 3/1

10000TCP 3/1

Power Rating

10KVA/9KW

20KVA/18KW

10KVA/9KW

Frequency (Hz)

50/60

Current

L1/L2/L3:23A MAX

L1/L2/L3:46A MAX

L1/L2/L3:23A MAX

Battery

Voltage

288VDC

240VDC

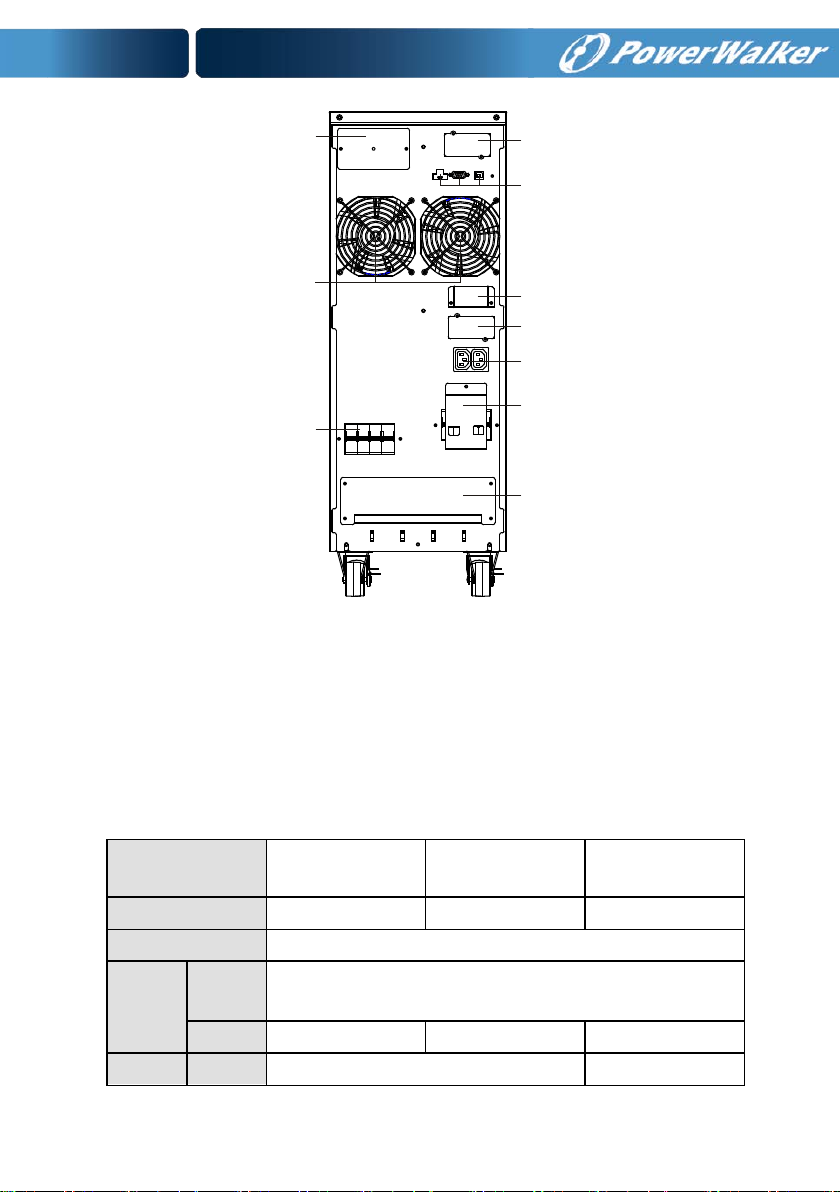

Parallel Port

(Optional)

Intelligent Slot

EPO、、RS232 USB

Fan

AS400

Input Breaker

Terminal Blocks

Cover

External Battery

IEC Connector

Maintenance and Output

Switch Cover

PowerWalker VFI 10000TCP 3/1 REAR VIEW

3.2 Product Specification an d Performance

1) General Sp e c i f ic ation

Input

Fig. 3-1 the rear view of the tower 3-phase series UPS

Model

Voltage (110-276)VAC (Depends on Load Level)

PowerWalker VFI

PowerWalker VFI

PowerWalker VFI

10

Page 14

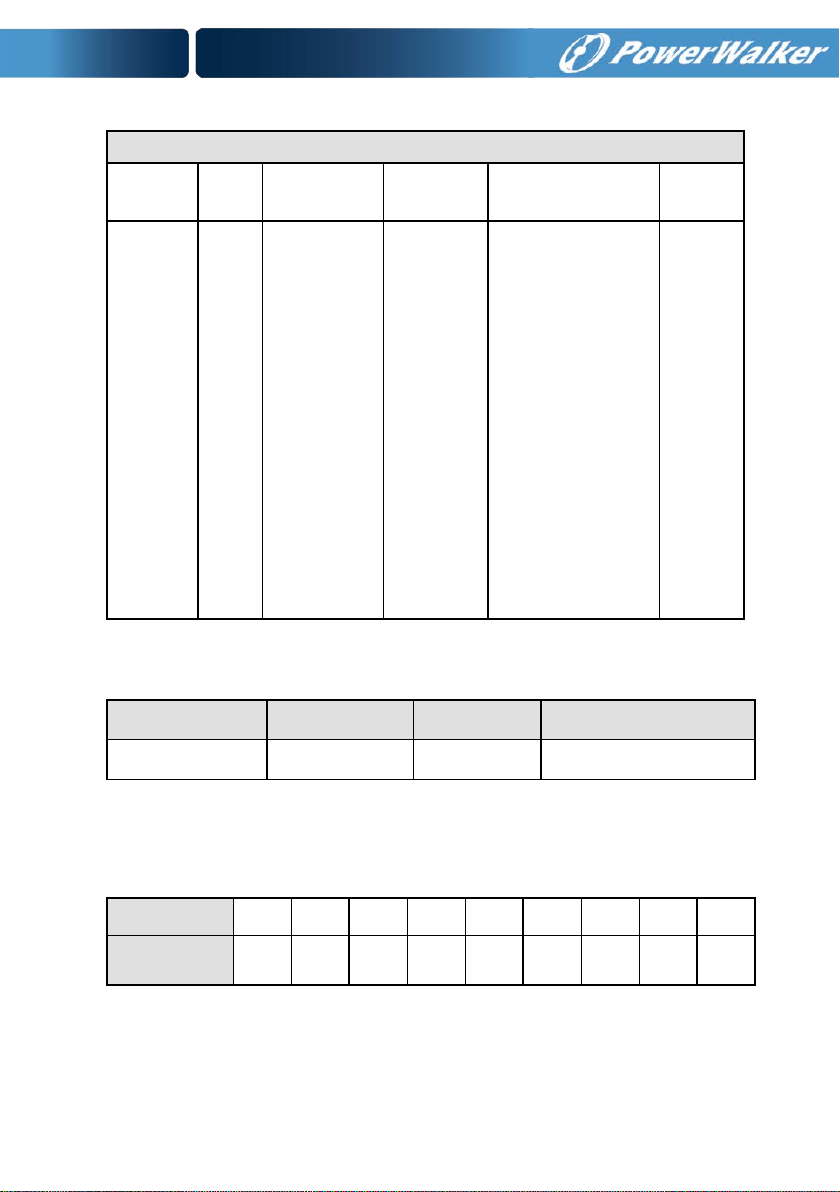

Current

43A MAX

86A MAX

51.8A MAX

Voltage

200VAC/208VAC/220VAC/230VAC/ 240VAC*

3.5A/41.7A

7.0A/83.3A

3.5A/41.7A

(WxDxH) mm

Net Weight (kg)

127

188

85

Model

Voltage

Frequency

Power Factor

PowerWalker VFI

PowerWalker VFI

PowerWalker VFI

10000TCP 3/1

Output

Dimension

Current

45A/48.1A/45.5A/4

350x650x890 260*550*708

90A/96.2A/90.9A/8

45A/48.1A/45.5A/4

2) Electrical Performan c e

Input

10000TP 3/1

20000TP 3/1

Three-phase 50/60 Hz±10% >0.99(@Full load)

*:If output voltage be set 200V, output power will derating to 90% of power

rating

11

Page 15

Power

Output

Voltage

Regulation

±1% 0.9 lag

Power

Factor

Frequency

tolerance.

Synchronized

50/60Hz±10%

in Line mode

(AC mode)

±0.1% of

normal

frequency in

Battery mode

Distortion Overload capacity

100%-110% load

transfers to Bypass

mode after 5

minutes

THD<2%

Full load

(Linear

Load)/

<5% for

reference

non-linear

load

110%-130% load

transfers to Bypass

mode after 1

minutes

130%-150% load

transfers to Bypass

mode after 10

second

>150% load

transfers to Bypass

mode after 2 second

Current

crest ratio

3) Operating Environment

Temperature Humidity Altitude Storage temperature

0°C-45°C

<95% <1000m

-15°C-50°C

3:1

Note: if the UPS is installed or used in a place where the altitude is

above than 1000m, the output power must be derated in use, please

refer to the following:

Altitude (M) 1000 1500 2000 2500 3000 3500 4000 4500 5000

Maximum

100% 95% 91% 86% 82% 78% 74% 70% 67%

12

Page 16

4. Installation

The system may be installed and wired only by qualified

electricians in accordance wit h applicable safety regulations!

4.1 Unpacking and Inspection

1. Moving to th e in stallation site

The tower 3-phase series UPS has wheels making it easy to move the

UPS to the installation site after it has been unpacked. However, if the

receiving area is far from the installation site, we recommend you to

move the UPS by using a pallet jack or a lifter before you start to

unpack the UPS.

2. Unpacking and inspection

1) At the installation site, the utmost care shall be taken when

removing t he pac kaging i n o rder to a voi d damagi ng t he equi pment.

Check all packaging materials to ensure that no items are missing.

The shipping package contains:

● A UPS

● A user manual

● A communication cable

● Parallel port cover plate

13

Page 17

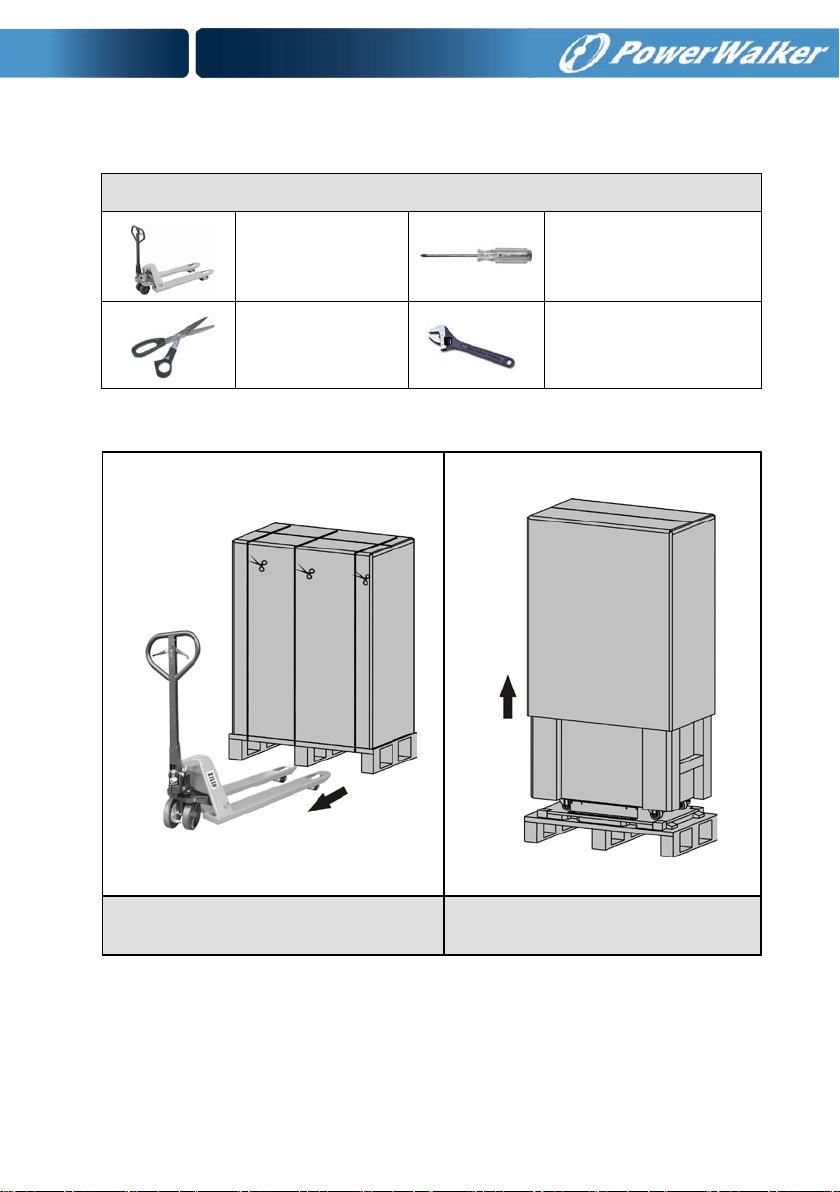

Tools kit

Remove the packa ging foll owing t he seque nce illustrated in Fig. 4-1 to

Fig. 4-4. (only for PowerWalker VFI 10000-20000 TP 3/1)

Lifter

Scissors

Phillips screwdriver

Wrench

Fig. 4-1 Unpacking-step1 Fig. 4-2 Unpacking-step2

14

Page 18

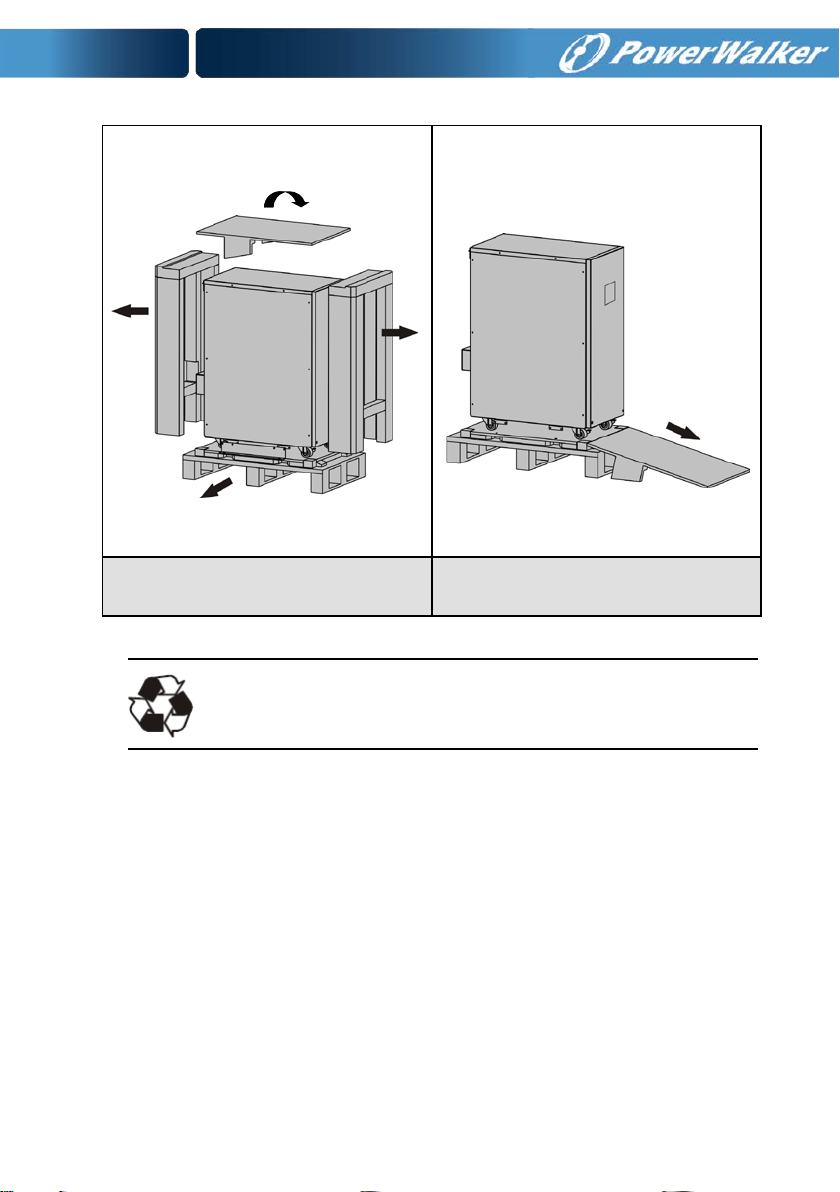

Fig. 4-3 Unpacking-step3 Fig. 4-4 Unpacking-step4

The shipping materials are recyclable. After unpacking,

save them for later use or dispose of them appropriately.

2) Inspect the appearance of the UPS to see if there is any damage

during transportation. Do not turn on the unit and notify the carrier

and dealer immediately if there is any damage or lacking of some

parts.

15

Page 19

4.2 Input and Output Power Cords and Protective

Earth Ground Installation

1. Notes for installation

1) The UPS must be installed in a location with good ventilation, far

away from water, inflammable gas and corrosive agents.

2) Ensure the air vents on the front and rear of the UPS are not

blocked. Allow at least 0.5m of space on each side.

3) Condensation to water drops may occur if the UPS is unpa cked in a

very low temperature environment. In this case it is necessary to

wait until the UPS is fully dried inside out before proceeding

installation and use. Other wi se t here are hazards of electric sh oc k .

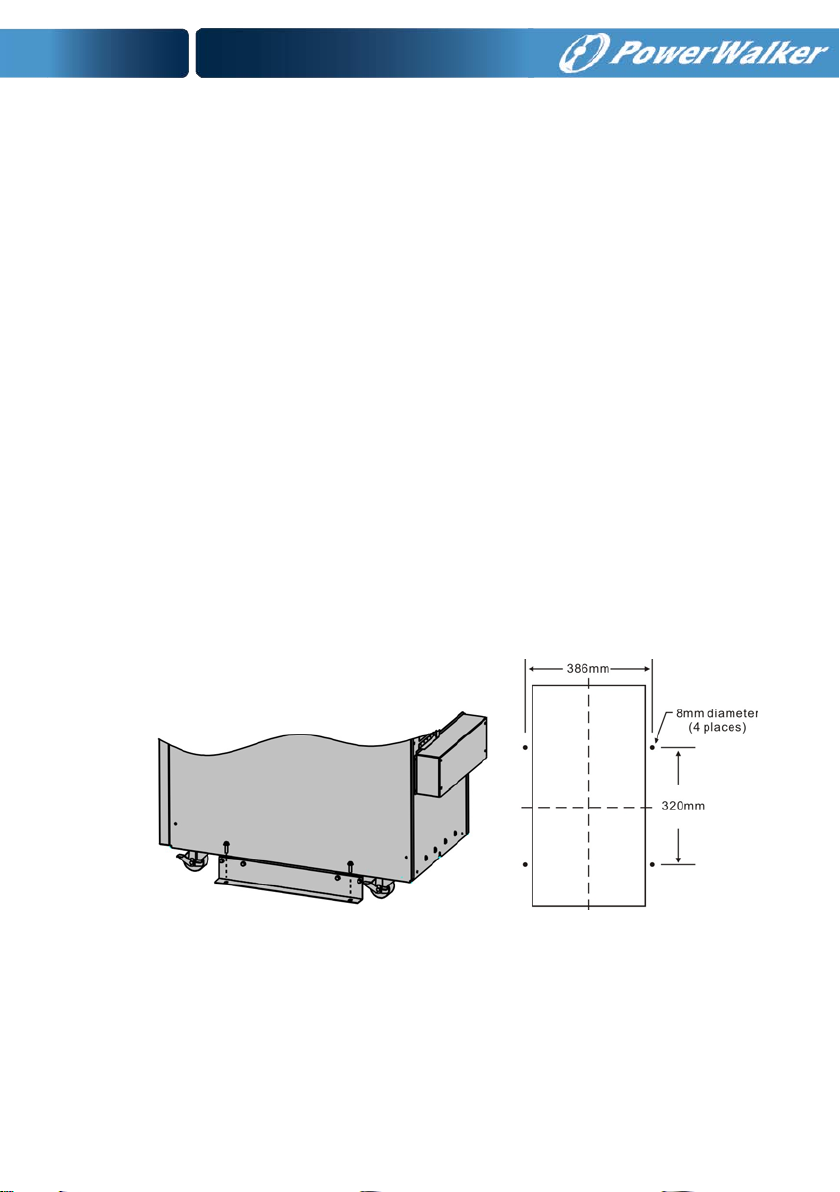

4) Once the installation is completed, the side mounting brackets

(used in shipping)shall be fixed back to ensure the sta bility of the

UPS enclosure. If impossible, additional stability can be added by

anchoring the mounting br ackets to the floor with M8 bolts. See Fig.

4-5. (only for PowerWalker VFI 10000-20000 TP 3/1)

Fig. 4-5 Additional stability

2. Installa t ion

Installation and wiring must be performed in accordance with the

local electric code and the following instructions by professional

personnel.

16

Page 20

For safety, please cut off the mains power switch before installation.

1) Op en the terminal block cover located on the rear panel of the

UPS, please refer to the appearance diagram.

2) For tower PowerWalker VFI 10000TCP 3/1 UPS, it is

recommended to select the UL1015 8AWG(10mm

2

) wire or other

insulated wire which complies with AWG Standard for the UPS

input and output wirings.

3) For PowerWalker VFI 20000TP 3/ 1 U PS, it is recommended to

select the UL1015 6AWG(25mm

2

) wire or other insulated wire

which complies with AW G Standa rd f or the UPS in put and out put

wirings.

Note: Do not use the wall receptacle as the input power source

for the UPS, as its rated current is less than the UPS’s

maximum input current. O therwise t he receptacle m ay be

burned and destroyed.

4) C onnect the input and output wires to the corresponding input

and output terminals according to the following diagram.

Note: you must make sure that the input and output wir es and

the input and output terminals are connected tightly.

5) The protective earth ground wire refers to the wire connection

between the equipment which consumes electri c eq uipment an d

the ground wire. The wire diameter of protective earth ground

wire should be at least as above mentioned for each model and

green wire or green wire with yellow ribbon wire is used.

6) A fter having completed the installation, make sure the wiring is

correct.

7) P lease install the output breaker between the output terminal

and the load, and the breaker should with leakage current

protective function if necessary.

17

Page 21

8) To connect the load with the UPS, please turn off all the loads

first, then perform the connection and finally turn on the loads

one by one.

9) No matter the UPS is connected to the utility power or not, the

output of the UPS may have electricity. The parts inside the unit

may still have hazardous voltage after turning off the UPS. To

make the UPS have no output, power off the UPS, and then

disconnect the utility power supply.

10) Suggest charging the batteries for 8 hours before use. After

connection, turn the M1/M2/N input breaker (for PowerWalker

VFI 10000-20000TP 3/1), turn the input switch (for PowerWalker

VFI 10000TCP 3/1 ) in the "ON" position, the UPS wil l cha r ge the

batteries automatically. You can also use the UPS immediately

without charging the batt eries first, but the backup time may be

less than the standard value.

11) If it is necessary to connect the inductance load such as a

monitor or a laser printer to the UPS, the start-up power should

be used for calculating the capacity of the UPS, as its start-up

power consumption is too big when it is started.

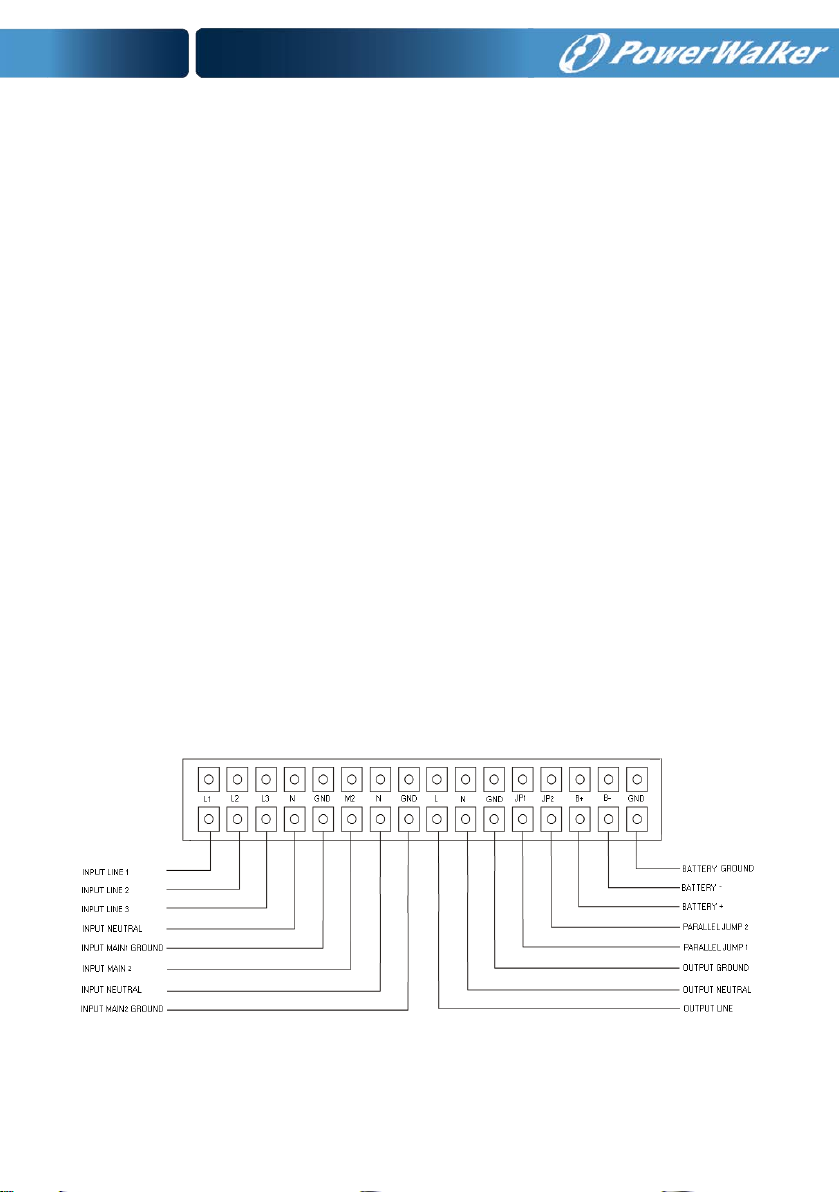

PowerW a lk er VFI 10000-20000TP 3/1

18

Page 22

10000TP 3/1

20000TP 3/1

Max.conducto r cross se ct io n[ mm2]

4

10

Input L1,L2,L3 breaker (A)

40A,250VAC

60A,250VAC

Max.conducto r cross se ct io n[ mm2]

13

25

Input M2 breaker (A)

63A,250VAC

100A,250VAC

Input fuse (A)

30A,250VAC

50A,690AC

Max.conducto r cross se ct io n[ mm2]

13

25

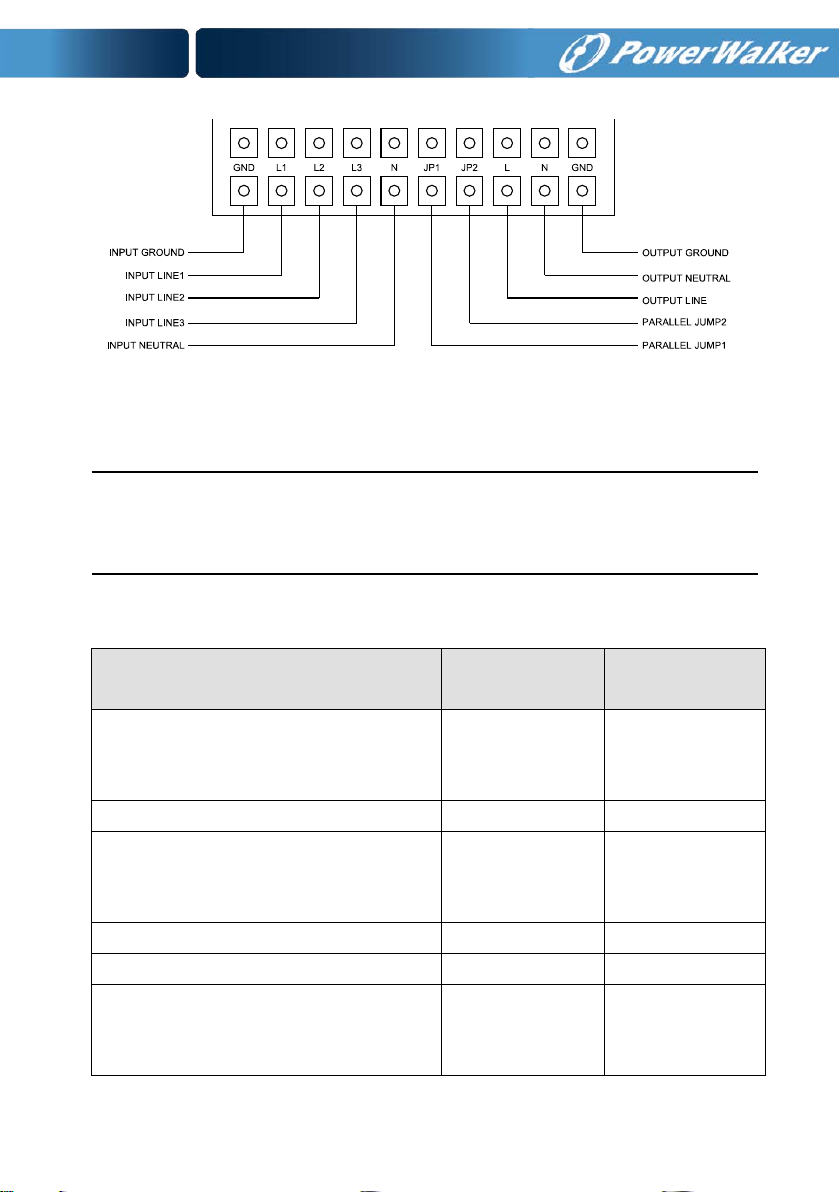

PowerWalker VFI 10000TCP 3/1 model

Fig. 4-6 Input and output Terminal Block wiring diagram

Important notes: If the UPS is used in single mode, JP1 and JP2 must

be connected. If the UPS is used in parallel mode, the J umper between

JP1 and JP2 must be removed.

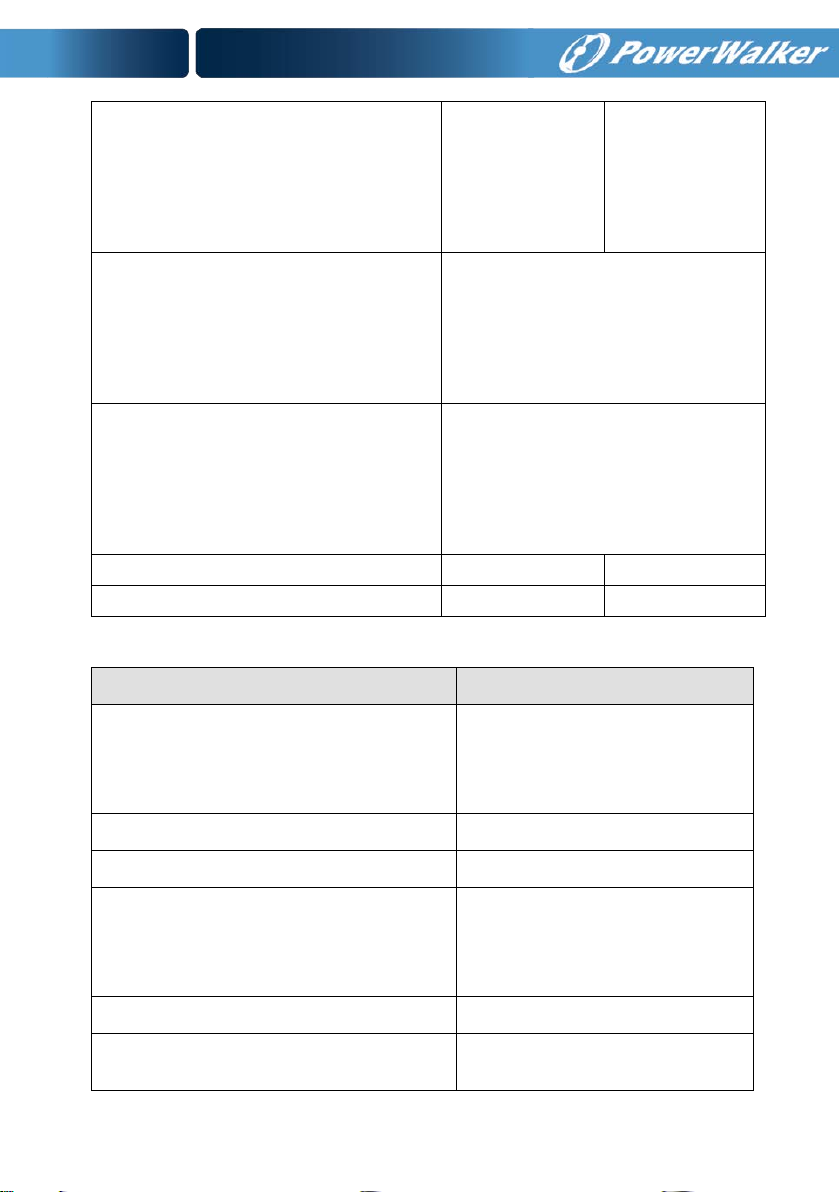

Use cable cross section and protective device specification

Model PowerWalker VFI

Input L1,L2,L3

Min.conductor cross section[mm

Input N, M2

Min.conductor cross section[mm

Output L,N,

Min.conductor cross section[mm

2

2

2

]

]

]

19

2.5

10

10

PowerWalker VFI

6

21

21

Page 23

Max.conducto r cross se ct io n[ mm2]

13

25

protection in line input.

protection in line input.

Protective Earthing conductor[mm2]

Max.13

Max.25

Torque for fixing above terminals

(10 1b in)

(18 1b in)

External Battery Cabinet Positive

Pole(+),Neutral pole,Negative

pole(-),

Min.conductor cross section[mm

2

]

10

21

Line input Backfeed protection

device

M2 input Backfeed protect io n dev ice A 2-pole disconnection device with

A 4-pole disconnection device with

100A/250VAC, less than 15s break

time and min. 1.4mm clearance will be

used in final installation for backfeed

100A/250VAC, less than 15s break

time and min. 1.4mm clearance will be

used in final installation for backfeed

Sheet.1 PowerWalker VFI 10000-20000TP 3/1 models

Model PowerWa lk er VFI 10000TCP 3/1

Input L2,L3

Min.conductor cross section[mm2]

Max.conducto r cross se ct io n[ mm2]

Input L1,L2,L3,N switch (A) 63A,250VAC

2.5

4

Output switch(A)/maintain switch(A) 63A,250VAC

Input L1,N

Min.conductor cross section[mm2]

Max.conducto r cross se ct io n[ mm2]

Input fuse (A) 30A,250VAC

Output L,N,

10

13

20

Page 24

Min.conductor cross section[mm2]

10

Max.conducto r cross se ct io n[ mm2]

External Battery Cabinet Positive

Pole(+),Neutral pole,Negative

pole(-),

Min.conductor cross section[mm2]

Max.conducto r cross se ct io n[ mm2]

Protective Earthing conductor[mm2] MAX 13

Torque for fixing above terminals (10 1b in)

13

10

13

Sheet.2 PowerWalker VFI 10000TC P 3/1 model

4.3 Operating Procedure for Connecting with The

External Battery

1. For P owerWalk er VFI 10000-20000TP 3/1, The nominal DC voltage of

external battery pack is 288VDC. Each battery pack consists of 24

pieces of 12V maintenance free batteries in series. For PowerWalker

VFI 10000TC P 3/1 model, the nominal DC voltage of external batter y

pack is 240VDC. Each battery pack consists of 20 pieces of 12V

maintenance free batterie s in series ,To achieve longer backup time,

it is possible to connect multi-battery packs, but the principle of

“same voltage, same type” should be strictly followed.

2. For PowerWalker VFI 10000-20000TP 3/1, select the UL1015 8AWG

(10mm

2

)/6AWG ( 25mm2) wire respectively or other insulated wire

which complies with AWG Standard for the UPS battery wirings. The

procedure of installing bat tery bank should be c omplie d with strictly.

Otherwise you may encounter the hazardous of electric shock.

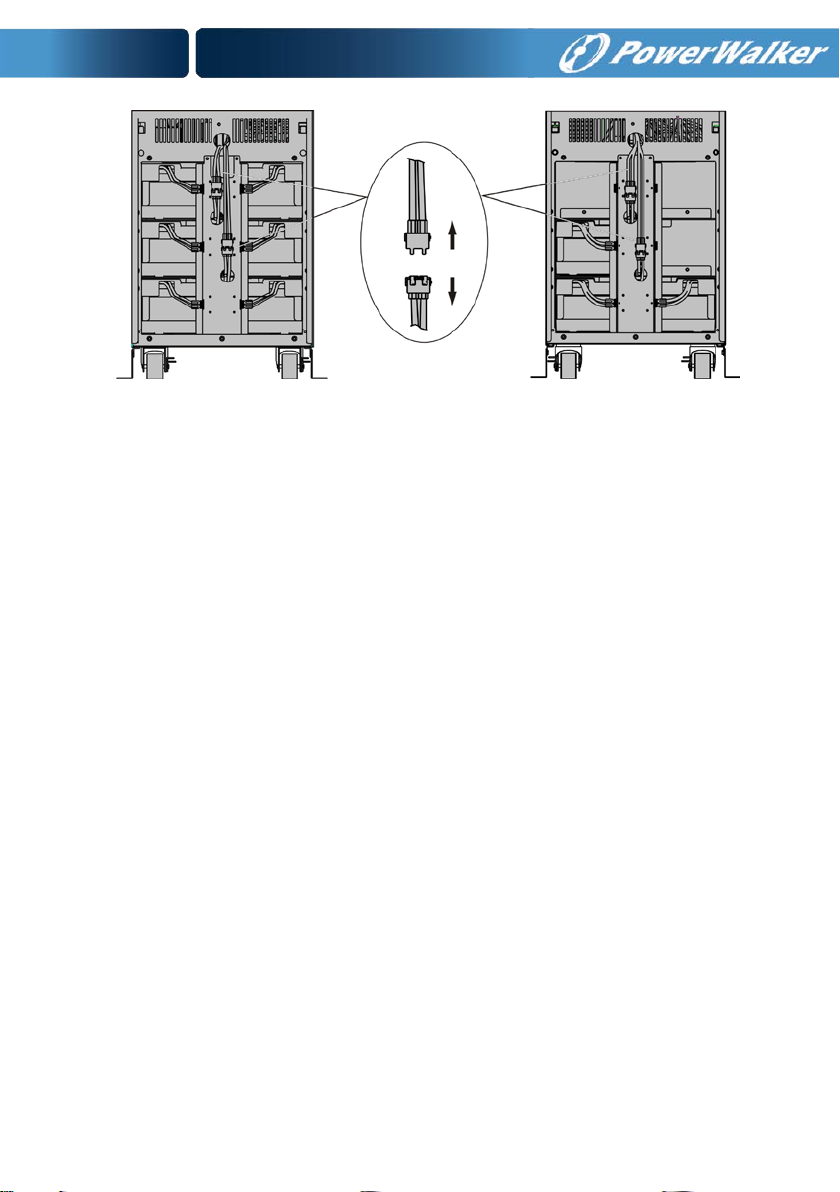

1) For tower 3/1 series if the UPS has internal bat tery pack, first of

all, disconnect the internal battery pack DC connectors.

21

Page 25

PowerWalker VFI 20000TP 3/1 PowerWalker VFI 10000TP 3/1

Fig. 4-7 Disconnect the internal battery pack DC connectors

2) A D C breaker mus t be connected between the external battery

pack and the UPS. The capacity of break er must be n ot less than

the data specified in the general specification.

3) Set the external battery pack breaker in “OFF” position and

connect the batteries (24 pieces for PowerWalker VFI

10000-20000TP 3/1, 20 pieces for PowerWalker VFI 10000TCP

3/1) in series.

4) For PowerW alke r VFI 10000-20000TP 3/1, Connect the external

battery pack to the battery terminals. For PowerWalker VFI

10000TCP 3/1 model, Connect the external battery pack to the

battery anderson connect or.

5) Reconnect the internal battery pack DC connectors, if you had

did step one.

3. Do not attempt to connect any loads to the UPS now. You should

connect the input power wire to t he right position first. And then set

the breaker of the battery pack in the “ON” position. After that set

the input breaker in the “ON” position. The UPS begins to charge the

battery packs at the time.

22

Page 26

5. Operation

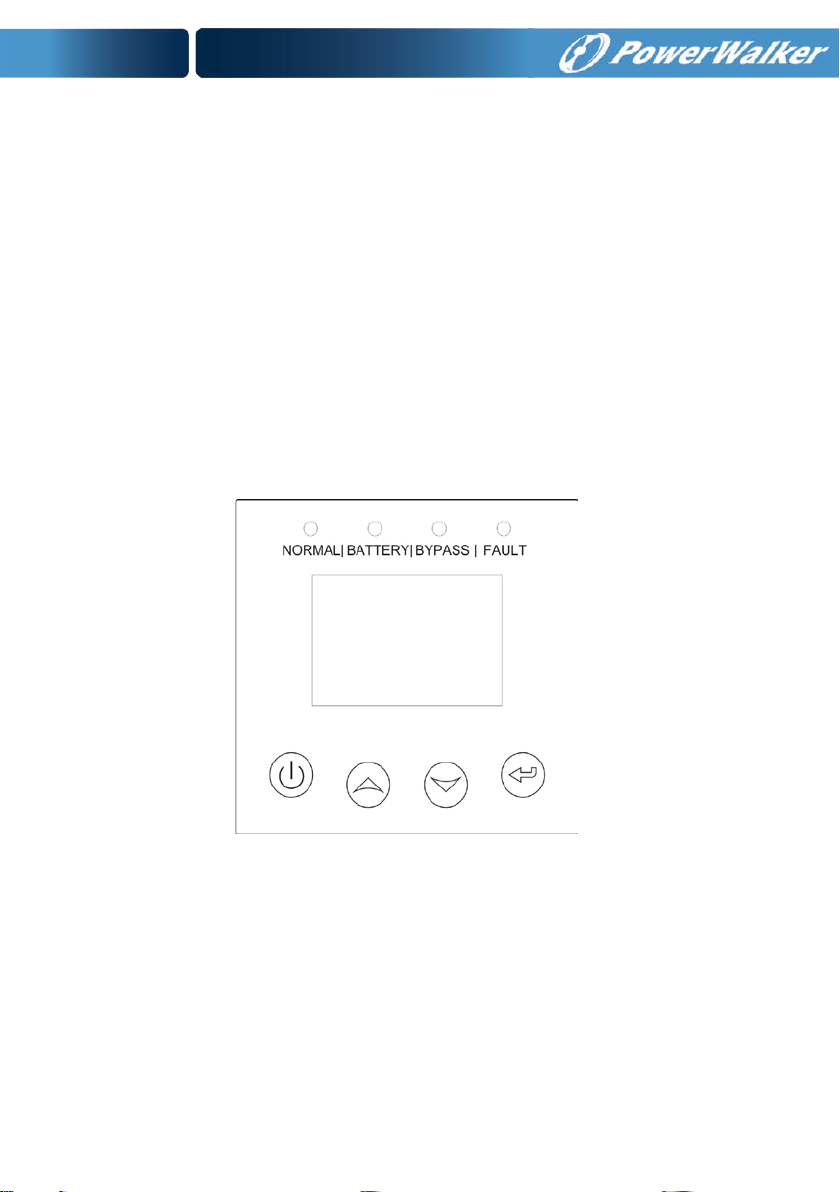

5.1 Display Panel

The UPS has a four-button graphical LCD with dual color backlight.

Standard back-li ght is used to light u p the display with w hite text and

a blue background. When the UPS has a critical alarm, the backlight

changes the text to dark amber and the backgrou nd to red. Besides

the graphical LCD, the UPS has four colorized LEDs to provide you

more convenient info.

See Figure Below

Fig. 5-1 PowerW a lk e r VFI 10000-20000TP 3/1/ PowerWalker VFI

10000TCP 3/1 UPS Control Panel

23

Page 27

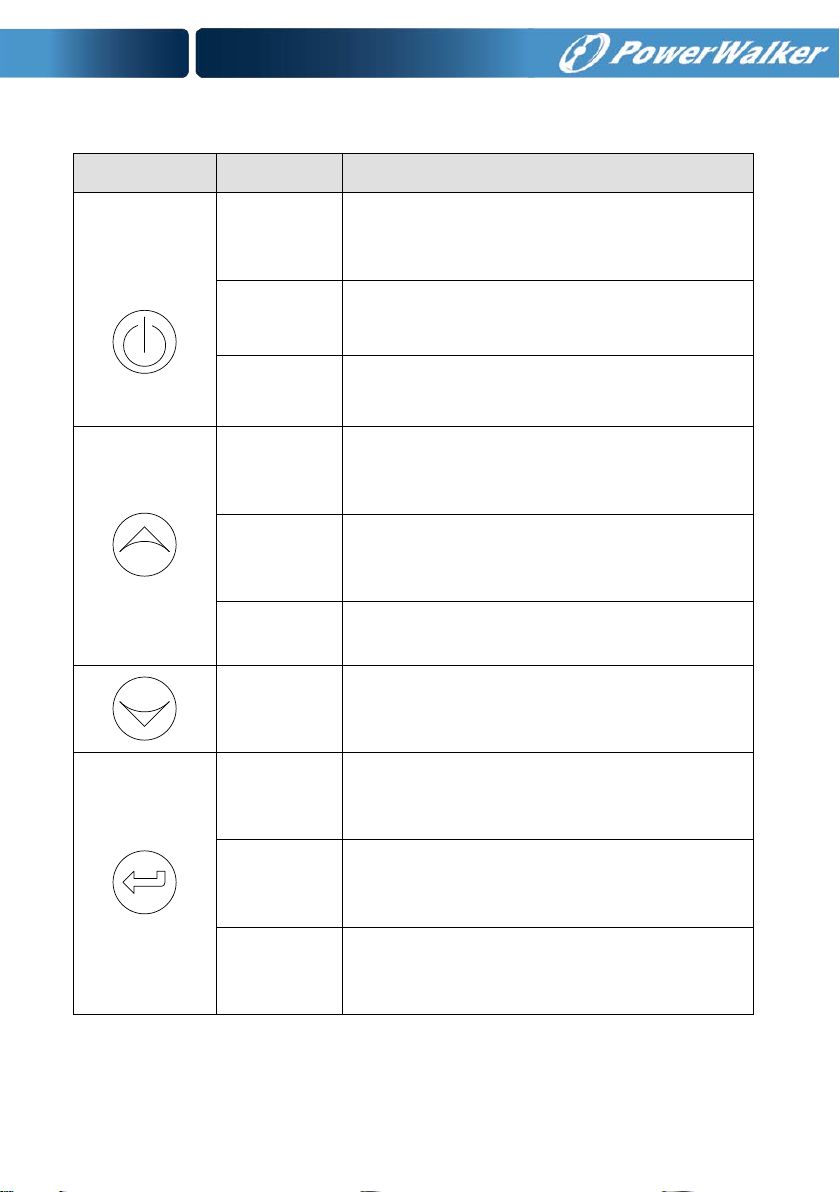

Table 5-1 Co n tr ol Button Functions

The Button Function Illustration

Power on

When the unit is no power and has connected

with battery, press this button for >100ms&<1s

to power on

Turn on

Turn off

Enter main

menu

Exit main

menu

Scroll up

Scroll down

Enter next

menu tree

When the unit is powered on and in Bypass

mode, press this button for >1s to turn on

When the unit has been turned on, press this

button for >3s to turn off

When displaying default UPS status summary

screen, press this button for >1s to enter the

main menu tree

Press this button for >1s to exit the present menu

to default system status display menu without

executing a command or changing a setting

Press this button for >100ms&<1s to scroll up the

menu option

Press this button for >100ms&<1s to scroll down

the menu option

Press this button for >100ms&<1s to select the

present menu option, or enter next menu, but do

not change any settin g

Press this button for >100ms&<1s to select the

present menu option, or enter next menu, but do

not change any setting

Press this button for >1s to confirm the edited

options and change the setting

Select one

menu option

Confirm the

present

setting

24

Page 28

(Green)

(Yellow)

(Yellow)

(Red)

with no output

with output

Table 5-2 LED definition

UPS state

Bypass mode

Bypass mode

Turning on

Line mode

Battery mode

HE mode

Battery test mode

Fault mode

Warning

Normal LED

△ △

●

●

●

●

△ △

↑ ↑

↑

Battery LED

△ △

△ △

Bypass LED

★

●

●

↑

Note:

●: Lightened constantly

△: #1-#4 Lightened circularly

★: Flashing

↑: Depended on the fault/warning status or other status

Fault LED

↑

↑

↑

↑

↑

●

★

Table 5-3 Buzzer definition

UPS condition Buzzer status

Fault active Continuous

Warning active Beep every second

Battery output

Bypass output Beep every 2 minutes

Beep every 4 seconds, if battery low, buzzer Beep every second

25

Page 29

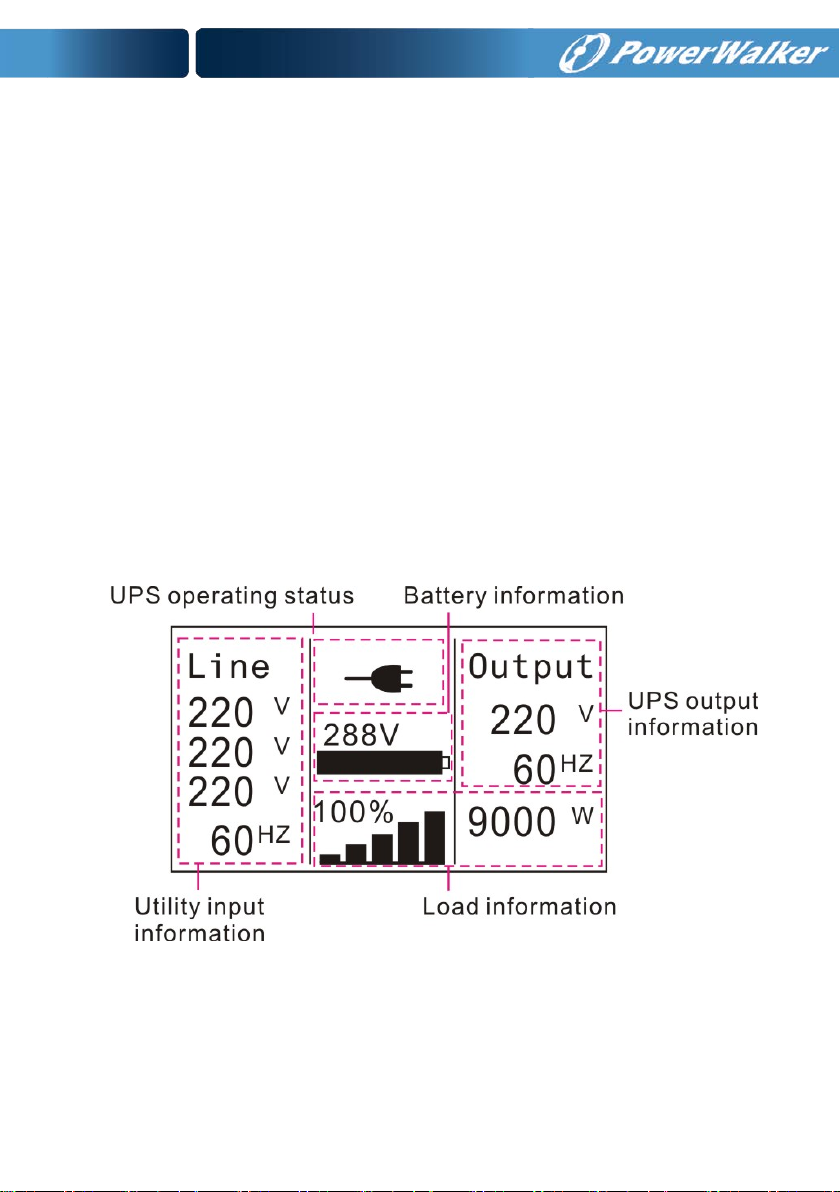

The UPS provides useful information about UPS itself, load status, events,

measurements, identification, and settings through the front panel display.

After powering on, the LCD will display the “WELCOME” logo for several

seconds and then enter to the default page which shows the UPS status

summary. The display automatically returns to the default UPS status

summary screen when no button has been pressed within 15 minutes.

On the UPS status summary screen it provides the following information:

Status summary, including mode and load

Alarm status, if any are present

Notes: alarm including fault and warning information

Battery and charger status, including battery voltage, charger

level and charger status

Running information including parallel UPS and running time

Fig. 5-2 The default LCD display

The more detailed operation of LCD is illustrated in the chapter of 5.4.

26

Page 30

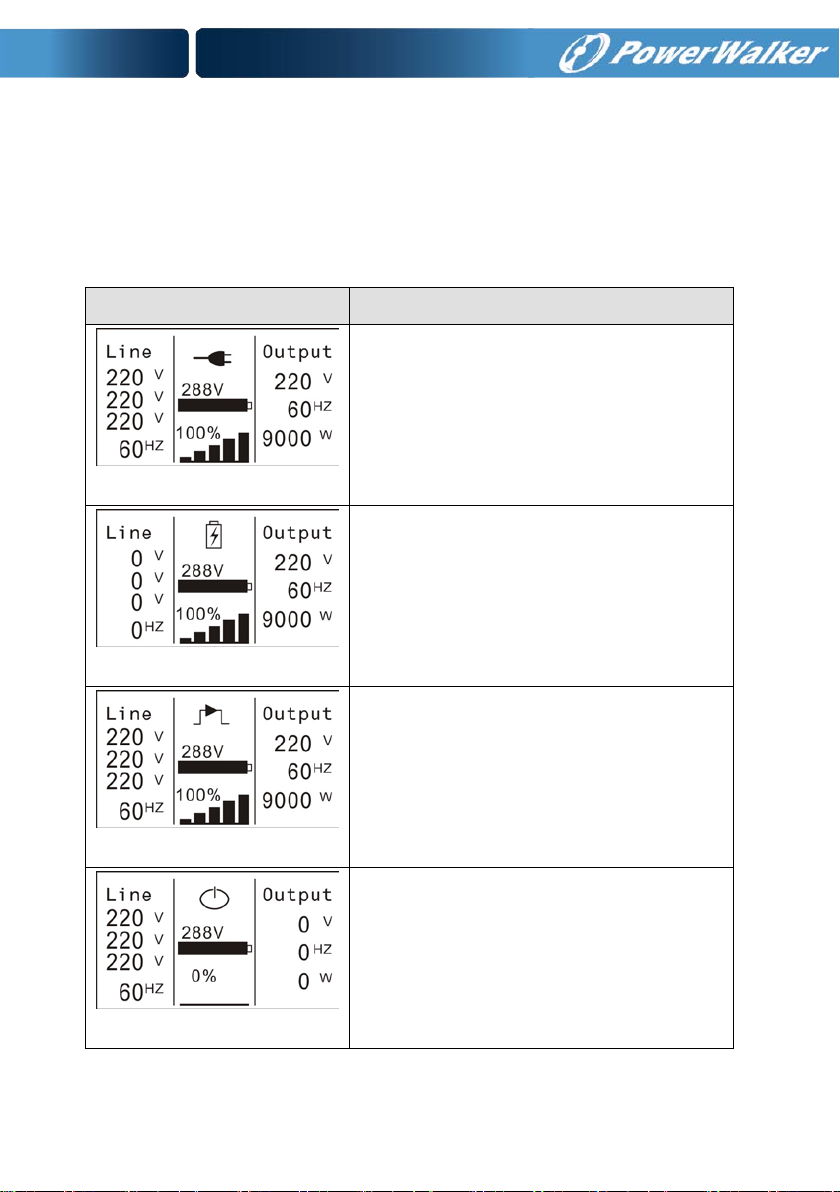

5.2 Operating Mode

The different graphic symbol could be displayed corres ponding to current

operating mode or status.

Table 5-4 St atu s Summary Screens

Status Summary Screen

Fig 5-3

Fig 5-4

Fig 5-5

Description

Normal mode:

The UPS is operating in Normal mode from

utility power.

Battery mode:

When the UPS is running in battery mode, the

buzzer beeps once every 4 seconds.

Bypass with output:

The UPS does not have the backup function

when it is in bypass mode. The power used by

the load is supplied from the utility power via

internal filter. The UPS will beep once every 2

minutes in bypass mode.

Fig 5-6

Bypass without output:

The UPS in bypass mode without output

27

Page 31

internal filter while the utility power is in

mode or Battery mode and the load is

the LCD setting or the software

UPS output from HE mode to battery

long for some sensitive load.

the LCD setting or the software

The load should be derated to 60%

single phase input, and there is no

High Efficiency Mode:

After the UPS is turned on, the power used by

the load is sup pli ed fro m th e u tilit y pow er via

normal range, so the high efficiency could be

Fig 5-7

Fig 5-8

gained in the HE mo de. Once the mai ns is loss

or abnormal, the U PS would transfer to Lin e

supplied continuously.

1) The function could be enabled through

(Winpower, etc.).

2) It is attention that the transfer time of

mode is about 10ms. But it is still too

Converter mode

In converter mode, the UPS would free run

with f ixed output frequency ( 50Hz or 60Hz).

Once the mains is loss or abn ormal, the UPS

would transfer to battery mode and the load is

supplied continuously.

1) The function could be enabled through

2)

Warning:

When the warning occurs, it illustrates that

Fig 5-9

there are some abnormal problems during the

operation of UPS. Normally t he problem s are

not fatal and the UPS continues working, but

they should be pai d attention to, o r the UPS

may fail.

(Winpower, etc.).

when running in converter mode with

derating with three phases input.

28

Page 32

fatal problems happened, the UPS would

directly cut off the output or transfer to

LCD would also turn to red.

Fault:

When the fault occurs, it illustrates that some

Fig 5-10

Fig 5-11

Fig 5-12

Fig 5-13

bypass, and keep alarmin g. The backlight of

Overload:

When the UPS is overload, the alarm will beep

twice every sec ond. Som e unnec essary lo ads

should be get r id of one by o ne to decrease

the loads connected to the UPS.

Battery Test

UPS is executing a battery test

Battery fail:

if the battery status detected is “bad battery

detected” or “battery disconnected”, the

symbol of battery failure would be shown and

UPS would alarm.

5.3 Turning On and Turning Off UPS

Attention: Please switch off the connected loads first before turning on

the UPS, and switch on the loads one by one after the UPS is turned on.

Switch off all of the connected loads before turning off the UPS.

29

Page 33

5.3.1 Turning On UPS With Utility

1) Check that power supply connection is correct. Check the breaker

of battery pack is in “ON” position (this step only for long backup

time model).

2) For PowerWalker VFI 10000-20000TP 3/1 set input breaker(M1 &

M2)in “ON” position, for PowerWalker VFI 10000TCP 3/1 model

set input 4P-switch in “ON” position .At this time the fan begins t o

rotate. LCD will show “WELCOME” logo. Then LCD will show the

system status summary screen after UPS finishing self-test.

3) By pressing

buzzer will beep 1s, UPS starts to turn on.

4) A few seconds later, the UPS turns into Line mode. If the utility

power is abnormal, the UPS will transfer to Battery mode without

output interruption of the UPS.

5.3.2 Turning On UPS Without Utility

1) Check the breaker of the battery pack is in “O N” position (this step

only for long backup time model).

2) By pressing

would be powered on. At this time the fan begins to rotate, LCD

will show the “WELCOME” logo. Then LCD will show the default

UPS status summary screen after UPS finishing self-test.

3) By pressing

buzzer will beep 1s, UPS starts to turn on.

4) A few seconds later, the UPS turns into Battery mode. If the utility

power comes back, the UPS will transfer to Line mode without

output interruption of the UPS.

5.3.3 Turning Off UPS With Utility

button continuously for more than 1 second, the

button continuously for mo re than 100ms, t he UPS

button continuously for more than 1 second, the

1) T o turn off the inve rter of UPS by pressin g

for more than 3 seconds and the buz zer will beep 3s. The U PS will

turn into Bypass mode at once.

30

button continuously

Page 34

2) When completing the above action, UPS output voltage is still

present. In order to cut off the UPS output, simply cut off the utilit y

power supply. A few seconds later, LCD display shuts down and n o

output voltage is available from the UPS output terminal.

5.3.4 Turning Off UPS Without Utility

1) To power off the UPS by pressing

than 3 second, and the buzzer w ill beep 3s. The UPS will cut off t he

output at once.

2) A few seconds later, LCD shuts down and no voltage is available

from the UPS output.

button continuously for more

5.4 LCD Operation

Except the default UPS status summary screen, the user could get

more useful information about UPS current status, detailed various

measurements, old events which ever occurred, UPS own

identification, and could change the settings to fit the user own

requirements, optimize the function of UPS.

5.4.1 The Main Menu

In the default UPS status summary screen, when pressing

<1s, the detailed information about alarm, the system status, battery

would be shown.

In the default UPS status summary screen, when pressing

the display would enter main menu tree.

or

>1s,

The main menu tree includes six branches: UPS status menu, event

log menu, measurement menu, control menu, identification menu,

setting menu.

31

Page 35

Fig. 5-14 Main me nu tree

32

Page 36

5.4.2 The UPS Status Menu

By pressing

the next UPS status menu tree.

The content of UPS status menu tree is same as the default UPS status

summary menu .

By pressing

tree.

The detail information about “UPS status”, please see Fig5-14

5.4.3 The Event Log Menu

By pressing on the menu of “Event log”, the display would enter

the next event menu tree.

All the old event, alarm and fault have been recorded here. The

information includes the illustr ation, the event c ode, and the operati ng

time of UPS when the event happened. By press

the event could be displayed one by one.

The max number of record is 30, when the number is larger than 30,

the oldest one would be changed to the newest information.

By pressing

tree.

on the menu of “UPS status”, the display would enter

>1s, the display would return the last main menu

or <1s, all

>1s, the display would return the last main menu

33

Page 37

Fig. 5-15 Event menu tree

5.4.4 The Measurement Menu

By pressing

enter the next measurement menu tree.

A lot of detailed useful information could be checked here, Ex. the

output voltage and frequency, the output current, the load capacity,

the input voltage and frequency, etc.

By pressing

tree.

on the menu of “Measurement”, the display would

>1s, the display would return the last main menu

34

Page 38

Fig. 5-16 Measurement menu tree

5.4.5 The Control Menu

By pressing

next control menu tree.

1) Start B attery Test: is one command to control the UPS to d o the

battery test.

2) Clear EPO status: once EPO status is enabled, the UPS output

would be cut off. To recover to normal status, first EPO connector

should be opened, and enter this menu to clear EPO status, then

UPS would stop alarm and recover to Bypass model. And UPS

needs be turned on by manual operation.

3) Reset Fault status: when fault occurs, UPS would keep in Fault

mode and alarm. To recover to normal status, enter this menu to

reset error status, then UPS would stop alarm and recover to

Bypass mode. And the reason of fault should be checked and

deleted before UPS is turned on again by manual ope r at ion .

on the menu of “Control”, the display would e nter the

35

Page 39

4) Restore factory settings: all the settings would be recover to

default factory settings. It could only be done in Bypass mode.

Fig. 5-17 Cont r ol menu tree

36

Page 40

5.4.6 The Identification Menu

By press

the next identification menu tree.

The identification information includes UPS serial number, f irmware

serial number, model type, would be shown here.

By press

on the menu of “Identification”, the display would ente r

>1s, the display would return the last main menu tree.

Fig. 5-18 Identification menu tree

5.4.7 The Setting Menu

Please contact your local distributor for further information before

using the settings. Some s et tings would ch ange t he s pecification, and

some settings would enable or disable some f unction s. The unsuit able

option set by user may result in potential failures or protecting

37

Page 41

function loss, eve n directly damage the load, battery o r UPS.

The most of settings could only be done while UPS is in Bypass mode .

Fig. 5-19 Setting menu tree

*:Password is USER when enabled

38

Page 42

Output voltage

<

230V

>

...

By press or <1s

The option would flash

Output voltage

<230

V>

By press <

1s

Setting menu tree

Output voltage

<220V>

By press or <1s, to select the wanted option

Output voltage

<220

V>

By press

>1s,

to confirm the setting

The option would stop flashing

after being confirmed

Example: set rated output voltage value

Fig. 5-20 Set rated output voltage value

39

Page 43

6. Special Function

The series UPS has some special functions, which could satisfy some

special application of user. And the functions have own features,

please contact your local distributor for further information before

using the function.

6.1 HE Function

6.1.1 Brief Introduction of HE Function

If HE function is set to enable, after the UPS is turned on, the power

used by the load is directly supplied from the ut ility power via internal

filter while the utility power is in normal range, so the high efficiency

could be gained in HE mode. It is a lso called econo my mode. O nce the

mains is loss or abnormal, the UPS would transfer to Line mode or

Battery mode and the load is supplied continuously.

The great virtue is over all high ef ficiency >0.97 of UPS, to save powe r

for user.

But the disadvantage is 1) the load can not be protected as well as in

Line mode, for the load is directly supplied from the utility; 2) the

transfer time of UP S output from HE mode to Battery mode is about

10ms.

So the function is not suitable t o so me sens itive loads, and the region

where the utility power is unstable.

6.2 Converter Function

6.2.1 Brief introduction of Converter function

In converter mode, the UPS would free run with fixed output

frequency (50Hz or 60Hz). Once the mains is loss or abnormal, the

UPS would transfer to Battery mode and the load is supplied

continuously.

40

Page 44

The great virtue is the output frequency is fixed, which is required by

some very sensitive loads.

But the load should be derated to 60% when running in converter

mode with single phase input, and there is no derating with three

phases input.

6.3 Parallel Function

6.3.1 Brief introduction of the redundancy

N+X is currently the most reliable power supply structure. N

represents the minimum UPS number that the total load needs, X

represents the redundant UPS number, i.e. the fault UPS number that

the system can handle simultaneously. When the X is larger, the

reliability of the powe r syste m i s higher. For occasions where reliabilit y

is highly depended on, N+X is the optimal mode.

As long as the UPS is equipped with parallel cables, up to 4 UPSs can

be connected in parallel to realize output power sharing and power

redundancy.

6.3.2 Parallel installation a nd operati o n

How to install a new parallel UPS system:

1) Before installing a new parallel UPS system, user need to prepare

the input and output wires, the output breaker, and the parallel

cable.

2) Users need to use a standard 25-pin communication cable, whic h

should have 25 cores, corresponding stitches and shield, as the

UPS parallel cable. The length of the paralle l cable is appropriate to

be less than 3m. And there is one standard parallel cable in the

accessor i e s of every UPS.

3) Remove the cover plate of the parallel port on the UPS, connect

each UPS one by one with the parallel cable, and re-screw the

Parallel port cover which is supplied in the accessories.

41

Page 45

4) Strictly follow the chapter of 4, the wiring requirement o f single

UPS to perform the wiring of each UPS.

5) Connect the output wires of each UPS t o an output breaker panel.

6) Disconnect the Jumper on JP1 and JP2 of the terminal block f irst,

and connect each output breaker to a main output breaker and

then to the loads.

7) Each UPS need an independent battery pack.

8) Please refer to the wiring diagram in the following diagram.

9) The distance between th e UPSs in p arallel and the breaker pan el is

required to be less than 20 meters. The difference between the wires

of input and output of the UPSs is required to be less than 20%.

Fig. 6-1 Input and output Terminal Block wiring diagram of

PowerW a lk er VFI 10000-20000TP 3/1

42

Page 46

Fig. 6-2 Input and output Terminal Block wiring diagram of

PowerW a lk er VFI 10000-20000 TP 3/1 model

Fig. 6-3 Parallel Installation Diagram

43

Page 47

10) Do not switch on the output breaker of each UPS, switch on the

input breaker of the each UPS, the UPS should work in bypass with

output, observe their display to check if there are any warning or

fault information, measure the output voltage of each UPS

separately to check if the voltage difference between them is less

than 1V. If the difference is more than 1V, check the wiring.

11) Press the

all the UPSs would transfe r to the INV mode togethe r. Measure the

output voltage of each UPS separately to check if the voltage

difference between them is less than 0.5V. If the difference is more

than 1V, the UPSs need to be regulated.

12) Press the

and transfer to the Bypass mode, switch on the output breaker of

each UPS to parallel all the output of UPSs together.

13) Press the

after turning on, the UPSs should work parallel in the Line mode.

How to join a new UPS to a parallel system:

1) First the parallel system must be installed one main maintenance

mechanical switch or static switch.

2) Regulate the output voltage of the new UPS separately: check if

the output voltage difference between the new UPS and the

parallel system is less than 0.5V.

3) Ensure the bypass of the parallel system is normal and the bypass

setting is “enable”, remove the cover plate of maintenance switch

on the rear panel of each UPS, the UPS system would transfer to

bypass automatically, For P owerW alker VFI 1000 0-20000TP 3/1,set

the own maintenance switch of each UPS from “UPS” to “BPS”. For

PowerWalker VFI 10000TCP 3/1 model, turn the maintenance

switch in the “ ON” position, and tu rn the output switch in the “ OFF”

position.

button of one UPS , e a ch UPS w ou l d sta rt to t urn on ,

button of one UPS, each UPS would start to turn off

button of one UPS , e a ch UPS w ou l d sta rt to t urn on ,

44

Page 48

4) For PowerWalker VFI 10000-20000TP 3/1,Set the main

maintenance switch or static switch from “UPS” to “BPS”, For

PowerWalker VFI 10000TCP 3/1 model, turn the maintenance

switch in the “ ON” position, and tu rn the output switch in the “ OFF”

position, switch off the main output breaker and the main input

breaker, the UPSs would shut down.

5) Ensure the UPSs shut down totally, add the new UPS and reinstall

the new UPS parallel system by following step 1) to 9) of last

chapter - “install a new parallel UPS system”.

6) For PowerWalker VFI 10000-20000TP 3/1, Switch on the main

input breaker and the main output breaker, and set the main

maintenance switch or static switc h from “BPS” to “UPS”, then set

the UPS own maintenance switch from “BPS” to “ UPS” and screw

the maintenance cover plate back again. Press the

one UPS, each UPS would start to turn on, after turning on, the

UPSs should work parallel in the Line mode.

For PowerWalker VFI 10000TCP 3/1 model, t urn the maintenance

switch in the “ OFF” position, and tu rn the output switch in the “ON”

position, then turn the UPS own maintenance switch in the “OFF”

position, and turn the UPS own output switch in the “ON” position,

then screw the m aintenance cover p late back again. Pres s the

button of one UPS, each UPS would start to turn on, after turning

on, the UPSs should work parallel in the Line mode.

butto n of

How to remove a single UPS from a parallel system:

1) First the parallel system must be installed one main maintenance

mechanical switch or static switch.

2) Ensure the bypass is normal and the bypass setting is “enable”,

remove the cover plate of maintenance switch on the rear panel of

each UPS, the UPS system would transfer to bypass automatically,

For PowerWalker VFI 10000-20000TP 3/1,set the own

45

Page 49

maintenance switch of each UPS from “UPS” to “BPS”. For

PowerW a lk er VFI 10000TCP 3/1 model, t urn the own maintenance

switch in the “ON” position, and turn the own output switch in the

“OFF” position.

3) For PowerWalker VFI 10000-20000TP 3/1, Set the main

maintenance switch or static switch f rom “UPS” to “B PS”, switch off

the main output breaker and the main input brea ker, and the UPSs

would shut down.

For PowerWalker VFI 10000TCP 3/1 model, turn the own

maintenance switch in the “ON” position, switch off the main

output switch and the main input switch, and the UPSs would shut

down.

4) Ensure the UPSs shut down totally, remove the wan ted UPS and

reinstall the new UPS parallel system by following step 1) to 9) of

last chapter - “install a new parallel UPS system”.

5) If the removed UPS or the remained UPS will be used in a

stand-alone mode, then JP1 and JP2 on the terminal block should

be connected with a short connection wire.

6) Switch on the main input breaker/switch and the main output

breaker/switch, For PowerWalker VFI 10000 -20000TP 3/1 ,set the

main maintenance switch or static switch f rom “BPS” to “ UPS”, then

set the UPS own maintenance switch from “BPS” to “UPS” and

screw the maintenance cover plate back again. For PowerWalker

VFI 10000TCP 3/1 model, turn the maintenance switch in the

“OFF” position, then turn the own maintenance switch in the “OFF”

position and screw the maintenance cover plate back again, t hen

Press the

after turning on, the UPSs should work parallel in the Line mode.

button of one UPS, each UPS would start to turn on,

46

Page 50

6.4 PowerWalker VFI 10000TP 3/1 Optional Design of

Charger Current

6.4.1 Our charger output current has two optional levels

(2A&4A) for different battery pile.

6.4.2 Operate method:

2A charger current method

Insert short circuit pin 104-10000-01 in the C N7 positi on of charger

board. This is charging for 7AH*24 pcs or 9AH*24 pcs.

4A charger current method

Pull out short circuit pin 104-10000-01 from CN7 position of charger

board. This is for 2 piles of 7AH*24 pcs or 2 piles of 9AH*24 pcs.

Short circuit pin 104-10000-01

47

Page 51

6.5 Backfeed Protection

To support protection against UPS backfeeding a new logic is integrated

into PowerWalker VFI 10000-20000TP 3/1 model. But in PowerWalker

VFI 10000TCP 3/1 model,there’s no this function.

Using backfeed protection

On customers side an additional external isolation device (magnetic

contactor, MC or minimum voltage tripping device) must be provided as

shown in F ig. 6-3. The isolation device must be able to carry the UPS

input current (see resp. table of basic UPS operating instructions ).

The isolation device has to be installed in the bypass source path.

Cabling of the backfeed terminals contains a jumper and two cables to

the optional external isolation device.

48

Page 52

PSDR board

Coil

MC/coil.out

MC/coil.in

Mains 2:

L/N

F

(2A)

slow

blow

Terminals

Output/L

Output/N

Relay

Normally closed

Backfeed

No active

Optional Magnctic

Contactor(MC)

UPS

Mains T.B

Backfeed T.B

MC/coil.out

MC/coil.in

Fig. 6-4 Power Walker VFI 10000-20000 TP 3/1 and external isolation

device(in this example a magnetic contactor (MC))

Fig. 6-5 Backfeed terminal

49

Page 53

Operation

If bypass thyristor is short (short circuit) and UPS runs in double

conversion mode (online) the following steps follow:

The backfeed relay opens and the message “backfeeder” is shown on the

LCD panel

Reset

T o reset the backfeed logic the UPS device must be switched Off for some

seconds

50

Page 54

Alarm code:71

Alarm code:72

on.

Alarm code:84

Alarm code:15

Alarm code:14

Alarm code:92

7. Trouble Shooting

If the UPS system does not operate correctly, first check the operating

information on the LCD display.

Please attempt to s olve the problem using the ta ble below . If the proble m

still persists, consult your dealer.

7.1 Trouble Shooting According To Warning Indication

Problem Displayed Possible cause Remedy

Epo Active

On Maintain Bypass

Battery Disconnect

Alarm code:11

Battery low

Alarm code:12

Output Overload

Alarm code:41

Fan Failure

Charger Fail

Over Charge

Model Pin Error

EPO connector is closed Check the EPO connector status

Maintain bypass switch

is open

Battery pack is not

connected correctly

Battery voltage is low When audible alarm sounding

Overload Check the loads and remove some

Fan abnormal Check if the fan is running

The charge fails Consult dealer.

Battery is over charged The UPS will turn off the charger

UPS internal fault Consult dealer.

Check the maintain bypass switch

status

Do the battery test to confirm.

Check the battery bank is

connected to the UPS.

Check the battery breaker is turn

every second, battery is almost

empty.

non-critical loads.

Check if some loads are failed.

normally.

until the battery voltage is normal

51

Page 55

Alarm code:86

Alarm code:E3

Alarm code:E4

disconnected

has no this case)

same input source.

are forbidden to parallel.

are forbidden to parallel.

Alarm code:EB

Heatsink Over

Temperature

Inside temperature of

UPS is too high

Check the ventilation of UPS and

the ambient temperature.

Para Cable Male Loss

Para Cable Fema le Loss

Para Bat Differ

Alarm code:E6

Para Byp Differ

Alarm code:E8

(PowerWalker VFI

10000TCP 3/1 mode

Para Line Differ

Alarm code:E7

Para Work Mode Differ

Alarm code:E9

Para Rate Power Differ

Alarm code:EA

The parallel cable is

disconnected

The parallel cable is

disconnected

The battery packs of

some UPSs are

The M2 bypass input of

some UPSs is

disconnected

The M1 line input of

some UPSs is

disconnected

There are different

power strategy setting

in parallel system

There are different UPSs

in parallel system

Check the parallel cable.

Check the parallel cable.

Check if all the battery pack is

connected.

Check the building wiring and

input cable.

Check if the M2 breaker is closed.

Ensure the UPSs are connected to

same input source.

Check the building wiring and

input cable.

Check if the M1 breaker is closed.

Ensure the UPSs are connected to

The UPSs with different power

strategy setting (Ex. one Line

mode and one Converter mode)

The UPSs with different capacity

(Ex. one 10KVA and one 20KVA)

ECO In Para

HE function is enabled

in parallel system

52

HE function is forbidden in parallel

system.

Page 56

Check if some loads are failed.

Check if some loads are failed.

turning on again.

center.

Alarm code:21

Alarm code:22

Alarm code:23

Alarm code:24

Alarm code:25

Alarm code:32

7.2 Trouble Shooting According To Fault Indication

Problem Displayed Possible cause Remedy

Inv Overload Fault

Alarm code:42

Byp Overload Fault

Alarm code:43

Output Short Circuit

Alarm code:31

Heatsink Over

Temperature Fault

Alarm code:81

Bus Over Voltage

Overload

Overload

Output short

circuit

Inside

temperature of

UPS is too high

UPS internal fault Consult dealer.

Check the loads and remove some

non-critical loads.

Check the loads and remove some

non-critical loads.

Remove all the loads. Turn off the UPS.

Check if UPS output and loads is short

circuit.

Ensure short circuit is removed before

Make sure the UPS is not overloaded; the

air vents are not blocked and the

ambient temperature is not too high.

Wait for 10 minutes for the UPS to cool

down before turning on again. If failed,

please contact the distributor or service

Bus Under Voltage

Bus Unbalance

Bus short

Bus Softstart Fail

Inv Over Voltage

UPS internal fault Consult dealer.

UPS internal fault Consult dealer.

UPS internal fault Consult dealer.

UPS internal fault Consult dealer.

UPS internal fault Consult dealer.

53

Page 57

Alarm code:33

Alarm code:34

capacitive

there is no overload, then turn on UPS.

Alarm code:E2

utility power. Please Consult dealer.

Inv Under Voltage

UPS internal fault Consult dealer.

Inv Softstart Fail

Negative Power Fault

Alarm code:E1

Cable male and female

Loss fault

Backfeeder

Alarm code:93

UPS internal fault Consult dealer.

The load is pu r e

inductive and

The parallel cable

is disconnected

UPS internal fault

Remove some non-critical loads.

Bypass supplies the load first, ensure

Check the parallel cable.

Don’t touch any terminal of the

equipments which connect one utility

power with the UPS even you cut off the

7.3 Trouble Shooting In Else Cases

Problem Possible cause Remedy

No indication, no

warning tone even

though system is

connected to mains

No input voltage Check the building wiring and input

cable.

Check if the input breaker is closed.

power supply

BYPASS LED light up

even though the power

supply is available

BATTERY LED lights up,

and audible alarm

sounding every 1 beep

in every 4 seconds

Inverter not switched

on

Input voltage and/or

frequency are out of

tolerance

Press On-Switch “I” to turn on UPS.

Check input power source.

Check the building wiring and input

cable.

Check if the input breaker is closed.

54

Page 58

Emergency supply

period shorter than

nominal value

Please have the following information at hand before calling the

After-Sales Service Department:

1. Model number, serial number

2. Date on which the problem occurred

3. LCD/LED display information, Buzzer alarm status

4. Utility power condition, load type and capacity, environment

temperature, ventilation condition

5. The information (battery capacity, quantity) of external battery

pack if the UPS is “S” model

6. Other information for complete description of the problem

Batteries not fully

charged / batteries

defect

Charge the batteries for at least 12

hours and then check capacity.

55

Page 59

8. Battery Maintenance, Replacement and

Disposal

8.1 Maintenance

■ This series UPS only requires minimal maintenance. The battery

used for standard models are value regulated sealed lead-acid

maintenance free battery. These models require minimal repairs.

The only requirement is to charge the UPS regularly in order to

maximize the expected life of the battery. When being connected

to the utility power, whether the UPS is turned on or not, the UPS

keeps charging the batteries and also offers the protective

function of overcharging and over-discharging.

■

The UPS should be ch arged once eve ry 4 t o 6 months if it has n ot

been used for a long time.

■

In the regions of hot climates, the battery should be charged and

discharged every 2 months. The standard charging time should

be at leas t 12 hours.

■

Under normal conditions, the battery life lasts 3 to 5 years. In

case if the battery is found not in good condition, earlier

replacement should be made. Battery replacement should be

performed by qualified personnel.

■

Replace batteries with the same number and same type of

batteries.

■

Do not replace the ba ttery individually. All the batteries should be

replaced at the same time following the instructions of the battery

supplier.

■

Normally, the batteries should be charged and discharged once

every 4 to 6 months. Charging should begin after the UPS shuts

down automatically in the course of discharging, the standard

charging time for the standard UPS should be at least 12 hours.

56

Page 60

8.2 Replacement and Disposal of Batteries

1) Before disposing of batteries , remov e condu cti ve jewe lry su ch as

necklace, wrist watches and rings.

2) If it is necessary to replace any connection cables, please

purchase the original materials from the authorized distributors or

service cen ters, so as to avoid overheat or spar k resulting in fire

due to insufficient capacity.

3) Do not dispose of batteries or battery packs in a fire, they may

explode.

4) Do not open or mutilate batteries, released electrolyte is highly

poisonous and harmful to the skin and eyes.

5) Do not short the positive and negative of the battery electrode,

otherwise, it may result in electric shock or fire.

6) Make sure that there is no voltage before touching the batteries.

The battery circuit is not isolated from the input potential circuit.

There may be hazardous voltage between the battery terminals

and the ground.

7) Even though the input breaker is disconnected, the components

inside the UPS are still co nnected wit h the bat teries, a nd there a re

potential hazardous voltages. Therefore, before any maintenance

and repairs work is carried out, switch off the breaker of the

battery pack or disconnect the jumper wire of connecting between

the batteries.

8) Batteries contain hazardous voltage and current. Battery

maintenance such as the battery replacement must be carried out

by qualified personnel who are knowledgeable about batteries. No

other persons should handle the batteries.

Easy for Battery Replacement (for PowerW alk er VFI 10000-20000 TP

3/1model)

57

Page 61

Open the front panel and request service engineer to replace

batteries. Steps:

1) Remove the fr ont panel a nd disconne ct the connector on the LCD

display boa rd. See Fig. 8-1.

Fig. 8-1 Easy for Battery Replacement -Step 1

2) Disconnect the battery pack DC connectors and remove the

battery fixed plate. See Fig. 8-2.

battery fixed plate

Fig. 8-2 Easy for Battery Replacement -Step 2

58

Page 62

3) Remove the battery pack from the cabinet. See Fig. 8-3.

Fig. 8-3 Easy for Battery Replacement -Step 3

4) Replace t he old battery packs with the new ones.

5) Reconnect the DC cables.

Note: The battery pack is 20kg weight, be careful not to fall off when

you operate the battery replacement.

If you want to replace batteries without powering down the UPS, you

need to set the UPS work in Bypass Mode. That is to remove the

maintenance switch cover plate of UPS an d set t he mainte nance swit ch

from “UPS” to “BPS”, turn the M1/M2/N input breaker in the “OFF”

position(you need open the N breaker’s cover at first), and then you can

repla ce it.

59

Page 63

Pin #

Description

I/O

2

TXD

Output

3

RXD

Input

5

GND

Input

9. Communication Port

9.1 RS232&USB Interface

RS232&USB interface is for the monitoring software and firmware

update. There is only one option can work in the same time and same

product.

1) The following is the pin assignment and description of DB-9

connector.

2) The USB port is compliance with USB 1.1 protocol for its

communication software.

9.2 Intelligent Slot

This series is equipped with two intelligent slot for Webpower

(optional accessory) or other optional card to achieve remote

management of the UPS through internet / intranet. Please contact

your local distributor for further information.

9.3 AS400 Interface (Option)

Except for the communication protocol as mentioned above, this series

UPS has AS400 card (an optional accessory) for AS400 communication

protocol. Please contact your local distributor for details. The following

is the pin assignment and description of DB -9 conne ctor in AS400 car d.

60

Page 64

1

UPS Fail

Output

6

Bypass

Output

2

Summary Alarm

Output

7

Battery Low

Output

3

GND

Input 8 UPS ON

Output

9

Line Loss

Output 5 Common

Input

Pin # Description I/O Pin # Description I/O

4 Remote Shutdown Input

Fig. 9-1 signal of AS400 interface

61

Page 65

10. Software Installation

WinPower is UPS monitoring software, featuring user-friendly interface to

monitor and control your UPS. This unique software provides complete

power protection for computer system while power failure. With the

software us ers can moni to r an y UP S st at us on th e sa me LAN. Furthermore,

a UPS can provide security protection for more than one computer o n the

sam e LAN at the same time, such as shutting down system in security,

saving application data and shutting down the UPS when power fails.

Software Installation on your PC:

Connected by USB to a PC or notebook, the Software enables

communication between the UPS and the computer. The UPS software

monitors the status of the UPS, shuts down the system before the UPS is

exhausted and can remotely observe the UPS via the Network (enabling

users to manage their system more effectively). Upon AC failure or UPS

battery low, UPS takes all necessary actions without intervention from the

system administrator. In addition to automatic file saving and system

shut-down functions, it can also send warning messages via pager, e-mail

etc.

• Use the bundled CD and follow the on-screen instructions t o install

the software WinPower.

• Enter the following serial No. to install software:

511C1-01220-0100-478DF2A

• After the software is successfully inst alled, the communicatio n with

UPS has been established and an green icon will appear in the

system tray.

• Double-click the icon to use the monitor software (as above).

62

Page 66

• You can schedule UPS shutdown/start-up and monit or UP S statu s

through PC.

• Detail instructions please refer to the e-manual in the software.

Check www.powerwalker.com/winpower.html from time to time to get the latest

version of monitoring software.

63

Page 67

Page 68

Online USV

PowerWalker VFI 10000TCP 3/1

PowerWalker VFI 10000TP 3/1

PowerWalker VFI 20000TP 3/1

Bedienungsanleitung (DE)

Unterbrechungsfreies Stromversorgungssystem

Page 69

Inhaltsverzeichnis:

1. Sicherheit ..................................................................................................... 1

1.1 Installation............................................................................................... 1

1.2 Betrieb .................................................................................................... 2

1.3 Wartung, Instandhaltung und Störungen ................................................ 3

1.4 Transport ................................................................................................ 4

1.5 Lagerung ................................................................................................ 4

1.6 Standards ............................................................................................... 5

2. Beschreibung der verwendeten Symbole ................................................ 6

3. Einführung ................................................................................................... 7

3.1 System- und Modellbeschreibung .......................................................... 7

3.2 Produkt- und Leistungsbeschreibung ................................................... 11

4. Installation ................................................................................................. 13

4.1 Auspacken und Überprüfen .................................................................. 13

4.2 EIN- UND AUSGANGSNETZKABEL UND SCHUTZERDUNG ........................ 16

4.3 Bedienungshinweise für den Anschluss einer externen Batterie ......... 21

5. Bedienung ................................................................................................. 23

5.1 Anzeige-Display .................................................................................... 23

5.2 Betriebsmodus ...................................................................................... 27

5.3 USV Ein- und Ausschalten ................................................................... 30

5.4 LCD-Bedienung .................................................................................... 32

6. Spezialfunktion ......................................................................................... 41

6.1 HE-Funktion .......................................................................................... 41

6.2 Konverterfunktion ................................................................................. 42

Page 70

6.3 Parallel-Funktion ................................................................................... 42

6.4 PowerWalker VFI 10000TCP 3/1 Optionales Design des Ladegeräts . 48

6.5 Nachspeiseschutz ................................................................................ 49

7. Fehlerbehebung ........................................................................................ 52

7.1 Fehlerbehebung gemäß der Warnanzeige ........................................... 52

7.2 Fehlerbehebung gemäß der Fehleranzeige ......................................... 54

7.3 Sonstige Fehlerbehebung .................................................................... 56

8. Batteriewartung, Austausch und Entsorgung ....................................... 57

8.1 Wartung ................................................................................................ 58

8.2 Austausch und Entsorgung der Batterien ............................................. 59

9. Kommunikationsport ................................................................................ 62

9.1 RS232&USB Schnittstelle .................................................................... 62

9.2 Intelligent Slot ....................................................................................... 62

9.3 AS400 Schnittstelle (Option)................................................................. 62

10. Software Installation ..................................... Error! Bookmark not defined.

Page 71

1. Sicherheit

Bitte lesen Sie die folgenden Sicherheitshinweise und die

Bedienungsanleitung vor der Installation und Erstbenutzung

aufmerksam durch!

1.1 Installation

★ Wenn das USV-System aus einer kalten Umgebung in den

Betriebsraum gebracht wird, kann eine Kondensation auftreten.

Das USV-System muss vor der Inbetriebnahme absolut trocken

sein. Betreiben Sie das Gerät erst nach einer

Akklimatisierungszeit von mindestens 2 Std.

★ Betreiben Sie das Gerät nicht in der Nähe von Wasser oder in

einer feuchten Umgebung.

★ Stellen Sie das US V -System nicht in der Nähe v on W ärmequellen

auf oder setzen Sie es nicht direkter Sonneneinstrahlung aus.

★ Halten Sie die Ventilationsöffnungen des USV-Gehäuses frei.

★ Schließen Sie keine Geräte an die Ausgang-Buchse oder

Klemmen an, die Die USV überlasten (z.B. Laserdrucker etc.).

★ Platzieren Sie das Kabel so, dass niemand darauf treten oder

darüber stolpern kann.

★ Die USV ist mit Erdungsklemmen im Endkonfigurationssystem

ausgestattet, mit Potenzialausgleich zur externen

USV-Batteriebox.

★ Eine integrierte Notvorrichtung welche verhindert, dass die

Page 72

Spannung zu hoch wird, sollte vorgesehen sein.

★ Für den Kurzschlussschutz sind bauseits Sicherungen und

Lasttrennschalter erforderlich.

★ Für den Anschluss von Drei-Phasen-Geräten an ein IT-Netz,

sollte eine vierpolige Vorrichtung in der Gehäuseverdrahtung

vorgesehen sein, die alle Phasenleiter und Neutralleiter trennt.

★ Dies sind permanent angeschlossene Vorrichtungen, die nur von

qualifiziertem Fachpersonal installiert werden sollten.

★ Vor dem Anschluss des Gerätes an die Stromversorgung, zuerst

die Erdung anschließen.

1.2 Bedienung

★ Das Erdungskabel während des Betriebs nicht von der

USV-Anlage abziehen, da sonst die Schutzerdung der

USV-Anlage und aller angeschlossenen Verbraucher aufgehoben

wird.

★ Die Ausgangsklemmen können stromführend sein, auch wenn

die USV nicht an die Steckdose bzw. an die Einspeisung der

Hausinstallation angeschlossen ist.

★ Um die USV völlig abzuschalten, stellen Sie die

Eingangsschutzschalter M1/M2/N in die “OFF” Position (für

PowerWalker VFI 10000-20000 TP 3/1), die

Eingangsschutzschalter R/S/T/N i n die “OFF” Position stellen (für

PowerWalker VFI 10000TCP 3/1), dann das Netzkabel ziehen.

Page 73

★ Stellen Sie sicher, dass keine Flüssigkeit oder sonstige

Fremdkörper in die USV gelangen.

1.3 Wartung, Instandhaltung und Störungen

★ Das USV-System arbeitet mit gefährlichen Spannungen.

Reparaturen sind grundsätzlich nur von qualifiziertem und

geschultem Wartungspe rs onal du r chzuf ühren.

★ Achtung - Gefahr eines elektrischen Schlags. Selbst nach

Trennung vom Stromversorgungsnetz (Gebäudeverkabelung)

bleiben Bauteile innerhalb der USV an die Batterien

angeschlossen und befinden sich unter gefährlichem

Spannungspotential.

★ Trennen Sie vor jeder Dienstleistung und/oder Wartung die

Batterien. Stellen Sie sicher, dass kein Strom und keine

gefährliche Spannung im Kondensator oder BUS-Kondensator

vorhanden sind.

★ Batteri en dürfen nur von qualifiziertem Personal ersetzt werden.

★ Achtung - Gefahr eines elektrischen Schlags. Der

Batteriestromkreis ist nicht von der Eingangsspannung isoliert.

Zwischen den Batterieanschlüssen und der Erdung können

gefährliche Spannungen auftreten. Stellen Sie vor der Wartung

sicher, dass keine Spannung vorhanden ist!

★ Batterien können Stromschlag verursachen und weisen hohen