HSEUIreg04801 DIN Rail

Made in Germany

480W Programmable Power Supply

current and voltage programmable

Specification:

• Metal housing

• 90% efficiency

• -25°C...+60°C full output power

• Natural convection

• Galvanic insulated

• Continuous short circuit protected

• Overload (OVP) & low voltage protected

• Soft start & auto-recovery

• Hold up time >50ms

• No base load required

• Electronic inrush current limiter 13.8Apeak

Available outputs: 0…18V, 0…30V, 0…50V, 0...90V, 0...130V, 0...180V, 0...240V

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

• Analogue interface 0-5Vdc/0-10Vdc/0-20mA/4-20mA

• Real time output monitoring of voltage and current

• External shutdown

• Sense control

• Series & parallel operation

• DIN Rail 35mm & wall mount

• Screw terminals AWG20...AWG6

• High reliability, shock & vibration proof

• 24 hours burn in test

• EMI/EMS EN61000-6-2,3, EN55022 class B

• IEC(EN)60950-1 in accordance to cUL60950/16950

In accordance with IEC60950-1

www.powersolve.co.uk sales@powersolve.co.uk

p.1/9 05.12D

AC

Input 90..132Vac / 184..265Vac , 47…63Hz , 250…375Vdc

AC Input Rating

115Vac<8.8A 230Vac<4.3A 250Vdc<2.4A 375Vdc<1.6A

Rated DC Voltage

0...18V

0...30V

0...50V

0...90V

0...130V

0...180V

0...240V

Overvoltage Protection

22Vdc

35Vdc

59Vdc

105Vdc

150Vdc

210Vdc

280Vdc

Max. DC Current

-

25°C...+60°C

0...40A

0...24A

0...15A

0...8A

0...5,5A

0...4A

0...3A

Max. DC Current +70°C

0...30A

0...18A

0...11,3A

0...6A

0...4,1A

0...3A

0...2,3A

Ripple Peak 230Vac 20MHz

40mVpp

40mVpp

100mVpp

150mVpp

200mVpp

300mVpp

400mVpp

Pmax

480W continuous

Operation Failure Relay

Yes, break contact (fig.4), protective electrical separation

≤60Vdc

Sense Function

Compensation 2V per lead load, protective electrical separation

≤60Vdc

Remote Shutdown

Yes, protective electrical

separation

≤60Vdc

Analogue Interface

Yes, protective electrical separation

≤60Vdc

Digital Interface

Yes, available option (incl. Software), protective electrical separation

≤400Vdc (t.b.a.)

Derating

+60°C...+70°C 2.5%/°C

Accurancy

< ± 1.5% interface

Load Regulation

< ± 0.05% 0

-

100%

Slew Rate

15ms rise time 0V

...

Umax

Response Load Change

<1ms 10

-

100%, 100

-

10%

Base Load

None

Efficiency 230Vac

90% typical

Short Circuit Protection

Continuous

Idling

-

proof

Yes, continuous

Temperature Control

Yes,

thermal shutdown with auto recovery (+70°C, metering distance 10mm)

Hold Up Time

>50ms 230Vac

Inrush Current

<9,8Aeff < 13.8Apeak (230Vac) active inrush current limiter

Softstart

100ms typical

Cooling

Natural convection

Ambient Operating Temp.

-

25°C…+70°C

Ambient Storage Temp.

-

40°C…+85°C

Environment

Humidity 95% non

-

condensing @ 25°C,

climate

class. 3k3, pollution rate II

EMI EN55022 class B

EMS EN61000

-6-

2,3

Safety

cUL60950, EN60950

-1

Safety class 1(A)

VDE0805, VDE0100

Isolation Path

> 8mm

Input / Output

Galvanic insulated 3000Vac

Meantime By Failure (MTBF)

400000h (IEC61709)

Dimensions (HxWxD)

130x200x114,5mm

Weight

2900g

Screw Terminals (In/Out)

AWG20...AWG6 , 0,5...16mm²

work.resist.Ω

Progamme [V]

0...10Vdc

1 MΩ

Progamme

[V] 0...5Vdc

1 MΩ

Progamme [A]

0...20mA

500 Ω

Progamme [A]

4...20mA

500 Ω

Monitoring [V]

0...10Vdc/5mA

Monitoring [V]

0...5Vdc/5mA

Shutdown

Open Collect.

Sensing

2V

Reference [V]

10Vdc/5mA

Reference [V]

5,2Vdc/5mA

Power Good

Relay

“b” contact

per lead load

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

p.2/9 05.12D

Ordering Information:

to the control inputs. Be aware that your PLC is capable to

Output Type (DIN-Rail standard) Part Number Built-in 5W Power Sink Part Number Option Part Number

0...18V HSEUIreg04801.18T 304.1083.001CA HSEUIreg04801.18TPS 304.1083.011CA USB 2.0 Interface

0...30V HSEUIreg04801.30T 304.1083.002CA HSEUIreg04801.30TPS 304.1083.012CA

0...50V HSEUIreg04801.50T 304.1083.003CA HSEUIreg04801.50TPS 304.1083.013CA ADTW201

0...90V HSEUIreg04801.90T 304.1083.004CA HSEUIreg04801.90TPS 304.1083.014CA

0...130V HSEUIreg04801.130T 304.1083.005CA HSEUIreg04801.130TPS 304.1083.015CA PS200 External

0...180V HSEUIreg04801.180T 304.1083.006CA HSEUIreg04801.180TPS 304.1083.016CA

0...240V HSEUIreg04801.240T 304.1083.007CA HSEUIreg04801.240TPS 304.1083.017CA Wall Mount Kit 220.1002.001CA

Conception

The HSEUIreg power supply series realizes very high power efficiency in a

space-saving housing. Latest generation electrical devices relate to the high

reliability of all CAMTEC products. The CAMTEC philosophy is, to employ

125°C low ESR ultra long life capacitors where expedient to achieve a

superior lifetime of our products. The HSEUIreg-series is made for

Measuring & Control-Units to allow an easy design of P- or PI-controllers at

an attractive price value.

Thermal shutdown (p.6 fig.3)

The HSEUIreg-series is featured with a thermal overload shut down and

auto recovery behaviour.

Control type

The power supplies accurately works down low output voltages down to 0V.

Thereby the switching frequency is absolute stabile.

The output response is linear to the input signal.

Sensing feature (p.5)

The HSEUIreg has a sense operation mode to compensate potential drop at

the supply line. It is a standard for the 0..18Vdc, 0..30Vdc and 0..50Vdc

types. For all other types it is a feature up on request.

Shutdown feature

All HSEUIreg units are featured with a shut down (open collector). ON=

open contact, OFF= closed contact 1Vdc max. . The shutdown connections

have an internal pull-up resistor with 6800 Ω at the plus line (+15V inserted).

UI-characteristic:

Programmable Outputs:

Output Voltage & output current control:

The output voltage is linear proportional to the input signal.

10% input signal will deliver 10% of the maximum output voltage, 50% input

will give a ratio of 50% output and 100% will provide 100% output. The

USEUIreg features 0-5Vdc, 0-10Vdc, 0-20mA or 4-20mA control signal input.

The setting has to be chosen from a DIP-switch at the front-side. The input

impedance is 1MΩ with voltage control mode settings. The input impedance

is 500Ω with current control mode settings.

Tolerance compensation adjust:

It is not necessary to adjust the basic of the output voltage or output current

level. The engineers abandoned a compensation potentiometer to prevent

malfunction from wrong basic adjustments.

Warning:

Tuning the output voltage over the maximum level may cause deviations

from the technical data table. If the control inputs are not connected at all

this may cause a minimum voltage of 100mV at the device main outputs.

All control I/O are connected to Uref

The current operation mode features a 500R input impedance

trigger recommended line power.

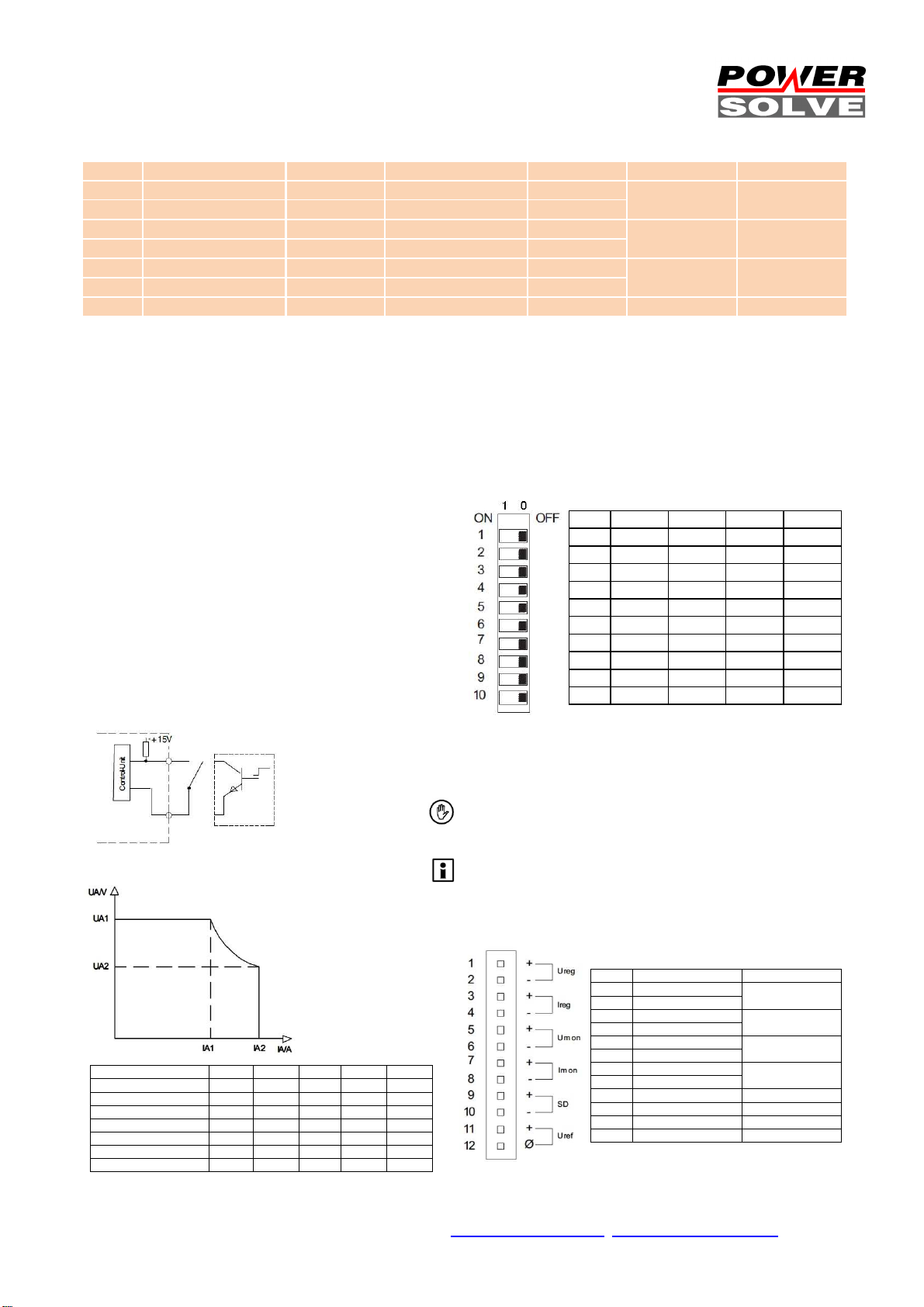

Pos. 0 - 5V 0 - 10V 0 - 20mA 4 - 20mA

S01 0 0 1 1

S02 0 1 1 0

S03 0 0 0 1

S04 0 0 1 1

S05 0 1 1 0

S06 1 0 0 0

S07 0 0 0 1

S08 0 1 1 1

S09 0 1 1 1

S10 0 1 1 1

UI.Drive Software

XP/W7/W8

DC-repeater

200W Power Sink

304.1098.001CA

304.1090.001CA

304.xxxx.001CA

Type UA1 IA1 UA2 IA2 Pmax

HSEUIreg04801.18 18V 26.7A 12V 40.0A 480W

HSEUIreg04801.30 30V 16.0A 20V 24.0A 480W

HSEUIreg04801.50 50V 9.6A 32V 15.0A 480W

HSEUIreg04801.90 90V 5.3A 60V 8.0A 480W

HSEUIreg04801.130 130V 3.7A 87V 5.5A 480W

HSEUIreg04801.180 180V 2.7A 120V 4.0A 480W

HSEUIreg04801.240 240V 2.0A 160V 3.0A 480W

PIN Description Value

01 + V progr. input 0-5V 0-10V

02 - V progr. input

03 + A progr. input 0-5V 0-10V

04 - A progr. input

05 + V progr. output 0-5V/0-10V 5mA

06 - V progr. output

07 + A progr. output 0-5V/0-10V 5mA

08 + A progr. output

09 + SD shutdown Open collector

10 - SD shutdown Open collector

11 + Uref 5.2V /10V 5mA

12 - Uref ref return

0-20mA 4-20mA

0-20mA 4-20mA

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

p.3/9 05.12D

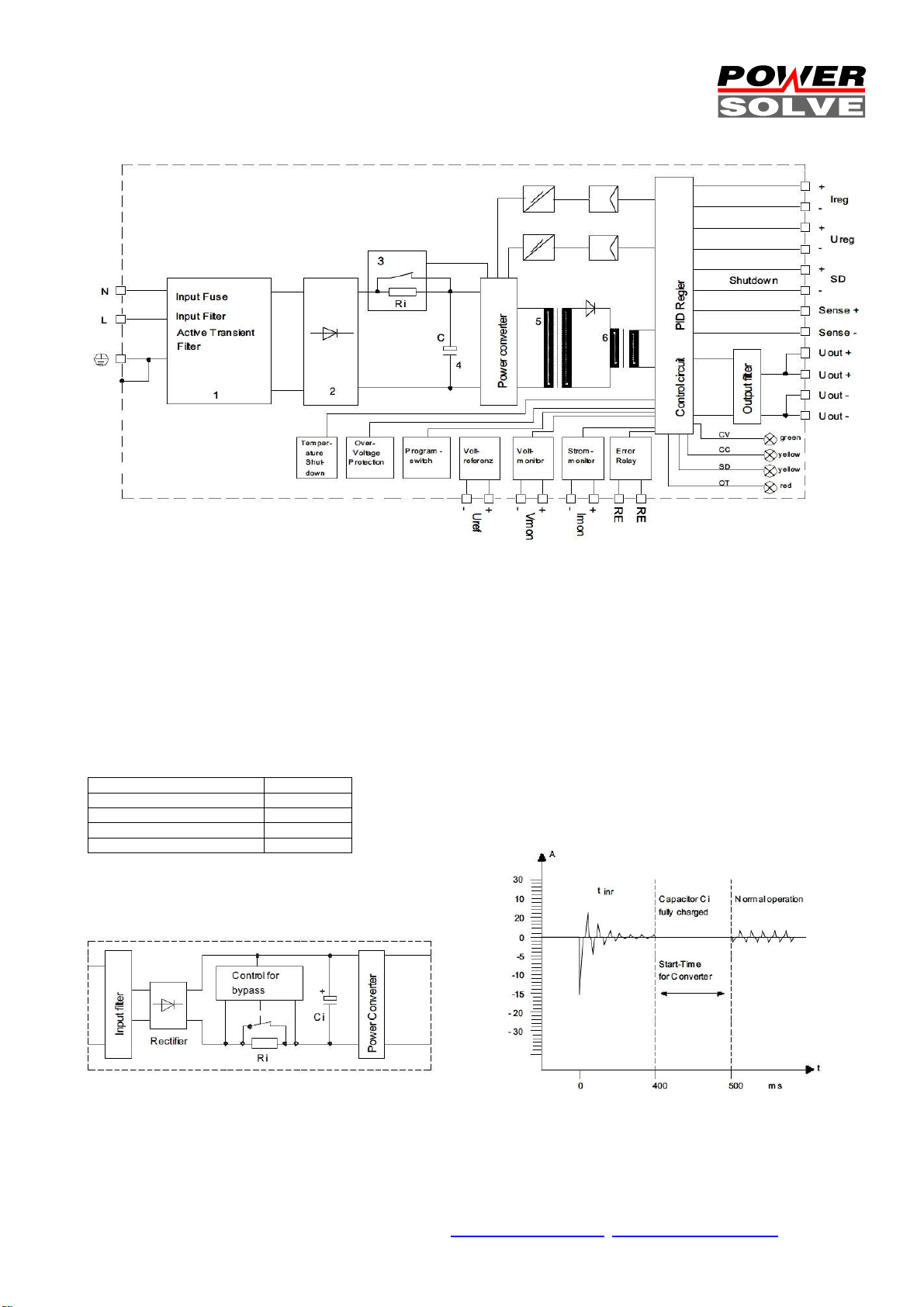

1) Active Transient Filter 2) Rectifier 3) Inrush Current Limiter 4) Load Capacitor 5) Power Transformer 6) Storage Choke

Lighting: CV = constant voltage operation CC = constant current operation SD = shutdown operation OT = temperature failure >70°C

Technical Description

The HSEUIreg-Series is a programmable switch mode power supply. Engineered and manufactured in by CAMTEC in Germany, it is

designed for challenging applications like railway, drives, test-stands and machine-building. The HSEUIreg provides a low Ripple-Noise, good

Load- Regulation and high efficiency >90% (typ. @ 230Vac). High-end long life capacitors guarantee Hold-up-Time and extended lifetime of

the power supply. Our HSEUIreg-design starts complex loads easily. The internal control manages illegal operating conditions to prevent your

system from failures. An operation failures recording is on board via galvanic insulated relay connection (page 2 table). All HSEUIreg power

supplies are idling-proof and short circuit protected. Supply units of the same type and output voltage feature parallel or series operation.

The HSEUIreg also features active high input transients with suppressor diodes, X2-capacitors and varistors. The design rules set value on

extended interference immunity and safety. The PSU is engineered in accordance to EN60950-1 and EMC-compatibility to EN55022 class B.

Indicator 230Vac

Peak inrush current 13.8A peak

Effektive inrush current

Inrush duration (tinr) 400ms

Over all power-up time 500ms

Inrush Current Limiter Block Diagram

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

(RMS)

9.8Aeff

www.powersolve.co.uk sales@powersolve.co.uk

p.4/9 05.12D

Monitor Outputs SCM (fig.1) Monitor Output Connections (fig.2)

Monitor O

utputs

Program Inputs SCM (fig.3) Program Input Connections (fig.4)

(example with external poti)

Local Sensing (fig.5) Remote Sensing (fig.6)

Battery Charger Mode (fig.7) External Sense Protection (fig.8)

Maximum Sense Compensation (fig.9)

The monitor outputs are buffered with OP-amplifiers, preresistors & parallel connected zener diodes (fig.1). The

monitor outs can be selected between +5Vdc or +10Vdc

control voltage. The signal is absolute proportional to the

adjusted output voltage and current. The monitor outputs

are non-floating. Connections see figure 2.

Programmable Inputs

The output voltage and the output current are

programmed with an analogue signal. The input signal is

selectable between 0-5Vdc, 0-10Vdc, 0-20mA or 4-20mA

with a front sided DIP-switcher. The response is very

exact and. The output response behaves linear to the

control signal.

The inputs are protected with internal pre-resistors,

zener diodes and capacitors (fig.3). The capacitor limits

the slew rate, accurately. The program inputs are nonfloating. The monitor GND is connected to the negative

pole of the main outputs. An incorrect connection triggers

an internal PTC fuse. Unlocking the incorrect connection

resets this fuse to being recovered (auto recovery).

External potentiometer control mode (fig.4)

The USEUIreg features an internal reference voltage of

Uref = 5,2Vdc or 10,4Vdc, selected with the DIP-switch.

An external pre-resistor or a potentiometer of 10k can be

connected to adjust the output voltage and current.

Sense Mode

The HSEUIreg provides sensing connections to

compensate voltage drop down from wire system. The

maximum compensation is 2V (fig.9). Be aware that this

operation mode may recommend extended preparations

concerning interference elimination or other protections. It

should be set by the advanced user.

Non-sense mode recommends the S +/- connected to

AUX +/- with very short wires = Local Sensing (fig.5)

Remote Sensing (2V per lead load, fig6)

Disconnect local sensing wires (fig.1) from the AUX +/and the S +/- connections. Connect the sense lines to the

load. Be sure that +/- connections are matching!

To basically prevent from interferences enable to twist

sense compensation lines. To reduce inductive influences

make sure that load wires are installed closely each

other. Driving a pulsative load requires a large electrolytic

and a ceramic capacitor being connected (see fig.6 C1 &

C2). Make sure that C1 & C2 are not oscillating with load

wires. This would cause ripple voltage into the lines. The

internal over voltage protection (OVP) controls the output

voltage directly at the output connectors. It opens

automatically in case of failure from the source (p.6 fig.4).

Battery Charger Mode (fig.7)

The HSEUIreg is the perfect a battery charger. It can be

used as constant voltage (CV) or constant current

charger (CC). As a stand-alone solution the HSEUIreg

features constant charging with automatic over charging

protection. Used with an external control unit (PLC) the

HSEUIreg charges any battery backup application you

need to install, at very low investment cost with a perfect

control and system compatibility from the PLC.

We advise to use a circuit breaker to prevent from

disconnections. Use fast Z-types with the double battery

dc-voltage capability, like being used for semiconductor

protection.

Remote Sensing with battery charger

Using the HSEUIreg as a battery charger, avoid remote

sensing operation mode. It may cause serious damage to

the unit when the battery connections are being mixed

up. If you really need to install Remote Sensing apply to

the figure 8 circuit. Good values are 250mA for Si fuses

and 3…5A capability for the diodes.

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

p.5/9 05.12D

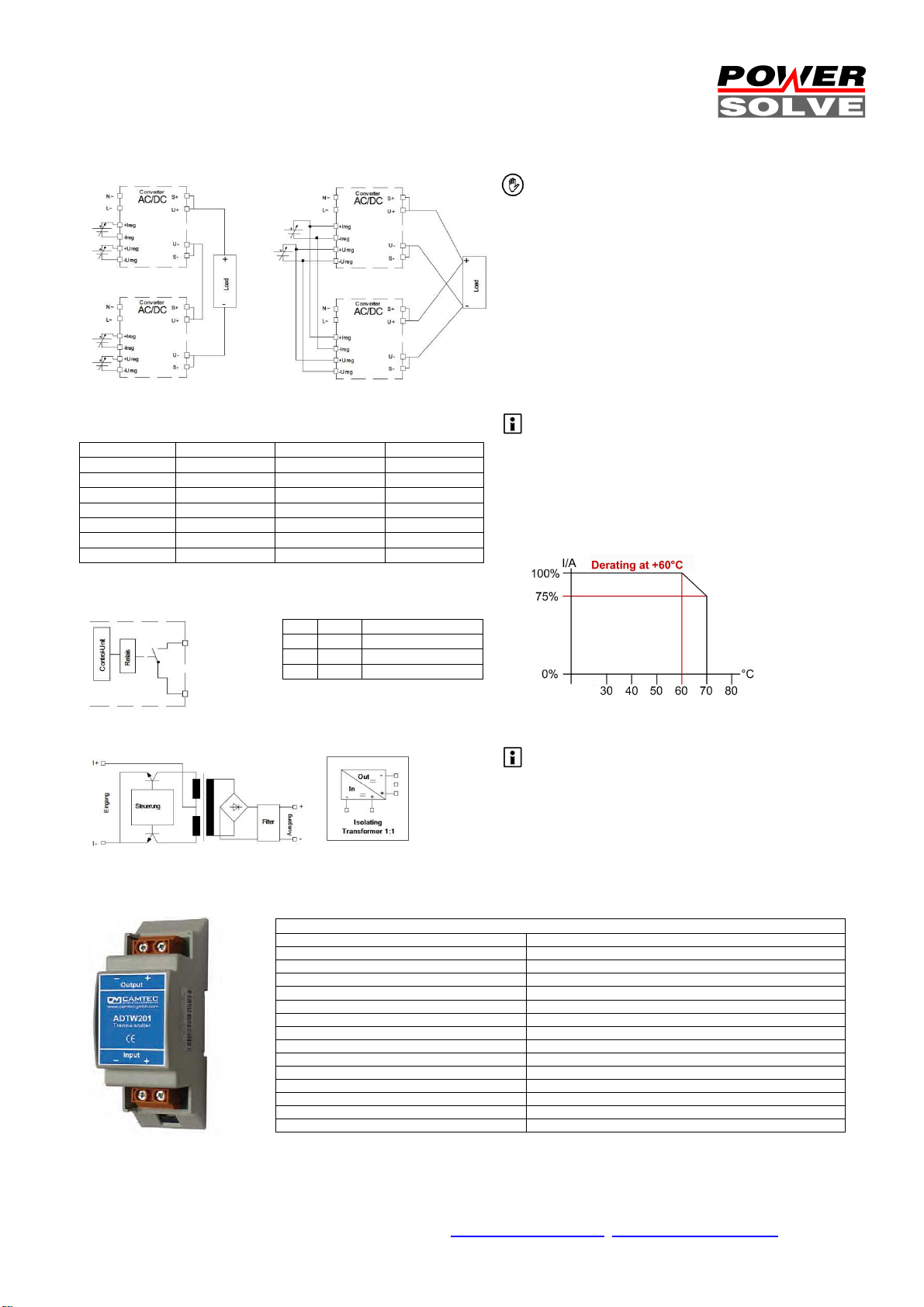

Series Connection (fig.1)

Technical Information ADTW201 external DC

-

Repeater

Series Connection (fig.1) Parallel Connection (fig.2)

Over Voltage Protection (3a) Temperature Derating (fig.3)

Vout OVP Iout

-25°C...+60°C

Iout

+70°C

0...18Vdc 22Vdc 40.0A 30.0A

0...30Vdc 35Vdc 24.0A 18.0A

0...50Vdc 59Vdc 15.0A 11.3A

0...90Vdc 105Vdc 8.0A 6.0A

0...130Vdc 150Vdc 5.5A 4.1A

0...180Vdc 210Vdc 4.0A 3.0A

0...240Vdc 280Vdc 3.0A 2.3A

Power Good (fig.4) Function LED-Bar

30Vac 1000mA

30Vdc 500mA

60Vdc 300mA

CV GRN Constant voltage

CC YEL Constant current

SD YEL shutdown

OT RED Over temperature

ADTW201 Isolating Transformer (fig5)

To increase output voltage equal HSEUIreg can be

connected in series. The control I/O should be galvanic

insulated in the series mode. If not the minus main output

is connected to the control I/O. Use our external option

Isolating Transformer ADTW201 being validated with the

HSEUIreg. Be aware of safety norms if your target output

voltage exceeds safety voltage.

Parallel Connection (fig.2)

To increase the output power up to 5 HSEUIreg can be

parallel connected. Advise using busbars to connect

HSEUIreg in parallel. Always use identical length and

identical cross sections to the busbar.

ADTW201 Isolating Transformer (option) (fig.5)

The isolating transformer is used to galvanic isolate

impressed current. The device is self powered. The input

to output ratio is 1:1. For further information seek advice

from page 10.

Derating & Over Temperature (fig.3)

If the ambient temperature exceeds trigger pint >70°C the

HSEUIreg shuts down (metering point 10mm from

outside device). After being recovered from over

temperature the device restarts automatically to normal

operation.

OVP Over Voltage protection (3a)

The HSEUIreg features over voltage protection.

Exceeding OVP results in a locked shutdown mode.

Resuming the failure causes automatic restart into normal

operation.

Power Good Signal (fig.4)

Galvanic insulated open with failure, closed at normal

operation.

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

Input (Ie) 0…20mA, 4…20mA (max. 50mA)

Voltage drop (Uw) Uw>1.5V (Ie=20mA)

Max. apparent ohmic resistance (Ra) 500R @ Ie=20mA

Input Impedance (R) R=Ra+Uw/IE

Barrier Frequency (Fa) Fa=5kHz (-3dB) with Ra=500R @ Ie=20mA

Output 1:1

Ripple / Noise >0,5% with 20mA and Ra=500R

Linear Failure >0,03% / 100R

Transient oscillation current 35uA

Latency 150us 0..20mA, Ra=500R, 10…90%

Isolation Voltage Input/output 500V

Operation Temperature 0…50°C

Temperature Drift Approx. 15ppm/K

Weight 21g

Ordering Information Part No: 304.1090.001CA

www.powersolve.co.uk sales@powersolve.co.uk

p.6/9 05.12D

Power Sink (Option)

Dynamic re

sponse

Technical Data

The power sink option features returned power to be terminated very quickly. The power sink records the output power status and guarantees

a constant output voltage. The power sink also provides quicker response time on setting down the output voltage.

Applications sample: DC-drives & ATE test systems

Most of modern dc-drives are controlled by a PWM (pulse wide modulation) controller. Such controllers feature a very flexible speed control

and high efficiency. A disadvantage of PWM controlled drives is the returned power into the system while decelerating the motor. The

dragging of the motor inverts the drive into a generator. The returned power may cause trouble or serious defects to the dc-system, but

definitely slows down the decelerating process of a drive. The returned energy is not terminated quickly enough and results in rising system

voltage. An integrated load, called power sink, terminates the returned power very quickly and enables the drive to small dynamic latency

(see figure).

ATE test-systems require quick down programming of the output voltage. Most ATE applications need to drag down the output voltage to 0V

as a new testee is put into the system. A power supply without a power sink is simply not quick enough to terminate the energy at the output

capacitors. Therefore an electronic power sink manages the output voltage to reset very quickly. Overall test time is being reduced and the

testee is uncontrolled transient voltage protected.

Conventional power supply circuit

simplified, without power sink

Power sink equipped power supply

Latency of conventional power supply Latency of power sink

equipped power supply

Conventional power supply:

breaking power charges output

capacitor Co

Power sink equipped power

supply: absorbs breaking energy

Dynamic reaction of conventional

power supply: uncontrolled voltage

rises with negative reverse current

Dynamic reaction of power sink

equipped power supply:

load current switches between

positive and negative

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

A common power supply is

usually not designed to absorb

returned power from its

connected load.

The negative load current will

recharge the capacitor Co. The

output voltage starts rising and

get out of control.

This is essential to the

mathematic formula dv/dt=i/C.

As an electronic power sink

module is equipped to the

power supply unit, the output

voltage will constantly being

kept at the desired level. The

power sink provides very quick

dynamic response. The output

voltage only rises to a minimal

notching ratio for a very short

spell.

Using a power supply unit

without equipped power sink in

such application may result into

serious damage or uncontrolled OVP activity to the

power supply unit.

Outline Factory

Continuous

Power

Capability

Peak Power

Capability

built in

5W

10W

(100ms)

p.7/9 05.12D

Coating

Option

We offer the USEUIreg-series with optional coating. It is to be used in e.g. dusty, dirty, high humidity, or in awaiting quick temperature

Test Time A B C

¹) D

Type Test

Factory Test

Field Test

Terminal Connec

ts:

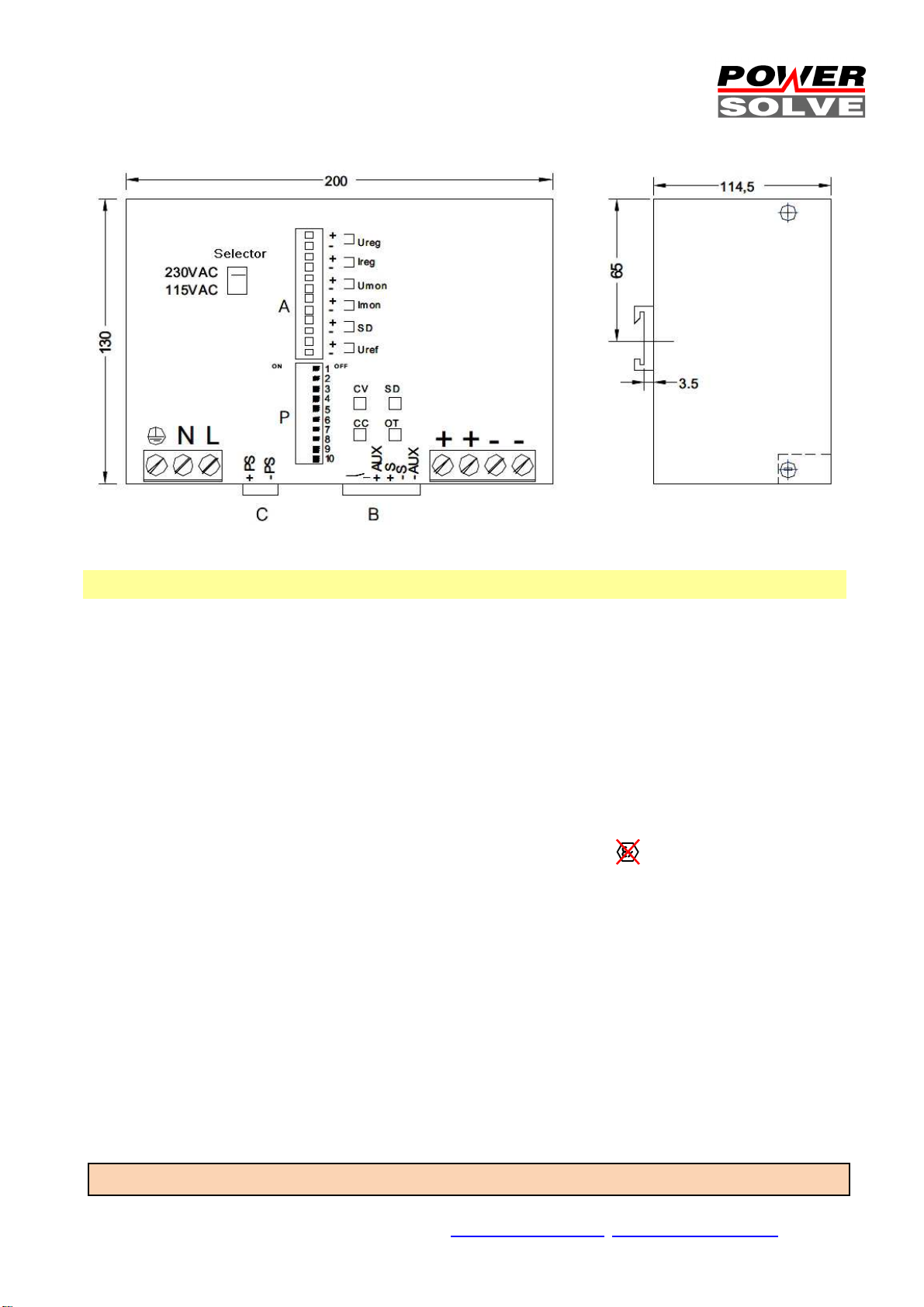

Mechanics & Installation of the HSEUIreg

Backplate Option

changes. Short circuit and corrosion at print board lines and at solder points can be prevented. The coat itself is a transparent acrylic

resin. It is procured with a robotics varnishing machine.

Peters SL 1306 N-FLZ (transparent) IEC60216-1 2001, IPC-CC-830B, UL listed as permanent coating FileNo.: E80315 , UL94V-0

Ordering Information: ad extension C to the type number: HSEUIreg04801.180TC

Type test and factory tests are

60s 2500Vac 3000Vac 500Vdc 500Vdc

5s 2000Vac 2000Vac 500Vdc 500Vdc

2s 2000Vac 2000Vac 500Vdc 500Vdc

¹) ≥90Vdc = 1500Vac

a) Use approriate test equipment which apply the voltage with a slow ramp

b) Connect L1 and N together, as well as all output poles

c) Use only AC test-voltages with 50/60Hz. The output voltages is floating and has

no ohmic reference to ground.

d) If testing output voltages are ≥60Vdc remain to security directives.

Use only isolated screw drivers to adjust output voltages.

AC Main Input

GND common

N - wire

L - wire

DC Mains Outputs

DC + voltage

DC + voltage

DC - voltage

DC - voltage

Inputs/Outputs

Ureg = programmable voltage input

Ureg = programmable current input

Umon = voltage monitor output

Imon = current monitor output

SD = shut down input

Uref = reference voltage (poti connection)

conducted by the manufacturer.

Do not repeat the test in field.

Field test rules:

Standard Feature Connects

C= external power sink

B= sense connections (S+/-) &

operation failure relay (output)

Stable metal/aluminium housing IP20. To allow adequate convection, a free air space of 50mm (top/bottom) and 5mm (sidewalls) is

required; for active devices 15mm space from the sidewalls. For free air convection it is necessary to install the HSEUIreg horizontal. You

can use the DIN-Rail installation (equiped standard) with our patented 35mm DIN-Rail bracket according to EN60275. It is easy to

mount/dismount while snaping it onto the 35mm DIN-Rail - any tools necessary. A wallmount backplate (option) is availble, too

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

p.8/9 05.12D

Safety Instructions:

ready to hand.The HSEUIreg must be installed by specialist staff only.

Installation:

1.) The HSEUIreg is designed for systems fulfilling the safety norms of

dangerous voltages/energy and fire prevention

2.) Installation is restricted to specialists only, make sure that the AC

wire system is free of voltage

3.) Opening the HSEUIreg, making any modifications to it, dismounting

any screws from it, operating the HSEUIreg out of specification

and/or using it in appropriate area will unevitably result in loosing

manufactureres guarantee; we decline taking any responsibility for

risk of demages caused to someones health or to any installed

system.

4.) Attention: The HSEUIreg has an internal input fuse. It is necessary

to wire an automatic circuit braker to the line. We suggest to use a

16A-type with B-characteristic. It is verboten to operate the

HSEUIreg without protective earth wired. It essential to install a line

switch before the HSEUIreg.

Please read all warnings and advices carefully before installing or operating the HSEUIreg. Retain this operation manual always

Warnings

Disregard these warnings can cause fire, electic shock, serious

accident and death.

:

1. Never operate the HSEUIreg without Protective Earth

Conductor

2. Before connecting the HSEUIreg to the AC wire system

make all wires free of voltage and assure accidently

switch on

3. Allow neat and professionel cabeling

4. Never open nor try to repair the HSEUIreg by yourself.

Inside are dangerous voltages that can cause electric

shock hazard.

5. Avoid metal pieces or other conductive material to fall into

the HSEUIreg

6. Do not operate the HSEUIreg under damp or wet

conditions

7.

It is verboten to operate the HSEUIreg under Ex

conditions or in Ex-Area

All parameters base on 15 minutes run-in @ full load / 25°C / 230Vac 50/60Hz, as otherwise stated.

Powersolve Electronics Ltd., Unit 8A Arnhem Road, Newbury RG14 5RU, United Kingdom

Tel 0044 (0)1635 521858 Fax 0044 (0)1635 523771

(Subject to alterations. This product is not designed to be used in applications such as life support systems wherein a failure or malfunction could result in injury or death)

www.powersolve.co.uk sales@powersolve.co.uk

p.9/9 05.12D

Loading...

Loading...