Power Soak Systems Inc PS Installation Manual

Owner's Manual

PRODUCE SOAK

Table of Contents

Introduction and Conventions .................................. 1

Product Introduction ..................................................................................2

Produce Washing Chemicals and Antimicrobials ......................................2

Explanation of Warning Messages ...........................................................3

Danger ......................................................................................................3

Warning ....................................................................................................3

Chemical Hazard ......................................................................................3

Operating Instructions .............................................. 5

Preparing the Produce Soak .....................................................................6

Placing the Wash Components .............................................................6

Rib sets .................................................................................................7

Partitions ...............................................................................................9

Flow Guides ........................................................................................ 12

Filling the Produce Soak ......................................................................... 16

Washing Tips ...................................................................................... 22

Emptying the Produce Soak .................................................................... 23

Preventive Maintenance .......................................... 29

Troubleshooting ...................................................... 31

Installation ................................................................ 34

Electrical Requirements .......................................................................... 36

Plumbing Requirements .......................................................................... 37

Introduction and Conventions

Produce Soak

1

Product Introduction

Thank you for purchasing a Produce Soak fruit and vegetable washing

system. Your new Produce Soak washing system will provide years of

dependable, efficient and trouble-free service.

As a Produce Soak owner, you will benefit in numerous ways:

• Your produce washing operation will be more efficient.

• Your produce will more free of soil.

• Your produce will harbor fewer microbes.

• Your water usage will decrease.

• Your produce washing hours will decrease and your employee

morale will increase.

Every system is manufactured to last, with only high-quality, heavy-duty, 14

gauge stainless steel used in its construction. All electrical components

used in a Produce Soak system are of the highest quality. The faucet and

drain are designed for quick filling and emptying of the system's sink.

At Power Soak Systems, we take pride in manufacturing the Produce Soak

and are committed to standing behind our customers and products 100%.

Should you ever need assistance, please contact us directly at the factory

by dialing 800-444-9624 or fax 816-761-0544.

Produce Washing Chemicals and Antimicrobials

The produce wash product you select is best if it:

• Requires a minimal wash time, ideally, two minutes or less

• Requires no rinsing

• Is non-corrosive when properly diluted

• Is dispensed through fixed dilution rate equipment

• Is FDA and/or EPA approved for both whole and cut fruit and

vegetables.

Consult your chemical provider for a suitable product.

2

Explanation of Warning Messages

Be sure to read, understand and follow all DANGER and WARNING

messages located in this guide and on the equipment.

Danger

Personal Injury and Property Damage hazard.

May result in serious injury or death.

May cause extensive equipment damage

Warning

Property Damage Hazard.

May result in property or equipment damage.

Chemical Hazard

May result in serious injury or death. Instructions, labels and

Material Safety Data Sheets (MSDSs) should be supplied

with all produce treating chemicals. The manufacturers,

importers and distributors of your treating chemicals are

responsible for providing this information.

Power Soak Systems is not a manufacturer, importer, or distributor of

antimicrobials. Power Soak Systems, Inc. will not make specific brand

recommendations these chemicals.

3

- -This page left intentionally blank - -

4

Operating Instructions

Produce Soak

5

Preparing the Produce Soak

Placing the Wash Components

Begin by removing any debris left from previous batches of produce.

Disinfect all work surfaces according to the standard practices of your

institution.

6

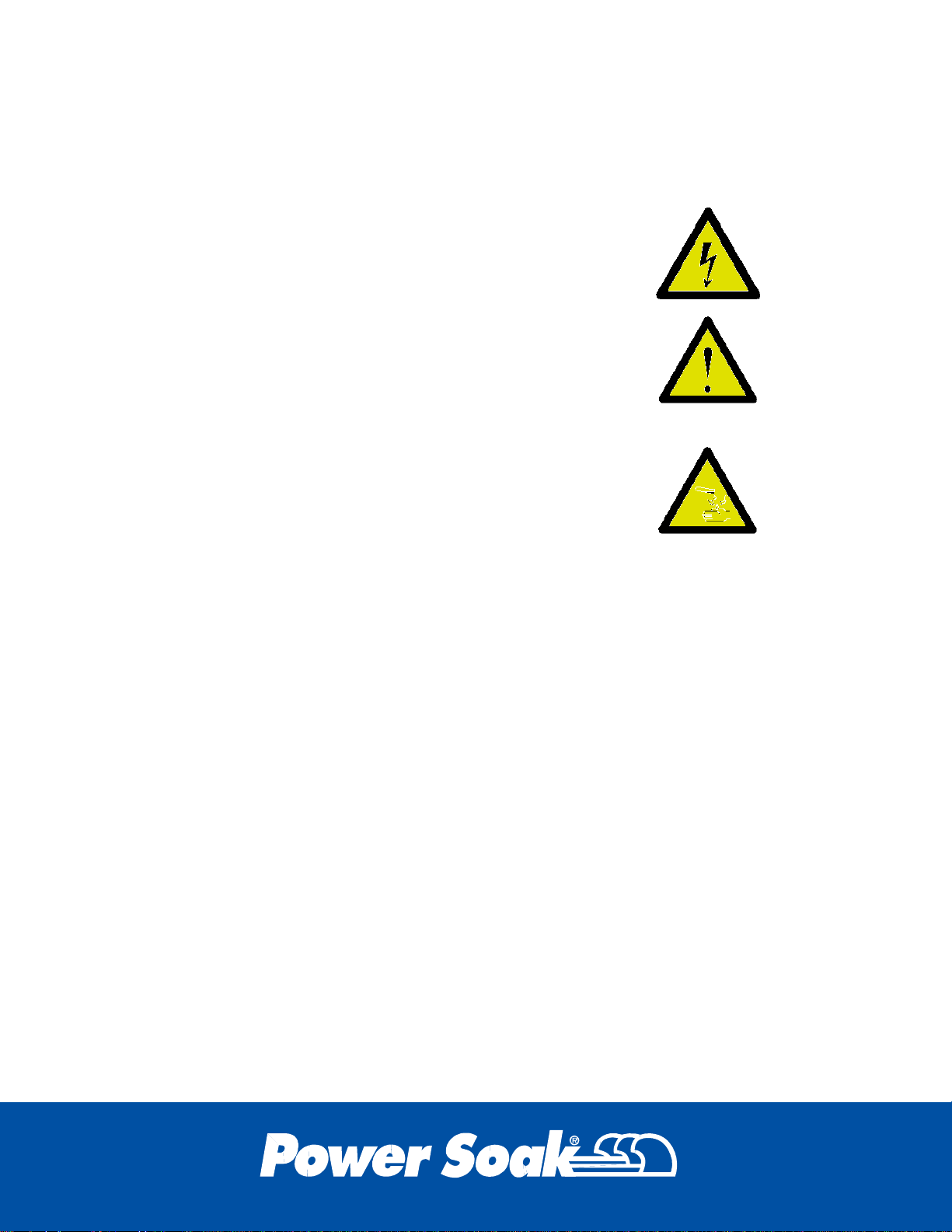

Rib sets

Once the system is clean, the wash components can be installed. Begin

by placing a rear rib set against one of the rear corners of the sink.

Place the other rear rib sets against the back wall of the sink leaving a

finger-size gap between them.

7

When you have placed all of the rear rib sets, begin placing front rib sets

against the front wall of the sink. As with the rear rib sets, place the first

front rib set against a corner, and leave a finger-size gap between it and

the next front rib set.

8

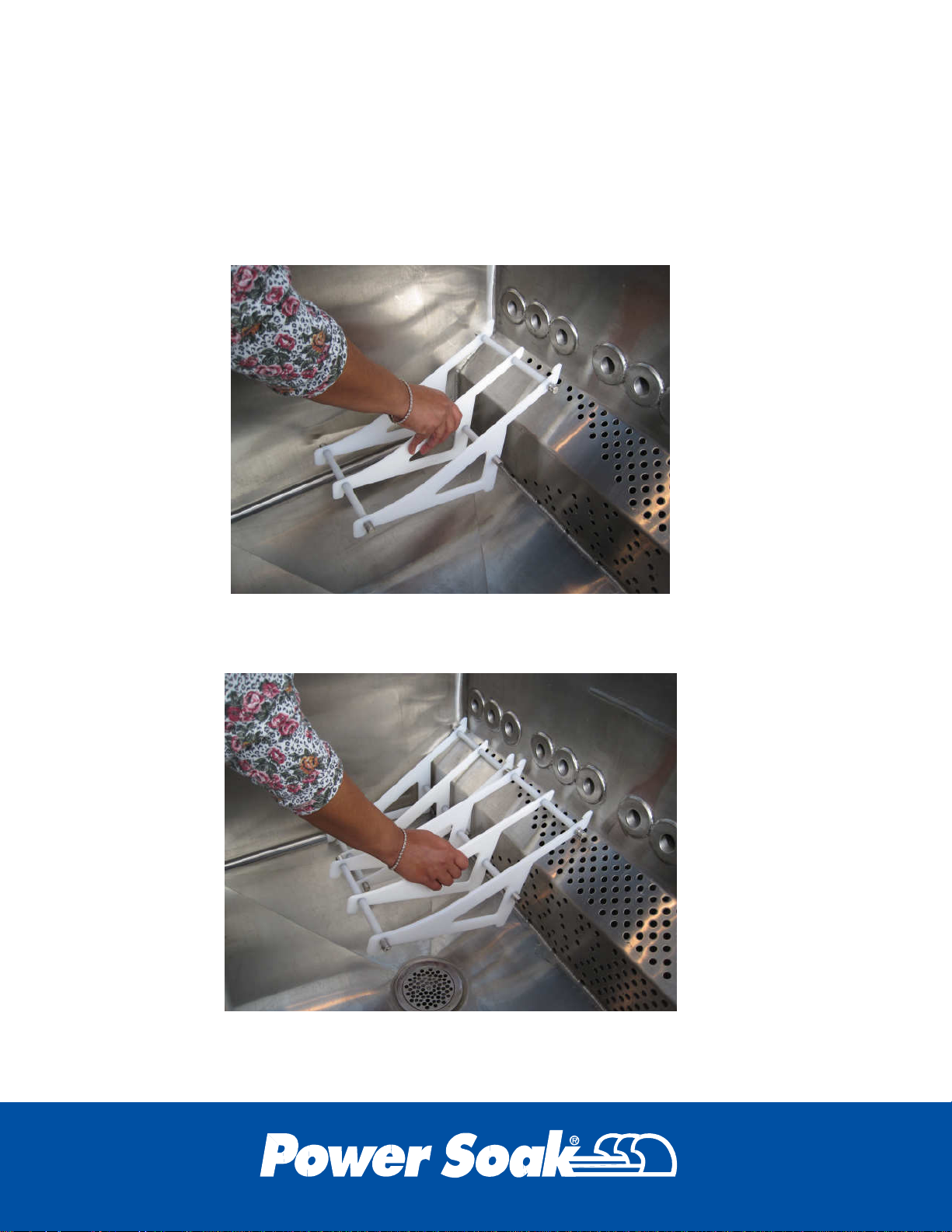

Partitions

Next, place partitions in the gaps between the front and rear pairs of rib

sets. Make sure the partitions go all the way down and are not snagged on

the ends of the rib sets.

9

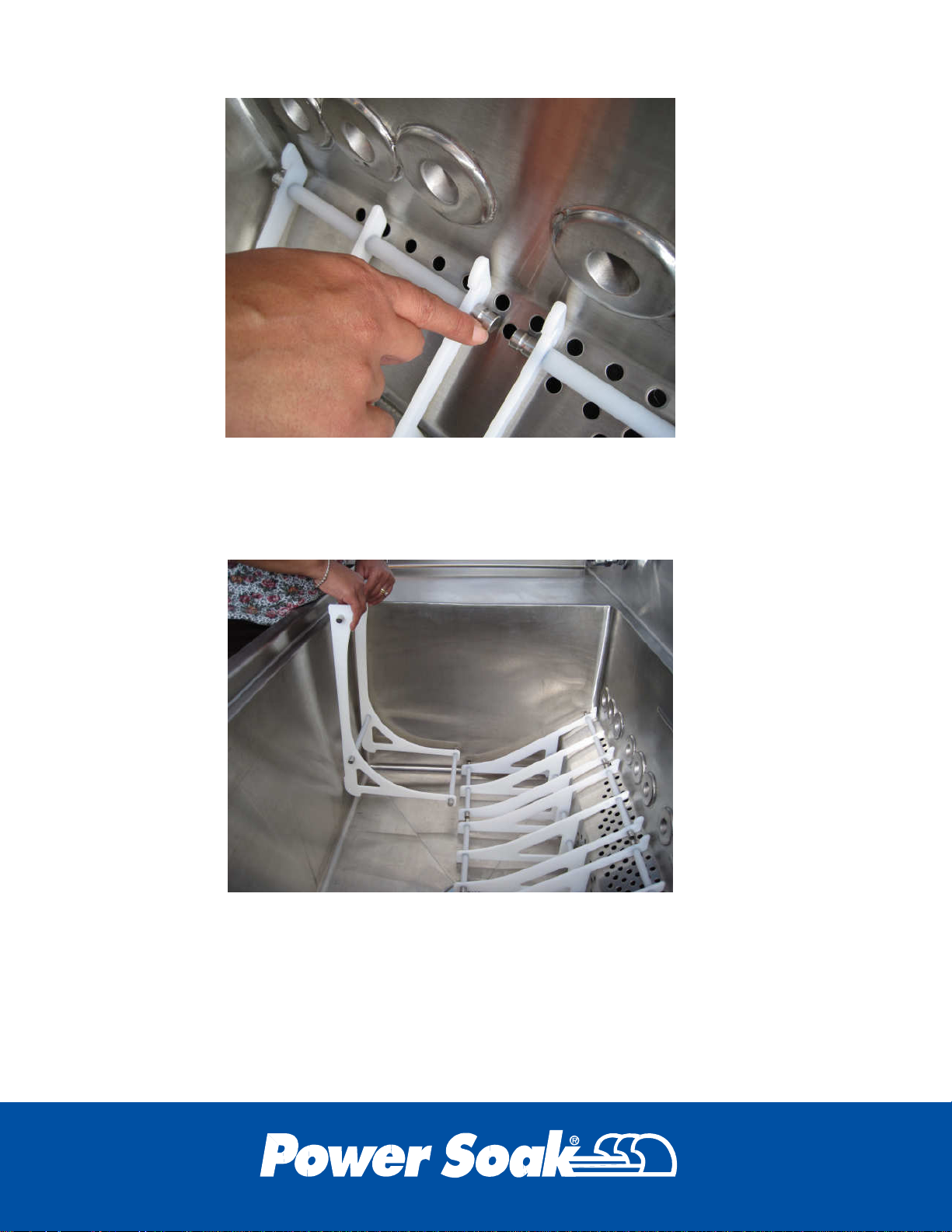

Gap between

Bottom of

partition

Continue until all three partitions are in place. It will be necessary to push

all previously placed components together to make room for the final

partition.

10

Loading...

Loading...