Power Soak PS-SWW-50 User Manual

optimal washing results.

Power Soak Systems, Inc.

ITEM#__________________________

_

903 E. 104th Street Suite 130

Kansas City , MO 64131

Ph: 816-222-2400

www.powersoak.com

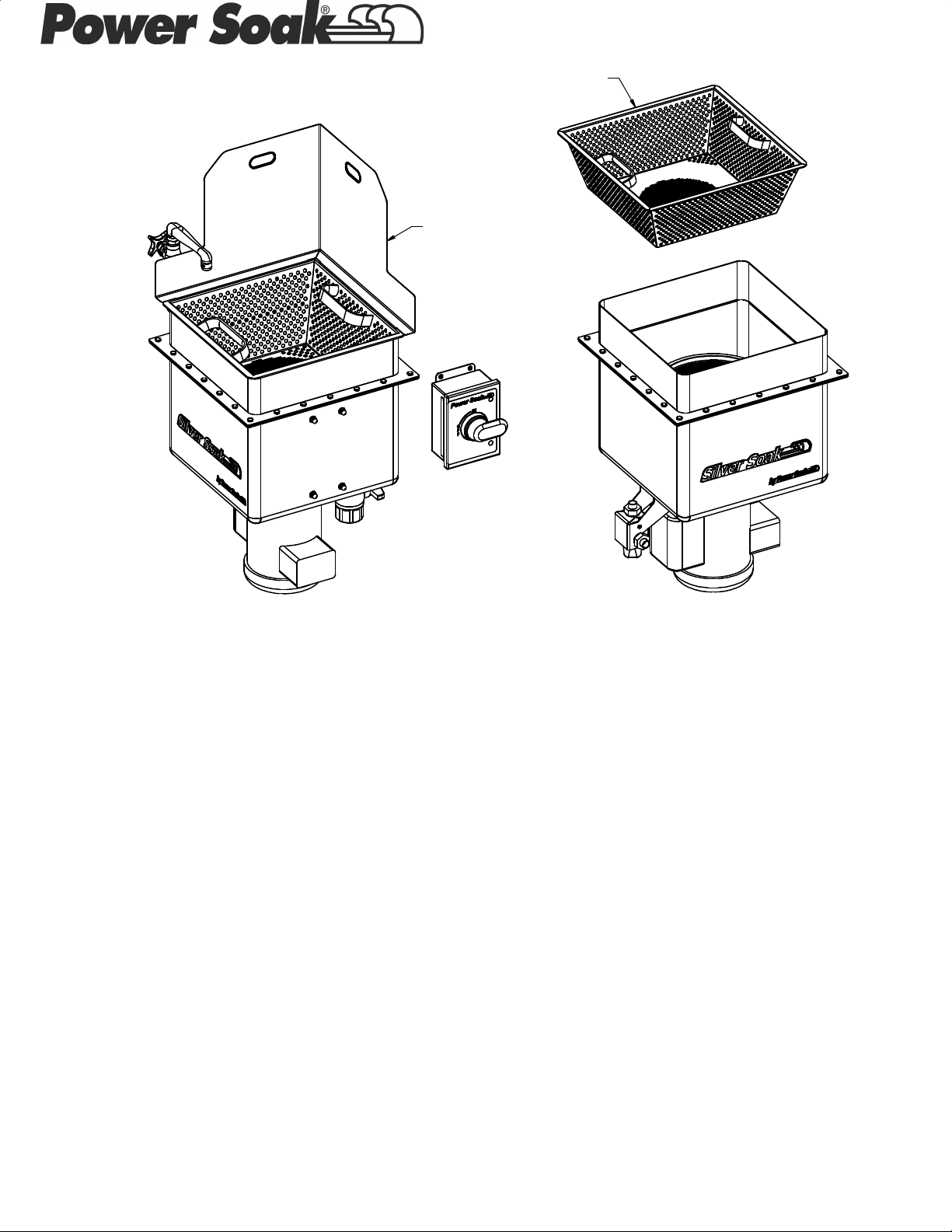

(2) Removable Wash Tank

Baskets Included

Optional Splash

Shield 35582

PS-SWW-50

SPECIFICATIONS

Weld-In Silverware Pre-Washing System Weld-In

Application

Recommended For All Customer Operations, (Excluding

Most Silverware Chutes) and where unit is not to be moved

for operation. Welds into standard dish tables.

Note: Must be Hard Plumbed & Wired.

Standard Specifications

Structural:

• 304 stainless steel construction with 14 gauge tank, legs,

and rim.

• Mounting bracket and mounting studs for control panel

included. Enables easy mounting of control panel to

wall, dish table or wash tank.

• Minimal footprint.

Electrical:

• 3/4 HP continuous heavy duty (TEFC) motor.

• Pistol grip On/Off mechanical Start/Stop switch with ½”

conduit connection.

Plumbing:

• ½” single handle faucet “hot only” included.

• Integrated mixing valve tempers incoming water to

dispense water at the appropriate temperature.

• 1 ½” inside diameter ball valve drain provided.

• 11 gallon wash tank capacity.

Operational:

• (2) removable stainless steel wash tank baskets

included.

• 600GPM Recirculation wash flow rate.

Standard Specifications (Continued)

Warranty:

•

Three years parts and labor warranty.

(Domestic only)

Specify Desired Electrical Service

Electrical Connection: ½” Conduit connection in PS-50

pistol grip mechanical Start/Stop control box.

3/4 HP 208/230 Single Phase 5.2/4.8 Full

Load Amps.

For international availability contact Power Soak Systems.

Options

Additional wash tank baskets.

Specify number of baskets here _________.

Splash guard.

Aluminum basket inserts for tarnish control on

silverplate or sterling silverware. (Box of 2)

Considerations

Electrical:

• Hardwire electrical connection needed.

• ½” conduit connection required.

Plumbing:

• ½” hot and cold water supply lines needed for fill source.

• 1 ½” drain line connection.

Operational:

• Low foaming, enzyme based chemical recommended for

- PAGE 1 -33628 - 8/30/2012

Patents Pending

Table Cutout Dimensions:

2.40

n

0.88 (TYP)

Plan View:

BASKET REMOVED

3.00

3.00

2.40

SUGGESTED FAUCET

HOLE LOCATIONS

R0.864X

15.40 SQR.

2.40

Control Panel Mounting

Bracket Dimensions:

0.84 3.33

3.00

DRAIN LOCATION

Elevation View:

BASKET REMOVED

4X n0.38

1.67

0.84

Optional Splash Shield:

PART NUMBER 35582

17.00

17.00

Silverware Basket:

16.38 SQR.

13.00

6.87

UNDERSIDE OF HEM

TO BOTTOM

OF BASKET

73°

10.82

- PAGE 2 -33628 - 8/30/2012

0.0518 GA

Patents Pending

Loading...

Loading...