Power Soak PS-200 Installation Manual

Installation Manual

PS-200 & PS-201

Table of Contents

Pre-Uncrating Checklist ............................................... 1

Verifying System Requirements .................................. 2

Verifying System Direction ................................................................... 2

Verifying the Electrical Requirements .................................................. 2

Removal of Existing Unit ............................................. 3

Existing Supply Lines ........................................................................... 3

Existing Sink Removal ......................................................................... 3

Wall Preparation .................................................................................. 3

Pre-Plumbing ............................................................... 4

Supply and Waste Lines ...................................................................... 4

Grease Trap ......................................................................................... 4

Post-Uncrating Instructions .......................................... 5

Uncrating ..................................................................... 6

Remove From Crate ............................................................................ 6

Component Installation ................................................ 7

Install Sink Drains ................................................................................ 7

Install Legs ......................................................................................... 10

JBZ Joint Installation ................................................. 12

Test Fit ............................................................................................... 12

Mating and Sealing the Joint .............................................................. 12

Wiring Connections ................................................... 14

Machine Wiring .................................................................................. 14

Optional Wireless Remote Alert Light System ................................... 14

Optional Chemical Dispenser Wiring ................................................. 14

Faucet Installation .............................................................................. 15

Completing the Installation ......................................... 17

Final Installation Steps .............................................. 18

Machine Placement ........................................................................... 18

Downturned-Backsplash Z-Clip Installation ....................................... 18

Upturned-Backsplash Level Attach to the Wall .................................. 18

Seal around the Backsplash and Screws ........................................... 19

Rinse Riser and Anchor Installation ................................................... 19

Plumbing Connections ....................................................................... 19

Electrical Connections ....................................................................... 20

Checking the Motor Rotation (“JOG” Feature) ................................... 20

Shelving ............................................................................................. 20

Validating the Installation ........................................... 21

Testing the Components ........................................... 22

Check for Leaks ................................................................................. 22

Check the Electrical Installation ......................................................... 22

Check Operation ................................................................................ 22

Check the Chemical Dispensing System ........................................... 22

Appendix.................................................................... 23

Pre-Uncrating Checklist

PS-200 & PS-201

1

IMPORTANT

Verifying System Requirements

Prior to completely removing the Power Soak unit from the crate, it is necessary

to verify certain requirements. Remove only the lid of the crate at this time.

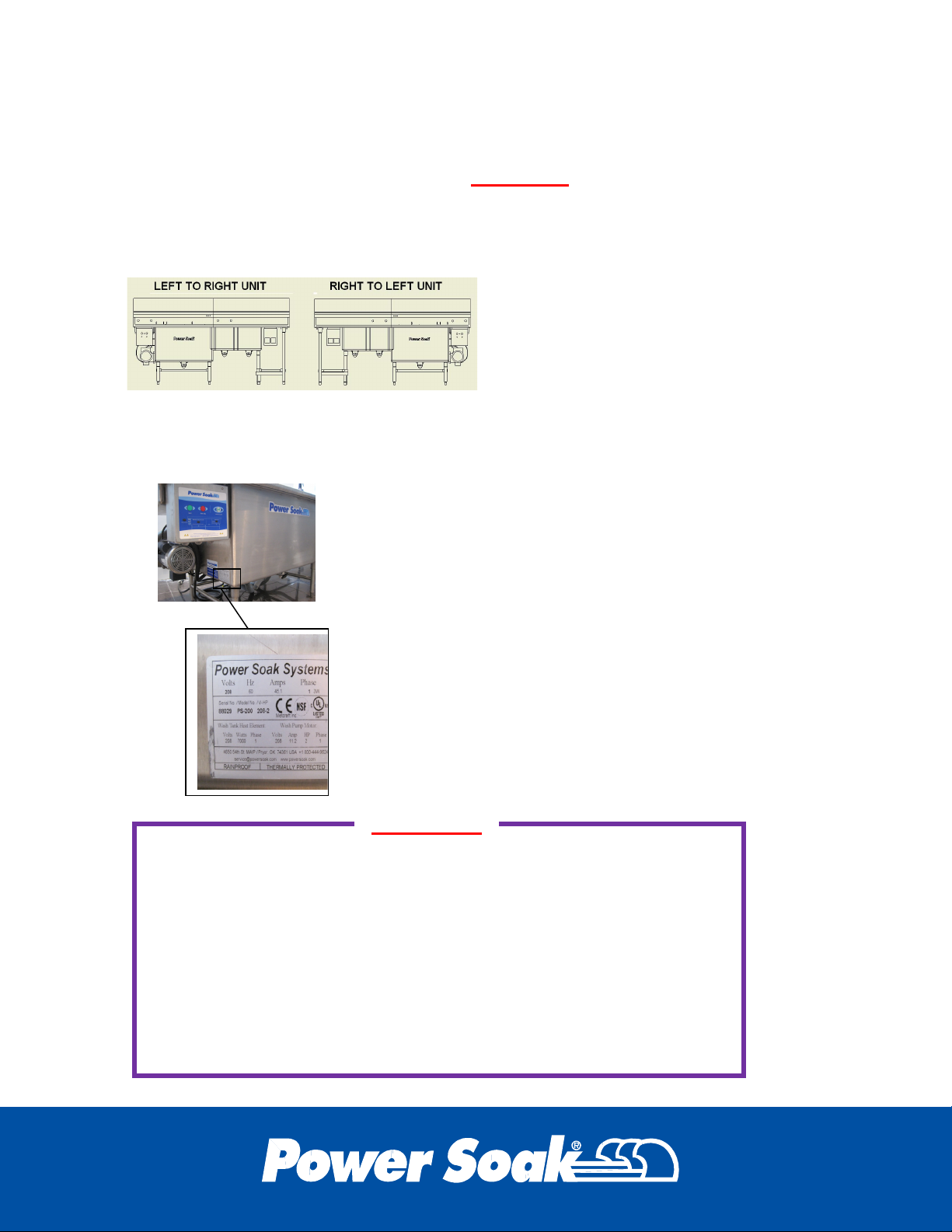

Verifying System Direction

The Power Soak can be built as a

“Left to Right” or as a “Right to Left”

configuration with a variety of

options. Look inside the crate and

verify that the configuration of the

machine matches the specifications

of the order description.

Verifying the Electrical Requirements

The electrical requirements for the machine are on

the machine identification tag located on the side

of the wash tank, next to the motor. The electrical

service in the facility where the machine is to be

installed must be rated for the capacity shown on

the identification tag. This machine will require a

permanently mounted disconnect that is in a

“liquid tight” enclosure. Do not use an in-line plug

for disconnecting the machine from the electrical

source. Contact a licensed and certified

electrician to make the enclosure installation if one

is not present. Use the tables in the appendix to

determine the appropriate breaker (overcurrent

protection) and wire size for the machine’s

electrical service.

WARNING: DO NOT connect the machine using a power cord and

plug or an extension cord of any kind.

WARNING: Kitchens are a wet environment which require all

electrical connections to be “liquid tight”.

Electrical installation must conform to all applicable local wiring codes.

All electrical connections must be “liquid tight” and readily accessible

for inspection after installation without moving the Power Soak

machine or any of its accessories.

2

Removal of Existing Unit

If the new Power Soak is not replacing an existing sink, skip this section. If

the removal of an existing sink is necessary, continue with this section.

Existing Supply Lines

The water and electrical source must be shut off before disconnecting or

cutting the water or electric lines.

WARNING

Failure to shut off the electrical and water supply will result in personal injury,

including serious injury or death, and extensive equipment damage.

Disconnect any electrical cord that is connected to the existing sink. Cut

the cold and hot water lines as closely as possible to the fittings on the

existing sink.

IMPORTANT

Be sure to leave enough of the existing piping for the installation of new shutoff

valves. See “Pre-Plumbing” section for reference.

Existing Sink Removal

Detach any fasteners holding the existing sink in place and remove the

existing sink along with any shelves that may interfere with the installation

of the Power Soak. Discard all unwanted materials in an appropriate

container or disposal area.

Wall Preparation

Clean the wall(s) where the new Power Soak will be installed. Fill all

existing holes with an appropriate filler material. Be sure that any outlet

that will be covered by the sink has been disconnected and a water tight

cover has been installed over the opening.

3

IMPORTANT

IMPORTANT

Pre-Plumbing

Supply and Waste Lines

The supply and waste lines must meet the following requirements:

• Hot and cold water supply must be ½” diameter or larger.

• Center lines of the hot and cold water supply must be 10” or less above

the floor to access the shutoff valves when the machine is installed.

• Waist drain must be 1-1/2” minimum diameter.

• Center line of the waste drain must be 11” or less above the floor to

allow the sink to drain properly.

Install new shutoff valves on the hot and cold water supply lines.

IT IS RECOMMENDED THAT ALL MACHINES BE INSTALLED USING

NEW ½” OR LARGER BALL-VALVE SHUT OFF VALVES.

Grease Trap

It may be necessary to relocate and/or replace the existing grease trap. Be

sure that the grease trap meets or exceeds the local plumbing codes.

WASTE PLUMBING MUST CONFORM TO LOCAL BUILDING CODES.

4

Post-Uncrating Instructions

PS-200 & PS-201

5

Loading...

Loading...