Page 1

POW64251 EN

1 APPLIANCE .................................................................................... 3

2 DESCRIPTION (FIG A) ................................................................... 3

3 PACKAGE CONTENT LIST ............................................................ 4

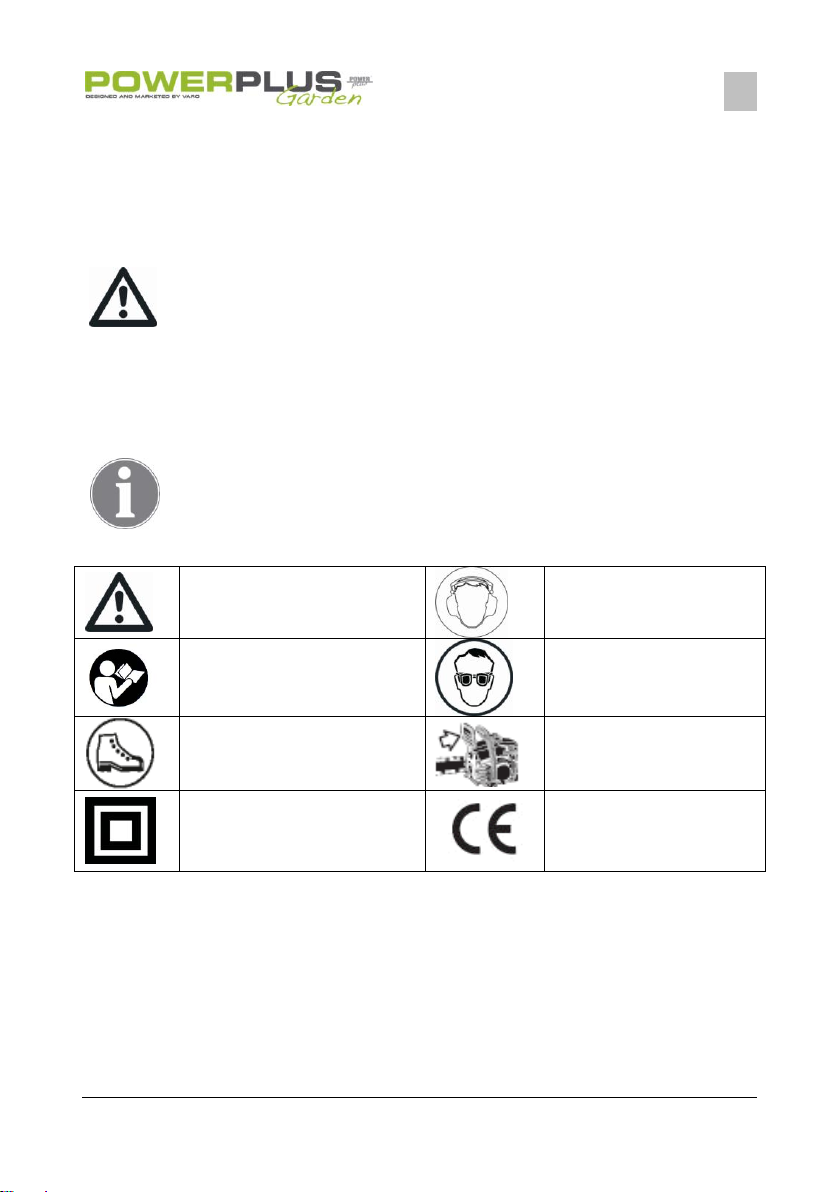

4 SYMBOLS ....................................................................................... 4

5 GENERAL POWER TOOL SAFETY WARNINGS ......................... 5

5.1 Work area ............................................................................................................... 5

5.2 Electrical safety ..................................................................................................... 5

5.3 Personal safety ...................................................................................................... 5

5.4 Power tool use and care ........................................................................................ 6

5.5 Service .................................................................................................................... 6

6 PARTICULAR SAFETY PRECAUTIONS WHEN WORKING WITH

THE CHAIN SAW ............................................................................ 6

7 KICKBACK SAFETY PRECAUTIONS ........................................... 7

8 ASSEMBLY ..................................................................................... 8

8.1 Fitting the guide bar and chain ............................................................................. 8

8.2 Lubricating oil for the saw chain .......................................................................... 9

9 POWER SUPPLY CONNECTION .................................................. 9

10 OPERATION.................................................................................. 10

10.1 Switching on and off............................................................................................ 10

10.2 Running the saw chain in .................................................................................... 10

10.3 Checking the chain lubrication ........................................................................... 10

10.4 Chain brake .......................................................................................................... 10

10.5 Kickback ............................................................................................................... 11

10.6 Push-back ............................................................................................................ 11

10.7 Pull-forward .......................................................................................................... 11

11 HOW TO WORK WITH THE CHAIN SAW ................................... 11

11.1 Cutting logs, branches, etc. ................................................................................ 12

11.2 Trimming trees ..................................................................................................... 12

11.3 To fell a tree ......................................................................................................... 12

12 CLEANING AND MAINTENANCE ............................................... 13

Copyright © 2010 VARO P a g e | 1 www.varo.com

Page 2

POW64251 EN

12.1 Re-tensioning the saw chain ............................................................................... 13

12.2 Insufficient chain lubrication .............................................................................. 14

12.3 To carry the chain saw ........................................................................................ 14

12.4 Saw chains ........................................................................................................... 14

12.5 Guide bar .............................................................................................................. 14

12.6 Drive sprocket ...................................................................................................... 14

12.7 Carbon brushes ................................................................................................... 14

13 TECHNICAL DATA ....................................................................... 14

14 SOUND EMISSION ....................................................................... 14

15 WARRANTY .................................................................................. 15

16 ENVIRONMENT ............................................................................ 15

17 DECLARATION OF CONFORMITY ............................................. 16

Copyright © 2010 VARO P a g e | 2 www.varo.com

Page 3

POW64251 EN

ELECTRICAL CHAINSAW 2400W

POW64251

1 APPLIANCE

This model is intended for infrequent use by homeowners, cottagers, and campers, and for

such general applications as clearing, pruning, cutting firewood, etc. They are not intended for

prolonged use. If the intended use involves prolonged periods of operation, this may cause

circulatory problems in the user’s hands due to vibration.

It is not designed for commercial use.

WARNING! Read this manual and general safety instructions carefully

before using the appliance, for your own safety. Your power tool should

only be passed on together with these instructions.

2 DESCRIPTION (FIG A)

1. Saw chain

2. Guide bar

3. Chain brake lever / hand guard

4. Front handle

5. Main handle

6. Oil tank cap

7. Bucking spike

LOW KICKBACK SAW CHAIN helps significantly reduce kickback, or the intensity of kickback,

due to specially designed depth gauges and guard links.

CHAIN BRAKE is a safety feature designed to reduce the possibility of injury due to kickback

by stopping a moving saw chain in milliseconds. It is activated by the Chain Brake lever.

CHAIN BRAKE LEVER / HAND GUARD protects the operator’s left hand in the event it slips

off the front handle while saw is running.

CHAIN CATCHER reduces the danger of injury in the event saw chain breaks or derails during

operation. The chain catcher is designed to intercept a whipping chain.

8. Bar retaining nut

9. Saw chain adjustment screw

10. Chain catcher

11. Cap for carbon brush

12. Safety locking button

13. On/Off switch

NOTE: Study your saw and be familiar with its parts.

WARNING Beware of kickback. Hold chain saw firmly with both hands when

using. For your own safety, please read and follow the safety precautions in

this manual before attempting to operate your chain saw. Improper use can

cause serious injury.

WARNING! When using gas tools, basic safety precautions, including the

following, should always be followed to reduce the risk of serious personal

injury and/or damage to the unit.

Copyright © 2010 VARO P a g e | 3 www.varo.com

Page 4

POW64251 EN

Denotes risk of personal injury

or damage to the tool.

Wearing of protection

against noise advised

Read manual before usage

Wearing of protection

goggles advised.

Wearing of protective shoes

advised

Make Sure the Chain Brake

is disengaged! Pull Hand

Guard/Chain Brake back to

run.

Class. II -Double insulated

In accordance with

essential applicable safety

standards of European

directives

3 PACKAGE CONTENT LIST

Remove all packing materials

Remove remaining packaging and transit supports (if existing)

Check the completeness of the packing content

Check the appliance, the power cord, the power plug and all accessories for

transportation damages.

Keep the packaging materials as far as possible till the end of the warranty period.

Dispose it into your local waste disposal system afterwards.

WARNING Packing materials are no toys! Children must not play with

plastic bags! Danger of suffocation!

1 Electrical chainsaw 2400W

1 Manual

2 chains

1 bar

1 bar sheath

1 set carbon brushes

When parts are missing or damaged, please contact your dealer.

4 SYMBOLS

In this manual and/or on the machine the following symbols are used:

Copyright © 2010 VARO P a g e | 4 www.varo.com

Page 5

POW64251 EN

5 GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and all instructions. Failure to follow all warnings and instructions

may result in electric shock, fire and/or serious injury. Save all warnings and instructions for

future reference. The term "power tool" in the warnings refers to your mains operated (corded)

power tool or battery operated (cordless) power tool.

5.1 Work area

Keep work area clean and well lit. Cluttered and dark areas invite accidents.

Do not operate power tools in explosive atmospheres, such as in the presence of

flammable liquids, gases or dust. Power tools create sparks which may ignite the dust or

fumes.

Keep children and bystanders away while operating a power tool. Distractions can cause

you to lose control.

5.2 Electrical safety

Always check that the power supply corresponds to the voltage on the

rating plate.

Power tool plugs must match the outlet. Never modify the plug in any way. Do not use

any adapter plugs with earthed (grounded) power tools. Unmodified plugs and matching

outlets will reduce risk of electric shock.

Avoid body contact with earthed or grounded surfaces such as pipes, radiators, ranges

and refrigerators. There is an increased risk of electric shock if your body is earthed or

grounded.

Do not expose power tools to rain or wet conditions. Water entering a power tool will

increase the risk of electric shock.

Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power

tool. Keep cord away from heat, oil, sharp edges or moving parts. Damaged or

entangled cords increase the risk of electric shock.

When operating a power tool outdoors, use an extension cord suitable for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of electric shock.

If operating a power tool in a damp location is unavoidable, use a residual current device

(RCD) protected supply. Use of an RCD reduces the risk of electric shock.

5.3 Personal safety

Stay alert, watch what you are doing and use common sense when operating a power

tool. Do not use a power tool while you are tired or under the influence of drugs, alcohol

or medication. A moment of inattention while operating power tools may result in serious

personal injury.

Use safety equipment. Always wear eye protection. Safety equipment such as dust

mask, non-skid safety shoes, hard hat, or hearing protection used whenever conditions

require will reduce personal injuries.

Avoid accidental starting. Ensure the switch is in the off position before plugging in.

Carrying power tools with your finger on the switch or plugging in power tools that have

the switch on invites accidents.

Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

Do not overreach. Keep proper footing and balance at all times. This enables better

control of the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from moving parts. Loose clothes, jewellery or long hair can be caught in

moving parts.

Copyright © 2010 VARO P a g e | 5 www.varo.com

Page 6

POW64251 EN

If devices are provided for the connection of dust extraction and collection facilities,

ensure these are connected and properly used. Use of these devices can reduce dust

related hazards.

5.4 Power tool use and care

Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

Do not use the power tool if the switch does not turn it on and off. Any power tool that

cannot be controlled with the switch is dangerous and must be repaired.

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store idle power tools out of the reach of children and do not allow persons unfamiliar

with the power tool or these instructions to operate the power tool. Power tools are

dangerous in the hands of untrained users.

Maintain power tools. Check for misalignment or sticking of moving parts, breakage of

parts and any other condition that may affect the power tool’s operation. If damaged,

have the power tool repaired before use. Many accidents are caused by poorly

maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to stick and are easier to control.

Use the power tool, accessories and tool bits etc., in accordance with these instructions

and in the manner intended for the particular type of power tool, taking into account the

working conditions and the work to be performed. Use of the power tool for operations

different from intended could lead to a hazardous situation.

5.5 Service

Have your power tool serviced by a qualified repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

6 PARTICULAR SAFETY PRECAUTIONS WHEN WORKING WITH

THE CHAIN SAW

When working with the chain saw, protective gloves, suitable shoes, leg protectors, eye

protectors and ear protectors should be used.

If the work involves any risk of head injury, a safety helmet must be worn When cutting

down trees and cutting and cutting off branches of felled or fallen trees. in addition a face

protector should be worn.

Always pull the plug from the socket outlet before attempting to check or adjust the chain

or to correct some fault and whenever moving one workplace to another.

Never switch on the chain saw unless you have a firm hold of the tool. a secure footing

and are sure that the guide bar and saw chain are not touching anything.

Always hold the saw with both hands (right hand on rear handle, left hand on handle 5).

Never saw above shoulder height, while standing on a ladder or In a tree or in any other

insecure position.

When sawing timber that has split, take particular care that no small pieces of wood are

broken off and thrown by the saw chain.

During breaks, the saw should be laid down in such a way that there Is no risk of injury

to anyone from the saw chain.

The chain saw should never be lent to or be allowed to come into the hands of persons

who are not familiar with the use of such a tool. The operating Instructions should also

go with the saw.

Copyright © 2010 VARO P a g e | 6 www.varo.com

Page 7

POW64251 EN

Rotational kickback

A = kickback path

B = kickback reaction zone

7 KICKBACK SAFETY PRECAUTIONS

KICKBACK may occur when the NOSE or TIP of the guide bar touches an object, or when

wood closes in and pinches the saw chain in the cut.

Tip contact in some cases may cause a lightning-fast reverse reaction, kicking the guide bar

up and back toward the operator.

PINCHING the saw chain along the BOTTOM of the guide bar may PULL the saw forward

away from the operator.

PINCHING the saw chain along the TOP of the guide bar may PUSH the guide bar rapidly

back toward the operator.

Any of these reactions may cause you to lose control of the saw, which could result in serious

personal injury.

With a basic understanding of kickback, you can reduce or eliminate the element of

surprise. Sudden surprise contributes to accidents.

Keep a good firm grip on the saw with both hands, the right hand on the rear handle, and

the left hand on the front handle, when the engine is running. Use a firm grip with thumbs

and fingers encircling the chain saw handles. A firm grip will help you reduce kickback and

maintain control of the saw. Don’t let go.

Make sure that the area in which you are cutting is free from obstructions. Do not let the

nose of the guide bar contact a log, branch, or any other obstruction which could be hit

while you are operating the saw.

Cut at high engine speeds.

Do not overreach or cut above shoulder height.

Follow manufacturer’s sharpening and maintenance instructions for the saw chain.

Only use replacement bars and chains specified by the manufacturer or the equivalent.

NOTE: Low-kickback saw chain is chain that has met the kickback

performance.

WARNING: Kickback can lead to dangerous loss of control of the chain saw

and result in serious or fatal injury to the saw operator or to anyone

standing close by. Always be alert. Rotational kickback and pinch-kickback

are major chain saw operational dangers and the leading cause of most

accidents.

Beware of:

Copyright © 2010 VARO P a g e | 7 www.varo.com

Page 8

The push (pinch kickback) and pull reactions a

= pull

B = solid objects

C = push

8 ASSEMBLY

8.1 Fitting the guide bar and chain

If the chain saw is already connected to the power supply: Pull the plug

from the socket outlet. Wear protective gloves whenever doing any work on

the saw chain.

POW64251 EN

Fig 1

Copyright © 2010 VARO P a g e | 8 www.varo.com

Page 9

POW64251 EN

Fig 2

The chain must be fitted over the

guide bar so that the cutting edges of

the cutters (a) face in the direction

that the chain runs.

The direction of rotation of the saw chain is indicated by two arrows on the drive-sprocket

cover.

Hold the guide bar with the nose up-wards and place the saw chain so on the blade.

Then put the saw chain round the drive sprocket and place the guide bar with its slot so onto

the threaded studs(11). Replace the drive-sprocket cover(1)and screw on the lock-on hand

wheel (2 and 4) but do not yet tighten them.

Turn the tensioning screw (4)

clockwise to take up any slack in the

saw chain. The chain is correctly

tensioned when it is still possible to

raise it by 3-4mm in the middle of the

guide bar (fig 3).

After tensioning the saw chain turn the nose of the bar upwards and tighten the lock-on hand

wheel (2 and 4) firmly.

8.2 Lubricating oil for the saw chain

Before starting up your new chain saw, the container must be filled with chain saw oil.

It allows operating the chain saw at ambient temperatures down to as low as -15°C.

Never use waste oil for lubricating the saw chain.

To top the saw up with lubricating oil unscrew the filler cap (3). Make sure that no dirt

gets into the oil container while filling up. The oil level can be checked through the gauge

glass (14)

9 POWER SUPPLY CONNECTION

The chain saw has purposely been fitted with a comparatively short power lead to

reduce the risk of the lead being cut by the saw chain while working with the tool.

It is best to fit the strain relief strap supplied between the plug on the saw’s power lead

and the coupler socket on the extension cord, to prevent the plug from being

unintentionally pulled out of the coupler socket.

Before plugging the extension cord into the supply socket check the cord for damage

and deterioration. Never operate the chain saw if the supply lead is not in perfect

condition.

The electricity supply where the chain saw is connected to should be provided with an

earth leakage or residual current device with a tripping current of not more than 30mA.

Copyright © 2010 VARO P a g e | 9 www.varo.com

Page 10

POW64251 EN

10 OPERATION

10.1 Switching on and off

When switching the chain saw on, the hand-protection guard (6) must be in its normal position,

i.e. be pressed in the direction of the arrow in Fig 1 against the handle (5).

The saw is provided with a safety device to prevent it being switched on accidentally.

To switch on:

-Grasp the handle (5) with the left hand

-With the thumb of the right hand push the locking button at the left side of the switch

handle, then

-With the locking button still depressed, squeeze the trigger and

-Release the locking button

To switch off:

-Release the trigger. (the locking button returns into the locked position)

The noise that the chain saw not being fitted with the guide bar and chain makes while the tool

is running down, is quite natural and has no ill effect on the function or service life of the saw.

10.2 Running the saw chain in

Before starting to saw, a new saw chain should be run in for 2-3 minutes and then its tension

should be checked as detailed under “fitting the guide bar and saw chain” and the chain be retensioned if necessary.

10.3 Checking the chain lubrication

Running the saw chain without chain lubrication will quickly damage the chain and the guide

bar beyond repair and so you should always check the oil level before starting up.

Never run the saw without chain lubrication.

TO check the lubricating system switch on the chain saw and hold it with the guide bar and

chain

above some light coloured area (an open newspaper will . A steadily increasing stain caused

spray

shows that the lubricating system is working properly.

10.4 Chain brake

The saw is fitted with a chain brake that brings the saw chain to a stop a tenth of a second

if the hand-protection guard (6) is brought into the tripping position either manually or.

while operating the chain saw, as a result of a kickback, by the back of the operator's hand

or

if the chain saw is switched off by releasing the trigger.

When the chain brake has been tripped by actuating the hand-protection

guard (6), do not run the motor of the saw unnecessarily long. Set the guard

immediately back to its normal position.

Before starting any work with the chain saw, be sure to check the proper

functioning of the chain brake (by actuating the hand-protection guard and

by releasing the trigger).

Copyright © 2010 VARO P a g e | 10 www.varo.com

Page 11

POW64251 EN

If the upper part of the guide-bar nose should

inadvertently be allowed to Touch against some rigid

objects, such as the bole of the tree when sawing off

branches, or some immediately adjacent object, a trunk

lying close to the one that is to be cut through, for

instance, the saw with the guide bar may kick back and

upwards against the operator in the direction of the arrow

in Fig.4.

Push-back will occur it an attempt is made to

saw with the saw chain at the top the guide

bar, if this part of the saw chain touches

against some rigid object or if it jams in the

cut.

If the spiked stop is not set against the timber

that is to be sawn, the chain at the bottom of

the guide bar will pull the saw forward if the

chain jams or comes against some solid

object in the timber.

It is therefore important to saw with the

spiked stop against the timber whenever

possible.

10.5 Kickback

Such dangerous kickbacks can largely be avoided by working quietly and with forethought in

the following manner:

While sawing, always watch the guide-bar nose

Never attempt to cut with the nose of the guide bar.

Take care when cutting thin and springy branches. The saw chain can easily catch against

them.

Particular care must be taken when inserting the saw with the guide bar to complete an

already started cut.

10.6 Push-back

10.7 Pull-forward

11 HOW TO WORK WITH THE CHAIN SAW

Each time you are about to start work, check that the saw is in perfect condition. It is

particularly important to ensure that the guide bar is properly fitted, that the chain is correctly

tensioned and that the chain brake is functioning correctly.

Before using the saw for the first time it is advisable to practise cutting logs on a saw-horse or

something alike.

When working with the chain saw, care should be taken to keep the extension cord away from

the saw chain.

Copyright © 2010 VARO P a g e | 11 www.varo.com

Page 12

POW64251 EN

When cutting timber with the chain saw, the left arm

should be kept almost straight Guide the saw so that no

part of your body extends beyond the imaginary line

«X» drawn through the guide bar.

Press the spiked stop (10) on the saw against the

timber and only then start cutting holding the tool by the

handle (5) and raising the switch handle.

Fig 8

11.1 Cutting logs, branches, etc.

If you cannot cut the timber right Through with a single stroke:

Apply light pressure to the handle(5) and continue sawing and

Draw the chain saw back a little, then

Apply the spiked stop a little lower and

finish the cut by raising the switch handle

Withdraw the saw from the cut while the chain is still running.

When cutting timber resting on the ground, never allow the saw chain to cut into soil under the

timber; this would dull the chain immediately.

When cutting trunks resting on a slope, the operator should always stand uphill of the trunk.

11.2 Trimming trees

When trimming trees, always cut from above to allow the branch to drop away downwards It

may however be useful to cut into the branch from below first.

When cutting off a branch the chain saw should be supported against the bole of the tree if at

all Possible.

Never attempt to cut off branches with the nose of the guide bar.

Particular care should be taken when sawing through a branch that is under tension and that

might spring up and hit you.

11.3 To fell a tree

Before commencing to cut down a tree, you must be clear where you want it to fall and be

sure that there is nothing in the way, such as power lines or a building that could be damaged

when the tree falls.

NO person or animal must be within 2 1/2 tree lengths of the base of the tree.

You should clear two escape routes. Each opening put at an angle of about 45 in the direction

opposite to that in which you plan that the tree should fall (Fig.10). These escape routes must

be clear and free of obstruction.

Copyright © 2010 VARO P a g e | 12 www.varo.com

Page 13

POW64251 EN

First an undercut notch has to be cut in the trunk of the tree to determine the direction in which

the tree is to fall. The undercut, which should have a, depth equal to about a quarter of the

diameter of the trunk, should first be sawn downwards at an angle and then horizontally

across to meet the top cut (Fig. 11).

The felling cut ③should be made slightly above the level of the bottom of the undercut. This

cut should not extend right through but should leave an uncut breakage strip ② Otherwise the

tree could fall out of control. The breakage strip should have a width of about one tenth the

diameter of the trunk.

Wedges should be driven into the felling cut in good time. Only wedges of wood, aluminium or

plastic should be used never wedges of iron or steel.

12 CLEANING AND MAINTENANCE

12.1 Re-tensioning the saw chain

When working with the chain saw, the chain expands as a result of the warming. It then

becomes slack and may slip off the guide bar.

If the saw chain is tensioned in this condition, it is very important to release the tension once

the saw work is finished, as otherwise the chain may contract so much on cooling that it will be

excessively tight.

Copyright © 2010 VARO P a g e | 13 www.varo.com

Page 14

POW64251 EN

Type

POW64521

Rated voltage/frequency

230V/50Hz

Rated power

2400W

No load chain speed

14m/s

Bar length

16”

Max. cutting length

385mm

Brake time

< 0.12s

Tank capacity of lubricating oil

90ml

Sound pressure level

LpA

97 dB (K = 3)

Sound power level

LwA

110 dB (K = 3)

Vibration

aw

4.5 m/s² (K = 1,5)

12.2 Insufficient chain lubrication

If after running the chain saw for about 20 minutes only a little lubricating oil has left the

container, the cause may be blockage of the oil duct (8) in the saw and/or the oil hole (16) in

the guide bar. If so, they should be cleaned.

To clean the oil duct (8) the cover plate (7) can be removed, if necessary, after unscrewing its

fastening screw.

12.3 To carry the chain saw

After use, the guide bar and chain should be covered with the chain guard that is supplied with

the tool.

12.4 Saw chains

Working with a blunt saw chain causes the chain, guide bar and drive sprocket to wear rapidly

and may even lead to the chain breaking and so it is important that the saw chain be

sharpened in good time.

It is advisable to have the chain be re-sharpened by a competent workshop.

The relevant angles on the saw-chain cutters are:

side-plate filing angle 85°

top-plate cuffing angle 60°

top-plate angle 30°

A 4 mm dia. round file should be used for sharpening the chain.

12.5 Guide bar

A small amount of ball-bearing grease should be fed occasionally with a grease gun through

the grease holes situated near the four rivets holding the nose sprocket on the guide bar.

The bottom edge of the bar is exposed to relatively heavy wear and so the bar should be

turned top to bottom whenever the chain is sharpened and at the same time the groove in the

bar and the oil holes (16) should be cleaned.

12.6 Drive sprocket

If the teeth of the drive sprocket (13) show any signs of wear. the sprocket should be replaced.

The drive sprocket should be changed with every second replacement of the chain.

12.7 Carbon brushes

When the chain saw's brushes are worn beyond a certain limit, a tripping device in the

brushes automatically stops the motor.

The brushes should be replaced by a specialist who has the right equipment. The saw can

then be given a thorough inspection at the same time and the motor be cleaned.

13 TECHNICAL DATA

14 SOUND EMISSION

Copyright © 2010 VARO P a g e | 14 www.varo.com

Page 15

POW64251 EN

15 WARRANTY

This product is warranted as provided by law for a 24 months period effective from the

date of purchase by the first user.

This warranty covers all material or production flaws. It does not include: defective parts

subject to normal wear & tear, such as bearings, brushes, cables, plugs or accessories

such as drills, drill bits, saw blades etc. ; damage or defects resulting from abuse,

accidents or alterations; nor the costs for transport.

We reserve the right to reject any claim where the purchase cannot be verified or when

it is clear that the product has not been properly maintained. (Clean ventilation slots,

carbon brushes serviced regularly,…)

Your purchase receipt must be kept as proof of date of purchase.

Your appliance must be returned un-dismantled to your dealer in an acceptably clean

state, (in its original blow moulded case if applicable to the unit), accompanied by your

proof of purchase.

16 ENVIRONMENT

Should your appliance need replacement after extended use, do not discard it

with the household rubbish but dispose of it in an environmentally safe way.

Waste produced by electrical machine items should not be handled like normal

household rubbish. Please recycle where recycle facilities exist. Check with your

Local Authority or retailer for recycling advice.

Copyright © 2010 VARO P a g e | 15 www.varo.com

Page 16

POW64251 EN

17 DECLARATION OF CONFORMITY

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier - BELGIUM, declares that,

product: Electrical chain saw 2400W

trade mark: POWERplus

model: POW64251

is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives, based on the application of European harmonized standards. Any

unauthorized modification of the apparatus voids this declaration.

European Directives, and their amending directives:

2006/95/EC The Low Voltage Directive

2004/108/EC The Electromagnetic Compatibility Directive

98/37/EC The Machinery Directive

2000/14/EC The Outdoor Noise Directive

LwA = 110dB

European harmonized standards, and their amendments;

EN60745-1 : 2006

EN60745-2-13 : 2007

EN55014-1 : 2006

EN55014-2 : 1997

EN61000-3-2 : 2006

EN61000-3-3 : 1995

The undersigned acts on behalf and under the power of attorney of the company

management,

Philippe Vankerkhove

Certification Manager

Date: 07/04/2008

Copyright © 2010 VARO P a g e | 16 www.varo.com

Loading...

Loading...