Page 1

POW6127

1

APPLICATION .................................................................................. 3

2

DESCRIPTION ................................................................................. 3

3

PACKAGE CONTENT LIST ............................................................. 3

4

SYMBOLS ........................................................................................ 4

5

GENERAL POWER TOOL SAFETY WARNINGS .......................... 4

5.1

Working area ........................................................................................................... 4

5.2

Personal safety ....................................................................................................... 4

5.3

Power tool use and care ......................................................................................... 5

5.4

Service ..................................................................................................................... 5

6

PETROL SAFETY WARNINGS ....................................................... 5

7

FUEL ................................................................................................. 6

7.1

Fuel and oil mixture ................................................................................................ 6

7.1.1 Mixing fuel ................................................................................................................. 6

7.2

Refuelling ................................................................................................................ 6

7.3

Storage of fuel ......................................................................................................... 7

8

OPERATING INSTRUCTIONS ........................................................ 7

8.1

Starting the engine .................................................................................................. 7

8.1.1 Cold starting .............................................................................................................. 7

8.1.2 Hot starting ............................................................................................................... 8

8.2

Stopping the engine ................................................................................................ 8

8.3

Angle change of rear handle .................................................................................. 8

8.3.1 How to change the angle: .......................................................................................... 8

8.3.2 Vertical operation ...................................................................................................... 9

EN

9

MAINTENANCE ............................................................................... 9

9.1

Blade lubrication ................................................................................................... 10

9.2

Safety lock ............................................................................................................. 10

9.3

Air cleaner ............................................................................................................. 11

9.4

Air cooling ............................................................................................................. 11

9.5

Sparking Plug ........................................................................................................ 11

9.6

Gearbox ................................................................................................................. 12

9.7

Silencer .................................................................................................................. 12

Copyright © 2010 VARO P a g e | 1 www.varo.com

Page 2

POW6127

9.7.1 After 100 hours of use ............................................................................................. 12

9.7.2 Maintenance before storage .................................................................................... 12

10

CLEANING ..................................................................................... 12

11

STORAGE ...................................................................................... 12

12

STARTING UP AFTER LONGER PERIODS OF INACTIVITY ..... 13

13

TECHNICAL DATA ........................................................................ 13

14

SERVICE DEPARTMENT .............................................................. 13

15

TROUBLE SHOOTING .................................................................. 14

16

WARRANTY ................................................................................... 15

17

ENVIRONMENT ............................................................................. 15

18

DECLARATION OF CONFORMITY .............................................. 16

EN

Copyright © 2010 VARO P a g e | 2 www.varo.com

Page 3

POW6127

EN

HEDGE TRIMMER 22.5 CC

POW6127

1 APPLICATION

The hedge trimmer should be used only for trimming hedges, bushes and shrubs. Other

uses of the trimmer not mentioned in this manual may damage the trimmer or seriously

injure the operator and are therefore expressly excluded from the application range.

It is not designed for commercial use.

WARNING! For your own safety, read this manual and the general safety

instructions carefully before using the appliance. Your power tool should

only be given to other users together with these instructions.

2 DESCRIPTION

1. Blades

2. Shield

3. Front handle

4. Choke lever

5. Silencer cover

6. Air filter cover

7. Primer pump

3 PACKAGE CONTENT LIST

Remove all packaging materials.

Remove remaining packaging and packing inserts (if included).

Check that the package contents are complete.

Check the appliance, the power cord, the power plug and all accessories for transportation

damage.

Keep the packaging materials as far as possible until the end of the warranty period. Then

take it to your local waste disposal system.

8. Starter rope

9. Fuel tank

10. Fuel cap

11. Ignition switch

12. Throttle lock

13. Throttle trigger

14. Rear handle

WARNING Packaging materials are not toys! Children must not play with

plastic bags! There is a danger of suffocation!

1 manual

1 bottle of oil

Tool kit: One socket spanner, one open-ended spanner, one screwdriver with two ends,

for both standard slotted screws and Phillips screws, and two Allen spanners.

If any parts are missing or damaged, please contact your dealer.

Copyright © 2010 VARO P a g e | 3 www.varo.com

Page 4

POW6127

4 SYMBOLS

The following symbols are used in this manual and/or on the machine:

EN

Denotes risk of personal

injury or damage to the tool.

Read manual before use

Wear noise protection

Wear eye protection

In accordance with essential

safety standards of

applicable European

directives

No naked flame Fuel and oil mixture

Keep hands away from blades. Do not touch the blades when starting or

while operating the unit.

Wear a mask In dusty

conditions

Never operate the machine in

the rain or in damp or wet

conditions. Moisture is an

electrical shock hazard.

Wear gloves

Wearing of protective shoes

advised

No smoking

5 GENERAL POWER TOOL SAFETY WARNINGS

5.1 Working area

Keep working area clean and well lit. Untidy and dark areas can lead to accidents.

Do not operate power tools in potentially explosive surroundings, for example, in the

presence of inflammable liquids, gases or dust. Power tools create sparks which may

ignite the dust or fumes.

Keep children and bystanders at a distance when operating a power tool. Distractions can

cause you to lose control of it.

5.2 Personal safety

Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use a power tool when you are tired or under the influence of drugs, alcohol or

medication. A moment of inattention when operating a power tool may result in serious

personal injury.

Use safety equipment. Always wear eye protection. Using safety equipment such as a

dust mask, non-skid safety shoes, a hard hat, or hearing protection whenever it is needed

will reduce the risk of personal injury.

Copyright © 2010 VARO P a g e | 4 www.varo.com

Page 5

POW6127

Avoid accidental starts. Ensure the switch is in the off position before inserting the plug.

Carrying power tools with your finger on the switch or plugging in power tools when the

switch is in the on position makes accidents more likely.

Remove any adjusting keys or spanners before turning on the power tool. A spanner or

key left attached to a rotating part of the power tool may result in personal injury.

Do not reach out too far. Keep your feet firmly on the ground at all times. This will enable

you retain control over the power tool in unexpected situations.

Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and

gloves away from the power tool. Loose clothes, jewellery or long hair can become

entangled in the moving parts.

If there are devices for connecting dust extraction and collection facilities, please ensure

that they are attached and used correctly. Using such devices can reduce dust-related

hazards.

5.3 Power tool use and care

Do not expect the power tool to do more than it can. Use the correct power tool for what

you want to do. A power tool will achieve better results and be safer if used in the context

for which it was designed.

Do not use the power tool if the switch cannot turn it on and off. A power tool with a broken

switch is dangerous and must be repaired.

Disconnect the plug from the power source before making adjustments, changing

accessories, or storing power tools. Such preventive safety measures reduce the risk of

starting the power tool accidentally.

Store power tools, when not in use, out of the reach of children and do not allow people

who are not familiar with the power tool or these instructions to operate it. Power tools are

potentially dangerous in the hands of untrained users.

Maintenance. Check for misalignment or jammed moving parts, breakages or any other

feature that might affect the operation of the power tool. If it is damaged, the power tool

must be repaired. Many accidents are caused by using poorly maintained power tools.

Keep cutting tools sharp and clean. Properly maintained cutting tools with sharp cutting

edges are less likely to jam and are easier to control.

Use the power tool, accessories and cutting tools, etc., in accordance with these

instructions and in the manner intended for the particular type of power tool, taking into

account the working conditions and the work which needs to be done. Using a power tool

in ways for which it was not intended can lead to potentially hazardous situations.

5.4 Service

Your power tool should be serviced by a qualified specialist using only standard spare

parts. This will ensure that it meets the required safety standards.

EN

6 PETROL SAFETY WARNINGS

WARNING: Use extra care when handling fuels. They are inflammable and

the vapours are potentially explosive. The following points must be

observed.

Use only an approved container.

Never remove the fuel cap or add fuel when the engine is running. Allow engine exhaust

components to cool before refuelling.

Do not smoke.

Never refuel the machine indoors.

Never store the machine or fuel containers in places where there is a naked flame, such

as a water heater.

Copyright © 2010 VARO P a g e | 5 www.varo.com

Page 6

POW6127

If fuel is spilt, do not attempt to start the power source before moving the machine away

from the spillage area.

Always replace and securely tighten the fuel cap after refuelling.

Whenever the tank is drained, this should be done outdoors.

EN

7 FUEL

7.1 Fuel and oil mixture

For best results use regular unleaded petrol mixed with 2-stroke air-cooled engine oil on a

ratio of 25:1.

WARNING: Never use unmixed petrol in your engine. This will cause

permanent damage and void the manufacturer’s warranty for the product.

Never use a fuel mixture that has been stored for more than 30 days.

WARNING: 2-stroke lubricant must be a premium grade oil for 2-stroke aircooled engines mixed at a 25:1 ratio. Do not use any 2-stroke oil product with

a recommended mix ratio of 100:1. If insufficient lubrication is the cause of

engine damage, it voids the manufacturer’s engine warranty.

7.1.1 Mixing fuel

Pour oil into an approved fuel canister followed by the petrol so that the petrol can mix with

the oil. Shake container to ensure a thorough mix.

WARNING: Lack of lubrication voids engine warranty. Petrol and oil must be

mixed at a 25:1 ratio.

7.2 Refuelling

The engine must be switched off.

Stop the engine during refuelling, keep away from naked flames and do not smoke.

Take care not to spill either fuel or oil in order to prevent soil contamination (environmental

protection). Clean the hedge trimmer immediately after fuel has been spilt.

Do not spill any fuel onto the engine. Wipe up if necessary to avoid fire.

Avoid any fuel contact with your clothing. Change your clothing instantly if fuel has been

split on it (to prevent it catching fire).

Inspect the fuel cap at regular intervals, making sure that it can be securely fastened and

does not leak.

Carefully tighten the fuel tank cap. Change location to start the engine (at least 3 metres

away from the place of refuelling).

Never refuel in enclosed rooms. Fuel vapours accumulate at ground level. (risk of potential

explosions).

Transport and store fuel only in approved containers. Make sure the fuel stored is not

accessible to children.

Thoroughly clean the area around the tank cap to prevent dirt from getting into the fuel

tank.

Unscrew the plug and fill the tank with fuel. Use a gauge funnel to filter the fuel.

Tightly screw on the plug by hand only.

Clean around the screw plug and the tank after refuelling.

Always wipe up any spilt fuel to prevent a fire.

Copyright © 2010 VARO P a g e | 6 www.varo.com

Page 7

POW6127

7.3 Storage of fuel

Fuel cannot be stored for an unlimited period of time.

Purchase only the quantity required for a 4-week operating period.

Use approved fuel storage containers only.

EN

8 OPERATING INSTRUCTIONS

8.1 Starting the engine

Move at least 3 metres away from the place of refuelling. Place the hedge trimmer on a

clean area of ground and make sure that the cutting tool does not come into contact with the

ground or any other objects.

Keep the blades clear of everything around, since they will start moving as

soon as the engine starts.

8.1.1 Cold starting

If the engine is cold or if it has been stopped for more than 5 minutes or if fuel has been

added to the engine.

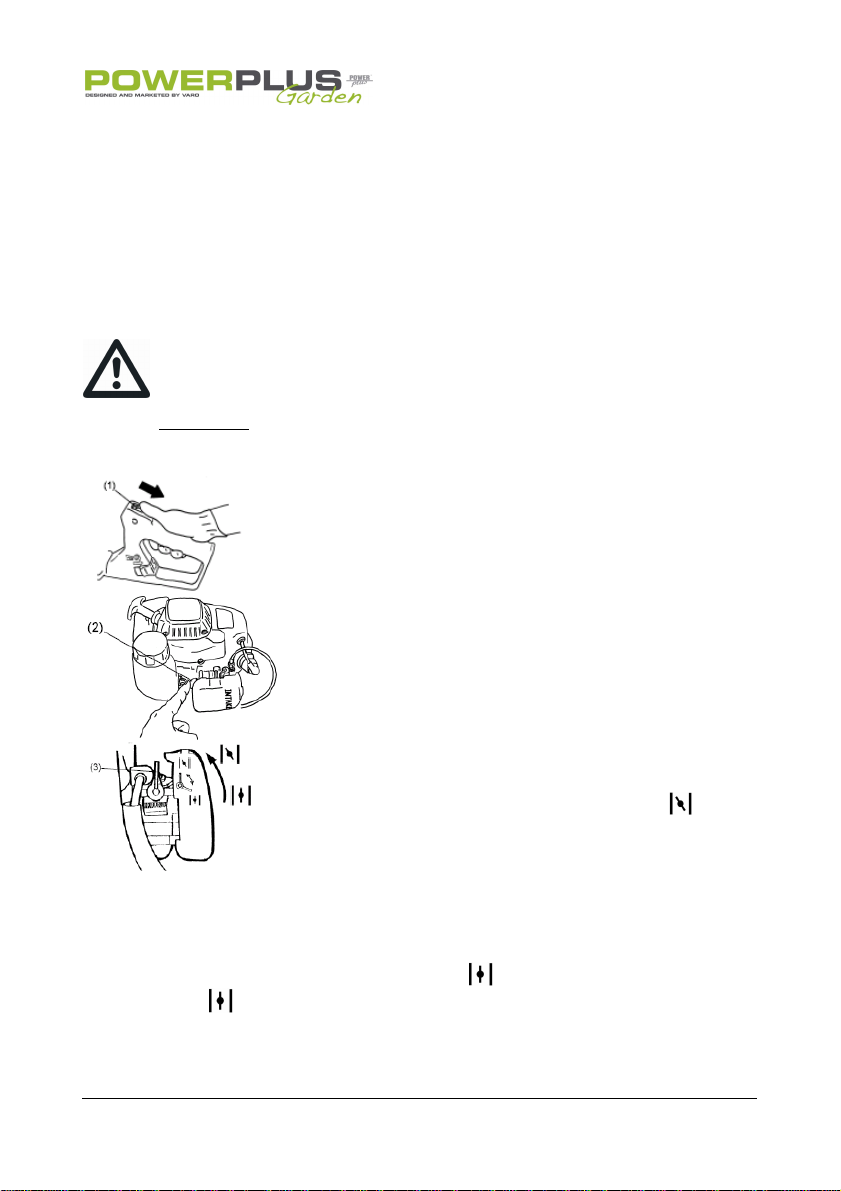

Push the I-O switch (1) to the “I” position

Push the primer pump gently (7 to 10 times) until

fuel begins to flow into it

Move the choke lever (3) to position “ ”

Hold the unit down firmly so that you will not lose control while cranking the engine. If not

held down properly, the engine could make you lose your balance or swing the cutting

blade into a nearby object or your body.

Pull out the starter handle slowly (10 to 15 cm), and check the pressure.

Pull strongly when you feel the pressure and start the engine.

When the engine starts, return the choke lever to “ ”. Please note that the choke lever

will return to “

opened.

Run the engine for approximately one minute at a moderate speed before moving up to

full speed.

Copyright © 2010 VARO P a g e | 7 www.varo.com

” position automatically when the throttle lever is moved and the throttle is

Page 8

Note: When restarting the engine immediately after stopping it, leave the

POW6127

choke open.

Note: Overchoking can make it hard to start the engine due to excess fuel. If

the engine fails to start after several attempts, open the choke and pull the

rope again, or remove the sparking plug and dry it.

8.1.2 Hot starting

Restarting immediately after the engine has stopped. When restarting a hot engine, first try

the above procedure: 1,2,4,5,6. If the engine does not start, repeat the above steps.

Do not pull the rope to the end or return it by releasing the knob. This can

cause starter failures.

8.2 Stopping the engine

Release the throttle lever completely.

Move the engine switch to the “O (STOP)”

position. The engine will now slow down and

stop.

Note: If the engine does not stop after moving the switch, close the choke to

make it stop.

EN

8.3 Angle change of rear handle

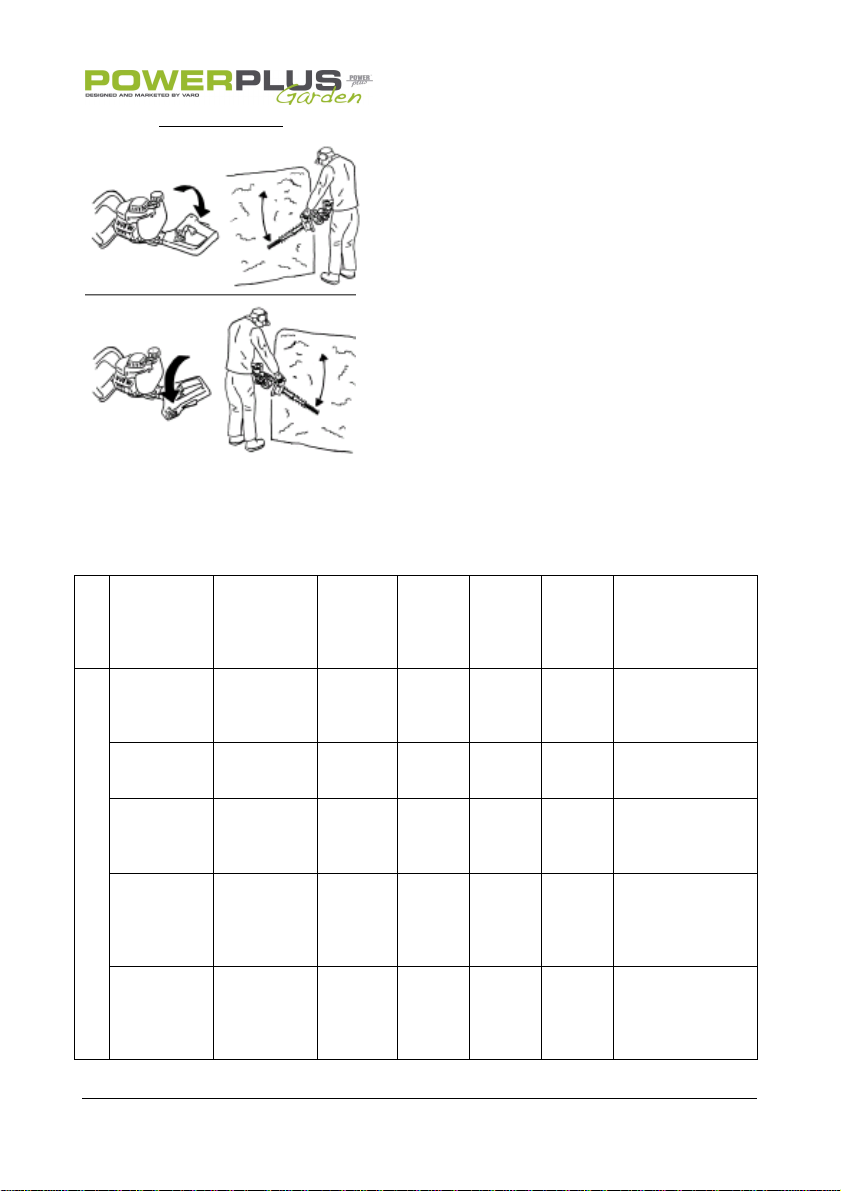

To permit vertical operation of the unit, the angle of the rear handle can be changed.

To reduce fatigue when trimming hedges, the handle can be swivelled 90° to the left or to the

right.

8.3.1 How to change the angle:

Push back the throttle lever, and rotate the rear

handle, pulling the rotation locking pin.

Rotate the rear handle 90 degrees to the right or

to the left.

After completing the rotation, release the locking

pin. To secure the rear handle, hold the rotation

locking pin gently with one finger.

Use only as much throttle as is needed to do the job. Excessive engine speed is

unnecessary.

Tilting the trimmer 5 to 10° towards the object to be cut will make things easier and

produce good results.

Always keep to the carburettor side of your trimmer, and never to the silencer side.

During the first few minutes when a new machine is first used, grease may come out of

the gearbox. Since this is excess grease, it is not a cause for alarm. Just wipe it off when

the engine has stopped.

Copyright © 2010 VARO P a g e | 8 www.varo.com

Page 9

POW6127

8.3.2 Vertical operation

When rotating the rear handle to the right, hold

the rear handle with your right hand, and the

front handle with your left hand.

When rotating the rear handle to the left, hold

the front handle with your right hand, and the

rear handle with your left hand. Cut using a

circular movement.

EN

9 MAINTENANCE

Our machines have been designed to operate for a long period of time with a minimum of

maintenance. Continuous and satisfactory operation presupposes proper machine care and

regular cleaning.

System /

compone

nt

Fuel

leaks,

fuel

spillage

Fuel tank,

air filter,

fuel filter

Idle

adjusting

screw

Sparking

plug

Cylinder

fins,

intake air

cooling

vent

Procedure Befor

Wipe up V

Inspect/cl

ean

See

adjusting

idling

speed

Clean

and

readjust

electrode

gap

Clean V

e use

V V

V

V

Ever

y 25

hour

s

Ever

y 50

hour

s

Ever

y

100

hour

s

note

Replace if

necessary

Replace

carburettor if

necessary

GAP: 0,60,7mm, replace

if necessary

Copyright © 2010 VARO P a g e | 9 www.varo.com

Page 10

POW6127

Shaft

Silencer,

spark

arrester,

cylinder

exhaust

port

Throttle

lever,

ignition

switch

Cutting

parts

Gearbox Grease V

Screw/nu

ts/bolts

9.1 Blade lubrication

Clean V

Check

operation

Replace

if

somethin

g is

wrong

Tighten/r

eplace

Warning: Before cleaning, inspecting, or repairing the unit, make sure that

the engine has stopped and is cool.

Warning: before lubricating, be sure your unit is switched off and that the

blade has come to a complete stop.

V

V

V V

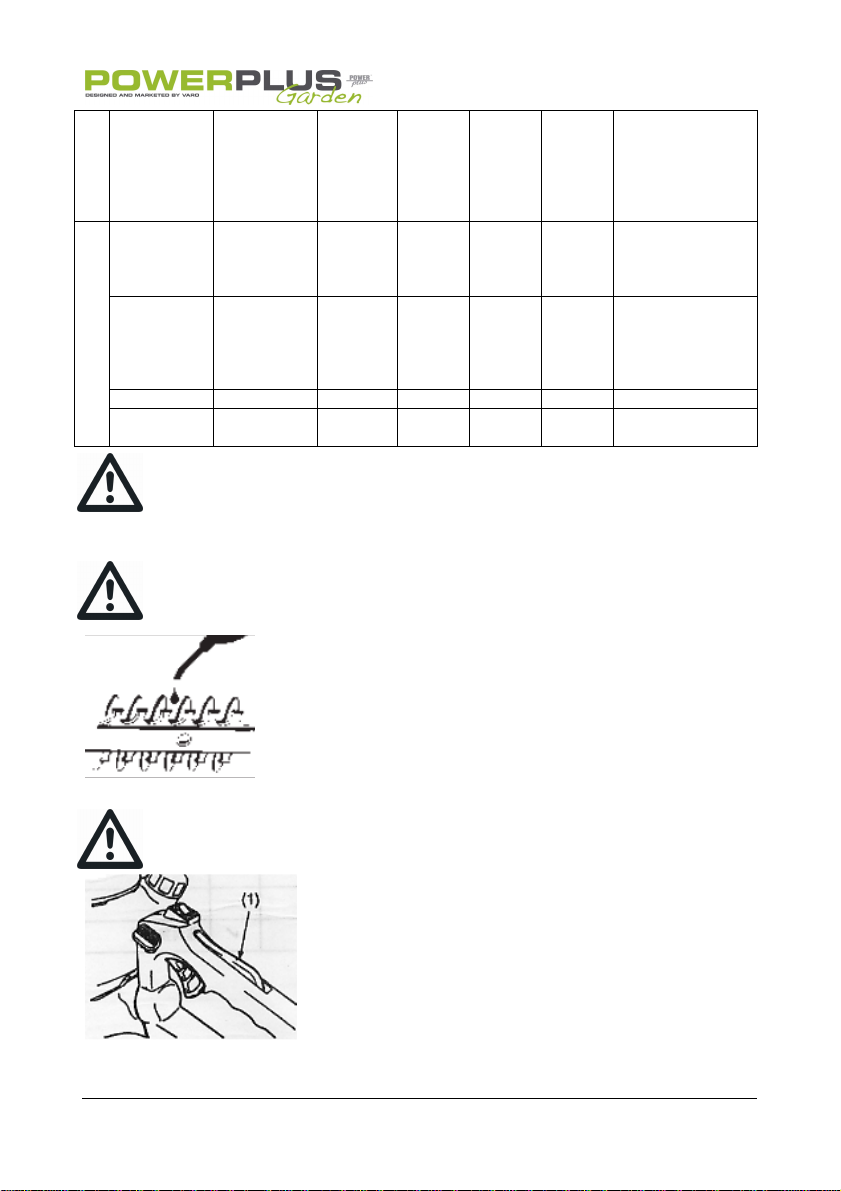

For easier operation and longer blade life,

lubricate the blade before and after each use.

Apply light machine oil along the edge of the

blade bar.

Not adjusting

screws

EN

9.2 Safety lock

Warning: Stop using the trimmer if the safety lock is defective.

Safety lock is the device which stops the throttle

lever from being activated unintentionally. If you

push the safety lock, you will activate the throttle

lever.

Copyright © 2010 VARO P a g e | 10 www.varo.com

Page 11

Safety lock:

Check that the throttle lever does not move if you do not push the safety lock.

Check that the throttle lever moves if you activate or release it while pushing the safety

lock.

Check that the safety lock returns to its original position if you take your hand from safety

lock.

If these checks reveal any defects, contact your nearest dealer and ask to have them

repaired.

9.3 Air cleaner

Important: a clogged air cleaner reduces engine performance. Operating with no element or

with a bent or damaged element causes irregular wear and tear of the engine mechanism.

9.4 Air cooling

This engine is air-cooled. Dust clogging up the air cooling inlet port and the cylinder fins will

cause the engine to overheat. Periodically check and clean the cylinder fins after removing

the air cleaner and the cylinder cover.

9.5 Sparking Plug

POW6127

Release the air cleaner cover and remove the

dust.

If the element is dirty, clean it by tapping it or by

blowing away the dirt.

If the element is bent or damaged, replace it.

After you have cleaned the element reattach it to

the cleaner body with the stamp on the outside

(facing the cleaner cover).

After that, replace the cleaner cover.

EN

Starting problems and misfiring are often caused

by a fouled sparking plug. Periodically clean the

sparking plug, and replace with a new one as and

when required.

Important: When dismounting the plug cap, be careful not to remove the

seal. Operating the engine without the seal may cause the engine to

overheat.

Important: When inserting the sparking plug, first screw it in with your

fingers, and then tighten it with the help of a suitable plug spanner. Overtightening will damage the cylinder and the piston.

Copyright © 2010 VARO P a g e | 11 www.varo.com

Page 12

POW6127

9.6 Gearbox

Apply multipurpose grease after every 25 hours of use.

9.7 Silencer

9.7.1 After 100 hours of use

Check to see if any oil or grease has worked its

way in between the clutch lining and drum, and if

it has, wipe it away using oil-free and unleaded

petrol.

9.7.2 Maintenance before storage

Use a dry rag to wipe away any fuel which has

been spilt onto the unit.

Extract fuel from the tank and run the engine

until it stops naturally.

Remove the sparking plug and put in 1-2cc of

2-stroke oil in the engine. Pull the starter rope

2-3 times, set the plug back, and stop it at the

contraction position.

Apply anti-rust oil to the metal parts such as the

throttle wire, etc., put the cover on the blade,

and keep it indoors to avoid exposing it to

dampness.

EN

10 CLEANING

Use a damp cloth to clean the plastic parts.

Do not use any detergents, solvents or pointed objects.

11 STORAGE

So that the hedge trimmer will work again after a long period of inactivity, you should

observe the following points:

Empty the petrol tank. To do this, start the engine and let it run until it reaches a standstill.

Dispose of the remaining petrol in an environmentally friendly way.

Let the engine cool and take out the sparking plug.

Pour a small spoonful of 2-stroke mixture into the sparking plug opening and slowly pull

the starter cord right through to the end several times. This gets rid of small deposits of

rust and lubricates the piston and cylinder.

Check the sparking plug and replace it if too much of the firing tip has been burnt off.

Keep the blade in a dry place – out of the reach of fire.

Copyright © 2010 VARO P a g e | 12 www.varo.com

Page 13

POW6127

EN

12 STARTING UP AFTER LONGER PERIODS OF INACTIVITY

Remove the sparking plug.

Quickly pull the starter cord right through several times in order to remove oil and deposits

in the engine compartment.

Check the sparking plug, replace it if necessary and screw it in.

Fill the petrol tank with the 2-stroke mixture.

13 TECHNICAL DATA

Engine Type Air-cooled, -2-cycle power stroke engine

Engine displacement 22.5cc

Double blade cutting

Cutting length 520mm

Overall length 600mm

Cutting speed 2000r/min

Cutting capacity 21mm

Knife distance 20mm

Output power 650W

Engine oil / petrol mixed ratio 1:25

Starter type Recoil starter

Fuel tank capacity 650ml

14 SERVICE DEPARTMENT

Damaged switches must be replaced by our after-sales service department.

If the connecting cable (or mains plug) is damaged, it must be replaced by a special

connecting cable which is available from our service department. Replacement of the

connecting cable should only be carried out by our service department (see last page) or by

a qualified specialist (qualified electrician).

Copyright © 2010 VARO P a g e | 13 www.varo.com

Page 14

15 TROUBLE SHOOTING

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

POW6127

EN

Unit won’t start

or starts but

will not run.

Unit starts, but

engine has

low power.

Engine

sputters.

No power

under load.

Runs

erratically.

Smokes

excessively.

Incorrect starting

procedures.

Incorrect carburettor

mixture adjustment

setting.

Fouled sparking plug.

Empty fuel tank.

Primer bulb was not

pressed enough.

Fuel filter is plugged.

Incorrect lever position.

Dirty spark arrester

screen.

Dirty air filter.

Incorrect carburettor

mixture adjustment setting

service dealer.

Incorrect carburettor

mixture adjustment

setting.

Air filter is plugged.

Old or improperly mixed

fuel.

Incorrect carburettor

mixture adjustment

setting.

Old or improperly mixed

fuel.

Air filter is plugged.

Fouled spark plug.

Incorrectly gapped

sparking plug.

Plugged spark arrester.

Dirty air filter.

Incorrect carburettor

mixture adjustment

setting.

Incorrect fuel mixture.

Follow instructions in the User

Manual.

Have carburettor adjusted by an

Authorized Service Centre.

Clean/gap or replace plug.

Fill fuel tank with properly mixed

fuel.

Press primer bulb fully and slowly 10

times.

Replace the fuel filter.

Move to RUN position.

Replace spark arrester screen.

Remove, clean and reinstall filter.

Have carburettor adjusted by an

Authorized Service Centre.

Have carburettor adjusted by an

Authorized Service Centre.

Replace or clean the air filter.

Drain gas tank/add fresh fuel

mixture.

Have carburettor adjusted by an

Authorized Service Centre.

Drain gas tank /add fresh fuel

mixture.

Replace or clean the air filter.

Clean/gap or replace plug.

Clean/gap or replace plug.

Clean or replace spark arrester.

Clean or replace air filter.

Have carburettor adjusted by an

Authorized Service Centre.

Use properly mixed fuel (25:1

mixture).

Copyright © 2010 VARO P a g e | 14 www.varo.com

Page 15

POW6127

EN

16 WARRANTY

This product is warranted as provided by law for a 24 -month period effective from the

date of purchase by the first user.

This warranty covers all material or production flaws. It does not include defective parts

subject to normal wear & tear such as bearings, brushes, cables, and plugs, or

accessories such as drills, drill bits, saw blades, etc. ; damage or defects resulting from

maltreatment, accidents or alterations; nor the cost of transportation.

We reserve the right to reject a claim whenever the purchase cannot be verified or when it

is clear that the product has not been properly maintained. (Clean ventilation slots, carbon

brushes serviced regularly, etc.).

Your purchase receipt must be kept as proof of date of purchase.

Your appliance must be returned undismantled to your dealer in an acceptably clean state,

(in its original blow-moulded case if applicable to the unit), accompanied by proof of

purchase.

17 ENVIRONMENT

Should your appliance need replacement after extended use, do not dispose of it with the

household refuse, but in an environmentally safe way.

Please dispose of used motor oil in a manner that protects the environment. We suggest you

take it in a sealed container to your local service station for recycling. Do not throw it into the

refuse or pour it on the ground.

Copyright © 2010 VARO P a g e | 15 www.varo.com

Page 16

POW6127

18 DECLARATION OF CONFORMITY

EN

VARO N.V. - Joseph Van Instraat 9 - BE2500 Lier - BELGIUM, declares that,

product: Hedge trimmer 22.5cc

trade mark: POWERplus

model: POW6127

is in conformity with the essential requirements and other relevant provisions of the applicable

European Directives as they relate to European harmonized standards. Any unauthorized

modification of the apparatus voids this declaration.

European Directives, and their amendments:

2004/108/EG De Richtlijn Elektromagnetische Compatibiliteit

98/37//EG De Machinerichtlijn

2000/14/EG Richtlijn geluidsemissie voor materieel voor gebruik buitenshuis

LwA = 108dB

97/68/EG Emissierichtlijn voor niet voor de weg bestemde mobiele machines

Motorklasse = SH2

keuringsinstantie: VCA, Bristol

European harmonized standards, and their amendments:

EN744 : 1996

EN ISO14982 : 1998

The undersigned acts on behalf of and under the power of attorney granted by the company

management,

Philippe Vankerkhove

Certification Manager

03/09/08

Copyright © 2010 VARO P a g e | 16 www.varo.com

Loading...

Loading...