Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

24-inch Wood Planer

Model WP2412

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-0460285

Ph.: 800-274-6848 Revision B 6/04

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared f or the owner and operators of a P owermatic Model WP 2412 Planer. Its

purpose, aside f rom machine oper ation, is to promot e safety using acc epted operati ng and maint enance

procedures. To obtai n maximum lif e and efficiency from your planer and to ai d in using it saf ely, please

read this manual thoroughly and follow the instructions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located throughout the United St ates can provide quick service or information.

In most cases, a WM H Tool Group Repair Station can as si st in authorizing r epair work, obtaini ng par ts, or

perform routi ne or m ajor maintenance repair on your Powermatic product.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEAR LI MITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the produc t at our discret ion, or r efund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specifi c legal right s; you m ay also have ot her right s, which

vary from state t o state.

WMH Tool Group sells through distributor s only. Members of the WMH Tool Group reserve t he right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................6

Description..............................................................................................................................................6

Specifications..........................................................................................................................................6

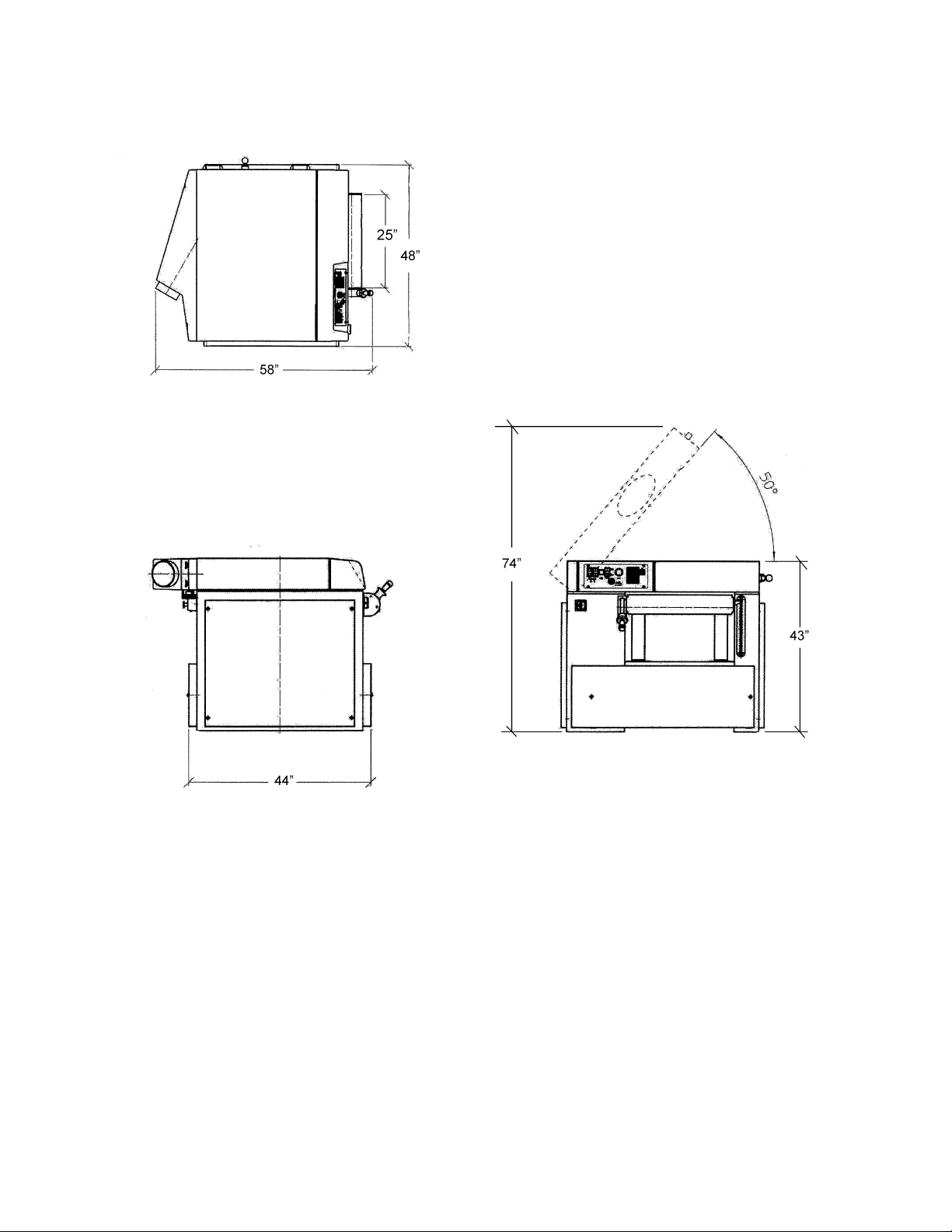

WP2412 Planer Dimensions ....................................................................................................................7

Unpacking...............................................................................................................................................8

Contents of the Shipping Container......................................................................................................8

Installation...............................................................................................................................................9

Electrical Connections..........................................................................................................................9

Dust Collection...................................................................................................................................10

Adjustments...........................................................................................................................................10

Controls .............................................................................................................................................10

Calibrating Digital Display...................................................................................................................11

Changing Fuses.................................................................................................................................12

Changing Knives................................................................................................................................12

Belt Tension & Replacement.............................................................................................................. 13

Drive Chain Replacement................................................................................................................... 13

Feed Rollers.......................................................................................................................................14

Table Rollers......................................................................................................................................14

Maintenance..........................................................................................................................................14

Troubleshooting: Operating Problems....................................................................................................15

Troubleshooting: Mechanical & Electric al P r oblem s ...............................................................................16

Replacement Parts................................................................................................................................18

Parts List: Drawing No. 1....................................................................................................................19

Drawing No. 1....................................................................................................................................21

Parts List: Drawing No. 2....................................................................................................................22

Drawing No. 2....................................................................................................................................23

Parts List: Drawing No. 3....................................................................................................................24

Drawing No. 3....................................................................................................................................25

Parts List: Drawing No. 4....................................................................................................................26

Drawing No. 4....................................................................................................................................27

Parts List: Drawing No. 5....................................................................................................................28

Drawing No. 5....................................................................................................................................29

Parts List: Electrical Box.....................................................................................................................30

Electrical Box.....................................................................................................................................31

Parts List: Control Panel.....................................................................................................................32

Electrical Connections – 230 Volt...........................................................................................................33

Electrical Connections – 230 Volt...........................................................................................................34

3

Page 4

Warning

1. Read and understand the entire owners manual befor e attempti ng assem bly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This planer i s designed and intended f or use by properly trai ned and experienced personnel onl y. If

you are not familiar with the proper and safe operation of a planer, do not use until proper training and

knowledge have been obtained.

5. Do not use this planer f or other t han its intended use. If used for other pur poses, WMH Tool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Al ways wear ap prov ed saf ety glasses/f ac e shiel ds whil e u sing thi s pl aner. Everyday eyegl asses onl y

have impact resistant lenses; they are not safet y gl asses.

7. Before operating t his planer, remove tie, ri ngs, watches and other jewelry , and roll sleeves up past

the elbows. Rem ove all l oose clothing and confine long hair . Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tir ed or under t he i nfluence of drugs, alcohol or any medication.

11. Mak e c ertain the switch is in the OFF position before connecting the machine to the power supply.

12. Mak e c ertain the machine is properl y grounded.

13. Mak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting tools and wrenches. Form a habit of checking to see that adjusting tools and

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately after maint enanc e is com plete.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

17. Pr ov ide for adequate space surroundi ng work ar ea and non-glare, ov er head lighting.

18. Keep the floor around the machi ne cl ean and free of scrap material, oil and grease.

19. Keep v isitors a safe distance from the work area. Keep children away.

4

Page 5

blahblahblah

20. Mak e y our workshop child proof wit h padl oc k s, m aster switches or by removing starter keys.

21. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

22. Maintain a bal anced stance at all times so that you do not fall or lean against t he knives or other

moving part s. Do not over r eac h or use exc essive force to perform any machine oper ation.

23. Use the right t ool at the corr ect speed and f eed rat e. Do not forc e a tool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and safer.

24. Use recom mended accessories; improper accessories may be hazardous.

25. Mai ntain tools with care. K eep knives sharp and clea n for the best and saf est performance. Foll ow

instructions for lubricating and changing accessories.

26. T ur n off the machine before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

27. Do not stand on the machine. Serious injur y c ould oc c ur if the m ac hine tips over.

28. Never leave the machine r unning unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

29. Remove loose items and unnecessary work pi eces from the area before starting the machine.

Familiarize you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in mi nor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for a Model WP2412 Powermatic Planer. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordance wi th

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

Description

This multi-featured 15 horsepower pl aner is built for the rugged, industrial environment . It features a quick

change Tersa

and dual drive chains and sprockets. The cutterhead and infeed and outfeed rollers have double

bearings. The pl aner frame is built with heav y plate steel, and the cast i ron table is supported by f our

massive col umns – this mac hine will not vi brate under load. Knif e changes are qui ck wit h the self- seating

knives. The planer will ac c om odate rough to finish work, and multiple piece planing.

TM

cutterhead with rev ersible knives, segmented i nfeed roller with secti onal chip break er,

Specifications

Model Number............................................................................................................................. WP2412

Stock number..............................................................................................................................1791295

Main motor (TEFC).......................................................................................15HP, 3Ph, 230V, 60Hz, 60A

Table raising motor (TEFC)............................................................................................................0.75HP

Feed Motor (TEFC).............................................................................................................................1HP

Variable feed speed (f t/min.).........................................................................................................16 to 72

Cutterhead speed (RPM) .......................................................................................................... 5200 RPM

Cutterhead diameter (in).....................................................................................................................4.75

Knives TERSA

Max. chip removal single pass (in)..................................................................................................0.3125

Serrated infeed roller (in)....................................................................................................................2.75

Outfeed rollers (in)..............................................................................................................................2.75

Table dimensions (in)................................................................................................................24.8 x 45.6

Thickness capaci ty (in) ..........................................................................................................................12

Dust port (in)............................................................................................................................................6

Belts......................................................................................................................................three V-belts

Overall dimensions (in LxWxH)...............................................................................................58 x 48 x 43

Overall dimensions (crated) (in LxWxH)..................................................................................63 x 53 x 49

Net weight (lbs).................................................................................................................................2,310

Shipping weight (lbs).........................................................................................................................2,640

TM

(in).................................................................................................................four @ 25”

The above specifications were current at the time this manual was published, but because of our policy of

continuous im provement, WHM Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

6

Page 7

WP2412 Planer Dimensions

7

Page 8

Unpacking

Open shipping crate and check for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Read this

instruction manual thoroughly for assembly,

maintenance and safety instructions.

Contents of the Shipping Container

1 Planer

3 Lifting hooks

4 Open-end wrenches (10, 13-17, 19-22, and

24mm)

5 Hex wrenches (4, 5, 6, 8 and 10mm)

1 Brass punch

1 Owner's manual

1 Warranty card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mpl y may cause seri ou s injury.

8

Page 9

Installation

Tools required for installation

wrench set (provided)

level

forklift or cr ane with straps

1. Remove the crate from around the planer

and any fasteners secur ing t he pl aner to t he

skid.

2. Remove the side covers and place t he lifting

hooks into the slot s (Figure 1). Place straps

under them and l if t t he machi ne off the ski d.

The planer should be located on a sturdy

floor, pref erably concrete, in a dry area with

sufficient lighting. Leave enough space

around the machine for loading and

offloading stock and routine maintenance

work.

3. When the planer is situated, use the leveling

screws (Figur e 2) to lev el the mac hine.

4. Exposed metal areas of the planer have

been factory coated with a protectant. This

should be removed with a soft cloth and

kerosene. Do not use an abrasive pad. Do

not let solvent contact the plastic parts of

the machine, as it may damage t hem .

Figure 1

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. The

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The planer may be fitt ed with a 230 volt plug, or

may be “hard-wired” directly to your electrical

panel. If hard-wired to a panel, make sure a

disconnect i s available for the operator.

IMPORTANT: The 230 volt model of the

WP2412 planer is wired for 230 volt only; it is

not convertible to 460 volt.

1. Make sure the machine’s plug is

disconnected f rom the power source. If it is

hard-wired, m ake sure the fuses hav e been

removed or t he breakers hav e been tripped

in the circuit to which the saw will be

connected. Pl ace a warning placard on the

fuse holder or circuit breaker to prevent it

being turned on while the machine i s being

wired. Always follow proper Lock Out/Tag

Out procedures when perf orming any wiri ng

on this machine.

Figure 2

9

Page 10

2. Make sure the voltage of the power source

corresponds to the v oltage of the pl aner as

recorded on the mot or pl ate.

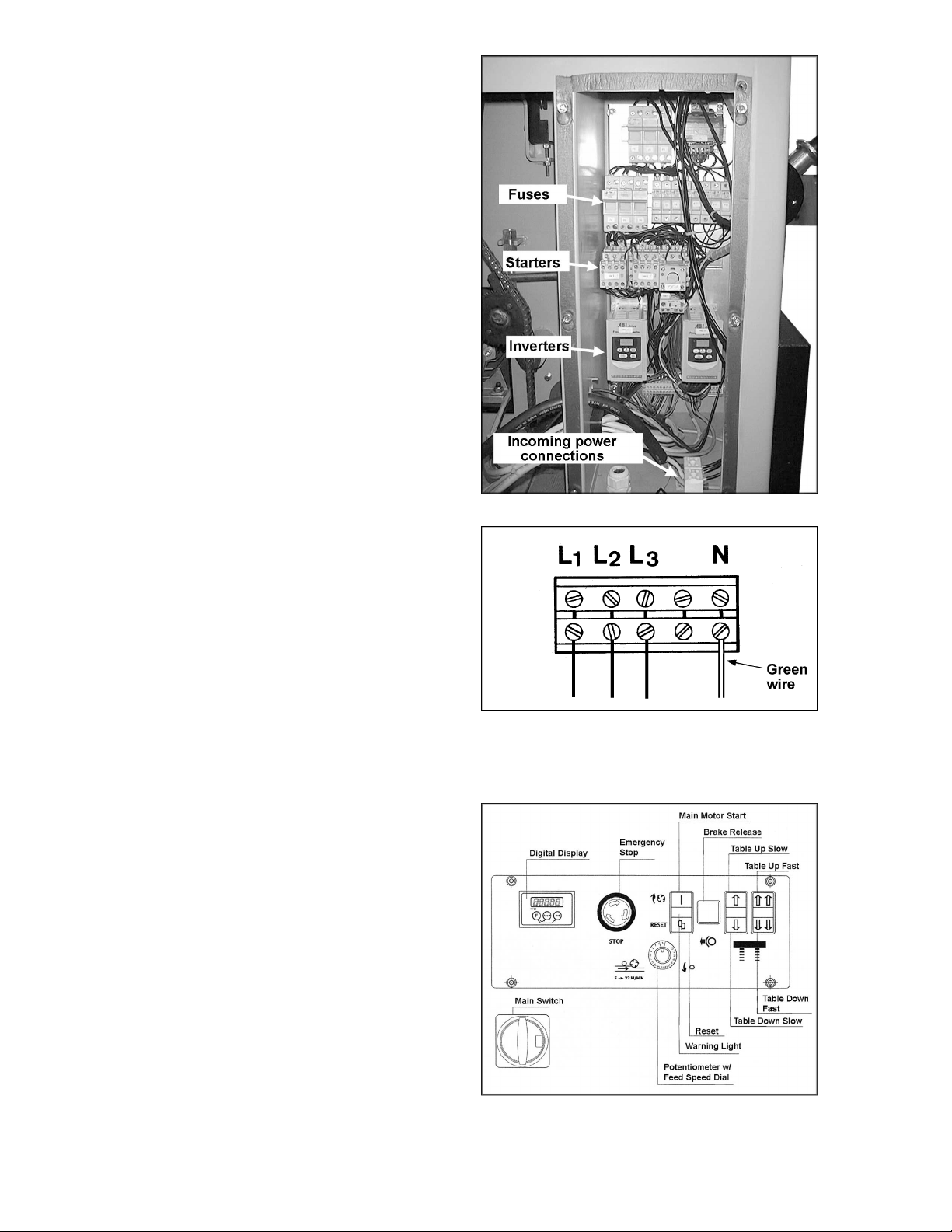

3. Open the electrical enclosure on the left

side of the machi ne (Figure 3) by loosening

the screws and sliding the panel upward.

4. Connect the three phases to the terminals

marked L1, L2, L3 (Figur e 4) .

5. Connect the green neutral wire to terminal

“N”.

6. Connect the mac hine to power (or install t he

fuses or reset the breakers at the power

source).

7. Test the rotation of the cutterhead. Turn on

the main power switch (see Figure 5) and

then the main m otor switch (Figure 5) . The

pulley on the main mot or (on the side near

the electrical enclosure) should rotate

counterclockwise. If it rotates clockwise,

stop the machine with the red stop button

(Figure 5 ).

8. Disconnect machine from power source,

and exchange leads L1 and L2.

Figure 3

9. Reconnect power, and close the electrical

cover.

Dust Collection

It is strongly recommended this planer be

connected to a dust extraction system, via the 6”

(160mm) dust port at the rear of the planer. Your

dust collector should have at least 1500 CFM

capacity.

Adjustments

Controls

Figure 5 shows the control panel for the planer.

Starting procedure

NOTE: The planer will not start if the hood is

raised, or if the brake release light is on (see

below).

1. Turn Main Switch to position “I”. [NOTE: The

main switch has a lock-out hole, through

which a padlock or similar device can be

inserted, when the swit c h is in “O” position]

Figure 4

2. Push the Mai n M otor S tart butt on; t he mot or

will start in Star-Delta. After a few seconds

you will hear the motor switch over to full

speed operation. NOTE: The inverters (see

Figure 3) have been factory programmed

and their setti ngs should not be altered.

Figure 5

10

Page 11

3. The Reset button (Figure 5) will light up if

the machine becomes overloaded. Press

this button to re- start the machine.

4. The Emergenc y Stop Butt on shuts down all

operations on the planer. An automatic

brake stops the m otor within 10 secon ds. A

similar stop but ton can be found at the back

of the machine. To restart the machine,

simply twist the stop button and allow it to

pop back up

5. To begin the feed motor and rotati on of the

feed roll ers, press the Potentiom eter button

on the dial. Rotate the dial to set the feed

speed. Speed ranges fr om 16 to 72 feet per

minute. The num bers on the dial are shown

as 1 to 11; the higher t he number , t he faster

the speed. To stop the feed mot or press the

Potentiom eter butt on again.

6. The Brake Release switch frees the

cutterhead so t hat it can be mov ed by hand

(e.g. when changing knives). When the

brake release is o n, the switch stays lit. As a

safety feature, the planer’s motor will not

start if t he brake release switch is l it. And if

the switch i s pushed during operat ions, the

motor will automatically stop. To restart the

planer, de-press the brake release switch;

the light will turn off.

7. To raise the table press the up-arrow

buttons; to l ower the table pr ess the downarrow buttons. The single arrows raise the

table slowly, t he double arrows rapidly.

Calibrating Digital Display

Before operating the planer, the digital display

should be checked for accuracy and c alibrated if

necessary. Use a scrap board.

1. Set the table to just under t he thickness of

your scrap board, u si ng the scale next to t he

table (Fi gure 6). Feed t he board thr ough the

planer to achiev e a planed si de.

2. Raise the table slightly until the adjoining

scale pointer is set evenly on a number.

3. Fli p the board over and f eed it through the

planer, then c arefully measure it s thickness

with calipers. Compare this with the digital

display.

4. If the display needs correcting, press and

hold “Function,” and press “Reset”. The

display will return to zero.

5. Press and hold “Function,” and press “Set”

until the di splay shows the thi ck ness of your

board. Tapping the “Set” button will move

the display by increments; hol ding down the

“Set” button will move the display rapidly.

Figure 6

11

Page 12

Changing Fuses

Disconnect pl aner f rom power source, and o pen

the electri cal enclosure. Pull open the cov er on

a fuse holder, as shown in Figure 7, and slide

out the old f use. Replace it with a new one of

the proper amperage. Close the cover.

Do not use a fuse with

amperage rating different than what is listed

on the cover of the fuse holder.

Changing Knives

The planer has a Ters aTM Monobloc cutt erhead.

Knife changing is simple, and the two-sided

knives are self seating once the cutterhead

begins rotating. Tersa

from your dealer or most woodworking supply

stores.

Do not l oosen any screws o n

the cutterhead .

1. Push brake release button (see Figure 5).

The brake release light will come on.

2. Pull out on the lever at the ri ght side of the

machine, and r aise the hood.

After prolonged use of the

planer, the cast iron frame and areas aroun d

the cutterhead may be hot.

3. Disconnect machine from power source.

4. Rotate the cutterhead to gain access to a

knife. Use the provided brass punch to

gently tap down the segmented gibs, as

shown in Figure 8. This will release the

knife.

TM

knives are available

Figure 7

Figure 8

5. Align the knife and caref ully slide it through

the hole in the side of the bearing casting

(Figure 9).

6. To install a new knife (or the same knife

reversed for a new edge), insert it through

the hole. Make sure the knife is properly

seated upon the bead (Figure 8) and the

ends are not prot rudi ng past t he end s of the

cutterhead. When the machine is started

later, the gibs will automatically secure the

knife in place.

7. Repeat this procedure for the other three

knives.

8. Lower the hood and reconnec t power to t he

machine. Press the brake release button

(Figure 5). The warning light will go out.

Figure 9

12

Page 13

9. After adjusting or changing knives, the

digital display should be checked and

recalibrated if necessary. See “Calibrating

Digital Displ ay .”

Belt Tension & Replacement

Note: Belts should be replaced as a matched set

of three.

1. Loosen the three bol ts (A, Fi gure 10) which

hold the motor support br ac k et to the frame.

2. Turn the hex nuts (B, Figure 10) on the

tension rod as needed.

3. When finished, tighten the three bolts (A,

Figure 10).

Drive Chain Replacement

The drive chains do not require tension

adjustment, since tension is always assured

by an idle chain tensi oner ( C, Fi gur e 11) .

To replace the main drive chain, pull the

tensioner (C, Figure 11) backward and

remove the c hain from around the sprockets.

When the new chain has been mounted,

always make sure the ten sioner is well plac ed

on the chain.

To replace the chain for the table raising

mechanism, pull the lever (D, Figure 12) to

the back and remove the chain. When the

new chain has been m ounted, pu sh the lev er

(D, Figure 12) bac k into posi tion.

Figure 10

Figure 11

Do not tu rn th e sprockets o n

the table raising screws with the chain

removed. Doing so will mi sali gn the t abl e.

Figure 12

13

Page 14

Feed Rollers

The infeed and out feed rollers and chipbreaker

have been factory set. However, if spring

tension adjustment should ever be necessary,

use the appropriate adjustment assembly

located beneath the lip of the frame – one is

shown in Figure 13.

1. Loosen the nut and t urn the screw in or out.

When finished, tighten nut.

2. Perform the same adjustment at the

opposite end of the rol ler.

Table Rollers

The table roll ers can be raised or lowered with

the handle (Figure 14). A label is affixed near

the handle for ref er enc e.

Maintenance

Before any intervention on

the machine, di sconnect it from the electrical

supply by pulling out the plug or switching

off the main switch! Follow lockout/tagout

procedures. Failure to comply may cause

serious injury.

The anti-kickback fingers m ust hang down f reely

and operate independently by gravity. They

should be inspected frequently and cleaned

whenever necessary.

Figure 13

Figure 14

The table should be k ept clean and free of rust

or deposits.

The lead screws and posts beneath the table,

and the driv e chains, should be kept clean and

oiled.

Periodic ally blow out saw dust from the motor’s

cooling fan.

14

Page 15

Troubleshooting: Operating Problems

Trouble Probable Cause Remedy

Table rollers not set pr oper ly. Adjust rollers to proper height.

Snipe

(NOTE: Snipe can be

minimized but not

eliminated)

Fuzzy Grain

Torn Grain

Rough or Raised

Grain

Inadequate support of long boards.

Uneven feed roller pressure front to

back.

Dull knives. Reverse or replace knives.

Lumber not butted properly.

Planing wood with high moisture

content.

Dull knives. Reverse or replace knives.

Too heavy a cut. Adjust proper dept h of cut.

Knives cutting against grain. Cut along the grain.

Dull knives. Reverse or replace knives.

Dull knives. Reverse or replace knives.

Too heavy a cut. Adjust proper dept h of cut.

Moisture cont ent too high.

Support long boards wit h ex tension

rollers.

Adjust feed roller tension.

Butt end to end each piece of stock

as they pass through.

Remove moisture content from wood

by drying, or choose other stoc k .

Remove moisture content from wood

by drying, or choose other stoc k .

Rounded, glossy

surface

Poor feeding of

lumber

Dull knives. Reverse or replace knives.

Feed speed too slow. Increase speed.

Cutting dept h too shal low. Increase depth.

Adjust feed roller tension. If proper

Inadequate f eed r oller pressure.

Planer bed rought or dirty.

Transmission v-belt slipping. Tighten transmission v-belt.

Surface of feed rollers too smooth.

Bed rollers too low.

tension cannot be achieved, replace

feed rollers.

Clean pitch and residue, and wax

planer tabl e.

Lightly roughen t he feed roller surface

with sandpaper.

Raise bed roll er s to proper dept h for

stock.

15

Page 16

Troubleshooting : Mechanical & Electrica l Problems

Trouble Probable Cause Remedy

Board thickness does

not match digital

display

Digital displ ay not calibrated properly. Foll ow calibration procedures.

Chain jumping

Machine will not

start/restart or

repeatedly t rips

circuit breaker or

blo ws fu ses.

Inadequate chain tension. Adjust chai n tension.

Sprockets mi sali gned. Align sprockets.

Sprockets worn. Replace sprockets.

No incoming power.

Overload aut omatic reset has not

reset.

Planer frequently trips.

Verify unit is connected to power, and

main switch is set to “I”.

When planer overl oads on the ci r c uit

breaker built into the motor starter, it

takes time for the machine to cool

down before restar t. Allow unit to

adequately cool bef ore attempting

restart. If pr oblem persists, check

amp setting on the mot or start er

inside the electrical enclosure.

One cause of overl oading trips which

are not electric al in nature is too

heavy a cut. The solution is to take a

lighter cut. If too deep a c ut is not t he

problem, then chec k the amp setting

on the overload rel ay . Match the full

load amps on the motor as noted on

the motor plate. If amp setting is

correct then ther e is probably a loose

electric al lead. Check amp setting on

motor starter.

Building circuit breaker trips or fuse

blows.

Loose electri c al c onnec tions.

Motor starter failure.

Verify that planer is on a circuit of

correct size. If circuit size is correct,

there is probabl y a loose el ectr ic al

lead. Check amp setting on motor

starter.

Go through all the electrical

connections on the planer including

motor connecti ons, verifying the

tightness of each. Look for any signs

of electrical ar ci ng whic h is a sure

indicator of loose connections or

circuit overload.

Examine motor star ter for burned or

failed component s. If damage is

found, replace motor starter. If motor

starter look s okay but is still suspect,

you have two options: Have a

qualified elec trician test the motor

starter for function, or purchase a new

starter and establish if that was the

problem on changeout . (continued)

16

Page 17

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly t rips

circuit breaker or

blo ws fu ses.

Motor starter failure.

Motor failure.

Miswiring of the unit.

If you have access to a voltmeter, you

can separate a starter f ailure from a

motor fai lu re by fi r st, verify ing

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20. If incoming voltage is incorrect,

you have a power supply problem. If

voltage between start er and m otor is

incorrect, y ou hav e a starter pr oblem.

If voltage bet ween start er and m otor

is correct, you hav e a motor pr oblem .

If electri c mot or i s suspect, you have

two options: Have a qualified

electrician test the motor for function

or remove the motor and take it t o a

qualified elec tric motor repair shop

and have it tested.

Double check to confirm all electrical

connections are cor r ec t and properly

tight. The elect ri c al c onnec tions other

than the motor are pre- assembled

and tested at the factory. Therefore,

the motor connections should be

double checked as the highest

probability for error. If problems

persist, double c hec k the factory

wiring.

On/off switch failure.

If the on/off switch is suspect, you

have two options: Hav e a qualified

electrician test the switch for function,

or purchase a new on/off switc h and

establish if that was the pr oblem on

changeout.

17

Page 18

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:00 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quic kly and

accurately.

18

Page 19

Parts List: Drawing No. 1

Index No. Part No. Description Size

1............... WP2412-101........... Outfeed Roll er ...................................................

2............... WP2412-102........... Chipbreaker Section..........................................

2a.............WP2412-102A......... Chipbreaker Section Spacer..............................

3............... WP2412-103........... Spring Bar.........................................................

3a.............TS-1504081............Socket Head Cap Screw........................M8 x 40

4............... WP2412-104........... Spring................................................................

5............... WP2412-105........... Socket Set Screw................................M16 x 16

6............... WP2412-106........... Suction Outlet Cover..........................................

6a.............WP2412-106A......... Dust Hood Assembly .........................................

7............... WP2412-107........... Chipbreaker Axle...............................................

8............... WP2412-108........... ABS Chip Deflector............................................

8a.............TS-1482021............Hex Cap Scr e w......................................M6 x 12

8b.............TS-1550041............Flat Washe r.................................................. M6

10.............WP2412-110........... Tersa

11.............WP2412-111........... Infeed Roller Axle ..............................................

11a...........WP2412-111A......... Infeed Section Spacer........................................

11b...........WP2412-111B......... Infeed Serrated Roller Section ...........................

11c...........WP2412-111C......... Infeed Roller S ection S pri ng...............................

11d...........WP2412-111D......... Complete Infeed Roll Assembly .........................

12.............WP2412-112........... Chipbreaker Section..........................................

12a...........WP2412-112A......... Chipbreaker Section Spacer..............................

13.............WP2412-113........... Anti-K ic k b a ck Finger..........................................

13a...........WP2412-113A......... Anti-K ic k b a ck Finger Spacer..............................

14.............WP2412-114........... Anti-K ic k b a ck Finger Axle..................................

15.............WP2412-104........... Spring................................................................

16.............WP2412-116........... Chipbreaker Axle...............................................

17.............WP2412-103........... Spring Bar.........................................................

17a...........TS-1504081............Socket Head Cap Screw........................M8 x 40

18.............WP2412-105........... Socket Set Screw................................M16 x 16

19.............TS-2279351............Socket Set Screw................................M10 x 35

20.............TS-1540071............Hex Nut.......................................................M10

21.............WP2412-121........... Planer Table......................................................

22.............TS-1525041............Socket Set Screw................................M10 x 20

23.............WP2412-123........... Roller Actuator Axle...........................................

24.............WP2412-124........... Roller Raise Eccentrics......................................

25.............WP2412-125........... Roller Raise Actuator.........................................

26.............WP2412-126........... Strip...................................................................

27.............TS-1550061............Flat Washe r.................................................. M8

28.............TS-1490061............Hex Cap Scr e w......................................M8 x 35

29.............WP2412-129........... Spacer...............................................................

30.............WP2412-130........... Right Brace........................................................

30a...........WP2412-130A......... Left Brace..........................................................

31.............WP2412-131........... Table Column....................................................

32.............WP2412-132........... Table Raise Nut.................................................

33.............TS-1524051............Socket Set Screw..................................M8 x 20

34.............TS-1490031............Hex Cap Scr e w......................................M8 x 20

35.............WP2412-135........... Upper Column Disc............................................

36.............WP2412-136........... Table Column Seal Ring....................................

37.............WP2412-137........... Lower Column Backup Disc...............................

38.............WP2412-138........... Table Raising Screw..........................................

38a...........WP2412-138A......... Table Raising Screw Assembly..........................

41.............BB-51104................Table Raise Screw Bearing ......................51104

43.............BB-51104................Table Raise Screw Bearing.......................51104

46.............TS-1490051............Hex Cap Scr e w......................................M8 x 30

47.............TS-1550061............Flat Washe r.................................................. M8

48.............WP2412-148........... Bearing Housing................................................

TM

Monobloc Cutt erhead............................

19

Page 20

Index No. Part No. Description Size

49.............WP2412-149........... Table Raise Sprocket.........................................

50.............WP2412-150........... Spacer Disc.......................................................

................. WP2412-151........... Top Cover Plate (not shown)..............................

................. WP2412-152........... Rear Frame Reinforcement (not shown).............

................. WP2412-153........... Top Cover Corner Strip (not shown)...................

................. WP2412-154........... Brass Punch - Knife Change (not shown)...........

20

Page 21

Drawing No. 1

21

Page 22

Parts List: Drawing No. 2

Index No. Part No. Description Size

1............... TS-1541041 ............ Nylon Insert Locknut....................................M10

2............... TS-1550071 ............ Flat Wash er.................................................M10

3............... WP2412-203........... Upper Feed Roller Adjust Stud...........................

4............... WP2412-204........... Feed Roller Bearing Housing .............................

5............... WP2412-205........... Outfeed Roll er F eed Chain ................................

6............... WP2412-206........... E-Stop Housing .................................................

7............... WP2412-207........... Short Chain Tensioner Assembly.......................

8............... WP2412-208........... Tensioner Spring ...............................................

9............... WP2412-209........... Hood Raising Lift ...............................................

10.............WP2412-208........... Tensioner Spring ...............................................

11.............WP2412-211........... Long Chain Tensioner Assembly........................

12.............WP2412-212........... Feed Chain........................................................

13.............TS-1541031............Nylon Insert Locknut..................................... M8

15.............WP2412-215........... Lower Feed Roller Adjust Stud ...........................

16.............TS-1540061............Hex Nut........................................................ M8

17.............WP2412-217........... Feed Roller Pressure Bracket ............................

18.............WP2412-218........... Feed Roller Pressure Spring..............................

19.............WP2412-219........... Table Roller Handle...........................................

20.............WP2412-220........... Handle Spring....................................................

21.............WP2412-221........... Locking Handle..................................................

22.............WP2412-222........... Lever.................................................................

23.............TS-1504041............Socket Head Cap Screw........................M8 x 20

24.............WP2412-224........... Bushing.............................................................

25.............WP2412-123........... Roller Actuator Axle...........................................

26.............TS-1525041............Socket Set Screw................................M10 x 20

27.............WP2412-227........... Handle Cover Plate............................................

22

Page 23

Drawing No. 2

23

Page 24

Parts List: Drawing No. 3

Index No. Part No. Description Size

1............... WP2412-301........... Main Bearing Housing, Left................................

2............... BB6209VV ............. Cutterhead Bearing.............................6209-2RS

3............... WP2412-303........... Retaining Ring...................................................

4............... WP2412-304........... Disc...................................................................

5............... TS-2312241 ............ Hex Jam Nut................................................M24

6............... WP2412-306........... Hood Latch........................................................

7............... WP2412-307........... Hood Latch Pin..................................................

8............... WP2412-308........... Main Bearing Housing, Right..............................

9............... TS-1524051 ............ Socket Set Screw..................................M8 x 20

10.............WP2412-310........... Cutterhead Pulley..............................................

12.............WP2412-312........... Disc...................................................................

13.............TS-1515031............Socket Head Flat Screw.........................M8 x 25

14.............WP2412-314........... Hood Hinge .......................................................

15.............WP2412-315........... Hinge Pin, Front.................................................

15a...........WP2412-315A......... Hinge Pin, Rear.................................................

16.............WP2412-316........... Hinge Reinforcement Plate ................................

17.............TS-1515031............Socket Head Flat Screw.........................M8 x 25

18.............TS-1504041............Socket Head Cap Screw........................M8 x 20

19.............WP2412-319........... Adjustment Nut..................................................

20.............WP2412-320........... Belt Adjustment Rod..........................................

21.............WP2412-321........... Drive Belts.........................................................

22.............WP2412-322........... Motor Pulley.............................38mm arbor dia.

23.............WP2412-323........... Washer..............................................................

24.............TS-1515041............Socket Head Flat Screw.........................M8 x 30

25.............WP2412-325........... Frame Leveling Bolt...........................................

25a...........WP2412-325A......... Leveling Bolt Nut................................................

24

Page 25

Drawing No. 3

25

Page 26

Parts List: Drawing No. 4

Index No. Part No. Description Size

1............... WP2412-401........... Hood Handle......................................................

2............... WP2412-121........... Planer Table......................................................

3............... BB6003VV ............. Table Roller Bearing........................... 6003-2RS

4............... WP2412-404........... Table Roller.......................................................

5............... WP2412-405........... Bushing.............................................................

6............... TS-1490041 ............ Hex Cap Screw......................................M8 x 25

7............... TS-1550061 ............ Flat Wash er.................................................. M8

8............... WP2412-125........... Roller Raise Actuator.........................................

9............... WP2412-409........... Side Strip...........................................................

10.............BB6003VV ............. Table Roller Bearing...........................6003-2RS

12.............TS-1491041............Hex Cap Scr e w....................................M10 x 30

13.............WP2412-413........... Feed Axle..........................................................

14.............WP2412-414........... Feed Unit Assembly ...........................................

15.............BB-6006VV ............ Feed Unit Bearing...............................6006-2RS

16.............WP2412-416........... Retainer Ring.....................................................

17.............WP2412-417........... Sprocket............................................................

18.............WP2412-418........... Sprocket Spacer................................................

19.............TS-1550061............Flat Washe r.................................................. M8

20.............TS-1490031............Hex Cap Scr e w......................................M8 x 20

21.............WP2412-421........... Retaining Ring...................................................

22.............WP2412-422........... Spacer...............................................................

23.............BB-6003VV ............ Bearing...............................................6003-2RS

24.............WP2412-424........... Sprocket Assembly............................................

25.............WP2412-425........... Retainer Ring.....................................................

26.............WP2412-426........... Bushing.............................................................

27.............BB-6003VV ............ Bearing...............................................6003-2RS

28.............BB-6005VV ............ Feed Roller Beari ngs ..........................6005-2RS

29.............WP2412-429........... Retaining Ring...................................................

30.............WP2412-430........... Bushing.............................................................

31.............WP2412-105........... Socket Set Screw................................M16 x 16

32.............WP2412-432........... Outfeed Roller Sprocket Mount..........................

32a...........WP2412-432A......... Infeed Roller Sprocket Mount.............................

33.............WP2412-433........... Sprocket............................................................

34.............WP2412-434........... Spacer...............................................................

35.............WP2412-433........... Sprocket............................................................

36.............WP2412-436........... Bushing Spacer.................................................

37.............TS-2342161............Nylon Insert Locknut....................................M16

38.............TS-155010..............Flat Wash er.................................................M16

26

Page 27

Drawing No. 4

27

Page 28

Parts List: Drawing No. 5

Index No. Part No. Description Size

1............... WP2412-501........... Main Motor............................. 15HP, 230V, 3Ph

2............... WP2412-502........... Feed Motor with Reducer.............................1HP

3............... WP2412-503........... Spring................................................................

4............... WP2412-504........... Gear Box Mounting Plate...................................

5............... WP2412-505........... Table Raising Chain...........................................

6............... TS-1550061 ............ Flat Wash er.................................................. M8

7............... TS-1490111 ............ Hex Cap Screw......................................M8 x 60

8............... WP2412-508........... Front Cover.......................................................

9............... WP2412-509........... Side Cover.........................................................

10.............TS-1490081............Hex Cap Scr e w......................................M8 x 45

11.............WP2412-511........... Plate..................................................................

12.............WP2412-512........... Plate Spanner....................................................

13.............WP2412-513........... Support Plate .....................................................

14.............WP2412-514........... Toothed Lever ...................................................

15.............WP2412-515........... Spring................................................................

16.............WP2412-516........... Adjustment Pawl................................................

17.............WP2412-517........... Table Raise Motor with Reducer...............3/4HP

18.............WP2412-518........... Rear Cover........................................................

19.............TS-1490111............Hex Cap Scr e w......................................M8 x 60

20.............TS-1550061............Flat Washe r.................................................. M8

................. WP2412-LH ............ Lifting Hooks (not shown)...................................

28

Page 29

Drawing No. 5

29

Page 30

Parts List: Electrical Box

Index No. Part No. Description Size

A ..............W P2412-601...........Fuse Holder...................................3 poles, 50 A

B ..............W P2412-602...........Fuse Holder......................................1 pole, 32A

C.............. WP2412-603........... Magnetic Starter................................................

D.............. WP2412-604........... Auxiliary Contact................................................

E ..............W P2412-605...........Mechanical Interlock between Mag. Starters......

F...............WP2412-606...........Timer Relay Star-Delta......................................

G..............WP2412-607........... Thermal Overload Relay....................................

H.............. WP2412-608........... Transformer.......................................................

I ................WP2412-609........... Frequency V ari ator............................................

30

Page 31

Electrical Box

31

Page 32

Parts List: Control Panel

Index No. Part No. Description Size

J...............W P2412-701...........Main On-O ff S witch............................................

K ..............W P2412-702...........ELGO Read-out Z 20.........................................

L............... WP2412-703........... E-Stop Operator.................................................

M..............WP2412-704........... Motor On/Table Reset Operator.........................

N.............. WP2412-705........... Brake Release Operator....................................

O..............WP2412-706........... Table Slow Operator..........................................

P ..............W P2412-707...........Table Fast Operator...........................................

Q..............WP2412-708........... Potentiometer....................................................

................. WP2412-709........... ELGO Magnetic Tape ........................................

................. WP2412-710........... Sensor Cable.....................................................

................. WP2412-711........... Hood Limit Switch..............................................

................. WP2412-712........... Fuse............................................................50A

................. WP2412-713........... Fuse............................................................40A

................. WP2412-714........... Fuse..............................................................6A

................. WP2412-715........... Fuse..............................................................2A

................. WP2412-716........... Fuse..............................................................1A

................. WP2412-717........... Open Contact ....................................................

................. WP2412-718........... Closed Contact..................................................

32

Page 33

Electrical Connections – 230 Volt

33

Page 34

Electrical Connections – 230 Volt

34

Page 35

35

Page 36

WMH Tool Gr ou p

2420 Vantage Drive

Elgin, Illinois 60123

Phone: 800-274-6848

www.wmhtoolgroup.com

36

Loading...

Loading...