Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

Wide Belt Sanders

Models WB-25, WB-37, WB-43

Powermatic

427 New Sanford Rd.

LaVergne, TN 37086 Part No. M-1790825

Ph.: 800-274-6848 Revision D1 03/2014

www.powermatic.com Copyright © 2014 Powermatic

model WB-37 shown

Page 2

1.0 Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa tion

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

2.0 Table of Contents

Section Page

1.0 Warranty and Service ....................................................................................................................... 2

2.0 Table of Contents ............................................................................................................................. 3

3.0 Safety warnings ................................................................................................................................ 5

4.0 Introduction ....................................................................................................................................... 7

5.0 Specifications ................................................................................................................................... 7

6.0 Unpacking ........................................................................................................................................ 8

6.1 Contents of Shipping Container ..................................................................................................... 8

7.0 Assembly .......................................................................................................................................... 9

7.1 Air Supply Connection ................................................................................................................... 9

7.2 Dust Collection .............................................................................................................................. 9

7.3 Installing/Replacing Sanding Belt................................................................................................. 10

8.0 Electrical ......................................................................................................................................... 10

8.1 Grounding Instructions ................................................................................................................ 10

8.2 230 Volt Operation ...................................................................................................................... 11

8.3 460 Volt Conversion .................................................................................................................... 12

8.4 Extension cords ........................................................................................................................... 12

9.0 Adjustments .................................................................................................................................... 12

9.1 Sanding Belt Tracking and Oscillation

9.2 Oscillation Air Flow ...................................................................................................................... 13

9.3 Oscillation Speed ........................................................................................................................ 13

9.4 Platen Position ............................................................................................................................ 14

9.5 Replacing Graphite and Felt Pad ................................................................................................. 14

9.6 V-Belt Tension and Replacement ................................................................................................ 14

9.7 Conveyor Belt Tension ................................................................................................................ 15

9.8 Conveyor Belt Tracking ............................................................................................................... 15

9.9 Feed Rate ................................................................................................................................... 16

9.10 Pressure Bar Adjustment ........................................................................................................... 16

9.11 Table Parallelism ....................................................................................................................... 17

10.0 Operating Controls ........................................................................................................................ 18

10.1 Amperage Meter ....................................................................................................................... 18

10.2 LED Controller and Keypad ....................................................................................................... 18

11.0 Operation ...................................................................................................................................... 19

11.1 Braking System ......................................................................................................................... 19

12.0 Maintenance ................................................................................................................................. 20

13.0 Dust Port Layout ........................................................................................................................... 20

14.0 Troubleshooting the Sander .......................................................................................................... 21

15.0 Troubleshooting the LED Unit ....................................................................................................... 23

16.0 Replacement Parts ....................................................................................................................... 23

16.1.1 Base and Motor Assembly – Model WB-25 ONLY ................................................................... 24

16.1.2 Parts List: Base and Motor Assembly – Model WB-25 ............................................................. 25

16.2.1 Base and Motor Assembly – Model WB-37 ONLY ................................................................... 26

16.2.2 Parts List: Base and Motor Assembly – Model WB-37 ............................................................. 27

16.3.1 Base and Motor Assembly – Model WB-43 ONLY ................................................................... 28

16.3.2 Parts List: Base and Motor Assembly – Model WB-43 ............................................................. 29

16.4.1 Upper Cabinet Assembly – Model WB-25 ONLY ..................................................................... 30

16.4.2 Parts List: Upper Cabinet Assembly – Model WB-25 ............................................................... 31

16.5.1 Upper Cabinet Assembly – Models WB-37, WB-43 ................................................................. 32

16.5.2 Parts List: Upper Cabinet Assembly – Model WB-37 ............................................................... 33

16.5.3 Parts List: Upper Cabinet Assembly – Model WB-43 ............................................................... 33

16.6.1 Table Raising Assembly – Models WB-25, WB-37, WB-43...................................................... 34

16.6.2 Parts List: Table Raising Assembly – Model WB-25 ................................................................ 35

16.6.3 Parts List: Table Raising Assembly – Model WB-37 ................................................................ 36

16.6.4 Parts List: Table Raising Assembly – Model WB-43 ................................................................ 37

16.7.1 Table and Conveyor Belt Assembly – Models WB-25, WB-37, WB-43..................................... 39

16.7.2 Parts List: Table and Conveyor Belt Assembly – Model WB-25 ............................................... 40

16.7.3 Parts List: Table and Conveyor Belt Assembly – Model WB-37 ............................................... 41

16.7.4 Parts List: Table and Conveyor Belt Assembly – Model WB-43 ............................................... 42

........................................................................................... 12

3

Page 4

16.8.1 Pressure Bar Assembly – Models WB-25, WB-37, WB-43 ...................................................... 43

16.8.2 Parts List: Pressure Bar Assembly – Model WB-25 ................................................................. 43

16.8.3 Parts List: Pressure Bar Assembly – Model WB-37 ................................................................. 44

16.8.4 Parts List: Pressure Bar Assembly – Model WB-43 ................................................................. 44

16.9.1 Platen Assembly – Model WB-25 only .................................................................................... 45

16.9.2 Parts List: Platen Assembly – Model WB-25 ........................................................................... 45

16.10.1 Platen Assembly – Models WB-37, WB-43............................................................................ 47

16.10.2 Parts List: Platen Assembly – Model WB-37 ......................................................................... 47

16.10.3 Parts List: Platen Assembly – Model WB-43 ......................................................................... 48

16.11.1 Air Regulator Assembly – Models WB-25, WB-37, WB-43..................................................... 50

16.11.2 Parts List: Air Regulator Assembly – Model WB-25 ............................................................... 50

16.11.3 Parts List: Air Regulator Assembly – Model WB-37 ............................................................... 51

16.11.4 Parts List: Air Regulator Assembly – Model WB-43 ............................................................... 52

16.12.1 Sanding Belt and Accessories – Models WB-25, WB-37, WB-43 ........................................... 53

16.12.2 Parts List: Sanding Belt and Accessories – Model WB-25 ..................................................... 54

16.12.3 Parts List: Sanding Belt and Accessories – Model WB-37 ..................................................... 54

16.12.4 Parts List: Sanding Belt and Accessories – Model WB-43 ..................................................... 54

16.13.1 Tension Roller Assembly – Models WB-25 and WB-37 ONLY ............................................... 55

16.13.2 Parts List: Tension Roller Assembly – Model WB-25 ............................................................. 56

16.13.3 Parts List: Tension Roller Assembly – Model WB-37 ............................................................. 57

16.14.1 Tension Roller Assembly – Model WB-43 ONLY ................................................................... 59

16.14.2 Parts List: Tension Roller Assembly – Model WB-43 ............................................................. 60

16.15.1 Electrical Box Assembly – Models WB-25 and WB-37........................................................... 62

16.15.2 Parts List: Electrical Box Assembly – Model WB-25 .............................................................. 63

16.15.3 Parts List: Electrical Box Assembly – Model WB-37 .............................................................. 64

16.16.1 Electrical Box Assembly – Model WB-43 ONLY .................................................................... 65

16.16.2 Parts List: Electrical Box Assembly – Model WB-43 .............................................................. 66

17.0 Electrical Connections................................................................................................................... 67

17.1 Models WB-25 and WB-37 ONLY .............................................................................................. 67

17.2 Model WB-43 ONLY .................................................................................................................. 68

4

Page 5

3.0 Safety warnings

1. Read and understand the entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This sander is designed and intended for use by properly trained and experienced personnel only. If

you are not familiar with the proper and safe operation of a sander, do not use until proper training

and knowledge have been obtained.

5. Do not use this sander for other than its intended use. If used for other purposes, Powermatic

disclaims any real or implied warranty and holds itself harmless from any injury that may result from

that use.

6. Always wear approved safety glasses/face shields while using this sander. Everyday eyeglasses only

have impact resistant lenses; they are not safety glasses.

7. Before operating this sander, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves. Steel toed shoes are recommended because heav y parts

can fall off the conveyor table onto feet.

8. Wear ear protectors (plugs or muffs) during extended periods of operation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

11. Make certain the switch is in the OFF position before connecting the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

14. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

15. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

16. Provide for adequate space surrounding work area and non-glare, overhead lighting.

17. Keep the floor around the machine clean and free of scrap material, oil and grease.

18. Keep visitors a safe distance from the work area. Keep children aw ay.

5

Page 6

3.0 Safety w arnings

19. Make your workshop child proof with padlocks, master switches or by removing starter keys.

20. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

21. Remove loose items and unnecessary work pieces from the area before starting the machine.

22. Maintain a balanced stance at all times so that you do not fall or lean against the conveyor belt or

other moving parts. Do not overreach or use excessive force to perform any machine operation.

23. Keep hands clear while feeding workpieces onto the conveyor table. The workpiece will be forced

down as it begins to feed into the machine, causing a pinching action between workpiece and

conveyor table.

24. Stand to one side of the conveyor table and do not let anyone else stand in line with the table while a

workpiece is being fed through the machine.

25. Do not attempt to sand stock shorter than 12 inches long without butting a board of equal thickness

behind it to help it through the machine. Do not sand stock less than 1/8” thick.

26. Never reach into a running machine. Turn off and disconnect from power source before attempting to

retrieve parts from within the machine.

27. Use the right tool at the correct speed and feed rate. Do not force a tool or attachment to do a job for

which it was not designed. The right tool will do the job better and safer.

28. Use recommended accessories; improper accessories may be hazardous.

29. Turn off the machine and disconnect from power before cleaning. Use a brush or compressed air to

remove chips or debris — do not use your hands.

30. Do not stand on the machine. Serious injury could occur if the machine tips over.

31. Never leave the machine running unattended. Turn the power off and do not leave the machine until

all parts come to a complete stop.

Familiariz e you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

6

Page 7

4.0 Introduction

This manual is provided by Powermatic covering the safe operation and maintenance procedures for a

Powermatic WB Series Wide Belt Sander. This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance instructions and parts breakdown. This machine

has been designed and constructed to provide years of trouble free operation if used in accordance with

instructions set forth in this manual. If there are any questions or comments, please contact either your

local supplier or Powermatic. Powermatic can also be reached at our web site: www.powermatic.com.

5.0 Specifications

Model Number ............................................ WB-25 ................................ WB-37 ............................. WB-43

Stock Number.......................................... 1790825 ............................. 1790837 ...........................1790843

Working Width (in.) ............................................ 25 ....................................... 37 .................................... 43

Maximum Stock Thickness (in.) ........................... 6 .........................................6 ...................................... 6

Minimum Stock Thickness (in.) ......................... 1/8 ...................................... 1/8 ................................... 1/8

Minimum Board Length (in.) ............................... 12 ....................................... 12 .................................... 12

Table Height from Floor (in.) ......... 31-3/8 to 37-3/8 .................. 31-3/8 to 37-3/8 ................31-3/8 to 37-3/8

Main Drive Motor ................ 15HP, 3Ph, 230/460V* ........20HP, 3Ph, 230/460V* ..... 25HP, 3Ph, 230/460V*

Power Feed Motor .................................. 1HP, 3Ph ............................ 1HP, 3Ph ......................... 2HP, 3Ph

Table Hoist Motor ................................ 1/4HP, 3Ph ......................... 1/4HP, 3Ph ...................... 1/4HP, 3Ph

Sanding Belt Size (in.) ................................. 25x75 ................................. 37x75 ...............................43x75

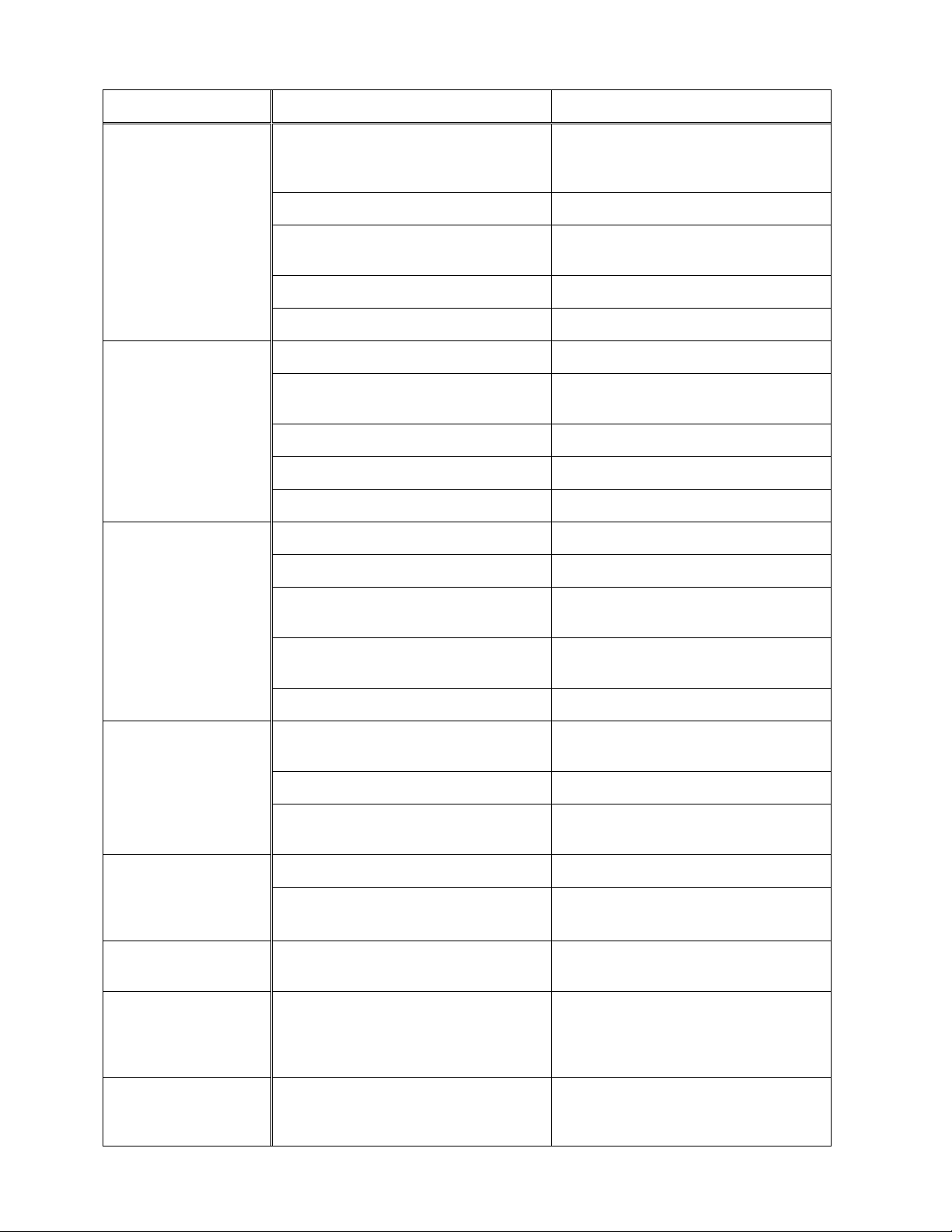

Dust Ports ................................ two @ 5” diameter ............three @ 5” diameter ......... three @ 5” diameter

Dust Collection CFM Required ......................... 800 ................................... 1600 ................................ 1900

Required Air Pressure (PSI)...................... 75 to 80 .............................. 75 to 80 ........................... 75 to 80

Overall Dimensions (LxWxH/in.) ......... 53 x 45 x 72 ........................53 x 58 x 72 ..................... 53 x 65 x 72

Gross Weight (lbs.) ....................................... 1,760 .................................. 2,090 ............................... 2,530

Net Weight (lbs.) ........................................... 1,650 .................................. 1,970 ............................... 2,400

* NOTE: The sander is pre-wired 230V. Conversion to 460V requires the purchase and installation of two

overload relays. See parts list for stock numbers.

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, Powermatic reserves the right to change specifications at any time and without

prior notice, without incurring obligations.

7

Page 8

6.0 Unpacking

Open shipping container and check for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the sander is

installed and running properly.

Compare the contents of your container with the

following parts list to make sure all parts are

intact. Missing parts, if any, should be reported

to your distributor. Read this instruction manual

thoroughly for assembly, maintenance and

safety instructions.

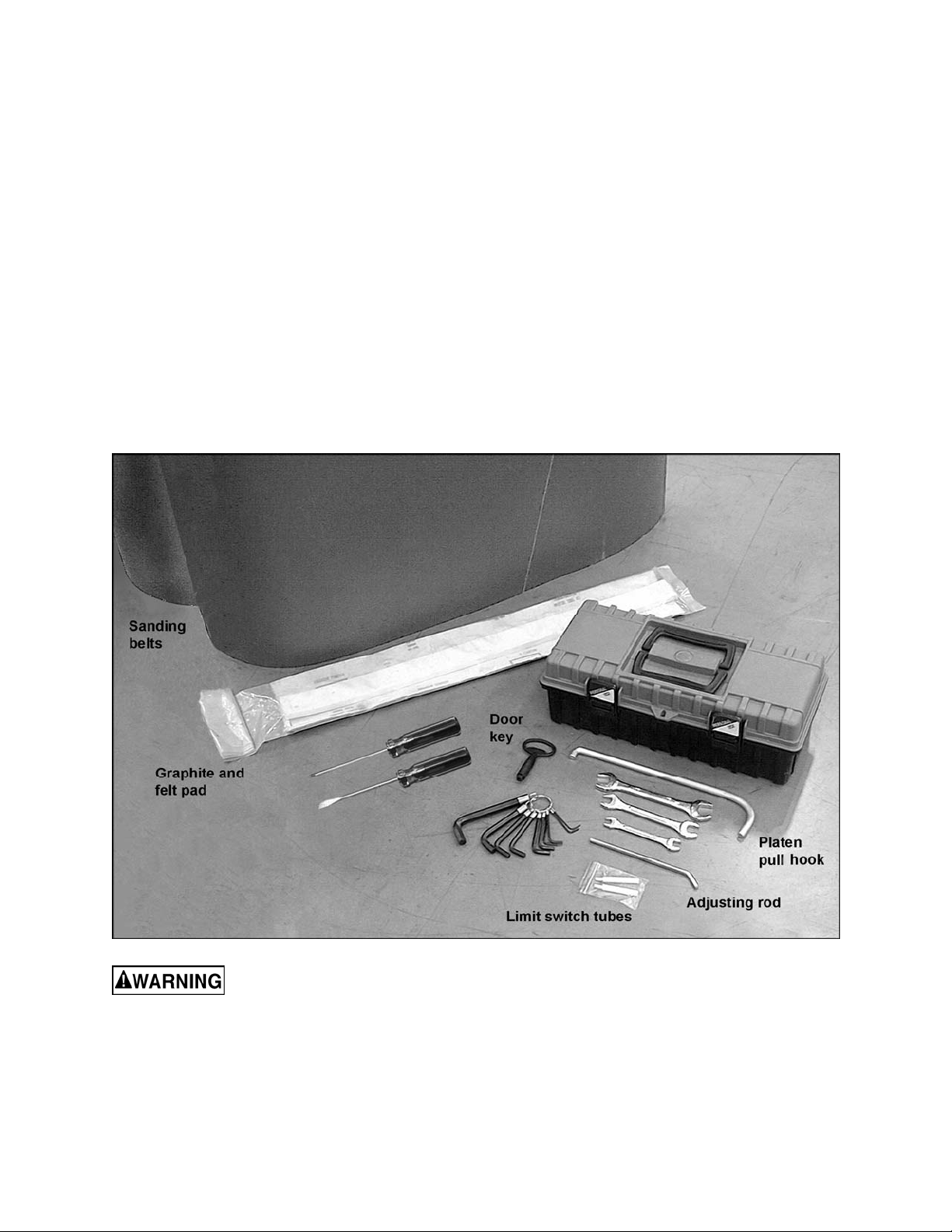

6.1 Contents of Shi pping Container

1 Sander

2 Sanding belts (100 and 180 grit)

1 Felt pad

1 Graphite strip

1 Tool box containing:

1 Door key

1 Platen pull hook

1 Adjusting rod

2 Limit switch tubes

1 Flat blade screwdriver

1 Cross point screwdriver

3 Open-end wrenches, 8-10, 12-14, 17-19

1 Set of hex wrenches

1 Owner's manual

1 Warranty card

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

8

Page 9

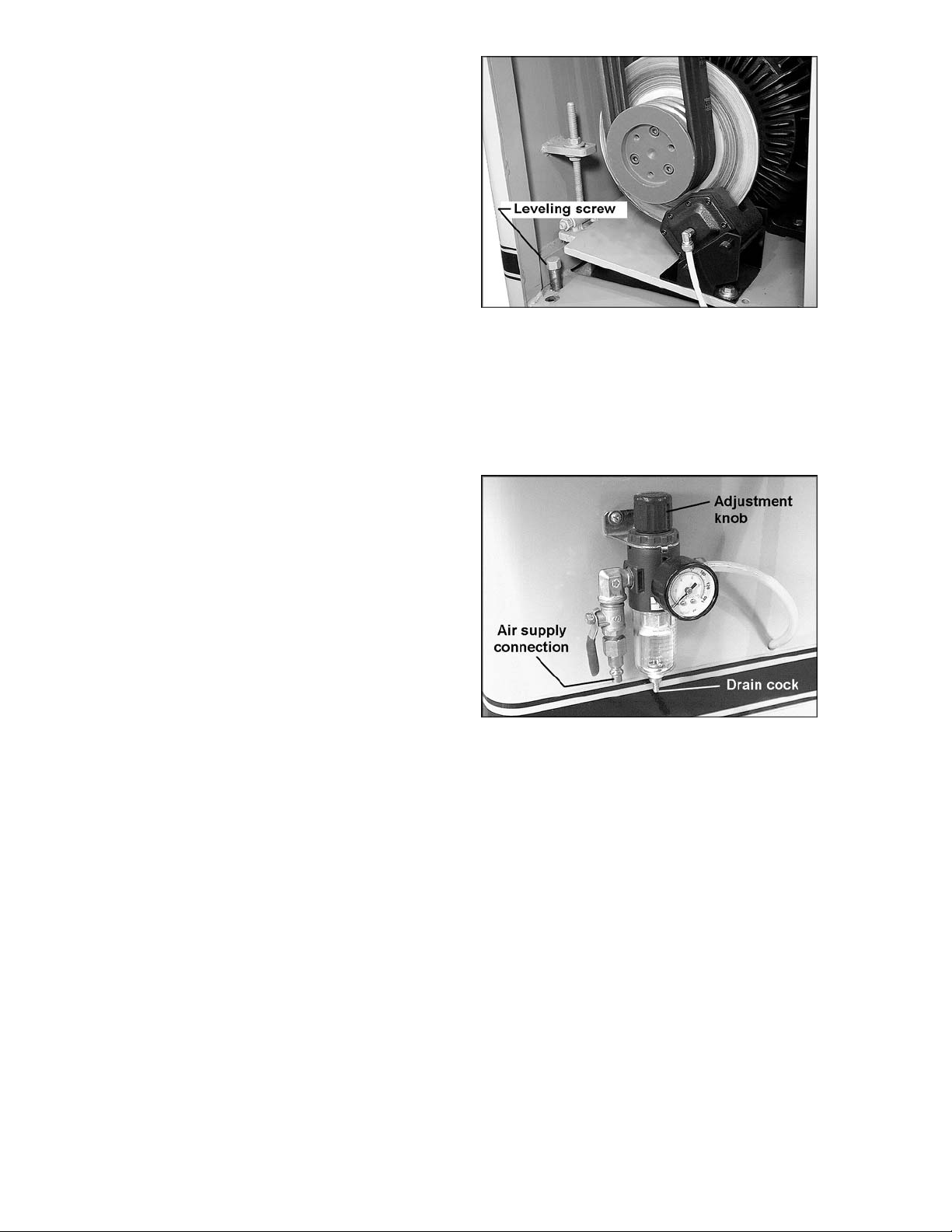

7.0 Assembly

The sander should be placed on a level, sturdy

floor, preferably concrete, with plenty of space

surrounding it for on- and off-loading of stock,

and general maintenance work.

Open the two lower side panels and use the

leveling screws inside the cabinet (Figure 1) to

level the sander. The machine can also be

secured to the floor with high quality lag screws

(not provided) through the four mounting holes

inside the cabinet.

Remove the protective coating from exposed

metal surfaces with a soft cloth moistened with

kerosene or a good commercial solvent. Do not

use acetone, gasoline or lacquer thinner, as

these have a low flash point and can be a fire

hazard, as well as damage the paint finish. Do

not get solvents on rubber or plastic areas of the

machine.

7.1 Air Supply Connection

Figure 1

The sander must be connected to an air supply

unit. The recommended working pressure is 75

to 80 PSI.

The air connection is on the Filter/Regulator unit

located at the back of the sander (Figure 2).

Attach the incoming air supply to the connector

with a flexible hose.

The working pressure can be adjusted with the

pressure regulator. Lift up on the adjustment

knob and rotate it clockwise to increase air

pressure, counterclockwise to decrease air

pressure. When the desired pressure is shown

on the pressure gauge, push down the

adjustment knob to lock the setting.

7.2 Dust Collection

Connect a dust collection system (not provided)

to the dust ports atop the sander cabinet with 5”

flexible hose and hose clamps. Make sure your

dust collector has sufficient capacity for this

machine.

Figure 2

Always turn on the dust collector prior to

operating the sander.

9

Page 10

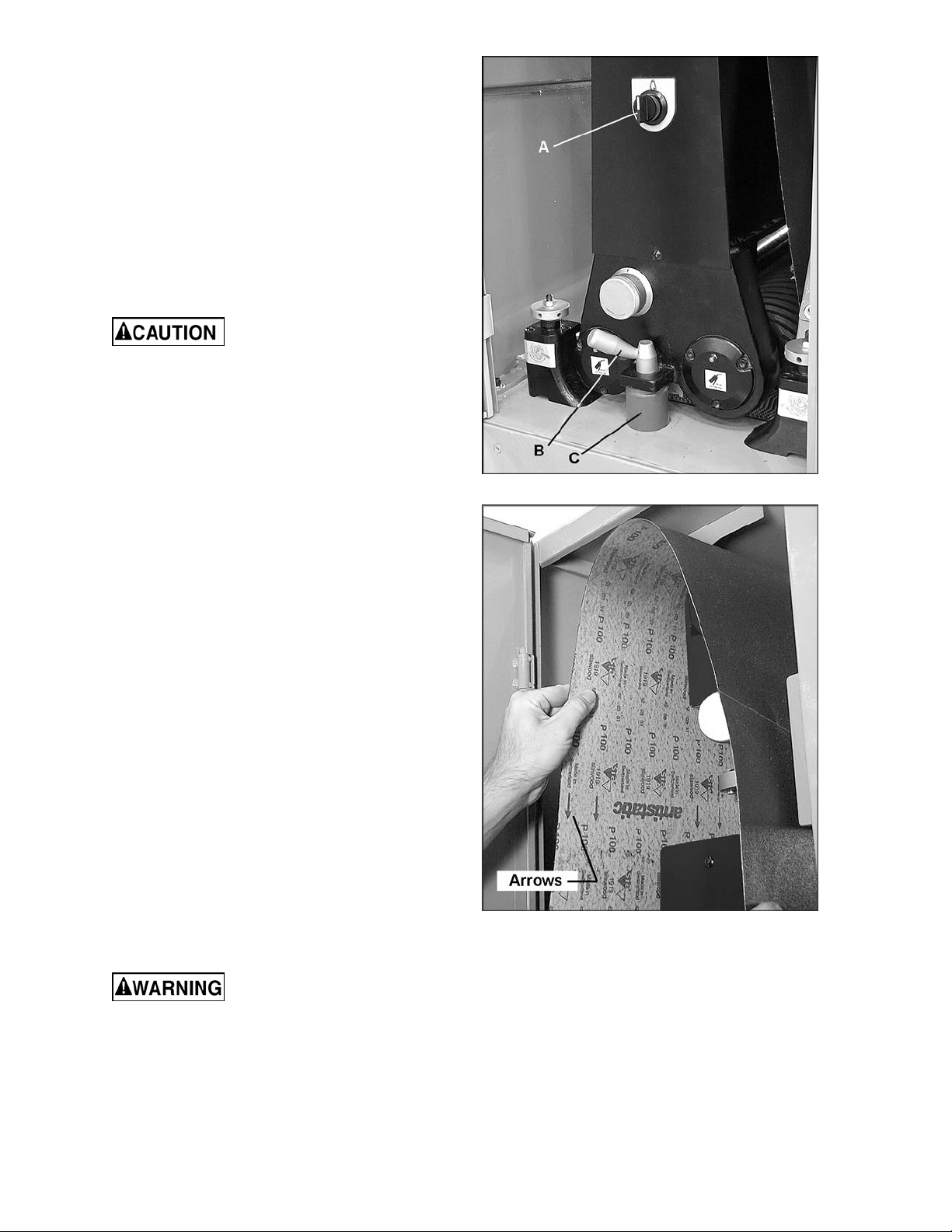

7.3 Installing/Replacing Sanding Belt

1. Machine should be disconnected from

power source.

2. Turn the air valve switch (A, Figure 3) to Off

position.

3. Remove the lock screw (B, Figure 3) by

turning it counterclockwise and lifting up.

4. Remove the spacer block (C, Figure 3).

5. Inspect the sanding belt for defects such as

chipped or torn edges. Do not use a belt if it

is damaged.

Make sure the direction of

the arrows on the inside of the sanding belt

matches the rotation of the machine. See

Figure 4.

6. Install the new belt by placing it first over the

upper roller, then over the free and contact

rollers, and slide the belt all the way onto

the rollers.

7. Center the belt while avoiding contact with

the limit switch fingers that are located on

each side of the belt.

Figure 3

8. Re-install the spacer block (C, Figure 3) and

lock screw (B, Figure 3) and tighten the lock

screw by turning clockwise.

9. Turn the air valve switch (A, Figure 3) to ON

to tension the sanding belt.

10. Make sure there is clearance between

sanding belt edges and the limit switch

fingers on either side. If there is not, make

the appropriate corrections (with the air

valve turned OFF).

NOTE: The sander will not start if a limit

switch is engaged.

11. Before doing any sanding, the sanding belt

should be tested for proper tracking and

oscillation. See the appropriate sections in

this manual.

8.0 Electrical

8.1 Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded while in

use to help protect the operator from

electrical sho ck and po ssib le fatal injury.

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

Figure 4

10

Page 11

electric current to reduce the risk of electric

shock to the operator.

Improper connection of the equipmentgrounding conductor can result in risk of electric

shock. The conductor, with insulation having an

outer surface that is green with or without yellow

stripes, is the equipment-grounding conductor. If

repair or replacement of the electric cord or plug

is necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded.

The sander should be connected to a dedicated

circuit with a minimum 100 Amp service. The

sander has been factory wired to run at 230 volt

operation. It can be converted to 460 volt if

desired. See the appropriate sections below.

8.2 230 Volt Operation

The sander may be fitted with a 230 volt plug, or

may be “hard-wired” directly to an electrical

control panel. If hard-wired to a panel, make

sure a disconnect is available for the

operator.

Refer to the diagram inside the sander’s

electrical box for clarification of electrical

connections. These diagrams are also shown in

sections 17.0 and 18.0 of this manual.

1. Make sure the machine’s plug is

disconnected from the power source. If it will

be hard-wired, make sure the fuses have

been removed or the breakers have been

tripped in the circuit to which the sander will

be connected. Place a warning placard on

the fuse holder or circuit breaker to prevent

it being turned on while the machine is

being wired. Always follow proper Lock

Out/Tag Out procedures when performing

any wiring on this machine.

2. Make sure the power source corresponds to

the specifications of the sander as recorded

on the sander’s motor plate.

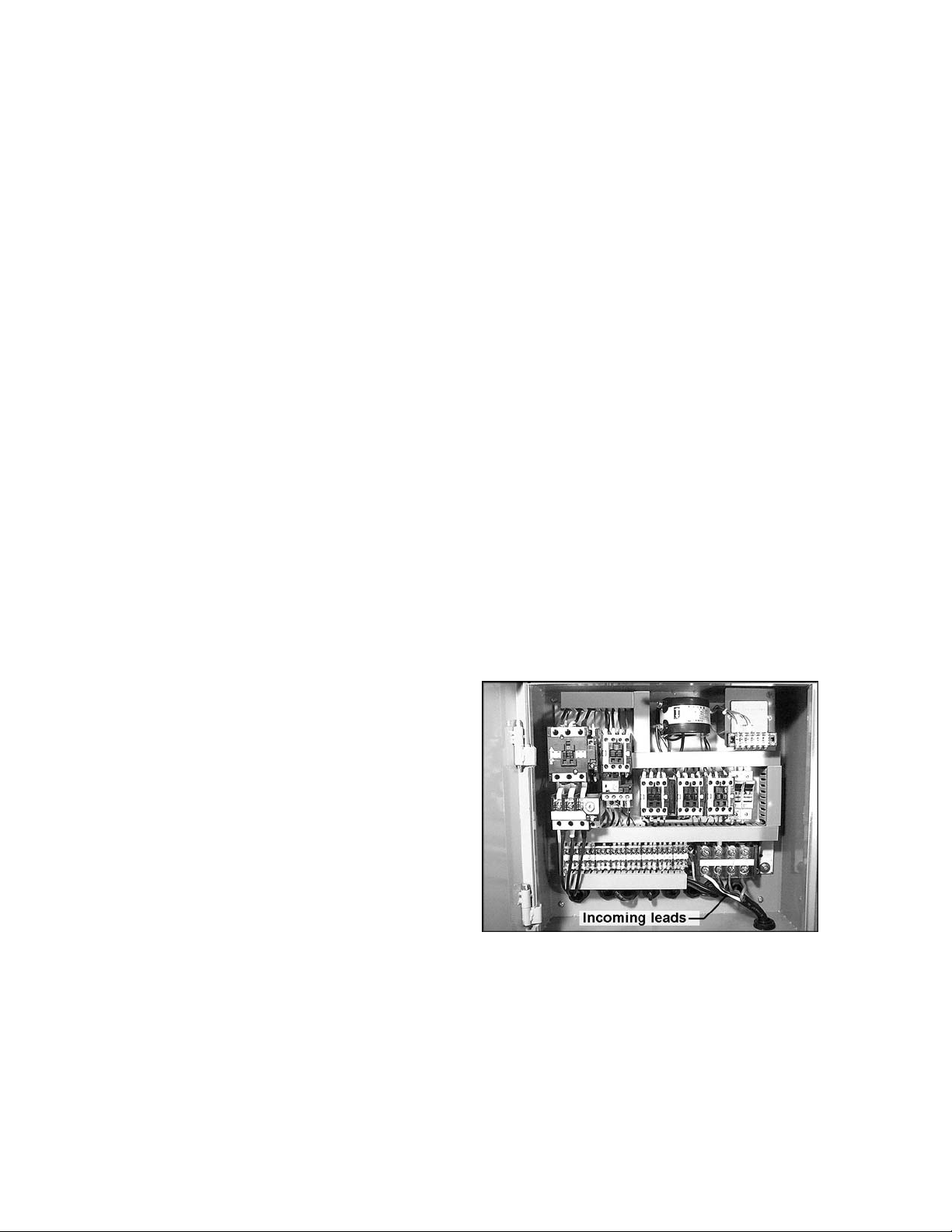

3. Open the sander’s electrical box and

connect the three incoming power leads to

the terminals marked R,S,T. See Figure 5.

Connect the green ground wire to grounding

terminal E.

4. Connect the machine to power (or install the

fuses or reset the breaker at the power

source). The power light (see Figure 19)

should now be lit.

Figure 5

(Model WB-25 shown)

11

Page 12

5. Press the Up S or Down T button on the

keypad (see page 18 for detailed keypad

instructions). Make sure the conveyor table

moves in the same direction as indicated on

the button.

6. If the conveyor table moves in the wrong

direction, turn off the machine and

disconnect from power. Switch any two of

the three incoming power leads at R,S,T.

7. Re-connect power to the sander.

8.3 460 Volt Conversion

To convert the sander to 460V:

1. Disconnect sander from power source.

2. In the electrical cabinet, switch the “R” wire

on the transformer from the 220V to the

440V terminal. See Figure 6. (Refer to the

wiring diagram on the inside cover of the

electrical box for clarification.)

3. Replace two 230V overload relays with two

460V overload relays (not included; see

parts list for stock numbers).

4. Change the wiring at the main motor, the

conveyor table motor, and the table

elevating motor, according to the wiring

diagrams inside their respective junction

boxes.

5. If using a plug, install a UL/CSA-listed plug

appropriate for 460V operation.

8.4 Extension cords

The use of an extension cord for this sander is

discouraged, because of the machine’s high

amperage draw. If an extension cord becomes

necessary, make sure the cord rating is suitable

for the amperage listed on the machine’s motor

plate. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating.

9.0 Adjustments

9.1

Sanding Belt Tracking and

Oscillation

Figure 6

The sanding belt should oscillate left and right

without a tendency to slide off the rollers. If the

sanding belt runs outside of the normal track, it

will contact a limit switch and the machine will

stop automatically.

The oscillation settings have been made at the

factory, but should be checked by the operator.

NOTE: When a new sanding belt is installed,

there may be a slight length tolerance between

the right and left sides of the sanding belt which

12

Page 13

may result in incorrect tracking. If this occurs,

the oscillation timing can be set to compensate.

1. Adjust oscillation while the machine is

running. Turn on the air valve switch and

press the sanding belt start button (see

Figure 19).

2. The upper roller will pivot left and right. The

duration of the sanding belt’s oscillation to

the right side and to the left should be equal.

For example, if the oscillation time to the

right is one second, then the oscillation time

to the left should also be one second.

3. If the oscillation time to the right side is one

second, but the oscillation time to the left

side is longer, then loosen the tracking

adjustment lever (rotate it counterclockwise)

and move it to the left until proper timing is

achieved. See Figure 7.

4. When finished, tighten the tracking

adjustment lever.

5. If the oscillation time to the left side is one

second, but the oscillation time to the right

side is longer, then loosen the tracking

adjustment lever and move it to the right

until proper timing is achieved. Tighten the

tracking adjustment lever.

9.2 Oscillation Air Flow

For correct sanding belt oscillation, there must

be adequate air flow through the holes of the

oscillation bracket (Figure 8). When the sanding

belt is operating, its edge will pass over the

holes in the oscillation bracket. The blocked air

flow will cause a sensor to activate the tracking

cylinder, which pivots the upper roller and shifts

the belt back out, causing it to leave the air flow.

This process will continually repeat itself.

Figure 7

Figure 8

If there is inadequate air flow, the sanding belt

will track too far and contact a limit switch.

Adjust the air flow using the air flow control knob

(Figure 9). Loosen the jam nut and rotate the

knob clockwise to decrease air flow,

counterclockwise to increase air flow. Tighten

the jam nut to lock the setting.

Frequently inspect the holes in the oscillation

bracket – make sure they are clean and clear of

obstructions.

9.3 Oscillation Speed

To adjust the speed of the oscillation, loosen the

jam nut on the speed control knob (Figure 9),

then turn knob clockwise to decrease oscillation

speed or counterclockwise to increase

oscillation speed. When finished, tighten jam

nut.

Figure 9

13

Page 14

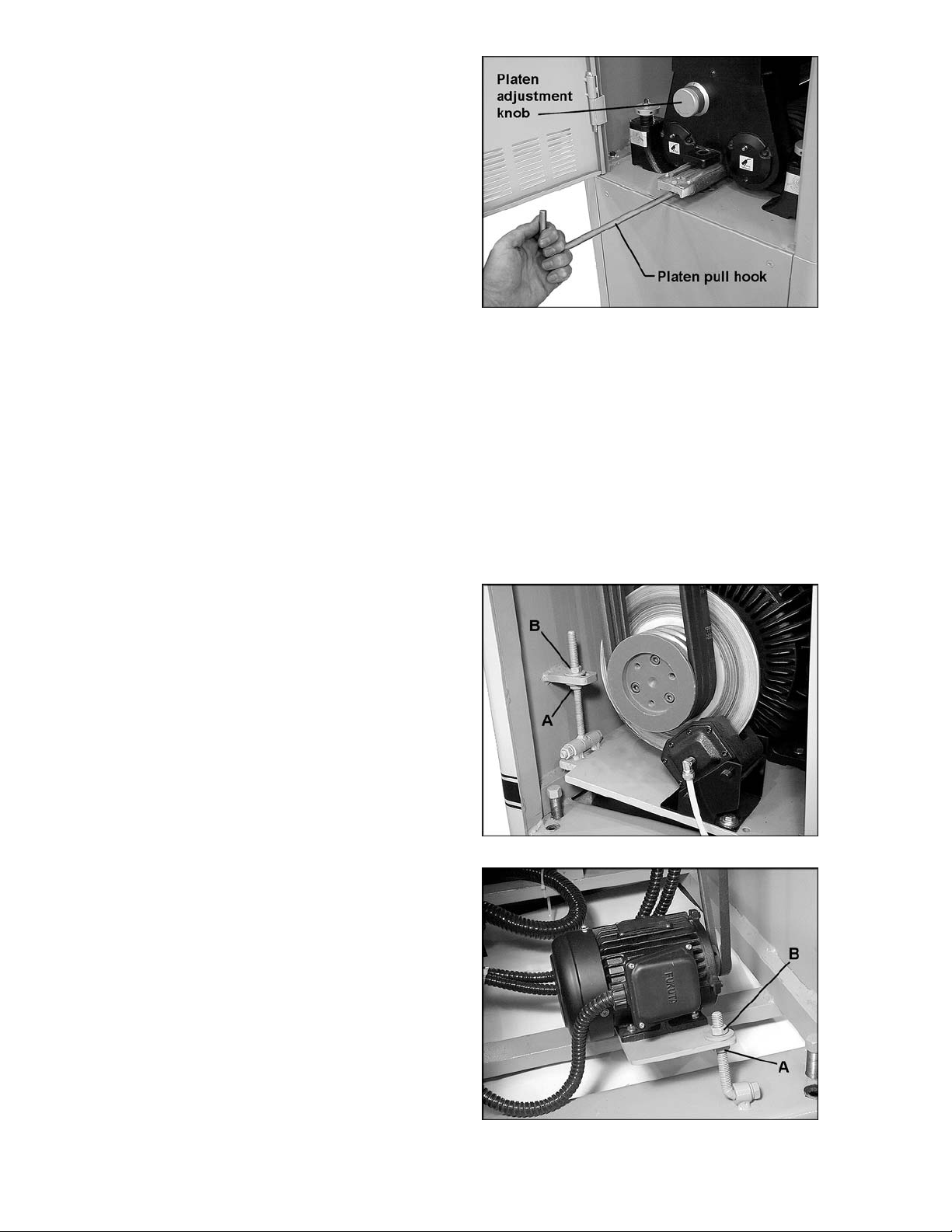

9.4 Platen Position

The sander has a removable platen with a

graphite strip and a felt pad to reduce friction

against the sanding belt. Positioning of the

platen depends upon the type of wood being

used.

The height of the platen is set at the factory, but

can be re-adjusted by rotating the platen

adjustment knob (Figure 10). Each mark on the

scale indicates a raising or lowering

measurement of 0.005mm. One complete

rotation of the scale moves the platen 0.2mm or

approximately 8/1000 of an inch.

Theoretically, optimum finish sanding results are

obtained when the bottom of the platen extends

slightly below the bottom of the conveyor rollers.

The main consideration in adjusting the platen is

to make sure that both ends are symmetrical

and level.

NOTE: The platen must be kept clean. After

sanding, if the workpiece has straight notches

across it, the graphite and felt pad have worn

out and should be replaced immediately.

Figure 10

9.5 Replacing Graphite and Felt Pad

To replace the graphite strip and felt pad,

proceed as follows:

1. Remove the lock screw (B, Figure 3) and

the spacer block (C, Figure 3).

2. Place the platen pull hook into the hole on

the end of the platen and pull out the lower

portion of the platen assembly, as shown in

Figure 10. NOTE: The platen is tightly fitted

and will require a firm pull with the pull hook.

3. Note carefully how the current graphite and

felt strip are mounted. Replace them with

the new ones.

4. Re-install the platen by aligning the end of it

with the dovetail track on the fixed portion of

the platen assembly, and push it all the way

in using the pull hook.

5. Replace the spacer block and lock screw.

9.6 V-Belt Tension and Replacement

For the first few days of operation a new belt

should be checked occasionally and adjusted for

tension as necessary until the belt is properly

“worn in.”

Figure 11

The v-belts on the main motor and table

elevating motor should be checked for proper

tension.

Tighten any of the v-belts as follows:

Figure 12

14

Page 15

1. Disconnect sander from power source.

2. Loosen the lower hex nut (A, Figure 11/12)

on the motor base.

3. Tighten the top hex nut (B, Figure 11/12) to

lower the motor plate until proper tension is

achieved.

4. When the belt is properly tensioned, you

should be able to push in the belt

approximately 3/4” at a point midway

between the pulleys using moderate finger

pressure.

5. Re-tighten the bottom hex nut (B, Figure

11/12) against the bottom of the motor plate.

If installing a new v-belt, use the hex nuts to

raise the motor plate enough to remove the old

belt and mount the new one.

NOTE: When replacing v-belts on the main

motor, replace the entire set of three

simultaneously.

9.7 Conveyor Belt Tension

Check the tension of the conveyor belt on the

infeed and outfeed rollers – the conveyor belt

should be tight enough that you cannot shift it

with your hands. If the conveyor belt needs

tightening, proceed as follows.

1. Disconnect sander from power source.

2. Rotate the adjustment screws (the left one

is shown in Figure 13) as needed with a

19mm wrench. Rotate clockwise to increase

tension, counter-clockwise to decrease

tension. (NOTE: Removal of the emergency

stop cover is not necessary for tensioning.)

NOTE: Do not over-tighten the screws as this

will hasten wear of the conveyor belt.

9.8 Conveyor Belt Tracking

The conveyor belt should remain centered upon

the rollers during operation. If it approaches to

either the left or right side, adjustment is

necessary.

First check that the conveyor belt tension is

correct. If the tension needs adjustment, do this

first before you adjust the tracking (see

“Conveyor Belt Tension”). Then proceed as

follows.

Conveyor belt tracking should be adjusted while

the conveyor belt is running. Make adjustments

in increments and allow the conveyor belt time

to respond to each change.

Figure 13

Keep hands away from the

moving conveyo r bel t.

15

Page 16

1. Remove the four screws securing the

emergency stop cover and remove the

cover. See Figure 13. This will allow better

inspection of the belt’s movement on the

roller.

2. Turn on the conveyor belt.

3. Adjust tracking using the same adjustment

screws that were used for tensioning in

Figure 13.

4. If the conveyor belt is moving to the right

side, turn the right screw clockwise. This will

return the tracking toward the left.

5. If the conveyor belt is moving to the left

side, turn the left screw clockwise. This will

return the tracking toward the right.

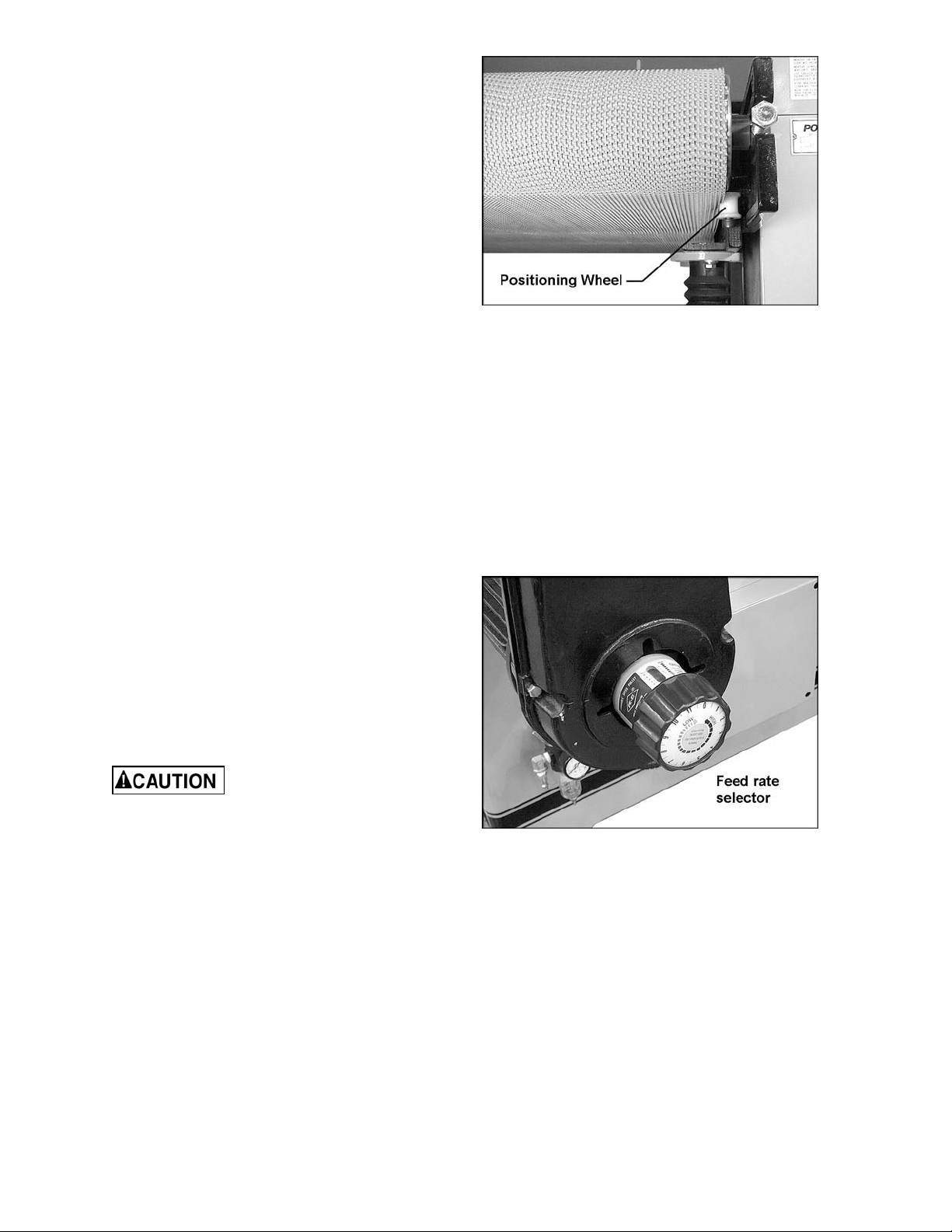

6. A positioning wheel (Figure 14) has been

provided on the right and left sides of the

conveyor belt to limit the belt tracking. When

adjusting the tracking, the conveyor belt

should be moved until its edge just touches

the positioning wheels.

7. Allow the sander to run for several minutes

while observing the conveyor belt tracking

and readjust if necessary.

8. Turn off the conveyor belt and re-install

emergency stop cover.

Figure 14

9.9 Feed Rate

The feed rate is infinitely variable within the

provided range, in order to meet the sanding

requirements of a wide variety of materials.

Selecting a proper feed rate is largely a matter

of experience. In general, soft woods require a

higher feed rate, while hard woods require a

lower feed rate.

Change the feed rate only

while the conveyor belt is running. Failure to

comply may cause damage to the g earbo x.

Adjust the feed rate with the selector knob on

the worm gear reducer (Figure 15). Turn the

selector knob clockwise to decrease the

conveyor belt speed, counterclockwise to

increase it.

9.10 Pressure Bar Adjustment

The front and rear sets of pressure bars have

been factory adjusted. This setting should,

however, be checked before operating the

sander.

Figure 15

The pressure bars should be parallel to the

conveyor table with equal pressure on each end,

and are set slightly below the level of the

sanding belt.

16

Page 17

If the ends of the workpiece are sniped, the front

pressure bars are too low. The pressure should

be enough to firmly hold the workpiece against

the conveyor, but not so hard that the ends of

the workpiece spring up after clearing the bar.

Also, if the ends of the bars are not exerting

equal pressure, the workpiece will tend to move

sideways on the conveyor during sanding.

To raise or lower each set of pressure bars:

1. Disconnect sander from power source.

2. The sanding belt should be installed, and

the air valve turned ON.

3. Place a sanded panel with even thickness

on the conveyor table and under the

pressure bars. The panel should be long

enough to contact both front and back sets

of pressure bars.

4. Raise the table manually using the

handwheel (Figure 16) until the panel

contacts the pressure bars.

5. Make sure the pressure at the right and left

side of pressure bars is even.

6. If adjustment is needed, release the lock nut

(A, Figure 17) with a 14mm wrench.

7. Insert the adjusting tool (B, Figure 17) into a

hole in the adjusting knob. Rotate the

adjusting knob clockwise to raise that side

of the pressure bar, counterclockwise to

lower it.

8. When finished, re-tighten lock nut (A, Figure

17).

9.11 Table Parallelism

Parallelism of the conveyor table to the contact

roller has been factory-set and should not

require further adjustment. However, as the

machine receives extended use, this setting

should be checked.

Inspect parallelism by one of two methods:

1. Use a sanded board of equal thickness.

Pass the board several times through the

machine at a sanding depth of

approximately 1/64”, then measure the

thickness of the board at different points

along the edges with calipers. If excessive

variation occurs, the table needs adjusting.

OR, remove the sanding belt and place a

gauge of some kind at one side of the

conveyor table and below the contact roller.

Raise the table manually using the

handwheel until the gauge just touches the

contact roller. Repeat at the other side of

the table and compare the gauge readings.

Figure 16

Figure 17

17

Page 18

If the readings are different, the table needs

adjusting.

2. Disconnect sander from power source.

3. At the area of the table that needs

adjustment, loosen the two screws (A,

Figure 18) on the bracket of the elevation

screw, and rotate the bracket as needed.

(The elevation screw is protected by the

dust guard bellow.) Turn the elevating screw

clockwise to lower the table in that area,

counterclockwise to raise the table (see

Figure 18).

IMPORTANT: Turn both elevating screws at

one side of the table an equal amount, in

order to maintain front-to-back parallelism

with the rollers.

4. Tighten screws (A, Figure 18).

5. Re-connect sander to power, and make

further test runs. Make additional

adjustments as needed, with the machine

disconnect ed from power.

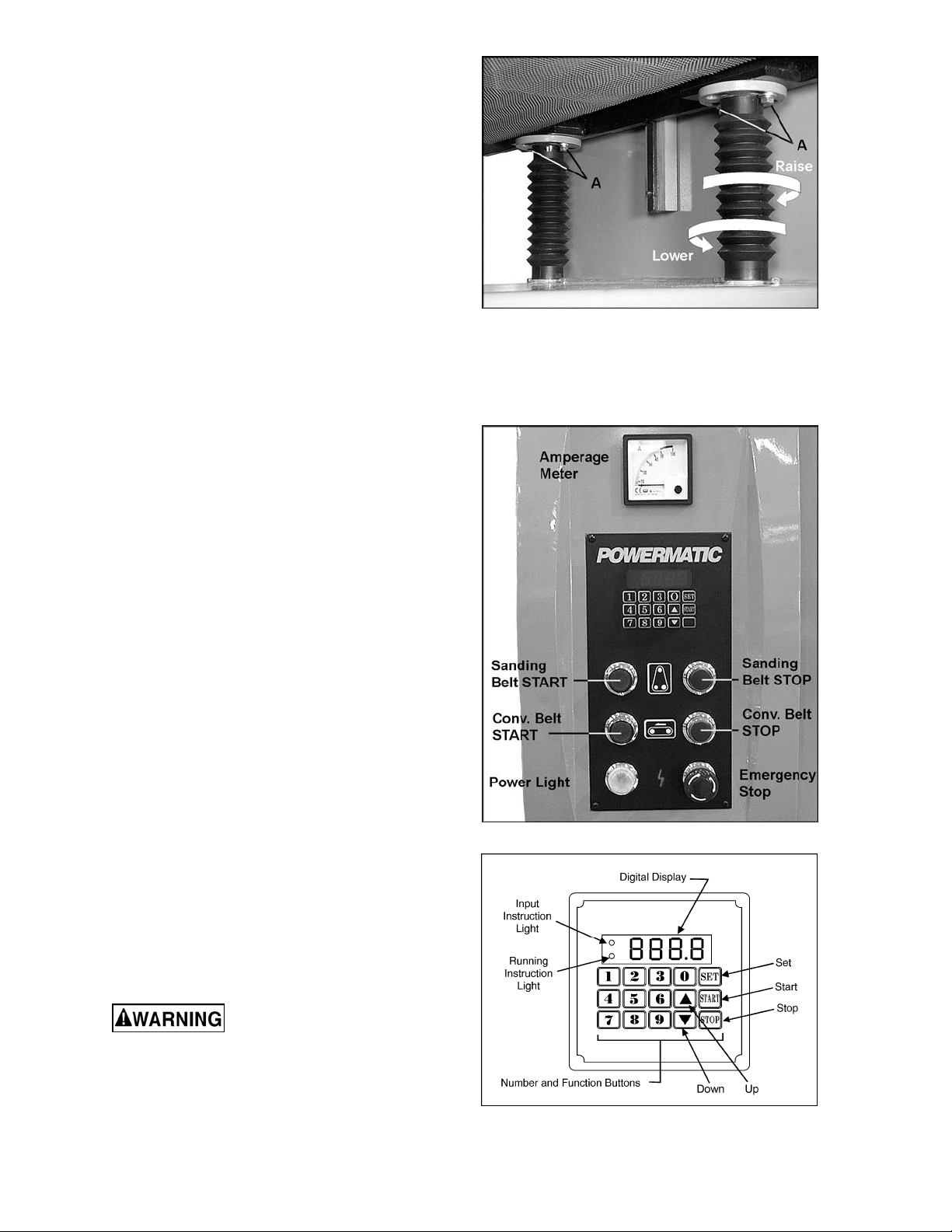

10.0 Operating Controls

Figure 18

Figure 19 shows the control panel functions.

The emergency stop button shuts down all

machine operations. The button remains

engaged after being pushed. To disengage,

rotate the ring until the emergency stop button

pops back out.

The emergency stop cover has a plate (shown

in Figure 16) which shuts down all machine

operations when it is pushed.

10.1 Amperage Meter

The amperage meter (Figure 19) continually

monitors the load upon the sander. To avoid

tripping of the circuit breaker and the overload

relays, reduce the load immediately when the

amperage meter indicates excessive amperage

pull.

10.2 LED Controller and Keypad

The controller is used for precise positioning of

the conveyor table based upon the workpiece

thickness and your desired sanding depth.

Figure 20 shows the key features of the unit.

Figure 19

T he LED control unit comes

pre-programmed from the factory. Do NOT

alter the specifications of your control unit

without authorization from WMH Tool Group.

Incorrect programming of the device could

cause uni t failure as w ell as risk o f injury to

people and damage to the sander.

Figure 20

18

Page 19

10.2.1 Calibr ation

To establish the distance between conveyor

table and sanding belt, proceed as follows:

1. Connect power and air to the sander, and

turn the air valve switch on to tighten the

sanding belt. NOTE: The controller will not

move the table if the air valve switch is off.

2. Press and hold the UP S button on the

keypad to raise the conveyor table until the

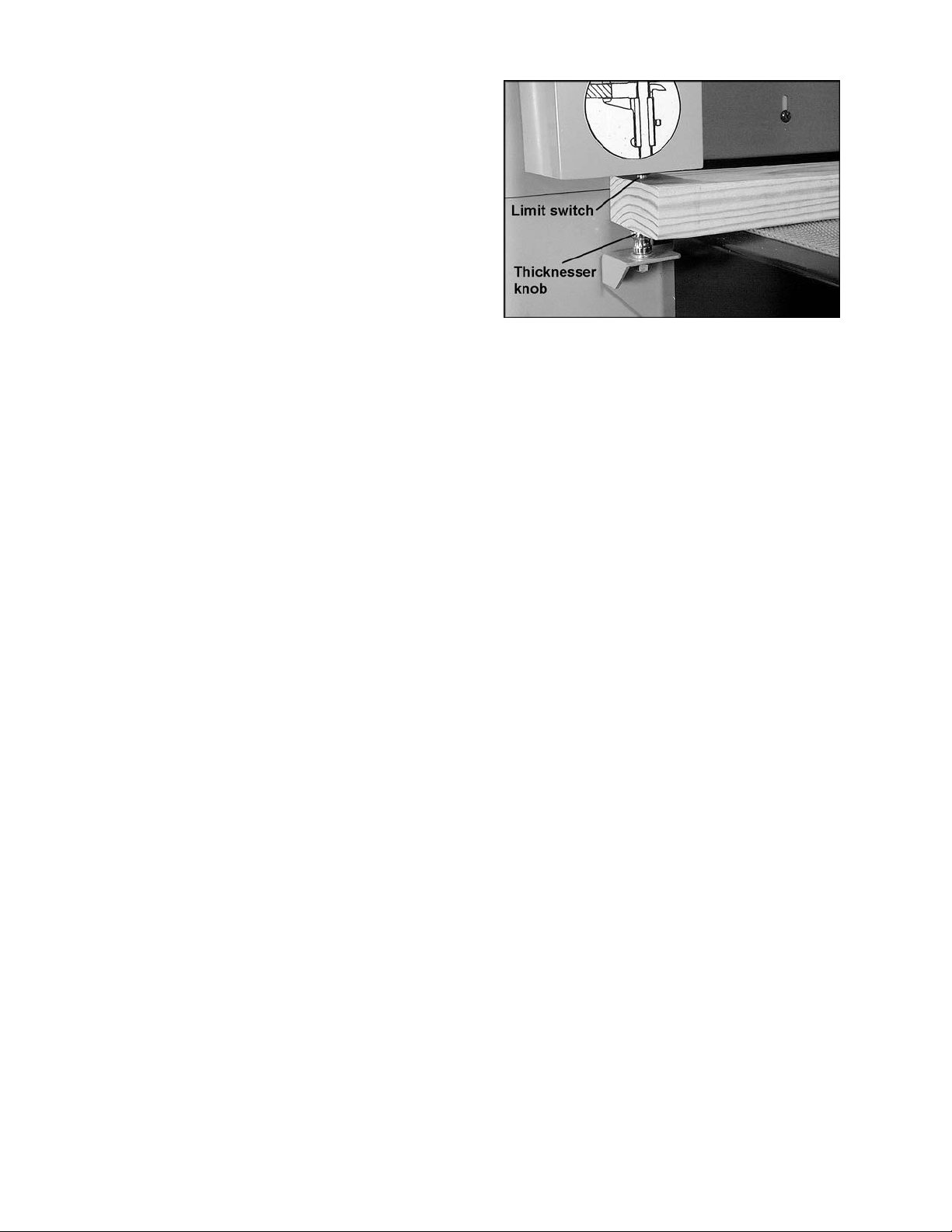

thicknesser knob (Figure 21) contacts the

limit switch. The table will automatically stop

while making slight contact with the sanding

belt.

3. Press “0” (zero) on the keypad (the display

will begin flashing and the input light will be

lit). Then press SET for 2 to 3 seconds. The

display will now read zero. This is the

distance between sanding belt and conveyor

table, upon which further movement of the

table can be based.

4. Input a number using the keypad (display

will begin flashing and the input light will be

illuminated).

5. While the display is still flashing, press the

START button on the keypad (run light will

now be illuminated). The conveyor table will

move to the desired distance from the

sanding belt.

10.2.2 Using the LED for Operations

The sander has a thicknesser which

automatically sets the table at the thickness of

your workpiece:

1. Place your workpiece upon the conveyor

table and move it below the thicknesser, as

shown in Figure 21. Keep the workpiece flat

upon the table. Press and hold the UP S

button on the keypad to raise the conveyor

table. When the workpiece contacts the limit

switch the conveyor table will stop. The table

is now positioned at the thickness of your

workpiece.

2. Remove the workpiece.

3. Press and release the UP S button, which

will raise the table for the first sanding pass.

NOTE: The arrow buttons are programmed

to move the table in .005” increments.

10.2.3 Inch/Metric Toggle

At any time you may switch between standard

and metric measurements by pressing and

holding SET for ten seconds.

Figure 21

4. Press the sanding belt START button and

the conveyor table START button on the

control panel, and feed the workpiece

through the machine.

5. Make further passes as needed, raising the

table each time using the UPS button.

11.0 Operation

Before operating the sander, make sure that:

1. The dust collection system is turned on.

2. Sanding belt tracking and oscillation are

working properly.

3. Conveyor belt tracking is correct.

4. All screws and handles are tightened

securely.

5. Working air pressure is correct. (Normal

working pressure is 75 to 80 PSI.) Do not

operate sander until normal pressure is

reached.

6. Thickness is correctly input into the LED

unit.

7. Feed rate is correctly set.

8. Workpiece is free of nails, knots and other

obstructions.

11.1 Braking System

The sander will not start or will halt operations if

any of the following occur:

• No air supply to the machine.

• No sanding belt installed.

• Improper belt tension.

• Sanding belt runs out of track.

• The emergency stop button on the control

panel is pressed.

• The emergency stop plate on the conveyor

table is pushed.

19

Page 20

If the sanding belt breaks, all movement will be

stopped, though the conveyor table can still be

raised or lowered.

Once the machine has stopped, the operator

should find where the braking system was

tripped, and make the necessary adjustments.

The machine can then be re-set and started.

12.0 Maintenance

Before doing any

maintenance on the sander, disconnect it

from the electrical supply by pulling out the

plug or switching off the main switch.

Failure to compl y may cause seri ou s injury.

The interior of the machine should be thoroughly

cleaned each day after using the sander.

Remove the sanding belt before cleaning and

re-install it when finished.

Keep the sanding belt clean using cleaning

sticks or pads (not provided).

Blow dust off the conveyor belt with compressed

air or use a dust collector vacuum attachment.

The bearings should be greased after every 150

work hours.

The water should be removed daily from inside

the filter cups. On the filter/regulator at the back

of the cabinet, press the drain cock (see Figure

2). On the filter inside the cabinet, unscrew the

cup to empty it.

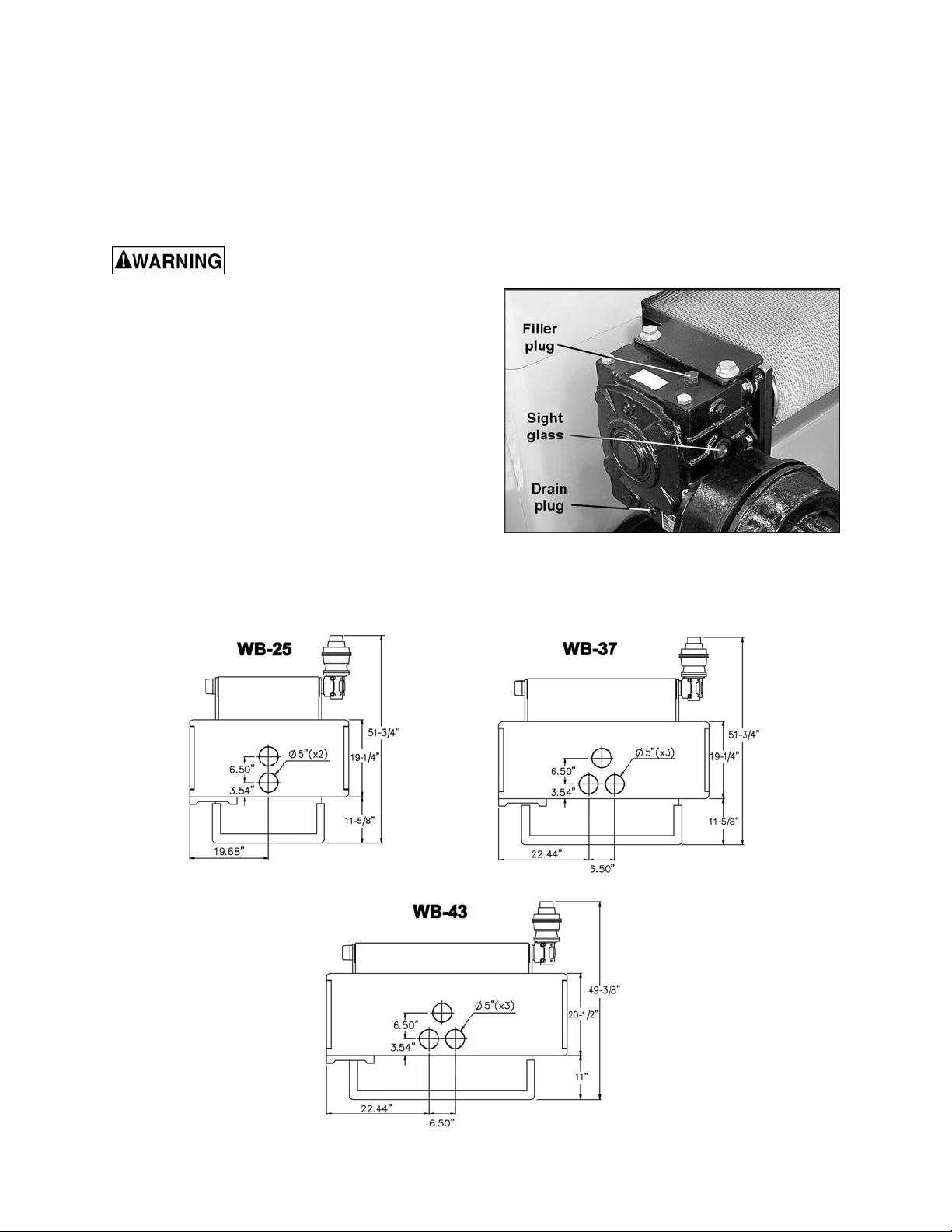

The oil inside the gear reducer should be

replaced after the first 100 work hours and every

2500 work hours thereafter. Recommended oil is

#90 gear oil. Pour oil into the filler hole until the

level is above the dot on the sight glass. See

Figure 22.

Figure 22

13.0 Dust Port Layout

20

Page 21

14.0 Troubleshooting the Sander

Trouble Probable Cause Remedy

Sander will not start. No incoming power. Check that sander is connected to

power, fuses are not blown or circuit

breakers are not tripped.

Low voltage. Check voltage at power source.

Loose wiring. Inspect and remedy any loose

connections on sander.

Starting switch is defective. Replace switch.

Motor is defective. Replace motor.

Sanding belt clogs

too quickly.

Sanding belt will not

run, or slips on the

rollers.

Sanding belt keeps

triggering the limit

switches.

Grit of sanding belt is too fine. Choose a larger grit of sanding paper.

Too much material being sanded off. Reduce the amount of material being

removed.

Wood is too oily. Choose different stock.

Too much dirt or glue on the wood. Choose cleaner stock.

Wood is too moist. Allow wood to dry before sanding.

Air valve switch is Off. Turn on air valve.

Emergency stop button is engaged. Disengage the stop button.

Limit switches are activated. Position sanding belt so it is between

the limit switches.

Insufficient air pressure causing belt

to slip on rollers.

Dust or debris on conveyor rollers Clean conveyor rollers.

Tracking adjustment/oscillation is not

correct.

Air flow control is closed. Open air flow control (page 13).

Make sure air pressure regulator is

set at 75 to 80 PSI (page 9).

Set tracking correctly. See page 12

and 13.

Machine takes too

long to stop after

emergency switch is

activated.

Grinding noise when

brake is activated.

Too much rounding

occurs along edges

when solid wood is

sanded.

The front end of stock

is thinner than the

rear.

Sensors are blocked on the air

cylinder bracket.

Air pressure is too low. Set air pressure to 75 to 80 PSI.

Brake pads are worn. Replace brake pads.

Brake pads are worn. Replace brake pads (rotor may need

Too much material is being removed,

making the contact drum press too

tightly.

Rear pressure bar is too low in

relation to the contact drum.

Clean the sensor areas on the

cylinder bracket. See page 13.

turning also).

Reduce the amount of material being

removed.

Raise rear pressure bar (page 16-17).

21

Page 22

Trouble Probable Cause Remedy

The rear end of stock

is thinner than the

front.

Uneven thickness

between the left and

right sides of the

workpiece.

Uneven thickness

between the front and

rear ends of the

workpiece.

Front pressure bar is too low in

relation to the contact drum.

Table not positioned correctly in

relation to contact drum.

Front pressure bar not in correct

position in relation to contact drum.

Graphite strip and felt pad are worn

out.

Conveyor belt is worn. Replace conveyor belt (contact

Feed rate is too high. Reduce feed rate. See page 16.

Too much stock removal. Reduce amount of material being

Grit of sanding belt too fine. Use larger grit sanding belt.

Unequal position of pressure bars. Adjust pressure bars to produce equal

Table not parallel front to back. Adjust table until it is parallel front to

Raise front pressure bar (page 16).

Adjust table until it is parallel left to

right (pages 17-18).

Adjust front pressure bar to parallel.

See page 16.

Replace graphite strip and felt pad.

See page 14.

Powermatic Technical Service).

removed.

pressure on stock.

back (pages 17-18).

Workpiece slips on

conveyor belt.

Straight strip of

notches or grooves in

the workpiece.

“Snake” marks on

workpiece.

Straight parallel

running stripes over

entire width of

workpiece.

Glossy spots on the

wood.

Not enough pressure between

pressure bar and workpiece.

Too much dust or debris on conveyor

belt.

Rear pressure bar too low, halts the

workpiece.

Dirty pressure bar. Clean pressure bar.

Contact drum is scratched. Replace contact drum.

Graphite strip and felt pad are worn. Replace graphite and pad.

Local damage to the sanding belt. Replace sanding belt.

Joint of the sanding belt is too thick or

is open.

Sanding belt is too old. Replace with new sanding belt.

Rear pressure bar is too low. Raise rear pressure bar.

Increase pressure between pressure

bar and workpiece.

Clean conveyor belt with compressed

air.

Raise rear pressure bar until proper

contact is achieved.

Repair joint or replace sanding belt.

22

Page 23

15.0 Troubleshooting the LED Unit

Trouble Probable Cause Remedy

The display fails to

show figures.

Display shows

abnormal figures.

Display shows

figures, but they do

not change in

conjunction with the

hoist motor’s

operation.

Travel dimension

incorrect.

Fuse is burned out. Replace 1A fuse.

Control unit is malfunctioning. Unit must be repaired or replaced by

authorized service personnel.

Wrong figures were input. Input the proper numbers in

accordance with the actual

dimensions.

If the above step is ineffective, turn

the power off and then on. If the

display is still not working properly, it

should be repaired or replaced.

Contact Powermatic Technical

Service.

Proximity switch is not functioning. Have proximity switch replaced by

authorized service personnel.

Distance between induction unit and

induction sheet is more than 1mm.

Encoder not running in accordance

with the table movement.

Distance between sanding roller and

conveyor belt has not been input

correctly into the unit.

Adjust distance between induction

unit and induction sheet to less than

1mm.

Encoder should be repaired or

replaced by a service representative.

Correct control unit parameter. See

page 19.

Table will not

respond to figures

input into unit.

Air valve turned off, sanding belt not

tensioned.

Turn air valve on.

16.0 Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848, Monday through Friday (see our website for business hours, www.powermatic.com).

Having the Model Number and Serial Number of your machine available when you call will allow us to

serve you quickly and accurately.

23

Page 24

16.1.1 Base and Motor Assembly – Model WB-25 ONLY

Parts list on page 25.

24

Page 25

16.1.2 Parts List: Base and Motor Assembly – Model WB-25

Exploded view on page 24.

Index No. Part No. Description Size Qty

1 ............... WB25-201 ................Machine Base........................................................................................ 1

2 ............... WB25-202 ................Motor Plate ............................................................................................ 1

3 ............... WB25-203 ................Rod ....................................................................................................... 1

4 ............... WB25-149 ................Hex Nut ..............................................................1/2-12 ......................... 3

5 ............... WB25-205 ................Motor Adjusting Screw ........................................................................... 1

6 ............... TS-0720111 .............Lock Washer ......................................................1/2 .............................. 1

7 ............... TS-0060061 .............Hex Cap Screw ..................................................3/8-16x1-1/4 ............... 4

8 ............... TS-0680061 .............Flat Washer ........................................................1/2 .............................. 2

9 ............... WB25-209 ................Motor ..................................................................15HP, 230/460V, 3Ph . 1

10 ............. W B25-210 ................Motor Pulley .......................................................................................... 1

11 ............. TS-0208071 .............Socket Head Cap Screw .....................................5/16-18x1-1/4 ............. 3

12 ............. W B25-212 ................Leveling Nut .......................................................................................... 4

13 ............. W B25-213 ................Key.....................................................................8x10x74 ..................... 1

14 ............. TS-0051051 .............Hex Cap Screw ..................................................5/16-18x1 ................... 4

15 ............. TS-0720081 .............Lock Washer ......................................................5/16 ............................ 4

16 ............. W B25-216 ................Disc Brake ............................................................................................. 1

17 ............. W B25-217 ................Pulley Bushing....................................................................................... 1

18 ............. VB-B73 ....................V-Belt .................................................................B-73 ........................... 2

19 ............. W B25-219 ................Brake Base ............................................................................................ 1

20 ............. TS-0680041 .............Flat Washer ........................................................3/8 .............................. 2

21 ............. TS-0060031 .............Hex Cap Screw ..................................................3/8-16x3/4 .................. 2

22 ............. 6294280...................Limit Switch ........................................................................................... 2

23 ............. 6294281...................Limit Switch Plate .................................................................................. 2

24 ............. TS-0050021 .............Hex Cap Screw ..................................................1/4-20x5/8 .................. 2

25 ............. TS-0680021 .............Flat Washer ........................................................1/4 .............................. 2

26 ............. TS-0270071 .............Set Screw ...........................................................5/16-18x3/4 ................ 4

27 ............. W B25-227 ................Bushing ................................................................................................. 2

28 ............. W B25-131 ................Flat Head Screw .................................................M5x8 .......................... 4

29 ............. TS-0720071 .............Lock Washer ......................................................1/4 .............................. 2

30 ............. W B25-230 ................Brake Housing ....................................................................................... 1

31 ............. W B25-231 ................Front Cover ........................................................................................... 1

32 ............. W B25-232 ................Brake Lining .......................................................................................... 1

33 ............. W B25-233 ................Brake Lining .......................................................................................... 1

34 ............. W B25-234 ................Bushing ................................................................................................. 1

35 ............. W B25-235 ................Spring.................................................................................................... 1

36 ............. W B25-236 ................Inner Plate ............................................................................................. 1

37 ............. TS-1514041 .............Flat Head Socket Screw .....................................M6x25 ........................ 1

38 ............. W B25-238 ................Pin......................................................................................................... 2

39 ............. TS-1502051 .............Socket Head Cap Screw .....................................M5x20 ........................ 6

40 ............. TS-0720091 .............Lock Washer ......................................................3/8 .............................. 7

41 ............. TS-0561031 .............Hex Nut ..............................................................3/8-16 ......................... 2

42 ............. TS-1503031 .............Socket Head Cap Screw .....................................M6x12 ........................ 1

43 ............. W B25-243 ................Gasket................................................................................................... 1

44 ............. W B25-244 ................Leveling Screw ...................................................................................... 4

25

Page 26

16.2.1 Base and Motor Assembly – Model WB-37 ONLY

Parts list on page 27.

26

Page 27

16.2.2 Parts List: Base and Motor Assembly – Model WB-37

Exploded view on page 26.

Index No. Part No. Description Size Qty

1 ............... WB37-201 ................Machine Base........................................................................................ 1

2 ............... WB37-202 ................Motor Plate ............................................................................................ 1

3 ............... WB37-203 ................Rod ....................................................................................................... 1

4 ............... WB25-149 ................Hex Nut ..............................................................1/2-12 ......................... 4

5 ............... WB37-205 ................Motor Adjusting Screw ........................................................................... 1

6 ............... TS-0720111 .............Lock Washer ......................................................1/2 .............................. 6

7 ............... WB25-701 ................Hex Cap Screw ..................................................1/2-12x1-1/2 ............... 4

8 ............... TS-0680061 .............Flat Washer ........................................................1/2 .............................. 2

9 ............... WB37-209 ................Motor ..................................................................20HP, 230/460V, 3Ph . 1

10 ............. W B37-210 ................Motor Pulley .......................................................................................... 1

11 ............. TS-0208071 .............Socket Head Cap Screw .....................................5/16-18x1-1/4 ............. 3

12 ............. W B25-212 ................Leveling Nut .......................................................................................... 4

13 ............. W B37-213 ................Key.....................................................................8x12x105 ................... 1

14 ............. TS-0051051 .............Hex Cap Screw ..................................................5/16-18x1 ................... 4

15 ............. TS-0720081 .............Lock Washer ......................................................5/16 ............................ 4

16 ............. W B25-216 ................Disc Brake ............................................................................................. 1

17 ............. W B37-217 ................Pulley Bushing....................................................................................... 1

18 ............. VB-B73 ....................V-Belt .................................................................B-73 ........................... 3

19 ............. W B37-219 ................Brake Base ............................................................................................ 1

20 ............. TS-0680041 .............Flat Washer ........................................................3/8 .............................. 2

21 ............. TS-0060031 .............Hex Cap Screw ..................................................3/8-16x3/4 .................. 2

22 ............. 6294280...................Limit Switch ........................................................................................... 2

23 ............. 6294281...................Limit Switch Plate .................................................................................. 2

24 ............. TS-0050021 .............Hex Cap Screw ..................................................1/4-20x5/8 .................. 2

25 ............. TS-0680021 .............Flat Washer ........................................................1/4 .............................. 2

26 ............. W B25-131 ................Flat Head Screw .................................................M5x8 .......................... 4

27 ............. TS-0720071 .............Lock Washer ......................................................1/4 .............................. 2

28 ............. 6294284...................Brake Housing ....................................................................................... 1

29 .............

30 ............. 6294286...................Brake Lining .......................................................................................... 1

31 ............. 6294661...................Rear Brake Lining .................................................................................. 1

32 ............. 6294287...................Bushing ................................................................................................. 1

33 ............. 6294288...................Spring.................................................................................................... 1

34 ............. 6294289...................Inner Plate ............................................................................................. 1

35 ............. TS-081F031 .............Flat Head Screw .................................................1/4-20x1/2 .................. 1

36 ............. 6294291...................Pin......................................................................................................... 2

37 ............. TS-0206041 .............Socket Head Cap Screw .....................................10-24x3/4 ................... 8

38 ............. TS-0720091 .............Lock Washer ......................................................3/8 .............................. 3

39 ............. TS-0561031 .............Hex Nut ..............................................................3/8-16 ......................... 2

40 ............. TS-0207031 .............Socket Head Cap Screw .....................................1/4-20x5/8 .................. 2

41 ............. 6294296...................Gasket................................................................................................... 1

42 ............. W B25-244 ................Leveling Screw ...................................................................................... 4

6294285...................Front Cover ........................................................................................... 1

27

Page 28

16.3.1 Base and Motor Assembly – Model WB-43 ONLY

Parts list on page 29.

28

Page 29

16.3.2 Parts List: Base and Motor Assembly – Model WB-43

Exploded view on page 28.

Index No. Part No. Description Size Qty

1 ............... WB43-201 ................Machine Base........................................................................................ 1

2 ............... WB43-202 ................Motor Plate ............................................................................................ 1

3 ............... WB43-203 ................Rod ....................................................................................................... 1

4 ............... WB25-149 ................Hex Nut ..............................................................1/2-12 ......................... 4

5 ............... 6294262...................Motor Adjusting Screw ........................................................................... 1

6 ............... TS-0720111 .............Lock Washer ......................................................1/2 .............................. 6

7 ............... WB25-701 ................Hex Cap Screw ..................................................1/2-12x1-1/2 ............... 4

8 ............... TS-0680061 .............Flat Washer ........................................................1/2 .............................. 2

9 ............... WB43-209 ................Motor ..................................................................25HP, 230/460V, 3Ph . 1

10 ............. W B43-210 ................Motor Pulley .......................................................................................... 1

11 ............. TS-0208071 .............Socket Head Cap Screw .....................................5/16-18x1-1/4 ............. 3

12 ............. W B25-212 ................Leveling Nut .......................................................................................... 4

13 ............. W B43-213 ................Key.....................................................................9×14×105 ................... 1

14 ............. TS-0051051 .............Hex Cap Screw ..................................................5/16-18x1 ................... 4

15 ............. TS-0720081 .............Lock Washer ......................................................5/16 ............................ 4

16 ............. W B25-216 ................Disc Brake ............................................................................................. 1

17 ............. W B43-217 ................Pulley Bushing....................................................................................... 1

18 ............. VB-B70 ....................V-Belt .................................................................B-70 ........................... 3

19 ............. W B37-219 ................Brake Base ............................................................................................ 1

20 ............. TS-0680041 .............Flat Washer ........................................................3/8 .............................. 2

21 ............. TS-0060031 .............Hex Cap Screw ..................................................3/8-16x3/4 .................. 2

22 ............. 6294280...................Limit Switch ........................................................................................... 2

23 ............. 6294281...................Limit Switch Plate .................................................................................. 2