Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

14” Woodworking Band Saw

Model PWBS-14CS

Powermatic

427 New Sanford Rd.

LaVergne, TN 37086 Part No. M-1791216

Ph.: 800-274-6848 Revision F1 01/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provi de proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Information

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 5

Introduction ............................................................................................................................................. 6

Features and Specifications ..................................................................................................................... 7

Grounding Inst r uc tions ............................................................................................................................. 8

115 Volt Operati on ............................................................................................................................... 8

230 Volt Operati on ............................................................................................................................... 8

Extension Cords................................................................................................................................... 9

Unpac king ............................................................................................................................................. 10

Contents of the Shipping Container .................................................................................................... 10

Installation and Assembly ...................................................................................................................... 12

Mounting Band Saw to Stand ............................................................................................................. 12

Installing Drive Belt ............................................................................................................................ 13

Installing Trunnion Support................................................................................................................. 14

Installing Extension Table .................................................................................................................. 14

Installing Main Table .......................................................................................................................... 14

Leveling the Extension Table ............................................................................................................. 15

Installing Rear Rail ............................................................................................................................. 15

Installing Fr ont Rail and Rip Fence ..................................................................................................... 16

Resaw Guide ..................................................................................................................................... 18

Blower Nozzle .................................................................................................................................... 18

Work Lamp ........................................................................................................................................ 18

Installing Quick Tension Lever............................................................................................................ 19

Stand Attachments ............................................................................................................................. 19

Dust Collection ................................................................................................................................... 19

Riser Block Accessory........................................................................................................................ 19

Adjustments ................................................................................................................... ....................... 2 0

Tilting th e Table ............................................................................................................. .................... 2 0

Adjusting 90° Table Stop .................................................................................................................... 20

Table Aligned wit h Bl ade .................................................................................................................... 21

Installing Blades ................................................................................................................................. 21

Blade Tension .................................................................................................................................... 22

Blade Tracking ................................................................................................................................... 23

Guide Post and Upper Bl ade Guard ................................................................................................... 23

Upper Bearing G uides ........................................................................................................................ 24

Lower Bearing Guides ........................................................................................................................ 24

Miter Gauge ....................................................................................................................................... 25

On/Off Switch ..................................................................................................................................... 2 6

Maintenance .......................................................................................................................................... 26

Blade Selecti on ..................................................................................................................................... 27

Width ................................................................................................................................................. 27

Pitch ......................................................................................................................... ......................... 27

Shape ................................................................................................................................................ 27

Set ..................................................................................................................................................... 28

Material .............................................................................................................................................. 28

Blade Breakage ................................................................................................................................. 28

Operation .............................................................................................................................................. 2 9

General Procedure ............................................................................................................................. 29

Ripping .............................................................................................................................................. 29

Crosscutting ....................................................................................................................................... 29

Resawing ........................................................................................................................................... 30

Blade Lead ........................................................................................................................................ 30

Troubleshooting – Mechanical and Elect ri c al P r oblem s .......................................................................... 31

Troubleshooting – Operating Problems .................................................................................................. 32

Optional Accessories ............................................................................................................................. 34

Blade Selecti on Guide ........................................................................................................................... 35

For Radius Cutti ng ............................................................................................................................. 35

3

Page 4

Replacement Parts ................................................................................................................................ 36

Parts List: Body Assembly .................................................................................................................. 3 6

Body Assembly .................................................................................................................................. 39

Parts List: Closed St and A ssembly ..................................................................................................... 40

Closed Stand Assembl y ..................................................................................................................... 41

Parts List: Fence and Rail Assembly .................................................................................................. 4 2

Fence and Rail Assembly ................................................................................................................... 43

Parts List: Table and Trunnion Assembly............................................................................................ 44

Parts List: Miter Gauge Assembly....................................................................................................... 45

Parts List: Bl ade Tension Lever .......................................................................................................... 46

Electri c al Connec tions for PWBS-14CS ................................................................................................. 47

4

Page 5

Warning

1. Read and understand this entire owner’s manual before attempting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This band saw is designed and i ntended for use by pr operl y tr ained and ex peri enced personnel only .

If you are not familiar with the proper and safe operation of a band saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approved saf ety gl asses/face shi elds whil e using this ba nd saw. (Ev eryday ey eglasses

only have impact resi stant lenses; they are not saf ety glasses.)

7. Before operating the band saw, r emove ti e, rings, watches and other jewel r y , and roll sl eeves up past

the elbows. Remove all loose clothing and confine long hair. Non- sl ip footwear or anti-ski d floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of operati on.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other r epr oduc tive harm. Some exam ples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under the influence of drugs, alcohol or any m edic ation.

11. Make certain t he switc h is i n the OFF position before connect ing the machine to the power supply .

12. Make certain t he machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately.

16. Make sure the band saw is firmly secured to the stand or a work bench befor e use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Provide f or adequate space surrounding work area and non- glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

20. Keep visit or s a safe di stanc e from the work area. Keep children away.

21. Make your workshop chil d pr oof with padlocks, master switc hes or by r emoving starter key s.

5

Page 6

22. Make your workshop chil d pr oof with padlocks, master switc hes or by r emoving starter key s.

23. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

24. Maintain a balanced stance at all times so that you do not f all or lean against the blade or other

moving part s. Do not over r eac h or use excessive force to perform any m ac hine oper ation.

25. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

26. Make relief cut s where possibl e, when cutting curved stock.

27. W hen feeding sm all work piece s into the bl ade, al ways use a pus h stic k, fix ture, or simil ar devi ce to

keep hands at a safe distanc e.

28. Use recommended accessories; improper accessories may be hazardous.

29. Do not expose machine t o rai n or use in wet or dam p locations.

30. Mai ntain tools with care. Keep bl ades sharp and clean for the best and saf est performance. Follow

instructions for lubricating m ac hine and c hanging accessories.

31. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

32. Do not stand on the machine. S eri ous i njur y c oul d oc c ur if the mac hine tips over.

33. Never leave t he m ac hine r unning unattended. Turn the power off and do not l eav e the mac hine until it

comes to a complete stop.

34. Remove loose it em s and unnecessary work pieces from the ar ea before starting the machine.

Familiariz e you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious and possibly fat al

injury.

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Powermatic Model PWBS-14CS Band Saw. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordanc e with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or Powermatic. Powermatic can also be reached at our web site: www. powermatic.com.

The specifi cati ons in thi s m anual were cur rent at the t i m e this m anual was publi shed, but b ecau se of our

policy of c ontinuous improvement, Powermatic reserves the right to change specifications at any time and

without pri or notic e, without incurri ng obligations.

6

Page 7

Features and Specifications

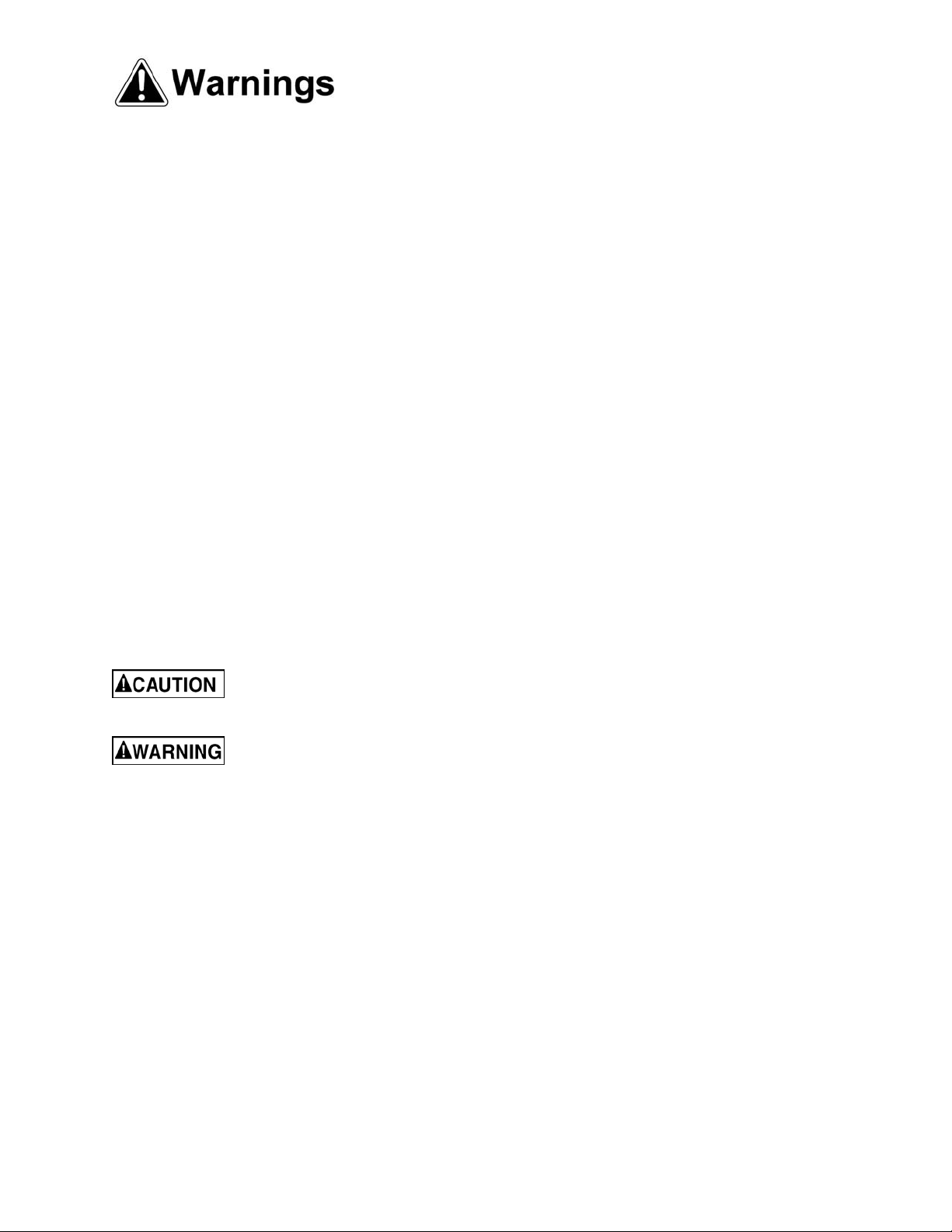

Figure 1

Model Number ....................................................................................................................... PWBS-14CS

Stock Num ber............................................................................................................................ 1791216K

Resaw (Height) Capacity (in.) .................................................................................................................. 6

Cutting Widt h (Thr oat Capacity)(in.) ................................................................................................. 13-1/2

Minimum Saw Blade Width (in.) ............................................................................................................ 1 /8

Maximum Saw Blade Wi dth (in.) ........................................................................................................... 3/4

Blade Length (in.) ............................................................................................................................ 93-1/2

Main Table Size (Lx W)( in .) ............................................................................................................. 15 x 15

Extension Table Size (LxW)(in.) .................................................................................................. 15 x 5-1/2

Blade Speed (SFPM ) ......................................................................................................................... 3000

Table Tilt (deg.) ................................................................................................................45 Right, 10 Left

Table He ight from Floo r (in .) .................................................................................................................. 44

Dust Chute Outside Diameter (in.) ........................................................................................................... 4

Minimum Dust Coll ecti on CFM Required .............................................................................................. 350

Motor ......................................................... TEFC, 1.5HP, 1PH, 115/230V (prewired 115V ) , 11/5.5A, 60Hz

Recommended cir c uit

Overall Dim ensi ons – Body and Stand fully assembled (LxWxH) (in.)....................................... 20 x 34 x 68

Stand Footpri nt (LxW)(in.) ......................................................................................................... 16 x 17-1/2

Approximate Weights:

Body (Net/Shipping)(lbs.) ......................................................................................................... 166/178

Closed Stand (Net/Shipping) (l bs.) ................................................................................................ 84/88

(*subject to local electrical codes) ............................................. 30A (115V ) , 20A (230V)

7

Page 8

Grounding Instructions

This tool must be grounded while in use to protect the operator from electric

shock.

In the event of a malfunction or breakdown, groundi ng provides a path of least resistance f or electric

current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-gr ounding conductor and a groundi ng plug. The pl ug must be plugged into a matc hing outlet

that is properly installed and grounded in acc or danc e with all local codes and ordinances.

Do not modify the plug provided. If it will not fit the outl et, have the proper outl et installed by a qualif ied

electrician.

Improper connection of the equipment-grounding conductor can result in a risk of electric shock. The

conductor, with insulation having an outer surface that is green with or without yellow stripes, is the

equipment-gr ounding conduct or. If repai r or replacem ent of the electri c cord or plug i s necessary, do not

connect the equipment-grounding conduc tor to a live terminal.

Check with a qualified electrician or servi ce personnel if the grounding instructions are not completely

understood, or if in doubt as to whether t he tool is properly gr ounded. Use only three wire ex tension cords

that have thr ee- pr ong gr ounding plugs and three-pole recept ac les that accept the tool’s plug.

Repair or replace a dam aged or worn cord im mediately.

It is recommended that the PWBS-14CS Band Saw, when operated at 115 volts, be connected to a

grounded and dedi cated 30 amp ci rcuit with circuit breaker or time delay f use. When oper ated at 230

volts, c onnect t he saw to a 20 am p dedi cat ed ci rc uit with breaker or tim e del ay f use. Lo cal co d es take

precedence o ver recommendations.

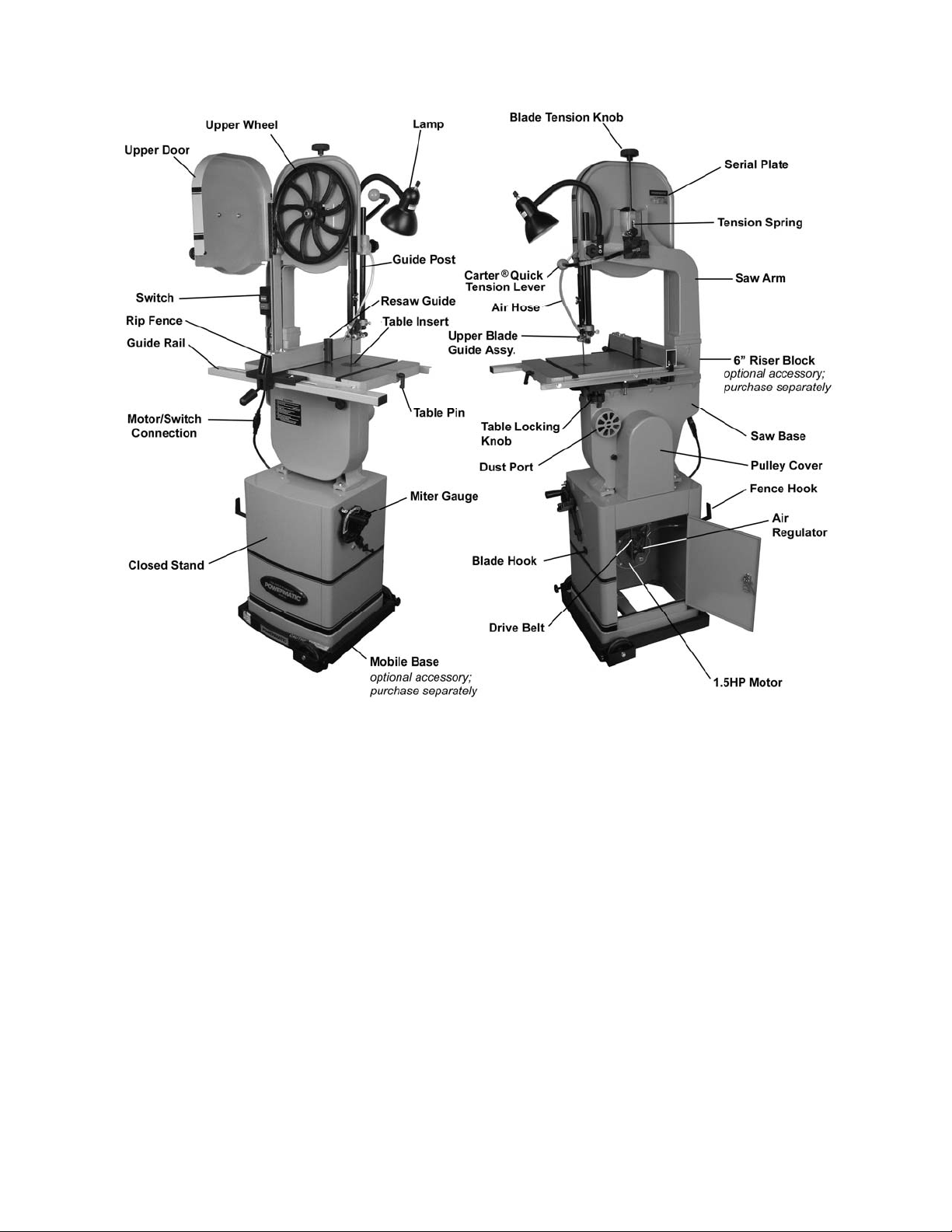

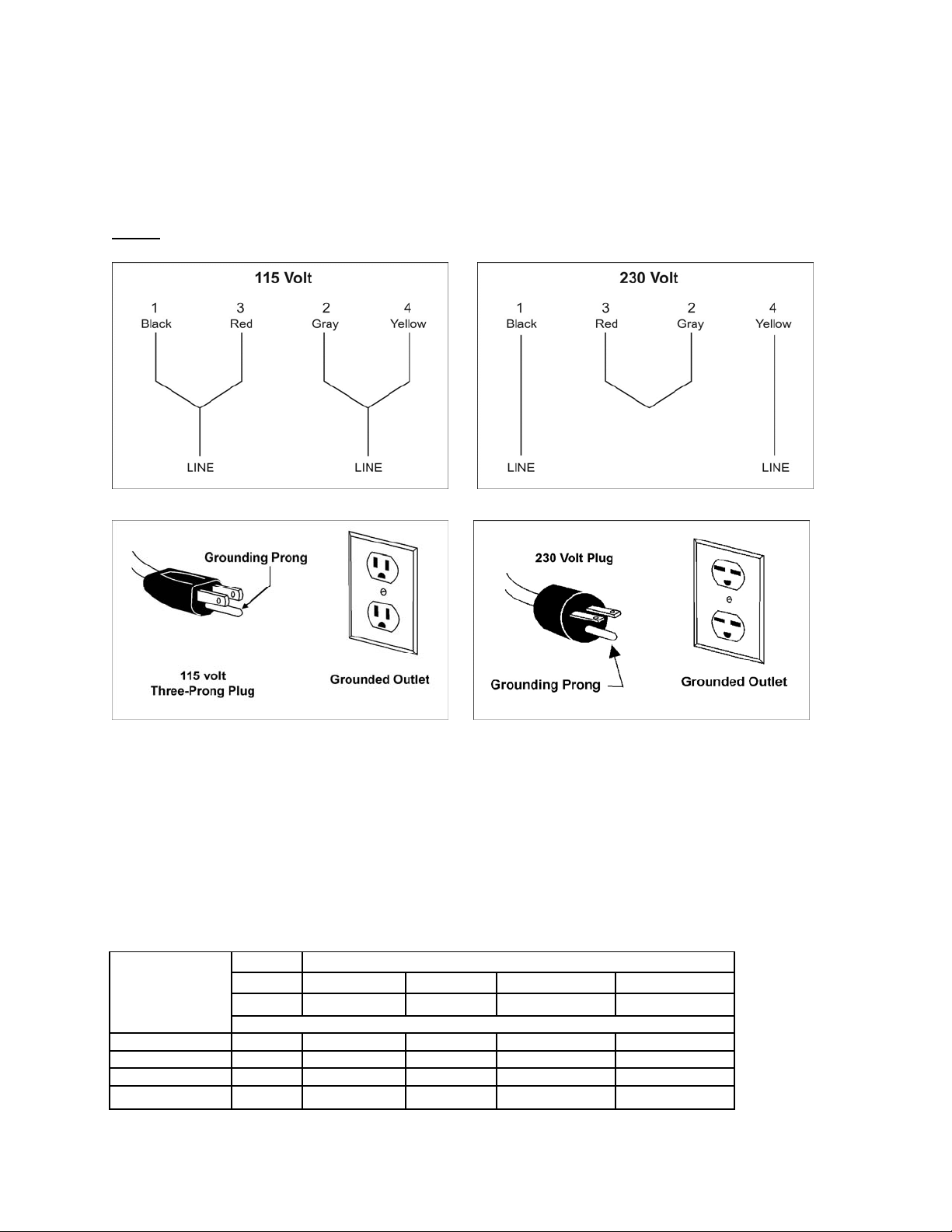

115 Volt Operation

As received fr om the factory, your band saw is wired to run at 115 volt oper ation. This band saw, when

wired for 115 volts, is i ntended for use on a circuit that has an outlet and a plug that looks like the one

illustrated in Figure 2. A temporary adapter, which looks like the adapter illustrated in Figure 3, m ay be

used to connect this plug to a two-pole receptacle, as shown in Figure 3 if a properly grounded out let is

not available. The temporary adapter should only be used until a properly gr ounded outlet can be

install ed by a qualif ied electrician. This adapter is not applicable in Canada. The green colored ri gid

ear, lug, or tab, extending from the adapter, m ust be connected to a permanent gr ound such as a

properly grounded outlet box, as shown in Figur e 3.

Figure 2 Figure 3

230 Volt Operation

If 230V, singl e- phase operat ion is desired, the f ollowing instructions must be followed:

Disconnect the mach in e f rom the power sou rce.

This band saw is supplied with four motor leads that are connected for 115V operation, as shown in

Figure 4. Reconnect these four motor leads for 230V operation, as shown in Figure 5. These diagrams

are also found insi de the cover of the motor junction box.

8

Page 9

The 115V attachment plug (shown in Figure 6) supplied with the band saw, must be replaced with a

A

UL/CSA listed pl ug suit able f or 230V oper ati on (s hown i n F igur e 7). Cont act your l ocal aut hori zed Walt er

Meier (Manuf acturi ng) Inc., serv ic e center or qualifi ed elec trici an for pr oper proc edures to i nstall the pl ug.

The band saw must comply with all local and national codes after the 230 volt plug is installed.

The band saw with a 230 v olt pl ug should only be connec ted to an o utlet having t he same confi gurati on

(see Figure 7). No adapter is available or should be used with the 230 volt plug.

Important: In all cases (115 or 230 vol t s) , make certain the receptacl e in quest io n i s properly

grounded. If you are not su re, h ave a regi st ered el ectri cian check the recept acle.

NOTE: The lamp is designed fo r use wi th 115V power. I f the saw i s converted to 230V, discontinue

use of the lamp, and use an alt ernate lamp with an independent electrical source.

Figure 4 Figur e 5

Figure 6 Figure 7

Extens ion Cords

If an ext ension cord is necessary, make sure the cord r ating is suitabl e for the amperage l isted on the

machine’s mot or plat e. An undersized c ord will cause a drop i n line v oltage r esulting in loss of power and

overheating.

Use the chart in Figure 8 as a general guide in choosing the correc t size extension c or d for the band saw.

If in doubt, use the next heav ier gauge. The smaller the gauge number, the heavier the cord.

Recommended Minimum Gauge (AWG) of Extension Cords

Volts Total Length of Cord in Feet

115 V 25 ft. 50 ft. 100 ft. 150 ft.

230 V 50 ft. 100 ft. 200 ft. 300 ft.

Ampere Rating

< 6 18 16 16 14

6 to 10 18 16 14 12

10 to 12 16 16 14 12

12 to 16 14 12 Not recommended Not recommended

WG

Figure 8

9

Page 10

Unpacking

The band saw is shipped i n two cartons. Open

both cartons and inspect contents for shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Band

Saw is assembled and running properly.

Compare the contents of both cartons and all

internal boxes with the following parts list to

make sure all parts are intact.(*) Missing parts, if

any, should be report ed to your distributor. Read

this instruc tion manual thoroughl y for assembly,

maintenance and safety instructions.

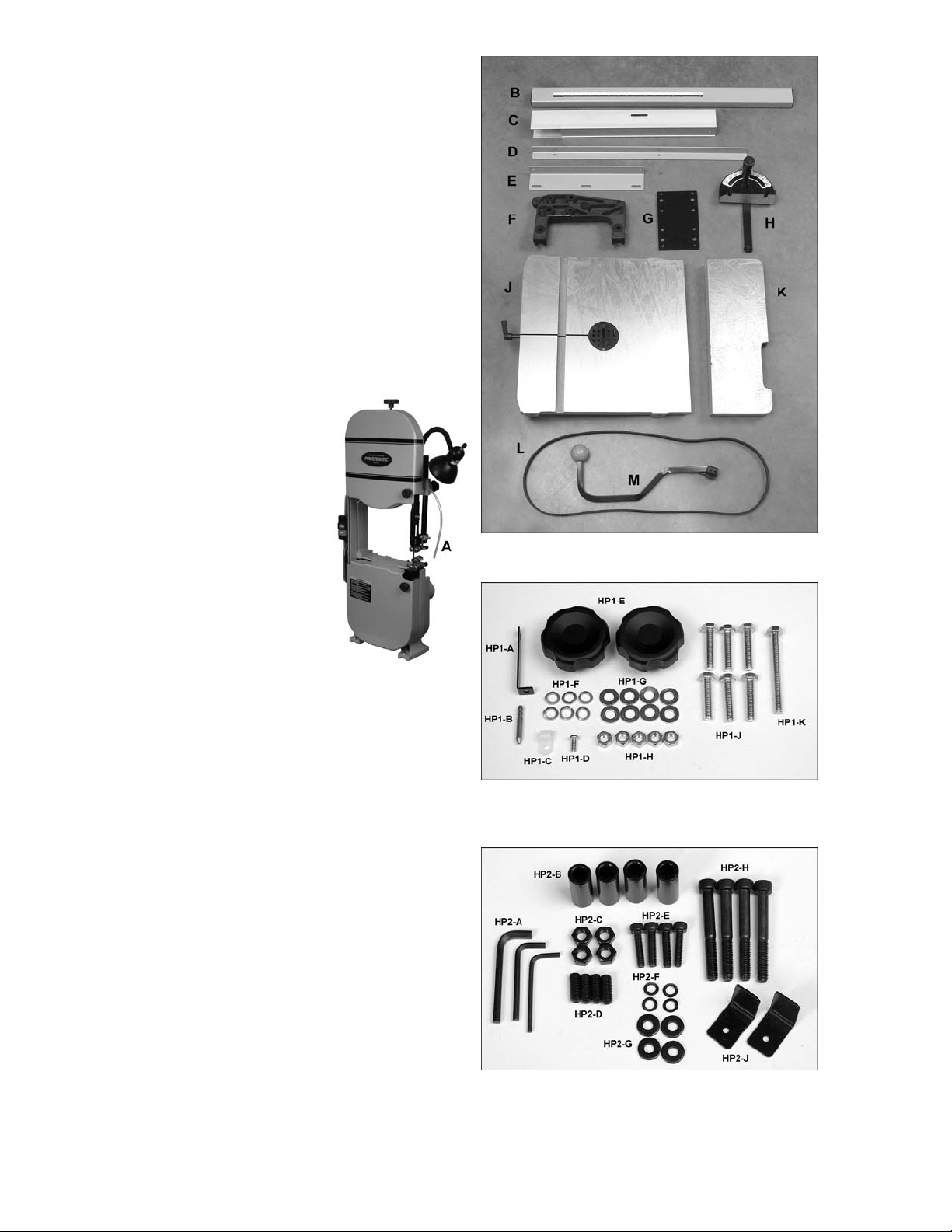

Contents of the Shipping Conta iner

Carton #1 – Band Saw:

Refer to Figure 9.

1 Band Saw – (A)

1 guide rail – (B)

1 rip fence – (C)

1 rear rail – (D)

1 front rail – (E)

1 trunnion support – ( F)

1 level board – (G)

1 miter gauge – (H)

1 main table – (J)

1 extension table – (K)

1 drive belt – (L)

1 quick tension l ev er – (M)

1 owner's manual ( not shown)

1 warranty card (not sho wn)

2 Hardware packages, as follows.

Hardware Package #1 cont ains:

Refer to Figure 10.

1 support plate (HP1-A)

1 air jet nozzle (HP1-B)

1 cord clamp (HP1-C)

1 pan head screw, M5x12 (HP1-D)

2 table locking knobs (HP1-E )

6 lock washers, M8 (HP1-F)

8 flat washers, M8 (HP1-G)

5 hex nuts, M8 (HP1-H)

6 hex cap screws, M8x40 (HP1-J)

1 hex cap screw, M8x80 (HP1-K)

Hardware package #2 contains:

Refer to Figure 11.

3 hex (Allen) wrenches, 3,4, 5mm (HP2-A)

4 spacers (HP2-B)

4 hex nuts, M8 (HP2-C)

4 socket set screws, M8x20 (HP2-D)

4 socket head cap screws, M6x25 (HP 2-E)

4 lock washers, M6 (HP2-F)

4 flat washers, M6 (HP2-G)

4 socket head cap screws, M8x65 (HP 2- H )

2 L-spacers (HP2-J)

Figure 9

Band Saw carton

Figure 10

Hardware package #1

(stock no. PWBS14- HP 1)

Figure 11

Hardware package #2

(stock no. PWBS14- HP 2)

10

Page 11

Carton #

2

- Stand:

Refer to Figure 12.

1 Stand with mot or (N)

1 pulley cover (O)

1 fence body (P)

2 hardware packages, as follows.

Hardware package #3 contains:

Refer to Figure 13.

2 fence hooks (HP3-A)

2 miter gauge hooks (HP3-B)

1 blade hook (HP3-C)

2 pulley cover knobs (HP3-D)

4 carriage bolts, M8x 16 (HP3-E )

4 flanged hex nuts, M8 (HP3-F)

2 pan head screws, M5x12 (HP3-G)

2 pan head screws, M4x10 (HP3-H)

Hardware package #4 contains:

Refer to Figure 14.

1 resaw pin (HP4-A)

1 resaw pin knob (HP4-B)

1 fence rear hook (HP4-C)

2 hex nuts, 1/4” (HP4-D)

1 flat washer, 1/4” (HP4-E)

1 lock washer, 1/4” (HP4-F)

1 sliding pad (HP4-G)

4 hex cap screws, 5/16”x3/4” (HP4-H)

4 lock washers, 5/16” (HP4- J)

4 flat washers, 5/16” (HP4-K )

7 hex cap screws, M6x20 (HP4-L)

7 lock washers, 1/4” (HP4-M)

7 flat washers, 1/4” (HP4-N)

(*) the identifying letters/numbers in parentheses are

used throughout the text to clarify assembl y. For

actual part numbers if re-ordering, see the part

breakdowns at the back of this manual.

Figure 12

Stand carton

Figure 13

Hardware package #3

(stock no. PWBS14- HP 3)

Figure 14

Hardware package #4

(stock no. PWBS14- HP )

11

Page 12

Installation and Assembly

Tools required for assembly:

open-end or box wrenches– 10mm , 12mm, 1/2”

[in some c ases, a socket wrench set can be

used to speed assembly time]

hex (Allen) wrenches – 3, 5, 6mm

Cross point (Phillips) screwdriver

square

straightedge

NOTE: If further clarification is needed for any of

the following assembly procedures, consult the

exploded views at the bac k of t his manual.

Exposed met al surf aces on the Ban d Sa w, such

as the table, have been given a protective

coating at the factory. This should be removed

with a soft cl oth moistened with a l ight solvent.

Do not use gasoline, lacquer thinner, acetone,

or other highl y volatile solvents f or this. Do not

use an abrasive pad as it may scratch the

polished metal surfaces.

IMPORTANT: The Band Saw must be

disconnect ed from the power source bef ore

any assembly procedu res!

Mounting Band Saw to Stand

Refer to Figures 15 and 16.

1. Remove loose items from inside of stand.

2. Place stand upright on a level surface. If

desired, the stand can be f urther stabilized

by securing it to the floor with lag screws

through the inside corner holes. If using a

mobile base, lock the casters before

assembling or oper ating the band saw.

T he saw body is heavy – u se

caution when l ifting, and stab iliz e until fi rmly

attached to the stand . Failure to co mply may

cause serious inj ury.

3. With the aid of a second person, lift the

Band Saw out of t he shipping cont ainer and

place on top of the stand. Make sure that

front of saw (with Powermatic nameplate)

faces same direction as curved stand front.

4. Line up holes in t he saw base wit h holes in

the top of the st and. F asten saw base to the

stand with four M8x40 hex cap screws

(HP1-J), eight M8 flat washers (HP1-G) , four

M8 lock washers (HP1-F), and f our M8 hex

nuts (HP1-H). Use a 1/2” wrench to tighten.

Figure 15

12

Page 13

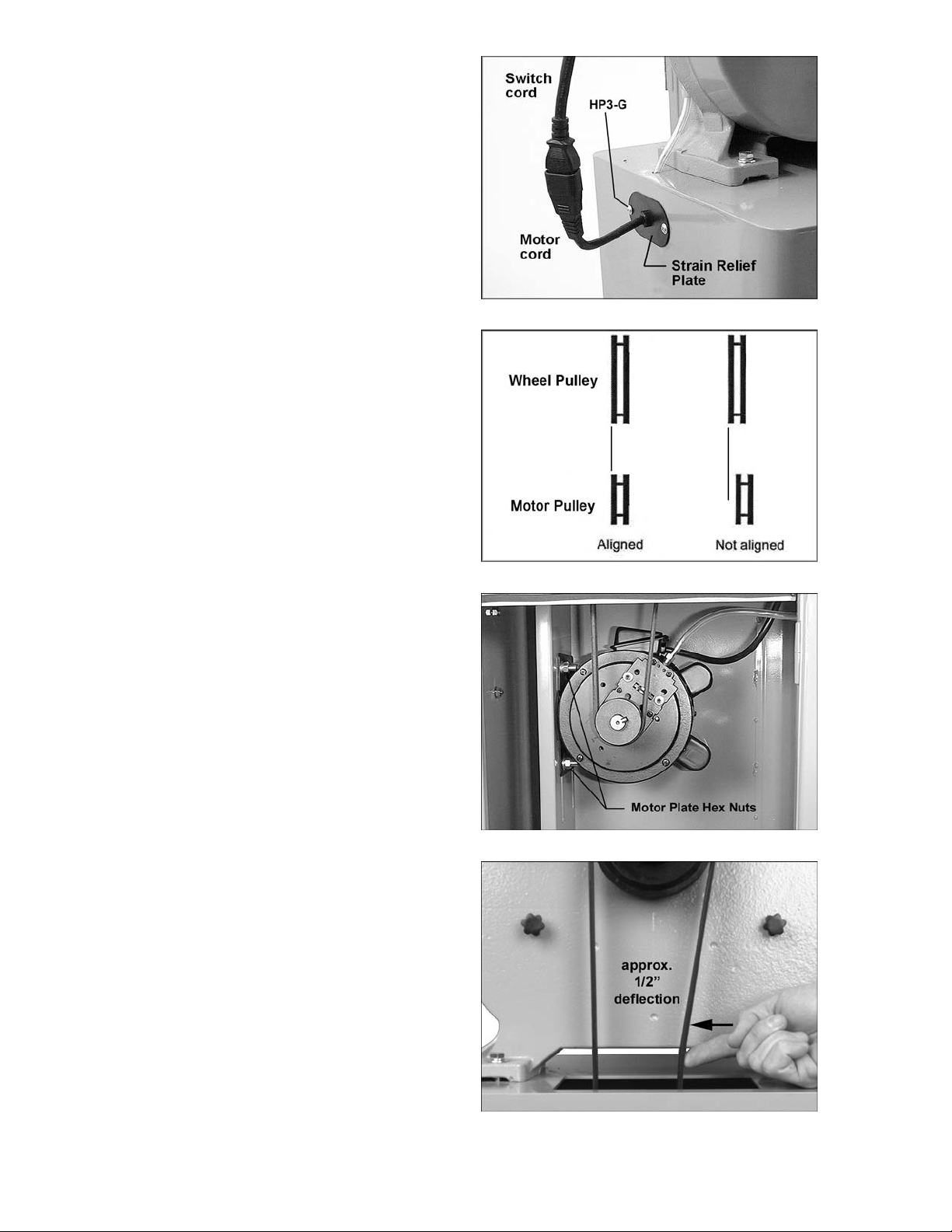

5. Push motor cord and strain relief plate

through the opening to the outside of the

stand, as shown in Figure 16. Fasten the

strain relief plate to the stand with two

M5x12 pan head screw s (HP3-G) .

6. Connect the plugs of the switch cord and

motor cord (Figure 16). Do not connect

machine to power source during

assembly.

Installing Drive Belt

Refer to Figures 17 t hr ough 20.

1. The motor and wheel pulleys have been

accurately aligned with each other by the

manufacturer. However, the user may wish

to verify this setting in case misalignment

has occurred during transit. Misaligned

pulleys can produce excessive wear on

drive belts.

2. If the pulleys do not lie in a straight plane

(Figure 17) , loosen the set scre w on one of

the pulley s and shif t the pul l ey in or out until

both pulleys lie in a straight plane. Tighten

set sc rew.

3. Open the lower door, and loosen the four

hex nuts on the motor plate an equal

amount, with a 1/ 2” wrench (see Figur e 18).

Lift up on t he motor to provi de slack for t he

drive belt installation.

4. Install t he belt around the mot or pulley and

the wheel pull ey.

5. Tension the drive belt by pushing down on

the motor. You may have to push down

harder on the pulley end of the motor to

overcome t he pressure of the driv e belt and

keep the motor pulley aligned wit h the wheel

pulle y.

6. Tighten the f our hex nut s on the m otor plate.

NOTE: The belt is properly tensioned when

finger pressure between the two pulleys

causes approximately 1/2” def lection (Fi gure

19).

Figure 16

Figure 17

Figure 18

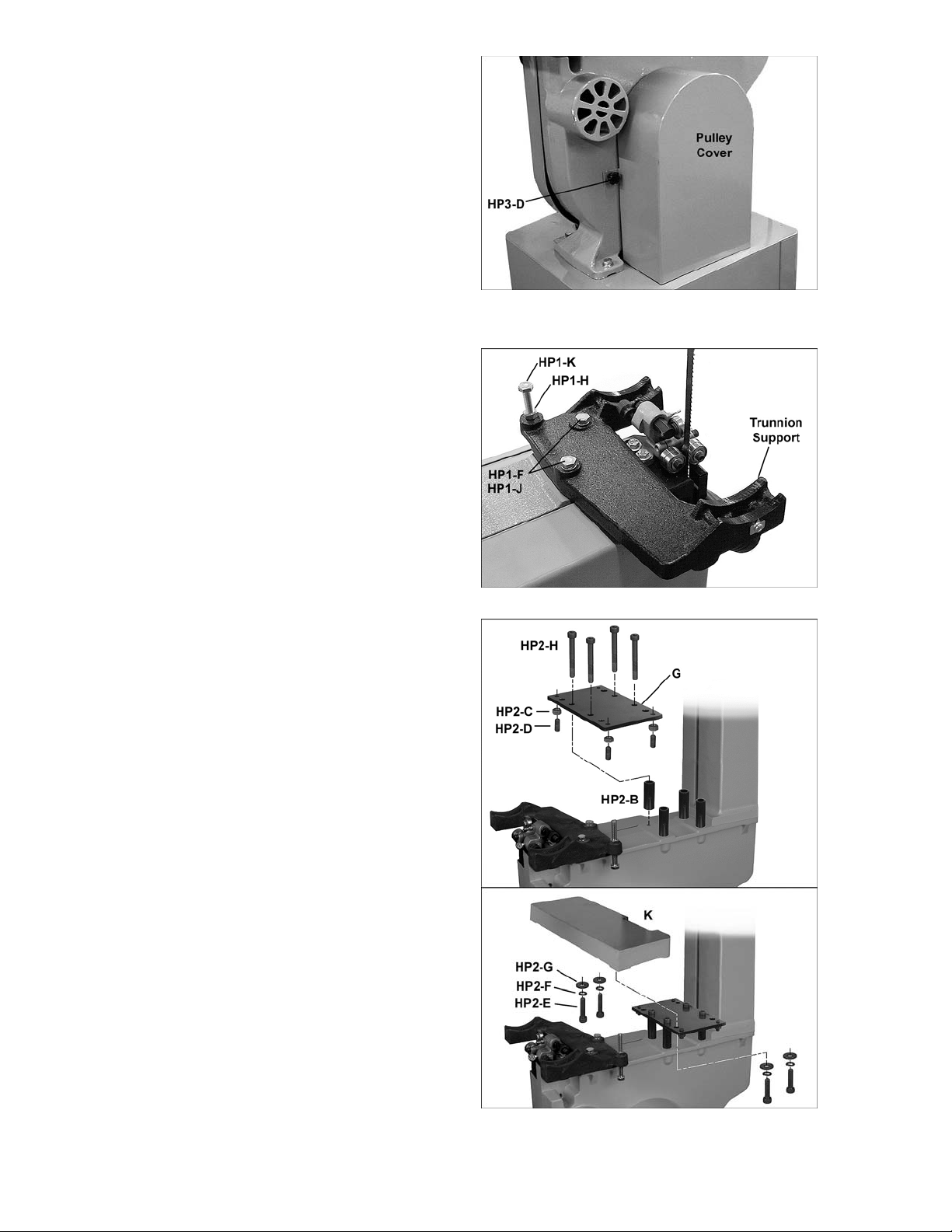

7. Screw the two pulley cover knobs (HP3-D)

into the threaded holes in the back of the

saw, as shown in Fi gure 20. Sli de the pull ey

cover down ov er the knobs, and ti ghten the

knobs.

Figure 19

13

Page 14

Installing Trunnion Support

Refer to Figure 21.

1. Use the two locating pins attached to the

saw body to help position the trunnion

support. Attach trunnion support to saw

body with two M8x30 hex cap sc rews (HP1-

J) and two M8 lock washers (HP1-F).

Tighten with a 1/ 2” wrench.

2. Thread M8 hex nut (HP1-H) onto t he M8x80

hex cap screw (HP1-K) and install into the

trunnion support as shown. Finger tighten

the hex nut; this will be f ully tightened l ater

for the 90° table stop sett ing.

Installing Extension Table

Refer to Figure 22.

1. Install a M8 hex nut (HP2-C) on each of the

four M8x20 set screws (HP2-D), then install

these set screws into t he four outer holes of

the level board (G), as shown.

2. Leave t he set screws fl ush with the top side

of the level board for now. These will be

adjusted later during leveling.

Figure 20

3. Place four spacers (HP2-B) over the holes

in the saw body, and pl ace the level board

on them, as shown. Ali gn t he four innerm ost

holes of the level board with the spacers,

and insert four M8x65 socket head cap

screws (HP2-H). Firmly tighten these screws

down into the base through the spacers,

using a 6mm hex wrench.

4. Position the extension table (K) over the

level board. Insert four M6x25 sock et head

cap screws (HP2-E) with four M6 lock

washers (HP2-F) and four M6 flat washers

(HP2-G) up through the rem aining holes of

the plate and into the underside of extension

table. Hand ti ghten only at this time.

Installing Main Table

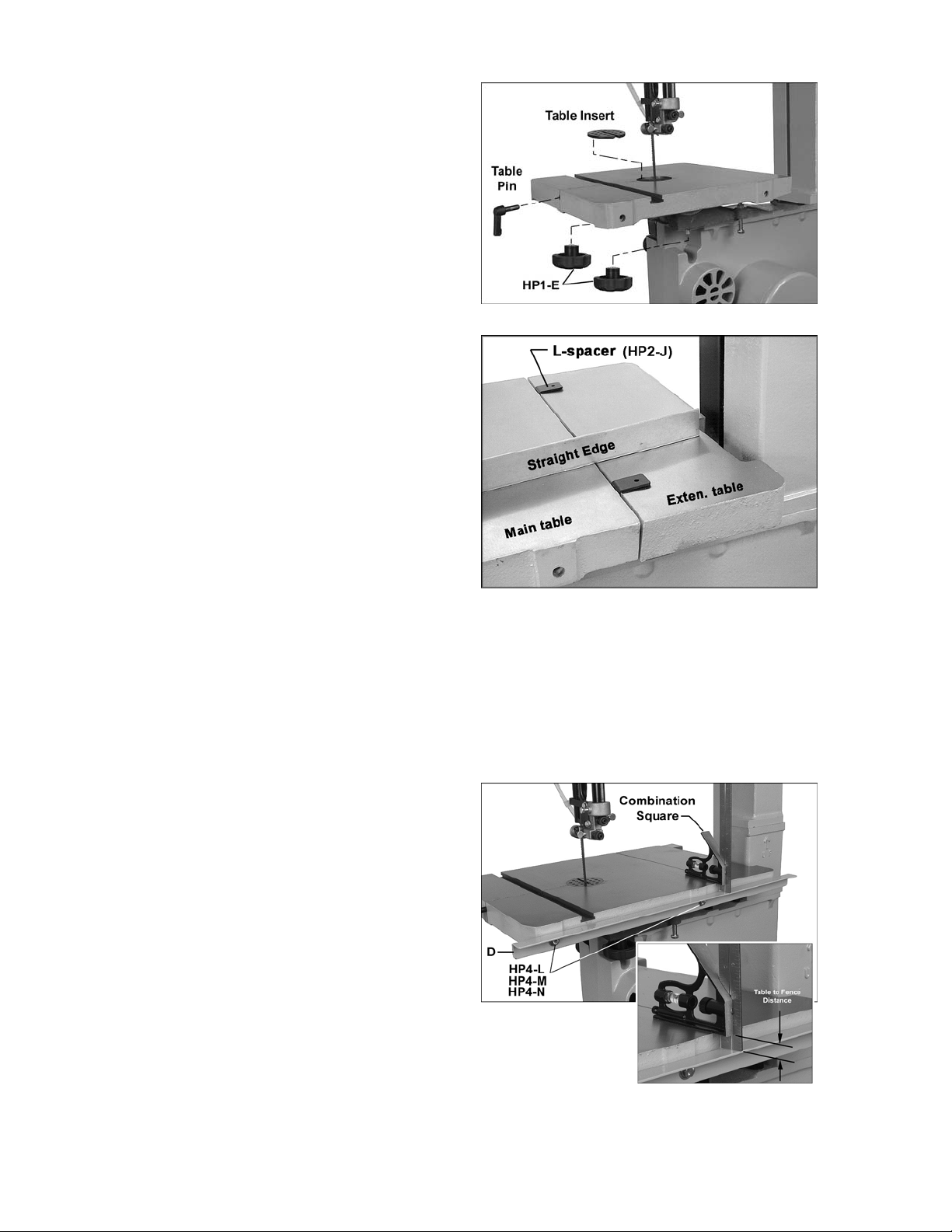

Refer to Figure 23.

1. To m ount the main table, remove t able pin

by pulling it straight out, twisting it if needed.

Remove the table insert by pushing it up

from beneath t he table.

2. Rotate the tabl e so that the sa w bl ade will

slide through the slot in the table. Then

orient the t able so the screws will sli de into

the holes on the trunni on support, as shown

in Figure 23. Attach the two table locking

knobs (HP1-E) to t hese screws and ti ghten.

Figure 21

3. Re-install table pin and table insert.

Figure 22

14

Page 15

Leveling the Extension Table

NOTE: Before leveling the extension table, the

90-degree stop of the main table should be

verified. Read “Adjusting 90° Table Stop” on

page 20, then retur n to t his page.

Refer to Figures 22 and 24.

1. Position the main table at 90-degrees and

tighten the table locking knobs.

2. Place a straight edge (Figure 24) across

both tables, at several points along the

tables. If t he extensi on table is not l evel wit h

the main tabl e, use the level board beneath

to achieve this, as follows.

3. With the four M6x25 socket head cap

screws (HP2-E, Figure 22) still slightly

loose, loosen the hex nut s (HP 2-C) and t urn

any of the four set screws (HP2-D) with a

4mm hex wrench, t o raise or l ower that par t

of the extension table.

4. When the extension table is level with the

main tabl e, use a 1/2” wrench to tight en the

hex nuts (HP2-C) up against the level

board, to secure the setting of the set

screws.

Figure 23

5. Adj ust the gap between the extension t able

and the main tabl e. This gap can be easil y

set by using the pr ov ided L- spacers (HP2- J)

(Figure 24). Place the L-spacers between

the tables as shown, and nudge the

extension t able toward the m ain table as far

as it will go.

6. Snug the socket head cap screws (HP2-E)

with a 5mm hex wrench, a nd remov e the Lspacers.

7. Tilt the main t able to ensure that i t does not

rub against the edge of the extension table.

8. Securely tighten the four socket head cap

screws (HP2-E), making sure the extension

table doesn’t shif t during tightening.

Installing Rear Rail

Refer to Figure 25.

1. Disconnect machine from power source.

2. Install rear rail (D) to the main table using

two M6x20 hex cap screws (HP4-L), two

1/4" lock w ashers (HP4-M ) and two 1/4" flat

washers (HP4-N). Finger tighten only.

Figure 24

3. The rear r ail should lie parall el to the table

top. Place a combination square on the

main table at one end of the rear rail to get a

measurement showing tabl e-to- rail di stance,

as shown. Check t he other end of the fence;

the measurement shoul d be the same.

Figure 25

15

Page 16

4. Shift either end of the fence as needed to

gain identical distance from tabl e top.

5. Ti ghten both screws in the rear r ail using a

10mm wrench.

Installing Front Rail and Rip Fence

Refer to Figures 26 t hr ough 29.

1. Install front rail (E, Figure 26) to the main

table using two M6x20 hex cap screws

(HP4-L), two 1/4" lock washers ( HP 4- M ) and

two 1/4" flat washers (HP4-N). Finger

tighten only at t his tim e.

2. Install guide rail (B, Fi gure 27) to the slot s in

the front rail using three M6x20 hex cap

screws (HP4-L), three 1/4" lock washers

(HP4-M) and three 1/4" flat washers (HP4-

N). Tighten with a 10mm wrench.

3. Attach the fence (C, Fi gure 28) to the fence

body (P) with four 5/16”x3/4” hex cap

screws (HP4-H), four 5/16” lock washers

(HP4-J) and four 5/16” flat washers (HP4-K).

Tighten the screws with a 12mm wrench.

4. At the rear of the fence, thread a 1/4” hex

nut (HP4-D, Figure 29) onto the sliding pad

(HP4-G) and insert the sliding pad through

the fence and r ear hook (HP4-C). Secure in

place using a 1/4” flat washer (HP4- E), 1/4”

lock washer (HP4-F) and a 1/4” hex nut

(HP4-D). The rear hook should be adj usted

so that it overlaps the rear rail by

approxim ately 1/8".

Figure 26

Figure 27

5. Hook t he fence assembly over the rear rail,

and onto the guide rai l, as shown in Fi gure

28.

6. When t he fence assembl y is placed on the

table, the rear hook (HP4-C) should be

almost contac ting the undersi de of the rear

rail, as shown. The sliding pad will ride

along the top of the rear r ail.

Setting Fence-to-Table Gap

The gap between the bottom of the rip fence

and the table t op should be high enough that the

fence will not scrape along the table, yet low

enough that thi n workpieces won’t slip beneath

it. The gap should be equ al along the l ength of

the fence. Adjust as follows:

Refer to Figures 29 and 30.

1. Lock the f ence assembly t o the front rail by

pushing the fence handle down. The front

rail screws should still have “play” in them.

2. Lift up on bot h guide rail and fence toget her

until the f ence/table gap at the front edge of

the table is acceptable.

Figure 28

Figure 29

16

Page 17

3. Tighten bot h scr ews on the front rail (HP4-L,

Figure 26) with a 10mm wrench.

4. Adjust the height of the sliding pad at the

rear of the fence (Figure 29) if further

adjustment i s needed to even the gap along

the length of the fenc e.

Aligning Fence to Blade

Refer to Figure 31.

1. Place the table at 90-degrees. (Make sure

the 90° Tabl e Stop sett ing has been v erifi ed

– see page 20.)

2. Lock the fence to the guide rail with the

handle.

3. Place a square on t he table and agai nst the

fence, as shown in Figure 31.

4. If the fence is not square to the table,

slightly loosen the two screws in the front

rail (see Figure 26) and raise or lower one

end of the f ront rail assembly until f ence is

square to table.

5. Re-tighten screws. The fence face is now

square to the tabl e, and thus parallel to the

blade.

The fence must al so be set so that it aligns wit h

the blade front- to-back, as follows:

6. Move the fence so that it just contacts the

blade without bendi ng it, and lock t he fence

to the guide rail.

7. Check that the fence is aligned with the

blade; that is, it contacts front and back of

blade evenly. If the fence does not al ign with

the blade, loosen the four hex cap screws

(HP4-H).

8. Align t he fence wit h the blade, t hen tighten

the four hex cap screws.

Figure 30

Figure 31

Checking zero setting

Refer to Figure 31.

1. With the fence now aligned with the blade,

and still contacting the blade as shown in

Figure 31, check to see that the pointer is

aligned wit h zero on t he guide r ail scale.

2. If minor adjustment i s necessary, l oosen the

screw that holds the pointer in place, and

adjust the poi nter. Re-tighten the screw.

3. If major adjustment i s necessary, l oosen the

guide rail screws (HP4-L, Figure 27), and

slide the entire fence/ guide rail t ogether until

the fence just contac ts the bl ade. Re- ti ghten

guide rail screws, and make further minor

adjustment wit h the pointer.

17

Page 18

NOTE: The pointer’s zero position should be

tested later by cutting a straight piece of stock,

carefully measuring its width, and comparing it

to the scale reading.

Resaw Guide

Refer to Figure 32.

For resawing operati ons, att ach the r esaw guide

(HP4-A) to the fence using the knob (HP4-B)

through the slotted hole. Position the resaw

guide so that it is centered approximately with

the front edge of t he saw blade.

The resaw guide offers a taller, single-point

contact surface that allows pivoting of the

workpiece in order to keep the blade on the

cutting line.

Blower Nozzle

Refer to Figures 33 and 34.

1. The air hose, which is already connected to

the saw body, should be inserted through

the hole in the stand (visible in Figure 16)

and connected to the nozzle of the air

regulator on the motor (Figure 33). Use a

lighter or match to briefly heat the end of the

hose so that it will slip over the nozzle. A s it

cools, it will form a tight seal over the

nozzle.

Figure 32

Figure 33

2. Attach the plate (HP1-A) to the blade guide

assembly.

3. Connect the top end of the air hose to the

plate (HP1-A) with the M5x12 pan head

screw (HP1-D) through the cord clamp

(HP1-C). Heat the end of the hose with a

lighter or m atch, then push the wide end of

the nozzle (HP1-B) into the hose; the

tapered end points down toward the tabl e as

shown.

Work L amp

Refer to Figure 35.

The goose-neck l am p uses a m edium base l ight

bulb (not prov ided) which should be 60 watts or

less. The work lamp is operated independentl y

of the main saw switch.

IMPORTANT: If you are using 115 volt power

for the band saw, use a standard 110 v olt light

bulb. If you are using 230 volt power for the

band saw, discontinue use of the prov ided lamp,

and use an alternat e lamp with an independent

power cord.

Figure 34

Figure 35

18

Page 19

Installing Quick Tension Lever

Refer to Figure 36.

Install the quic k tension lever (M) onto the shaft

as shown, and tight en the two set screws using

a 3mm hex wrench. T he m ov ement of t he blade

tension lever is explained under “Installing

Blades”.

Stand Attachments

Refer to Figure 37.

1. Mount the two miter gauge hooks (HP3-B)

to the side of the stand with two M8x16

carriage bolts (HP 3-E) and two M8 flanged

hex nuts (HP3-F ). Position the hooks at an

angle, similar to that shown in Figure 38.

The miter gauge can be stored in these

hooks.

2. Mount the blade hook (HP3-C) with two

M4x10 pan head screw s (HP3- H) as shown.

The blade hook can store a roll ed-up spare

blade.

3. Mount the two fence hooks (HP3-A) to the

opposite side of the stand with two M8x16

carriage bolts (HP 3-E) and two M8 flanged

hex nuts (HP3-F). The rip fence can be

stored in these hooks when not i n use.

Dust Collection

Refer to Figure 38.

The use of a dust collection system (not

provided) is strongly advised when using the

band saw. It will hel p keep your shop clean, and

reduce the ri sk of heal th problems due to wood

dust inhalation. The dust collector should have

sufficient capacity for this size band saw

(minimum 350 cubi c feet per mi nute).

Figure 36

Figure 37

Connect a 4” diam eter dust coll ection hose (not

provided) to the port at the back of the band

saw, and secure tightly with a hose clamp, as

shown.

Note: Dryer vent hose is not suitable for dust

collection pur pose s.

Riser Block Accessory

A Riser Block kit (stock no. 1791217, not

provided) is available as an accessory. When

install ed, it increases resaw capacit y (workpiece

height capacity) to 12 inches. If you have

purchased the Riser Block, consult the

instruction sheet that accompanies it.

Figure 38

19

Page 20

Adjustments

Tilting the Table

Unplug the machine from the

power source before making any repair or

adjustment.

Refer to Figure 39.

1. Loosen the table l oc ki ng k nobs.

2. Til t table up to 45 degrees to the right. T he

angle is indic ated on the trunnion scale.

3. Tighten the table locking knobs.

4. You can place a measuring device on the

table and against the blade t o verif y the 45°

setting.

Adjusting 90° Table Stop

Refer to Figures 39 and 40.

1. Disconnect machine from power source.

2. Loosen tabl e locking knobs and tilt table t o

the left until it rests against the table stop

screw.

Figure 39

3. Use a square placed on the table and

against the bl ade, as shown in Figure 40, to

verify that the table is 90 degrees to the

blade. Make sure the table insert is level

with the table surface, to ensure an acc ur ate

reading.

4. If an adjustm ent is necessary, tilt the table

out of the way and tight en the table locking

knobs.

5. Loosen jam nut (Figure 39) and turn table

stop screw left or right to raise or lower the

stop. Tighten jam nut down against the

trunnion support t o hold table stop screw in

place.

6. Unlock the table and tilt it back on to the

table stop screw to confirm table is 90

degrees to the blade. Repeat this process

as necessary unti l tabl e is 90 degrees to the

blade.

7. Make sure pointer (Figure 39) indicates

zero. If it does not, l oosen screw and mov e

pointer to align wi th zero. Re-tighten screw.

NOTE: After adjusting the 90-degree stop, it

may be necessary t o re-set the ext ension table

so it is level with the main tabl e. See “Leveling

the Extension Table. ”

Figure 40

20

Page 21

Table Aligned with Blade

For accurate crosscuts using the miter gauge,

the table (i.e. miter slot) must be aligned with the

blade. This alignment has been set by the

manufacturer, but the operator may wish to

verify it, as follows. NOTE: This procedure

works best with a wide bl ade.

Refer to Figure 41.

1. Place a straightedge along the side of the

blade, with very light pressure (do not

deflect the blade). The straightedge should

contact bot h front and back of blade.

2. Measure carefully with a fine rule from the

straightedge to the edge of the miter slot.

Do this at front and back of the table; the

distance should be the same.

3. If the mit er slot is not aligned wit h t he blade,

slightly loosen the six screws holding the

trunnions to t he table.

4. Nudge the table as needed, until the miter

slot is aligned wit h blade (distances are the

same front to back ).

5. Tighten trunnion screws. (NOTE: After this

adjustment, the alignment of fence to blade

may need to be re-checked. See “Aligning

Fence to Blade” on page 17.)

Figure 41

Installing Blades

Unplug the machine from the

power source before removing or installing

blades.

The PWBS-14CS Band S aw is provi ded with a

3/8” wide x 0.020 thi c k x 93.5” long, 6TPI blade.

Refer to Figure 42.

The blade tension lever is a patented Carter®

Quick-Rel ease™ lever, and has three positions:

high (tension) , mi ddle (partial tension), and low

(blade rel ease). Push the lever up slightly, then

out, and mov e it into positi on, allowing it to rest

on the appropriate ledge of the block.

1. Disconnect machine from power source.

2. Move tension lever to blade release

position, as shown in Fi gur e 42.

(Note: When using t he larger width blades,

it may also becom e neces sary to l oosen t he

tension knob to release al l tension.)

3. Remove the table insert and the table pin.

4. Open both wheel guards.

5. Back off t he upper and lower guide beari ngs

so that nothing conflicts with the blade.

Figure 42

21

Page 22

6. Remove the current blade from the upper

wheel, then t he lower wheel. Turn blade to

direct it through t he sl ot in the table.

New blades are usually

packaged in co iled position. Use gloves and

grasp the coil with one hand while slowly

uncoiling the blade with the other hand.

7. Guide new blade through table slot. Place

blade in upper and l ower blade guide s, and

around upper and lower wheels.

Note: Make sure blade teeth point forward

and down toward t he table. If the teeth won’t

point downward no matter how you orient

the blade, then the blade is twisted insideout. Remove blade and, usi ng gloves, twist

it into correct ori entation, then re-install.

8. Position blade so it lies on t he c enter of bot h

upper and lower wheels.

9. Raise tension lever to partial tension

position.

10. Re-install table insert and table pin.

11. Tension and track the blade before

operating saw. Proceed to "Blade Tension"

and “Blade Trac k ing" .

Blade Tension

Refer to Figure 43.

1. Disconnect machine from power source.

2. Place tension lever in full tension position

(see Figure 42).

3. Turn blade tension knob (Figure 43)

clockwise to t ension blade. A gauge on the

upper wheel slide bracket indicates the

approximate tension according to the width

of the blade. Initially, set the blade tension

to correspond to bl ade width.

The ten sion lever must b e in

highest (tension) position when setting blade

tension. Failure to comply may cause

damage to locating block at base of lever.

As you become fami liar with the saw, you may

find it necessary to change the blade tension

from the initial setting. Changes in blade width

and the type of material being cut will have an

effect on blade tension. Keep in mind that too

little or too much blade tension can cause bl ade

breakage.

Figure 43

TIP: If the band saw is to sit idle for a period of

time while the blade is installed, place tension

lever in partial tension position; this will help

prevent blade f atigue and tire deform ation, and

save wear on bearings and band wheel s.

22

Page 23

Blade Tracking

Disconnect machine from

power source. Do not adjust blade tracking

with the machine running.

“Tracking” r efers to how the blade is posit ioned

on the wheels whil e in moti on. The bl ade should

track approximately in t he c enter of both wheels,

as shown in Fi gure 44. Track ing on the PW BS14CS Band Saw has been factory-adjusted;

however, it should be checked periodically,

including aft er ev er y bl ade c hange.

Refer to Figure 45.

1. The blade must be properly tensioned

before adjusting blade tracking. Make sure

blade guides and blade bearings do not

interfere with the blade.

2. Place the tension lever at full tension

position.

3. Open the upper door and rotate the upper

wheel forward by hand. Observe the

position of the blade on t he wheel - it should

be in the center.

Figure 44

4. If the bl ade tends to shift t o one side or the

other of the wheel, loosen wing nut (Figure

45).

5. If the blade i s tr acki ng toward the f ront edge

of the wheel, rotate the tracking knob

clockwise – the upper wheel will tilt toward

the back and the blade will move to the

center of the wheel.

If the bl ade is tracking toward the back edge

of the wheel, rotate the tracking knob

counterclockwise: the upper wheel will tilt

toward the f ront and the blade will move t o

the center of the wheel.

IMPORTANT: This adjustment is sensitive;

perform it in small increment s and give the

blade time to react to the changes, as you

continue to rot ate the wheel.

6. When blade is tracking properly at the

center of the wheel, r e- tighten the wing nut.

7. Turn on saw and verify proper tracking while

the machine is running.

8. If further tracking adjustments are needed,

disconnect from power, and repeat

instructions above.

Figure 45

Guide Post and Upper Blade Guard

Refer to Figure 46.

1. Disconnect machine from power source.

Figure 46

23

Page 24

2. Loosen lock knob and raise or lo

w

blade guide assembly to approximately

3/16” above the material being cut.

3. Tighten lock knob.

4. The guide post (Fi gure 46) is spring l oaded.

To adjust the tension on the spring, unscre w

and completely remove knob, then tighten

or loosen set screw, until desired tension is

reached. Re-i nstall knob.

er upper

Upper Bearing Guides

Refer to Figures 47, 48, 49.

1. Disconnect machine from power source.

2. Blade must already be tensioned and

tracki ng properly.

3. Loosen thumb screw (A, Figure 47) and

move guide block by turning knob (B) so

that the front of the guide wheels (C) are

just behind the gullet (curved area at base

of tooth) of the blade, as shown in Figure

48. This di stance is usually about 0.016” ( or

1/64”).

4. Tighten thumb screw (A, Figure 47).

5. Loosen the socket screw (D) and turn the

screw (E) on each guide wheel to m ov e the

guide wheels about 0.004” from the blade.

(A quick way to set t his distance is t o place

a crisp dollar bill, which is approximately

.004” thic k, between guide wheel and bl ade,

and move t he guide until it just contact s the

bill.)

6. Tighten socket screw (D) when adjustment

is satisfactory.

Figure 47

Figure 48

Thrust Bearing

The thrust bearing (F, Figure 49) supports the

back edge of t he blade during operat ion, and is

set so that the blade will c ontact it only when the

blade is under pressure during a c ut.

7. Loosen thumb screw (G, Figure 49) and tur n

knob (H) to move the thrust beari ng (F) in or

out until t he bearing is approxim ately 0. 016”

(or 1/64”) behi nd the blade. You can use a

feeler gauge to set this distance, or simply

place a crisp dollar bill folded twice (four

thicknesses) between the thrust bearing and

the blade. (A dollar bill is approximately

0.004” thick, so four thicknesses provides

the necessary distanc e.)

8. Tighten thumb screw (G, Figure 50).

Lower Bearing Guides

Refer to Figure 50.

1. Disconnect machine from power source.

Figure 49

Figure 50

24

Page 25

2. Blade must already be tensioned and

tracki ng properly.

3. Loosen thumb screw (J) and move guide

block by t urni ng knob (K) so that t he front of

the guide wheels (L) are just behind the

gullet (curved area at base of tooth) of the

blade.

4. Tighten thumb screw (J).

Thrust Bearing

5. Loosen thum b screw (M) and turn knob (N)

to move the support bearing (O) in or out

until the beari ng is approxim ately 0.016” (or

1/64") behind the blade. You can use a

feeler gauge to set this distance, or simply

place a dollar bill folded twice (four

thicknesses) between the support bearing

and the blade. (A dol lar bill i s .004” t hic k, so

four thicknesses provides the necessary

distance.)

6. Tighten thumb screw (M).

7. Loosen the socket screw (P) and turn the

screw (R) on each gui de wheel to mov e the

guide wheels about .004” from the blade.

Tighten socket screw (P) when finished.

Miter Gauge

Refer to Figures 51, 52.

Figure 51

Figure 52

A miter gauge is provi ded for crosscutti ng. Slide

the miter gauge i nto the T-slot from the edge of

the table.

To use the mit er gauge, loosen the handle and

rotate the gauge body u nt il t he desired angl e on

the scale lines up with the pointer. Tighten

handle.

For preci se crosscuts, t he 90° angl e of t he mit er

gauge to the blade can be verified as follows

(Refer to Figure 52). A wide blade works best for

this procedure.

1. Set the miter gauge at 90°.

2. Place a square agai nst the mi ter gauge and

against the bl ade, as shown.

3. Adjust t he miter gauge until t he square lies

flush against bot h it and the blade.

4. Loosen the screw and shift the pointer as

needed. Retight en scr ew.

The miter gauge, when not in use, can be

placed int o the hooks on the stand. See Figur e

53. Loosen the miter gauge handle, and slide

the miter gauge into the top hook. Pivot the

miter gauge bar into the lower hook, then tight en

the miter gauge handle to secure the miter

gauge to the stand.

Figure 53

25

Page 26

On/Off Switch

The band saw is equipped with a push-button

switch that will accept a safety padlock (not

included). To safeguard your machine from

unauthorized operation and accidental starting

by young chil dren, the use of a padl ock is hi ghly

recommended – see Figur e 54.

Maintenance

Before doing maintenance,

disconnect machine from electrical supply

by pulling out the plug or switching off the

main switch! Failure to comply may cause

serious injury.

Clean the band saw regularly to remove any

resinous deposits and sawdust. Use a brush,

vacuum or compressed air to blow out excess

dust. (Wear safet y goggles while doing this.)

Keep the mit er slot in the table free of dust and

debris. Keep the gui de bearings clean and free

of resin. Use a commercially avail able gum and

pitch remover if needed.

Keep the guide po st clean; occasionall y apply a

light coat of oil.

Oil any pi ns, shaf ts, and j oi nts. Do not get oi l on

pulleys or belt s.

Bearings on the band sa w are sealed for life and

do not require att ention.

Check that the cleaning brush over the lower

wheel is working proper ly; adjust if necessary.

Remove any deposits from the band wheels and

tires to avoid vibration and blade breakage.

NOTE: Do not use s olv ents around tires. If signs

of wear or deform ation occ ur , replace the tires.

Figure 54

The table surf ac e m ust be k ept clean and fr ee of

rust for best results. If rust appears, use a

mixture of household ammonia, a good

commercial detergent and #000 steel wool.

Alternatively, commercial rust removers can be

found at many hardware stores.

Apply a light, protective coating over the table,

such as paste wax. Product s in aerosol f orm are

also available in hardware stores and supply

catalogs. Whatever method is chosen, the

coating should protect the metal and provide a

smooth surf ac e, wit hout staining the wood.

26

Page 27

Blade Selection

Using the proper bl ade for the job will incr ease

the operating ef ficiency of your band saw, help

reduce necessary saw maintenance, and

improve your pr oduc tivity. Thus, it is import ant to

follow certain guidelines when selecting a saw

blade.

Here are factors to consider when selecting a

blade:

• The type of materi al y ou will be c utti ng.

• The thickness of the workpi ec e.

• The features of the workpiece, such as

bends or curves wit h small radii.

These factors are important because they

involve basic concepts of saw blade design.

There are five (5) blade features that are

normally changed to meet certain kinds of

sawing requirements. They are:

1. width

2. pitch (number of teeth per inch)

3. tooth form (or shape)

4. the “set” of the teeth

5. the blade material itself

A fine pi tch (more teet h per inch) will cut slowly

but more sm oothly. A coar se pitch (f ewer teeth

per inch) will cut f aster but more roughly.

As a rule of thumb, the thicker the workpiece,

the coarser will be the bl ade pitch. If you have to

cut a hard or very brittle material, you will

probably want to use a blade wit h a finer pitch i n

order to get clean c uts.

Using a blade with too few teeth may cause

vibration and a r ough cut, while too m any teeth

may cause the gullets to fill with sawdust and

overheat the blade.

As a general rule, try to use a blade that will

have from 6 to 12 teeth in the workpiece at any

given time.

Shape

Figure 56 shows comm on types of t ooth shape,

or form. Tooth shape has an effect on cutting

rate.

Width

Band saw blades come in different standard

widths, measured from the back edge of the

blade to the tip of the tooth. Generally, wider

blades are used for ripping or making straight

cuts, such as resawing. Narrower blades are

often used when the part being cut has curves

with small r adii. When cut ting straight lines with

a narrow blade, t he blade may hav e a tendency

to drift (see “Bl ade Lead” ) .

Pitch

Pitch is m easured in “ teet h per i nch” ( T. P.I.) and

can be constant or variable. Figure 55 shows

blades with different pitches.

Figure 56 – Blade Toot h Shape

The Regular, or standard blade, has evenly

spaced teeth that are the same size as the

gullets, and a zero-degree rake (i.e. cutting

angle). T hese offer precise, cl ean cuts at slower

rates. It is usually a good choice for cutting

curves and making cr osscuts.

The Skip type has fewer teeth and l arger gullet s

with a zero rake. It allows faster cutting rates

than the Regular type, with a slightly coarser

finish. It i s useful for re-sawing and rippi ng thick

stock, as well as cutti ng softwoods.

The Hook ty pe blade has l ar ger teeth and gullet s

and a positive rake angle for more aggressive,

faster cutting when re-sawing or ripping thick

stock, especially hardwoods.

Figure 55

Variable-tooth blades combine features of the

other shapes, with tooth style and spacing

varying on the same blade. This produces

smooth cuts whil e dam pening v ibration.

27

Page 28

Set

The term “set” ref er s to the way in which the saw

teeth are bent or positioned. Bending the teeth

creates a kerf that is wider than t he back of t he

blade. This hel ps the operator m ore easily pivot

a workpiece through cur ve cuts, and decrease s

friction bet ween blade and workpi ece on strai ght

cuts.

Set patterns are usually selected depending

upon the type of material that needs to be cut .

Three comm on set patt erns ar e sho wn in F i gure

57.

Blade Breakage

Band saw blades are subject to high stresses

and breakage may sometimes be unavoidable.

However, many f actor s can be controlled t o hel p

prevent most blade breakage. Here are some

common causes for break age:

1. Misalignment of the blade guides.

2. Feeding workpiec e too quickly.

3. Using a wide blade to cut a tight radius

curve.

4. Excessive tension.

5. Teeth are dull or impr oper ly set.

6. Upper guides are set too high off the

workpiece.

7. Faulty weld on bl ade.

Although not essential, some users round or

“stone” the back edge of their blade. This is

done by placing a s harpeni ng stone on the tabl e

and in li ght contact with t he back corners of t he

blade as the blade is running. Rounding can

help the back blade edge m ove more smoothly

through the kerf, smooths the weld, and helps

prevent crack s fr om start ing at the back corners.

Figure 57

Generally, the Raker set is used for cutting

metal workpieces; the Wavy set, when the

thickness of the workpiece changes, such as

cutting hol low tubi ng or struc tural s. The Straight,

or Alternate, set is the one most used for

woodworking blades, and is also used to cut

plastics.

Material

Band saw blades can be made from different

types of metals. The most common include

spring steel, carbon steel, bimetal (alloy steel

equipped with a high speed cobalt steel edge

welded to it), or carbide tips.

Because of the im portance of blade sel ection, it

is recommended that you use the blade

selection guide on page 35. Also, listening to

experienced band saw users will provide

valuable information as to the types of blades

currentl y on the market along wit h their pros and

cons.

28

Page 29

Operation

The following sect ion c ontains basic i nf ormati on,

and is not intended to cover all possible

applicati ons or techniques using the Band Saw.

Consult published sources of information,

acquire formal training, and/or talk to

experienced Band S aw us ers t o gain pr of i ciency

and knowledge of band saw operations. (The

Figures used may or may not show your

particular saw model, but the procedures are

identical.)

General Procedure

1. Make sure t he bl ade is adj usted correc tly for

tension and tracking, and that upper and

lower guide beari ngs and thr ust bear ings are

set in proper relati on to the blade.

Ripping

Ripping is cutting lengthwise down the

workpiece, and with the grain (of wood stock).

See Figure 58. Always use a push stick or

similar safety device when ripping narrow

pieces.

2. Adjust gui de post so that the guide bear ings

are just above the workpiece (about 3/16”)

allowing minim um ex posure t o the blade.

3. If using the f ence, move i t into position and

lock it t o the guide rail. If you are usi ng the

miter gauge for a crosscut, t he fence should

be moved safely out of the way.

4. Turn on the band saw and allow a few

seconds for t he machine to reach full speed.

Whenever possible, use a

push stick, hold-down, power feeder, jig, or

similar device while feeding stock, to prevent

your hands getting too close to the blade.

5. Pl ace the straightest edge of the workpiece

against the f ence f or a rip c ut; or against t he

miter gauge for a crosscut. Push the

workpiece slowly into the blade, while also

keeping it pressed again st the f ence or held

against the miter gauge. Do not force the

workpiece int o the blade.

Some further operat ing tips:

Make relief cuts whenever possibl e. A relief cut

is an extr a cut made through t he waste porti on

of a workpiece up to the layout line. When that

intersection is reached by the blade while

following the layout line, the waste portion

comes free. This helps prev ent pinching of the

back edge of the blade in t he cut.

Figure 58

Crosscutting

Crosscutting is cutting across the grain of the

workpiece, while using the miter gauge to feed

the workpiece i nto the blade.

The right hand shoul d hold the workpiece steady

against the miter gauge, while the left hand

pushes the miter gauge past the blade, as

shown in Figure 59.

Figure 59

Do not use the fence in conjunction with the

miter gauge. The offcut of the workpiece must

not be constrained during or after the cutting

process.

When cutting, do not

overfeed the blade; overfeeding will reduce

blade life, and may cause the bl ade to break.

When cutting long stock, the operator should

use roller stands, suppor t tabl es, or an assistant

to help stabilize the workpiece.

Using the fence in

conjunction with the miter gauge can cause

binding and possible damage to the blade.

29

Page 30

Resawing

Resawing is the process of slicing stock to

reduce its thickness, or to produce boards that

are thinner t han the origi nal workpiece, such as

veneers.

The ideal bl ade for resawing is the widest one

the machine c an handle, as the wider the bl ade

the better it can hold a str aight line.

Resawing can be per formed using t he rip f ence

or the resaw guide. When using the rip fence,

use a push block, push stic k, or simil ar device to

keep your hands away from the blade. The

resaw guide offers a pivot point by which you

can carefully follow your layout line; it is

especially useful for sawing curves, when the

fence can’t be used and it’s difficult to c ontrol the

cut freehand.

Figure 60 demonstrates resawing with the rip

fence; Figur e 61, wit h the resaw guide.

It is more common with small, narrow blades,

and is almost always attributable to poor blade

quality, or lack of proper adjustments. Inspect

the band saw for the following:

• Fence is not parallel to miter slot and blade.

• Blade is not tensioned c or r ec tly.

• Blade is dull.

• Teeth have too much “set” on one side of

the blade.

• Workpiec e is bei ng fed t oo quic kl y.

Figure 62

Figure 60

Figure 61

Blade Lead

Blade lead, or drift, is when the blade begins to

wander off t he cutting li ne even when the band

saw rip fence i s being used. Figur e 62 shows an

example of blade lead.

If the blade is suspect, but replacing it is not

currently an option, the blade lead can be

temporarily compensated for by skewing the

fence:

1. Cut a scrap pi ece of wood about the same

length as the band saw tabl e, and joint one

edge along its lengt h, or rip it on a table saw

to give it a straight edge.

2. Draw a line on the board parallel with the

jointed, or str aight edge of the board.

3. Move the band saw fence out of the way,

and carefully make a freehand cut along

your drawn line on the board. Stop about

midway on the board, and shut off the band

saw (allow the blade t o come to a complete

stop) but do not all ow the board to move.

4. Clamp the board to the table.

5. Loosen the four hex cap screws on the

fence and slide the fence over, lining it up

against the board. Loc k the f enc e down.

6. Re-tighten the four hex cap screws.

NOTE: Skewing the f ence to correct blade lead

is effectiv e for that particular blade; when a new

blade is installed, the fence will need readjustment and re-squaring to miter slot. See

appropriate sect ions in this manual.