Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

10-inch Cabinet Saw

Model PM2000B

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-PM231B

Ph.: 800-274-6848 Edition 1 09/2017

www.powermatic.com Copyright © 2017 Powermatic

Shown with 30-inch rail set

Page 2

1.0 IMPORTANT SAFETY

INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING

THIS MACHINE.

WARNING – To reduce risk of injury:

1. Read and understand the entire owner’s

manual before attempting assembly or

operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace the warning labels if they become

obscured or removed.

4. This table saw is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar with the

proper and safe operation of a table saw, do

not use until proper training and knowledge

have been obtained.

5. Do not use this table saw for other than its

intended use. If used for other purposes,

Powermatic disclaims any real or implied

warranty and holds itself harmless from any

injury that may result from that use.

6. Always wear approved safety glasses or face

shield while using this table saw. Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.

7. Before operating this table saw, remove tie,

rings, watches and other jewelry, and roll

sleeves up past the elbows. Do not wear loose

clothing. Confine long hair. Non-slip footwear

or anti-skid floor strips are recommended. Do

not wear gloves.

8. Wear ear protectors (plugs or muffs) during

extended periods of operation.

9. WARNING: Drilling, sawing, sanding or

machining wood products generates wood

dust and other substances known to the State

of California to cause cancer. Avoid inhaling

dust generated from wood products or use a

dust mask or other safeguards to avoid

inhaling dust generated from wood products.

10. Wood products emit chemicals known to the

State of California to cause birth defects or

other reproductive harm. (California Health

and Safety Code Section 25249.6)

11. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

12. Make certain the machine is properly

grounded.

13. Make all machine adjustments or maintenance

with the machine unplugged from the power

source. A machine under repair should be

RED TAGGED to show it must not be used

until maintenance is complete.

14. Remove adjusting keys and wrenches. Form a

habit of checking to see that keys and

adjusting wrenches are removed from the

machine before turning it on.

15. Keep safety guards in place at all times when

the machine is in use. If removed for

maintenance purposes, use extreme caution

and replace the guards immediately.

16. Check the alignment of the riving knife, fence

and miter slot to the blade. A caution decal is

installed on each guard to remind the operator

of the dangers of improper machine operation.

17. Check damaged parts. Before further use of

the machine, a guard or other part that is

damaged should be carefully checked to

determine that it will operate properly and

perform its intended function. Check for

alignment of moving parts, binding of moving

parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should

be properly repaired or replaced.

18. Provide for adequate space surrounding work

area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and

free of scrap material, oil and grease.

20. Keep visitors a safe distance from the work

area. Keep children away.

21. Make your workshop child proof with padlocks,

master switches or by removing safety keys.

22. Give your work undivided attention. Looking

around, carrying on a conversation and “horseplay” are careless acts that can result in

serious injury.

23. Maintain a balanced stance at all times so that

you do not fall or lean against the blade or

other moving parts. Do not overreach or use

excessive force to perform any machine

operation.

24. Use the right tool at the correct speed and

feed rate. Do not force a tool or attachment to

do a job for which it was not designed. The

right tool will do the job better and safer.

25. Use recommended accessories; improper

accessories may be hazardous.

26. Maintain tools with care. Keep blade sharp and

clean for the best and safest performance.

Follow instructions for lubricating and changing

accessories.

Page 3

27. Check the saw blade for cracks or missing

teeth. Do not use a cracked or dull blade or

one with missing teeth or improper set. Make

sure the blade is securely locked on the arbor.

28. Keep hands clear of the blade area. Do not

reach past the blade to clear parts or scrap

with the saw blade running. Never saw

freehand. Avoid awkward operations and hand

positions where a sudden slip could cause

your hand to contact the blade.

29. Do not attempt to saw boards with loose knots

or with nails or other foreign material, on its

surface. Do not attempt to saw twisted, warped

or bowed stock unless one edge has been

jointed for guiding purposes prior to sawing.

Excessively warped stock should not be used.

30. Do not attempt to saw long or wide boards

unsupported where spring or weight could

cause the board to shift position.

31. Always use the riving knife, blade guard, push

stick and other safety devices for all operations

where they can be used. On operations such

as dadoing or molding where the blade guard

cannot be used, use feather boards, fixtures

and other safety devices and use extreme

caution. Reinstall the riving knife and blade

guard immediately after completing the

operation that required their removal.

32. Be sure the saw blade rotates clockwise when

viewed from the motor side (left side) of the

machine.

33. Turn off the machine before cleaning. Use a

brush or compressed air to remove chips or

debris — do not use bare hands.

34. Do not stand on the machine. Serious injury

could occur if the machine tips over.

35. Never leave the machine running unattended.

Turn the power off and do not leave the

machine until it comes to a complete stop.

36. Remove loose items and unnecessary work

pieces from the area before starting the

machine.

37. Blade should have minimum exposure during

cuts. Adjust blade to approximately 1/8” inch

above surface of workpiece.

kickback, the high-speed expulsion of material from

the table that can strike the operator. Kickback can

also result in the operator’s hands being pulled into

the blade.

Kickback Prevention

Tips to avoid the most common causes of

kickback:

• Make sure the riving knife is always aligned

with the blade. A workpiece can bind or stop

the flow of the cut if the riving knife is

misaligned, and result in kickback.

• Use a riving knife during every cut. The riving

knife maintains the kerf in the workpiece,

which will reduce the chance of kickback.

• Never attempt freehand cuts. The workpiece

must be fed parallel to the blade, otherwise

kickback will likely occur. Always use the rip

fence or miter gauge to support the workpiece.

• Make sure that rip fence is parallel to blade. If

not, the chances of kickback are very high.

Take the time to check and adjust the rip

fence.

• Feed cuts through to completion. Anytime you

stop feeding a workpiece that is in the middle

of a cut, the chance of binding, resulting in

kickback, is greatly increased.

Tips for Kickback Protection

Kickback can happen even if precautions are taken

to prevent it. Listed below are some tips to protect

you if kickback does occur:

• Stand to the side of the blade when cutting. An

ejected workpiece usually travels directly in

front of the blade.

• Wear safety glasses or a face shield. Your

eyes and face are the most vulnerable part of

your body.

• Never place your hand behind the blade. If

kickback occurs, your hand will be pulled into

the blade.

• Use a push stick to keep your hands farther

away from the moving blade. If a kickback

occurs, the push stick will most likely take the

damage that your hand would have received.

1.1 Kickback

The most common accidents among table saw

users, according to statistics, can be linked to

3

Page 4

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or possible

machine damage.

This means that if precautions are not heeded, it may result in serious or possibly fatal injury.

2.0 About this manual

This manual is provided by Powermatic covering the safe operation and maintenance procedures for a

Powermatic Model PM2000B Cabinet Saw. This manual contains instructions on installation, safety

precautions, general operating procedures, maintenance instructions and parts breakdown. Your machine has

been designed and constructed to provide consistent, long-term operation if used in accordance with the

instructions set forth in this document.

This manual is not intended to be an exhaustive guide to table saw operational methods, use of jigs or aftermarket accessories, choice of stock, etc. Additional knowledge can be obtained from experienced users or

trade articles. Whatever accepted methods are used, always make personal safety a priority.

If there are questions or comments, please contact your local supplier or Powermatic. Powermatic can also be

reached at our web site: www.powermatic.com.

Retain this manual for future reference. If the machine transfers ownership, the manual should accompany it.

Read and understand the entire contents of this manual before attempting assembly

or operation! Failure to comply may ca use serious injury!

4

Page 5

3.0 Table of contents

Section Page

1.0 IMPORTANT SAFETY INSTRUCTIONS ....................................................................................................... 2

1.1 Kickback ..................................................................................................................................................... 3

2.0 About this manual .......................................................................................................................................... 4

3.0 Table of contents ............................................................................................................................................ 5

4.0 Table Saw terminology ................................................................................................................................... 7

5.0 Specifications for PM2000B ........................................................................................................................... 8

5.1 Kit configurations ........................................................................................................................................ 9

6.0 Setup and assembly ..................................................................................................................................... 10

6.1 Shipping contents ..................................................................................................................................... 10

6.2 Tools required for assembly ..................................................................................................................... 10

6.3 Unpacking and cleanup ............................................................................................................................ 11

6.4 Installing extension wings ......................................................................................................................... 11

6.5 Handwheel, knobs, levers ........................................................................................................................ 12

6.6 Rails and Fence ....................................................................................................................................... 12

6.7 Motor cover .............................................................................................................................................. 12

6.8 Table insert ............................................................................................................................................... 12

6.9 Installing and removing blade ................................................................................................................... 13

6.10 Installing guard/knife assembly .............................................................................................................. 13

6.11 Dust port ................................................................................................................................................. 14

7.0 Electrical connections .................................................................................................................................. 14

7.1 GROUNDING INSTRUCTIONS ............................................................................................................... 14

7.2 Voltage conversion (3-phase model only) ................................................................................................ 15

7.3 Extension cords ........................................................................................................................................ 15

7.4 Magnetic switch and safety key ................................................................................................................ 15

8.0 Adjustments ................................................................................................................................................. 16

8.1 Tools required for adjustments ................................................................................................................. 16

8.2 Fence alignment ....................................................................................................................................... 16

8.3 Blade raising and tilting ............................................................................................................................ 16

8.4 Caster mechanism ................................................................................................................................... 16

8.5 Miter gauge .............................................................................................................................................. 16

8.6 Blade tilt stop adjustment ......................................................................................................................... 17

8.7 Riving knife alignment .............................................................................................................................. 18

8.8 Table to blade alignment .......................................................................................................................... 18

8.9 Belt adjustment ......................................................................................................................................... 19

8.10 DRO calibration and operation ............................................................................................................... 20

9.0 Operations .................................................................................................................................................... 20

10.0 Safety devices ............................................................................................................................................ 25

10.1 Feather board ......................................................................................................................................... 25

10.2 Push stick and push block ...................................................................................................................... 25

11.0 User-maintenance ...................................................................................................................................... 26

11.1 General inspection ................................................................................................................................. 26

11.2 Cleaning ................................................................................................................................................. 26

11.3 Lubrication .............................................................................................................................................. 26

11.4 Arbor/Arbor Bearing Removal ................................................................................................................ 26

11.5 Additional servicing ................................................................................................................................ 26

12.0 Optional accessories .................................................................................................................................. 27

13.0 Troubleshooting PM2000B Cabinet Saw ................................................................................................... 28

13.1 Motor and electrical problems ................................................................................................................ 28

13.2 Mechanical and operational problems .................................................................................................... 28

14.0 Replacement Parts ..................................................................................................................................... 29

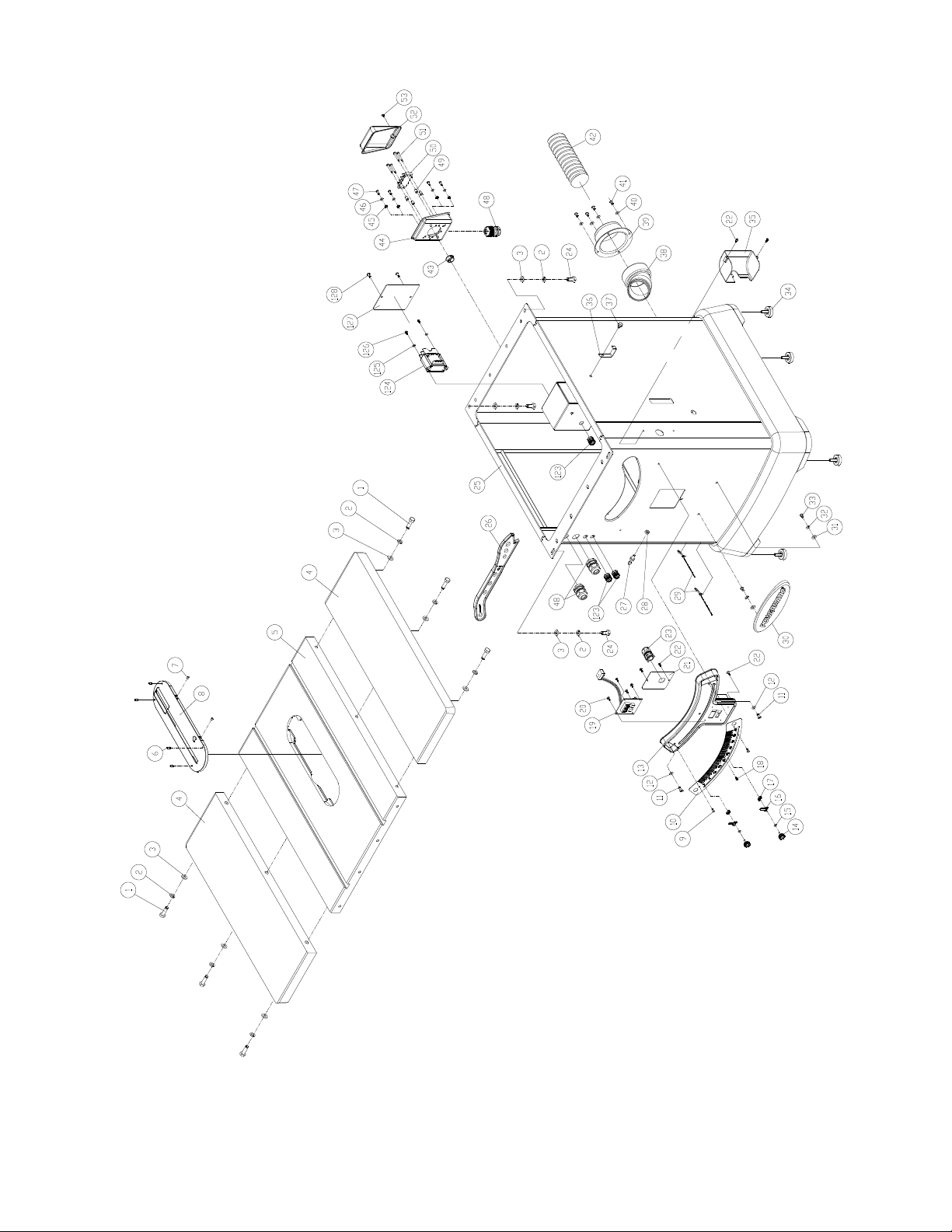

14.1.1 PM2000B Table and Cabinet Assembly I – Exploded View ................................................................ 30

14.1.2 PM2000B Table and Cabinet Assembly II – Exploded View ............................................................... 31

14.1.3 PM2000B Table and Cabinet Assembly – Parts List ........................................................................... 32

14.2.1 PM2000B Motor and Trunnion Assembly I – Exploded View .............................................................. 35

14.2.2 PM2000B Motor and Trunnion Assembly II – Exploded View ............................................................. 36

14.2.3 PM2000B Motor and Trunnion Assembly – Parts List ......................................................................... 37

14.3.1 PM2000B Blade Guard and Miter Gauge Assemblies – Exploded View ............................................ 40

5

Page 6

14.3.2 PM2000B Blade Guard and Miter Gauge Assemblies – Parts List ..................................................... 41

14.4.1 PM2000B Motor Cover Assembly – Exploded View ........................................................................... 42

14.4.2 PM2000B Motor Cover Assembly – Parts List .................................................................................... 42

15.0 Electrical Connections ................................................................................................................................ 43

15.1 PM2000B Wiring diagram – 3HP, 230V, 1PH ......................................................................................... 43

15.2 PM2000B Wiring diagram – 5HP, 230V, 1PH ........................................................................................ 44

15.3 PM2000B Wiring diagram – 5HP, 230V, 3PH ........................................................................................ 45

15.4 PM2000B Wiring diagram – 5HP, 460V, 3PH ........................................................................................ 46

16.0 Warranty and Service ................................................................................................................................. 47

6

Page 7

4.0 Table Saw terminology

Arbor: Metal shaft that connects the drive

mechanism to the blade.

Bevel Edge Cut: Tilt of the saw arbor and blade

between 0° and 45° to perform an angled cutting

operation.

Blade Guard: Mechanism mounted over the saw

blade to prevent accidental contact with the cutting

edge.

Crosscut: Sawing operation in which the miter

gauge is used to cut across the grain of the

workpiece.

Dado Blade: Blade(s) used for cutting grooves and

rabbets. A stacked dado set can be used for wider

grooves.

Dado Cut: Flat bottomed groove in the face of the

workpiece made with a dado blade.

Featherboard: Device used to keep a board

against the rip fence or table that allows the

operator to keep hands away from saw blade.

Freehand: Moving the workpiece into the blade

using only the hands, without a fixed positioning

device. (This is a dangerous, unacceptable

procedure – always use appropriate devices to

feed the workpiece through the saw blade during

cutting operations.)

Kerf: The resulting cut or gap made by a saw

blade.

Kickback: An event in which the workpiece is lifted

up and thrown back toward an operator, caused

when a workpiece binds on the saw blade or

between the blade and rip fence (or other fixed

object). To minimize or prevent injury from

kickbacks, see the Operations section.

Miter Gauge: A component that controls the

workpiece movement while performing a crosscut

of various angles.

Non-Through Cut: A sawing operation that

requires the removal of the blade guard and

standard riving knife, resulting in a cut that does

not protrude through the top of the workpiece

(includes dado and rabbet cuts).

The blade guard and riving knife must be reinstalled after performing a non-through cut to

avoid accidental contact with the saw blade during

operation.

Parallel: Position of the rip fence equal in distance

at every point to the side face of the saw blade.

Perpendicular: 90° (right angle) intersection or

position of the vertical and horizontal planes such

as the position of the saw blade (vertical) to the

table surface (horizontal).

Push Board/Push Stick: An instrument used to

safely push the workpiece through the cutting

operation by keeping the operator’s hands at a

distance.

Rabbet: A cutting operation that creates an

L-shaped channel along the edge of the board.

Rip Cut: A cut made along the grain of the

workpiece.

Riving Knife: A metal plate fixed relative to the

blade, which moves with the blade as cutting depth

is adjusted. Thus, it maintains not only the kerf

opening in the workpiece, but also the knife-toblade distance. A low-profile riving knife sits lower

than the top edge of the blade, for making a nonthrough cut.

Splitter (Spreader): A stationary metal plate to

which the blade guard is attached that maintains

the kerf opening in the workpiece during a cutting

operation. (Powermatic table saws use the superior

riving knife system instead.)

Standard Kerf: 1/8" gap made with a standard

blade.

Straightedge: A tool used to check that a surface

is flat or parallel.

Through Sawing: A sawing operation in which the

workpiece thickness is completely sawn through.

Proper blade height usually allows 1/8" of the top

of blade to extend above the wood stock. Keep the

blade guard down, the anti-kickback pawls down,

and the riving knife in place over the blade.

7

Page 8

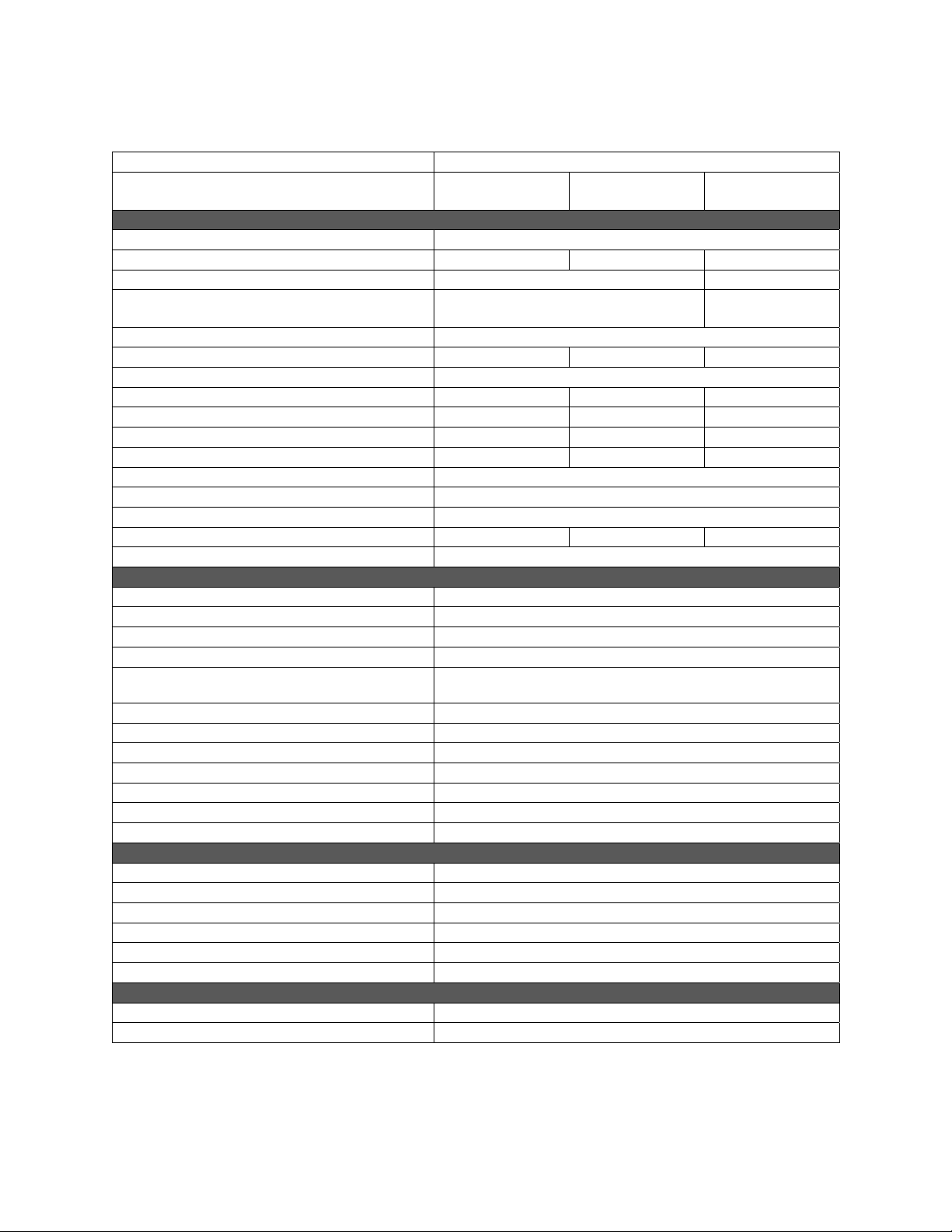

5.0 Specifications for PM2000B

Table 1

Model number

Stock number – saw only

(see Table 2 below for kit configurations)

Motor and Electricals

Motor type Totally enclosed, fan cool ed, induction

Horsepower 3 HP 5 HP 5 HP

Motor phase 1 PH 3 PH

Motor voltage 230 V

Cycle 60 Hz

Listed FLA (full load amps) 14.5 A 21 A 13 / 6.5 A

Motor speed 3450 RPM

Starting amps 86 126 120

Running amps (no load) 4.9 4.8 6.5

Start capacitor 400MFD 125VAC 400MFD 250VAC n/a

Run capacitor 40µF 350VAC 30µF 500VAC n/a

Power transfer Poly-V belt

On/off switch Magnetic switch, with safety key

Power cord and plug not supplied

Recommended circuit size 2 20 A 30 A 20 A

Sound emission without load 3 84 db at 100cm; 89 dB at 50cm

Arbor and blade

Arbor diameter 5/8 in. (15.875 mm)

Arbor speed 4500 RPM

Arbor lock yes

Arbor wrench included

Blade included Ø10 in. (254mm), 0.079 in. (2.0mm) thk, 0.118 in. (3.0mm) kerf,

Maximum depth of cut at 90 degrees 3-1/8 in. (80 mm)

Maximum depth of cut at 45 degrees 2-1/8 in. (54 mm)

Maximum rip to right of blade 30 in. (762 mm) or 50 in. (1270 mm)

Maximum rip to left of blade 13-1/2 in. (343 mm)

Dado maximum width 13/16 in. (21 mm)

Dado maximum diameter 8 in. (203 mm)

Blade tilt Left, 0° to 45°

Table

Main table dimensions, L x W 30-1/2 x 22 in. (775 x 559 mm)

Table dimensions with extensions, L x W 30-1/2 x 42 in. (775 x 1067 mm)

Table area in front of blade at maximum height 11-1/4 in. (286 mm)

Table surface from floor, casters disengaged 35 in. (889 mm)

Miter T-slot, W x D 2 slots; 3/4 x 3/8 in. (19 x 10 mm)

Edge bevel Front and rear

Dust collection

Dust port outside diameter 4" (101.6 mm)

Recommended minimum extraction volume 400 CFM (0.5 CMM)

PM231B PM251B PM253B

PM2000B

40T, AB, carbide tips

230/460 V

(prewired 230 V)

1

8

Page 9

Main materials

Main table cast iron

Table insert aluminum

Extension wings cast iron

Cabinet steel

Base steel

Center trunnion cast iron

Bearing arm cast iron

Pulleys steel

General Dimensions

Base footprint 23 x 28 in. (584 x 711 mm)

Assembled, w/ extension wings only, L x W x H 42-5/8 x 32-3/4 x 40-3/8 in. (1083 x 832 x 1026 mm)

Assembled, with 30-in. rail set, L x W x H 66-3/4 x 39-1/8 x 40-3/8 in. (1694 x 993 x 1026 mm)

Assembled, with 50-in. rail set, L x W x H 84-3/4 x 39-1/8 x 40-3/8 in. (2151 x 993 x 1026 mm)

Caster elevation (approximate) 3/4 in. (19 mm)

Shipping dimensions, saw only, L x W x H 29-7/8 x 33 x 43-1/2 in. (760 x 840 x 1105 mm)

Weights

Saw only – net weight 385 lb. (175 kg) 405 lb. (184 kg) 398 lb. (181 kg)

Saw only – shipping weight 535 lb. (243 kg) 555 lb. (252 kg) 548 lb. (249 kg)

1

Note: For 460V operation, an overload relay (Part No. PM2000B-2107BORA) must be purchased separately and

installed. A qualified electrician is recommended.

2

subject to local/national electrical codes.

3

The specified values are emission levels and are not necessarily to be seen as safe operating levels. As workplace

conditions vary, this information is intended to allow the user to make a better estimation of the hazards and risks

involved only.

L = length, W = width, H = height, D = depth

n/a = not applicable

5.1 Kit configurations

Stock numbers

Saw only

Saw with 30-inch rail set, wood ext table PM23130K PM25130K PM25330K

Saw with 50-inch rail set, wood ext table PM23150K PM25150K PM25350K

Saw with 50-inch rail set & router lift PM23150RK PM25150RK PM25350RK

Saw with 50-inch rail set & workbench PM23150WK PM25150WK PM25350WK

PM231B PM251B PM253B

Table 2

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Powermatic reserves the right to change specifications at any time and without prior notice,

without incurring obligations.

9

Page 10

Read and understand the

entire contents of this manual before

attempting set-up or operation. Failure to

comply may cause serious injury.

6.0 Setup and assembly

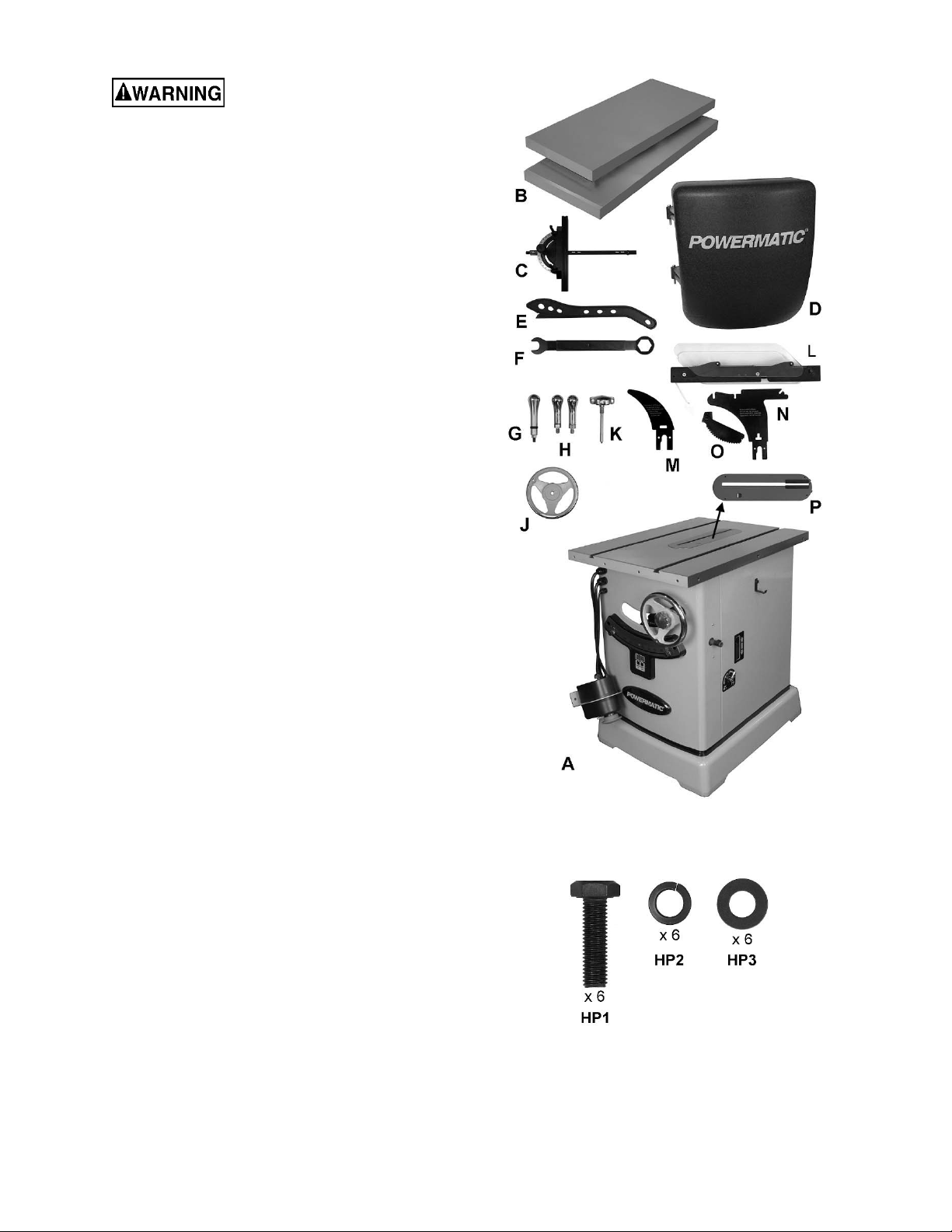

6.1 Shipping contents

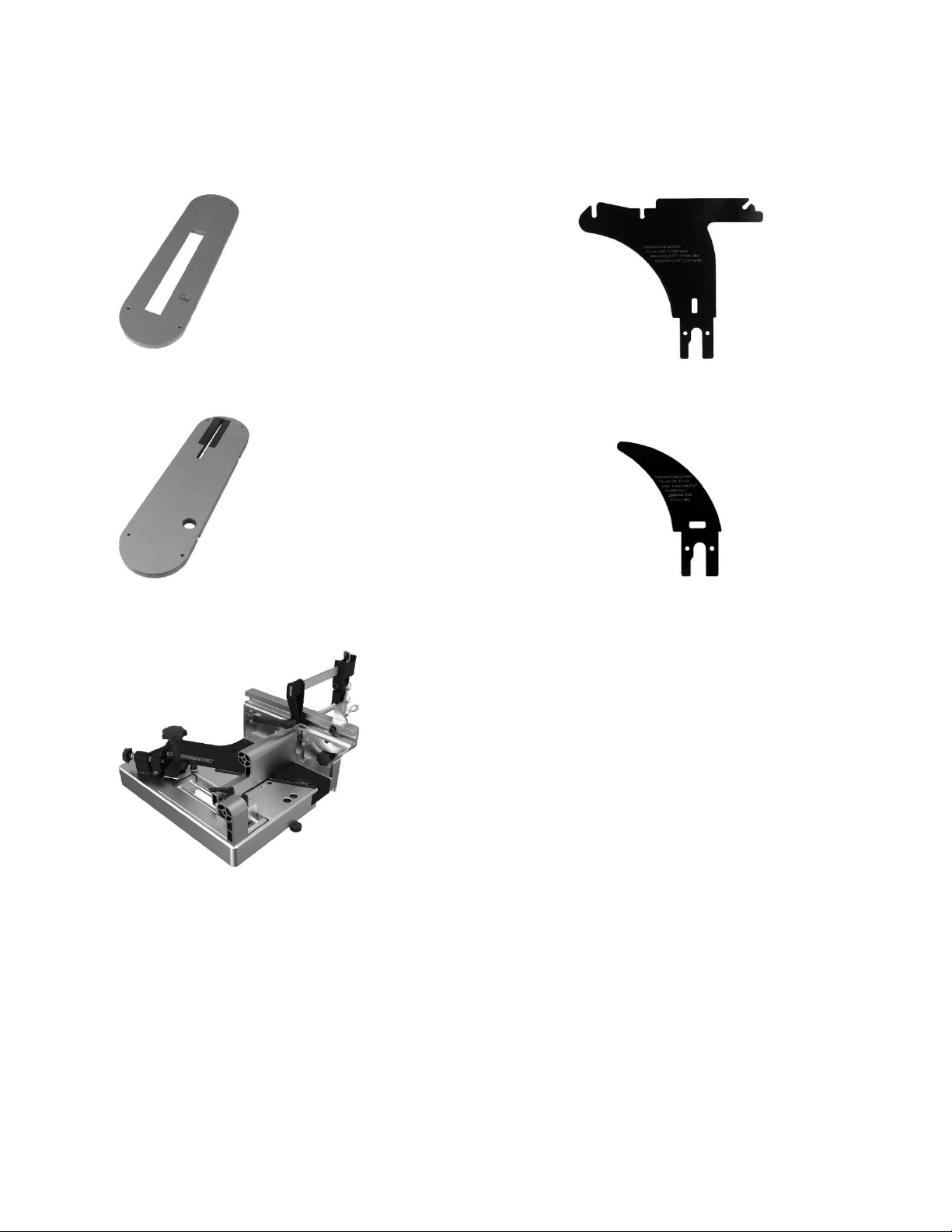

See Figure 6-1.

Remove all accessory boxes from shipping pallet.

Remove items from inside cabinet. Do not discard

any packing material until saw is assembled and

running satisfactorily.

Compare contents of your container with parts list

below to make sure all parts are intact. Any

missing parts should be reported to your

distributor. (Check saw first in case parts were

preinstalled.)

1 Cabinet saw with switch – A

2 Cast iron extension wings – B

1 Miter gauge assembly – C

1 Motor cover with hinge pins – D

1 Push stick – E

1 Arbor wrench – F

1 Caster elevating handle – G

2 Handles – H

1 Handwheel – J

1 Handwheel lock knob – K

1 Blade guard – L

1 Low profile riving knife – M

1 Riving knife – N

1 Anti-kickback pawl assembly – O

1 Table insert (preinstalled) – P

1 Blade (preinstalled)

1 Product registration card

1 Operating Instructions and Parts Manual

1 Hardware package

6.1.2 Hardware package #PM2000B-HP

See Figure 6-2.

6 Hex cap screws, M10x35 (HP1)

6 Lock washers M10 (HP2)

6 Flat washers M10 (HP3)

NOTE: Fence and rail assemblies with fasteners,

and wood extension tables and legs with fasteners,

are shipped in separate boxes.

Figure 6-1 (items not to scale)

6.2 Tools required for assembly

Hex key 2.5mm

Open end wrenches: 14mm, 17mm

Straight edge

Rubber mallet (or hammer with block of wood)

Note: A ratchet wrench with sockets will speed

assembly time. Additional tools may be needed for

assembly of fence and rails.

Figure 6-2 hardware package (PM2000B-HP)

10

Page 11

The saw must be discon-

nected from power source during assembly.

Failure to comply may cause serious injury.

6.3 Unpacking and cleanup

1. Use a hoist to lift saw off pallet; or remove

nailed boards holding saw cabinet to pallet and

slide saw off pallet onto floor. (Be careful not to

damage caster system while sliding it off

pallet.)

2. The cabinet saw should be placed in an area

with a sturdy level floor, good ventilation and

sufficient lighting. Leave enough space around

the machine for mounting extension tables and

rail assemblies, and loading and off-loading

stock and general maintenance work.

3. Exposed metal surfaces, such as table top and

extension wings, have been given a protective

coating at the factory. This should be removed

with a soft cloth moistened with kerosene or a

cleaner-degreaser. Do not use acetone,

gasoline, or lacquer thinner for this purpose.

Do not use solvents on plastic parts, and avoid

using an abrasive pad as it may scratch

surfaces.

Figure 6-3: installing accessories

Figure 6-4: leveling extension wings, method 1

Method 1 (Figure 6-4):

6.4 Installing extension wings

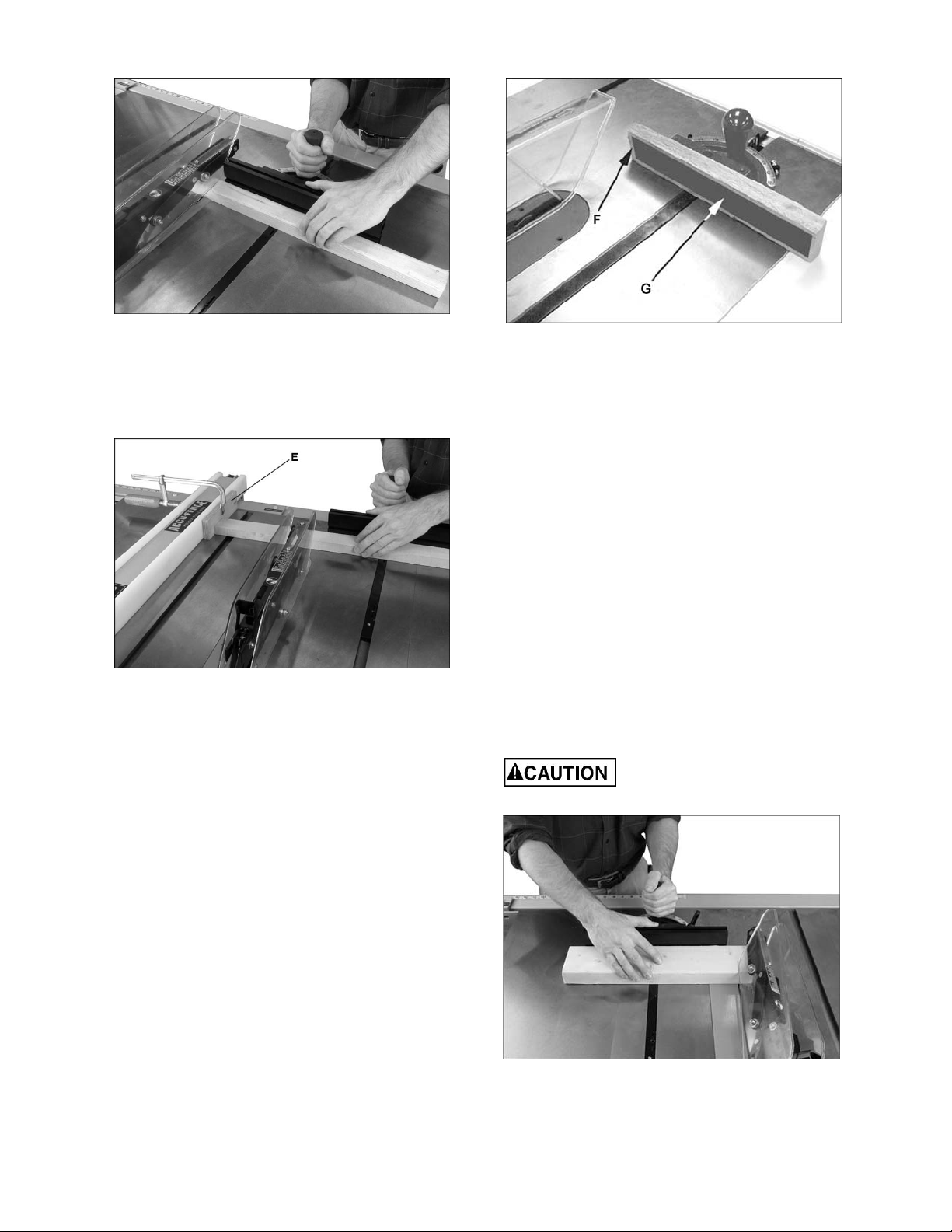

See Figure 6-3.

1. Mating edges of table and wings should be

clean and free of burrs.

2. Attach an extension wing (B) to saw table.

(Extension wings are identical). Use three

screws, lock washers and flat washers (HP1/2/3). Lightly snug screws with 17mm wrench

or socket. Do not fully tighten yet.

Assembly Tip: If you are doing this without an

assistant, lift extension wing perpendicular to

table edge. Install center screw and washers,

and make snug. Then pivot wing parallel to

saw table to insert remaining two screws.

3. Repeat for opposite extension wing. Lightly

snug screws. Do not fully tighten yet.

4. The front edge of extension wings must be

flush with front edge of saw table. If needed,

tap front edge of wing with a rubber mallet to

make flush. See Figure 6-4.

6.4.1 Leveling extension wings

Level extension wings to saw table using a straight

edge. A metal straight edge is ideal, though a

carefully jointed board may also be used.

Two methods are described below: one using a

rubber mallet, the other using clamps on the table

edges.

1. Shift extension wing so it is slightly above saw

table surface.

2. Begin by tightening the three screws beneath

extension wing that secure it to saw table.

Tighten these just enough to hold wing in

place but loose enough to change wing height

by tapping on it. (Tap with rubber mallet, or

hammer over a flat block of wood. Never use a

steel-faced hammer directly on the tables.)

3. Lay straight edge across saw table and

extension wing, extending it out past edge of

wing as shown in Figure 6-4.

4. Move straight edge to several places along

wing, as you continue to nudge wing level with

saw table. Also brush your fingertips over the

seam to ensure the transition feels smooth. As

each area of wing becomes flush with table,

tighten screw under that area. Continue until

all three screws are fully tightened. NOTE:

Make sure front edge of wing remains flush

with front edge of saw table.

5. Repeat above steps for opposite extension

wing.

Method 2 (Figure 6-5):

1. Follow steps 1 through 3 from Method 1.

2. Position clamps over seam, one at front, one

at back of table. Use a pad or flat block

beneath clamp jaw to prevent damage to table

surface. See Figure 6-5.

11

Page 12

3. Tighten both clamps to align front and back

edges of tables. Make sure front edge of wing

remains flush with front edge of saw table.

4. Tighten screws incrementally, and position

straight edge at various places across seam,

especially checking at the center. Make further

adjustments as needed.

5. Fully tighten screws.

Figure 6-6: installing switch

6.6.2 Wood Extension Table

Figure 6-5: leveling extension wings, method 2

6.5 Handwheel, knobs, levers

See Figure 6-3.

1. Remove tape from around shaft to expose

threads and shaft key (J

2. Ensure that set screw in handwheel (J

backed out sufficiently to prevent interference.

3. Ensure that key is in slot. Slide handwheel

onto shaft, aligning keyway with key.

4. Push handwheel on shaft as far as it will go,

then tighten set screw (J

5. Install locking knob (K, Figure 6-3) and

handles (H). Use wrench on flat of handles to

tighten against handwheels.

, Figure 6-3).

1

).

2

) is

2

6.6 Rails and Fence

For instructions on mounting the accessory wood

extension table, consult Accu-Fence

M-2195079B.

manual, no.

6.7 Motor cover

See Figure 6-7.

Slide pins of motor cover into hinge barrels on saw.

Close motor cover until it catches on post on saw.

Note: The catch mechanism may require

adjustment to ensure proper closure. Loosen screw

and position as needed. Retighten screw.

With extension wings properly mounted, the rails

and Accu-Fence

to saw. Consult manual no. M-2195079B which

accompanies the fence, then proceed with sect.

6.7 below.

®

assembly can now be mounted

6.6.1 Switch bracket

See Figure 6-6.

The switch bracket is installed at the same time as

guide tube. Use two screws with washers which

are provided with the rails.

Figure 6-7: installing motor cover

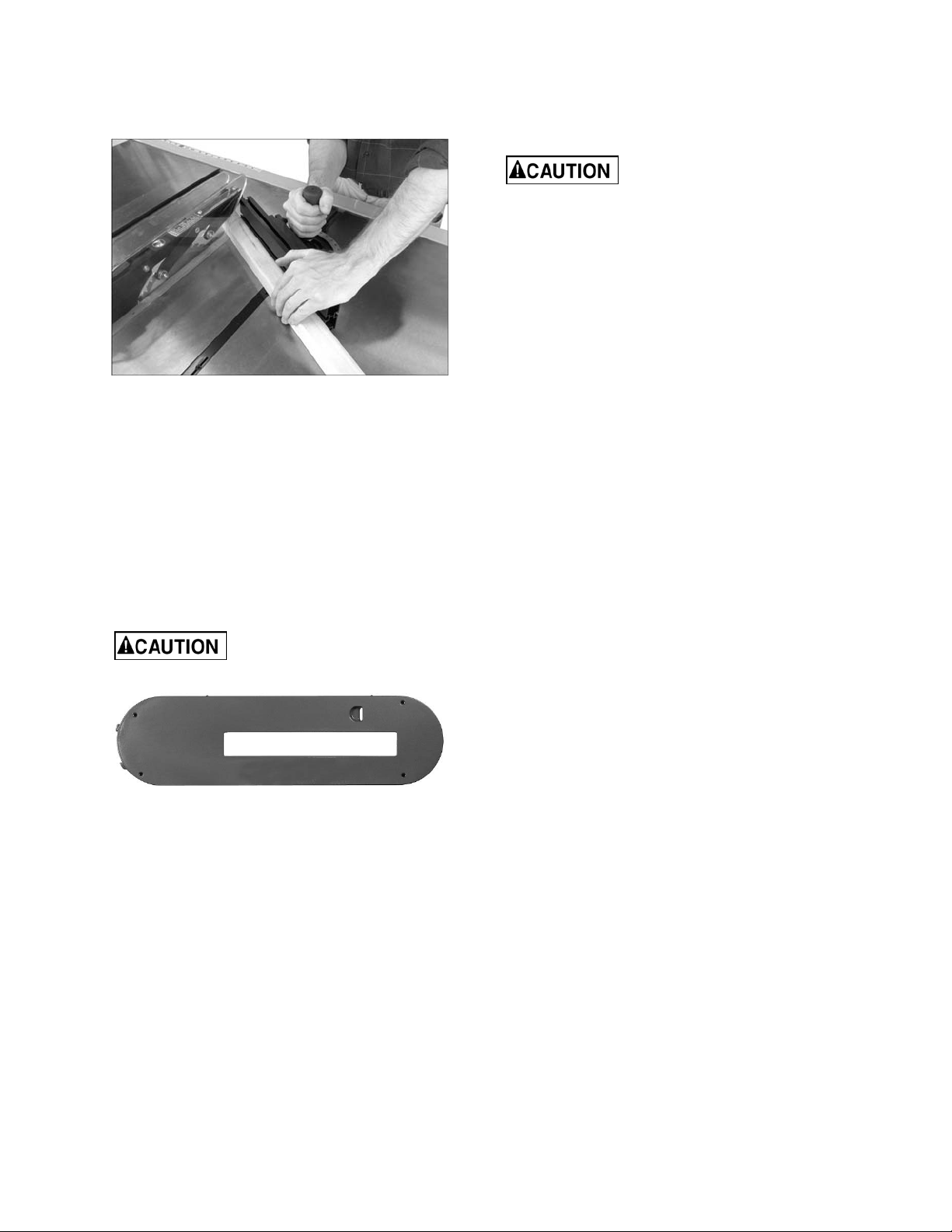

6.8 Table insert

See Figure 6-8.

Place insert into table opening. Verify that insert

lies flush with table surface by resting a straight

edge across it at various points. If insert is not flush

along its length, turn any of 4 set screws to raise or

lower that area of insert.

12

Page 13

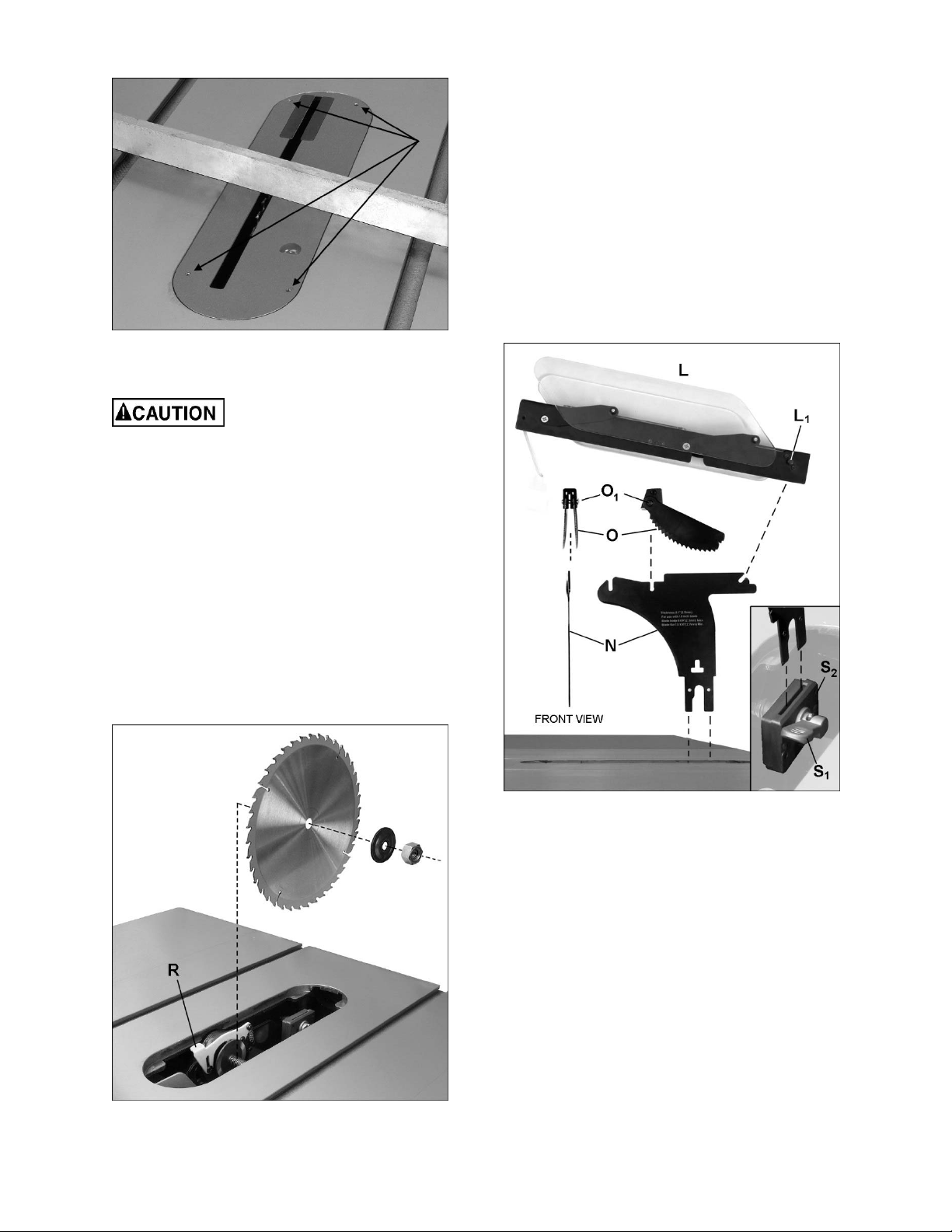

Figure 6-8: leveling table insert

6.9 Installing and removing blade

Use caution when working

with or near sharp saw blades to prevent injury.

See Figure 6-9.

1. Disconnect machine from power source.

2. Remove table insert.

3. Raise blade arbor to highest position, and set

blade tilt to 0°.

4. Install blade onto arbor, making sure teeth

point downward toward front of saw.

5. Install flange and nut as shown.

6. Press down and hold lever (R, Figure 6-9), and

rotate blade until arbor lock engages. Tighten

nut clockwise with provided arbor wrench. Do

not overtighten nut.

7. To remove blade, engage arbor lock and

remove nut with wrench.

6.10 Installing guard/knife assembly

See Figure 6-10.

6.10.1 Riving knife

1. Remove table insert.

2. Raise blade arbor to highest position and set

blade tilt to 0°.

3. Pull clamp lever (S

clamp plate (S

away from the fixed base, leaving a gap.

, Figure 6-9) upward. The

1

) is spring loaded and will move

2

Figure 6-10: installing guard assembly

4. Slide prongs of riving knife (N) into slot on

clamping base, and push riving knife down as

far as it will go.

5. Push clamp lever (S

6. Riving knife must be parallel to saw blade. See

sect. 8.7 for inspection and adjustments.

NOTE: A low-profile riving knife is also provided,

for making non-through cuts on the table saw.

) down to closed position.

1

6.10.2 Anti-kickback pawls

See Figure 6-10.

1. Install insert plate into table.

Figure 6-9: installing blade

2. Position anti-kickback pawl assembly (O,

Figure 6-10) so that angled side of pawl block

faces toward front of saw, as shown.

13

Page 14

3. Lower pawl assembly onto center notch of

riving knife, with pawls straddling knife. Push

and hold button on pawl block (O

10), and push pawl block down until it securely

engages in notch.

4. Allow pawls to drop freely to table.

, Figure 6-

1

6.10.3 Blade guard

See Figure 6-10.

1. Push and hold button (L

guard.

2. Push guard (L) down at an angle, as shown,

until pin engages rear slot in riving knife, and

release button.

3. Push down front of guard until it seats

properly, and is parallel to table top. The

transparent guard leaves (L

freely to the table.

NOTE: The transparent leaves can be kept in

raised position by swinging them up and forward.

Guard, riving knife, and pawl

assemblies must be securely installed, and

leaves must be in contact with table, before

beginning any through-cutting operation.

) at back end of

1

) should drop

2

7.0 Electrical connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal injury.

A power plug is not provided with the PM2000B.

You may either connect the proper UL/CSA listed

plug or “hardwire” the machine directly to your

electrical panel provided there is a disconnect near

the machine for the operator. Consult electrical

drawings in sect. 15.0 for further clarification of

wiring setup.

Before connecting to power source, be sure switch

is in off position.

It is recommended that the 3HP 1-phase, and 5HP

3-phase table saws be connected to a dedicated

20 amp circuit with breaker or fuse.

The 5HP 1-phase saw should be connected to a

30 amp circuit with breaker or fuse.

If connected to a circuit protected by fuse, use time

delay fuse marked “D”. Local codes take

precedence over recommendations.

The riving knife clamping base is adjusted by the

manufacturer and no further adjustment of blade

guard and riving knife assembly should be

necessary. However, proper alignment is very

important. Before operating table saw, read sect.

8.7, Riving knife alignment, to verify and follow

adjustment procedure if necessary.

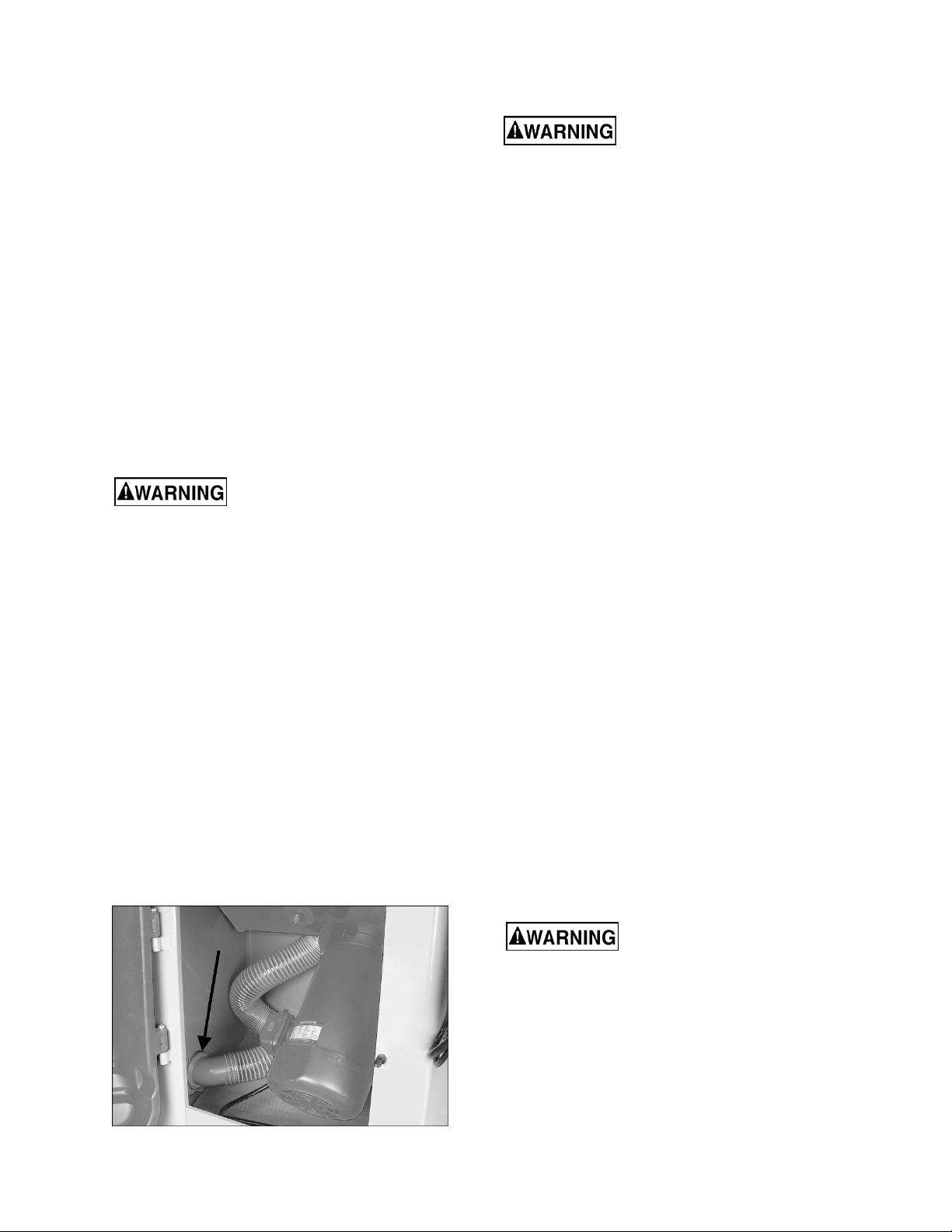

6.11 Dust port

Use of a dust collection system (not provided) is

strongly recommended during table saw operation.

It will help keep the shop clean, as well as prevent

potential health issues due to dust inhalation.

Make sure internal hose is pushed into external

dust port (Figure 6-11). Attach hose from your dust

collection system to the 4-inch dust port at base of

saw, and secure with wire hose clamp (not

provided).

7.1 GROUNDING INSTRUCTIONS

This machine must be grounded. In the event of a

malfunction or breakdown, grounding provides a

path of least resistance for electric current to

reduce the risk of electric shock. This tool is

equipped with an electric cord having an

equipment-grounding conductor. A plug is not

provided. A proper UL/CSA listed plug may be

installed or the machine may be “hard-wired” to a

circuit panel. If hard-wired, make sure a disconnect

is available to the operator.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

conductor with insulation having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or a plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified

electrician or service personnel if the

grounding instructions are not completely

understood, or if in doubt as to whether the

tool is properly grounded. Failure to comply

may cause serious or fatal injury.

Figure 6-11

Repair or replace damaged or worn cord

immediately.

14

Page 15

7.2 Voltage conversion (3-phase

model only)

1. Remove transformer cover at back of machine,

and move fuse from 230V position to 460V

position on transformer.

2. Switch the incoming power leads to the motor

for 460 volt operation, according to wiring

diagram on inside cover of motor junction box.

A similar diagram is found in sect. 15.0 of this

manual. (In case of discrepancy, diagram in

junction box takes precedence.)

3. Replace the 230V overload relay with a 460V

overload relay (additional purchase, part

number PM2000B-2107BORA).

4. If using a plug, the 230V plug must be

replaced with a UL/CSA listed plug rated for

460V.

7.3 Extension cords

USE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When

using an extension cord, be sure to use one heavy

enough to carry the current your product will draw.

An undersized cord will cause a drop in line voltage

resulting in loss of power and overheating. Table 3

shows correct size to use depending on cord

length and nameplate ampere rating. If in doubt,

use the next heavier gauge. The smaller the gauge

number, the heavier the cord.

When power is connected to the machine, the

green light is always on regardless of whether the

saw is running or not.

Stop – Press red switch to stop.

Reset – If the saw stops without pressing the stop

button, as the result of a tripped fuse or circuit

breaker:

1. Press red button to reset.

2. Press green button to restart machine.

7.4.1 Safety Key

The switch is equipped with a magnetic safety key.

When in place on the switch as shown in Figure 72, the safety key trips a relay which will allow the

machine to start and stop when the respective

switches are pressed. Being magnetic, the key can

be removed to make the machine inoperable and

can be hidden for safe storage by attaching it

underneath the rail or another magnetic surface.

When using the saw, place the key on the switch

cover lining up the arrow on the key with the

REMOVE arrow on the cover. Then rotate the key

so the arrow lines up with the LOCK arrow. This

prevents the safety key from vibrating loose when

machine is in use.

Amp Rating Volts Total length of cord (ft.)

More

Than

Not

More

Than

00 06 18 16 16 14

06 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12

Table 3: extension cord recommendations

240 50 100 200 300

AWG

Not

Recommended

7.4 Magnetic switch and safety key

Refer to Figure 7-2.

Power Indicator Light – The start switch has a

power indicator lamp which is on whenever there

is power connected to the saw, not just when the

saw is running. Do not assume that no light means

there is no power to the machine. If the bulb is bad,

there will no indication. Always check before use.

Do not rely that no light means

no power to the machine. Always check for

power first. Failure to comply may cause

serious injury.

Start – Press green start switch.

Figure 7-2

15

Page 16

8.0 Adjustments

8.5 Miter gauge

Refer to Figures 8-2 and 8-3.

8.1 Tools required for adjustments

Hex keys: 2.5mm, 3mm, 4mm

Wrenches: 13mm, 19mm, 22mm (or adjustable)

Straight edge

Square

8.2 Fence alignment

Before using the Accu-Fence®, verify that it is

properly aligned with the blade. Consult manual no.

M-2195079B that accompanied the fence.

8.3 Blade raising and tilting

See Figure 8-1.

To raise or lower blade, loosen lock knob (A,

Figure 8-1) and turn handwheel (B) on front of saw

until desired height is reached. Tighten lock knob

(A). The blade should be raised about 1/8" above

top surface of material being cut.

To tilt blade, loosen lock knob (C) and turn

handwheel (D) until desired angle is obtained, as

shown on tilt scale or DRO. Retighten lock knob

(C).

The DRO, or digital readout (E) displays the angle

for quick positioning. See sect. 8.10 for calibration

of the DRO.

Reference pointers (F) can be positioned at any

point along scale; loosen knob and slide pointer to

position, then tighten knob. These provide a quick

reference point for aligning the angle indicator.

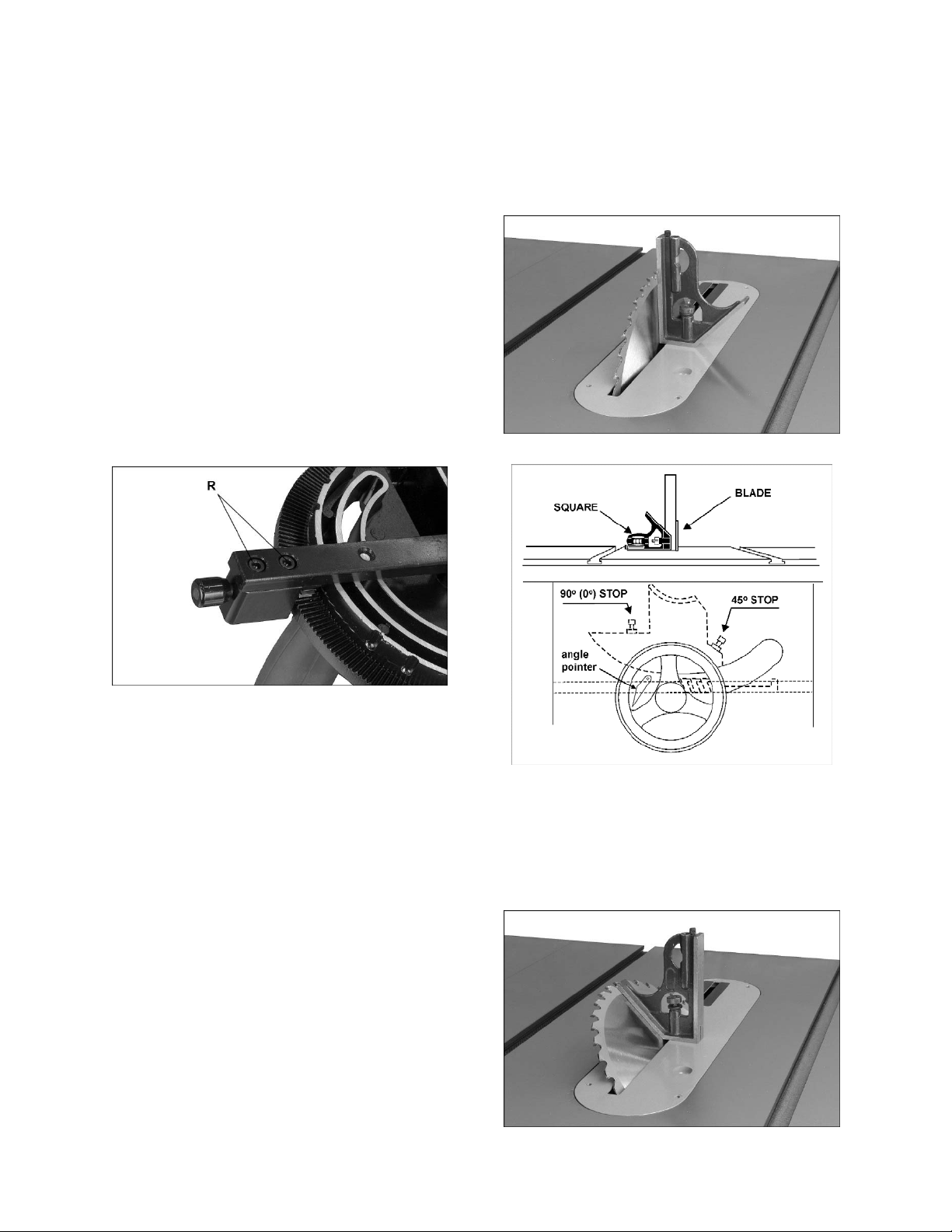

8.5.1 Setting miter angle

The miter gauge has rack and pinion adjustment

for setting angle. To operate:

1. Slide miter gauge into table slot.

2. Loosen lock handle (H, Figure 8-2) by turning

counterclockwise.

3. Pull out spring-loaded knob (J) and rotate knob

until body (K) of miter gauge is at desired

angle as indicated on scale.

4. Tighten lock handle (H).

8.5.2 Indent settings

There are indents at 0º, 30º and 45º right and lef t

positions. At these settings, release knob (J) to

engage indent. Then tighten lock handle (H).

Note: Do not rely solely on the indents for an

accurate setting. After stop rod engages at the 0º,

30º and 45º positions, make a fine adjustment with

the knob (J) if necessary, setting it against the

scale indicator (L).

Figure 8-1: blade adjustments

8.4 Caster mechanism

To engage caster system, pump handle (G, Figure

8-1) about 4 or 5 times.

Disengage caster system by turning handle (H)

counterclockwise. Casters must be disengaged

before operating saw.

Note: It is recommended that saw be lowered to

resting position after being moved to desired

location. If left in raised position for an extended

period, saw will gradually settle back to floor – this

is normal.

Figure 8-2

8.5.3 Miter gauge fence

The miter gauge fence (M, Figure 8-2) can be

adjusted by sliding to right or left, or removed

entirely.

To adjust, loosen two lock handles (N), slide fence

and retighten lock handles. Make sure end of

fence is not in blade path.

NOTE: The lock handles (N) are adjustable. Pull

out on handle, rotate it to different position, then

release, making sure it seats itself upon the pin.

To remove miter gauge fence, slide it completely

off and remove lock handles (N) and mounting

hardware.

8.5.4 Miter gauge calibration

1. Place miter gauge into table slot.

16

Page 17

2. Set miter gauge at 90º to blade (0º setting on

scale) by loosening lock handle (H, Figure 8-

2), then pulling out spring-loaded knob (J) and

turning body (K) until 0º is indicated on scale.

3. Measure accuracy of miter gauge against slot

with a square.

If adjustment is needed:

4. Adjust body (K) until it is square (90º) to miter

slot.

5. Tighten lock handle (H).

6. Verify that scale indicator (L) reads 0º. If it

does not, loosen screw (P) and adjust

indicator (L) until it reads 0º. Retighten screw

(P).

7. If the above procedure does not satisfactorily

align the miter gauge, loosen two screws (R,

Figure 8-3) beneath mounting block and shift

block as needed. Retighten screws when

finished.

5. If adjustment is required, loosen nut on 90°

stop screw (Figure 8-5) with 13mm wrench,

and turn screw to proper height. Verify setting

and retighten nut against trunnion.

6. Check pointer position on scale (Figure 8-5). If

needed, loosen screw and adjust pointer to

zero. Retighten screw.

Figure 8-4

Figure 8-3

NOTE: The miter gauge bar has two slots with set

screws (S, Figure 8-2). Adjust these set screws to

eliminate any play between bar and miter slot.

8.6 Blade tilt stop adjustment

The stops for 90°, 45° blade tilt, and elevation

settings have all been factory set, and should

require no immediate adjustment. The settings

should be confirmed by the operator, however, and

especially if cuts become inaccurate. Both tilt stops

are located on the trunnion.

8.6.1 Tilt stop 90°

1. Disconnect machine from power source.

2. Make sure table insert has been leveled with

table surface (sect. 6.8).

3. Raise blade to highest position, and place a

square on table and against blade (Figure 8-

4). Make sure that a blade tooth does not

obstruct the actual reading.

4. Tilt blade with handwheel until square and

blade are flush.

Figure 8-5: blade stops

8.6.2 Tilt stop 45°

Follow same procedure as above, but with blade

tilted at 45°, as shown in Figure 8-6.

Adjust 45° stop shown in Figure 8-5. Confirm

setting, then retighten nut.

Figure 8-6

17

Page 18

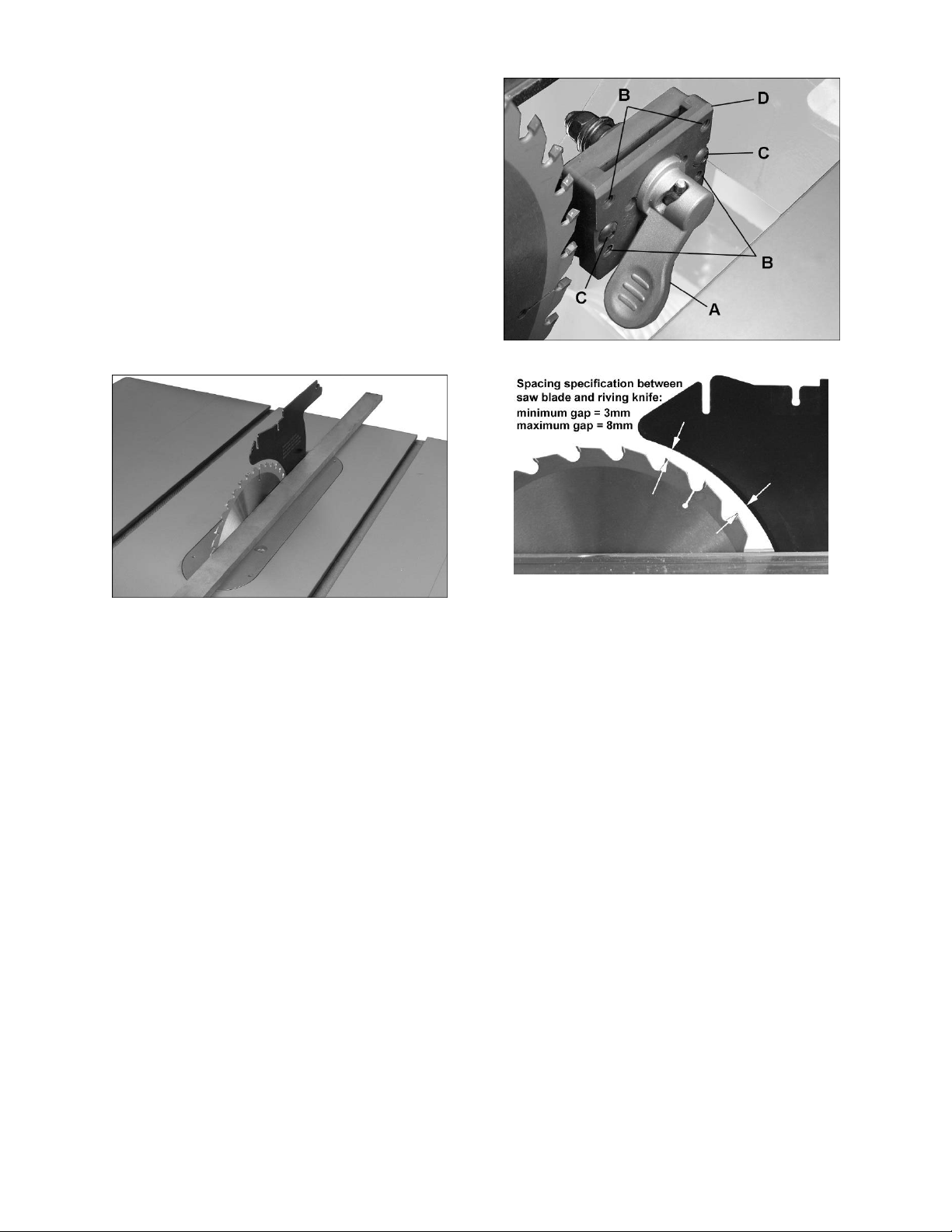

8.7 Riving knife alignment

8.7.1 Lateral alignment

Saw blade and riving knife must be as closely

aligned as possible (lateral alignment) for

prevention of kickback. This should be checked

upon initial blade guard and riving knife installation.

Alignment should also be reaffirmed after each

blade change.

Inspect alignment as follows:

1. Remove blade guard and pawl assembly.

2. Place a straightedge on table so it rests

against blade and riving knife. See Figure 8-7.

Rotate blade so that top of blade tooth touches

straightedge.

Figure 8-8

Figure 8-7

The saw blade and riving knife must be in line. If

adjustment is needed:

3. Pull up lever (A, Figure 8-8) and remove riving

knife, making note as to which direction riving

knife needs to be moved to align it with saw

blade.

4. Use 3mm hex key to make adjustments to four

set screws (B, Figure 8-8). Adjust any of the

set screws required to bring riving knife in

alignment with saw blade.

5. Reinsert riving knife, secure by tightening lever

(A) and check alignment per step 2.

6. Repeat steps 3–5 until alignment is correct.

8.7.2 Blade proximity alignment

The gap between saw blade and riving knife must

be between 3mm (0.12in.) and 8mm (0.32in.). See

Figure 8-9.

If adjustment is needed, note whether blade-toknife gap needs to be increased or decreased.

Then adjust as follows:

7. Remove blade guard, pawl assembly, table

insert and riving knife.

8. Use 3mm hex key to loosen two socket head

button screws (C, Figure 8-8). This will allow

the clamp plate (D) to slide back and forth on

the fixed base.

Slide clamp plate (D) toward or away from saw

blade as required. Attempt to make the gaps

as even as possible.

9. Tighten screws (C).

10. Reinsert riving knife; engage lever (A) and

check that saw blade/knife gap is between

3-8mm (Figure 8-9).

Figure 8-9

8.8 Table to blade alignment

See Figures 8-10 and 8-11.

The table has been squared to the blade by the

manufacturer and no adjustment should be needed

now. If cuts become inaccurate, check table/blade

squareness and correct if necessary.

1. Disconnect saw from power source.

2. Raise blade to maximum height.

3. Mark one tooth (A, Figure 8-10) with a grease

pencil and position the tooth slightly above top

edge of table at the front.

18

Page 19

4. Raise miter gauge slightly out of its slot to

serve as a shoulder. Using a sliding square (B)

against the side of the bar, slide the scale over

until it touches the tip of the blade, and lock

scale in position.

Figure 8-10

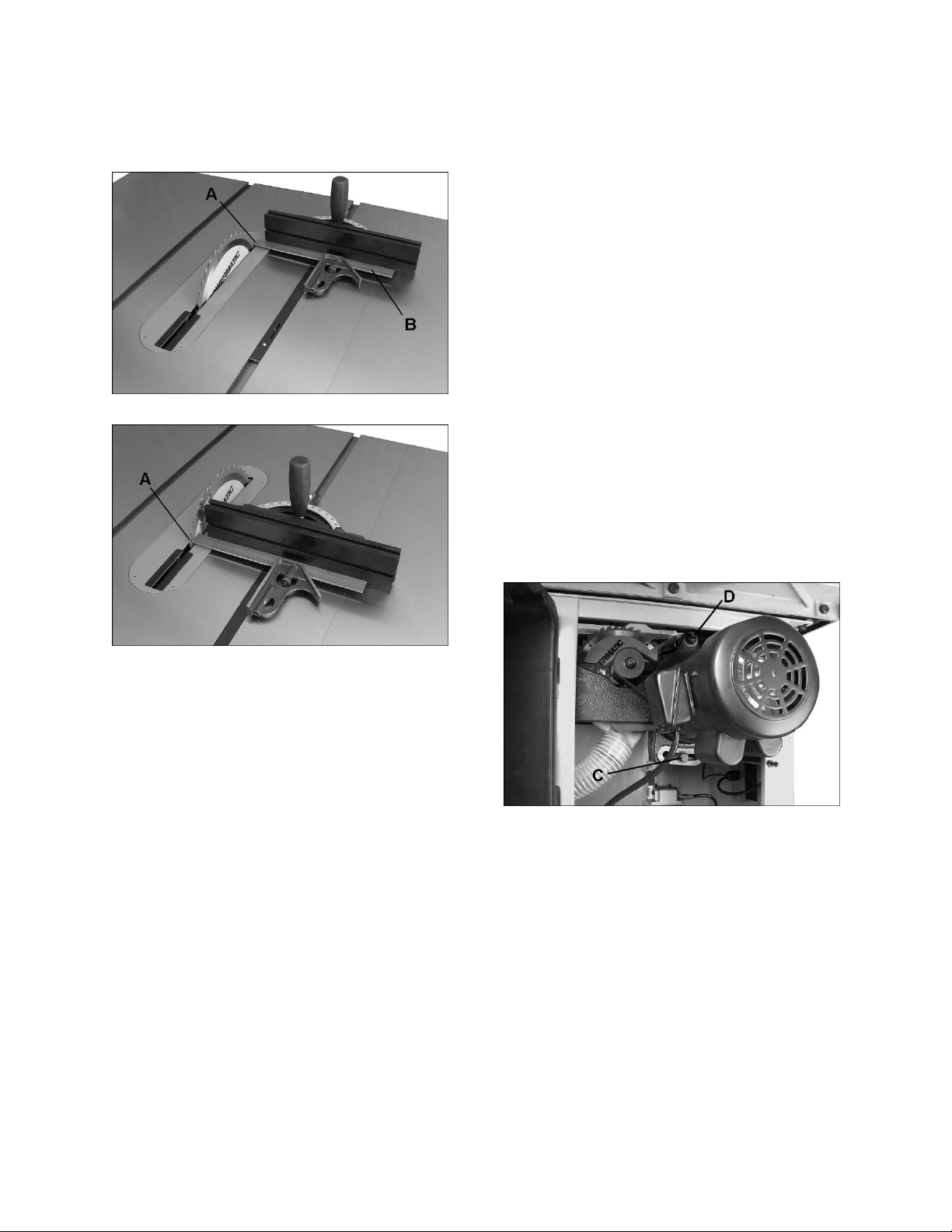

2. Loosen screw (C, Figure 8-12) with 17mm

wrench.

3. Slightly loosen nut (D) with 1-1/4” (or

adjustable) wrench.

4. Push motor to the right and tighten screw (C)

to tension belt. Retighten nut (D). Verify proper

tension by pushing on belt midway between

pulleys; deflection should be about 1/2-inch.

If belt shows signs of wear, fraying, cracks, etc. it

should be replaced, as follows.

8.9.2 Belt replacement

See Figure 8-12.

1. Lower trunnion completely.

2. Loosen screw (C) with 17mm wrench.

3. Slightly loosen nut (D) with 1-1/4” (or

adjustable) wrench.

4. Pivot motor to the left to release tension.

5. Replace belt.

6. Push motor to the right and tighten screw (C)

to tension new belt. Retighten nut (D). Verify

proper tension by pushing on belt midway

between pulleys; deflection should be about

1/2-inch.

Figure 8-11

5. Rotate marked tooth (A) so that it is slightly

above table top at the rear, using the square

as before to verify that distance to blade is

identical. See Figure 8-11. If the two distances

are not the same, make a careful note of the

difference.

6. Loosen table screws (item #24, sect. 14.1.1),

and nudge table according to the distance you

noted.

7. Retighten screws firmly.

8. Verify alignment, angle pointer setting, fence

setting, etc. Make any needed adjustments.

8.9 Belt adjustment

8.9.1 Belt tension

See Figure 8-12.

Drive belt tension should be inspected after the first

few days of operation, as a belt may stretch slightly

during initial use; also inspect it periodically

thereafter.

To tighten belt:

1. Disconnect machine from power source.

Figure 8-12

19

Page 20

8.10 DRO calibration and operation

When the 0° and 45° blade tilt stops have been

verified to be correct, the DRO (digital readout) can

be calibrated to match the settings.

Sect. 8.10.1 describes general calibration

procedure. Sect. 8.10.2 describes mandatory

calibration procedures if the PCB sensor is ever

replaced in the table saw.

8.10.1 General calibration

1. Blade tilt stops must be correctly set. See sect.

8.6.

2. Connect machine to power source. DRO will

be illuminated.

3. If saw blade is relatively close to 0°, set blade

to exactly 0° and press “SET 0” button.

Readout will display 0.00. See Figure 8-13.

Or, if saw blade is relatively close to 45°, set

blade to 45°, and press “SET 45” button.

Readout will display 45.0.

4. Calibration is complete.

NOTE: If power is disconnected, digital display will

reset to 0.00. When power is restored, repeat

above procedure.

8. Press and hold both SET buttons until display

shows “---“ (Figure 8-14).

9. Release buttons and display will show “45.0”.

10. Calibration at 45° is complete. (If “45.0” does

not display, disconnect from power, reconnect

and repeat above procedure.)

Figure 8-14

9.0 Operations

Familiarize yourself with the location and operation

of all controls and adjustments and the use of

accessories such as miter gauge and rip fence.

Note: The following figures are general in nature

and may not show your particular saw model.

Figure 8-13

8.10.2 PCB replacement calibration

1. Blade tilt stops must be correctly set. See sect.

8.6.

2. Connect machine to power source. DRO will

be illuminated.

3. Tilt saw blade to 0°.

4. Press and hold both SET buttons until display

shows “---“ (Figure 8-14).

5. Release buttons and display will show “00.0”.

6. Calibration at 0° is complete. (If “00.0” does

not display, disconnect from power, reconnect

and repeat above procedure.)

7. Tilt blade to 45°.

9.1 Kickback prevention

Serious injury can result from kickbacks which

occur when a workpiece binds on the saw blade or

binds between the blade and rip fence or other

fixed object. This binding can cause the workpiece

to lift up and be thrown toward the operator.

Listed below are conditions which can cause

kickbacks:

Confining the cutoff piece when crosscutting

or ripping.

Releasing workpiece before completing

operation or not pushing workpiece all the

way past saw blade.

Not using splitter/riving knife when ripping or

not maintaining alignment of splitter/ riving

knife with saw blade.

Using dull saw blade.

Not maintaining alignment of rip fence so that

it tends to angle toward rather than away

from saw blade front to back.

Applying feed force when ripping to the cutoff

(free) section of workpiece instead of the

section between saw blade and fence.

Ripping wood that is twisted (not flat), or

does not have a straight edge, or has twisted

grain.

20

Page 21

To minimize or prevent injury from kickbacks:

Avoid conditions listed above.

Wear a safety face shield, goggles, or safety

glasses.

Do not use miter gauge and rip fence in the

same operation unless provision is made by

use of a facing board on the fence, to allow

the cutoff section of workpiece to come free

before the actual cut begins (See Figure 9-

8).

As the machine receives use, the operation

of the anti-kickback pawls should be checked

periodically (Figure 9-1). If the pawls do not

stop the reverse motion of a workpiece,

resharpen all the points.

9.2 Rip sawing

Ripping is feeding the workpiece with the grain into

the saw blade using the fence or other positioning

device as a guide to ensure desired width of cut

(Figure 9-2).

Before starting a rip cut, verify

that fence is clamped securely and aligned

properly.

Never rip freehand or use miter gauge in

combination with the fence.

Never rip workpieces shorter than the saw

blade diameter.

Never reach behind the blade with either

hand to hold down or remove the cutoff piece

with the saw blade rotating.

Figure 9-1

Where possible, keep your face and body out

of line with potential kickbacks, including

when starting or stopping the machine.

Dull, badly set, improper, or improperly filed

cutting tools, and cutting tools with gum or

resin adhering to them can cause accidents.

Never use a cracked saw blade. The use of a

sharp, well maintained, and correct cutting

tool for the operation will help avoid injuries.

Support the work properly and hold it firmly

against gauge or fence. Use a push stick or

push block when ripping short, narrow (6"

width or less), or thin work. Use a push block

or miter gauge hold-down when dadoing or

molding.

Never use the fence as a length stop when

crosscutting. Do not hold or touch the free

end or cutoff section of a workpiece. On

through-sawing operations, the cutoff section

must NOT be confined.

Always keep your hands out of line of the

saw blade and never reach back of the

cutting blade with either hand to hold the

workpiece.

Bevel ripping cuts should always be made

with the fence on the right side of saw blade

so that the blade tilts away from the fence

and minimizes possibility of the work binding

and the resulting kickback.

Figure 9-2

Always use blade guard, splitter/riving knife and

anti-kickback pawls. Make sure splitter/riving knife

is properly aligned. When wood is cut along the

grain, the kerf tends to close and bind on the blade

and kickbacks can occur.

Note: A warning decal is affixed to the guard to

remind the operator of some basic safety

procedures.

The rip fence should be set for the width of the cut

by using the scale on the front rail, or by measuring

the distance between blade (A) and fence (B).

Stand out of line with saw blade and workpiece to

avoid sawdust and splinters coming off the blade or

a potential kickback.

If the workpiece does not have a straight edge, nail

an auxiliary straight edged board on it to provide

one against the fence. To cut properly, the board

must make good contact with the table. Do not

attempt to cut warped boards.

21

Page 22

Figure 9-3

In ripping, use one hand to hold the board down

against the fence or fixture, and the other to push it

into the blade between blade and fence. If

workpiece is narrower than 6" or shorter than 12",

use a push stick or push block to push it through

between fence and blade (Figure 9-4). Never push

in a location such that the pushing hand is in line

with the blade. Move the hand serving as a holddown a safe distance from blade as cut nears

completion.

For very narrow ripping where a push stick cannot

be used, use a push block or auxiliary fence.

Always push the workpiece completely past the

blade at the end of a cut to minimize the possibility

of a kickback.

When ripping long boards, use a support at front of

table (C, Figure 9-5), such as a roller stand, and a

support or "tailman" at the rear (D).

Never use the rip fence beyond the point where the

carriage is flush with the end of the rails.

Have the blade extend about 1/8" above top of

workpiece. Exposing the blade above this point can

be hazardous.

9.3 Resawing

Resawing is a ripping operation in which thick

boards are cut into thinner ones. Note: A band saw

is the ideal tool for resawing.

If the table saw is used for

resawing, take precautions such as using an

auxiliary fence, resaw barrier or similar devices

to stabilize the workpiece and provide operator

safety.

Narrow boards up to 3" can be resawn in one pass.

Wider boards up to 6" must be resawn in two

passes.

In resawing wider boards, adjust the blade height

so as to overlap the two cuts by 1/2" as shown in

Figure 9-6. Too deep a first cut can result in

binding and possible kickbacks on the second cut.

Always use the same side of the board against the

fence for both cuts.

Figure 9-4

Figure 9-5

Figure 9-6

9.4 Crosscutting

Crosscutting is where the workpiece is fed cross

grain into the saw blade using the miter gauge to

support and position the workpiece (Figure 9-7).

22

Page 23

Figure 9-7

Crosscutting should never be done freehand nor

should the fence be used as an end stop unless an

auxiliary block (E, Figure 9-8) is clamped to the

front of the blade area such that the cutoff piece

comes free of the block before cutting begins.

Figure 9-8

Length stops should not be used on the free end of

the workpiece in the cutoff area.

Do not crosscut workpieces shorter than 6". Before

starting a cut, be sure the miter gauge is securely

clamped at the desired angle. Hold the workpiece

firmly against the table and back against the miter

gauge. Always use the saw guard and riving knife

and make sure the riving knife is properly aligned.

For 90 degree crosscutting, most operators prefer

to use the left-hand miter gauge slot. When using it

in this position, hold the workpiece against the

gauge with the left hand and use the right hand to

advance the workpiece. When using the right hand

slot for miter and compound crosscutting so that

the blade tilts away from the gauge, the hand

positions are reversed.

When using the miter gauge, the workpiece must

be held firmly and advanced smoothly at a slow

rate. If the workpiece is not held firmly, it can

vibrate causing it to bind on the blade and dull the

saw teeth.

Figure 9-9

To augment the effectiveness of the miter gauge in

crosscutting, some users mount an auxiliary wood

extension face (F, Figure 9-9) with a glued-on strip

of sandpaper (G) to help grip the workpiece.

Provide auxiliary support for any workpiece

extending beyond the table top with a tendency to

sag and lift up off the table.

Have the blade extend about 1/8" above the top of

the workpiece. Exposing the blade above this point

can be hazardous.

9.5 Bevel and miter operations

Bevel cut – A bevel cut is a special type of

operation where the saw blade is tilted at an angle

less than 90-degrees to the table top (Figure 9-10).

Operations are performed in the same manner as

ripping or crosscutting, except the fence or miter

gauge should be used on the right-hand side of the

blade to provide added safety in avoiding a binding

action between blade and table top. When beveling

with the miter gauge, the workpiece must be held

firmly to prevent creeping.

Never use a zero-clearance

insert with saw blade in tilted position.

Figure 9-10

Mitering – Crosscuts made at an angle to the edge

of the workpiece are called miters (Figure 9-11).

Set the miter gauge at the required angle, and

23

Page 24

make the cut the same as a normal crosscut

except the workpiece must be held extra firmly to

prevent creeping.

Figure 9-11

Note: When making compound miters (with blade

tilted) use the miter gauge in the right hand slot to

provide more hand clearance and safety.

Have the blade extend only 1/8" above the top of

the workpiece. Exposing the blade above this point

can be hazardous.

9.6 Dado cutting

Upon completion of the operation requiring removal

of the guard, the entire guard assembly must be

placed back on the machine in its proper working

order.

Never use a dado head in a

tilted position. Never operate the saw without

the blade guard, riving knife and anti-kickback

pawls for operations where they can be used.

Dadoing is cutting a wide groove into a workpiece

or cutting a rabbet along the edge of a workpiece.

A dado insert (optional accessory, shown in Figure

9-12) is necessary for this type of operation.

Do not use the standard table

insert for dadoing operations.

Figure 9-12

The process of cutting 1/8" to 13/16" grooves in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable type blade

mounted on the saw arbor. By using various

combinations of stacked dado blades, or properly

setting the dial on an adjustable blade, an accurate

width dado can be made. This is very useful for

shelving, making joints, tenoning, etc.

The guard, riving knife, and anti-kickback pawls

supplied with the saw should be used for all cutting

operations where they can be used.

When performing operations where the guard

cannot be used, as in some dadoing operations,

alternative safety precautions should be taken.

These include push sticks, feather boards, filler

pieces, fixtures, jigs and any other appropriate

device that can be utilized to keep operators’

hands away from the blade.

24

Page 25

10.0 Safety devices

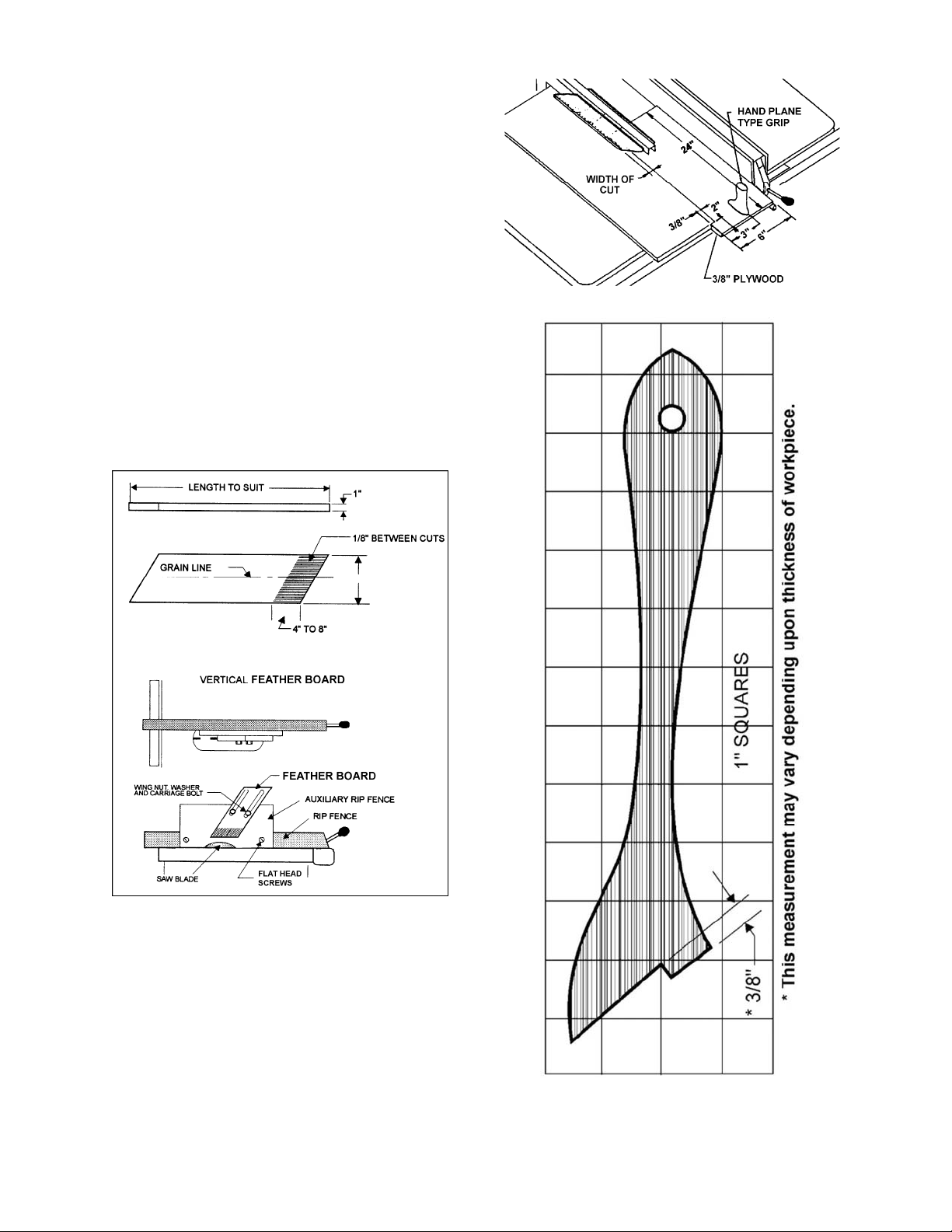

10.1 Feather board

Feather boards, or “combs,” can be purchased at

most tool stores, or made by the operator to suit

particular applications. The feather board (Figure

9-13) should be made of straight grain hardwood

approximately 1" thick and 4" to 8" wide depending

on the size of the machine. The length is

developed in accordance with intended use.

Feather boards can be fastened to the table or rip

fence by use of C-clamps. Alternatively, drilled and

tapped holes in the table top allow the use of wing

nuts and washers as a method of clamping. If this

method of fastening is used, provide slots in the

feather board for adjustment. (The illustration

shows a method of attaching and use of the

feather board as a vertical comb. The horizontal

application is essentially the same except that the

attachment is to the table top.)

Figure 9-14: push block template

Figure 9-13: feather board

10.2 Push stick and push block

The use of a push block or push stick provides an

added level of safety for the operator. A push stick

is included with your table saw, but you may wish

to make others personalized for different cutting

procedures. The templates in Figures 9-15 and 915 offer construction details.

Figure 9-15: push stick template

25

Page 26

11.0 User-maintenance

Always disconnect power to

machine before performing maintenance.

Failure to comply may result in serious

personal injury.

PERIODICALLY:

• Keep cabinet interior and trunnion area clean.

Vacuum dust and chips.

• Check for excessive play in tilting and raising

mechanism and in saw arbor, and adjust as

required.

11.1 General inspection

Always be aware of the condition of your machine.

Routinely check the condition of the following items

and repair or replace as necessary:

• Mounting bolts

• Power switch

• Saw blade

• Blade guard assembly

11.2 Cleaning

Note: The following maintenance schedule

assumes the saw is being used daily.

DAILY:

• Wipe down table surface and T-slots.

• Clean pitch and resin from saw blade.

WEEKLY:

• Table surface must be kept clean and free of

rust for best results. To facilitate this, apply a

coat of paste wax to the surface. Alternatively,

commercial spray protectants are available

from local hardware and tool stores. A good

protectant should provide rust protection for

the surface without staining workpieces.

• Clean the motor fan housing with compressed

air.

• Wipe down fence rails with a dry silicon

lubricant.

• Check belt for proper tension, and for wear,

cracks, frays, etc.

11.3 Lubrication

• Grease the tilting worm gear, raising worm

gear, and the trunnion areas with a good grade

non-hardening grease.

• Check all adjustments after lubricating, such

as handwheel action, blade stops, DRO

setting, etc.

11.4 Arbor/Arbor Bearing Removal

The saw arbor is press fitted in the saw raising arm

housing. If the arbor needs to be removed for

bearing replacement, it should be done by a

qualified service technician. Contact Powermatic

customer service.

11.5 Additional servicing

Any additional servicing should be performed by

authorized service personnel.

26

Page 27

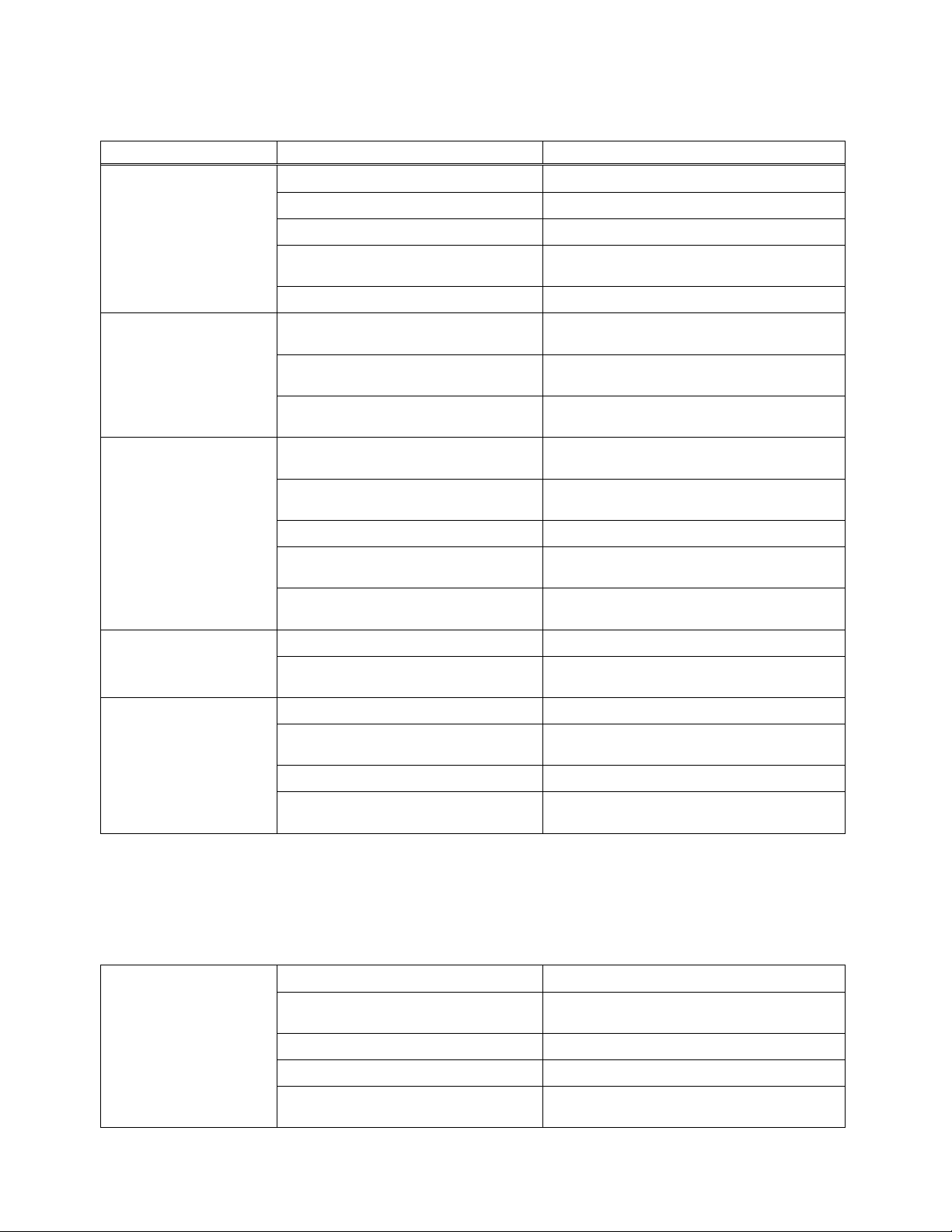

12.0 Optional accessories

These accessory items (purchased separately) can enhance the functionality of your PM2000B table saw.

Contact your dealer to order, or call Powermatic at the phone number on the cover. Additional accessories may

be available; see our website.

# 1791788B – Dado Insert

# 1791786B – Zero-clearance insert

# 1791791B – High-Profile Thin-Kerf Riving Knife

0.079” (2.0mm) thick

# 1791792B – Low-Profile Thin-Kerf Riving Knife

0.079” (2.0mm) thick

# 1799000 – PM-TJ Tenoning Jig

27

Page 28

13.0 Troubleshooting PM2000B Cabinet Saw

13.1 Motor and electrical problems

Symptom Probable Cause Remedy

Saw will not start.

Saw will not start: fuse

blows or breaker trips.

Motor starts slowly or

fails to reach full speed.

Motor overheats. Motor overloaded. Reduce load on motor.

No incoming power. Check plug connection.

Safety key removed from switch. Install safety key.

Low voltage. Check power line for proper voltage.

Open circuit in motor or loose

connection.

Power cord damaged. Replace cord.

Short circuit in line cord or plug. Inspect cord or plug for damaged insulation

Short circuit in motor or loose

connections.

Incorrect fuses or circuit breakers in

power line.

Low voltage.

Power line overloaded.

Undersized wires in supply system. Increase supply wire size.

Centrifugal switch not engaging.

Motor malfunction.

Inspect all connections on motor for loose or

open connections.

and shorted wires.

Inspect all connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Request voltage check from power company

and correct low voltage condition.

Correct overload condition. Use dedicated

circuit for table saw.

Replace centrifugal switch (qualified

personnel only).

Have motor checked by a qualified

inspector. Repair or replace.

Improper cooling of motor; lack of air

circulation.

Motor stalls, resulting in

blown fuses or tripped

breaker.

Motor overloaded. Reduce load on motor.

Short circuit in motor or loose

connections.

Low voltage. Correct low voltage conditions.

Incorrect fuses or circuit breakers in

power line.

Table 4

13.2 Mechanical and operational problems

Excessive feed. Reduce feed.

Dull or incorrect blade.

Motor stalls or workpiece

binds or burns.

Miter slot misaligned. Realign table to blade.

Fence misaligned. Realign fence (see Accu-Fence manual).

Motor malfunction.

Clean sawdust from fan and duct areas of

motor.

Inspect connections on motor for loose or

shorted terminals or worn insulation.

Install correct fuses or circuit breakers.

Replace blade; use proper type of blade for

cut needed.

Have motor checked by a qualified

inspector. Repair or replace.

28

Page 29

Machine slows or stalls

when operating.

Applying too much pressure to

workpiece.

Poly-v drive belt is loose. Tighten belt.

Feed workpiece more slowly.

Loud, repetitive noise

coming from machine.

Excessive vibration.

Blade not square with

miter slot, or fence not

square to blade.

Blade does not reach 90

degrees.

Cuts out-of-square when

crosscutting.

Cuts not true at 90 or 45

degrees.

Tilting or raising

handwheel difficult to

turn.

Pulley setscrews or keys are missing