Page 1

POWERMATIC PM201HH, 22" Planer

The POWERMATIC PM201HH, 22" Planer is a rock solid,

1300-LB cast iron and steel planer designed to be

accurate, productive and cost effective in the small to

medium shop environment for many years to come. User

friendly features like simple controls, a quick access

hinged top and 5”-diameter, top-mounted dust port make

the POWERMATIC PM201HH, 22" Planer easy to operate

and maintain. The high tech helical cutterhead is designed

to produce silky-smooth surfaces on the wood without

constant sharpening or cutter replacement.

The POWERMATIC PM201HH, 22" Planer is available in

three versions. The #1791267 201HH, 22" Planer comes

with a 7.5HP 1PH 230V motor. The #1791268 201HH, 22"

The Powermatic PM201HH Planer

is built to be tough, accurate and

easy to maintain in the shop

environment.

Planer also has a 7.5HP motor but runs on 3PH 230V

power. The #1791269 201HH, 22" Planer, has a 7.5HP motor that runs on 3PH 460V

for most industrial applications.

Helical Cutterhead

The POWERMATIC PM201HH, 22" Planer features the

innovative, 3-1/4”-diameter helical cutterhead equipped with

150, four-sided carbide inserts. These high-quality inserts

are designed for use with the 4800-RPM cutterhead speed

to produce a superior finish while dramatically reducing

sound levels as compared to conventional knife type

cutterheads. Because each insert has four identical cutting

edges, their useable life is greatly extended.

The sophisticated helical head

creates ultra-smooth surface

with far less cutter replacement

or maintenance than with

conventional knife systems.

This four sided insert design also means maintenance is f

and easy. Each insert is installed on a precision-mach

ined

seat that eliminates complicated setup, shimming or

alignment procedures. That drastically reduces costly

downtime. Plus, if a piece of metal is accidentally passed

through the POWERMATIC PM201HH, 22"

Planer, only the inserts directly in line with the

metal might have to be indexed or replaced. This

dramatically reduces replacement parts costs as

well as related downtime.

Smart Feed System

Anti-kickback fingers along the front edge of the

infeed side help prevent stock from being kicked

The segmented feed rollers make working

with various thickness pieces safe and

consistent. The result is higher production

without sacrificing quality.

ast

Page 2

out should something go wrong under the cutterhead. A pressure bar located close to

the cutterhead increases the stability of the wood to help the POWERMATIC

PM201HH, 22" Planer

produce an exceptional

finish. Infeed and outfeed

rollers, cutterhead and

many other rotating parts

turn in high quality roller

bearings that extend their

lifespan, increase accuracy

and reduce maintenance.

The 3”-diameter sectional

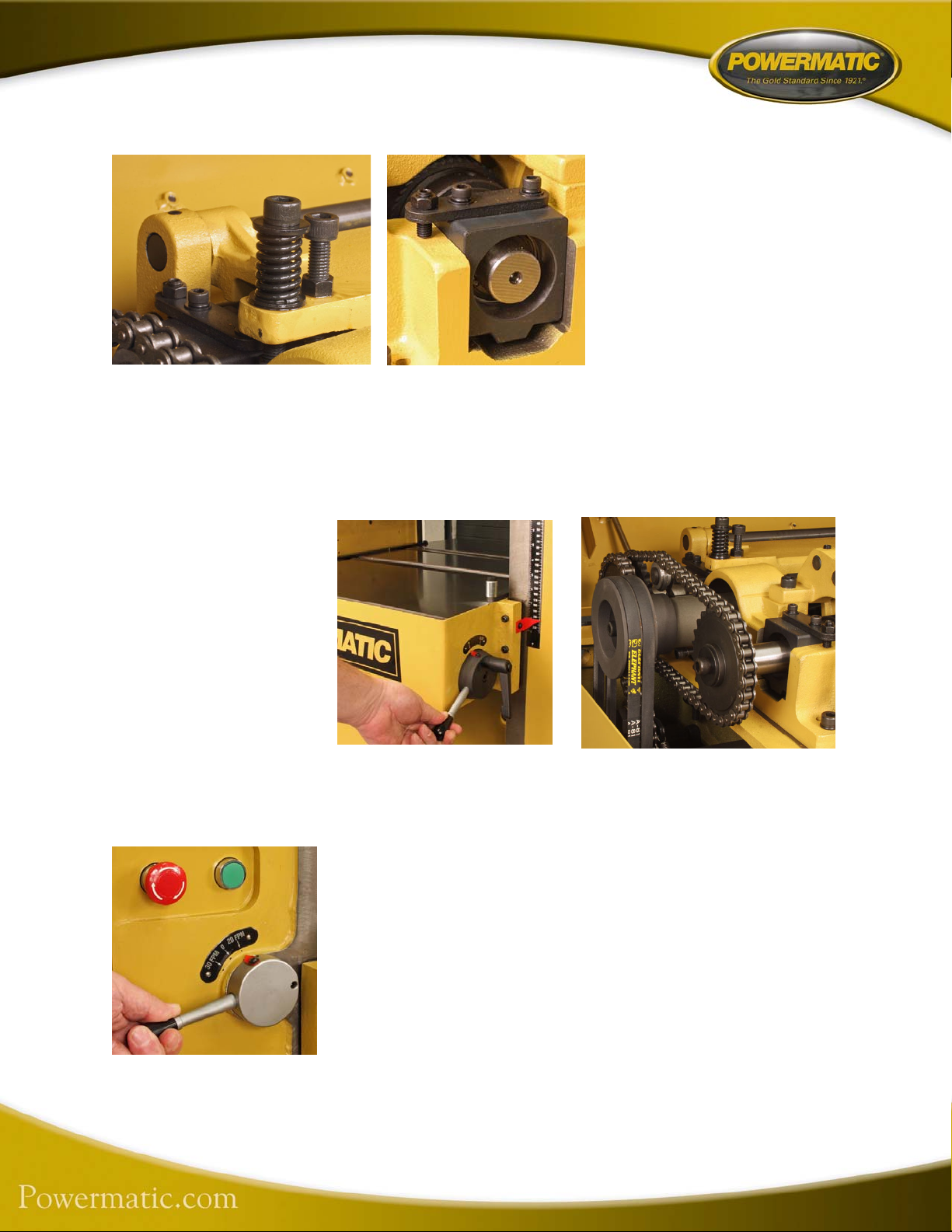

Adjustment of the feed and roller systems is easy with top-mounted

adjusters. (left) All of the major rotating parts run in high quality ball bearings

(right) for maximum accuracy and life with minimal downtime.

infeed roller system and

chip breaker are specially

designed to allow feeding

multiple boards with

different thicknesses through the POWERMATIC PM201HH, 22" Planer simultaneously.

This feed system also

accepts work pieces

with uneven surfaces,

moving them

consistently so they

are machined correctly

the first time.

A pair of adjustable

bed rollers facilitates

both rough and finish

planing. These bed

rollers are adjustable

from outside of the

The twin in-bed rollers are adjustable from the front of the PM201HH (left) so

these changes can be made quickly without disturbing cut depth. The cutterhead

is powered by a dual belt and the rollers with a slip-free chain drive. (right)

POWERMATIC

PM201HH, 22" Planer so “on the fly” corrections are easy to make without having to

disturb the table height setting and delaying production. The

solid steel outfeed roller is machined with small serrations to

insure a smooth finish yet provide positive feeding.

The two-speed gearbox that drives the feed rollers is quickly

shifted with a handle at the front of the POWERMATIC

PM201HH, 22" Planer. Changing between the 20 and 30

fpm (feet per minute) feed rates is done while the machine

is running (only) and makes switching from rough to finish

planing easy. Heavy-duty side rollers guide the stock so it

Changing feed rates is done “on-

the-fly” with this handle on the

front of the PM201HH.

moves beneath the cutterhead properly.

Page 3

The massive, 321/4" x 24" ribbed

cast iron table is

precisely

ground to insure

it is flat. This

heavy table is

raised and

The large handwheel (left) makes raising and lowering the heavy cast iron table easy. The

specially designed dust ports under the top cover (right) help evacuate the dust to keep

the shop environment cleaner.

lowered with a

large-diameter

iron handwheel.

Each full turn of

the handwheel produces a 1/16” change in table height, making ultra-precise cut

changes easy to make. The height of the cast iron table is controlled by a pair of heavyduty lead screws that keep it stable and insure that it remains parallel to the cutterhead

throughout its travel. The versatile POWERMATIC PM201HH, 22" Planer has a

maximum planing thickness of 9-3/4", minimum stock thickness of 1/8”, a maximum cut

depth of 3/16” and can plane wood with a minimum length of just 10”!

The massive cast iron

table has gib

adjustments at each

side on the front for

long term clearance

adjusting to keep the up

and down motion

smooth and play free.

The lead screws are

adjustable as well.

Heavy duty adjusting

hubs atop each lead

screw allow for quick

The table has gib adjustments (left) at either side to eliminate play that might

develop over the years. Each of the massive lead screws has an adjusting collar

at its top (right) to keep the table parallel to the cutterhead.

adjusting of the table

parallelism.

The POWERMATIC PM201HH, 22" Planer was designed for small to medium shops

with continuous planing requirements. Its 42”-long x 49”-wide and 59”-height packs

remarkable planing capabilities into a floor space saving footprint. The rugged

construction and labor-saving design means the POWERMATIC PM201HH, 22" Planer

will minimize downtime and maintenance costs while maximizing production.

Loading...

Loading...