Page 1

POWERMATIC PM1900 Dust Collector

The POWERMATIC

PM1900 is designed with the

power to work with planers,

wide belt sanders and most

woodworking machines. Its

powerful dust-evacuating

suction, effective filtering,

multiple connection and

large collection capacity

make the POWERMATIC

PM1900 a capable central

dust collection system for the

whole shop. Plus, it packs

those capabilities into a

durable, space-saving

package that accommodates

virtually any shop size and

needs.

The POWERMATIC

PM1900 is shipped as a bare

The POWERMATIC DC1900 is essentially the same machine but can be equipped

with the fabric style bags (left) or the canister kit. (right) The difference in height

between the bag and canister setups can be important in some shop environments with

low ceilings or other height restrictions.

machine without filter elements or catch bags allowing the buyer to “design” the system they

want. The fabric filter and catch bag sets as well as the pleated canister filters with five plastic

catch bags are sold as individual kits. This allows the purchaser to save money by getting the

POWERMATIC PM1900 with the filter style wanted without paying for and then discarding an

unused “standard” filter and bag sets.

Filtering Efficiency

The bag filter elements are 20” in diameter and 48” in length. Upright hooks are included to

support the bags when the POWERMATIC PM1900 is not running. Spring steel band clamps

secure the filter bags to the twin collector housings. The fabric collector bags use spring retaining

rings sewn into their upper edges that fit into a groove in the collector housings making

installation and removal tool free. Many manufacturers use an outside band for securing

collection bags that can be very difficult to work with, especially when done alone.

The bag type elements filters out 96% of 30 micron particles.

The canister filters are 20” in diameter and 29” long. The canisters mount directly to the collector

housings and seal with factory installed foam gaskets within the canister flanges. Four fingeroperated knobs lock each canister to the collector housings. Despite the canisters compact overall

size, its pleated filter element has six times the filtering surface area of the fabric bag type.

Page 2

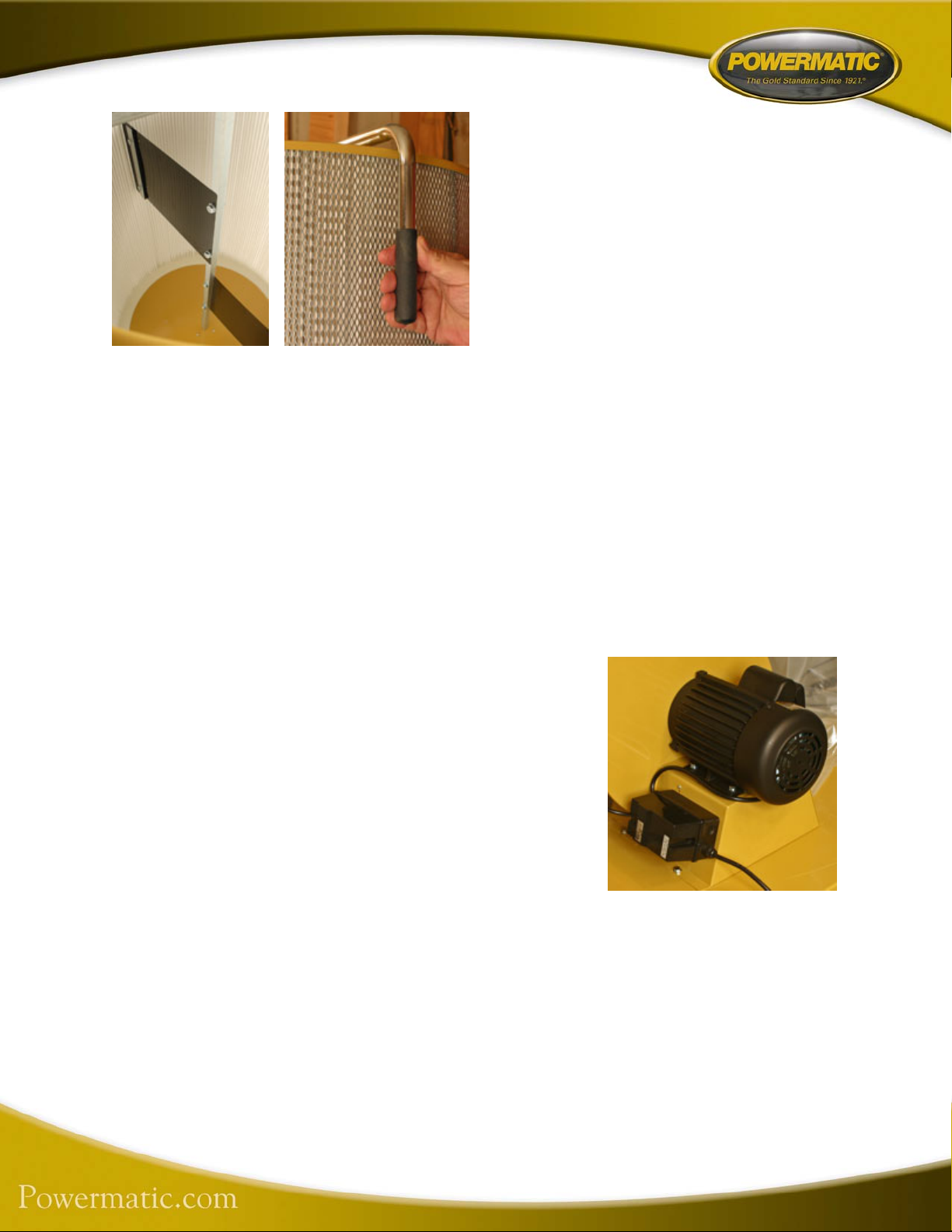

The canisters filter 86% of 1 micron particles

and 98% of 2 micron particles. To maintain

that efficiency, a top-mounted handle operates

a pair of “hands” within the canister. When

turned the hands wipe across the interior filter

pleats, flexing them to knock off excessive

dust buildup but leaving the beneficial layer.

Turning the top-mounted handle one full

revolution per month (per canister) under

normal conditions is all that is required. The

A pair of “hands” (left) within the canister flex the pleated

element to knock off excess buildup. The hands are operated by

the external handle (right), which is generally turned through

one revolution per month in most home woodshop

circumstances.

oval POWERMATIC sticker on the canister

exteriors can be easily peeled off the canisters

wire mesh if one wants to remove any

possible impact on performance though none

has been recorded.

The difference in height between the fabric and canister filter elements can be an issue in shop

spaces with low ceilings or overhead clearances. The POWERMATIC PM1900 has an overall

height of just under 6 feet with the canisters installed compared to 92 ½” when equipped with the

fabric filter bags and their hangars.

Collector (catch) bag capacity for both the fabric and plastic bags is 10 cubic feet.

Power and Control

The POWERMATIC PM1900 is available in two

configurations. First is with a 3HP, 1Ph 220V (only) TEFC

(totally enclosed fan cooled) motor. We also offer a version

with a 3HP motor running on 3Ph, 230/460V power, wired for

230V from the factory. POWERMATIC motors are rated

using a continuous duty cycle rather than the “peak” or “max

developed” claims so common in the industry. Very often new

POWERMATIC users are pleasantly surprised by the amount

of power our motors actually deliver when compared to other

motors with similar power ratings in their shop.

The motor is secured to a common mount with the blower

section, directly on the base platform. This creates a very low

center of gravity that makes moving the POWERMATIC

The 3 HP motor (1Ph version only)

features a magnetic start switch that

protects the motor itself, and you from

unexpected power variations or outages.

PM1900 safe and easy.

Because woodworkers sometimes locate their dust collector in an out of the way portion of the

shop or connected to a permanently installed hard tubing system, we added a full-function,

infrared remote control (1Ph version only) that emits its invisible light-based signal in a 120degree cone. That means the pocket-sized remote unit will turn the POWERMATIC PM1900 on

and off from virtually anywhere (line of sight) in most shops, saving untold numbers of steps and

Page 3

time. Eliminating those trips back and forth between a machine and dust collector can increase

safety in the shop as well.

Our remote control also has a timer function that allows

programming in a specific amount of run time between 1 and

99 minutes. When activated, the timer function allows the

POWERMATIC PM1900 to run a specific amount of time

before it shuts off automatically.

The infrared remote (1Ph version only)

can save untold steps back and forth to

the DC1900. It also has a timer function

that allows programming in up to 99

minutes of run time before the DC1900

shuts off automatically.

The POWERMATIC PM1900 comes with a magnetic starter

(1Ph version only) that protects the motor from excessive

current variations. It also prevents the POWERMATIC

PM1900 from restarting unexpectedly should the power go

out, and then come back on. When the power is restored, the

On button (on the machine or the remote) must be pushed to restart the machine.

Fan System

We designed a super efficient air system for the POWERMATIC

PM1900, based on a specially designed 14”-diameter impeller and

housing. The heavy-duty impeller has been optimized to both move large

amounts of air and to maintain that volume consistently in a wide range

of usage situations.

The fan section develops 1,891 CFM (cubic feet per minute) of airflow

at 8” of water. Velocity, also at 8” of water is 5,393.7 FPM (feet per

minute). Static pressure is 12.15 inches of water.

To make the POWERMATIC PM1900 compatible with the widest range

of machines, it comes with a single 8”-diameter inlet port fitted with a

triple 4”-port adapter. Two of the 4” ports come with tethered, friction fit

covers that seal them when not in use.

The impeller is specifically

designed for maximum

efficiency and consistency

in the DC1900.

The inlet ports are mounted directly to

the blower housing, putting them low on

the POWERMATIC PM1900 and on an

even plane with the dust outlets on many

machines. This alignment keeps more of

the hose flat on the floor for safety and

eliminates much of the lifting loss higher

inlet ports experience to enhance

performance.

The smooth surfaces and curves of the sheet metal chute (left)

enhance airflow and efficiency. This triple 4”-outlet adapter (right)

slips onto an 8”-diameter port to provide the most versatility in your

shop.

To further enhance overall airflow we

replaced the common flex hose

connection between the fan and collector

Page 4

housings with a curved, smooth-walled sheet metal chute. The ends of the chute have flange-type

connections with gaskets that help prevent even small leaks. This chute has a larger inside area

than a hose initially, and then tapers down slightly as it splits and then runs to the collector

housings. The smooth, flowing shape of the chutes interior surfaces move air efficiently and

contribute to the overall performance of the POWERMATIC PM1900.

The strength and rigid mounting of the sheet metal duct adds a considerable amount of stability

to the POWERMATIC PM1900 making it possible to eliminate two of the three legs normally

needed to support each collector housing. Eliminating two legs at each collector housing creates

substantially more unobstructed space that makes changing the collection bags much easier.

The collector housings are specially designed to create a cyclonic effect that helps separate

particles from the air to enhance filtering and venting. The swirl of air also helps distribute the

dust evenly in the catch bag.

Mobility

The POWERMATIC PM1900 is built on a heavy-duty base

that features full-swivel, smooth-rolling casters at each corner.

This base, along with the low center of gravity makes moving

the POWERMATIC PM1900 around the shop effortless and

safe. We also added a pair of handles to each collector housing

that make moving the POWERMATIC PM1900 easier.

Full swivel casters at each corner of the

solid metal base make moving the

DC1900 around the shop safe and easy.

Loading...

Loading...