Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

18-inch Band Saw

Model PM1800

Powermatic

427 New Sanford Rd.

LaVergne, TN 37086 Part No. M-1791800

Ph.: 800-274-6848 Revision B1 01/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa t io n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning ................................................................................................................................................... 5

Introduction ............................................................................................................................................. 7

Specifica tions ................................................................................................................ .......................... 7

Features and Terminology ....................................................................................................................... 8

Unpac king ............................................................................................................................................... 9

Installation ............................................................................................................................................. 10

Assembly .............................................................................................................................................. 10

Rear Rail............................................................................................................................................ 10

Front Rail and Guide Tube ................................................................................................................. 11

Fence Assembly ................................................................................................................................ 11

Resaw Fence ..................................................................................................................................... 11

Fence to Table Clearance .................................................................................................................. 12

Setting Cursor (Zero) Position ............................................................................................................ 12

Setting Table Parallel to Blade ........................................................................................................... 12

Setting Fence Parallel to Blade .......................................................................................................... 13

Fence Loc kin g Tightness ................................................................................................................... 13

Dust Collection ...................................................................................................................................... 1 4

Electri c al Connec tions ........................................................................................................................... 14

Extension Cords................................................................................................................................. 15

Adjustments .......................................................................................................................................... 15

Table Til t ............................................................................................................................................ 15

90° Table Stop ................................................................................................................................... 15

Installing/Changing Blades ................................................................................................................. 16

Blade Tension .................................................................................................................................... 17

Blade Tracking ................................................................................................................................... 18

Upper Blade Guides ........................................................................................................................... 19

Upper Thrust Bearing ......................................................................................................................... 19

Lower Blade Guides ........................................................................................................................... 20

Guide Post ......................................................................................................................................... 21

Guide Post Parallelism ....................................................................................................................... 21

Resaw Pin ......................................................................................................................................... 22

Miter Gauge ....................................................................................................................................... 22

Blade Speed Adjustment .................................................................................................................... 23

Drive Belt Tensi on and Replacement.................................................................................................. 23

Wheel Bru sh ...................................................................................................................................... 24

Insert Block ........................................................................................................................................ 24

Operating Controls ................................................................................................................................ 24

Safety Ke y ......................................................................................................................................... 25

Brake Pedal ....................................................................................................................................... 25

Operation .............................................................................................................................................. 2 6

General Procedure ............................................................................................................................. 26

Resawing ........................................................................................................................................... 27

Blade Lead ........................................................................................................................................ 27

Ripping .............................................................................................................................................. 26

Crosscutting ....................................................................................................................................... 26

Blade Selecti on ..................................................................................................................................... 29

Width ................................................................................................................................................. 29

Pitch ......................................................................................................................... ......................... 29

Shape ................................................................................................................................................ 29

Set ..................................................................................................................................................... 30

Material .............................................................................................................................................. 30

Blade Breakage ................................................................................................................................. 30

Blade Selecti on Guide ........................................................................................................................... 31

3

Page 4

Troubleshooting – Operational Pr oblem s ............................................................................................... 32

Troubleshooting – Mechanical and Electrical Problems .......................................................................... 34

Replacement Parts ................................................................................................................................ 35

Upper Wheel Assembly – Exploded View ........................................................................................... 36

Upper Wheel Assembly – Parts List ................................................................................................... 37

Lower Wheel and Motor A ssembly – Exploded View .......................................................................... 38

Lower Wheel and Motor A ssembly – P arts Li st ................................................................................... 39

Blade Guide Assembly – Exploded View ............................................................................................ 41

Blade Guide Assembly – P arts Li st ..................................................................................................... 42

Table and Fence Assembly – Exploded View ..................................................................................... 44

Table and Fence Assembly – Parts List .............................................................................................. 45

Electri c al Connec tions – 5HP 1PH 230V ................................................................................................ 47

Electri c al Connec tions – 5HP 3PH 230V ................................................................................................ 48

Electri c al Connec tions – 5HP 3PH 460V ................................................................................................ 49

4

Page 5

Warning

1. Read and understand the ent ire owner’s manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or remov ed.

4. This band saw is designed and i ntended for use by pr operl y tr ained and ex peri enced personnel only .

If you are not familiar with the proper and safe operation of a band saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this band saw for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Al ways wear approved safety glasses/f ace shields while using this band saw. Ever yday eyeglasses

only have impact resi stant lenses; they are not saf ety glasses.

7. Before operating this band saw, remove tie, rings, watches and other jewelry, and r oll sleeves up past

the elbows. Secur e all loose cl othing and c onfine long hair . Non-sli p footwear or anti- skid fl oor strips

are recommended. Do not wear gloves when operating the machine.

8. Wear ear protector s (plugs or muffs) during extended periods of operati on.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other r epr oduc tiv e harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lum ber .

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machine while tired or under t he influence of drugs, alcohol or any m edi c ation.

11. Make certain the switch is in the OFF position before connecti ng the machine to the power supply.

12. Make certain the machine is properly grounded.

13. Make all machine adjustments or maintenance with the machine unplugged fr om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replac e the guards immediately after m aintenance is complete.

16. Make sure the band saw is firmly secured to the floor or bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Provide for adequate space surrounding work area and non-glare, overhead lighti ng.

19. Keep the floor around the machine clean and free of scrap mater ial, oil and grease.

20. Keep visi tors a safe distance from the work area. Keep children away.

5

Page 6

21. Make your workshop child proof with padloc k s, m ast er switc hes or by r em oving starter keys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintain a balanced stance at all times so that you do not f all or lean against the blade or other

moving part s. Do not over r eac h or use excessive force to perform any m ac hine oper ation.

24. Adjust the upper guides to approximately 3/16” above the workpiece.

25. Make relief cuts when sawing curves.

26. Use the ri ght t ool at the cor rect speed and f eed rate. Do not for ce a t ool or attachm ent to do a j ob for

which it was not designed. T he ri ght tool will do the job better and more safely.

27. Use recomm ended ac c essories; improper accessories may be hazardous.

28. Mai ntain tools with care. Keep bl ades sharp and clean for the best and saf est performance. Follow

instructions for lubricating and c hanging accessories.

29. Turn of f the m achine and discon nect f rom power bef ore cleani ng. Use a bru sh or com pressed air to

remove chips or debris — do not use your hands.

30. Do not stand on the machine. Serious injury c ould oc c ur if the machine tips over.

31. Never leav e the machine running unattended. Turn the power off and do not leave the mac hine until it

comes to a complete stop.

32. Remove loose items and unnecessary work pieces from the area before starting the machine.

Familiariz e you rself with the following safet y no tices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

6

Page 7

Introduction

This manual is provided by Powermati c covering the safe operat ion and maintenance pr ocedures for a

Powermatic Model PM1800 Band Saw. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordanc e with

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or Powermatic. Powermatic can also be reached at our web site: www.powermatic.com.

Specifications

Model Number .............................................................................................................................. PM1800

Stock Number (5HP 1PH) .............................................................................................................1791800

Stock Number (5HP 3PH) .............................................................................................................1791801

Motor (1PH) ........................................................................................ TEFC, 5HP, 1PH, 230V, 60Hz, 21A

Motor (3PH) ................................................ TEFC, 5HP, 3PH, 230/460V (pre-wired 230V ) *, 60Hz, 13/6.5A

Blade Speeds (SFP M) ........................................................................................................ 1800 and 4200

Maximum Cutti ng Height/Resaw Capacity (in. )....................................................................................... 18

Throat Capacit y (i n.) .............................................................................................................................. 18

Minimum Blade Width (in.) .................................................................................................................. 1/16

Maximum Blade Width (in.) ................................................................................................................ 1-1/2

Blade Length (in.) ................................................................................................................ 160 to 161-1/2

Blade provided (in.) ............................................................................. Hook Type, 3/4 W x 0.03 Thk, 4TPI

Resaw Fence (L x H)(in.) ............................................................................................................ 30 x 6-1/2

Resaw Pin (Dia. x H)(in.) ..............................................................................................................2 x 6-1/2

Table Dimensions (L x W x Thk)(in.) ......................................................................................... 24 x 24 x 2

Table Thi ck n e ss (in.) ............................................................................................................................... 2

Table Tilt (deg.) .................................................................................................................. 45 right, 15 left

Table Height from Floor @ 90 deg. (in.) ........................................................................................... 3 7-1/2

Miter Gauge Positive Stops (deg.) .............................................................................................. 45 and 90

Wheel Diameter (in.) ........................................................................................................................ 18-1 /2

Power Transfer ................................................................................................................. poly-V belt drive

Switch ................................................................................................ magnetic, with power indic ator lam p

Dust Port Diameter (in.) ........................................................................................................................... 4

Dust Collection CFM Required ............................................................................................................. 400

Overall Dimensions (L x W x H)(in.) .................................................................................. 38 x 42 x 81-1/2

Net Weigh t (lb s.) .................................................................................................................................. 806

Shipping Weigh t (lbs.) .......................................................................................................................... 90 2

*NOTE: For 460V operation, m agnetic switch (part no. PM2000-293C) m us t be purchased separat ely and

installed. A qualified elec trician is recomm ended.

The above specifications were current at the time this manual was published, but bec ause of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligations.

7

Page 8

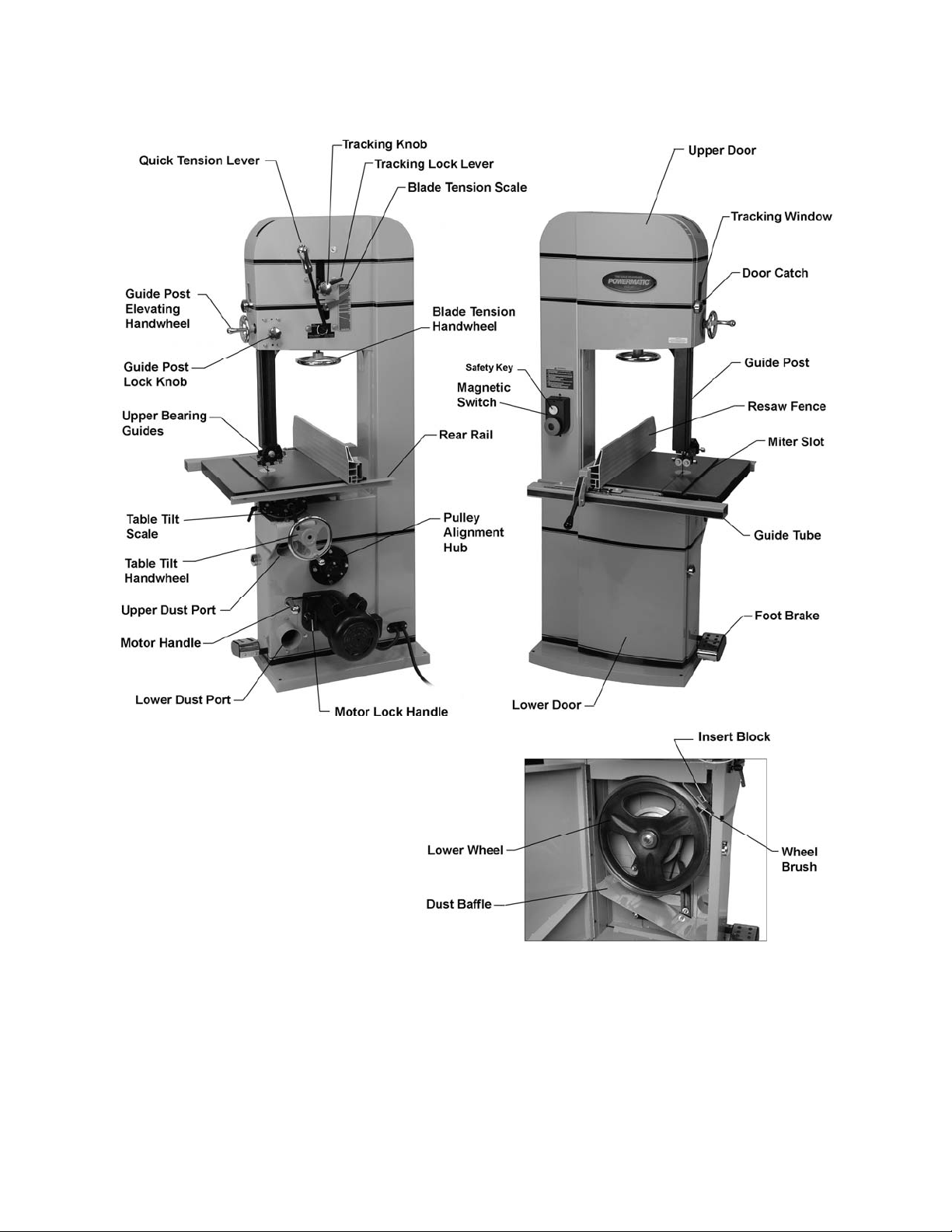

Features and Terminology

Figure 1

8

Page 9

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shippi ng material until the Band Saw

is assembled and r unning pr oper ly.

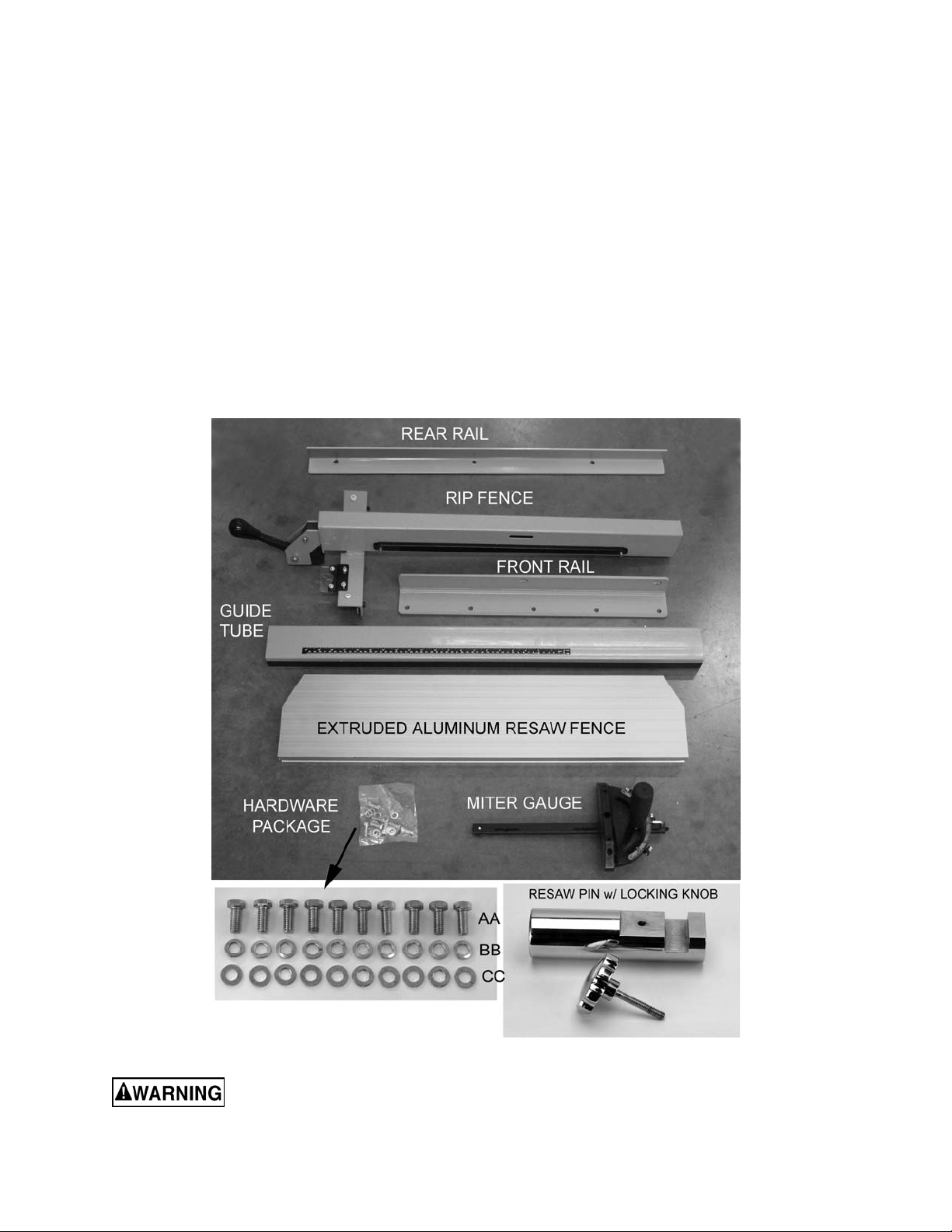

Compare the c ontent s of y our cont ainer wit h t he

following parts list and photos to make sure all

parts are intac t. Missing part s, if any, shoul d be

reported to your di stributor. Read the instruct ion

manual thoroughly for assembly, maintenance

and safety instruc tions.

Contents of the Shipping Container

1 Band Saw (not shown)

1 Rip Fence Body

1 Extruded Aluminum Resaw Fence

1 Front Rail

1 Rear Rail

1 Guide Tube

1 Resaw Pin with Locking Knob

1 Hardware Package cont aining:

10 Hex Cap Screws, 5/16”-18 x 3/4” (AA)

10 Lock Washers, 5/16” (BB)

10 Flat Washers, 5/16” (CC)

1 Miter Gauge

1 Owner's Manual (not shown)

1 Warranty Car d (not shown)

Figure 2

Read and understand the entire contents of this manual before attempting set-up

or operation! Failure t o co mply may cause serious injury.

9

Page 10

Installation

Tools requi red for assemb ly and set up:

7/32” hex (Allen) wrench

6mm hex (Allen) wrench

12mm open-end wrench

Square

Hoist or forklift, with straps

Remove all crati ng and plastic from around the

machine. Remov e any screws or straps hol ding

the band saw to the shippi ng pallet.

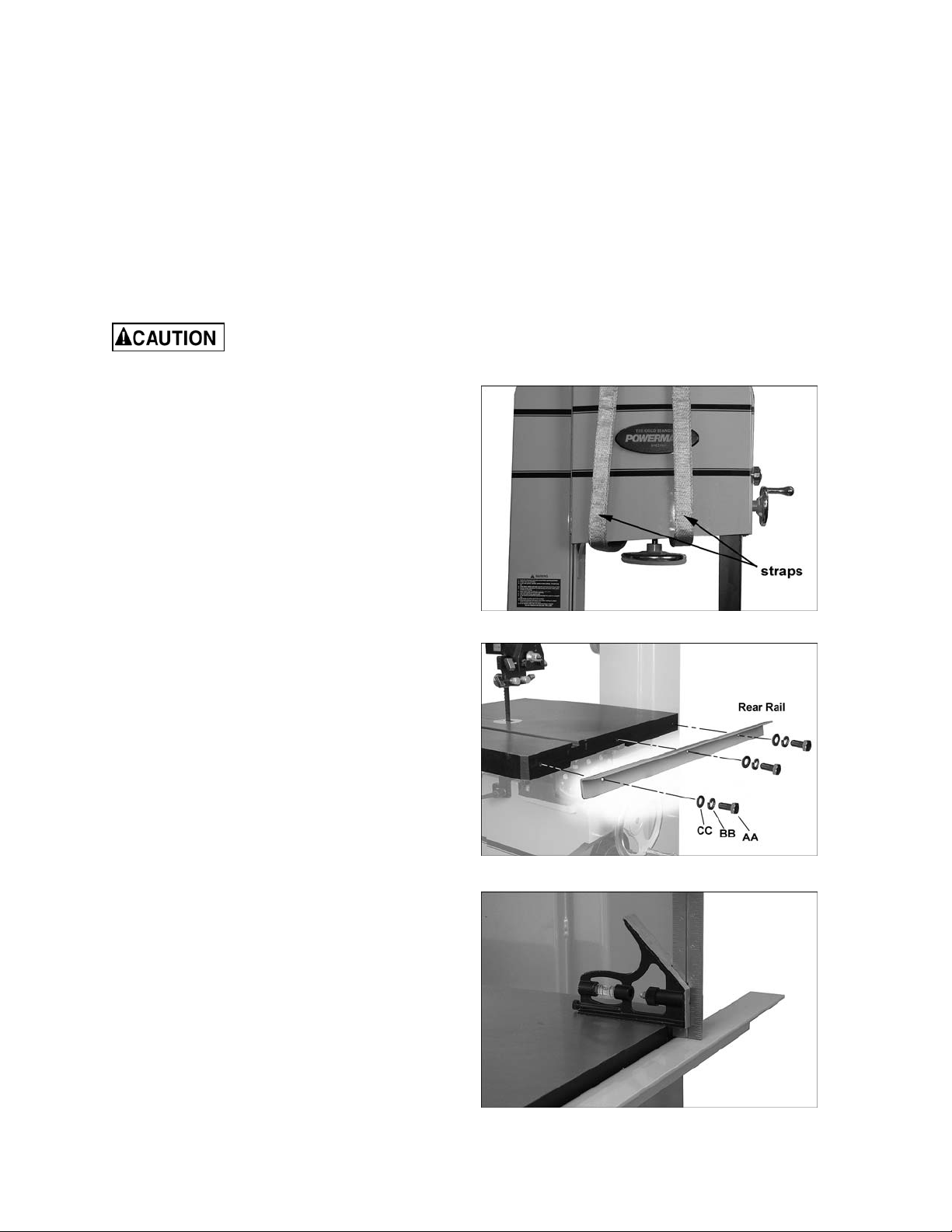

Exercise care when

removing the machine from the shipping

pallet.

Use a hoist or f orklift with straps to rem ove the

machine fr om the pallet. The straps used shoul d

have a minimum 1,000 lb. lifting capacity. Do

NOT place forks or straps directly beneath the

table or against handles or levers - place the

straps under the top portion of the frame, as

shown in Figure 3.

Move the band saw to its permanent location,

which should be dry and well lit, with enough

space on all sides to handle long stock or

perform routine maintenance on the machine.

Make sure the fl oor is able to support t he weight

of the machi ne. If desired, the band saw can be

secured to the floor using lag screws (not

provided) t hr ough the four holes in the base.

Exposed metal surfaces, such as the table

surface and blade guides, have been given a

protective coating at the factory. This coating

should be rem oved wit h a soft c loth moistened

with solvent . Do not get solvents near pl astic or

rubber parts; and do not use an abra siv e pad as

it may scratch the exposed surfaces.

Assembly

Rear Rail

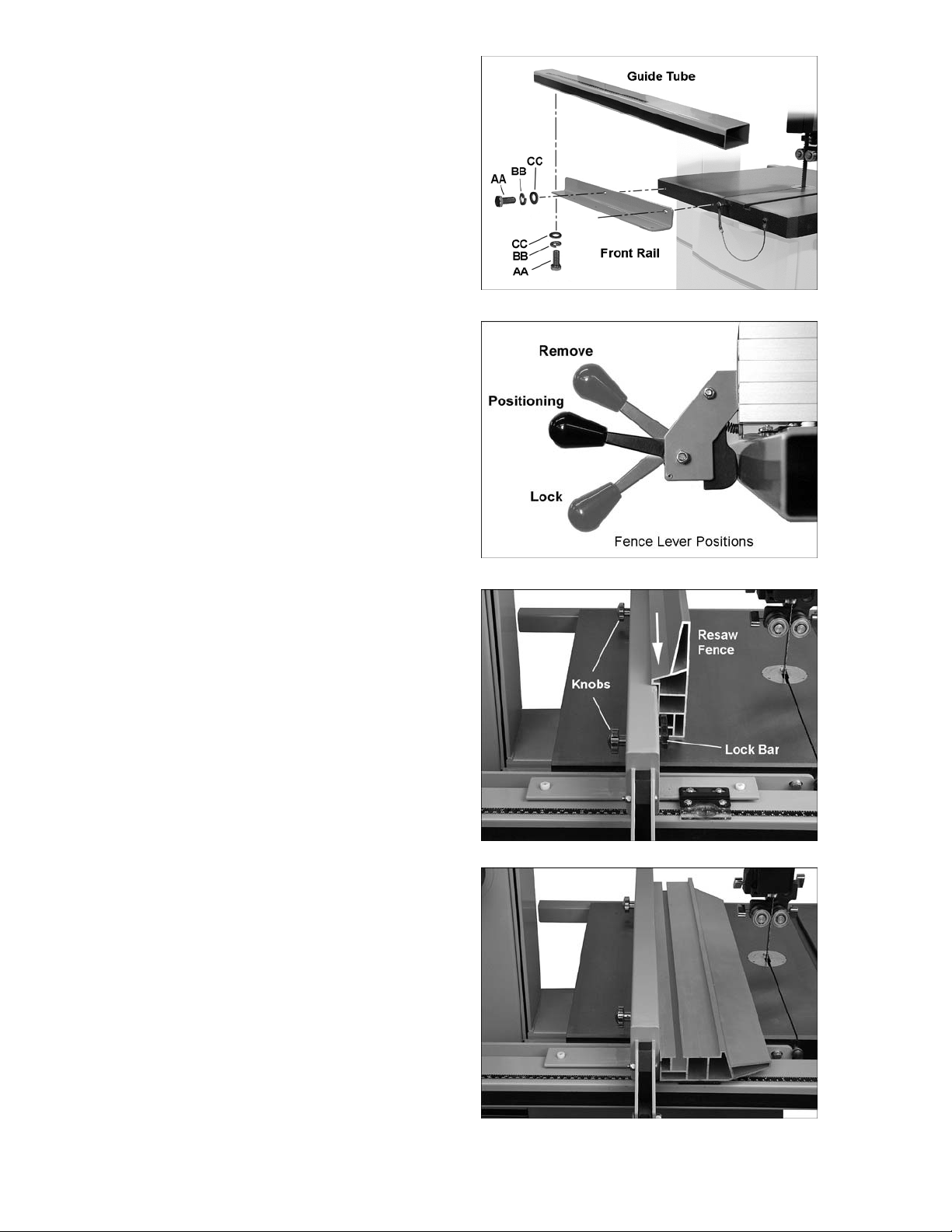

Refer to Figures 4 and 5.

1. Install the rear rail to the rear edge of the

table, using three 5/16-18 x 3/4 hex cap

screws (AA), three 5/16 lock washers (BB),

and three 5/16 f lat washers (CC) as shown.

Hand tighten only .

Figure 3

Figure 4

2. The exact distance from rear rail to table top

is not important , but the rear rail should be

made parallel to the table top. Place a

measuring device, such as a combination

square (Figure 5) at front and back of the

table as shown.

Figure 5

10

Page 11

The measurement should be the same at

both ends of the rear rail. Adjust as needed.

3. Tighten the three screws with a 12mm

wrench.

Front Rail and Guide Tube

Refer to Figure 6.

4. Install the front rail t o the front edge of the

table, using two 5/16-18 x 3/4 hex cap

screws (AA), two 5/16 lock washers (BB),

and two 5/16 f lat w ashers (CC), through t he

slotted holes in the rail. Place the screws

approximately center of the slots; this can

be adjusted later as needed. Tighten the

two screws with a 12mm wrench.

5. Install the guide tube to the bottom holes in

the front rail, using five 5/16-18 x 3/4 hex

cap screws (AA), five 5/16 lock washers

(BB), and five 5/16 flat w ashers (CC) . Hand

tighten only. Pull the guide tube away from

the table as far as it will go, then tighten all

five screws in the guide tube with a 12mm

wrench. Do not overtighten.

Figure 6

Figure 7

Fence Assembly

Refer to Figures 7 and 8.

Place the fence body onto the guide tube (as

shown in Fi gure 8). Rai se the fence l ev er all the

way up to install or remove the fence from the

guide tube. Midway lever position allows the

fence to slide along the gui de tube. Lowest lever

position locks the fence in place.

Resaw Fence

Refer to Figures 8 and 9.

Loosen the lock bar using the knobs, until the

lock bar protrudes enough to sl ide t he al uminum

resaw fence on from one end, as shown in

Figure 8. Re-ti ghten the knobs.

NOTE: The aluminum resaw fence can be

installed in one of two positions; vertically

(resaw position), as shown in Figure 8; or

horizontally as shown in Figure 9. Horizontal

position is useful for smaller workpieces. (The

zero setting of the cursor cannot be used with

the horizontal fence position.)

Figure 8 (resaw f enc e vert ic al pos ition)

Figure 9 (horizontal fence posit ion)

11

Page 12

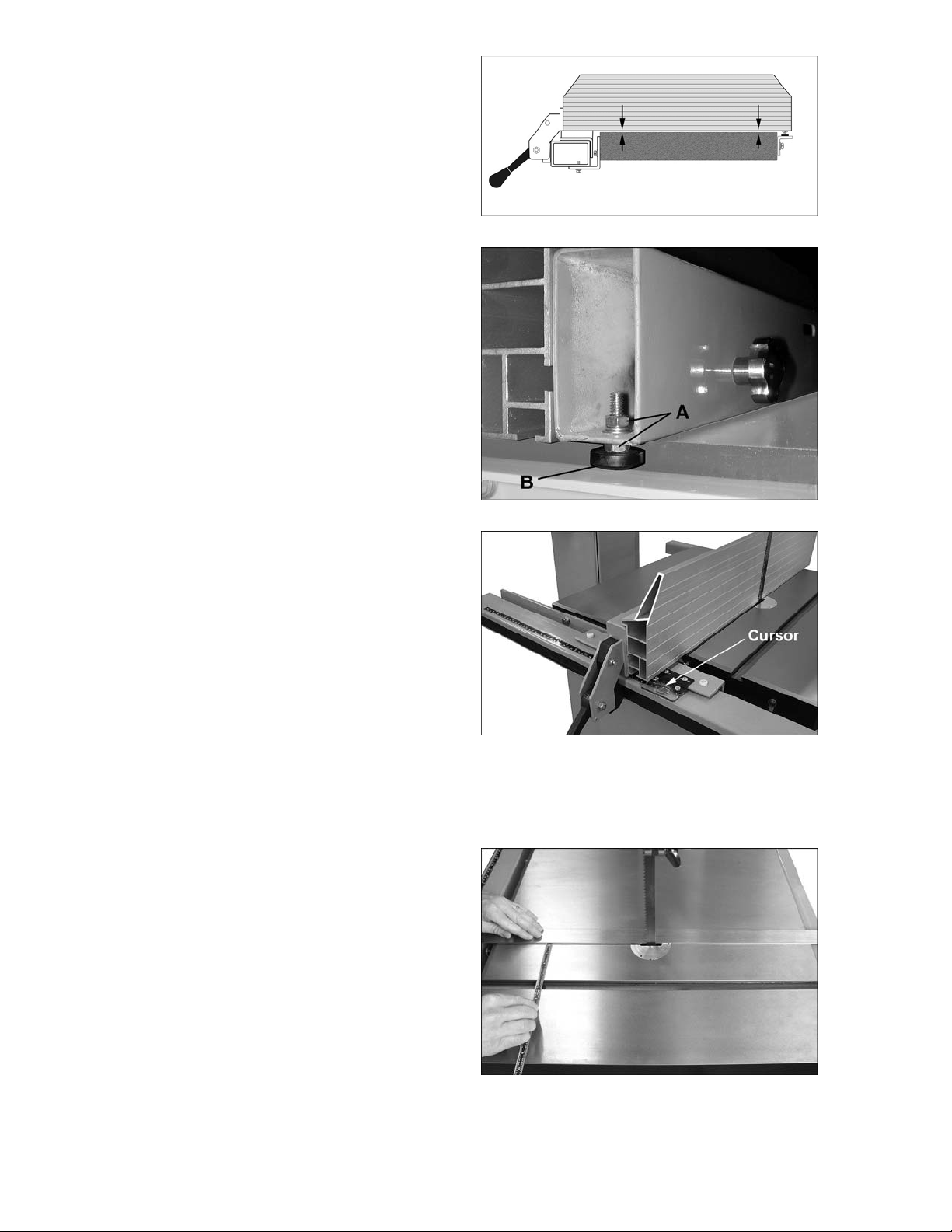

Fence to Table Clearance

1. Check the cl earance between the table and

the bottom of the fence (Figure 10). The

fence should not rub against the table

surface but be slightly above it. This gap

should be the sam e at the front of the tabl e

as it is at the back.

2. If the clearance is not the same, use a

combination of the following two

adjustments:

• With a 7/32” hex wrench, rotate the two

nylon adjustm ent screws (A, Figure 16) t he

same amount to raise or lower the fence

body from the guide tube. Clockwise rai ses

the fence body, count er c lockwise lowers.

• And/or....A djust the back end of the fence

by loosening one hex nut and tight ening the

other (A, Figure 11) in order to raise or

lower the sliding pad (B, Figure 11) as

needed. When the fence-to-table gap is

equal, make sure both hex nuts are

tightened against the fence body.

Setting Cursor (Zero) Position

Figure 10

Figure 11

Refer to Figure 12.

The fence must be set so that the cursor reads

zero at the line of the blade. The resaw fence

must be installed on the f ence body in vertical

position, and the blade must be installed and

fully tensioned.

1. Slide the fence flush against the flat of the

blade, as shown. (Do not force the fence

into the blade so that t he blade bends.)

2. If the cursor is not at zero, loosen the t wo

screws and slide it as needed. Then retighten the screws.

Setting Table Parallel to Blade

Refer to Figures 13 and 14.

The table has been al i gned by t he m anuf act urer

so that the miter slot is parallel to t he flat of the

blade; it should not require adjustment.

However, i n the future y ou may wish to conf irm

this setting is still accurate. A wide blade is

recommended for the procedure.

1. Disconnect band saw f r om power source.

Figure 12

2. The blade should be fully tensioned and

properly t r acked (see pages 17 and 18).

3. Place a long straightedge flush against the

blade making sure it cont acts both front and

back of the bl ade. (Do not deflect the blade

by pushing into it. ) See Figur e 13.

Figure 13

12

Page 13

4. Use a gauge to carefully measure the

distance from miter slot to straight edge.

Take measurem ents at both front and back

of table – these should be the same.

5. If t he miter slot is not parallel to t he blade,

loosen the four hex cap screws that secure

the table to the trunnion (Figure 14 shows

three of them), and shift the table as needed

until the miter slot is parallel to the blade.

6. Tighten the four hex cap screws.

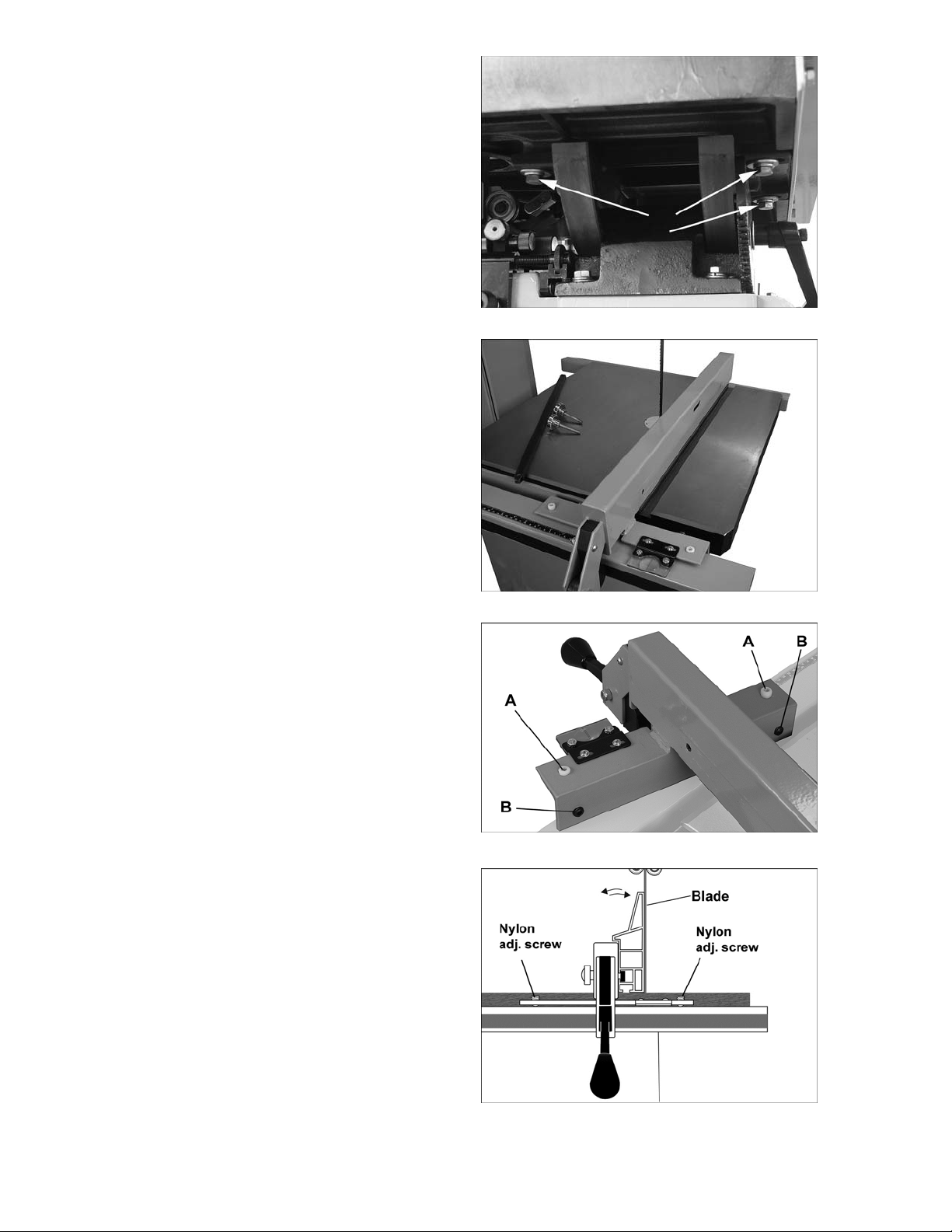

Setting Fence Parallel to Blade

Refer to Figures 15 and 16.

The fence should be parallel to the flat of the

blade for accurate cutting. Since the miter slot

has been set parallel to the blade from the

manufacturer (and confirmed by the user, as

described above), you can use the table miter

slot to set the fence par allelism.

1. Remove the alumi num resaw fence and the

mounting bar f rom the f ence body, and sli de

the fence body t o the edge of the mi ter slot,

as shown in Figure 15. The fence should

align with the miter slot along the entire

length of the f enc e.

Figure 14

2. If adjustm ent is needed, use one of the back

adjustment sc rew s (B, Fi gure 16) t o tur n the

fence in line wit h the miter slot.

The fence must also be parallel to the blade

vertically. Refer to Figure 17.

3. Make sure t he tabl e ha s been set 90° t o the

blade (see “90° Table Stop”).

4. Mount the resaw fence, and slide the fence

up against the blade; do not push into the

blade. Turn either of the nylon adjustment

screws until fence is parallel to blade along

the vertical length of fence.

Fence Locking Tightness

The tightness of the fence against the guide

tube can be adjusted by rotating the two back

screws (B, Figure 16). Rotate the two screws

equally (clockwise to tighten) with a 5mm hex

wrench.

Because these screws are also used to align the

fence to t he blade, aft er adjusting f ence locking

tightness, you should double check fence-toblade relationship, as explained under “Setting

Fence Parallel to Blade.”

Figure 15

Figure 16

Figure 17

13

Page 14

Dust Collection

The use of a du st collection system is strongly

recommended for this band saw. It will help

keep the shop clean, as well as reduce pot enti al

health hazards caused by inhalation of wood

dust. The collector should have a capacity

sufficient for this size machine – 400 CFM is

recommended. Walter Meier has a line of dust

collection system s available; see your dealer or

visit our website li sted on the back cover.

Connect the hoses of your dust collection

system to the 4” dust ports at the rear of the

band saw. Secure ti ghtly with hose clamps (not

provided). S ee Figure 18.

Figure 18

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

Single Phase Connections

The single phase B and Saw is fact ory wired for

230 volt s. It is not supplied with a plug. Y ou may

either install a UL/CSA-listed plug suitable for

230 volt operati on, or “hard-wire” the B and Saw

directly to a service panel.

It is recommended that the single phase Band

Saw be connected to a grounded and dedi c ated,

minimum 50 amp circuit with a 50 amp circuit

breaker or time delay fuse. Local codes take

precedence o ver recommendations.

Three Phase Connections

The three phase Band Sa w is fact ory wired for

230 volt s. It is not supplied with a plug. Y ou may

either install a UL/CSA-listed plug suitable for

230 volt operati on, or “hard-wire” the B and Saw

directly to a service panel.

The three phase Band Sa w m ay be c onverted t o

460V operation. The current contactor m ust be

replaced with t he 460V magnetic contac tor (part

no. PM2000-293C, purchased separately). In

addition, re-connect the motor leads according

to the diagrams inside the motor junction box.

(Similar di agrams may be found at t he back of

this manual.)

It is recommended that the three phase Band

Saw be connected to a grounded and dedi c ated,

minimum 30 amp circuit with a 30 amp circuit

breaker or time delay fuse. Local codes take

precedence o ver recommendations.

If the single phase or t hree phase Band Saw is

to be “hard- wired” t o a serv i ce panel , m ake sure

a disconnect i s availabl e for the operator . During

hard-wiring of t he machine, make sure t he f uses

have been rem oved or the breakers hav e been

tripped i n the circuit to which the Band Sa w will

be connected. Place a warning placard on the

fuse holder or circuit break er to prevent it being

turned on while t he machine is being wired.

Grounding Instructions

This machi ne must be grounded. In the ev ent of

a malfuncti on or breakdown, grounding prov ides

a path of l east resistance for elect ric current to

reduce the ri sk of el ectri c shock .

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conduct or .

If repair or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool i s properly gr ounded. Repai r or

replace a damaged or worn cord im m ediately.

Make sure the voltage of your power supply

matches the specif ications on the m otor pl ate of

the Band Saw.

14

Page 15

Extens ion Cords

The use of extension cor ds i s di scouraged; try to

position t he machine within reach of the power

source. If an extension cord becomes

necessary, m ake sure the cord rati ng is suitable

for the am perage listed on t he machine’s m otor

plate. An undersized cord will cause a drop in

line voltage resulting in loss of power and

overheating.

Recomm end ed Ga ug es (A WG ) of Extensi on Co rd s

Extension Cord Length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

feet

feet

feet

feet

feet

feet

Use the chart i n F igur e 19 as a gener al gui de i n

choosing the c orrect size cord. If in doubt, use

the next heavi er gauge. The smaller the gauge

number, the heavier the cord.

Adjustments

Table Tilt

Refer to Figures 20 and 21.

1. Loosen the lock l ev er (A).

2. For right tilt (as viewed from front or

operator’s side of the saw), rotate the

handwheel (B) count erclockwise to ti lt table

up to 45°.

3. For left tilt (as viewed from front or

operator’s side of the saw), loosen the l ock

lever (A) and rotate the handwheel

clockwise a turn or two to release pre ssure

on the 90° stop bolt (C). Rot ate the circular

plate (D) out of the way. Then rotate the

handwheel cloc k wise to tilt the table to 15°.

The now-exposed hole in the band saw

body allows the stop bolt to descend

through it, to keep intact the setting of the

90° stop.

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting th e lin e voltag e drop t o 5V at 150% of the

rated amp eres.

NR: Not Recommended.

Figure 19

Figure 20

4. Tighten the lock lever (A, Figure 20) to

secure the setting.

NOTE: The circular plate (D) can be tight ened or

loosened as desired by using a 5/ 32” (4mm ) hex

wrench on the screw.

Also, the lever (A, Figure 20) can be pivoted to a

more conveni ent positi on. Simply lift str aight out

on the lever and rotate it on the pin, then release

the lever making sure i t seats itself on the pin.

90° Table Stop

Refer to Figures 20 t hr ough 22.

The 90° positiv e stop ensures that the tabl e will

always be perpendicular to the blade after the

table is returned to horizontal position. Check

and adjust this 90° stop as follows:

1. Disconnect machine from power source.

2. Make sure blade is under f ull tension.

Figure 21

15

Page 16

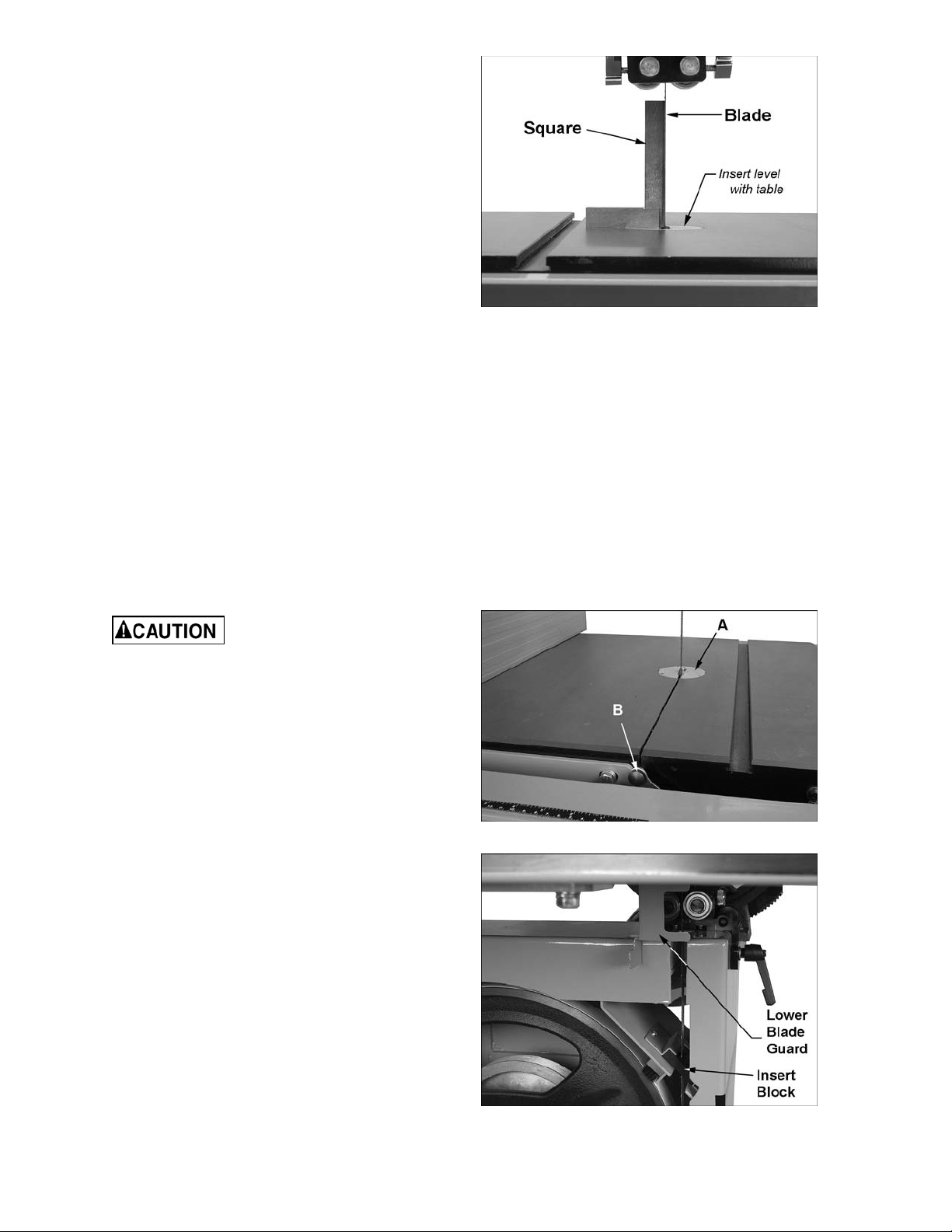

3. Loosen lever (A, Figure 20) and tilt table

with the handwheel (B), until the stop bolt

(C) rests on the circular plate (D).

4. Make sure the table insert is level with

surface of table by rotating one or more of

its set screws with a 5/164” (2mm) hex

wrench. Then place a square on the table

and against the bl ade to check that the table

is 90° to the blade. See Figure 22. NOTE:

Do not push square into blade.

5. If table and blade are not square, use a

9/16” (14mm) wrench t o loosen the lock nut

(E) then rotate the stop bolt. Turn the stop

bolt as needed until there i s no longer li ght

showing between the square and the blade.

6. Tight en lock nut (E) to secure the table st op

in position.

7. Tighten the lever (B).

8. Check that the scale pointer (F, Figure 20)

is at zero. If nec essary, loosen the scre w on

the pointer and shift the pointer to zero.

Then re-tight en the screw.

Figure 22

Installing/Changing Blades

Always wear gloves when

handling blades. New blades are usually

packaged in a coiled position; to prevent

injury uncoil them slowly and carefully, while

wearing work gloves and safety glasses.

The PM1800 Band Sa w is designed f or blades

from 1/16” to 1-1/2” wide. The Band Saw is

provided with a blade of the following

specific ations: 0.03” thick, 3/4” wide, 4 TPI.

Refer to Figures 23 and 24.

1. Disconnect machine from power source.

2. Remove the table insert (A, Figure 23) .

3. Pull out table pin (B) at the end of the slot.

4. Adjust upper and lower blade guides away

from the blade.

5. Move the quick tension lever to “Full

Release (Blade Change)” posi tion.

6. Open upper and lower door s by rotati ng the

door catches. Open the lower blade guard

and slide out the i nsert bloc k (Figur e 24).

Figure 23

7. Carefully remove the blade from the top

wheel, then f rom between upper and lower

blade guides and lower wheel. S lide the old

blade out through the sl ot in the table.

Figure 24

16

Page 17

8. Guide new blade through table slot. Place

blade loosely in the upper and lower blade

guides. Make sure blade teeth point down

toward table, and toward the front of the

saw. (If the teeth will not point down, no

matter how you orient the blade, then the

blade is twisted inside-out. Twist it into

correct position and re-install it .)

9. Position blade at the center of the upper and

lo wer wheels.

10. Re-install table insert (A) and table pin (B).

11. Before operating the band saw, the new

blade must be tensioned and tracked, in that

order. Find instructions for tensioning and

tracking the blade under “Blade Tension”

and “Blade Tracking.” The blade guides

must also be set properly according to the

instructions on pages 19 and 20.

Blade Tension

Refer to Figure 25.

1. Disconnect machine from power source.

2. Back off upper and lower guide beari ngs to

eliminat e any contact with the blade.

3. With the blade centered on the wheels,

move the quick tension lever to “Full

Tension” position, as shown in Figure 25.

NOTE: You will be abl e to feel the lev er fall

into each position.

4. Rotate the tension handwheel (C) until the

scale pointer (D) reaches the appropriate

measurement f or the width of the blade.

TIP: Use the band saw’s gauge setting initi ally.

As you become familiar with the machine and

with the dif fer ent proper ti es of band saw bl ades,

you may find it necessary to change the blade

tension fr om the initi al setti ng. Keep in mi nd that

not only changes in blade width, but also the

type of materi al being cut will have an effect on

blade tension. Too little or too much blade

tension can cause blade breakage and/or poor

cutting perf ormance.

Make a note of the speci fic tension setti ng f or a

particular blade. The tension can t hen be re-set

quickly when band saw operations are resumed.

IMPORTANT: When the band saw is not bei ng

used, move the quick tension lever to “Partial

Tension-Idle/Tracking” position. This will prolong

the life of the blade and tires, and r educe load

on wheels, bearings and other c om ponents.

Figure 25

17

Page 18

Blade Tracking

Refer to Figure 26.

After being properly tensioned, the blade must

be tracked. “Tracking” refers to the position of

the blade on t he wheel s while t he machi ne is in

operation. Tracking should be checked

periodical ly, and is mandatory after every blade

change. Blade t rack ing is done by ha nd with t he

machine disconnected from power.

1. Disconnect machine from power source.

2. The blade should be cor r ectly tensioned.

3. Make sure the blade gui des and other parts

of the machine will not interfere with the

movement of the blade. Lower the guide

post until you can see t he bl ade throu gh t he

tracki ng window.

4. Set the qui ck tension l ever intially t o “Partial

Tension-Idl e/Tracking” posi tion, as shown i n

Figure 26.

5. Open upper door to expose the upper

wheel. Rotate the wheel by hand, and

observe the position of the blade on the

wheel through t he tracking window. As you

rotate the wheel, move the lever to “Full

Tension” position. The blade should

continue to ride upon the center of the

wheel (Figure 27) .

IMPORTANT: Make tracking adjustments with

knob (F, Figure 26) while the blade is at full

tension. DO NOT use screws (G, Figure 26);

these were used by the manuf acturer for wheel

alignment and should NOT be used for tracking.

6. If the blade tends to move toward the edge

of the wheel, loosen loc king lever (E, Fi gure

26) and slightly rotate tracking knob (F) with

your right hand while continui ng to rotate the

wheel with your left. Observe the blade

through the tracking window. Rotating the

tracki ng knob cl ockwise will cause the blade

to move t oward the rear edge of the wheel.

Rotating t he tracking knob count erclock wise

will cause the blade to move toward the

front edge of the wheel.

Figure 26

Figure 27

IMPORTANT: This adjustment is sensitive;

perform it in small increment s and give t he

blade time to react t o the changes.

7. When the bl ade is tracking in the cent er of

the wheel, re-tighten locking lever (E), and

close upper door.

8. Move tension lever to “Full Tension”

position, and connect the band saw to

power. Turn i t on f or a brief time to observ e

the blade in action through the tracking

win dow.

18

Page 19

9. Make further adjustments as needed, with

the saw disconnected from power.

Upper Blade Guides

The bearing guides should be set so that

contact between blade and guides will occur

only when the blade is under pressure from a

workpiece. To adjust the upper bearing guides

for proper bl ade c ontrol, proceed as follows.

Refer to Figures 28 t hr ough 31.

1. Disconnect machine from power source.

2. Blade must already be tensioned and

tracking c orrectly. Place quick tension lever

in “Full Tension” posi tion.

3. Lower the guide post until the upper guide

bearings are a f ew inches off t he table. (T he

reason for this will be shown later under

“Guide Post Parallelism.”)

4. Loosen the locki ng screw (A, Figure 28).

5. Move the entire guide bracket by rotating

the knurled knob (B) until the front of the

guide bearings are about 0.015” (1/64”)

behind the blade’s gul let (curv ed area at the

base of the tooth). See Figure 30.

6. Tighten t he locking screw (A) to secure this

position.

7. Loosen the lock ing screw (C) for one of the

guide bearings.

8. The guide bearing rotates on an eccentric

shaft. Adjust the guide bearing by rotating

the knurled k nob (D) until the guide bear ing

is approximately 0.004” from the blade. A

quick way to achieve this spacing is by

placing a single thickness of a crisp dollar

bill (a dollar bill is approximately 0.004”

thick) between blade and guide bearing.

See Figure 31. Adjust the guide bearing

until it just lightly grips the dollar bill.

NOTE: Do not force the guide bearing

against the side of the blade. It should only

make contact with the blade when there is

pressure from the cutti ng oper ation.

Figure 28

Figure 29

Figure 30

9. Ti ght en locking screw (C) and remove dollar

bill.

10. Repeat process for opposite guide bearing.

Upper Thrust Bearing

Refer to Figures 29 and 32:

The thrust beari ng prev ent s backward def l ecti on

of the blade during cutting. The thrust bearing

has three options for stabilizing the back of the

blade (see Figur e 32) .

Figure 31

19

Page 20

v

-

shaped groove is f or blades 1/8” wide or

The

smaller. The flat bottomed groove supports

blades over 1/ 8” to 3/16” wide. The non-grooved

standard bearing surf ace at the left is for blades

over 3/16” wide. (The bl ade provided with your

band saw is 3/4” wide, t hus must ride along t he

flat non-grooved surface of the bearing, as

shown in Figure 32.)

1. Loosen the socket head cap screw (E,

Figure 29) and push the thrust bearing

bracket later ally to desired position.

2. Re-tighten the socket head cap screw (E).

3. Loosen the l ocking screw (F) and push the

thrust bearing up to the back of the blade.

4. Adjust the thrust bearing until the space

between the thrust bearing surface (or

groove bottom) and the back edge of the

blade is approximately 0.015” (1/64”). On

the non-groov ed surface, a conv enient way

to achieve t his spacing i s by placi ng a dol l ar

bill folded t wice (four thick nesses of a doll ar

bill is approximately 1/64”) between blade

and thrust bearing. If using a groove, set

this distance by ey e.

5. Tighten loc ki ng screw (F) .

6. Make sure all locking screws on the upper

guide bearing assembl y are tightened when

adjustments are finished.

Lower Blade Guides

Refer to Figure 33.

1. Disconnect band saw f r om power source.

2. Open lower door and lower bl ade guar d.

3. Adjust the lower guide bearings and lower

thrust bearing below the table, using the

same procedure and measurements as for

the upper guide bearings and upper thrust

bearing described above.

Figure 32

Movement summary: Loosen locking lever

(G) to move guide bracket using dial (H).

Loosen knob (J) to rotate side bearings,

using (K) and (L). Loosen locking screw (M)

to slide thrust bearing toward blade.

4. Make sure all screws, knobs and lever are

tightened when adjustments are complet e.

NOTE: The locki ng lever (G, Figure 33) c an be

re-positioned if needed. Simply pull out on the

lever, r otate it on the hub, and release it. Mak e

sure it re-seats itself on the hub.

Figure 33

20

Page 21

Guide Post

Refer to Figure 34.

1. Disconnect band saw f r om power source.

2. Loosen lock handle (A) and raise or lower

guide post by rotating the handwheel (B).

3. Position the blade guide assembly so that

the bottom of the guide beari ngs are about

3/16” above the material to be cut. Or,

simply lower the guide post until the scale

pointer (C) indicates the height of your

workpiece. Thi s provides minimal clearance

between the workpiece and the bottom of

the guide bearings, which will minimize

blade deflection as well as enhance

operator safety.

4. Tighten loc k handl e ( A).

Guide Post Parallelism

The guide post should be parall el to the blade

throughout the v ertical travel of the guide post;

thus the guide bearings will maintain their

relationship t o the blade at any height from the

table and they won’t hav e to be re- set each tim e

the guide post i s moved. Thi s setting has been

accurately made by the manufacturer and

should not require immediate attention, but it

may be checked in the fut ur e as follows:

1. Disconnect band saw f r om power source.

2. Move blade tension lever to “Full Tension”

position.

3. The guide bearings in low position should

already be set in relation to t he blade (see

“Upper Blade Guides”). Also, the table

should be square with the blade (See “90°

Table Stop”).

4. Loosen the lock handle (A, Figure 34) and

raise the guide post to a high position.

5. Confirm that the guide post travels straight

up and down, and the guide bearings

maintain t heir r elationship to the blade.

6. If the guide post does not go strai ght up and

down (the blade begi ns deflecti ng when the

guide post is rai sed), sli ghtl y loosen the four

hex cap screws (D, Figure 34).

Figure 34

7. Left and right adjustment is accomplished

using a combination of the four hex cap

screws (D); forward/back adjustment is

accomplished using the two set screws (E).

8. When finished adjusting, securely tighten

the four hex cap screws (D).

9. Re-check the setting by raising and lowering

the guide post.

21

Page 22

Resaw Pin

Refer to Figure 35.

A resaw pin is provided with the band saw. It

provides a single contact point while ripping a

workpiece int o thinner boards.

Remove the al uminum resaw fence and mount

the resaw pin to the slot in the fence body,

securing it with the knob, as shown. The resaw

pin is usually positioned so that its center is

approximately even with the front edge of the

blade.

See under “Operat ion” for further inf ormation on

using the resaw pin.

Miter Gauge

Refer to Figures 36 and 37.

A miter gauge is provided for crosscutting

operations. I nstall the miter gauge by sliding t he

end of the miter gauge bar into the table’s T-slot.

The miter gauge should fit snugly within the

miter slot whil e still sliding easi ly. The bar of the

miter gauge has two sl ots, each with a set screw

(Figure 36). Rotate one or both of these set

screws with a 5/32” (4mm) hex wrench as

needed to elimi nate any play bet ween the miter

gauge bar and miter slot .

If the tabl e/miter slot is square to t he blade (see

“Setting Table Parallel to Blade”), the miter

gauge will also be square to the blade. Before

operating, howev er, the 90° setti ng of the miter

gauge should be checked in relation to the

blade, as follows.

Figure 35

Figure 36

1. Place a square against the miter gauge

face, and against the flat of the blade, as

shown. (Place t he square against the fl at of

the blade, not the teeth which are set wider

than the blade body). A wide blade is

preferred for this procedure.

2. Flip the 90° stop plate (C) out of the way,

and loosen the handle (A). Shift the miter

gauge body unti l it is flush with t he square,

then re-tight en the handle (A).

3. Flip the stop plate (C) back down, and

loosen the 90° stop hex nut and adjust the

screw until it c ontacts the 90° stop plate.

4. Re-tighten hex nut.

5. Loosen the set screw at the base of the

pointer, and shi ft the poi nter so that it l ines

up with the 90° mark on the scale.

6. Re-tighten set screw.

Figure 37

22

Page 23

The 45° stops can be check ed in similar fashion,

using an angle gauge similar to that shown in

Figure 37.

To adjust the miter gauge angle for operations:

1. Loosen the handle (A ) .

2. Rotate t he gauge body until the pointer (B)

lines up wit h the desi red an gle on t he scale.

You may have to pivot the 90° stop plate (C)

out of the way to allow the body t o rotate.

3. Tighten the handle (A).

4. There are three stops – at 90° , and 45° lef t

and right. E ach of these can be a djusted by

loosening the hex nut (D) and turning the

screw (E) as needed. Re-ti ghten the hex nut

(D) when adjustment is finished.

Blade Speed Adjustment

Refer to Figures 38 t hr ough 40.

The band saw will operate at 1800 and 4200

SFPM (surface feet per minute). Figure 39

shows the appropriate belt position to achieve

each speed.

To change the speed:

1. Disconnect machine from power source.

2. Loosen the motor lock handle and r aise the

motor lift handle to release tension on the

belt.

3. Tighten the motor lock handle to k eep motor

in raised positi on.

4. Slide the belt onto the appropriate set of

pulle y s.

5. Loosen motor lock handle and allow motor

to lower. The weight of the motor itself

should produce the proper tension for the

belt. Check the tension by pushing with

moderate pr essure against the cent er of the

belt (Figure 40). An adequately tensioned

belt will deflect about 1/2”. If tension isn’t

strong enough, push down on the motor.

Figure 38

Figure 39

6. Tighten the motor lock handle.

Drive Belt Tension and Replacement

The drive bel t and pul leys are properl y adjusted

at the f actory. Howev er, belt tension should be

occasionally checked when the band saw is

new, as a new belt may stretch slightly during

the breaking-i n pr oc ess.

If the belt becomes worn, cracked, frayed or

glazed, it should be replaced as follows:

Refer to Figures 38 and 40.

1. Disconnect machine from power source.

Figure 40

23

Page 24

2. Open the upper and lower doors and

remove the blade.

3. Unscrew the hex nut from the lower wheel

shaft and remove the lower wheel.

4. Loosen the mot or lock handle.

5. Raise the motor lift handle and re-tighten

motor lock handle to hold motor in raised

position.

6. Remove old belt and install new one,

making sure it seats properly in the pulley

grooves.

7. Loosen motor lock handle and allow motor

to lower.

8. The weight of the motor itself should

generally pr oduce the proper t ension for t he

belt. Check the tension by pushing with

moderate pr essure against the cent er of the

belt (Figure 40). An adequately tensioned

belt will deflect about 1/2”. If tension isn’t

strong enough, push down on the motor.

9. Tighten motor lock handle, reinstall lower

wheel, and instal l hex nut securely on shaft.

10. Re- check blade tensi on and tracki ng before

operating the saw.

Wheel Brush

Refer to Figure 41.

The brush located nex t to the lower wheel must

contact the tire to clear the tire of dust and

debris befor e it touches the blade. Use the two

phillips head screws to make any adjustments to

the brush position.

Insert Block

Refer to Figure 41.

The insert block should remain in position to

prevent dust and chips from falling onto the

lower wheel. If it should ever become dam aged,

it should be replaced. Some band saw users

make their own out of scrap wood.

Operating Controls

Start/Stop

Power Indicator Light – The start switch has a

power indicator lamp which is on whenever

there is power connected to the Band Saw,

not just when the B and Saw is running. Do not

assume that no light means there is no power to

the machine. I f the bul b is bad, there will be no

indication. Always check before use.

Figure 41

24

Page 25

Do not rely that no light

means no power to the machine. Always

check for pow er first. Failure to comply may

cause serious inj ury!

Refer to Figure 42:

Start – Press the green start switch.

When power is connected to the machine, the

green light is always on regardless of whether

the Band Saw is running or not.

Stop – Press the red switch to stop.

Reset – In the event that the Band Saw stops

without pressing t he stop butt on, as the re sul t of

a tripped fuse or ci rcuit br eak er , etc.:

1. Press red button to re-set m ain switch.

2. Press the green button to restart the

machine.

Safety Key

The start/stop switch on the Band Saw comes

equipped with a magnetic safety key. When in

place on the switch as shown in Fi gure 42, the

magnetic safet y key trips a relay which will all ow

the machine to start and stop when the

respective switches are pressed. Being

magnetic, the lock can be r emoved t o make t he

machine inoperabl e and can be hidden for safe

storage by attaching it to another magnetic

surface.

When using the Band Saw, pl ace the key on t he

switch cov er lini ng up the arro w on the k ey with

the REMOVE arrow on the cover. Then rotate

the key so that t he ar r ow lines up wit h the LOCK

arrow on the cover. This will prevent the safety

key from coming l oose from vibrati on when the

machine is in use.

Figure 42

Brake Pedal

When the stop button is used to shut off the

Band Saw, the blade will coast sl owly to a stop

(approximat ely 12 to 15 seconds). An alternate

method of stoppi ng the machine is to press the

brake pedal, sho wn in Figure 43. The bl ade will

stop moving approximately four seconds after

the brake pedal i s pressed. Re-start the sa w by

pressing the start button on the column.

NOTE: Unnecessary and excessive use of the

brake pedal may shorten the life of the brake

band and brake belt.

After th e machi ne i s shu t o ff,

allow the wheels and blade to come to a

complete stop before opening the doors,

making adjustments, or leaving the area.

Figure 43

25

Page 26

Operation

The following sect ion contains basic information,

and is not intended to cover all possible

applicati ons or techniques using t he Band Saw.

Consult published sources of information,

acquire formal training, and/or talk to

experienced Band S aw users to gai n prof ici ency

and knowledge of band saw operations.

General Procedure

Ripping

Ripping is cutting lengthwise down the

workpiece, and with the grain (of wood stock).

See Figure 44. Always use a push stick or

similar device w hen r ipping nar r ow pieces.

Crosscutting

Crosscutting is cutting across the grain of the

workpiece, while using the miter gauge to feed

the workpiece i nto the blade.

1. Make sure the blade is adjusted correctl y for

tension and tracking, and that upper and

lower guide bearings and thrust bearings

are set in proper relation to the blade.

2. Adj ust gui de post so that t he guide be ari ngs

are just abov e the workpiece (about 3/16”)

allowing minim um ex posure t o the blade.

3. If using the fence, move it into positi on and

lock it to the gui de rail. If you are using the

miter gauge f or a cr osscut, the f enc e should

be moved safely out of the way.

4. Turn on the band saw and allow a few

seconds for t he machine to reach full speed.

Whenever possible, use a

push stick, hold-down, power feeder, jig, or

similar device wh il e f eeding stock, to preven t

your hands getting too close to the blade.

5. Pl ace the straightest edge of the workpiece

against the fenc e for a rip cut; or agai nst the

miter gauge for a crosscut. Push the

workpiece slowly into the blade, while also

keeping it pressed agai nst the f ence or held

against the miter gauge. Do not force the

workpiece int o the blade.

The right hand shoul d hold the workpiece steady

against the miter gauge, while the left hand

pushes the miter gauge past the blade, as

shown in Figure 45.

Do not use the fence in conjunction with the

miter gauge. The offcut of the workpiece must

not be constrained during or after the cutting

process.

Using the fence in

conjunction with the miter gauge can cause

binding and possible damage to the blade.

Some further operat ing tips:

Make relief cuts whenever possible. A relief cut

is an extra cut made through t he waste portion

of a workpiec e up to the layout l ine. When that

intersection is reached by the blade while

following the layout line, the waste portion

comes free. This helps prevent pinching of the

back edge of the blade in t he cut.

When cutting, do not

overfeed the blade; overfeeding will reduce

blade life, and may cause the bl ade to break.

When cutting long stock, the operator should

use roller stands, support tabl es, or an a ssistant

to help stabilize the workpiece.

Figure 44

Figure 45

26

Page 27

Resawing

Resawing is the process of slicing stock to

reduce its thickness, or to produce boards that

are thinner t han the original workpiece, such as

veneers.

The ideal blade for resawing is the widest one

the machine can handl e, as the wider the blade

the better it can hold a str aight line.

Resawing can be performed using the aluminum

resaw fence or the resaw pin. When using the

resaw fence, use a push block, push stick, or

similar device to keep your hands away from the

blade. The resaw pin offers a pivot point by

which you can caref ul ly f ollow your l ayout line; it

is especiall y useful for sawing curv es, when the

fence can’t be used and it’s difficult to control

the cut freehand.

Figure 46 demonstrates resawing with the

aluminum resaw fence; Figure 47, with the

resaw pin.

Blade Lead

Blade lead, or drift, is when the blade begins to

wander off t he cutting line even when the band

saw fence is being used. Figure 48 shows an

example of blade lead. It is m ore common with

small, narrow blades, and is almost always

attributable to poor blade quality, or lack of

proper adjustments. Inspect the band saw for

the following:

Figure 46

Figure 47

• Fence is not parallel to miter slot and blade.

• Blade is not tensioned c or r ec tly.

• Blade is dull.

• Teeth have too much “set” on one side of

the blade.

• Workpiec e is bei ng fed t oo quic kl y.

If the blade is suspect, but replacing it is not

currently an option, the blade lead can be

temporarily compensated for by skewing the

fence:

1. Cut a scrap pi ece of wood about the sam e

length as the band saw table, and joint one

edge along its length, or rip it on a t able saw

to give it a straight edge.

2. Draw a line on the board parallel with the

jointed, or str aight edge of the board.

3. Move the band saw fence out of the way,

and carefully make a freehand cut along

your drawn line on the board. Stop about

midway on the board, a nd shut of f t he band

saw (allow the bl ade t o come t o a compl ete

stop) but do not all ow the board to move.

4. Clamp the board to the table.

Figure 48

5. Slide the band saw fence over against the

board until it contacts the straight edge of

the board at some point. Lock the fence

down.

6. Use the back adj ustment scr ews (B, Figure

16) to line up the fenc e against the board.

7. Re-tighten the four hex cap screws.

NOTE: Skewing the f ence to correct blade lead

is effectiv e for that particular blade; when a new

blade is installed, the fence will need readjustment and re-squaring to miter slot. See

appropriate section in this manual.

27

Page 28

Maintenance

Before doing maintenance

on the machine, disconnect it from the

electrical supply by pulling out the plug or

switching off the main switch! Failure to

comply may cause seriou s injury.

Clean the band saw regularly to remove any

resinous deposits and sawdust.

Keep the miter slot, and the guide bearings,

clean and free of resi n.

Keep the blade clean and sharp. Check it

periodical ly for cracks or other signs of wear.

The drive bel t should be chec ked peri odicall y. If

it looks worn, frayed, glazed or otherwise

damaged, replac e it.

Remove any deposit s from the band wheels to

avoid vibrati on and potential blade break age.

Vacuum or blow out dust from inside the

cabinet. (Use proper dust mask equipment).

The table surf ac e m ust be k ept clean and fr ee of

rust for best r esul ts. If r ust appear s, y ou c an use

a mixture of household ammonia, good

commercial detergent and #000 steel wool.

Alternatively, commercial rust removers can be

found at many hardware stores.

Figure 49

Figure 50

Apply a light coat of paste wax to the table.

There are also products in aerosol form

available in major hardware stores and supply

catalogs. Whatever method is chosen, the

coating should protect the metal and provide a

smooth surf ac e, wit hout staining workpieces.

If the power cord is worn, cut, or damaged in

any way, have it repl ac ed immediately.

Lubrication Points:

Periodic ally apply a li ght, non-hardening gr ease

to the rack and pinion system of t he guide post

(Figure 49).

Grease the sliding surfaces of the table

trunnions (Figure 50). Also grease the contact

area of the tr unnion scale and handwheel gear

(Figure 50) and the other gears connected to the

handwheel (Figure 51).

Grease the blade t ensi on screw (Figure 52).

Oil any pi ns, shaf ts, and j oi nts. Do not get oi l on

the pulleys or bel ts.

Note: Beari ngs on the band saw are seal ed for

life and do not requi r e lubri c ation.

Figure 51

Figure 52

28

Page 29

Blade Selection

Using the proper bl ade for the job will incr ease

the operating ef ficiency of your band saw, help

reduce necessary saw maintenance, and

improve your pr oduc tivity. Thus, it is import ant to

follow certain guidelines when selecting a saw

blade.

Here are factors to consider when selecting a

blade:

• The type of materi al y ou will be c utti ng.

• The thickness of the workpi ec e.

• The features of the workpiece, such as

bends or curves wit h small radii.

These factors are important because they

involve basic concepts of saw blade design.

There are five (5) blade features that are

normally changed to meet certain kinds of

sawing requirements. They are:

1. width

2. pitch (number of teeth per inch)

3. tooth form (or shape)

4. the “set” of the teeth

5. the blade material itself

Width

Band saw blades come in different standard

widths, measured from the back edge of the

blade to the tip of the tooth. Generally, wider

blades are used for ripping or making straight

cuts, such as resawing. Narrower blades are

often used when the part being cut has curves

with small r adii. When cut ting straight lines with

a narrow blade, t he blade may hav e a tendency

to drift (see “Bl ade Lead” ) .

Pitch

Pitch is m easured in “ teet h per i nch” ( T. P.I.) and

can be constant or variable. Figure 53 shows

blades with different pitches.

Figure 53 – Blade Pitc h

Shape

Figure 54 shows comm on types of t ooth shape,

or form. Tooth shape has an effect on cutting

rate.

The Regular, or standard blade, has evenly

spaced teeth that are the same size as the

gullets, and a zero-degree rake (i.e. cutting

angle). T hese offer precise, cl ean cuts at slower

rates. It is usually a good choice for cutting

curves and making cr osscuts.

The Skip type has fewer teeth and lar ger gullet s

with a zero rake. It allows faster cutting rates

than the Regular type, with a slightly coarser

finish. It i s useful for re-sawing and rippi ng thick

stock, as well as cutti ng softwoods.

The Hook ty pe blade has l ar ger teeth and gullet s

and a positive rake angle for more aggressive,

faster cutting when re-sawing or ripping thick

stock, especially hardwoods.

Variable-tooth blades combine features of the

other shapes, with tooth style and spacing

varying on the same blade. This produces

smooth cuts whil e dam pening v ibration.

A fine pi tch (more teet h per inch) will cut slowly

but more sm oothly. A coar se pitch (f ewer teeth

per inch) will cut f aster but more roughly.

As a rule of thumb, the thicker the workpiece,

the coarser will be the bl ade pitch. If you have to

cut a hard or very brittle material, you will

probably want to use a blade wit h a finer pitch i n

order to get clean c uts.

Using a blade with too few teeth may cause

vibration and a r ough cut, while too m any teeth

may cause the gullets to fill with sawdust and

overheat the blade.

As a general rule, use a blade that will have

from 6 to 12 t eeth in the workpiec e at any giv en

time.

Figure 54 – Blade Toot h Shape

29

Page 30

Material

Band saw blades can be made from different

types of metals. The most common include

spring steel, carbon steel, bimetal (alloy steel

equipped with a high speed cobalt steel edge

welded to it), or carbide tips.

Because of the im portance of blade sel ection, it

is recommended that you use the blade

selection guide on page 31. Also, listening to

experienced band saw users will produce

valuable information as to the types of blades

currentl y on the market along wit h their pros and

cons.

Figure 55 – Blade Set

Set

The term “set” ref er s to the way in which the saw

teeth are bent or positioned. Bending the teeth

creates a kerf that is wider than t he back of t he

blade. This hel ps the operator m ore easily pivot

a workpiece through cur ve cuts, and decrease s

friction bet ween blade and workpi ece on strai ght

cuts.

Set patterns are usually selected depending

upon the type of material that needs to be cut .

Three comm on set patt erns ar e sho wn in F i gure

55.

Generally, the Raker set is used for cutting

metal workpieces; the Wavy set, when the

thickness of the workpiece changes, such as

cutting hol low tubi ng or struc tural s. The Straight,

or Alternate, set is the one most used for