Page 1

Operating Instructions and Parts Manual

This .pdf document is bookmarked

15-inch Woodworking Band Saw

Model PM1500

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1791500

Ph.: 800-274-6848 Revision B 08/2014

www.powermati c.c om Copyright © 2014 Powerm atic

Page 2

1.0 Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance. Powermatic woodworking machinery is designed to be used with

Woo d. Us e of th ese ma chines in the pr oces sing o f metal, plast ics, or other materia ls may void the warranty. The

exceptions are acrylics and other natural items that are made specifically for wood turning.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide proof

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informat io n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tat e Law A pplies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL O R

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

2.0 Table of contents

Section Page

1.0 Warranty and Service ..................................................................................................................................... 2

2.0 Table of contents ............................................................................................................................................ 3

3.0 Safety warnings .............................................................................................................................................. 5

4.0 About this manual .......................................................................................................................................... 6

5.0 Features and Terminology ............................................................................................................................. 7

6.0 Specifications ................................................................................................................................................. 8

6.1 Base Hole Centers (PM1500 Band Saw) ................................................................................................... 9

7.0 Setup and assembly ..................................................................................................................................... 10

7.1 Unpacking ................................................................................................................................................ 10

7.2 Shipping contents ..................................................................................................................................... 10

7.3 Location .................................................................................................................................................... 10

7.4 Dust Collection ......................................................................................................................................... 10

7.5 Electrical Connections .............................................................................................................................. 10

7.6 Grounding Instructions ............................................................................................................................. 10

7.7 Extension Cords ....................................................................................................................................... 11

8.0 Adjustments ................................................................................................................................................. 11

8.1 Fence assembly ....................................................................................................................................... 11

8.2 Fence plate ............................................................................................................................................... 11

8.3 Fence to Table Clearance ........................................................................................................................ 12

8.4 Setting Cursor (Zero) Position .................................................................................................................. 12

8.5 Setting Table Parallel to Blade ................................................................................................................. 12

8.6 Setting Fence Parallel to Blade ................................................................................................................ 13

8.7 Fence Locking Tigh tn ess ......................................................................................................................... 13

8.8 Table Tilt ................................................................................................................................................... 14

8.9 90° Table Stop .......................................................................................................................................... 14

8.10 Installing/Changing Blades ..................................................................................................................... 14

8.11 Blade Tension ........................................................................................................................................ 15

8.12 Blade Tracking ....................................................................................................................................... 16

8.13 Upper Blade Guides ............................................................................................................................... 16

8.14 Upper Thrust Bearing .................................................................................................... ......................... 17

8.15 Lower Blade Guides ............................................................................................................................... 17

8.16 Guide Post .............................................................................................................................................. 18

8.17 Guide Post Parallelism ........................................................................................................................... 18

8.18 Resaw Pin .............................................................................................................................................. 18

8.19 Miter Gauge ............................................................................................................................................ 19

8.20 Drive Belt Replacement and Tensioning ................................................................................................ 19

8.21 Brushes .................................................................................................................................................. 20

9.0 Operating Controls ....................................................................................................................................... 20

9.1 Start/Stop ................................................................................................................................................. 20

9.2 Safety Key ................................................................................................................................................ 21

9.3 Brake Pedal .............................................................................................................................................. 21

10.0 Operation ................................................................................................................................................... 21

10.1 General Procedure ................................................................................................................................. 21

10.2 Ripping ................................................................................................................................................... 22

10.3 Crosscutting ........................................................................................................................................... 22

10.4 Resawing ................................................................................................................................................ 22

10.5 Blade Lead ............................................................................................................................................. 22

11.0 Maintenance ............................................................................................................................................... 23

11.1 Lubrication Points ................................................................................................................................... 23

12.0 Blade Selection .......................................................................................................................................... 24

13.0 Blade Selection Guide ................................................................................................................................ 26

14.0 Troubleshooting the PM1500 Band Saw .................................................................................................... 27

14.1 Operational Problems ............................................................................................................................. 27

14.2 Mechanical and Electrical Problems ...................................................................................................... 29

15.0 Replacement Parts ..................................................................................................................................... 30

15.1.1 Complete Machine with Accessories – Ex ploded View ....................................................................... 31

15.1.2 Complete Machine with Accessories – Parts List ................................................................................ 33

15.2.1 Upper Wheel Sliding Bracket & Tension Mech anism Assembly – Exploded View ........................................... 36

15.2.2 Upper Wheel Sliding Bracket & Tension Mechanism Assembly – Parts List ...................................... 36

3

Page 4

15.3.1 Upper Wheel Assembly – Exploded View ........................................................................................... 37

15.3.2 Upper Wheel Assembly – Parts List .................................................................................................... 37

15.4.1 Lower Wheel Assembly – Exploded View ........................................................................................... 37

15.4.2 Lower Wheel Assembly – Parts List .................................................................................................... 37

15.5.1 Trunnion Support Bracket Assembly – Exploded View .................................................................... 38

15.5.2 Trunnion Support Bracket Assembly – Parts List ............................................................................. 38

15.6.1 Guide Bar Bracket Assembly – Exploded View ................................................................................... 39

15.6.2 Guide Bar Bracket Assembly – Parts List ........................................................................................... 39

15.7.1 Upper Blade Guide Assembly – Exploded View ................................................................................. 40

15.7.2 Upper Blade Guide Assembly – Parts List .......................................................................................... 40

15.8.1 Lower Blade Guide Assembly – Exploded View ................................................................................. 41

15.8.2 Lower Blade Guide Assembly – Parts List .......................................................................................... 41

15.9.1 Fence Assembly – Exploded View ...................................................................................................... 42

15.9.2 Fence Assembly – Parts List ............................................................................................................... 42

15.10.1 Miter Gauge Assembly – Exploded View .......................................................................................... 44

15.10.2 Miter Gauge Assembly – Parts Lis t ................................................................................................... 44

16.0 Electrical Connections – 3HP 1PH 230V ................................................................................................... 45

4

Page 5

3.0 Safety warnings

WARNING: For your own safety read instruction

manual before operating Band Saw.

- Wear eye prote cti o n.

- Do not remove jammed cutoff pieces until blade

has stopped.

- Maintain proper adjustment of blade tension,

blade guides, and thrust bearings.

- Adjust upper guide to just clear workpiece.

- Hold workpiece f irmly against table.

1. Read and understand entire owner's manual

before attempting assembly or operation.

2. Read and understand the warnings posted on

the machine and in this manual. Failure to

comply with all of these warnings may cause

serious injury.

3. Replace warning labels if they become

obscur e d or rem ov e d.

4. This band saw is designed and intended for

use by properly trained and experienced

personnel only. If you are not familiar with the

proper and safe operation of a band saw, do

not use until proper training and knowledge

have been obtained.

5. Do not use this band saw for other than its

intended use. If used for other purposes,

Powermatic disclaims any real or implied

warranty and holds itself harmless from any

injury that may result f rom that use.

6. Always wear approved safety glasses/face

shield while using this machine. (Everyday

eyeglasses only have impact resistant lenses;

they are not safety glasses.)

7. Before operating band saw, remove tie, rings,

watches and other jewelry, and roll sleeves up

past the elbows. Remove all loose clothing and

confin e lo n g hair . N on- sl i p f o otw e ar or a nt i- ski d

floor strips are recommended. Do not wear

gloves.

8. Keep work area clean. Cluttered areas and

benches invite accidents.

9. Use proper extension cord. Make sure your

extension cord is in good condition. When

using an extension cord, be sure to use one

heavy enough to carry the current your product

will draw. An undersized cord will cause a drop

in line voltage resulting in loss of power and

over heating. T able 1 shows th e correct size to

use depending on cord length and nameplate

ampere rating. If in doubt, use the next heavier

gage. The smaller the gage number, the

heavier the cord.

10. Secure work. Use clamps or a vise to hold work

when practical. It’s safer than using your hand

and it frees both hands to operate tool.

11. Disconnect tools before servicing; when

changing accessories, such as blade, bits,

cutter s an d the li ke.

12. Direction of feed: Feed work into a blade or

cutter against the direction of rotation of the

blade or cutter only.

13. Adjust upper blade guides to approximately

1/8” ab ov e wor k pi ec e.

14. Make sure blade tension, tracking and blade

guid es are all properly adjusted.

15. Make relief cuts where possible, when cutting

curved stock.

16. When feeding small work pieces into blade,

alway s us e pus h sti ck, fixt ur e, or si mi lar devic e

to ke ep hands at a safe distance.

17. Hold st ock fi rml y an d flat ag ai n st ta ble.

18. Wear ear protectors (plugs or muffs) during

extend e d periods of op er ati o n.

19. Some dust created by power sanding, sawing,

grinding, drilling and other construction

activities contain chemicals known to cause

cancer, birth defects or other reproductive

harm. Som e exa m ples of these chemicals are:

•

Lead from lead based paint.

•

Crystalline silica from bricks, cement and

other ma s o nry pr od u cts .

•

Arsenic and chromium from chemically

treated lumber.

Your risk of exposure varies, depending on

how oft en yo u do this t ype of w ork. To r educe

your exposure to these chemicals, work in a

well-ventilated area and work with approved

safety equipment, such as face or dust masks

that are specifically designed to filter out

microscopic parti cles.

20. Do not operate this machine while tired or

under the influence of drugs, alcohol or any

medication.

21. Make certain switch is in OFF position before

connecting machine to power supply.

22. Make cer t ai n ma c hin e is pro p erl y gr ou n d ed.

23. Do not back stock out of blade while blade is

running.

24. Remove adjusting keys and wrenches. Form a

habit of ch ecking to s ee that key s an d a dju sti n g

5

Page 6

wrenches are removed from the machine

before tur ning it on.

25. Keep safety guards in place at all times when

machine is in use. If removed for maintenance

purposes, use extreme caution and replace the

guards immediately after completion of

maintenance.

26. Check damaged parts. Before further use of

machine, a guard or other part that is damaged

should be carefully checked to determine that it

will operate properly and perform its intended

function. Check for alignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect it s o per ation. A gu ar d or oth er p art th at is

damaged should be properly repaired or

replaced.

27. Keep floor around machine clean and free of

scrap material, oil and grease.

28. Keep visitors a safe di stance from wor k area.

Keep c hil dr en aw a y.

29. Make your workshop child proof with padlocks,

master switc hes or by removing start er keys.

30. Give your work undivided attention. Looking

aroun d, c arryi n g on a c onv ers atio n an d “ho rs eplay” are careless acts that can result in

serious injury.

31. Maintain a bala nced st ance at all tim es so th at

you do not fal l int o blade or ot her m ovin g part s.

Do not overreach or use excessive force to

perform any machine operation.

32. Use the right tool at the correct speed and feed

rate. Do not forc e a tool or at tachm ent to do a

job for which it was not designed. The right tool

will do the job better and more safely.

33. Use recommended accessories; improper

accessories may be hazardous.

34. Maintain tools with care. Keep blades sharp

and clean for best and safest performance.

Follow instructions for lubricating and changing

accessories.

35. Turn off m achine befor e cle aning. Use a br ush

or com pres sed air to re mov e chi ps or de bris —

not your hands.

36. Do not stand on machine. Serious injury could

occur if machine tips over.

37. Never leave machine running unattended. Turn

power off and do not leave band saw until

blade comes t o a complete stop.

38. Remove loose items and unnecessary work

piec es fr om ar ea b efo r e star ting mac hine.

39. Keep h and s out of li ne of s aw bl ad e.

40. Don’t use in dangerous environment. Do not

expos e machi ne to rai n or use in w et or dam p

locations. Keep work area well lighted.

41. Remove safety key from switch whenever band

saw is turned “OFF”, and keep safety key out of

reac h of unauthorized persons or children.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or

possibly even death.

4.0 About this manual

This manual is provided by Powermatic covering the safe operation and maintenance procedures for a

Powermatic model PM1500 Band Saw. This manual contains instructions on installation, saf ety precautions,

general operating procedures, maintenance instructions and parts breakdown. Your machine has been

designed and constructed to provide years of trouble-free operation if used in accordance with the instructions

as set forth in this document.

This manual is not intended to be an exhaustive guide to band saw operational methods, use of j igs or aftermarket accessories, choice of stock, etc. Additional knowledge can be obtained from e xperienced users or

trade articles. Whatever accepted methods are used, always make personal safety a priority.

Retain this manual for future reference. If the machine transfers own ership, the manu al should accompan y it.

Read and understand the entire contents of this manual before attem pting assembly

or operation! Failure to comply may cause serious injury!

6

Page 7

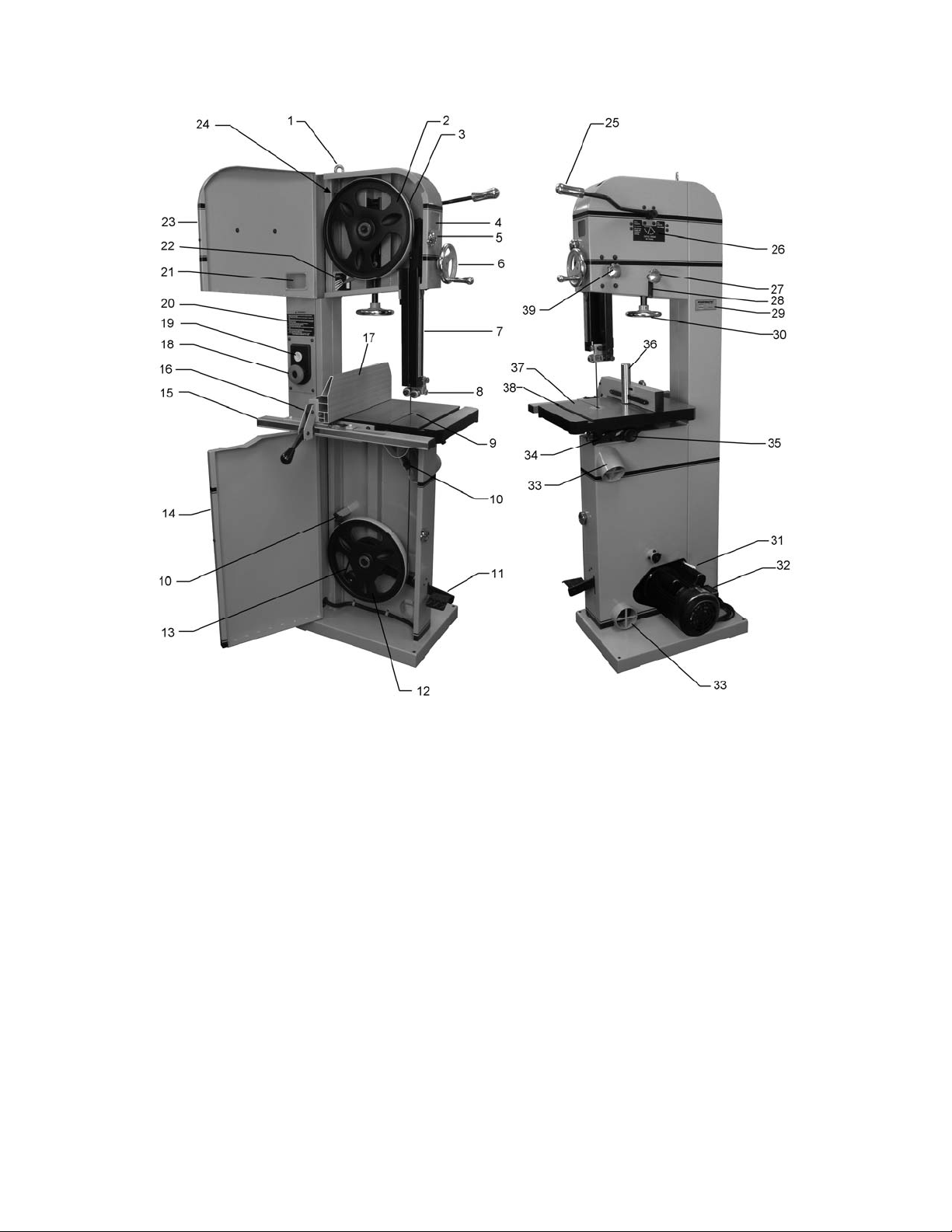

5.0 Features and Terminology

Figure 1

1. Lifting ring

2. Upper wheel

3. Tire

4. Tracking window

5. Door catch

6. Guide post handwheel

7. Guide post

8. Upper bearing blade guides

9. Table insert

10. Blade and wheel brushes

11. Brake pedal

12. Lower wheel

13. Drive belt and pulley

14. Lower door

15. Guide rail

16. Rip fence

17. Aluminum f ence plat e

18. Magnetic switch with power indicator light

19. Safety key

20. Warning label

21. Blade tension window

22. Blade tension scale

23. Upper door

24. Interlock switch

25. Blade tension lever

26. Tension lever position label

27. Tracking knob

28. Tracking knob lock lever

29. Serial number/machin e identificati on plate

30. Blade tension handwheel

31. Motor lift handle

32. 3 horsepower TEFC motor

33. Dust port

34. Trunnion lock handle

35. Trunnion fine adjust knob

36. Resaw pin

37. Cast iron table

38. Miter slot

39. Guide post locking knob

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Powermatic reserves the right to change specifications at any time and without prior notice,

without incurring obligations.

7

Page 8

6.0 Specifications

Model number ............................................................................................................................................ PM1500

Stock number ............................................................................................................................................ 1791500

Motor and electricals:

Motor type ....................................................................... totally enclosed fan cooled, induction, capacitor start

Horsepower ................................................................................................................................................ 3 HP

Phase ........................................................................................................................................................ single

Voltage ....................................................................................................................................................... 230V

Cycle .......................................................................................................................................................... 60Hz

Listed FLA (full load amps) .......................................................................................................................... 12A

Starting amps ............................................................................................................................................... 55A

Running amps (no load) .............................................................................................................................. 3.3A

Start capacitor ....................................................................................................................... 200MFD, 250VAC

Run capacitor ............................................................................................................................. 60µF, 300VAC

Power transfer ........................................................................................................... Poly-V 9 groove belt drive

On/off switch ..................................................................... Magnetic, with power indicator lamp and safety key

Motor speed ...................................................................................................................................... 1720 RPM

Blade speed .................................................................................................................................... 3100 SFPM

Power cord length ....................................................................................................................... 6.6 ft. (200cm)

Power plug installed ..................................................................................................................................... yes

Recommended circuit size 1 ......................................................................................................................... 20A

Sound emission...................................................................... 72 dB at 39” (1000mm) from blade, without load

1

subject to local and national electrical codes.

Capacities:

Maximum cutting height/resaw capacity ....................................................................................... 14” (355mm)

Throat capacity........................................................................................................................ 14-1/2” (368mm)

Minimum blade width .................................................................................................................... 1/8” (3.2mm)

Maximum blade width .................................................................................................................... 1” (25.4mm)

Blade length 2 .................................................................................................................. 153 +/-1/2” (3886mm)

Blade provided ................................................................................................. hook type, 3/8” x 0.065” x 6 TPI

Wheel diameter ............................................................................................................................. 15” (381mm)

2

blade length range is 152-1/2” to 153” for band saws with serial no. 12100002 to 12100052.

Miscellaneous:

Fence plate .................................................................................................. 19-3/4”L x 6-1/2”H (502 x 165mm)

Resaw pin .................................................................................................... 1-1/2” dia x 6-1/2”H (38 x 165mm)

Stand footprint ........................................................................................... 17-3/4”L x 25-1/4”W (450 x 641mm)

Overall dimensions, assembled .................................. 30-1/4”L x 34-3/8”W x 80-1/4”H (768 x 873 x 2038mm)

Miter gauge positive stops .................................................................................................................... 45°, 90°

Materials:

Table ........................................................................................................................................ ground cast iron

Trunnion ............................................................................................................................................... cast iron

Enclosed cabinet ........................................................................................................................................ steel

Band wheels......................................................................................................................................... cast iron

Tires .............................................................................................................................................. polyurethane

Blade guides ................................................................................................................................... ball bearing

Resaw fence ....................................................................................................................... extruded aluminum

Handwheels .................................................................................................................. cast iron, chrome finish

Paint finish...................................................................................................................................... powder coat

Table:

Table dimensions ....................................................................... 21-1/2”L x 16”W x 2”Thk (546 x 406 x 51mm)

Table tilt................................................................................................................................... 10° left, 45° right

Table height from floor at 90-degrees ......................................................................................... 40” (1016mm)

Miter T-slot ............................................................................. 7/8”W x 3/8”D; opening 3/4"W (22 x 9.5; 19mm)

Edge bevel .................................................................................................................................................. front

8

Page 9

Dust coll ection:

Dust port outside diameter .................................................................................................... two at 4” (100mm)

Minimum extraction volume required .................................................................................................. 600 CFM

Weights:

Net weight (fully assembled) ...................................................................................................... 394 lb (179 kg)

Shipping weight .......................................................................................................................... 502 lb (228 kg)

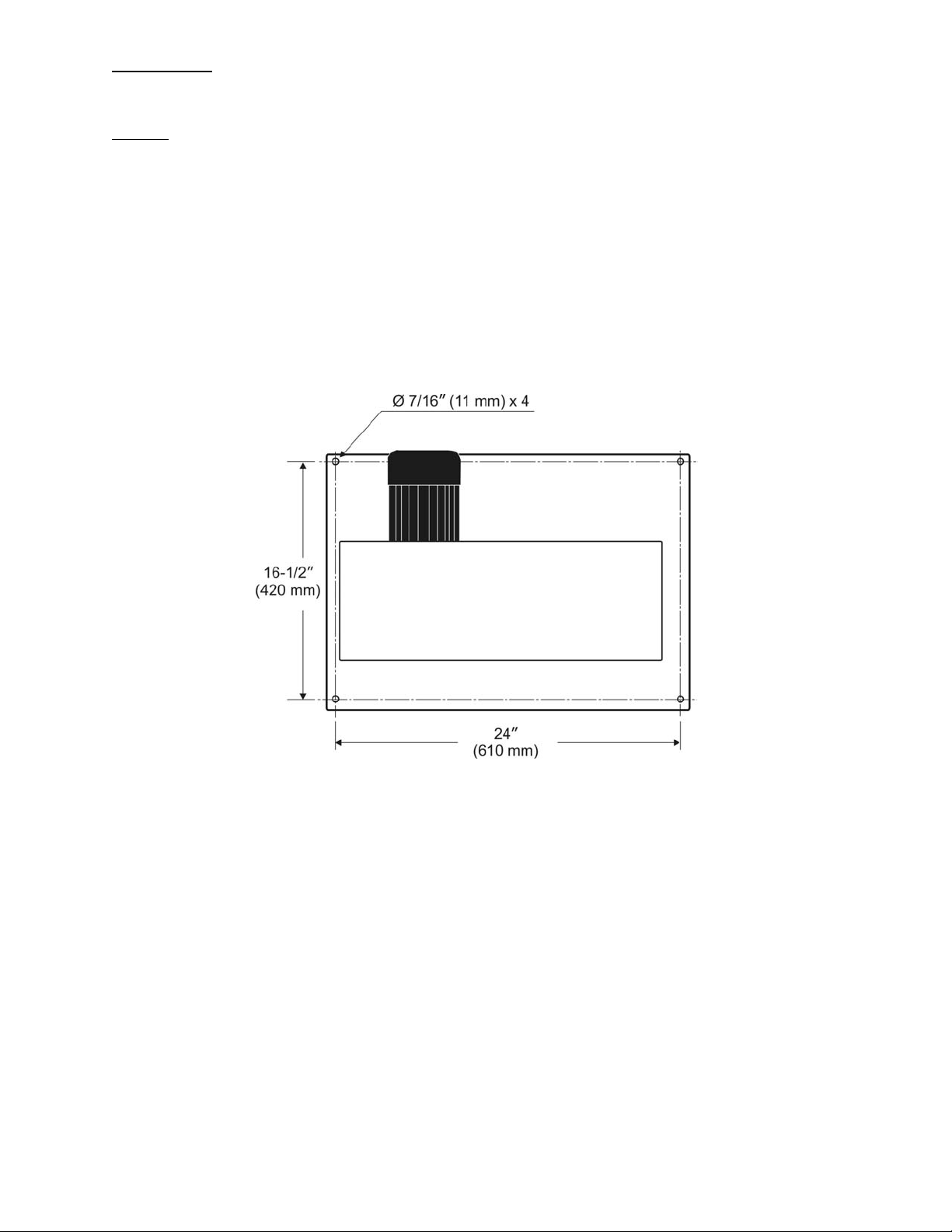

6.1 Base Hole Centers (PM1500 Band Saw)

Figure 2

9

Page 10

Read and understand all

instructions before attempting assembly or

operation of band saw. Failure to comply may

cause serious injury.

7.0 Setup and assembly

7.1 Unpacking

1. Remove all contents from shipping carton. Do

not discard any shipping material until band

saw is assembled and running satisfactorily.

2. Inspect contents for shipping damage. Report

any damage immediately to your distributor

and shipping agent.

3. Compare contents of shipping carton with the

contents list in this manual. Report shortages,

if any, to your distributor.

Note: Some parts may have come pre-assembled

to the saw.

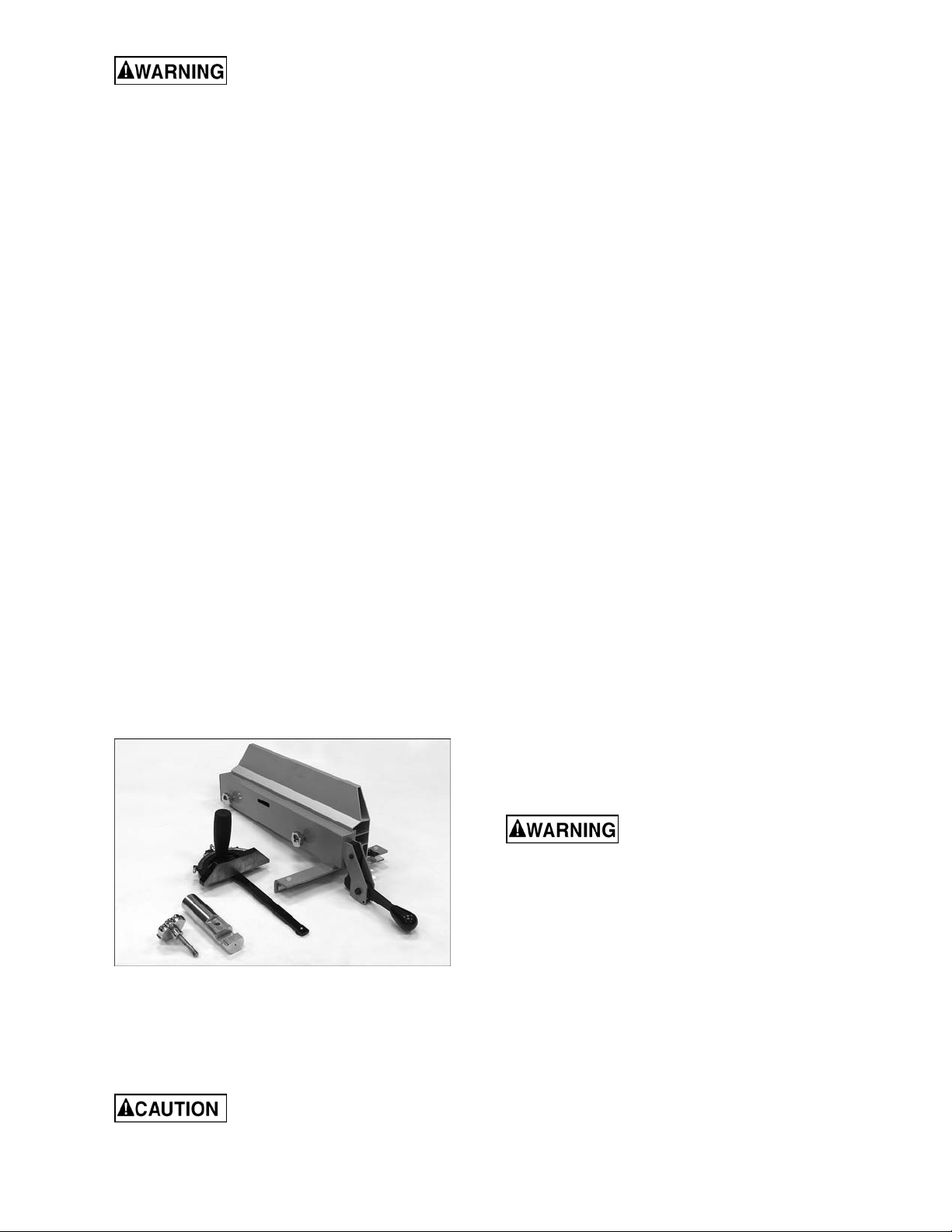

7.2 Shipping contents

Carton contents (see Figure 3):

1 Band saw (not shown)

1 Fence assembly with aluminum fence plate

1 Miter gauge

1 Resaw pin and handle

1 Owner’s manual (not shown)

1 Warranty card (not shown)

Tools required for set up and assembly:

Hoist or forklift, with straps

Machinist square

Use a hoist or forklift with straps to remove band

saw from pallet. The straps used should have a

minimum 500-lb. lifting capacity. Do NOT place

forks or straps directly beneath table or against

handles or levers – use the lifting eye atop the

band saw.

Move band saw to its permanent location, which

should be dry and well lit, with a level floor and

enough space on all sides to handle long stock or

perform routine maintenance on the machine.

Make sure floor is able to support weight of

machine. If desired, band saw can be secured to

floor using lag screws (not provided) through the

four holes in base. See Figure 2 for hole spacing.

Exposed metal surfaces, such as table surface and

blade guides, have been given a protective coating

at the factory. This coating should be removed with

a soft cloth moistened with solvent. Do not get

solvents near plastic or rubber parts; and do not

use an abrasive pad as it may scratch exposed

surfaces.

The handle on the front handwheel may be in

rever se posit ion for shipping. Reinst all it i n proper

position on the handwheel. Use a wrench on the

flat to tighten it to the handwheel.

7.4 Dust Collection

The use of a dust collection system is strongly

recommended for this band saw. It will help keep

the shop clean, as well as red uce potential health

hazards caused by inhalation of wood dust. The

collector should have a capacity sufficient for this

size machine – 400 CFM is recommended.

Powermatic has a line of dust collection systems

available; see your dealer or visit our website listed

on the cover.

Connect the hoses of your dust collection system

to the saw’s dust ports (4” outside diameter).

Secure tightly with hose clamps (not provided).

Figure 3

7.3 Location

Remove all crating and plastic from around

machine. Remove any screws or straps holding

band saw to shipping pallet.

Exercise care when removing

machine from shipping pallet.

7.5 Electrical Connections

Electrical connections must be

made by a qualified electrician in compliance

with all relevant codes. This machine must be

properly grounded to help prevent electrical

shock and possible fatal in j ury.

The band saw is factory wired for 230 volts. It is

recommended that the band saw be co nnected to

a grounded and dedicated 20 amp c ircuit wit h a 20

amp circuit breaker or time delay fuse. Local codes

take precedence over recommendations.

7.6 Grounding Instructions

1. All grounded, cord-connected tools:

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric current to reduce t he risk of electr ic shock.

This tool is equipped with an electric cord having

10

Page 11

an equipment-grounding conductor and a

grounding plug. The plug must be plugged into a

matching outlet that is properly installed and

grounded in accordance with all local codes and

ordinances. Do not modify the pl ug provided - if it

will not fit the outlet, have the proper outlet installed

by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in a risk of electric shock. The

cond uctor with insulatio n having an outer surface

that is green with or without yellow stripes is the

equipment-grounding conductor. If repair or

replacement of the electric cord or plug is

necessary, do not connect the equipmentgrounding conductor to a live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to whether

the tool is properly grounded. Use only 3-wire

extension cords that have 3-pro ng gro unding pl ugs

and 3 pole receptacles that accept the tool's plug.

Repair or replace damaged or worn cord

immediately.

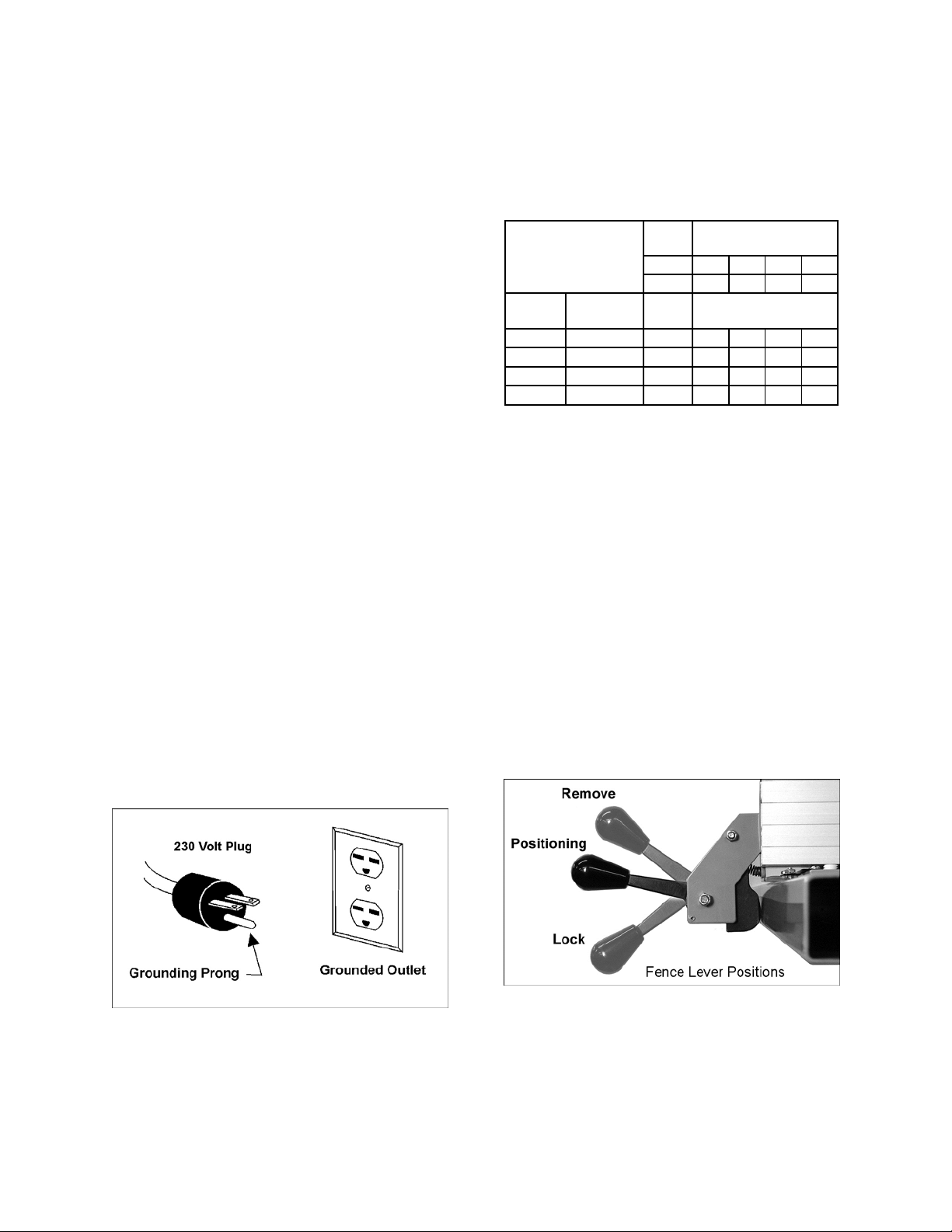

2. Grounded, cord-connected tools intended for

use on a supply circuit having a nominal rating

between 150 – 250 volts, inclusive:

This tool is intended for use on a circuit that has an

outlet that looks like the one illustrated in Figure 4.

The tool has a grounding plug that looks like the

plug illustrated in Figure 4. Make sure the tool is

connected to an outlet having the same

configuration as the plug. No adapter is available

or should be used with this tool. If the tool must be

reconnected for use on a diff erent type of electric

circuit, the reconnection should be made by

qualified service personnel; and after reconnection,

the tool should comply with all local codes and

ordinances.

Make sure the voltage of your power supply

matches the specifications on the motor plate of

the Band Saw.

on the machine’s motor plate. An undersized cord

will cause a drop in line voltage resulting in loss of

power and overheating.

Use Table 1 as a general guide in choosing the

correct size cord. The smaller the gauge number,

the heavier the cord. If in doubt, use the next

heavier gauge.

Recommended G auges (A WG ) of E x tension Cords

Volts Total length of cord

in feet

120 25 50 100 150

Ampere rating

More

than

0 6

6 10

10 12

12 16

Not more

than

NR: Not Recommended.

240 50 100 200 300

Table 1

Minimum gauge cord

18 16 16 14

18 16 14 12

16 16 14 12

14 12 NR NR

8.0 Adjustments

Tools required for adjustments:

Machinist square

Cross point (Phillips) screwdriver

Hex keys, 4mm/5mm/6mm

13mm wrench

Straight edge and gauge

8.1 Fence assembly

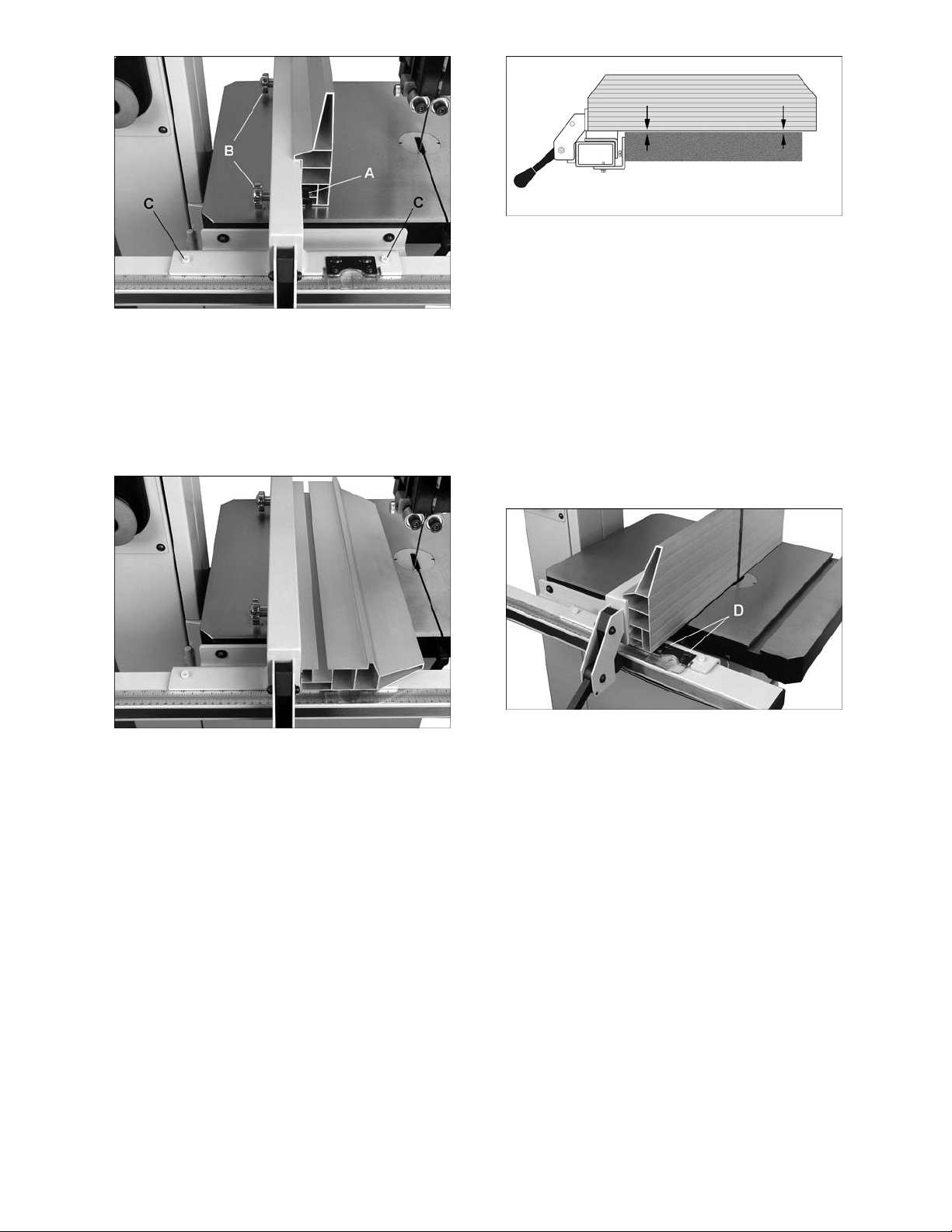

Refer to Figure 5.

Place fence body onto guide tube (as shown in

Figure 9). Raise fence lever all the way up to install

or remove fence from guide rail. Midway lever

position allows fence to slide along guide rail.

Lowest lever position locks fence in place.

Figure 4

7.7 Extension Cords

The use of extension cords is discouraged; try to

position machines within reach of power source. If

an extension cord becomes necessary, make sure

the cord rating is suitable for the amperage listed

Figure 5

8.2 Fence plate

Refer to Figures 6 and 7.

Loosen lock bar (A) using knobs (B). Pull out on

lock b ar unt i l it pr ot rud es e no ug h o n w hic h to s lid e

the aluminum fence plate from one end, as shown

in Figure 6. Retighten knobs.

11

Page 12

Figure 8

8.4 Setting Cursor (Zero) Position

Figure 6 – vertical position

The aluminum fence plate can be installed in one

of two positions; vertically (resaw position), as

shown in Figure 6; or horizontally as shown in

Figure 7.

Horizontal position is useful for smaller workpieces.

(The zero setting of the cursor cannot be used with

horizontal fence position.)

Figure 7 – horizontal position

8.3 Fence to Table Clearance

1. Check clearance between table and bottom of

fence (Figure 8). The fence plate should not

rub against table surface but be slightly above

it. This gap should be the same at both front

and back of table.

2. If clearance is not equal, use a 5mm hex key

to rotate the two nylon adjustment screws (C,

Figure 6) the same amount to raise or lower

fence body on guide tube. Clockwise raises

fence body, counterclockwise lowers.

Refer to Figure 9.

1. The fence must be set so that cursor reads

zero at line of blade. The fence plate must be

installed on fence body in vertical position, and

blade must be installed and fully tensioned.

2. Slide fence flush against flat of blade, as

shown. (Do not force fence into blade so that

blade deflects.)

3. If cursor is not at zero, loosen two screws (D,

Figure 9) and shift cursor as needed.

Retighten screws.

Figure 9

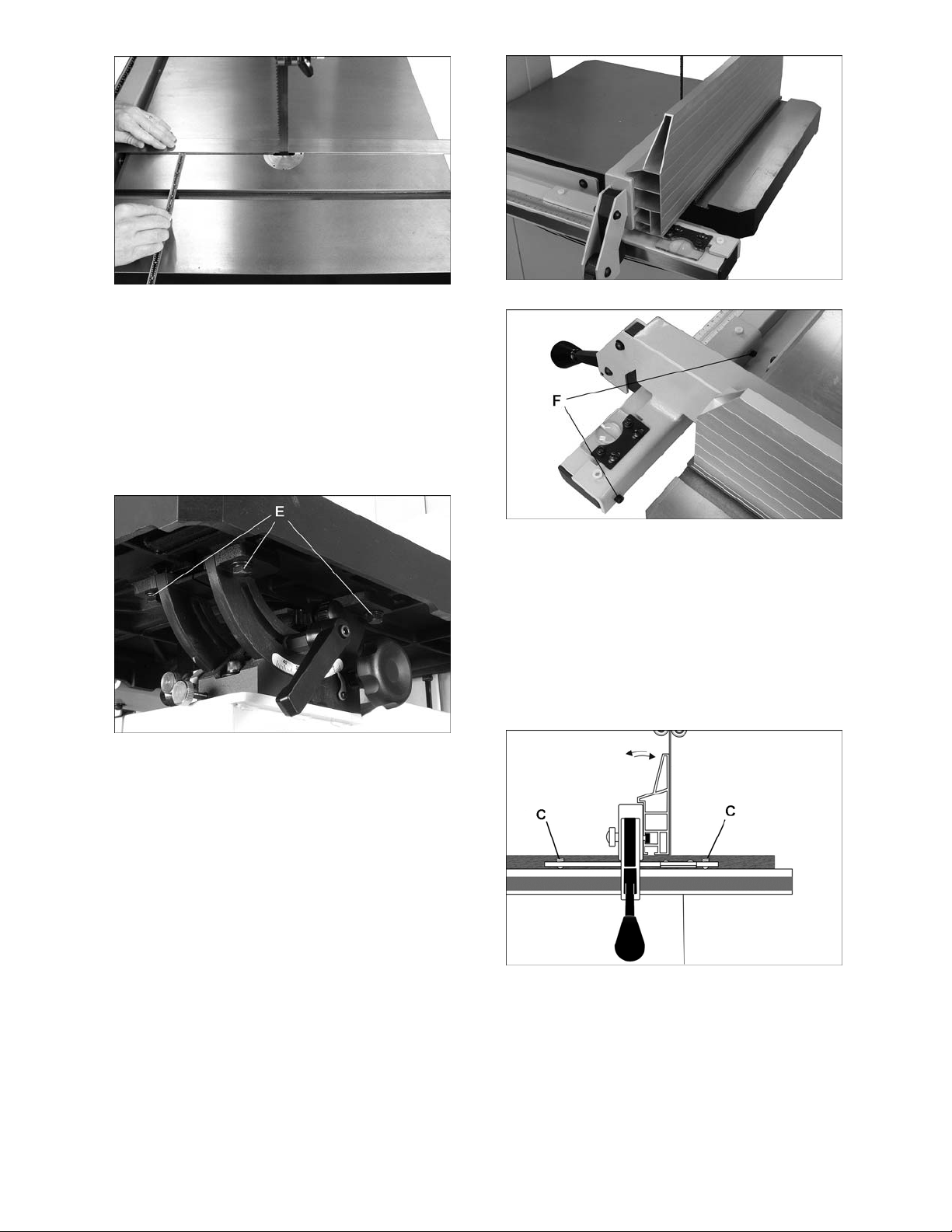

8.5 Setting Table Parallel to Blade

Refer to Figures 10 and 11.

1. The table has been aligned by the

manufacturer so that the miter slot is parallel to

the blade; it should not require adjustment.

However, in the future you may wish to confirm

the setting is still accurate. A wide blade is

recommended for the procedure.

2. Disconnect band saw from power source.

3. Blade should be fully tensioned (see section

8.11).

4. Place a long straightedge fl ush against blade,

making sure it contacts both front a nd back of

blade. (Do not deflect blade by pushing into it.)

See Figure 10.

12

Page 13

Figure 10

5. Use a gauge to carefully measure distance

from miter slot to straight edge. Take

measurements at both front and back of table

– these should be identical.

6. If m iter slot is not parallel to blade, loosen four

screws (E, Figure 11) that secure table to

trunnion, and shift table as needed until miter

slot is parallel to blade.

7. Tighten the four scre ws.

Figure 11

Figure 12

Figure 13

The fence must also be vertically parallel to blade.

Refer to Figure 14:

3. Make sure table has been set 90° to blade

(see section 8.9).

4. Slide fence (with aluminum plate securely

fastened) against blade; do not push into

blade. Turn either of the nylon adjustment

screws (C) until fence is parallel to blade along

vertical leng th of fenc e.

8.6 Setting Fence Parallel to Blade

Refer to Figures 12 through 14.

Fence must be parallel to flat of blade f or accurate

cutting. Since miter slot has been set parallel to

blade from the manufacturer (and confirmed by

user, as described in section 8.5), the miter slot

can be used to set fence parallelism.

1. Slide fence to edge of miter slot, as shown in

Figure 12. The fence should align with miter

slot along its entire length.

2. If adjustment is needed, use one of the back

adjustment screws (F, Figure 13) to t urn fence

in line with miter slot (5mm hex key).

Figure 14

8.7 Fence Locking Tightness

The tightness of fence against guide rail tube can

be adjusted by rotating back adjustment screws (F,

Figure 13). Rotate the two screws equally

(clockwise to tighten).

Because these screws are also used to align fence

to blade, after adjusting fence locking tightness,

13

Page 14

you should inspect fence-to-blade relationship, as

explained in section 8.6.

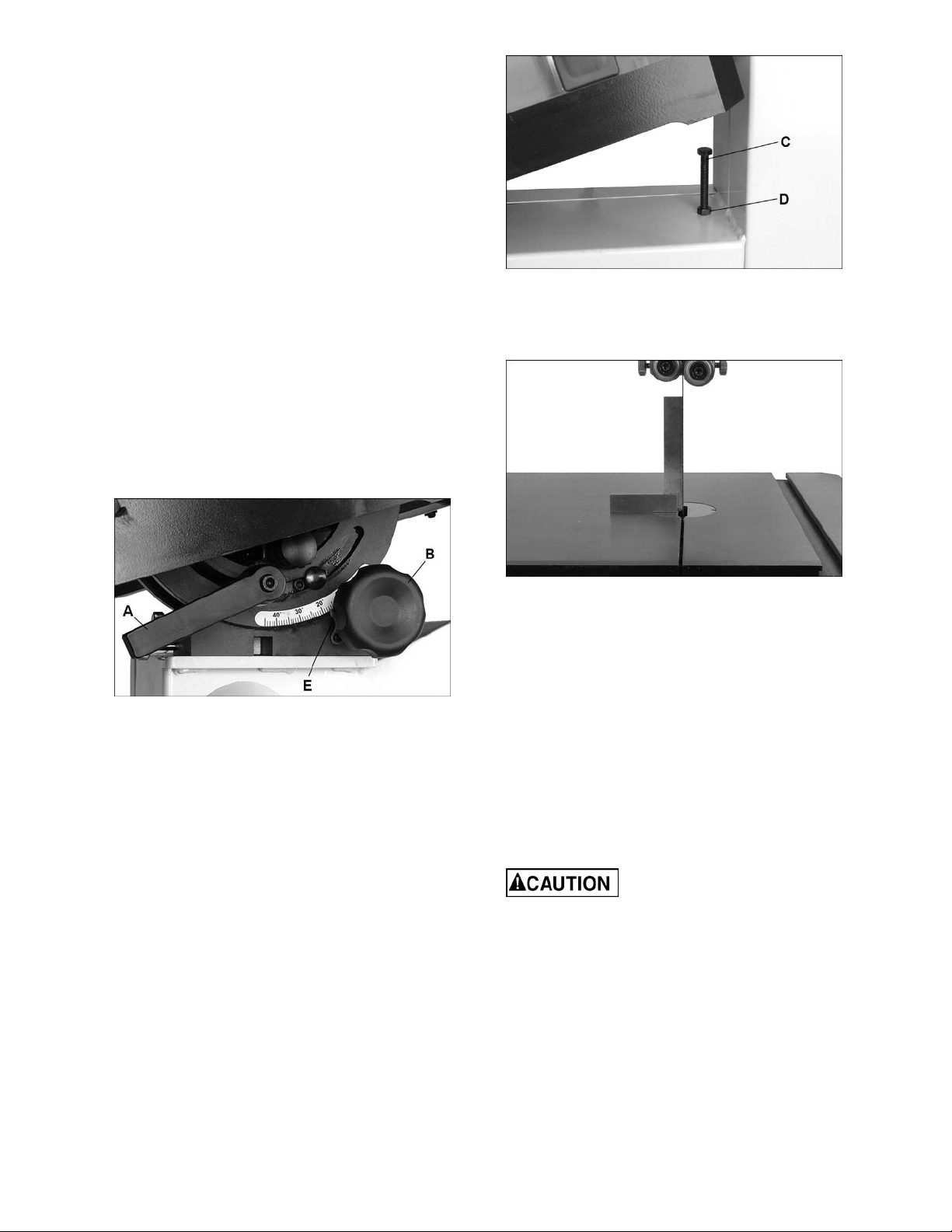

8.8 Table Tilt

Refer to Figure 15.

1. Loosen lock handle (A).

2. For right tilt (as viewed from front or operator’s

side of saw), push on table while rotating knob

(B) clockwise to tilt table up to 45°. Use knob

(B) for fine adjustment.

3. For left tilt (as viewed from front or operator’s

side of saw), loosen lock lever (A) and rotate

knob (B) clockwise a turn or two to release

pressure on the 90° stop bolt (shown in Figure

16). Remove stop bolt, then rotate k nob to tilt

table up to 15°.

4. Tighten lock handle (A) to secure setting.

NOTE: The lock handle (A) can be pivoted to

more convenient posit ions. Simply lift straight

out on handle and rotate it on the pin, then

release handle making sure it seats itself on

the pin.

Figure 16

4. Place a square on table and against blade to

check that table is 90° to blade. See Figure 17.

Do not push square into blade.

Figure 15

8.9 90° Table Stop

Refer to Figures 16 and 17.

The 90° positive stop ensures that table will always

be perpendicular to blade after table is returned to

horizontal position. Check and adj ust this 90° stop

as follows:

1. Disconnect machine from power source.

2. Make sure blade is under full tension.

3. Tilt table until it rests on stop bolt (C).

Figure 17

5. If table and blade are not square, use a 13mm

wrenc h to loo sen lo ck nut (D, F igure 1 6) t hen

rotate stop bolt. Turn stop bolt as needed until

there is no longer light showing between

square and blade.

6. Tighten lock nut (D) to secure table stop in

position.

7. Tighten lock handle (A, Figure 15).

8. Check that scale pointer (E, Figure 15) is at

zero. If necessary, loosen screw on pointer

and shift pointer to zero. Re-tighten screw.

8.10 Installing/Changing Blades

Always wear gloves when

handling blades. New blades are usually

packaged in coiled position; to prevent injury

uncoil them slowly and carefully, while wearing

work gloves and safety glasses.

The PM1800 band saw is designed for blades from

1/8” to 1” wide.

Refer to Figure 18.

1. Disconnect machine from power source.

2. Remove table insert (F, Figure 18).

3. Pull out table pi n (G).

14

Page 15

4. Adjust upper and lower blade guides away

from blade (see sections 8.13 and 8.15).

Figure 18

5. Move quick tension lever to “Full Release

(Blade Change)” position.

6. Open upper and lower doors by rotating door

catches.

7. Carefully remove blade from top wheel, then

from between upper and lower blade guides

and lower wheel. Slide blade out t hrough slot

in table.

8. Guide new blade through table slot. Place

blade loosely in upper and lower blade guides.

Make sure blade teeth point down toward

table, and toward front of saw. (If the teeth will

not point down, no matter how you orient

blade, then blade is twisted inside-out. Twist it

into correct position and re-install it.)

9. Position blade at center of upper and lower

wheels.

10. Reinstall table insert (F) and table pin ( G).

11. Before operating band saw, the new blade

must be tensioned and tracked, in that order.

Find instructions for tensioning and tracking

the blade in sections 8.11 and 8.12. The blade

guides must also be set properly according to

instructions in sections 8.13 through 8.16.

4. Open upper door.

5. Rotate tension handwheel (A, Figure 20) until

scale pointer (B) indicates width of installed

blade.

TIP: Use the band saw’s gauge setting initially.

As yo u becom e fam iliar wit h the m achi ne and

with different properties of band saw blades,

you may find it necessary to change blade

tension from initial setting. Keep in mind that

not only changes in blade width, but also type

of material being cut will have an effect on

blade tension. Too little or too much blade

tension can cause blade breakage a nd/or poor

cutting performance.

Figure 19

8.11 Blade Tension

Refer to Figure 19.

1. Disconnect machine from power source.

2. Back off upper and lower guide bearings to

eliminate any contact with blade.

3. With blade centered on wheels, move quick

tension lever to “Full Tension” position, as

shown in Figure 19. NOTE: You should feel

tension lever settle into each of its three

positions.

Figure 20

6. Make a note of the specific tension setting for

a particular blade. Tension can then be re-set

quickly when that blade is reinstalled.

IMPORTANT: When band saw is not being

used, move quick tension lever to “Partial

Tension-Idle/Tracking” position. This will

prolong the life of bla de and tires, and reduce

load on wheels, bearings and other

components.

15

Page 16

8.12 Blade Tracking

Refer to Figures 21 and 22.

After proper tensioning, the blade must be tracked.

“Tracking” refers to position of blade on the wheels

while machine is in operation. Tracking should be

checked periodically, and is mandatory af ter every

blade change. Blade tracking is done by hand wit h

machine disconnected from power.

1. Disconnect machine from power source.

2. Blade must be correctly tensioned (section

8.11).

3. Make sure blade guides and other parts of

machine will not interfere with blade

movement. Lower guide post until you can see

blade through tracking window (C).

7. If blade tends to move toward edge of wheel,

set lever to “Partial Tension-Idle/T racking.”

8. Loosen lock handle (D, Figure 21) and slightly

rotate tracking knob (E) with your right hand

while continuing to rotate wheel with your left.

Observe blade through tracking window.

Rotating knob clockwise will cause blade to

move toward rear edge of wheel. Rotating

knob counterclockwise will cause blade to

move toward front edge of wheel.

IMPORTANT: This adjustment is sensitive;

perform in small increments and give blade

time to react to changes.

9. When blade is tracking in center of wheel, retighten lock handle (D), and close upper door.

10. Move tension lever to “Full Tension” position,

and connect band saw to power. Turn it on for

a brief time to observe the blade in action

through tracking window.

11. If further adjustments are needed, disconnect

from power and repeat above procedure.

NOTE: An interlock switch in the upper housing

prevents operation of saw unless tension lever is in

ful l tensi o n position.

Figure 21

4. Set quick tension lever initially to “Partial

Tension-Idle/Tracking” position, as shown in

Figure 21.

5. Open upper door to expose wheel.

6. Rotate wheel by hand, observing position of

blade through tracking window. As you rotate

wheel, move lever to “Full Tension” position.

The blade should continue to ride upon center

of tire (Figure 22).

8.13 Upper Blade Guides

The bearing guides should be set so that contact

between blade and guides will occur only when

blade is under pressure from a workpiece. To

adjust upper bearing guides for proper blade

control, proceed as follows.

Refer to Figures 23 through 24.

1. Disconnect machine from power source.

2. Blade must already be tensioned and tracking

correctly. Place quick tension lever in “Full

Tension” position.

3. Lower guide post until upper guide bearings

are a few inches off the table. (The reason for

this will be evident la ter in section 8.17)

4. Loosen lock knob (F, Figure 23).

Figure 22

Figure 23

5. Slide entire guide bracket until front of guide

bearings are about 0.015” (1/64”) behind the

16

Page 17

blade’s gullet (curved area at base of tooth).

See Figure 24.

Figure 24

6. Tighten lock knob (F) to secure this position.

7. Loosen lock knob (G) for one of the guide

bearings.

8. The guide bearing rotates on an eccentric

shaft. Adjust guide bearing by rotating the

knurled knob (H) with a 5mm hex key, until

guide bearing is approximately 0.004” from

blade. A quick way to achie ve this spac ing is

by placing a single t hickness of a c risp dollar

bill (a dollar bill is approximate ly 0.004” thick)

between blade and guide bearing. See Figure

25. Adjust guide bearing until it just lightly grips

the dollar bill.

8.14 Upper Thrust Bearing

Refer to Figures 23 and 26:

1. The thrust bearing prevents backward

deflection of blade during cutting. A groove

provided in the bearing surface helps stabilize

the moving blade.

2. Loosen lock knob (I) and push thrust bearing

(J) up to back of blade.

3. Adjust thrust bearing until space between

groove bottom and back edge of blade is

approximately 0.015” (1/64”). Tighten lock

knob (I).

4. If lateral adjustment of bearing is needed to

align groove with blade, loosen set screw (K)

at front of bearing assembly, and shift bearing

as needed. Retighten set screw.

5. Make sure all lock knobs on upper guide

bearing assembly are tightened when

adjustments are finished.

Figure 25

NOTE: Do not force guide bearing against side

of blade. It should generally only make contact

with blade when there is pressure from the

cutting operation.

9. Tighten lock knob (G).

10. Repeat process for opposite guide bearing.

Figure 26

8.15 Lower Blade Guides

Refer to Figures 27 and 28.

1. Disconnect band saw from power source.

2. Adjust lower guide bearings and lower thrust

bearing below table, using same procedure

and measurements as for upper guide

bearings and thrust bearing described above.

Movement summary: Loosen lock knob (L) to

move guide bracket. Loosen lock knob (M) to

rotate side bearing, using knurled knob (N).

Loosen lock ring (O, Figure 27) and rotate

knob (P) to adjust thrust beari ng in relation to

blade.

3. Make sure all knobs are tightened after

adjustments are complete.

17

Page 18

8.17 Guide Post Parallelism

The guide post should be parallel to blade

throughout vertical travel of the guide post; thus the

guide bearings will maintain their relationship to

blade at any height from the table and won’t

require re-setting each time guide post is moved.

This setting has been accurately made by the

manufacturer and should not require immediate

attention, but may be checked in future as follows:

1. Disconnect band saw from power source.

Figure 27

Figure 28

8.16 Guide Post

Refer to Figure 29.

1. Disconnect band saw from power sour ce.

2. Loosen lock k nob (A) a nd raise or lower guide

post (B) using handwheel (C).

3. Position blade guide assembly so that bottom

of guide bearings are about 1/8” above

material to be cut. Or, simply lower guide post

until scale pointer (D) indicates the height of

your workpiece. This provides minimal

clearance between workpiece and bottom of

guide bearings, which will minimize blade

deflection as well as enhance operator safety.

4. Tighten lock knob (A).

2. Move blade tension lever to “Full Tension”

position.

3. The guide bearings in low position should

already be set in relation to blade (see section

8.13). Also, the table must be square with

blade (see section 8.5)

4. Loosen lock knob (A, Figure 28) and raise

guide post to a high position.

5. Confirm that guide po st travels straight up and

down, and guide bearings maintain their

relationship to blade.

6. If guide post doe s not go stra ight up and down

(blade begins deflecting when guide post is

raised), slightly loosen the four screws (E,

Figure 29) and adjust guide post assembly as

needed.

7. When finished adjusting, securely tighten the

four screws (E).

8. Verify the setting by raising and lowering guide

post.

8.18 Resaw Pin

Refer to Figure 30.

The resaw pin provides a single contact point while

ripping a workpiece into thinner boards.

Remove aluminum plate and mount resaw pin to

slot in fence body, securing it with knob, as shown.

The resaw pin is usually positioned so that its

center is approximately even with the front edge of

the blade.

Figure 29

Figure 30

18

Page 19

See section 10.4 for further information about using

resaw pin.

8.19 Miter Gauge

Refer to Figures 31 and 32.

A miter gauge is provided for crosscutting

operations. Install miter gauge by sliding end of

miter gauge bar into table T-slot.

The miter gauge should fit snugly within miter slot

while still sliding easily. The miter gauge bar has

two slots, each with a set screw (Figure 31). Rotate

one or both of these set screws with a 4mm hex

key as needed, to eliminate any play between miter

gauge bar and miter slot.

3. Flip stop plate (C) back dow n, and loosen 90°

stop he x nut. Adj ust sc rew u nti l it cont act s 90°

stop plate.

4. Re- t ight en he x nut .

5. Loosen set screw at base of pointer (B) and

shift pointer so that it lines up with 90° mark on

scale.

6. Re-tighten set screw.

7. The 45° stops can be checked in similar

fashion, using an angle gauge similar to that

shown in Figure 32.

To adjust miter gauge angle for operations:

1. Loosen handle (A).

2. Rotate gauge body until pointer (B) lines up

with desired angle on scale. You may have to

pivot 90° stop plate (C) out of the way to allow

the body to rotate.

3. Tighten handle (A).

4. There are t hree stops: at 90°, a nd 45° left and

right. Each of these can be adjusted by

loosening hex nut (D) and turni ng screw (E) as

needed. Re-tighten hex nut (D) when

adjustment is finished.

Figure 31

If table/miter slot is square to blade (see section

8.5) the miter gauge will also be square to blade.

Before operating, however, t he 90° setting of m iter

gauge should be checked in relation to b lade, as

follows.

1. Place a square against miter gauge face, and

against flat of blade, as shown in Figure 32.

(Place square against flat of blade, not against

the teeth which are set wider than the blade

body). A wide blade is preferred for this

procedure.

8.20 Drive Belt Replacement and

Tensioning

The drive belt and pulleys are properly adjusted at

the factory. However, belt tension should be

occasionally checked when the band saw is new,

as a new belt may stretch slightly during the

breaking-in process.

If belt becomes worn, cracked, frayed or glazed, it

should be replaced as follows:

Refer to Figures 33 and 34.

1. Disconnect machine from power source.

2. Open upper and lower doors and remove

blade.

3. Remove screw (F, Figure 33) from lower wheel

shaft with a 6mm hex key, and remove lower

wheel.

Figure 32

2. Flip 90° stop plate (C) out of the way, and

loosen handle (A). Shift miter gauge body until

it is flush with square, then re-tighten hand le

(A).

19

Page 20

Figure 33

4. Loosen motor lock h andle (G, Figure 34).

5. Raise motor lift handle (H) and retighten motor

lock handle to hold motor in raised position.

6. Remove old belt and install new one, making

sure it seats properly in pulley grooves.

7. Loosen motor lock handle (G) and allow motor

to lower.

8.21 Brushes

Refer to Figure 35.

Two adjustable brushes are located in lower wheel

housing. They should remain in constant contact

with blade or wheel to prevent buildup of gum and

debris.

Figure 35

9.0 Operating Controls

9.1 Start/Stop

Figure 34

8. The weight of the motor itself should produce

proper tension for the belt. Check tension by

pushing with moderate pressure on the belt

halfway between the pulleys. An adequately

tensioned belt will deflect about 1/2”. If tension

isn’t s trong enough, push down on motor.

9. Tighten motor lock handle (G).

10. Reinstall lower wheel, and tighten screw (F)

securely.

11. Install blade, and verify blade tension and

tracking before operating (sections 8.11 and

8.12).

Refer to Figure 36.

Power Indicator Light – The start switch (A) has

a power indicator lamp which is on whenever

there is power connected to the band saw, not

just when the band saw is running. Do not

assume that no light means there is no power

to the machine. If the bulb is bad, t here will be

no indication. Always check before use.

Do not rely that no lig ht means

no power to the machine. Always check for power

first. Failure to comply may cause serious injury!

Start – Press green start switch (A).

When power is connected to machine, the green

light is always on regardless of whether band saw

is running or not.

Stop – Press red switch (B) to stop.

Reset – If band saw stops witho ut pressing the

stop button (as result of tripped fuse or circuit

breaker, etc.) proceed as follows:

1. Press red switch to reset.

2. Press green switch to restart machine.

20

Page 21

Figure 36

before opening guards/doors, making adj ustments,

or leaving the area.

10.0 Operation

The following section contains basic information,

and is not intended to cover all possible

applications or techniques using the band saw.

Consult pub lished sources of inform ation, acquire

formal training, and/or talk to experienced band

saw users to gain proficiency and knowledge of

band saw operations.

(The following figures may or may not show your

specific model, but procedures are the same.)

9.2 Safety Key

The start/stop switch on the Band Saw comes

equipped with a magnetic safety key (C, Figure

36). When in place on the switch, the magnetic

safety key trips a relay which will allow the machine

to start and stop when the respective switches are

pressed. Being magnetic, the lock can be removed

to make the machine inoperable and can be

hidden for safe storage by attaching it to another

magnetic surface.

When using the band saw, place the key on the

switch cover, lining up arrow on key with REMOVE

arrow on cover. Then rotate key so that arrow li nes

up with LOCK arrow on cover. This will prevent the

safety key coming loose from vibration when

machine is in use.

9.3 Brake Pedal

When the stop button is used to shut off the band

saw, the blade will coast slowly to a stop. An

alternate method of stopping the machine is to

press and hold the brake pedal, shown in Figure

37. The blade will stop moving in approximately

three to four seconds after pedal is pressed.

Restart saw by pressing start switch on column.

NOTE: Unnecessary and excessive use of brake

pedal may shorten life of brake pad.

10.1 General Procedure

1. Make sure blade is adjusted correctly for

tension and tracking, and that upper and lower

guide bearings and thrust bearings are set in

proper relation to blade.

2. Adjust guide post so that guide bearings are

just above workpiece (about 1/8”) allowing

minimum exposure to blade.

3. If using the fence, move it into position and

lock it to guide rail. If using miter gauge for a

crosscut, the fence should be moved safely

out of the way.

4. Turn on band saw and allow a few seconds for

machine to reach full speed.

Whenever possible, use a push

stick, hold-down, power feeder, jig, or similar

device while feeding stock, to prevent your hands

getting too close to the blade.

5. Place the straightest edge of the workpiece

against the fence for a rip cut; or against the

miter gauge for a crosscut. Push workpiece

slowly into blade, while also keeping it pressed

against fence or held against miter gauge. Do

not force workpiece into blade.

Additional operating tips:

Make relief cuts whenever possible. A relief cut is

an extra cut made through the waste port ion of a

workpiece up to the layout line. When that

intersection is reached by the blade while following

the layout line, the waste portion comes free. This

helps prevent pinching of the back edge of the

blade in the cut.

Figure 37

After machine is shut off, allow

wheels and blade to come to a complete stop

When cutting, do not overfeed

blade; overfeeding will reduce blade life, and may

cause blade to break.

When cutting long stock, the operator should use

roller stands, support tables, or an assistant to help

stabilize the workpiece.

21

Page 22

10.2 Ripping

Ripping is cutting lengthwise down the workpiece,

along the grain of wood. See Figure 38. Always

use a push stick or similar device when ripping

narrow pieces.

Figure 38 (ripping)

10.3 Crosscutting

Crosscutting is cutting across the grain of the

workpiece, while using the m iter gauge to feed t he

workpiece into the blade.

The right hand should hold workpiece steady

against miter gauge, while left hand pushes miter

gauge past blade, as shown in Figure 39.

Do not use fence in conjunction wit h miter gauge.

The offcut of the workpiece must not be

constrained during or after the cutting process.

The ideal blade for resawing is the widest one the

machine can handle, as the wider the blade the

better it can hold a straight line.

Resawing can be performed using the aluminum

fence plate or the resaw pin. When using the plate,

use a push block, push stick, or similar device to

keep your hands away from the blade. The resaw

pin o ff ers a pivo t po int b y w hic h you c an c aref ull y

follow your layout line; it is especially useful for

sawing curves, when the fence cannot be used

and it is difficult to control the cut freehand.

Figure 40 demonstrates resawing with the

aluminum plate; Figure 41, with the resaw pin.

Figure 40 (resawing)

Using the fence in conjunction

with miter gauge can cause binding and possible

damage to blade.

Figure 39 (crosscut)

10.4 Resawing

Resawing is the process of slic ing stock to reduce

its thickness, or to prod uce boards t hat are thinner

than the original workpiece, such as veneers.

Figure 41 (resaw pin)

10.5 Blade Lead

Blade lead, or drift, is when the blade begins to

wander off the cutting line even when the band

saw fence is being used. Figure 42 shows an

example of blade lead. It is more common with

small, narrow blades, and is almost always

attributable to poor blade quality, or lack of proper

adjustments. Inspect the band saw for the

following:

• Fence not parallel to miter slot and blade.

• Blade not tensioned correctly.

• Blade is dull.

• Teeth have excessive “set” on one side of

blade.

• Workpiece being fed too quickly.

22

Page 23

Figure 42

If the blade is suspect, but replacing it is not

currently an option, the blade lead can be

temporarily compensated for by skewing the fence:

1. Cut a scrap piece of wood about the same

length as the band saw table, and joint one

edge along its length, or rip it on a table saw to

give it a straight edge.

2. Draw a line on the board parallel with the

jointed, or straight edge of the board.

3. Move the band saw fence out of the way, and

carefully make a freehand cut along your

drawn line on the board. Stop about midway

on the board, and shut off the band saw (allow

blade to come to a complete stop) but do not

allow the board to move.

4. Clamp the board to the table.

5. Slide the band saw fence over against the

board until it contacts t he straight edge of the

board at some point. Lock the fence down.

6. Use the back adjustment screws (F, Figure 13)

to line up fence against board.

NOTE: Skewing the fence to correct b lade lead is

effective for that particular blade; when a new

blade is installed, the fence will need re-adjustment

and re-squaring to miter slot. See appropriate

sections in this manual.

11.0 Maintenance

Before doing maintenance on

the machine, disconnect it from electrical supply by

pulling out plug or switching off main switch!

Failure to comply may cause serious injury.

Clean band saw regularly to rem ove any resinous

deposits and sawdust.

Keep miter slot, and guide bearings, clean and free

of resin.

Keep blade clean and sharp. Check it periodically

for cracks or other signs of wear.

The drive belt should be c hecked periodically. If it

looks worn, frayed, glazed or otherw ise damaged,

replace it.

Remove any deposits from band wheels to avoid

vibration and potential blade breakage.

Vacuum or blow out dust from inside cabinet. (Use

proper dust mask equipment).

The table surface must be kept clean and free of

rust for best results. If rust appears, it can often be

removed with a mixture of household ammonia,

good commercial detergent and #000 steel wool.

Alternatively, commercial rust removers can be

found at many hardware stores.

Apply a light coat of paste wax to table. There are

also products in aerosol form available in major

hardware stores and supply catalogs. Whatever

method is chosen, the coating should protect the

metal and provide a smooth surface, without

staining workpieces.

If the power cord is worn, c ut, or damaged in any

way, have it replaced immediately.

11.1 Lubrication Points

1. Periodically apply a light, non-hardening

grease to rack and pinion system of guide post

(Figure 43).

Figure 43

2. Grease the sliding surfaces of the table

trunnions (Figure 44).

23

Page 24

Figure 44

3. Grease blade tension screw (Figure 45).

Figure 45

4. Oil any pins, shafts, and j oints. (Do not get oil

on pulleys or belts.)

Note: Bearings on the band saw are pre-lubricated

and sealed, and do not require attention.

Width

Band saw blades come in different standard

widths, measured from back edge of blade to tip of

tooth. Generally, wider blades are used for ripping

or making straight cuts, such as resawing.

Narrower blades are often used when the part

being cut has curves with small radii. When cutting

straight lines with a narrow blade, the blade may

have a tendency to drift (see section 10.5).

Pitch

Pitch is measured in “teeth per inch” (TPI) and can

be constant or variable. Figure 46 shows blades

with different pitches.

A fine pitch (more teeth per inch) will cut slowly but

more smoothly. A coarse pitch (fewer teeth per

inch) will cut faster but more roughly.

As a rule of thumb, the thicker the workpiece, the

coarser will be the blade pitch. If you have to cut a

hard or very brittle materia l, you will probab ly want

to use a blade with a finer pitch in order to get

clean cu ts .

Using a blade with too few teeth may cause

vibration and a rough cut, while too many teeth

may cause the gullets to fill with sawdust and

overheat the blade.

As a general rule, use a blade that will have from 6

to 12 teeth in the workpiece at any given time.

12.0 Blade Selection

Using the proper blade for t he job will increase t he

operating efficiency of your band saw, help reduce

necessary saw maintenance, and improve your

productivity. Thus, it is important to follow certain

guidelines when selecting a saw blade.

Here are factors to consider during selection:

• Type of material you will be cutting.

• Thickness of workpiece.

• Features of workpiece, such as bends or

curves with small radii.

These factors are important because they involve

basic concepts of saw blade desig n. There are f ive

(5) blade features that are normally changed to

meet certain kinds of sawing requirements. They

are:

1. width

2. pitch (number of teeth per inch)

3. tooth form (or shape)

4. “set” of the teeth

5. the blade material itself

Figure 46 – Blade Pitch

Shape

Figure 47 shows common types of tooth shape, or

form. Tooth shape has an effect on cutting rate.

The Regular, or standard blade, has evenly spaced

teeth that are the same size as the gullets, and a

zero-degree rake (i.e. cutting angle). These offer

precise, clean cuts at slower rates. It is usually a

good choice for cutting curves and making

crosscuts.

The Skip type has fewer teeth and larger gullets

with a zero rake. It allow s faster cutting rates t han

the Regular type, with a s lightly coarser fi nish. It is

useful for resawing and ripping thick stock, as well

as cutting softwoods.

24

Page 25

The Hook type blade has larger teeth and gullets

and a positive rake angle for more aggressive,

faster cutting when resawing or rippi ng thick stock,

especially hardwoods.

Variable-tooth blades combine features of the other

shapes, with tooth style and spacing varying on the

same blade. This produces smooth cuts while

dampening vibration.

Figure 47 – Blade Tooth Shape

Set

The term “set” refers to the way in which the saw

teeth are bent or positioned. Bending the teeth

creates a kerf that is wider than the back of the

blade. This helps the operator m ore easily pivot a

workpiece through curve cuts, and decreases

friction between blade and workpiece on straight

cuts.

Set patterns are usually selected depending upon

the type of material that needs to be cut. Three

common set patterns are shown in Figure 48.