Page 1

This .pdf document is bookmarked

Instructions and Parts Manual

PM1300 Dust Coll ect or

PM1300 with Fil ter Bag Ki t (1791077BK) PM1300 with Canister Ki t (1791077CK)

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M- 1791077

Ph.: 800-274-6848 Revision C 11/2010

www. powermatic.com Copyright © 2010 Walt er Meier (M anufacturi ng) Inc.

Page 2

W arranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Serv ice Cent ers located t hroughout t he U nited States can g iv e you quick service. In m ost cases, any of these Walter

M eier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance

and m ajor repair on your POWERM A TIC® tools. For the name of an Authorized Serv ice Center in y our area call 1-800-2 74-684 8.

MO RE INF ORM AT ION

Walter Meier is consistently adding new products to the line. For com plete, up-to-date product inform ation, check with your local

Walter Meier distributor, or visit powermatic.com .

WARRANTY

POWERMATIC products carry a lim ited warranty w hich v aries in duration based upon the product.

WH AT IS CO VERED?

This warranty cov ers any defects in w orkm anship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consum ables are exc luded from warranty cov erage.

WHO IS CO VERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the tim e period specif ied in the product lit erature of each product.

WH AT IS NO T COVERED?

The Five Year Warranty does not cover products used f or commercial, industrial or edu cational purposes. Products w ith a Five

Year Warranty t hat are used f or comm ercial, indust r ial or education purposes revert t o a O ne Y ear Warranty. This w arranty does

not cov er defects due directly or indirectly t o misuse, abuse, negligence or accidents, norm al w ear-and-tear, improper repai r or

alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part m ust be returned for exam ination, post age prepaid, to a locat ion designated by us. For the nam e of t he

location nearest y ou, please call 1-800- 274-6848.

You must provide proof of initial purchase date and an explanation of the com plaint m ust accom pany the m erchandise. If our

insp e c tion disclose s a d e fec t, we will repa ir or re pla c e the p r oduct , or refund t he purchase pr ice, at our opt ion.

We will re turn the r e p aired p r oduct or re plac ement at our expense unless it is determined by us that there is no defect, or that th e

defect resulted f rom causes not within the scope of our warranty in which case we w ill, a t you r dire ct ion , d ispo se o f or ret urn t h e

product. I n t he event you choose to have the product returned, you will be r e sponsib le for the handling and sh ipp ing c ost s of t he

return.

HOW STATE LAW APPLIES

This warranty giv e s you specific legal rights; you may also have other rights which vary from st ate to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR M ERCHANTABILITY

AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION M AY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATI ON OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sel ls through distributor s only. The specificatio ns in Walter Meier catalog s are g iv en as general inform ation and are

not binding. Members of Walter Meier reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment w hich they m ay deem necessary f or any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Service..........................................................................................................................2

Table of Contents ...............................................................................................................................3

Warn in g .............................................................................................................................................4

In trodu ction ........................................................................................................................................6

Spe cifi cation s .....................................................................................................................................6

Unpacking ..........................................................................................................................................7

Contents of Shipping Carton ............................................................................................................7

Base Machine Assembly .....................................................................................................................8

Base and Casters ............................................................................................................................8

Motor and Fan Assembly .................................................................................................................8

Connector Tube and Switch Box ......................................................................................................8

Collector Housing ............................................................................................................................8

Support Bar ....................................................................................................................................8

Han dle s ..........................................................................................................................................9

Cone Installation .............................................................................................................................9

Filter System ...................................................................................................................................9

Filter Bag System Assembly .............................................................................................................. 10

Canister System Assembly ................................................................................................................ 11

Electrical Connect io ns....................................................................................................................... 12

Extension Cords ............................................................................................................................ 12

Overload Re-set ............................................................................................................................... 12

Operating the Machine ...................................................................................................................... 13

Setting the Timer ........................................................................................................................... 13

Connecting the Dust Collector to a Machine .................................................................................... 13

Mai nten ance .................................................................................................................................... 13

Cleaning the Filter Bag .................................................................................................................. 13

Removing the Collector Bag ........................................................................................................... 13

Cleaning the Canister Filter ............................................................................................................ 14

Motor ............................................................................................................................................ 14

Grounding I nstructions ...................................................................................................................... 14

Replacement Parts ........................................................................................................................... 15

Breakdown for PM1300 Dust Collect or ( Base Mac hine) ................................................................... 15

Parts List for PM 1300 Dust Collector (Base M achine) ...................................................................... 16

Breakdown for PM 1300 Canister Filter Sys t em ................................................................................ 18

Parts List for PM1300 Canister Filter Syst em .................................................................................. 19

Parts List for PM1300 Filter Bag Syst em ......................................................................................... 20

Electrical Connect io ns ................................................................................................................... 21

3

Page 4

Warning

1. Read and understand t he entire owner’s manual befor e attempting assembly or operation.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serio us injury.

3. Replace the warning labels if they become obscured or removed.

4. This dust collector is designed and intended for use by properly t rained and experienced personnel

only. If you are not familiar w ith the proper a nd safe oper ation of a dust collect or, do not use unt il

proper t r aining and knowledge have been obtained.

5. Do not use this dust collector f or other than its intended use. If used for other purposes, Walter Meier

(Manufacturing) Inc., disclaims any real or implied w arranty and holds itself harmless f rom any injury

that may result from that use.

6. Always wear approved safety glasses/face shields while using this dust collector. Everyday

eyeglasses only have impact r esist ant lenses; t hey are not safet y glasses.

7. Keep hair, loose clothing, f ingers, and all parts of body aw ay from opening and moving parts.

8. Wear ear pr otect or s (plugs or muffs ) during exte nded periods of oper at ion.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals k nown to cause cancer, birth defects or ot her repr oductive har m. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and ot her masonry products.

• Arsenic and chromium fr om chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate t his machine while tired or under the influence of drugs, alcohol or any medication.

11. Make cer tain the switch is in the OFF positio n before connecti ng the machi ne to t he power supply.

Turn off all controls before unpl ugg i ng.

12. Make c er t ain the machine is properly grounded. Co nnect t o a pr oper ly grounded outlet only.

13. Make all machine adj ustments or mainte nance with the mac hi ne unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the mac hine before tur ning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme cautio n and replace t he guards immed iately af t er maintenance is complet e.

16. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignme nt of moving part s, binding of moving part s, break age of part s, mounting

and any other condit ions t hat may affect its oper ation. A guard or other part that is damaged s hould

be properly repaired or r eplaced.

17. Provide for adequate space surrounding work ar ea and non-glare, overhead lighti ng.

18. Keep the floor around t he machi ne clean and free of scr ap material, oil and grease.

19. Keep visitors a safe distance from the work area. Keep children away.

4

Page 5

20. Make your workshop child proof with padlocks, master switches or by removing starter keys.

21. Give your work undivided att ention. Looking aro und, carrying on a conversat ion and “horse- play” are

careless acts that can result in serious injury.

22. To reduce the risk of electr ic shock, do not use outdoors or on wet surfaces.

23. Do not use the dust collector for anything except wood dust. Materials such as liquids, metal

shavings, metal dust, screws, glass, plastic or rock can cause sparks and/ or damage when coming

into contact with any part of the dust collector.

24. Do not pick up anything that is bur ning or smoking, suc h as cigarett es, matc hes or hot ashes.

25. Do not use to pick up flammable or c ombustible liquids s uch as gasoline or use in areas w here they

may be present.

26. Do not pull or carry by cord, use cord as a handle, close a door on cord, or pull cord ar ound sharp

edges or corners. Do not run dust collector over cor d. Keep cor d away from heated surfaces.

27. Do not use this dust collector w ith a damaged cord or plug.

28. Do not unplug by pulling on cord. To unpl ug, grasp the plug, not the cord.

29. Do not use without dust bag and/or f ilter s in place.

30. Do no t handle plug or m achine wi th we t hands.

31. Do not put a ny objects into t he openi ngs. Do not use with any openi ng blocked; keep f r ee of dust, lint,

hair, and anything that may reduce air flow .

32. Do not operat e without hose co nnected to the inlet. Hazardo us mo ving parts i nside. Unplug bef ore

removing inlet or inlet guard.

33. Use recommended acces sor ies; improper acces sor ies may be ha zardo us.

34. Maintain tools with care. Follow instructions f or lubricating and c hangi ng accessories.

35. Turn off the mac hine and disconnect from pow er befor e cleaning. Use a brus h or compressed air t o

remove chips or debris — do not use your hands.

36. Do not leave the machine when it is plugged in. Unplug from outlet when not in use and before

servicing.

37. Do not stand on the machine. Serious injury could occur if the machine tips over.

Familiarize yours elf with the f ollow ing saf et y not ices used in t his manual:

This means that if precautions are not heeded, it may result i n minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serio us injury or possibly

even death.

- - SAVE THES E I NSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Walter Meier (Manufacturing) Inc., covering the safe operation and

maintenance procedures for a Powermatic Model PM1300 Dust Collector. This manual contains

instructions on installation, safety precautions, general operating procedures, maintenance instructions

and parts breakdow n. This machi ne has been designed a nd constructed to pr ovide years of t rouble free

operation if used in accordance with instructions set forth in this manual. If there are any questions or

comments, please contact either your local supplier or Walter Meier. Or visit our web site:

www.powermatic.com.

Specifications

Model...................................................................................................................................... PM1300

Stock Numbers: ....................................................................................................................................

PM1300 Base Machi ne (inc l udes m otor , magnetic s tarter and r emote control) ........................1791077

PM1300 Base Machi ne with Filter Bag Syst em................................................................. 1791077BK

PM1300 Base Machi ne with Canister Filter Syst em .......................................................... 1791077CK

Filter Bag System only ...................................................................................................... 1791077B

Canister Filter System only ..................................................................................................1791086

Impeller Diameter (in.)....................................................................................................................... 12

Sound Rating at 3 feet (dB) .......................................................................................................... 7 5-90

Inlet Port Diameter (in.) ......................................................................................... two at 4”, or one at 6”

Air Flow (CFM) ............................................................................................................................ 1,300

Velocity at 6” (FPM) ..................................................................................................................... 5,374

Static Pressure (inch of water) ...................................................................................................... 11 .31

Filter and Collection Bag Diameter (in.) .............................................................................................. 20

Filter Bag Length (in.)........................................................................................................................ 34

Filter Bag Efficiency ...................................................................................... 96% of 30 micron particles

Canister Length (in.) ......................................................................................................................... 26

Canister Efficiency ................................................... 86% of 1 micron particles; 98% of 2 micron particles

Collector Bag Capacity ( cu. f t .) .......................................................................................................... 10

Remote Control Type ................................................................................................................ infra red

Overall Dimensions with Filter Bag System (LxWxH)(in.) ...................................................... 37 x 29 x 79

Overall Dimensions with Canister System (LxWxH)(in.) ........................................................ 37 x 29 x 72

Motor (TEFC) ......................................................1.75 HP, 1Ph 115/230V (pre-wired 115V), 18/ 9A, 60Hz

Net Weight:

PM1300 with Filter Bag System (approx.) ( lbs.) ............................................................................ 140

PM1300 with Canister System (appr ox.)( lbs. ) .............................................................................. 150

Shipping W e ight:

PM1300 with Filter Bag System (approx.) ( lbs.) ........................................................................... 150

PM1300 with Canister System (appr ox.) ( lbs. ) ............................................................................. 160

The above specificati ons were current at t he time this ma nual w as publis hed, but because of our policy of

continuo us impro vement, Walt er M eier r eser ves the right to change s pecificat ions at any time a nd without

prior notice, without incurring obligations.

6

Page 7

Unpacking

Remove all contents from the shipping carton

and check against the Contents of Shipping

Carton below to verify that all items have been

received.

Report any damage to your distributor.

Do not discard any shipping material until after

the dust collector has been assembled and is

running properly.

Yo u w ill als o req uir e e ither the Filter Bag System

or Canister Filter System. These items are

packaged separat ely and are not listed here.

Contents of Shipping Carton

Refer to Figur e 3 to identify items H–W.

H Base (1)

J Casters (4)

K Motor/Fan Assembly (1)

L Inlet Guard (1)

M Inlet Port w/ Cap (1)

N Lower Gasket ( 1)

O Co nnector Tube (1)

P Control Box (1)

R Upper Gasket ( 1)

S Collector Housing (1)

T Support Bar (1)

U Handle (2)

V Plate (2)

W Socket Head Cap Screw, M 8x12 (4)

-- Remote Control w/ batteries (not shown) (1)

-- Owner's Manual (not shown) (1)

-- Warranty Card (not shown) (1)

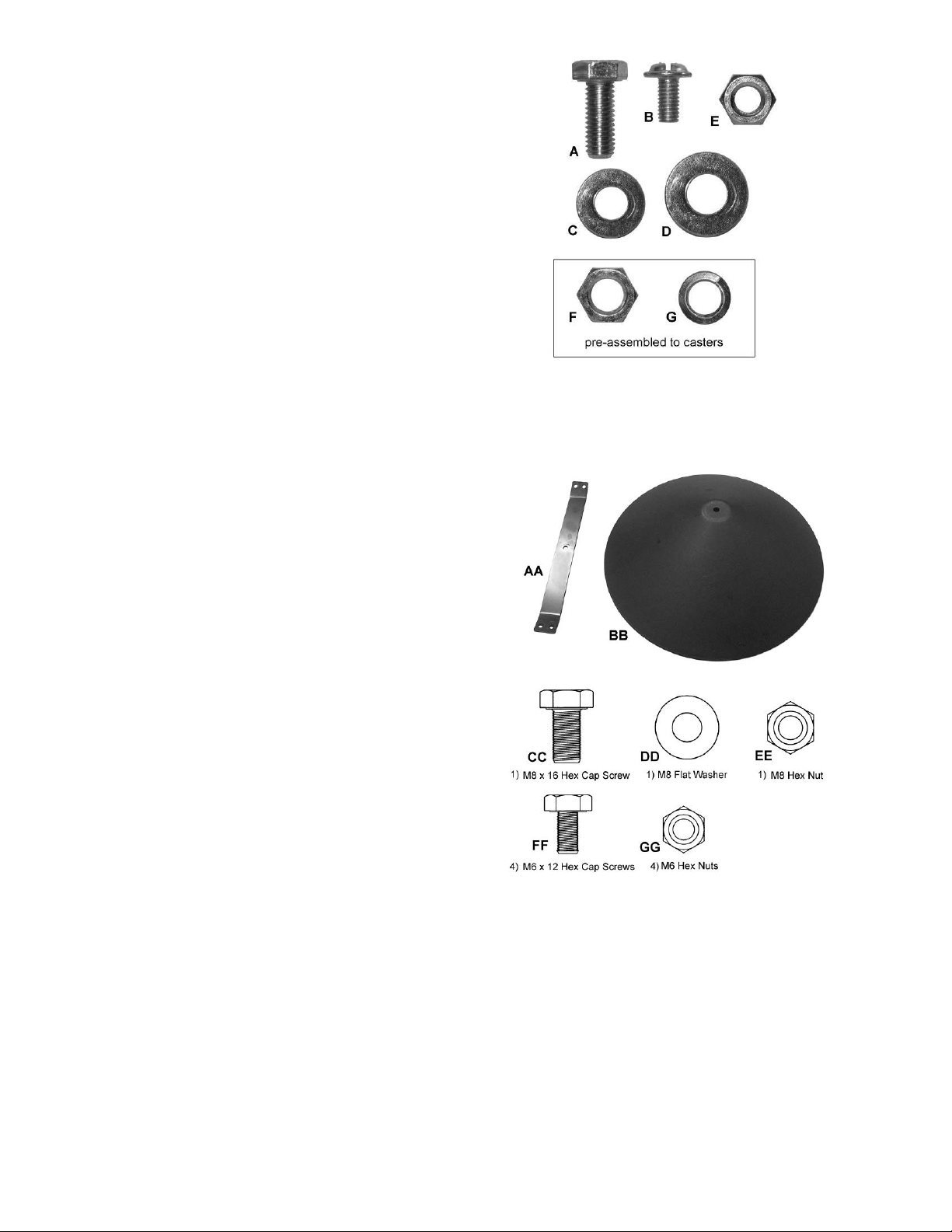

Main Hardware Ba g cont ent s ( Figure 1):

A – M8 x 20 Hex Cap Screws ( 24) *

B – M6 x 12 Pan Head Fla nge Screws ( 8) *

C – M8 Flat Washers (34) *

D – M10 Flat Washers (6) *

E – M8 Hex Nuts (16)*

F – 3/8" Hex Nuts (4) – on c asters

G – M10 Lock Washers (4) – on casters

Cone Assembly and Hard ware ( Figure 2):

AA – Support Bracket ( 1)

BB – Cone (1)

CC – M8 x 16 Hex Cap Screw ( 1)

DD – M8 Flat Washer (1)

EE – M8 Hex Nut (1)

FF – M 6 x 12 Hex Cap Screws ( 4)

GG – M6 Hex Nuts (4)

Figure 1: Main Hardware Bag contents

* A through E compri se PM1300-BMHP

Base Machine Hardwar e Package

Figure 2: Cone Assembl y and Har dware

CC through GG compr ise DC1100-HP2

Cone Assembly Hardware Package

Tools Require d f or Assembly

– 13mm Wrenches or Socket s

– 14mm Wrench

#2 Cross Point Screw Driver

6mm hex (“Allen”) wrench

7

Page 8

Base Machine Assembly

The dust collector must not be

connected to t he power source

during assembly. Failure to comply may result

in serious inj u ry!

All instructi ons on this page r efer to Figur e 3.

Base and Casters

1. The 3/8” hex nut (F) and M10 lock washer

(G) ar e pre-assembled to each caster (J) . For

shipping purposes, the lock washer has been

placed beneat h the hex nut. Remove hex nut

and lock washer from the caster shaft, reinstall the hex nut, then install the lock

washer above the hex nut, as shown.

2. I nstall the four casters (J) to t he underside of

the base (H) as follows:

3. Thread the caster shaft into the threaded hole

on the underside of the base (H), turn until

snug. Tighten the hex nut (F) against the

base with a 14mm wrench.

M otor and Fan Assembly

1. Place the base with casters down on the

ground.

2. Attach the motor and fan assembly (K) to the

base (H) using six M8x20 hex cap screws (A),

and six M10 flat washers (D). Hand tighten only

until all screws and washers are in place, then

adjust the motor a nd fan assembly ( K) until its

flanges are approximately f lus h with the edges

of the base (H). Tighten all screw s with a 13mm

wrench.

3. Attach the inlet guard (L) to fan housing (K)

using eight M6x12 pan head flange scr ews (B).

4. Press the inlet port (M) as far as it will go onto

the inlet guard (L).

To reduce the risk of injury f rom

moving parts, always keep both holes of inlet

port (M) covered with either the pr ovided cap or

dust hoses. Failure to comply may result in

ser io u s injur y !

Connector Tube and Switch Box

1. Place the lower gasket (N) on the fan housing

(K). Line up the rubber pegs on the gasket

(face down) with the holes in the housing.

2. Place the connector tube (O) on the fan

housing (K), making sure that the holes of the

mating flanges are aligned.

Note: Refer to Figure 3 to make sure that the

connector tube is facing the proper direct ion.

3. Insert an M8x20 hex cap screw (A), through the

M8 washer (C) and flanges of the connector

tube (O) and fan housing (K).

4. Place another washer (C) and a hex nut (E) on

the protrudi ng end of t he screw (A) and hand-

tighten only.

5. Mount the control box (P) to the two holes at

the front of the connector tube flange.

6. Repeat steps 3 a nd 4 for the rem aining screw

locations, hand tightening only.

7. Tighten all hex nuts wit h a 13mm wrench.

Collector Housing

Mount the collector housing (S) as follows:

1. Place an upper gasket (R) between the

collector housing (S) and connector tube (O).

Line up the pegs on the gasket (R) with the

holes in the housing (S).

2. Place the collector housing (S) on the

connector tube (O).

3. Insert a screw (A) through the washer (C),

connector tube flange (O), and collectorhousing f l ange (S).

4. Place another washer (C) and a hex nut (E) on

the protrudi ng end of t he screw (A) and hand-

tighten.

5. Repeat steps 1 through 4 for the seven

remaining screw locations.

6. Tighten all hex nuts wit h a 13mm wrench.

Support Bar

1. Align the bottom slots of the support bar (T)

with the holes in the base (H). Insert two

screws (A) and two flat washers (C) and hand

tighten only.

Note: If you are using the Canister Filter

System, proceed with steps 2 through 4

below. I f you are using the Filter Bag Syst em,

leave the support bar (T) as is, for further

assembly later, and proceed t o “ Handles”.

2. Align the top holes of the support bar (T) with

the holes at the rear of the collector housi ng

(S) and insert two screws (A) and two flat

washers (C).

3. Place a washer (C) and a hex nut (E) on the

protruding end of each screw (A) inside the

collector housi ng, and hand-t ig hten only.

4. Adjust the lower par t of the support bar (T) as

needed using its slots, until it is st r aight. Then

tighten all four screws on the support bar (T).

Page 9

Handles

1. Remove the plate (V) from the handle (U) by

loosening the two socket head cap screws

(W) with a 6mm hex wrench.

2. Install handle (U) to the holes in the collector

housing (S) by inserting the soc ket head cap

screws through the handle, the collector

housing, and into the plate on the opposite

side. Tighte n the screw s.

Note: Make sure the plate (V) is oriented

properly, as shown in the Detail in Figure 3:

The protrusions on the plate should face

away from the handle.

3. Install the seco nd handle to the housing.

Cone Installation

Install the cone assembly as shown in Figure 3a.

1. Mount the cone support bracket (AA) to the

housing with fo ur M6x12 hex cap screws (FF)

and tighten from beneath with four M6 hex

nuts (GG).

2. Install the cone (BB) fr om beneath using t he

M8x16 hex cap screw (CC), M8 flat washer

(DD) and M8 hex nut (EE).

Fi l t er S yst em

If your PM1300 Dust Collection system includes

filter bags, proceed to Filter Bag System Assembly

on page 10.

If your PM1300 Dust Collectio n system includes t he

canister kit, proceed to Canister System Assembly

on page 11.

Figure 3: Assembly and hardware identification

9

Page 10

Filter Bag System Assembl y

Note: If your dust collection system includes the

canister kit, proceed to Canister System

Assembly on page 11.

1. Insert a hanger bracket between support bar

and collector housing (Figure 4).

2. Align holes and secure with two M8x20 hex

cap screw s and two M8 flat washers outside

the housing, and two M8 flat washers and

two M8 hex nuts inside the housing. Hand

tighten only.

Figure 5

Figure 4

3. Make any needed adjustments to the

support bar, t hen tighten the two upper and

two low er screws on the support bar with a

13mm wrench.

4. Slide the hanger (Figure 4) onto the hanger

bracket as f ar down as it will g o. Rotat e the

hanger so that the hook at the top points

towar d the front of the machine.

5. Insert the ring (Figure 5) of the collector bag

into the bottom of the housing at an angle.

Pull down on the collector bag t o make sure

it “seat s” on the inner lip of t he housing.

6. Position the plastic window in front so that

you can easily see when collector bag is f ull.

7. Slide the top loop of the filter bag onto the

hanger hook ( Figure 6).

8. Thread the retainer strap (Figure 6) through

the loops on the filter bag, and fasten it to

the collector housing, as shown in Figure 7.

The retainer str ap should be tight enoug h to

provide a good seal.

Figure 6

Figure 7

Retainer strap

connection

10

Page 11

Canister System Assembly

(17mm wrench requi r ed)

9. Place the snap ring over the top of the

plastic collector bag, and fold over the bag

approximately t hree inc hes (Figure 8).

Figure 8

10. Insert t he snap ri ng of the collector bag into

the bottom of the housing at an angle

(Figure 9).

11. Pull down on the snap ring to make sure it

“seats” on the inner lip of the hous i ng.

Note: Make sure the snap ring “snaps” into

place in the housing, and also that the

plastic bag hangs down approximately 3

inches so that there are no air leaks.

12. Remove t he handle (Figure 10) from inside

the cani ster filter. M ount t he handle onto the

canister fil ter with two M10 hex nuts (A), two

M10 flat washers (B), and an M10 lock

washer (C). Arrange these fasteners

accordi ng to Figure 10. Tighten with a 17mm

wrench.

Figure 9

13. Place the canister on top of t he housing, and

push down to e nsure the canist er is seated

on the ho using.

14. Insert and tighten the four knobs into the

threaded holes on the canister ( Figure 10).

Note: The Powermatic® label on the front of t he

canister should have a negligib le effect upon air

flow. However, if zero effect is desired, t he label

can always be peeled off.

Figure 10

11

Page 12

Electr ical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be prop erly grounded t o help

prevent electrical shock and possible fatal

injury.

The PM1300 is equipped with a single phase,

115/230 volt motor. It is factory wired for 115

volts. Keep in mind that a circuit bei ng used by

other machines (tools, lights, heaters, etc.) at

the same time will add to the electrical load.

Thus, it is recommended that the machine be

connected to a dedicated circuit, w ith a 30 amp

circuit breaker or f use for 115 volt operation; a nd

a 20 amp circuit breaker or fuse for 230 volt

operation. Local codes will take precedence

over recommendations.

The dust collector can be re-wired for 230V

operation as follows:

To convert to 230 volt operat ion:

1. Disconnect from power sour ce; unpl ug!

2. Connect the motor leads as shown in the

diagram inside the motor junction box; this

diagram is also shown on page 21 of this

manual.

3. O pen the control box cover by remo ving the

six screws, and move the voltage switch to

230V.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly gr ounded.

Repair or replace a damaged or worn cord

immediately.

Extension Cords

If an extension cord is needed, make sure t he

cord rating is suitable for the amperage listed on

the machine’s motor plate. An undersize cord

will c a use a dr op i n li ne vo ltage r esulting in loss

of power and overheating.

Use the chart in Figure 11 as a general guide in

choosing the correct size cord. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Rec o mm e nd ed G a uge s (A W G) of E xte n si on C ord s

Extension Cord Length *

25

50

75

100

150

200

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

feet

feet

feet

feet

feet

feet

4. Replace t he plug on t he power cord w ith an

appropriate UL/CSA listed 230V p l ug.

5. When finished wiri ng, re-install juncti on box

and control box covers.

Ground i ng Inst r uct ions

This machine must be grounded. I n the event of

a malfunction or breakdow n, grounding provides

a path of least resistance for electric current to

reduce the risk of elect r ic shock.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor . If repair or replacement of

the electric cord or plug is necessary, do not

connect t he equipment-gr ounding conductor t o a

live terminal.

The hose or ductwork you use to connect the

tool to t he dust collector must also be grounded.

Make sure the voltage of your power supply

matches the specificat ions on the motor plate of

the dust collector.

*based on limit in g the line voltage drop to 5V at 150% of the

rated am per es.

NR: Not Recommended.

Figure 11

Overload Re-set

If t he Dust Coll ector overloa ds during operatio n,

press the re-set switch on the motor, shown in

Figure 12. Then re-start the machine.

Figure 12

12

Page 13

Operating the Machine

Connect the dust collector t o the power source.

If powe r is flo wing, a gr een in dicat or will lig ht o n

the face of the control panel.

To operate t he machine, use t he butto ns on the

control panel, or use the provided remote

control. To start the dust collector, pr ess the ON

button. If the remote control is used, aim it at the

control panel. The machine will remain running

until the OFF button is pressed. The digital

readout will always dis play 0 0 while running.

The remote control operates on two AAA

bat terie s . These will need replacing per iodica lly.

NOTE: The infrared sensor on the dust c ollector

has a 120° line-of-sight angle. See Figure 13.

Outside of this angle, the remote control may not

be effective.

Con nectin g the Dust Collect or to a

Machine

Use the proper type hose to connect the dust

collector to t he machi ne bei ng operated. Dryer

vent hose is not acceptable for this purpose.

Contact your nearest Powermatic distributor for

a full line of Dust Collector hoses and

accessories. You can customize your installatio n

and obtain maximum performance with dust

hoods, hoses, clamps, fitt ings, a nd blast gates.

Maintenance

Never perform maintenance

on this machine before turning it OFF and

removing p lug from power sour ce. Fa ilure to

comply may cause serious injur y!

Clean i ng the Filter Bag

Wearing a particle mask or

respirator for protection against fine dust

particles during cleaning is highly

recommended.

Figure 13

Setting the Timer

While the machine is running, press the TIME

button to activate the timer. Each time the button

is pressed and released, the run time is

incremented on the dig ital display by one minute

and can be set up to 99 minutes.

If t he TIME button is pressed and held, t he time

will scroll up to 99 minutes, then start again at

00. Release the button when the desired set

time is reached. The dust collector will run for

the amount of time displayed on the digital

display. If you scroll past 99 and release the

button at 10, for example, the machine will run

for ten minutes, not 110 minutes.

If the OFF button is pressed while machine is

running with the timer engaged, the machine

turns off and t he timer is dise ngaged; i.e., when

the machine is restarted, the timer must be

reset.

During first use a nd after cleaning, t he filter bag

may allow some d ust to esc ape. This is normal

and will stop aft er a short period of time.

Clean both the filter and collector bags

frequently to keep t he collector 's perf ormance at

its optimum. To clean:

1. Disconnect machi ne from the power s ource.

2. Unhook the filter bag from the hanger.

Shake the bag so that the majority of the

dust falls into the collector bag.

3. Loosen the retai ning str ap, and remove the

filter bag from the housing.

4. Turn the bag inside-out and clea n.

5. Turn the bag outside-i n and re-at tach to the

housing using the retainer str ap t o secure.

Removi n g the Collect or Bag

1. Disconnect machi ne from the power s ource.

2. Remove the collector bag by pushing the

ring of the collector bag upwards and pulling

the bag out at an angle.

3. Empty the contents into an appropriate

container.

4. Turn the bag inside-out and clea n.

5. Turn the bag outside-in and insert into the

housing.

13

Page 14

Clean i ng the Canist er Filter

Clean the canister filter frequently to keep the

collector's per formance at its opti mum. To clea n

the filter, turn the handle a couple of rotations so

the dust f alls into the clear plastic bag. Properly

discard the plastic collector bag when f ull.

Motor

Make fr equent inspections of the motor fan and

blow out (with low pressure air hose) or vacuum

any accumulatio n of for eign mater ial in order to

maintain nor mal motor ventilation.

Grounding Instructions

1. For all grounded, cord-connected tools:

This tool must be grounded. In the event of a malfunction or breakdown, grounding provides a path of least

resistance for electric current to reduce the risk of electric shock. This tool is equipped with an electric cord having an

equipment-grounding conductor and a grounding plug. The plug must be inserted into a matching outlet that is

properly installed and grounded in accordance with all local codes and ordinances.

WARNING: Improper connection of the equipment-grounding conductor can result in a risk of electric shock.

The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal. Do not modify the plug provided - if it will not fit the outlet, have the proper

outlet installed by a qualified electrician.

Check with a qualified electrician or service personnel if the grounding instructions are not completely

understood, or if in doubt as to whether the tool is properly grounded.

2. For grounded, cord-connected tools rated le ss than 15 am peres and intended for use on a nom inal

120V supply circuit:

This tool is intended for use on a nominal 120V circuit, and has a ground ed plug that looks like the plug

illustrated Sketch A in Figure 14. The tool has a grounding prong that looks like the plug illustrated in Sketch A in

Figure 14. A temporary adapter that looks like the adapter illustrated in Sketch B, may be used to connect this plug to

a 2 pole receptacle as shown in Sketch C if a properly grounded outlet is not available. The temporary adapter should

be used only until a properly grounded outlet (sketch A) can be installed by a qualified electrician. The green-colored

rigid ear, lug, and the like, extending from the adapter must be connected to a permanent ground such as a properly

grounded outlet box cover. Note: In Canada, the use of a temporary adapter is not permitted by the Canadian

Electrical Code.

Figure 14

3. For all other grounded, cord-connected tools:

This tool is rated more than 15 a mperes and is intended for use on a circuit having a no minal rating more

than 120 volts, and is factory-equipped with a specific electric cord and plug to permit connection a proper electric

circuit. Make sure that the tool is connected to an outlet having the same configuration as the plug. No adapter should

be used with this tool. If the tool must be reconnected for use on a different type of electric circuit, the reconnection

should be made by qualified service personnel.

14

Page 15

Replacement Parts

Replacement Parts are listed on the following pages. To order parts or reach our service department, call 1-800-2746848, Monday through Friday (see our website for business hours, www.powermatic.com). Having the Model Number

and Serial Number of your machine available when you call will allow us to serve you quickly and accurately.

Breakdown for PM1300 Dust Co llecto r ( Base Mach ine)

15

Page 16

Parts L ist for P M1300 Du st Collect or (Base Machine)

Index No. Par t No. Description Size Qty

1 .............. PM1300-101............Impeller Ho using................................................................................. 1

2 .............. PM1300-102............Housing Bracket ................................................................................. 1

3 .............. PM1300-103............Motor Bracket ..................................................................................... 1

5 .............. PM1300-105............Motor...................................................1-3/4HP, 115/230V, 1Ph .............. 1

................ PM1300-105MF .......Motor Fan (not shown) ........................................................................ 1

................ PM1300-105MFC ....Motor Fan Cover (not shown) .............................................................. 1

................ PM1300-105SC2 .....Starting Capacitor ( not shown)...........................300MFD, 125VAC ....... 1

................ PM1300-105RC2 .....Running Capacitor ( not show n) ..........................90µF, 250VAC............ 1

................ PM1300-105CS .......Centrifugal Switch (not shown) ............................................................ 1

................ PM1300-105RS .......Reset Switch (not shown) ..................................18A............................ 1

6 .............. PM1300-106............Motor Cord ......................................................................................... 1

7 .............. PM1300-107............Connector Tube .................................................................................. 1

8 .............. PM1300-108............Power Cord ......................................................14AWG x 3C .............. 1

9 .............. 420051....................Motor Ga sk e t...................................................................................... 1

10 ............ 430006....................Impeller ............................................................12” ............................. 1

11 ............ PM1300-111............Inlet Guard ......................................................................................... 1

12 ............ PM1300-112............Inlet Port ..........................................................2 @ 4”........................ 1

13 ............ 420203....................Inlet Cap ............................................................................................ 2

14 ............ 430034....................Rubber Gasket ................................................................................... 1

15 ............ PM1300-115............Base .................................................................................................. 1

16 ............ 402036....................Caster ................................................................................................ 4

17 ............ PM1300-117............Hou sing ............................................................................................. 1

18 ............ PM1900-122............Support Bar ........................................................................................ 1

19 ............ PM1300-119............Remote Control Switch Assembly ......................115/230V ................... 1

19-1 ......... DC RC-108 ..............S wi tc h Box ......................................................................................... 1

19-2 ......... DC RC-105 ..............D igi tal Swi tc h ...................................................................................... 1

19-3 ......... DC RC-106 ..............C ircuit Board ........................................................................... ........... 1

19-4 ......... DC RC-104 ..............S e a l ................................................................................................... 1

19-5 ......... DC RC-103 ..............S wi tc h Pl a te ............................................................................ ........... 1

19-6 ......... PM1900-108-6 .........Pan Head Screw...............................................M5x 8 ......................... 4

19-7 ......... DC RC-102 ..............S c re w ................................................................................................ 3

19-8 ......... ST039304 ...............Tapping Screw .................................................M3.5x12 ..................... 6

19-9 ......... DC RC-111 ..............T apping Screw .................................................M3.5x10 ..................... 1

................ PM1900-108-10 .......Display Label (not shown) ................................................................... 1

20 ............ PM1900-107............Mount Plate ........................................................................................ 1

21 ............ PM1900-129............Remote Control .................................................................................. 1

................ PM1900-129-1 .........Remote Control Label (not show n) ....................................................... 1

22 ............ ...............................Battery (local purchase) ....................................AA A ........................... 2

23 ............ 430035....................Rubber Gasket ................................................................................... 1

24 ............ 430036....................Rubber Gasket ................................................................................... 1

25 ............ PWBS14-254SN ......POWERMATIC Nameplate, Sm all ....................................................... 1

26 ............ 31A-208-2 ...............Strain Relief .....................................................PGA13.5 .................... 2

27 ............ PM1900-127............Han dle ............................................................................................... 2

28 ............ PM1900-128............Fastening Plate .................................................................................. 2

29 ............ TS-1490031 ............Hex Cap Screw ................................................M8x20...................... 24

30 ............ 6714154 ..................Hex Cap Screw ................................................1/4-20 x 3/8 ................ 2

31 ............ TS-2361061 ............Lock Washer ....................................................M6 ............................. 2

32 ............ KS050525 ...............Key ..................................................................5x5x25 ....................... 1

33 ............ TS-1550041 ............Flat Washer......................................................M6 ............................. 2

34 ............ TS-1540061 ............Hex Nu t............................................................M8 ........................... 20

35 ............ TS-0561031 ............Hex Nut............................................................3/8-16 ........................ 4

36 ............ TS-0561072 ............Hex Nut............................................................5/8-18UNF ................. 1

37 ............ TS-1490011 ............Hex Cap Screw ................................................M8x12...................... 11

39 ............ TS-1490041 ............Hex Cap Screw ................................................M8x25........................ 4

40 ............ SF069300 ...............Pan Head Flange Screw ...................................M6x12...................... 10

41 ............ TS-1550061 ............Flat Washer......................................................M8 ........................... 42

42 ............ TS-1550071 ............Flat Washer......................................................M10 ........................... 6

16

Page 17

43 ............ TS-155010 ..............Flat Washer......................................................M16 ........................... 1

44 ............ TS-2361018 ............Lock Washer ....................................................M8 ........................... 15

45 ............ TS-2361101 ............L ock Wash er ....................................................M10 ........................... 4

46 ............ TS-1504021 ............Socket Head Cap Screw ...................................M8x12........................ 4

50 ............ 998621....................Strain Relief ....................................................................................... 2

51 ............ PM1300-151............Inlet Guard ......................................................................................... 2

52 ............ 990855....................Pan Head Flange Screw ...................................3/16”x1/2”................... 1

53 ............ DC RC-111 ..............T apping Screw .................................................M3.5x10 ..................... 4

55 ............ PM1300-155............Cone.................................................................................................. 1

56 ............ DC1100-47-1 ...........Support Bracket .................................................................................. 1

57 ............ TS-1490021 ............Hex Cap Screw ................................................M8x16........................ 1

58 ............ TS-1550061 ............Flat Washer......................................................M8 ............................. 1

59 ............ TS-1540061 ............Hex Nut............................................................M8 ............................. 1

60 ............ TS-1482021 ............Hex Cap Screw ................................................M6x12........................ 4

61 ............ TS-231061 ..............Hex Nut............................................................M6 ............................. 4

................ PM2700-440............Wide Stripe (not shown) ............................................................... per ft.

................ PM2700-441............Narrow Stripe (not shown) ............................................................ per ft.

................ PM1300-BMHP........Base Machine Hardware Package (not show n) *................................... 1

................ DC 1100-HP2 ...........Hardware Package for Cone Assembly (index # 57 thru 61) ................. 1

* Base Machine Hardware Package i ncludes i ndex # 29, 34, 40, 41 and 42.

17

Page 18

Breakdown for PM1300 Canist er Filt er S yst em

18

Page 19

Parts L ist for P M1300 Can ister Fi lter System

Index No. Par t No. Description Size Qty

................ 1791086 ..................Canister Assembly (includes #1 thru 24) .............................................. 1

1 .............. PM1900-301............Fi l ter .................................................................................................. 1

2 .............. PM1900-302............Knob ................................................................M6x20........................ 4

3 .............. 331031....................Pad.................................................................................................... 1

4 .............. 331009....................Support .............................................................................................. 1

5 .............. ST049200 ...............Tapping Screw .................................................M4 x8 ......................... 4

6 .............. 331038....................Snap Ring .......................................................................................... 1

7 .............. 1791087 ..................Plastic Collection Bag (Package of 5) .................800x1050x0.1t mm ..... 1

8 .............. TS-1540071 ............Hex Nut............................................................M10 ........................... 2

9 .............. TS-1550071 ............Flat Washer......................................................M10 ........................... 2

10 ............ 331050....................Hand le ............................................................................................... 1

11 ............ 331051....................Soft Grip Ha ndle ................................................................................. 2

12 ............ TS-2361101 ............L ock Wash er ....................................................M10 ........................... 1

13 ............ BR000052 ...............Rivet ................................................................5-2 ............................. 3

14 ............ 331014....................Bracke t .............................................................................................. 1

15 ............ 150623....................Rubber Mount .................................................................................... 1

16 ............ TS-1540041 ............Hex Nut............................................................M6 ............................. 8

17 ............ 331052....................Shaft .................................................................................................. 1

18 ............ TS-1482041 ............Hex Cap Screw ................................................M6x20........................ 4

19 ............ TS-2361061 ............Lock Washer ....................................................M6 ............................. 4

20 ............ TS-1550041 ............Flat Washer......................................................M6 ............................. 4

21 ............ 331012....................Scraper .............................................................................................. 2

22 ............ 331017....................Plate .................................................................................................. 2

23 ............ 331015....................Plate .................................................................................................. 2

24 ............ TS-1482021 ............Hex Cap Screw ................................................M6x12........................ 4

................ PM1300-PLO...........Powermatic Label (not s hown) ...........................5-1/2x14 Oval ............. 1

................ PM1900-CHP ..........Canister Hardware Package (not shown) * ........................................... 1

*Canister Hardware Package includes index # 2, 8, 9 and 12.

19

Page 20

Parts L ist for P M1300 F ilter Bag S yst em

Index No. Par t No. Description Size Qty

................ 1791077B................PM1300 Collect io n and Filter Bag (i ncludes #1 t hru 5) .......................... 1

1 .............. 1791077F ................Filter Bag .........................................................30 micron ................... 1

2 .............. 410012....................Retainer Strap .................................................................................... 1

3 .............. 708699A .................Collection Bag .................................................................................... 1

4 .............. 402040....................Hanger............................................................................................... 1

5 .............. 523011....................Hanger Bracket .................................................................................. 1

20

Page 21

Elect ri cal Con nectio ns

21

Page 22

NOTES

22

Page 23

23

Page 24

WALTER MEIER (Manuf acturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.powermatic.com

www.waltermeier.com

24

Loading...

Loading...