Page 1

keep this manual for future reference

IMPORTANT:

This manual provides complete instructions for safely operating and maintaining your nailer.

Read and save these instructions. Refer to this manual each time before using your nailer.

E108024 Rev. 0 04/2014

Model No

CRN175P

Operator's Manual

Coil Roofing Nailer

Page 2

CONTENTS

IMPORTANT INFORMATION P1

EXPLANATION OF THE NAILING ACTION P1

GENERAL SAFETY RULES P1

WORK AREA P1

PERSONAL SAFETY P1

TOOL USE AND CARE P1

TOOL SERVICE P2

AIR SOURCE P2

DESCRIPTION AND SPECIFICATION P3

SPECIFICATION P3

FEATURES P4

ASSEMBLY/INSTALLATION P4

OPERATION P4

LUBRICATION P4

ADJUSTING AIR PRESSURE P4

CONNECTING AIR SUPPLY P4

TOOL TESTING P5

ADJUSTING THE OFFSET MAGAZINE P5

NAIL LOADING P6

METHODS OF OPERATION P6

COLD WEATHER OPERATION P6

ADJUSTING THE NAILING DEPTH P7

ADJUSTABLE THE EXHAUST P7

FIRING LOCK P7

MAINTENANCE P7

JAM CLEARING P7

CLEANING P7

STORAGE P8

HOOKUP INSTRUCTIONS FOR TOOL TO AIR SUPPLY

P8

RECOMMENDED HOOKUP

P8

TROUBLE SOLVING

P9

ESPAÑOL

P11

FRANÇAIS

P23

Page 3

1 - ENG LISH

IMPORTANT INFORMATION

WARNING

TO AVOID SERIOUS PERSONAL INJURY, ALL USERS AND

EMPLOYERS/OWNERS MUST READ AND UNDERSTAND

ALL INSTRUCTIONS IN THIS MANUAL BEFORE

OPERATING OR MAINTAINING THIS TOOL.

Keep this manual for the safety warnings and precautions,

operating, inspection, maintenance. Keep this manual and

the receipt in a safe and dry place for future reference.

EXPLANATION OF THE NAILING

ACTION

• SINGLE ACTUATION MECHANISM:

First, press the safety against the wood; next, pull

the trigger to drive the fastener. After fastening once,

fastening will not be possible again until the trigger is

released and pressed again.

• CONTACT ACTUATION MECHANISM:

First, press the safety against the wood; next, pull the

trigger to drive the fastener. First. Pull the trigger; next,

press the safety against the wood to drive the fastener.

If the trigger is held back, a fastener will be driven each

time when the safety is pressed against the wood.

• FULL SEQUENTIAL ACTUATION MECHANISM:

First, press the safety against the wood; next, pull the

trigger to drive the fastener. Follow the same sequence

to continue driving fasteners.

GENERAL SAFETY RULES

WORK AREA

• KEEP THE WORK AREA CLEAN AND WELL LIGHTED.

Cluttered benches and dark areas increase the risks of

accidents.

• DO NOT OPERATE THE TOOL IN EXPLOSIVE

ATMOSPHERES, such as in the presence of flammable

liquids, gases, or dust. The tool creates a spark which

may ignite flammable liquids, gases or dust.

• KEEP VISITORS AWAY. Do not let visitors handle the

tool. All visitors should be kept safety away from work

area.

• NEVER ENGAGE IN HORSEPLAY WITH THE TOOL.

Respect the tool as a working implement.

PERSONAL SAFETY

• OPERATORS AND OTHERS IN WORK AREA MUST

WEAR SAFETY GLASSES WITH SIDE SHIELDS. When

operating the tool, always wear safety glasses with

side shields, and make sure others in work area wear

safety glasses, too. Safety glasses must conform to the

requirements of American National Standards Institute,

ANSI Z87.1 and provide protection against flying

particles both from the front and side.

The employer must enforce the use of safety glasses by

the tool operator and others in work area.

• ALWAYS WEAR EAR AND HEAD PROTECTION. Always

wear ear protection to protect your ears from loud noise,

Always wear head protection to protect your head from

flying objects.

• USE SAFETY EQUIPMENT. A dust mask, non-skid safety

shoes and a hard hat must be used for the applicable

conditions. Wear a full face shield if you are producing

metal filings or wood chips.

• DRESS PROPERLY. Do not wear loose clothing or

jewelry. Contain long hair. Keep your hair, clothing, and

gloves away from moving parts. Loose clothes, jewelry,

or long hair can be caught in moving parts and increases

the risk of injury.

• STAY ALERT, WATCH WHAT YOU ARE DOING AND USE

COMMON SENSE WHEN OPERATING A POWER TOOL.

Do not use tool while tired or under the influence of

drugs, alcohol, or medication. A moment of inattention

while operating the tool may cause serious injury.

• AVOID UNINTENTIONAL FIRING. Keep fingers away

from trigger when not driving fasteners, especially when

connecting the tool to the air supply.

• DO NOT OVERREACH. Keep proper footing and balance

at all times. Proper footing and balance enables better

control of the tool in unexpected situations.

• MAKE SURE AIR HOSE IS FREE OF SNAGS AND

OBSTRUCTIONS. DO NOT ATTACH AN AIR HOSE OR

TOOL TO YOUR BODY. Entangled or snarled hoses

can cause a loss of balance or footing in addition to

unintentional tool operation. Attach the hose to the

structure to reduce the risk of loss of balance of the hose

shifts.

TOOL USE AND CARE

• NEVER POINT TOOL AT YOURSELF OR OTHERS

IN WORK AREA. Always assume the tool contains

fasteners. Never point the tool at yourself or others,

whether it contains fasteners or not. If fasteners are

mistakenly driven, it can lead to severe injuries. Never

engage in horseplay with the tool. Respect the tool as a

working implement.

• KEEP FINGERS AWAY FROM TRIGGER WHEN NOT

DRIVING FASTENERS TO AVOID ACCIDENTAL FIRING.

Never carry the tool with finger on trigger since you

could drive a fastener unintentionally and injure yourself

or someone else. Always carry the tool by the handle

only.

• NEVER MODIFY OR ALTER A TOOL. Doing so may

cause it to malfunction and personal injuries may result.

• KNOW THIS TOOL. Read manual carefully, learn its

applications and limitations, as well as the specific

potential hazards related to this tool.

• USE ONLY FASTENERS THAT ARE RECOMMENDED

FOR YOUR MODELS. Do not use the wrong fasteners or

load the fasteners incorrectly.

Page 4

2- ENG LISH

• CHECK FOR MISALIGNMENT OR BINDING OF

MOVING PARTS, BREAKAGE OF PARTS, AND ANY

OTHER CONDITION THAT MAY AFFECT THE TOOL'S

OPERATION. If damaged, have the tool serviced before

using. Many accidents are caused by poorly maintained

tools.

• CHECK SAFETY BEFORE USE. Make sure the safety

operates properly. Never use the tool unless the safety

is operating properly, otherwise the tool could drive a

fastener unexpectedly. Do not tamper with or remove the

safety, otherwise the safety becomes inoperable.

• DO NOT USE TOOL IF TRIGGER DOES NOT ACTUATE

PROPERLY. Any tool that cannot be controlled with the

trigger is dangerous and must be repaired.

• NEVER USE TOOL WHICH IS DEFECTIVE OR

OPERATING ABNORMALLY. If the tool appears to be

operating unusually, making strange noises, or otherwise

appears defective, stop using it immediately and arrange

for repairs by an authorized service center.

• MAINTAIN TOOLS WITH CARE. Keep the tool clean and

lubricated for better and safer performance.

• NEVER CARRY THE TOOL BY AIR HOSE.

• STORE TOOLS OUT OF THE REACH OF CHILDREN AND

OTHER UNTRAINED PEOPLE. Tools are dangerous in

the hands of untrained users.

• PLACE TOOL PROPERLY ON WORKPIECE. Do not drive

fasteners on top of other fasteners or with the tool at too

steep of an angle; the fasteners can ricochet and hurt

someone.

• DO NOT USE THE TOOL AS A HAMMER.

• KEEP ALL SCREWS AND COVERS TIGHTLY IN PLACE.

• KEEP FACE, HANDS AND FEET AWAY FROM FIRING

HEAD AT ALL TIMES. Never place your face, hands or

feet near the firing head.

• DO NOT DISCONNECT AIR HOSE FROM TOOL

WITH FINGER ON TRIGGER. The tool can fire when

reconnected to an air supply.

• DO NOT LOAD FASTENERS WITH TRIGGER PULLED

OR SAFETY DEPRESSED.

• NEVER PLACE A HAND OR ANY PART OF BODY IN

FASTENER DISCHARGE AREA OF TOOL.

• DO NOT DRIVE FASTENERS INTO THIN BOARDS OR

NEAR CORNERS AND EDGES OF WORKPIECE. The

fasteners can be driven or a way from the workpiece hit

someone.

• DISCONNECT AIR HOSE FROM TOOL WHEN:

1). Doing maintenance and inspection;

2). Turning the adjuster and top cover;

3). Clearing a jam;

4). It is not in use;

5). Leaving work area;

6). Moving it to another location;

7). Handing it to another person.

Never attempt to clear a jam or repair the tool unless you

have disconnected air hose from the tool and removed all

remaining fasteners from the tool. The tool should never

be left unattended since people who are not familiar with

the tool might handle it and injure themselves.

TOOL SERVICE

• USE ONLY ACCESSORIES THAT ARE IDENTIFIED

BY THE MANUFACTURER FOR THE SPECIFIC TOOL

MODEL.

• USE OF UNAUTHORIZED PARTS OR FAILURE TO

FOLLOW MAINTENANCE INSTRUCTIONS MAY

CREATE A RISK OF INJURY.

• USE ONLY THE LUBRICANTS SUPPLIED WITH THE

TOOL OR SPECIFIED BY THE MANUFACTURE.

• TOOL SERVICE MUST BE PERFORMED ONLY BY

QUALIFIED REPAIR PERSONNEL.

AIR SOURCE

• NEVER USE OXYGEN OR OTHER BOTTLED GASES AS

A POWER SOURCE. Explosion may occur. Combustible

gases and other bottled gases are dangerous and may

cause the tool to explode.

• DO NOT EXCEED MAXIMUM RECOMMENDED AIR

PRESSURE MARKED ON THE TOOL. Use only clean,

dry, regulated, compressed air within the rated pressure

range marked on the tool. Never connect the tool to

pressure as which potentially exceeds 200PSI the tool

can burst.

• DO NOT ABUSE THE AIR HOSE. Protect all hoses from

kinks, restrictions, solvents or sharp objects. Keep air

hose away from heat, oil, sharp edges or moving parts.

Replace damaged hoses immediately. Damaged hoses

can burst or whip around.

• CHECK ALL FITTINGS, HOSES, PIPES, CONNECTIONS

AND COMPRESSOR BEFORE EACH USE OF THIS

TOOL. Repair or replace damaged or leaking hoses

and connections immediately. Damage to a hose or

connection can cause a pressure hose to break and

whip around the work area, and can lead to injury.

Page 5

3 - ENG LISH

FUNCTIONAL DESCRIPTION AND SPECIFICATIONS

WARNING

Disconnect the tool from the air source before making any adjustments, changing accessories or storing the tool.

Such precautionary safety measures reduce the risk or unintentional tool operation.

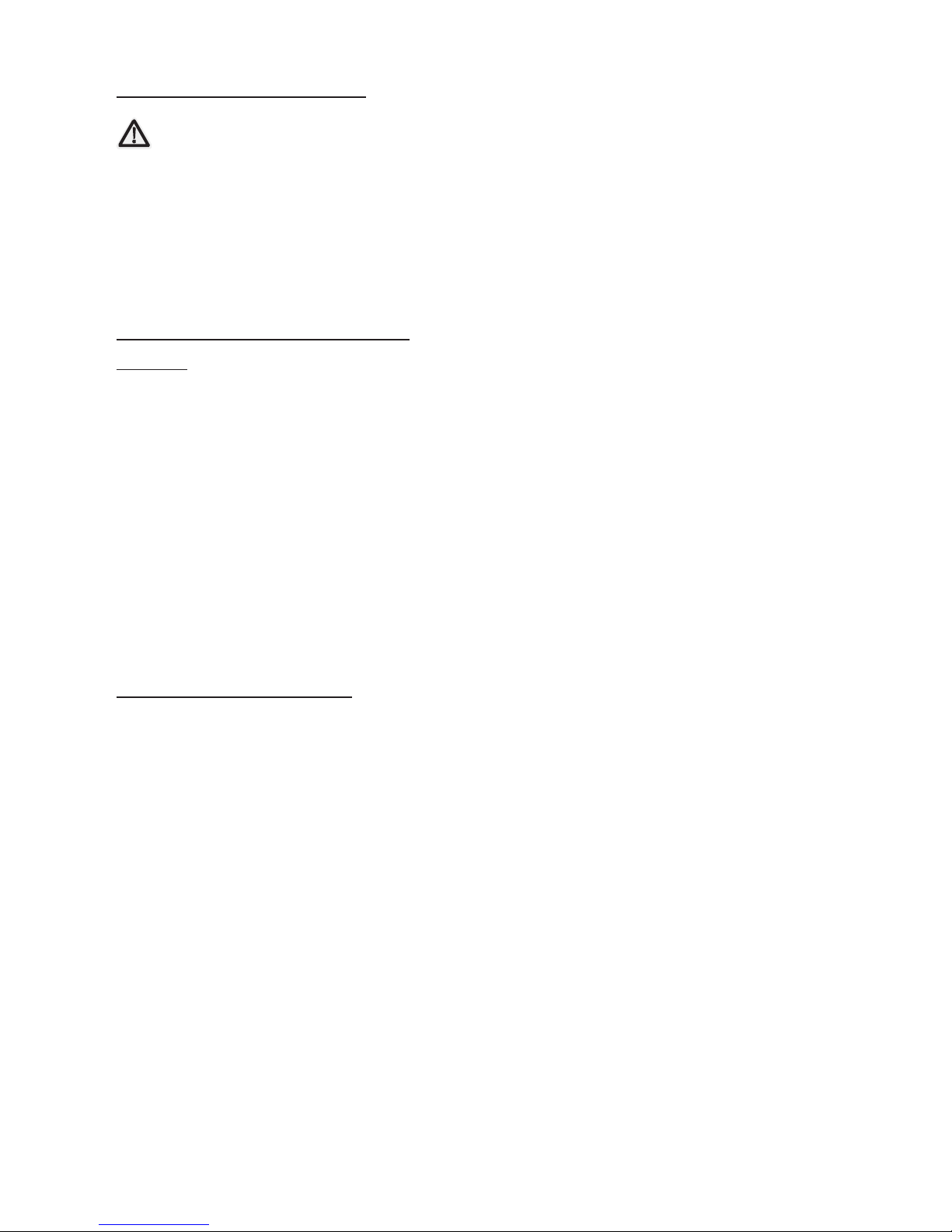

Trigger Lock

Magazine

Hand Grip

Air Cap

Body

FIG. 1

Air Plug

Exhaust Deflector

No-Mar Tip

Safety

Depth of Drive

Adjustment

Trigger

SPECIFICATIONS

Product Size:

Length: 10.63 (270mm)

Height: 11.26" (286mm)

Width: 5.35" (136mm)

Weight: 5.5Ibs (2.5kg)

Normal Operating Pressure: 70-115PSI (0.5-0.8MPa)

Magazine Capacity: 120pcs

Firing Mode: Contact Fire

Fastener Size Range: Wire collation:

3/4" - 1-3/4”(19-45mm)

FASTENER TYPE

0.39

( 10mm)

min 3/4"

(19mm)

max 1-3/4" (45 mm)

0.12

( 3.05mm)

11GA.

15°–16°

0.31"

(8mm)

Page 6

4- ENG LISH

FEATURES

• 360adjustableexhaust.

• Triggerlockforsafety.

• Toolfreedepthofdrive.

• Compactdesignanddurableindropping.

• Easyopennoseforquickjamclearing.

ASSEMBLY/INSTALLATION

Follow the instructions below to prepare your tool for

operation.

1. All tool operators and their immediate supervisors must

become familiar with the operator safety instructions

before operating the tool.

2. Included with each tool are one copy of these Operating/

Safety Instructions. Keep this publications for future

reference.

3. Install a filter, regulator, lubricator unit and moisture

trap on your air delivery system per the manufacturer's

instructions for these devices. Additionally, install

a pressure gauge as close as practical to the tool,

preferably within 10 feet (3 meters).

4. Select hoses with a minimum inner diameter of

1/4inch (6.4mm) and a maximum length of 100 feet

(30.5meters).

WARNING

To reduce the risk of injury from a hose bursting, select

hoses that are rated at least 200PSI.

5. Select fittings that are appropriately sized for the

selected hoses. The tool and air hose must have a hose

coupling such that all pressure is removed from the tool

when the coupling joint is disconnected.

WARNING

Never use non relieving couplers and/or female quick

disconnect couplings on the tool. Non relieving couplings

and female couplings will trap high pressure air in the tool

when the airline is disconnected. This will leave the tool

charged with enough air after it has been disconnected

to drive a nail. Only MALE pneumatic type air connectors

should be fitted to the tool, so that high pressure air in

the tool is vented to atmosphere as soon as the airline is

disconnected.

6. Set the regulator at the air delivery system to a PSI that

falls within the tool's operating range of 70-115PSI. The

correct pressure is the lowest pressure that will do the

job.

OPERATION

LUBRICATION

WARNING

USE ONLY THE AIR TOOL LUBRICANTS SUPPLIED WITH

THE TOOL. Do not use other lubricants as they may damage

the tool.

If the tool is not used with an in-line lubrication system on

the air supply it is necessary to periodically lubricate the tool

with air tool lubrication.

Under low use, lubricate once a day. Under heavy use,

lubricate twice a day. To lubricate, insert 2-3 drops of

lubricant into the air supply fitting attached to the tool

handle (FIG 2). Using too much oil will cause it to collect in

the tool and be noticeable in the exhaust.

2–3 Drops of

Air Tool Lubricant

FIG. 2

Do not use detergent oil, WD-40, transmission fluid, motor

oil, or other lubricants not specifically designated as air tool

lubricants. These lubricants will cause accelerated wear to

the seals, o-rings, and bumpers in the tool, resulting in poor

tool performance and frequent maintenance.

ADJUSTING AIR PRESSURE

Adjust the air pressure at recommended operating pressure

70-115PSI according to the length of nails and the hardness

of workpiece.

The correct air pressure is the lowest pressure which will do

the job. Using the tool at a higher than required air pressure

unnecessarily over stresses the tool. Don't exceed 115PSI.

FIG. 3

70PSI minimum

115PSI maximum

CONNECTING AIR SUPPLY

WARNING

Never use oxygen or other bottled gases as a power

source. Explosion may occur. Combustible gases and

other bottled gases are dangerous and may cause the

tool to explode.

Page 7

5 - ENG LISH

WARNING

Never connect the tool to an air source that is capable

of producing air pressure exceeding 200PSI. Excessive

pressure can cause abnormal operation or cause the tool to

burst, resulting in personal injury.

WARNING

Do not exceed maximum recommended air pressure

marked on the tool. Verify prior to using the tool that the

air source has been adjusted within the rated air-pressure

rang. Be sure the air pressure gauge is operating properly

and check it at least twice a day. Tools operated in excess of

their maximum pressure rating may operate abnormally or

burst resulting in personal injury.

To connect the tool to the compressor only use

pneumatic air hoses that meet the following criteria:

1. Minimum hose pressure rating, 200PSI.

2. Minimum hose inner diameter, 1/4inch (6.4mm).

3. Maximum hose length, 100 feet (30.5meters).

FIG. 4

Connect the air supply:

• Snaptheairhoseontothequickconnector.

• Checkforairleakage.Ifleakageisnoted,ceaseusing

the tool immediately and have the tool repaired by a

qualified service technician.

• Besuretheairpressuregaugeisoperatingproperlyand

check it at least twice a day.

TOOL TESTING

DANGER

OPERATORS AND OTHERS IN WORK AREA MUST

WEAR SAFETY GLASSES WITH SIDE SHIELDS WHICH

CONFORMS TO ANSI Z87.1 SPECIFICATIONS.

WARNING

NEVER USE TOOL UNLESS SAFETY IS OPERATING

PROPERLY.

Before actually beginning the nailing work, test the tool by

using the check list below. Conduct the test in the following

order.

If abnormal operation occurs, stop using the tool immediately

and have the tool repaired by a qualified service technician.

1. Disconnect air hose from tool. Remove all nails from tool.

• ALL SCREWS MUST BE TIGHTENED. If any screws

are loose, tighten them.

• THE SAFETY AND TRIGGER MUST MOVE

SMOOTHLY.

2. Adjust the air pressure to 70PSI, connect the air hose.

Do not load any nails in the tool.

• THE TOOL MUST NOT LEAK AIR.

3. Remove the finger from the trigger and press the safety

against the wood.

• THE TOOL MUST NOT OPERATE.

4. Separate the safety from the wood. Next, point the tool

downward, pull the trigger and then wait in that position

for 5 seconds or longer.

• THE TOOL MUST NOT OPERATE.

5. a. Without touching the trigger, depress the safety

against the workpiece. Pull the trigger.

• THE TOOL MUST OPERATE

b. Hold the trigger back while separating the safety from

the wood.

The tool will remain in operated status (the driver

blade will remain at the bottom).

c. Remove the finger from the trigger.

Tool operation will end (the driver blade will return to

the top).

6. If no abnormal operation is observed, you may load nails

in the tool. Drive nails into the workpiece that is the same

type to be used in the actual application.

• THE TOOL MUST OPERATE PROPERLY.

ADJUSTING THE OFFSET MAGAZINE

The load feature is designed for quick and easy reloads.

To avoid jamming, always adjust the magazine to the

correct position for the size nails you want to use. There

is an adjustment indicator inside the magazine to help you

choose the right position.

To adjust the magazine, pull up on the spool to the desired

position and then rotate it clockwise to set it. Rotate it

counterclockwise to lower that nail tray.

FIG. 5

Position Indicator

Spool

Page 8

6- ENG LISH

NAIL LOADING

WARNING

When loading the tool’s magazine, check that the nail tips

contact the wear rail and slide smoothly against the surface

of the magazine. If the nails are not loaded properly, the tool

will misfire and nails can be deflected, causing the tool to

react in an unexpected manner, and damage the tool.

1. Connect air supply.

2. Depress the feeder cover latch and open the cover

(FIG.6).

3. Open the magazine cover (FIG 7).

4. Slide the coil of nails onto the spool with the nails

pointing down (FIG 5).

5. Insert the first nail into the feeder (FIG 7). The first nail

should sit in the nose of the tool.

6. Position the second nail between the guides (FIG 7), the

nail heads should lie in the track.

7. Close the magazine cover (FIG 7).

8. Securely close the feeder cover (FIG 6), snapping it into

place. Be sure that the feeder cover is locked before

resuming operation.

FIG. 6

Latch

FIG. 7

Nailer

Magazine

Guide

Feeder

WARNING

KEEP THE TOOL POINTED AWAY FROM YOURSELF AND

OTHERS WHEN LOADING FASTENERS. FAILURE TO DO SO

COULD RESULT IN POSSIBLE SERIOUS PERSONAL INJURY.

NEVER LOAD FASTENERS WITH THE WORKPIECE CONTACT

OR TRIGGER ACTIVATED. DOING SO COULD RESULT IN

POSSIBLE SERIOUS PERSONAL INJURY.

REMOVING THE NAILS

1. Disconnect air supply.

2. Open the feeder cover and magazine cover (FIG 6).

3. Lift the nails strip from the spool and remove the

remaining coil nails.

METHODS OF OPERATION

This tool is equipped with the safety and does not operate

unless the safety is depressed.

The methods of operation to drive nails with this tool is

contact actuation mechanism.

WARNING

To avoid double firing or accidental firing due to recoil.

• Donot pressthetoolagainstthewoodwith excessive

force.

• Separatethetoolfromthewoodasitrecoilsafternailing.

1. Pull the trigger with the tool off the workpiece.

2. Depress the safety against the workpiece to drive a nail

3. Move the tool along the workpiece witha bouncing

motion. Each depression of the safety will drive a nail. As

soon as the desired number of nails have been driven,

remove finger from the trigger.

NOTE:

• Alwayshandle nails and package carefully.If nailsare

dropped, collating bent may be broken, which will cause

mis-feeding and jamming.

• Afternailing:

1. Disconnect air hose from the tool.

2. Remove all nails from the tool.

3. Supply 5-10 drops of pneumatic tool lubricant into

the air plug on the tool.

4. Open the petcock on the air compressor tank to drain

any moisture

COLD WEATHER OPERATION

WARNING

DO NOT USE A FROZEN TOOL. Allow tool to thaw before

using. Moisture frozen in the tool may impede internal

components resulting in the risk of injury and/or tool

damage.

Page 9

7 - ENG LISH

When using the tool in cold conditions the tool will cycle

slower than usual while driving the first nails. The cycle rate

will increase as the tool warms up. Keep tool warm to avoid

reduced cycle rate.

ADJUSTING THE NAILING DEPTH

WARNING

Disconnect the tool from the air source before making

adjustments. Such precautionary safety measures reduce

the risk or unintentional tool operation.

1. Disconnect tool from air supply.

2. Remove nails from the tool.

3. Adjust tool driving depth:

• Toreducethenaildepth,turntheadjustmentknob

counter clockwise (FIG 8).

• To drive thenail deeper, turnthe adjustment knob

clockwise (FIG 9).

4. Reload nails as described in the “Loading Nails” section

of this manual.

5. Reconnect air supply.

FIG. 8

Too Deep Flush

Turn the adjustment knob counter clockwise

Too Shallow

Turn the adjustment knob clockwise

FIG. 9

Flush

ADJUSTING THE EXHAUST

The direction of the exhaust vent can be changed by turning

the top cover (FIG 10).

FIG. 10

FIRING LOCK

The tool is equipped with a firing lock button beside the

trigger. Make sure it is in the position of the Lock Symbol

when tool is not in the use. Before using the tool, turn the

FIRING LOCK to the position of the Unlock Symbol.

MAINTENANCE

JAM CLEARING

Occasionally, a nailer may become jammed in the firing

mechanism of the tool, making the tool inoperable. To

remove a jammed nailer, follow the steps below:

1. Disconnect air hose.

2. Open the feeder cover and magazine cover.

3. Remove nails from the tool.

4. Remove jammed nail, using pliers or a screwdriver if

required.

5. Reconnect the tool to the air resource.

6. Reload the tool with nails.

7. Close the magazine cover. Close the feeder cover

securely.

CLEANING

WARNING

When cleaning a tool be careful not to disassembly any

portion of the tool since internal components may be

misplaced or safety components may be improperly

mounted. Certain cleaning agents such as gasoline, carbon

tetrachloride, ammonia. etc. may damage plastic parts and

o-rings.

WARNING

Do not attempt to clean by inserting pointed objects

through openings. Sharp edges may damage internal

components causing a serious hazard.

Ventilation openings, the work contact element, and the

trigger must be kept clean and free of foreign matter.

Page 10

8- ENG LISH

Periodically clean the tool with compressed air.

Clean the magazine. Remove metal or wooden chips which

may have accumulated in the magazine. Periodically clean

magazine with compressed air.

STORAGE

WARNING

Keep out of reach of children and personnel unfamiliar

with tool operation. Lock the storage area. Tools are

dangerous in the hands of personnel unfamiliar with the

tool.

When not in use, the tool should be disconnected and stored

in the storage case in a warm and dry place. When tool will

not be in use for an extended period, apply a thin coat of the

lubricant to the steel parts to avoid rust.

Do not store the tool in a cold weather environment.

HOOKUP INSTRUCTIONS FOR TOOL

TO AIR SUPPLY

NOTE:

For better performance, install a 3/8 inch quick plug (1/4inch

NPT threads) with an inside diameter of 0.315inch (8mm)

on the nailer and a 3/8 inch quick coupler on the air hose.

1. With ON/OFF switch in OFF position, plug compressor

into electrical outlet.

2. Close pressure regulator by turning all the way to the

left. Turn compressor ON and let it pump all the way up

to automatic shut-off pressure.

3. Attach air hose to regulator outlet. Adjust pressure

regulator by turning to the right so that outlet pressure is

between 70PSI to 115PSI.

4. Load fasteners into nailer.

5. Point the nailer in a safe direction while attaching to air

hose.

6. Nailer is ready for use. You may need to adjust outlet

pressure to achieve proper fastener depth.

RECOMMENDED HOOKUP

MINIMUM COMPONENTS REQUIRED FOR

HOOKUP

Air compressor: The air compressor must be able to

maintain a minimum of 70PSI when the nailer is being used.

An inadequate air supply can cause a loss of power and

inconsistent driving.

Pressure regulator: A pressure regulator is required to

control the operating pressure of the nailer between 70PSI

and 115PSI .

Air supply hose: Always use air supply hoses with a

minimum working pressure rating equal to or greater

than the pressure from the power source, or 150PSI,

whichever is greater. Use 1/4 inch air hose for runs up to

50 feet (15.2meters). Use 3/8 inch air hose for 50 feet

(15.2meters), run or longer.

Page 11

9 - ENG LISH

TROUBLE SOLVING

PROBLEMS POSSIBLE CAUSES SUGGESTED SOLUTIONS

Air leaking near the top of the tool or in

the trigger area.

1. Loose screws. 1. Tighten screws.

2. Worn or damaged O-rings or seals. 2. Install overhaul kit.

Air leaking near the bottom of the tool 1. Loose screws. 1. Tighten screws.

2. Worn or damaged O-rings or seals. 2. Install overhaul kit.

Tool dose nothing or operates sluggishly 1. Inadequate air supply. 1. Make sure the air compressor is set

between 70PSI and 115PSI.

2. Tool is too dry. 2. Add about 2-3 drops of lubrication

into the air connector.

3. Exhaust blocked. 3. Clean exhaust channel.

4. Worn or damaged O-rings or seals. 4. Install overhaul kit.

Fasteners are jammed in the tool

frequently.

1. Driver channel is worn. 1. Fix the drive channel.

2. Piston is broken or worn. 2. Replace the piston.

3. Bent fasteners. 3. Remove the bent fasteners, replace

with the right fasteners.

4. Dirty magazine. 4. Clean magazine.

5. Loose magazine. 5. Tighten screws.

6. Wrong fasteners 6. Verify that fasteners are the correct

size.

Page 12

Copyright © 2014 Sanborn Mfg. Division of MAT Industries, LLC

Loading...

Loading...