Page 1

High Performance Self-Priming Engine Pump

SAFETY PRECAUTIONS

Read and understand this manual completely before operation.

Below information should not be neglected for proper use of this product.

Your understanding can prevent harm or danger to user or others.

Following information is very important for safety in handling this product. Be sure to observe them.

DANG E R

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided,

will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided,

may resultin minor or moderate injury, or property damage.

• Thank you for choosing a Powermate Trash Pump.

R

• This manual is prepared for your safety when

operating pump. Please read carefully

and comprehend fully before use.

(Wrong usage could cause injury or death.)

• Please keep this manual handy for future

reference.

IM P O RT A N T

Instruction

manual

PROHI BITE D

DANGER

Avoid fire when refuel or

maintenance.

Highly inflammable!

Do not operate Trash pump

inside a room or under bad

ventilation condition. Harmful

substances are in exhaust gas.

There is danger of gas poisoning.

Do not put any obstacle

around engine muffler.

It may cause fire or breakage.

Read carefully and understand

fully before use.

Do not touch muffler or any

part of the engine. It could

cause burn.

Use correct type of suction hose.

Water temperature tolerance: 5

to 45 . May cause breakage if

use outside the mentioned range.

Please use suction hose for

suction side. Please purchase

suitable hose to fit to connection

dia and suitable length.

ALERT

Do not use pump on slope.

Fuel spillage at tank cap or

carburetor may cause fire.

In case of operating Trash Pump in

a well or in a hollow, the person

operating the pump must not

enter the small space as there is

danger of gas poisoning.

Do not overhaul or repair,

except by person who is

trained to do so.

Keep children away from

pump when in operation.

Do not run pump without

water inside the pump.

This will cause pump damage.

This pump is not Suitable:

drinking water, seawater, kerosene,

light oil, hea vy oil, gasoline,

chemical, acid, alkaline etc.

Please firmly connect hose

with coupling and hose band

when you connect suction or

delivery hose to pump.

Pramac America,LLC

P.O.Box 6001 Kearney, NE 68848

1-800-445-1805

WARNING

CAUTION

How to install Coupling

3

CAUTION

Hose band

Please install coupling in order of :

If you install coupling packing not in the above order,

air leakage may result, affecting water suction efficiency.

CAUTION

Make sure suction hose is connected properly

4

In case of no self-priming after filling pump with water and engine is started, check

suction hose connection carefully again. Most cases of no self-priming are caused

by improper hose connection.

CAUTION

Fill pump with water before use

5

As pump is self-priming type, fill water fully from priming

port into pump before running.

Insufficient water can cause damage to pump.

CAUTION

HOW TO USE

Ensure pump is fully filled up with water.

1

Ensure strainer at the end of suction hose is in water.

2

(If any mud or sand is at the bottom of water, suspend hose avoiding the bottom.)

Ensure no obstacle is at delivery hose side.

3

Flammable!! Avoid fire when refuel or maintenance.

Before starting engine, please check if engine oil is filled to required level.

Without engine oil or shortage of engine oil can cause trouble for engine.

Please read carefully Engine Operation Manual for engine oil instructions.

Flammable! Do not operate near open fire.

Any fuel spillage must be cleaned completely.

Check engine oil before operation. Check and refuel periodically.

Please read Engine Operation Manual for instructions.

Stop engine operation when refuelling engine oil.

Engine oil can be very hot after operation.

Different accessories are suitable for different models.

Please check connection diameter and install correct parts.

Coupling

Hose nipple Coupling packing

Do not change pump diameter by altering suction hose.

Use suction hose for suction side. Use couplings/hose band as provided

in accessory and attach hose properly. Installation of strainer at the end

of suction hose is necessary.

Running without filling water can damage

mechanical seal.

11-12 0070101

Priming port

BEFORE USE

Check accessories provided

1

List of accessories provided are printed in the pump manual.

4-stroke engine

4-stroke engine needs

"engine oil"

There is

no engine oil in the engine.

Before starting engine, engine oil must be filled. If you start engine without engine oil,

engine will burn out and it is difficult to repair. (Warranty does not cover such claim.)

Please use

DISASSEMBLY AND CLEANING (Parts replacement

"Unleaded Gasoline for Automobile"

.

)

1. Turn the knob counterclock-wise and remove the knob.

2. Pull the handle towards you, and then both front cover

and volute casing can be removed.

3. Remove the peripheral plug before taking impeller out.

The impeller can be detached by prying loose

with a rod or the like.

4. Draw out the mechanical seal from the engine shaft

along with the sleeve.

NOTE: Please do not hammer an impeller directly when you want to

take it out from

the machine. It might damage the impeller.

Instead, take out the plug set first and then insert something like a rod or tool

which is thin enough to get through the hole and hammer the rod or tool at

the other end. The impeller can be removed out easily without damaging it.

NOTE: When assembling the parts, do not forget to place the adjusting washer,

O-ring, etc., in the right positions. Also, correctly install the front cover

and evenly tighten the right and left knobs.

Note that incomplete assembling may affect the performance o

f the unit.

Beware of water hammering

Do not allow any vehicle to run over the delivery hose.

Do not close the delivery valve

CAUTION

abruptly because water-hammer

may occur.

This may result in heavy

damage to the pump.

Do not close delivery

valve abruptly

Collapse of

delivery hose

For engine manual and notes, please refer to Engine Operation Manual enclosed.

ATTENTION AFTER USE

Drain water after use

1

After use, remove the drain plug at the bottom and pour water

from the suction/discharge ports so that the remaining sand

is forced out of the pump. If the pump is used to transfer

muddy water over a long period of time, a large volume of

sand will be piled up in the pump casing, making it difficult to remove

the front cover. Therefore, clean the inside the pump periodically.

CAUTION

2

Long storage

Water inside may freeze at below 0 in winter and may damage pump.

After use, drain water from drain plug before storing.

Discharge fuel in fuel tank and carburetor completely. Unused fuel in

tank (if kept more than 30days) may cause engine failure.

*Please refer to Engine Operation Manual.

Drain

Do not smoke as fuel is highly flammable.

CAUTION

Unused fuel must not remain in the tank for long term

storage. Unused fuel may cause future engine failure.

Page 2

TROUBLESHOOTING GUIDE

PROBLEM

POSSIBLE CAUSE SOLUTION

Rusting inside engine

Pump does

not revolve

Burn out of engine

Stuck impeller

Intrusion of foreign matters

Refer to Instruction manual of engine

(Repair)

Disassemble & clean the impeller

SOLUTION

Remove foreign matters

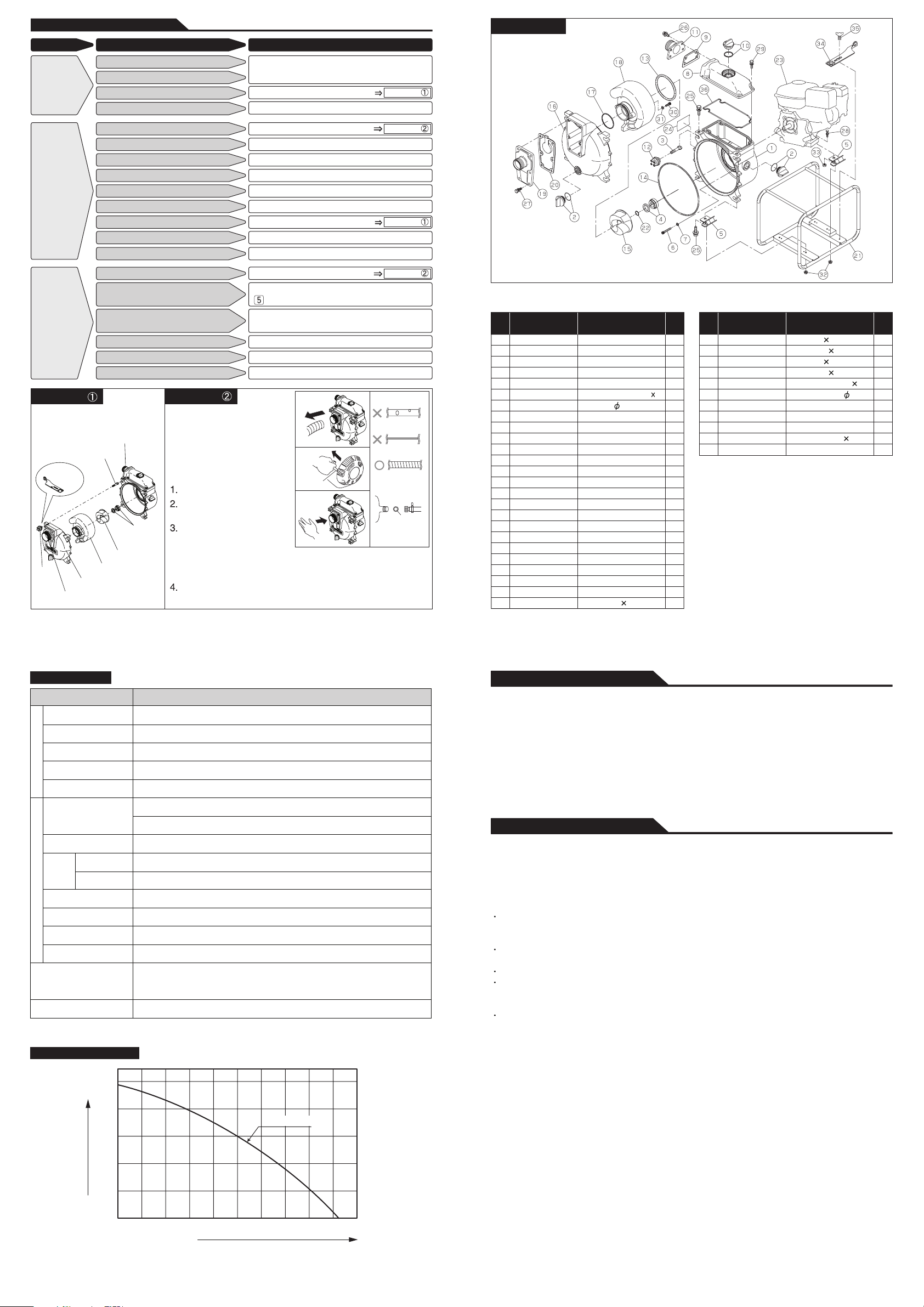

PARTS LIST

PP0100342

Air leakage from suction side

Output power down from engine

Damaged mechanical seal

Not enough

delivery

volume

Suction lift is high

Improper length/diameter. Kinked hose

Leakage of water from delivery hose or pipe

Clogging of foreign matters at impeller

Wearing out of impeller

High sand content

Air goes in from suction side

Insufficient priming water inside

Pump

does not

self-prime

water

pump casing

Drain plug is not tight

Improper revolution of engine

Air leakage from mechanical seal

Delivery hose is broken

SOLUTION SOLUTION

Remove obstacle in impeller.

(Do not remove impeller)

Delivery flange

Cover bolt

Engine

tool

Check suction pipe!

In case of no suction or

small delivery, the cause

is usually due to air

leakage at suction side.

In such case :

Remove suction hose.

Star t engine with water

inside the pump.

Press the palm of your

hand to c o ver the

suction hole and wait

30 seconds. If you feel suction on your palm, the pump

is working fine but hose connection needs correction.

Please check if rubber packing is installed and if

there is any hole on suction hose

Knob

Suction flange

Mechanical

Seal

Impeller

Volute casing

Front cover

Check piping at suction side

SOLUTION

Check & Repair engine

Replace mechanical seal (Repair)

Make suction lift lower

Ensure proper hose is used.Remove kinks

Check and stop leakage of water

Disassemble & clean the impeller

SOLUTION

Replace the impeller (Repair)

Remove sand content

Check piping at suction side

SOLUTION

Prime water fully. Refer [BEFORE USE]

"

Fill pump with water before use"

Tighten drain plug firmly. Please refer

"ATTENTION AFTER USE"

Refer to Engine Operation Manual.

Replace mechanical seal (Repair)

Replace delivery hose

1 4

Holes on hole

2

Recoil

Flat hose

Suction hose

(not bent hose)

3

Confirm

installing

packing!

PP0100342

REF.

PART NO. DESCRIPTION QTY

NO.

PPK0115446

1

PPK0118079

2

PPK0115580

3

PPK0115159

4

PPK0116172

5

PPK0116517

6

PPK0116493

7

PPK0115445

8

PPK0115490

9

PPK0118450

10

PPK0115444

11

PPK0115590

12

PPK0115578

13

PPK0115579

14

PPK0115447

15

PPK0115882

16

PPK0115676

17

PPK0115489

18

PPK0115492

19

PPK0115780

20

PPK0117816

21

PPK0110491

22

Note A

23

0070099

24

PPK743119083

25

DESCRIPTION QTY

Pump Housing

25A Plug and O-Ring

Cover Bolt

Mechanical Seal

Cushion Rubber

Flange Socket Bolt M8 60

Washer 8

Delivery Housing

Flange Packing

32A Plug and O-Ring

Delivery Flange

Knob

Casing Packing

Front Cover Packing

Impeller

Front Cover

O-Ring

Volute Casing

Suction Flange

Check Valve Packing

Base Set

Adjusting Washer

Engine Honda GX160

Name Plate

Bolt M12 45

REF.

1

2

4

2

4

4

4

1

1

1

1

4

Note A: Pramac America, LLC will not provide engines as

1

replacement parts. Engines are covered through the engine

manufacturer's warranty. Consult the accompanying engine

1

manual or contact our service department for assistance.

1

1

1

1

1

1

1

3

1

1

4

PART NO.

NO.

PPK743119046

26

PPK743119061

27

PPK743119051

28

PPK743119063

29

PPK734505066

30

PPK854255008

31

PPK842319008

32

PPK838719008

33

PPK0115778

34

PPK741305153

35

PPK0115548

36

Bolt M8

Bolt M10 25

Bolt M8 35

Bolt M10 30

Socket bolt M8 25

Seal Washer 8

Spring Nut M8

Nut M8

Tool

Wing Bolt M8 15

Head Packing

22

4

6

2

4

2

2

4

2

1

1

1

SPECIFICATIONS

Model

Connection Dia

Connection Thread

Total Head

PUMPENGINE

Delivery Volume

Max. Suction Head

Model

BSP T hread o r Fire Fighting Thread

Forced Air-coolel 4-s tro ke Gasoline Engine

PP0100342

50 m m (2")

98 ft (30 m)

185 US G/min (700 L/min )

26 ft ( 8 m)

HONDA GX160

Exhaust Volume

Rated Power

Output

Max. Power

Fuel

Fuel Tank Capacity

Continuous Operating Time

Starting Method

Standard Accessories

2.9k W(3.9PS) / 3600r pm

3.6k W(4.9PS) / 4000r pm

Automotive Unleaded Gasoline

Approx.2hrs (full tank)

1 Strainer, 2 Hose Couplings,

163 cc

0.819 USG (3.1 L)

Recoil st arter

3 Hose Bands, 1 Engine Tool Set

Net Weight

*Specifications may differ slightly depending on model.

**For the purpose of improvement, specifications are subject to changes without notice.

PERFORMANCE CURVE

104 lb s (47 kg)

(ft)

100

80

PP0100342

60

40

TOTAL HEAD

20

0

60 8020 40

DELIVERY VOLUME (

*Performance ratings are guaranteed minimum, not inflated maximum.

160 180 200100 120 140

USG/min

)

CUSTOMER SERVICE

Call our toll free number 1-800-445-1805

7 a.m. to 5 p.m. C.S.T. or www.powermate.com to obtain warranty service information or

order replacement parts or accessories. Please have the following information available:

1. Model Number.

2. Serial Number.

3. Date and where purchased.

4. Replacement numbers if you are ordering part

Pramac America, LLC P.O. Box 6001 Kearney, NE 68848

Attention: Warranty Service Department

www.powermate.com

LIMITED WARRANTY

Warranty Coverage: Pramac America, LLC (the Company) warrants to the original retail customer

in North America that it will repair or replace, free of charge, any parts found by the Company or its

authorized service representative to be defec- tive in material or workmanship. This warranty covers

the cost of replacement parts and labor for defects in material or workmanship.

Not Covered:

Transportation charges for sending the product to the Company or its authorized service

representative for warranty service, or for shipping repaired or replacement products back to the

customer; these charges must be borne by the customer.

Engine is covered exclusively by a separate warranty from the engine manufacturer, included

with the engine Manual.

Damages caused by abuse or accident, and the effects of corrosion, erosion and normal wear and tear.

Warranty is voided if the customer fails to install, maintain and operate the product in accordance

with the instructions and recommendations of the Company set forth in the owner's manual, or

if the product is used as rental equipment.

The Company will not pay for repairs or adjustments to the product, or for any costs or labor,

performed without the Company's prior authorization.

Warranty Period:

One (1) year from the date of purchase on products used for consumer,

business or commercial applications.

For warranty service, the customer must provide dated proof of purchase and must notify the Company

within the warranty period.

For warranty service: Call toll free 800-445-1805, or write to Pramac America, LLC, Product

Services, P. O. Box 6001, Kearney, NE 68848.

Exclusions And Limitations: The company makes no other warranty of any kind, express or

implied. Implied warranties, including warranties of merchantability and of fitness for a particular

purpose, are hereby disclaimed. The warranty service described above is the exclusive remedy

under this warranty; Liability for incidental and consequential damages is excluded to the extent

permitted by law.

This warranty gives you specific legal rights, and you may also have other rights which vary from state

to state. Some states do not allow a disclaimer of implied warranties, or the exclu-sion or limitation of

incidental and consequential damages, so the above disclaimers and exclusions may not apply to you.

Loading...

Loading...