Page 1

OWNER’S MANUAL

AIR-COOLED DIESEL SILENT GENERATORS

MANUALE D’ISTRUZIONI

GENERATORE DIESEL SILENZIOSO RAFFREDDATO AD ARIA

MANUAL DEL USUARIO

GENERADORES DIESEL SILENCIOSOS REFRIGERADOS POR AIRE

MODE D’EMPLOI DE L’USAGER

GROUPES ELECTROGENES SILENCIEUX REFROIDIS A AIR

PMD5000s / PMD5050s

1

Page 2

PREFACE

PREFACE

Thank you for purchasing products from our company.

The manuals will help you to operate and maintain the machines rightly.

Please make sure to read the manuals carefully before the operating the

machines. Then the generators can work in the best condition and prolong

the life.

.Consumers should notice that this manual might differ slightly from

the actual product as more improvements are made to our products.

Some of the pictures in this manual may differ slightly from the actual

product as

well. The manufacturer reserves the right to make changes

at any time without notice and without incurring any obligation.

Please notice the following

warning.

If you will not operate the machines according to the manuals, there may

be body injury and dead.

So you MUST operate the machines after the fully understanding of the

manuals.

2

PR INDUSTRIAL s.r.l.

Loc. Il Piano

CAP 53031, Casole D’Elsa (SI)

ITALIA

Page 3

TABLE OF CONTENTS

TABLE OF CONTENTS

Chapter 1 Technical Specifications and Data………………….1

1-1 Technical specifications and data……………………………………1

1-2 Basic operating parameters…………………………………………..2

1-3 General dimensions and overview of the generators………………2

1-4 Parts name and control panel………………………………………….3

Chapter 2 Operating the Diesel Generator……………………….....4

2-1 Main points of safety during operation of the generator…………..4

2-2 Preparation before operation…………………………………………5

2-3 Checking the operation of the diesel engine………………………..8

2-4 Starting the generator set……………………………………………..8

2-5 Proper operation of the generator set………………………………..9

2-6 Loading…………………………………………………………………10

2-7 Stopping the generator………………………………………………11

Chapter 3 Maintenance……………………………………………………..12

3-1 Maintenance schedules……………………………………………...12

3-2 Storing for long periods of time……………………………………...13

Chapter 4 Troubleshooting……………………………………………….14

4-1 Troubleshooting procedures………………………………………...14

4-2 Questions and doubts…………………………………………….….14

Chapter 5 Circuit diagram………………………………………………….15

Appendix ⅠType of socket……………………………………………………..18

Appendix ⅡGeneral power list of appliance…………………………………20

3

Page 4

TECHNICAL SPECIFICATIONS AND DATA

1

CHAPTER 1 TECHNICAL

SPECIFICATIONS AND DATA

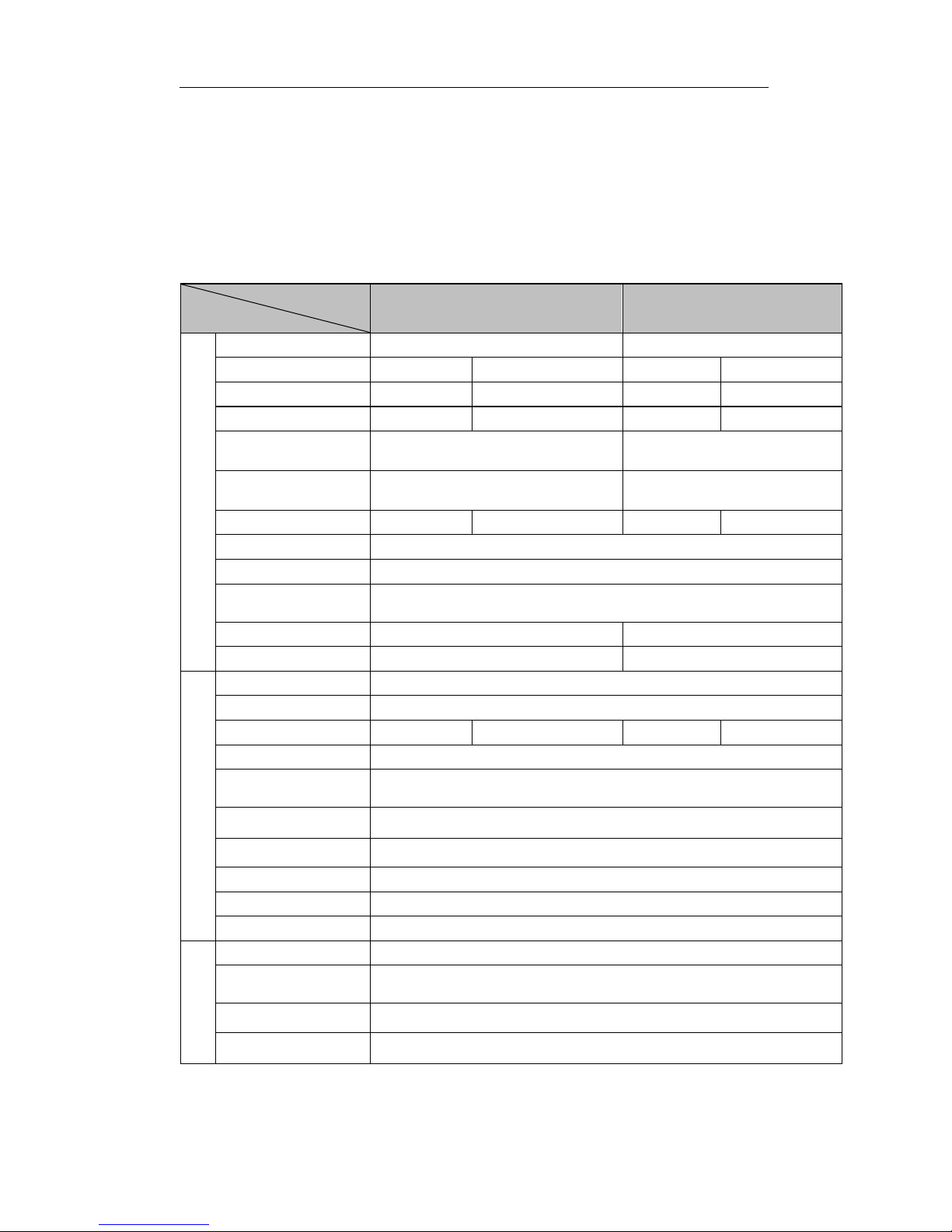

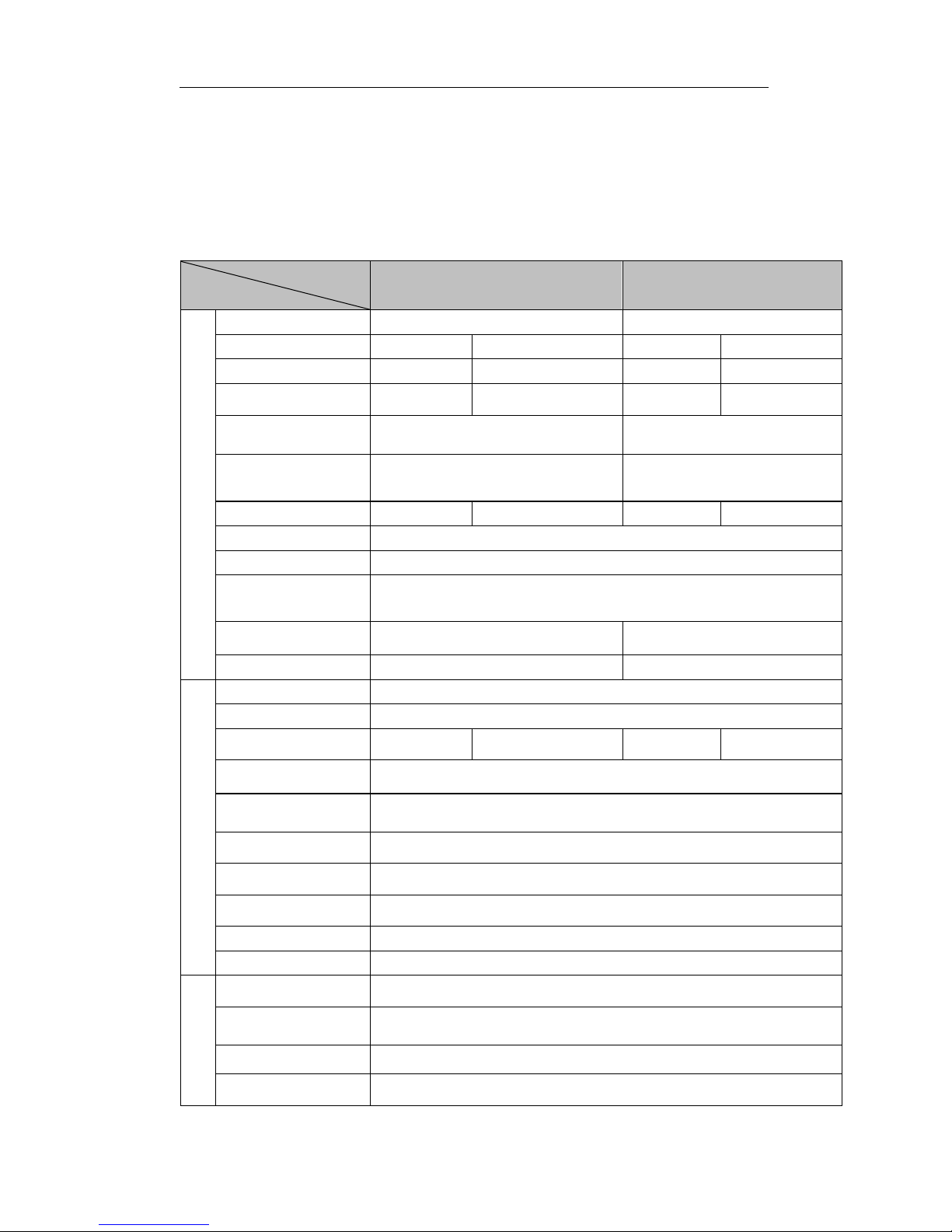

1-1 Technical specifications and data

Type

Item

PMD 5000s

PMD 5000s

Generator

Kind

Single phase

Three phase

Frequency(Hz)

50

60

50

60

Rated power (KVA)

4.2

4.5

4.2

4.5

Voltage (A.C)(V)

220V,230V,240V,110/220V,120/240V,

115/230V

400/230V,420/240V,380/220V,

127/200V

Excitation mode

Self-excitation brushless or

Self-excitation constant voltage(AVR)

Self-excitation constant

voltage(AVR)

Revolution (r/min)

3000

3600

3000

3600

Voltage (D.C)(V)

12

Current (D.C)(A)

7

Noise level dB(A)/7m

(0-100%load)

70-74

Power factor cosφ

1

0.8

Insulation grade F B

Diesel engine

Model of power

CF186F (E)

Kind

4-stroke single-cylinder air cooled direct injection

Max power (kW/rpm)

6.5

8.6

6.5

8.6

Bore × stroke (mm)

86×70

Cylinder displacement

(ml)

406

Cooling system

Force air-cooled

Lubricating system

Pressure splash, duplex type lubrication

Volume of lube oil (L)

1.65

Start system

Electric start

Fuel

Diesel fuel

Set

Fuel tank volume (L)

14.5

Low oil pressure

protection

Have

Total weight (kg)

186

Overall dimensions

(mm)

920×520×700

Note: Get this power only after 30 hours’ initial run.

4

Page 5

TECHNICAL SPECIFICATIONS AND DATA

1-2 Basic operating parameters

1-2.1 Under the given conditions, the generator will output

the specified power in the table listed below.

Table 1

Height above sea level (ft)

Ambient temperature

RH

0

+60°F (+20°C)

60%

<3280.8 ft (<1000 m)

41~104°F (5-40°C)

90%

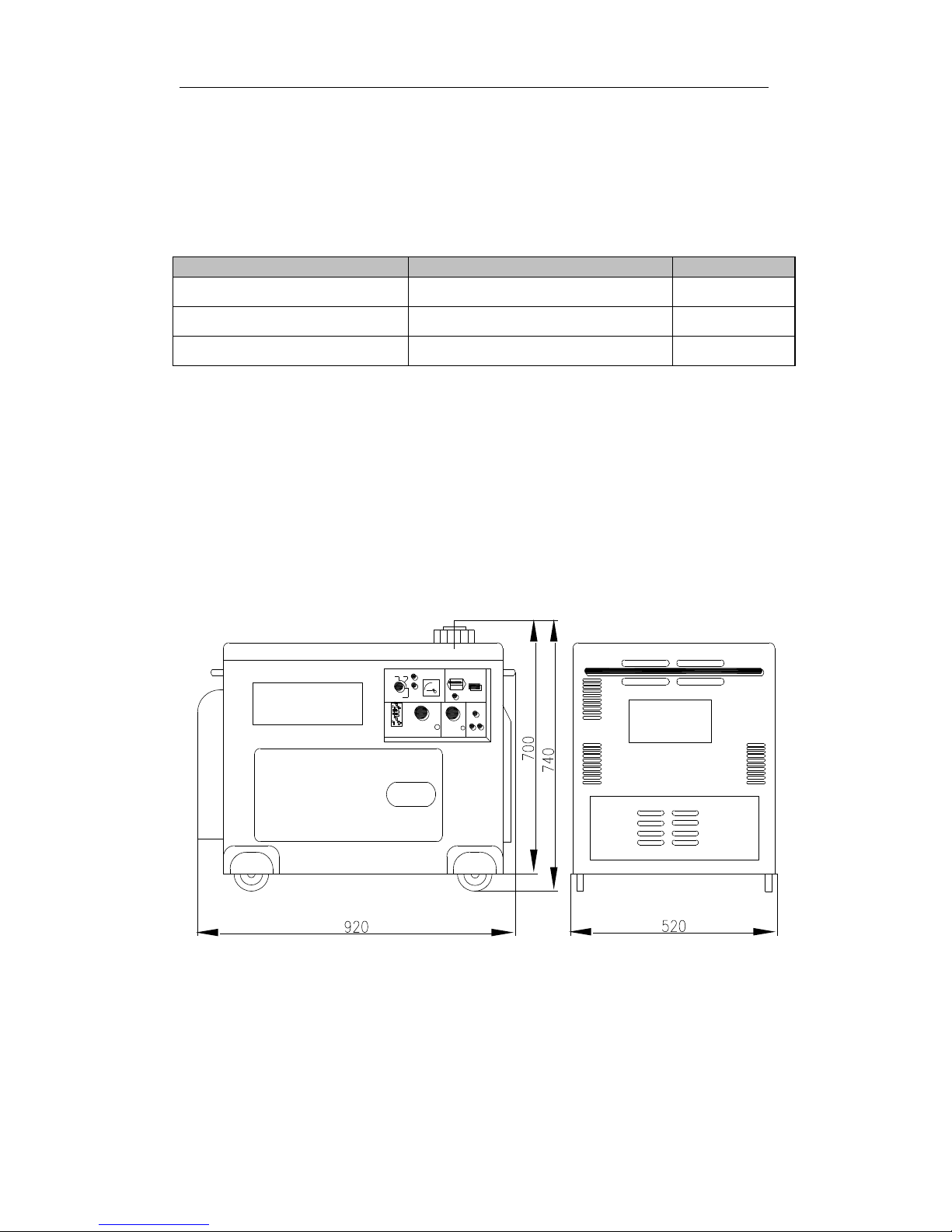

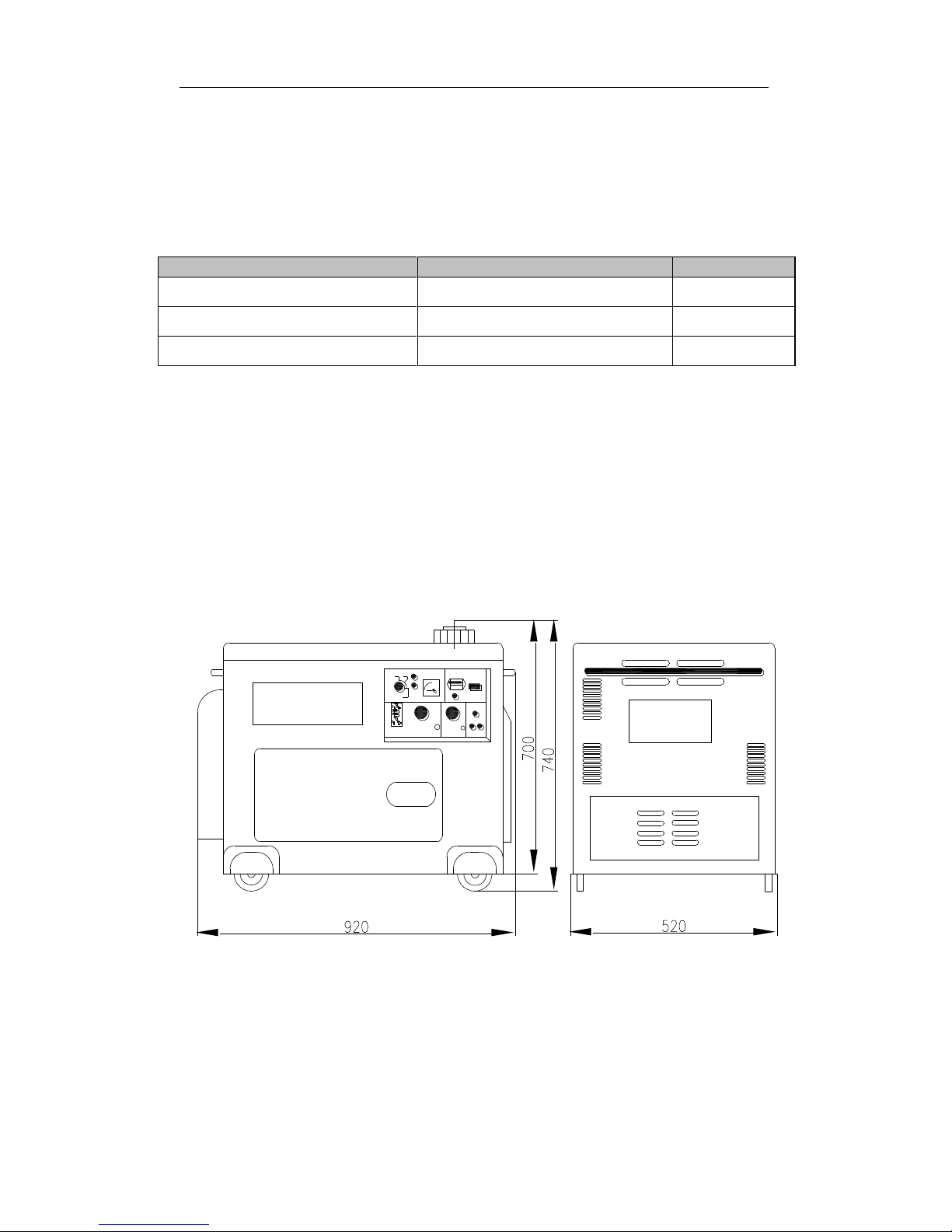

1-3 General dimensions and overview of the

generators

Please refer to the specification for the right dimension for

different models.

5

Page 6

TECHNICAL SPECIFICATIONS AND DATA

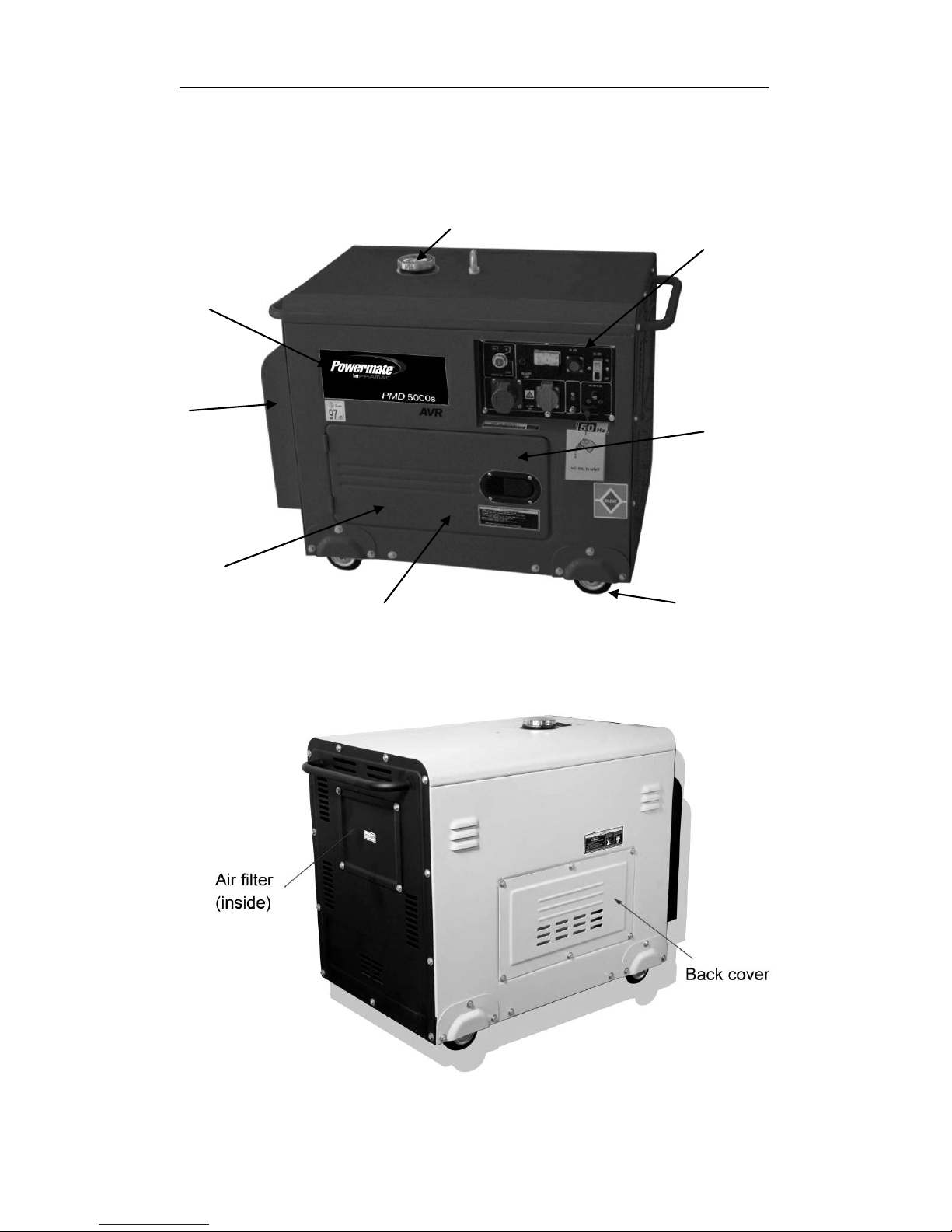

1-4 Parts name and control panel

1-4.1 Parts Name

Cover of fuel tank

Label

Muffler

(inside)

Battery

(inside)

Door

Wheel

Engine

(inside)

Control Panel

6

Page 7

OPERATING THE DIESEL GENERATOR

1-4.2 control panel

Single phase Control Panel

Three Phase Control Panel

Low oil protection

indicating lamp (12V)

Voltmeter

99T1-300V

2P support for

breaker

Fuse10 A

Red wire

holder (107)

Black wire

holder (107)

Bolt to the

grounded

Socket SCHUKO

230V 16A

Socket 2P+T

CEE 230V 16A

Electric start switch

Connector

7 contacts

Low oil protection

indicating lamp (12V)

Voltmeter

99T1-300V

2P support for

breaker

Fuse10 A

Red wire

holder (107)

Black wire

holder (107)

Bolt to the

grounded

Socket 2P+T

400V 16A

Socket 2P+T

CEE 230V 16A

Electric start switch

Connector

7 contacts

7

Page 8

OPERATING THE DIESEL GENERATOR

CHAPTER 2 OPERATING THE DIESEL

GENERATOR

2-1 General main points of safety during

operation of the generator set.

In order to operate the generator set safely, please follow all the

instructions provided in this manual carefully. Doing so otherwise may lead to

accidents and or equipment damage.

2-1.1 Fire prevention

Do not use gasoline, kerosene or other fuels other than light diesel fuel.

Keep all flammable fuels away from the generator as the generator may

spark and ignite these gases.

Keep the diesel generator at least 1.5 meters away from buildings and or

other equipment.

Always operate your diesel generator on a level site.

2-1.2 Prevention from inhaling exhaust gases.

Never inhales exhaust gases emitted by the engine. The exhaust gases

contain toxic carbon monoxide.

Never operate your generator in places with poor ventilation. In order to

operate this machinery indoors, a suitable ventilation system for the building is

required to draw the poisonous exhaust gases out.

2-1.3 Prevention from accidental burns

Never touch the muffler and its cover when the diesel engine is running.

Never touch the muffler and cover after the diesel engine has been used,

as the muffler remains hot for a good period of time.

2-1.4 Electric shock and short circuits

Never touch the generator if the generator is wet. Also never touch the

generator if your hand is wet.

Never operate your generator if the weather conditions call for any type of

precipitation such as rain, snow, or fog.

To prevent electrical shocks, the generator should be grounded. Please

refer to Fig. 2-1 before beginning to use the electric generator.

Fig. 2-1

8

Page 9

OPERATING THE DIESEL GENERATOR

NOTE

When connecting devices to the

generator, make sure all other devices

are rated lower than the generators

output. Any generator socket should not

be overloaded over its regulated limit.

2-1.5 Other safety points

Before operating this generator, all operators

should have a good knowledge of how to break

the circuit if any accidents occur. Also, all operators should be familiar with all

the switches and functions of the generator before using this machine. While

operating the generator, wear safe shoes and suitable clothes during operation.

Always keep children and animals away from the generator.

2-1.6 Battery

Wear protective gear when working with the battery to protect your eyes, skin,

and clothing,. If you come in contact with the electrolytic liquid, wash it

immediately with clean water. Also, if the electrolytic liquid comes in contact

with your eyes, see a doctor immediately.

2-2 Preparation before operation

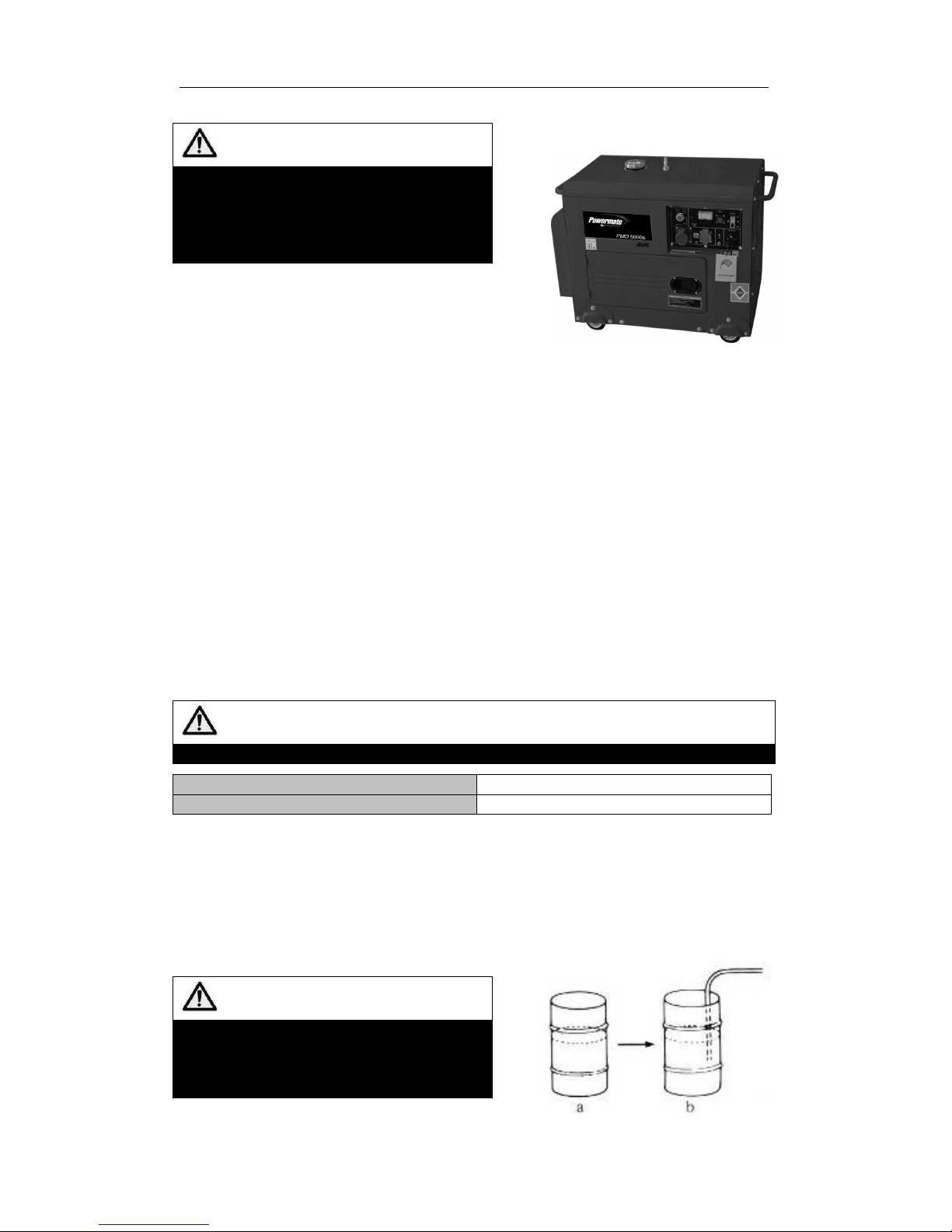

2-2.1 Fuel choices and fuel treatment

Use only light diesel fuel. Otherwise it will be difficult to start the generator.

The fuel should be filtered clean. Never let dust and water mix with fuel in

the fuel tank. Otherwise it will clog the fuel lines and oil nozzles. It may

also damage your pressure pump.

Note

It is dangerous to overfill the fuel tank. Never exceed the red piston in the filter.

Type

PMD 5000s

The effective volume of fuel tank:

14.5L

a. After purchasing fuel, put it into a drum and let it sit for 3-4 days.

Otherwise it contains granule, which will result to clog the fuel lines.

b. 3-4 days later, insert half of the fuel sucker into the drum, (water and

impurities stay in the lower portion of the drum) .Otherwise they will be taken in.

Contaminated fuel will cause accelerated wear to fuel system part.

NOTE

Never smoke near the opening of the

fuel tank. Do not let sparks get near the

fuel or fuel tank and do not overfill tank.

After filling, tighten the fuel cap.

9

Page 10

OPERATING THE DIESEL GENERATOR

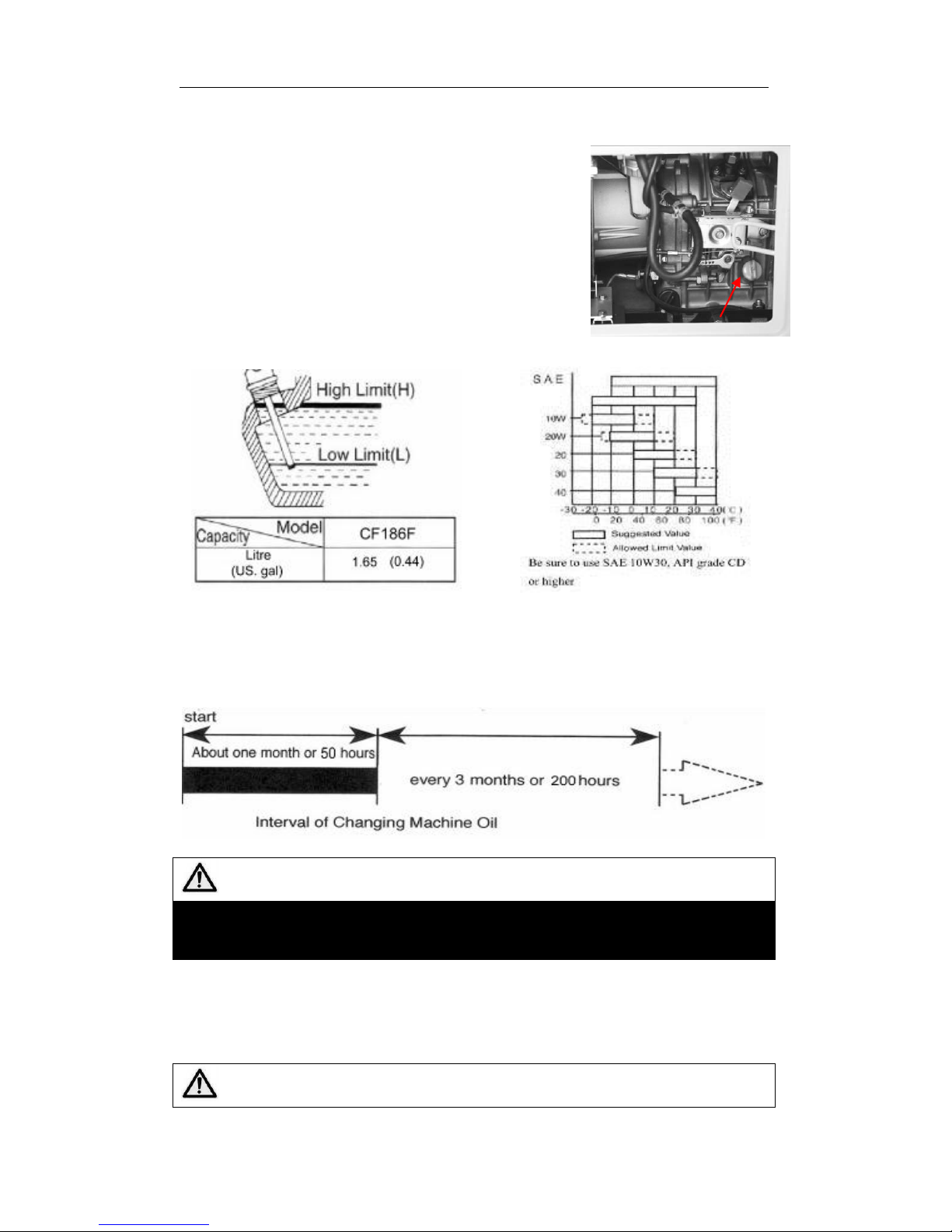

2-2.2 Check and fill engine oil

Make sure the generator is on level ground and

remove the dipstick from the engines. if not, the

oil level of the engine which show us are wrong.

Check if the oil level is between the high limit

and low limit. If the engine is new or oil is not

enough, fill the engine with the right engine

oil(10W30).

Put the dipstick back into the hole to check the

engine oil level.

Choose the right engine oil

Engine oil is the most important factor in determining the life of your generator

engine. If you use poor engine oil or if you don’t change the oil regularly, the

piston and cylinder will wear easily or seize up. Also, the life of the other parts

in your engine such as bearings, and other rotating parts will shorten

considerably.

NOTE

Although there is an alarm system to check for low oil pressure, it is always a

good idea to check the amount of oil inside the engine. If the oil level is low, fill

it before starting the engine.

A good time to drain the oil from the engine is when the diesel engine is still hot.

If the engine is fully cooled, it is more difficult to drain all the oil out or some

impurities will remain in the engine.

WARNING

Oil dipstick

10

Page 11

OPERATING THE DIESEL GENERATOR

DO NOT fill engine oil when the machines are running.

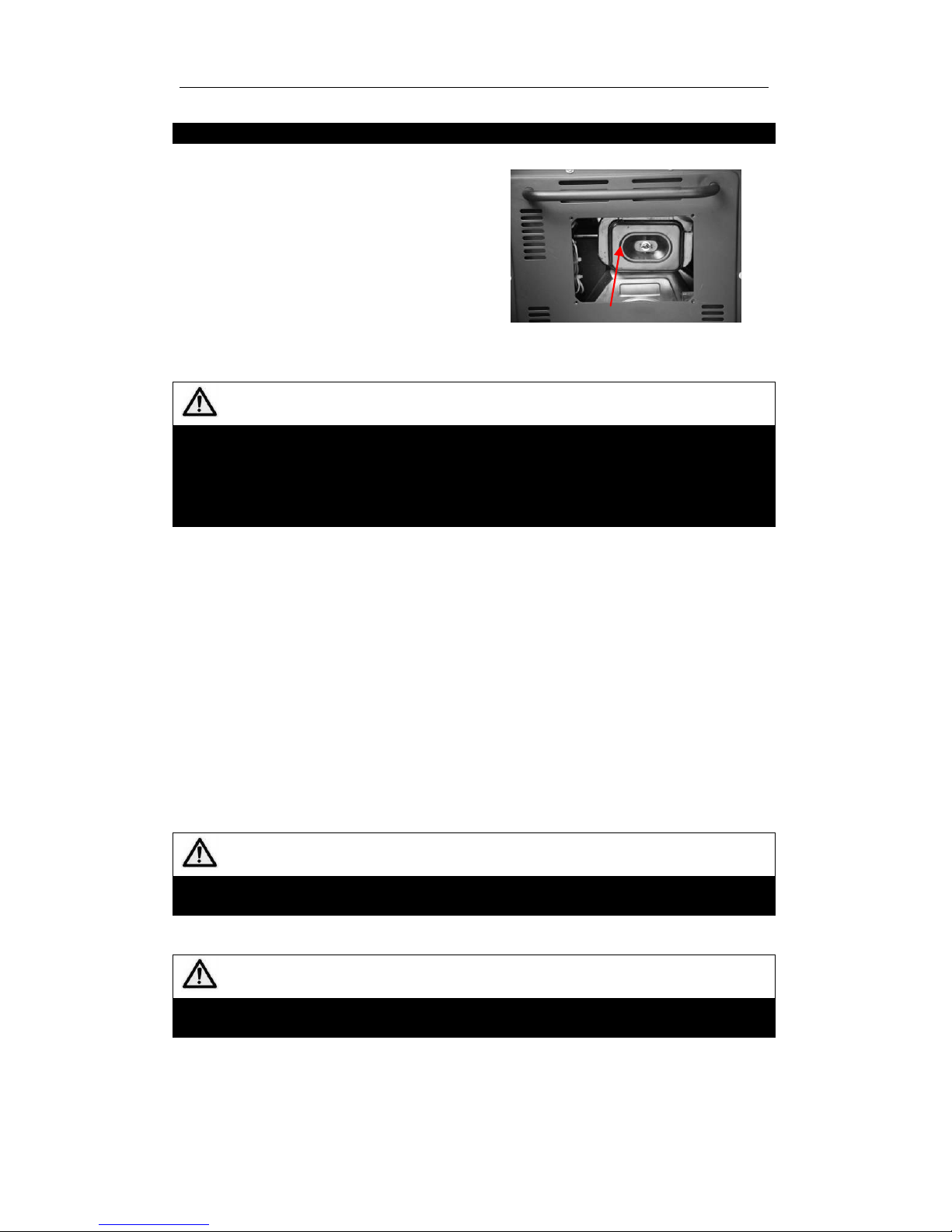

2-2.3 Checking the air filter

(1) Open the cover of generators, you will

see the air filter assembly.

(2) Loosen the butterfly nut of air filter,

take the cover of the air filter off and take

the air filter element out.

NOTE

Do not use detergent to wash the air filter element.

When the performance of the engine decreases or when the color of the

exhaust gases is bad, exchange the filter element.

Never start the engine without the air filter as foreign objects may enter the

intake and damage the engine.

(3) After replacing the air filter element, replace the cover and tighten the

butterfly nut firmly.

If not replace the air filter immediately, the dust in the air will not be adsorbed.

In that case, it stands a good chance to block the air way.

2-2.4 Check the oil way

The fuel and oil in a new engine is drained before sold. Before you start the

engine, please fill the fuel tank and engine oil first. Then, check to see if there

are air bubbles in the engine. If there are, follow these procedures. Loosen the

connecting nut between the oil injection pump and oil pipe. Bleed the air from

the system until there are no more bubbles. Then replace the connecting nut

and tighten it.

2-2.5 Check the generators

(1) Close the power switch and disconnect from any load. Otherwise it may

cause electric shock. Even make injures or death.

WARNING

Make sure to close the power switch.

Make sure to ground the generators.

(2) How to use double voltage generators

Push the voltage switch to the right voltage you will use.

WARNING

Make sure to disconnect any load before starting the generators. It is very

dangerous if not.

Air filter cover

11

Page 12

OPERATING THE DIESEL GENERATOR

Knob handle

2-3 Checking the operation of the diesel engine

2-3.1 Low-pressure alarm system.

Diesel engines have a low-pressure sensor system where if the oil pressure

drops too low, the sensor will shut the engine off. The purpose of having this

system is to ensure that the engine does not seize up. If there is not enough oil

in the engine, the temperature of the oil will be raised too high. On the contrary,

if there is too much oil in the engine, the engine oil can slow the engine down

considerably.

2-3.2 How to open the case door/cover

(1) Open the case door: Pull the handle outward and open the door. Do these

checks daily.

(2) Loosen the outer cover bolt of the air filter

and outer cover of the oil nozzle, and then

check the air filter.

(3) Check the outer cover of the oil nozzle.

Loosen the butterfly nut and open the outer

cover.

2-3.3 Engine break in

When you purchase a brand new engine, the engine must be properly broken

in. The break in period is about 20 hours.

(1) Avoid overloading the engine when brand new

(2) Change the engine oil according to specifications. An oil change for a brand

new engine is about 20 hours or every month, an older engine, the oil change

is about 100 hours or three months.

If not breaking in, it will reduce the serving life, reliability and cost performance

of the engine. At last, the life of the generator also be shortened.

2-4 Starting the generator set

2-4.1 Starting.

(1) Make certain the generator is on a " FLAT " or " LEVEL SURFACE ". If the

engine is tilled, fuel spillage may result.

(2) Disconnect all electrical loads from the generator. Never start and stop the

generator with electrical devices plugged in or turned on. Otherwise it will result

to short circuit, even break down the starter motor.

(3) Turn the Fuel Valve to the " ON " position. Otherwise fuel will be not enough

to start the generator.

(4). Push the speed level to " run " Position. If do not so, the start of generator

will be fail.

(5) Insert the ignition key to the “ off ” position.

(6) Electric Start: Turn the ignition key to the " Start " position and hold until

12

Page 13

OPERATING THE DIESEL GENERATOR

engine starts. Otherwise it will be abnormal to electrify. ( If the engine fails to

start within five seconds, release the key and wait at least ten seconds before

attempting to start the engine again. If holding on starting, it will heat up motor.)

(7) As engine warms up, move the ignition key to " on " position. Otherwise the

fuel way will cause serious trouble.

2-4.2 Battery

NOTE

If you crank the starter too long, the battery may be drained too much to

provide enough energy for proper engine ignition.

Also, when the diesel engine is operating, let the key retain in the “ON”

position.

IMPORTANT NOTE

All of our units come with a maintenance free battery. You do not need to add

any battery acid.

2-5 Proper operation of the generator set

2-5.1 Operating the diesel engine

1. Pre-heat the diesel engine for 3 minutes under no load conditions.

2. First check the low oil pressure indication light in the panel. If the light is red,

please fill into enough oil.

3. Do not adjust the speed limit regulation bolt or the fuel adjustment bolt.

These bolts have been set by the factory already, changing them will affect the

properties of the engine performance.

2-5.2 Checks during engine operation

1. Check to see if there are abnormal noises. Check the joint of oil passages,

fuel passages, water passages and air passages frequently to find out whether

there is any leakage. If any, remove at once. Otherwise serious troubles may

be caused.

2. Check to see if the performance is good or bad.

3. Check the color of the exhaust gases (whether it is too black or too white).

If any of these conditions exist, stop the engine and find the cause of the

problem. If no problems are found, please contact your local dealer or our

nearest company branch.

13

Page 14

OPERATING THE DIESEL GENERATOR

2-6 Loading

2-6.1 Connecting Electrical Loads:

1. Let the engine stably and warm up for a few minutes after starting.

2. Plug in and turn on the desired VOLTAGE AC Output with electrical loads.

IMPORTANT NOTE

DO NOT connect 3-phase loads to SINGLE PHASE Diesel Generator.

DO NOT overload this generator.

To prolong the life of your generator and properly connect your appliances,

please follow these steps to add electrical load:

3. Start the generator with NO ELECTRICAL LOAD ATTACHED.

4. Allow the engine to run for several minutes to STABILIZE.

5. Plug in and turn on the first item. It is best to attached the item with the

LARGEST LOAD first.

6. Allow the engine to stabilize.

7. Plug in and turn on the next item.

8. Allow the engine to STABILIZE.

9. Repeat step 4-5 for each capacity when adding loads.

2-6.2 Output of electricity

1. Raise the revolutions per minute (turn the speed handle to the max setting)

of the generator to get the maximum power out of the generator. If not, the

automatic voltage regulator device will excite and doing this for long periods

of time will cause the AVR to burn. For the rated speed of the generator,

please refer to Chapter 1, item 1-1 technical specification and data.

2. Observe the pointer of the voltmeter, it should point to the voltage you need

5%. Meanwhile put the switch in the GEN (generator) position. The AC

voltage from the socket of the power supply can be output.

2-6.3 Charging the battery

1. For the electric starter on the generator sets, the 12V battery is automatically

charged through the regulator on the side of the engine when it is running.

2. If the generator is not used for long periods of time, the battery should be

disconnected to avoid energy loss from the battery.

3. Do not connect the negative and positive terminals of the battery together at

any time. Doing so will damage the battery and cause serious injuries.

4. Do not reverse the polarities when attaching the battery cables to the battery.

NOTE

Do not start more than two devices simultaneously. Each device should be

started one by one to prevent overloading the generator.

The generator should be running at 3600 revolutions per minute in order to

achieve the (60 Hz) frequency. The speed of the engine can be adjusted from

the speed governor.

14

Page 15

OPERATING THE DIESEL GENERATOR

Doing so will damage both the battery and the electric starter.

5. When charging the battery, the battery produces flammable gases. Do not

smoke, let flames, and sparks get near the battery while it is charging as this

may cause a fire.

To avoid sparking while connecting the cables to the battery, first, connect the

cables to the battery then to the motor. To disconnect battery cables, first

disconnect the motor end of the cable.

2-7 Stopping the generator

1. Take the electrical load off the generator, when you want to stop the

generators.

2. Move the air switch to “off” position. If not, the short circuit will appear.

3. Put the speed handle in the “RUN” position and let the engine run for 3

minutes after unloading. Do not stop the diesel engine immediately let it warm

down. Stopping the diesel engine suddenly may raise the temperature of the

engine abnormally and lock the nozzle and damage the diesel engine.

NOTE

1. If you cannot stop the engine with a

load on it, then remove the load first

than stop the engine.

2. Press down on the brake handle.

3. If equipped with an electric starter,

turn the key to the “Off” position.

4. Put the fuel handle to the “S”

position.

4. Put the ignition key to “off” position. Then the generators will stop.

5. Move the speed level to “stop” position, which make sure to cut off the fuel

way.

6. Close the fuel valve. But don’t stall the generator by turning off the cock of

the fuel tank in case air enters fuel passages to cause difficult starting next

time.

Speed

handle

15

Page 16

MAINTENANCE

CHAPTER 3 MAINTENANCE

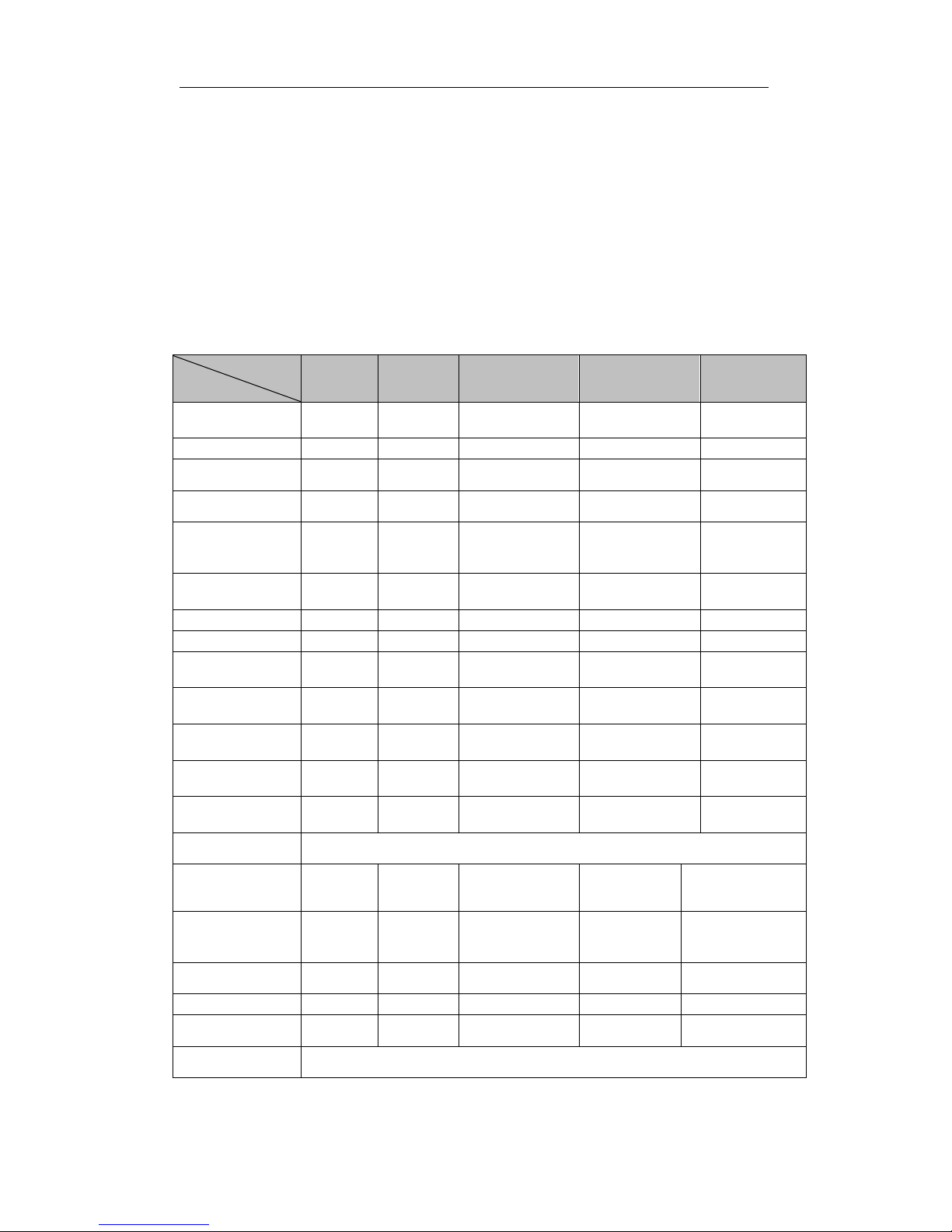

3-1 Maintenance schedules

Keeping your generator well maintained will prolong the life of your generator.

Everything needs to be checked including the diesel engine, generator, control

cabinet, and frame. For overhauling procedures, please refer to the instruction

manual of the relative subassembly. If you need these manuals, please call our

company and we will send you one.

Before starting the maintenance, make sure the diesel engine is off.

Please refer to the Table 3-1 for the proper maintenance schedule.

Table 3-1. Maintenance schedule for diesel generator set

Time

Item

Everyday

After 1

month or

50hours

Every 3 month

or 200 hours

Every 6 month

or 400 hours

Every 1year

or 1000 hours

Check the fuel

level and refill

○Before

starting

Drain the fuel tank

○

Check and fill

enough engine oil

○

Clean the fuel

filter

○

Check fuel oil

leakage

○after

every

operating

Check and screw

each fastened part

○

●screw the bolt of

cylinder head firmly

Check injector

●

Check injection pump

●

Check fuel pipe

●If necessary

exchange it

Check the lube. oil level in

the oil pan and refill

○before

starting

Replace the lube.

oil

○the first

time

○the second time

and afterward

Clean lube. Oil

filter

○the first

time

○the second time

and afterward

Check the air

cleaner element

○the first

time

○the second time

and afterward

Change the core

of air filter

If damaged or smeary , change it in time

Check the battery

liquid level and

refill

○

Adjusting the intake

and exhaust valve

clearance

●the first

time

●the second

time and

afterward

Grind air intake and

air exhausted gate

●

Exchange piston ring

●

Check electric brush

and slide ring

●

Check insulation

resistance

The time of stop is over 10 days ○

Note: the quality period of the injector and injection pump is 1500 hours

or two years. There into,● means it should operate with special

tools, or can be checked by dealer.

16

Page 17

MAINTENANCE

Dipstick

Oil drain bolt

3-1.1 Changing the engine oil (every 100 hours)

Take the oil cover off. Remove the oil drain plug

when the diesel engine is still hot. Be careful of

hot oil and hot engine as you may get burned. The

bolt is located at the bottom of the cylinder. After

draining the oil, put the bolt back and tighten it.

Then fill with the proper engine oil to the proper

level.

3-1.2 Air filter maintenance schedule

1. Clean air-filter every 6 months or 500 hours of operation.

2. If necessary, exchange it.

3. Do not use detergent to clean air filter element.

NOTE

Never start the engine without the air filter. This can cause serious damage to

the engine if foreign objects enter the intake system. Always change the air

filter on time.

3-1.3 Fuel filter maintenance

1. The fuel filter should be cleaned often to keep the engine running at

maximum performance.

2. The recommended time period for cleaning the fuel filter is 6 months or 500

hours of operation.

a. To do this, first drain the fuel from the fuel tank.

b. Loosen the small screws on the fuel switch and remove the fuel filter form

the port. Use diesel fuel to clean the fuel filter. Also, remove the fuel injector

and clean the carbon deposit around it. The recommended time period for this

is 3 months or 100 hours.

3-1.4 Cylinder head bolt tensions

The cylinder head bolts should be tightened to specifications please refer to the

diesel engine manual for specifications and the special tools required to do this.

3-1.5 Battery check

Make sure the battery acid is full. The engine uses a 12V battery. Due to

numerous starting cycles, the battery acid may be used up. Also, before filling,

verify that the battery is not damaged in any way. Add distilled water to the

battery when filling. Perform checks on the battery once a month.

3-2 Storing for long periods of time

If your generator needs to be stored for long periods of time, the following

preparations should be made.

1. Start the diesel engine for 3 minutes then stop it.

2. When the engine is still hot, change the engine oil with new engine oil of the

proper grade.

3. For electric started generator, press the decompression handle down and

crank the engine for 2-3 seconds. To do this, put the starter switch in the “Start”

position. (Do not start the diesel engine)

4. Clean the engine and store it in a dry place.

17

Page 18

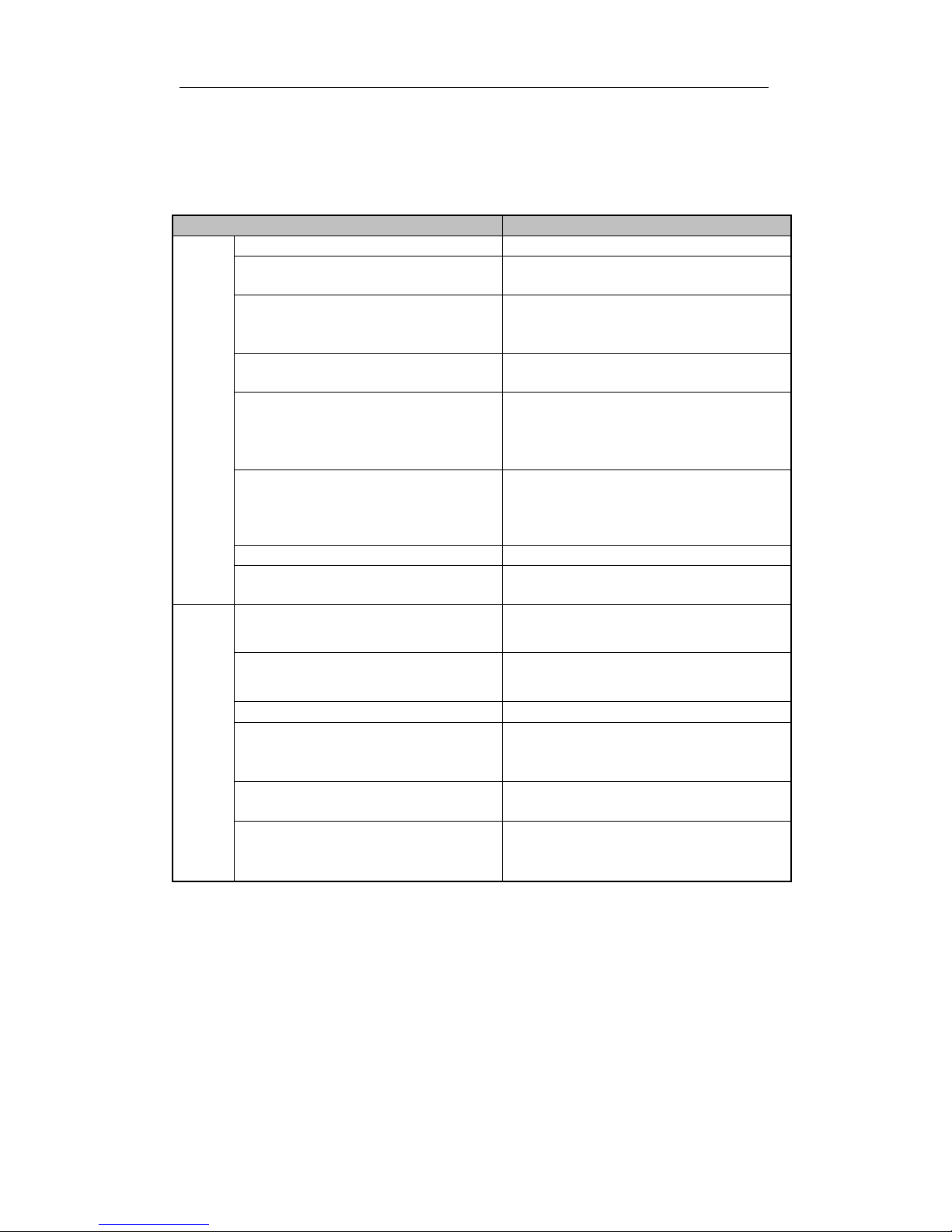

TROUBLESHOOTING

CHAPTER 4 TROUBLESHOOTING

4-1 Troubleshooting procedures

Causes of malfunction

Remedy

Diesel cannot be started.

Not enough fuel

Add enough fuel

The switch of fuel is not at

“OPEN” position.

Turn the switch of fuel to “OPEN”

position.

High-pressure pump and nozzle

do not inject fuel or the injected

amount is less.

Disassemble the nozzle and adjust it

at test table.

Speed control lever is not at

“RUN” position.

Turn speed control lever to “RUN”

position.

Check level of lubrication oil.

The standard oil amount of

lubricating oil should be between

high graduation “H” and low

graduation “L”.

It is not quick and powerful to pull

reactive starter.

Start diesel engine in accordance

with the requirements of “start

operation procedures”.

Nozzle exist dirt.

Clean the nozzle.

Accumulator has not electricity.

Charge the accumulator or

exchange it.

Generator cannot generate electricity

and has not welding voltage

Master switch (NFB) is not be

switched on.

Turn master switch handle to “ON”

position.

Carbon brush of generator was

worn. The contact is bad.

Exchange the carbon brush.

The contact of socket is bad.

Adjust the contact feet of socket.

The rated revolution of engine

cannot be reached.

Make it reach to the rated revolution

in accordance with the

requirements.

AVR automatic governor is

damaged.

Exchange it.

The potentiometer of current

regulation for electric welding is

damaged.

Exchange it.

If you are still having trouble, please contact with your nearest dealer or with

our company directly if necessary.

4-2 Questions and doubts

1. Model of diesel engine generator and engine model number.

2. State of residency.

3. Number of hours of operating equipment along with the problem that occurred.

4. A detailed condition and time when the problem occurred, in other words,

climate and atmosphere.

18

Page 19

CIRCUIT DIAGRAM

CHAPTER 5 CIRCUIT DIAGRAM

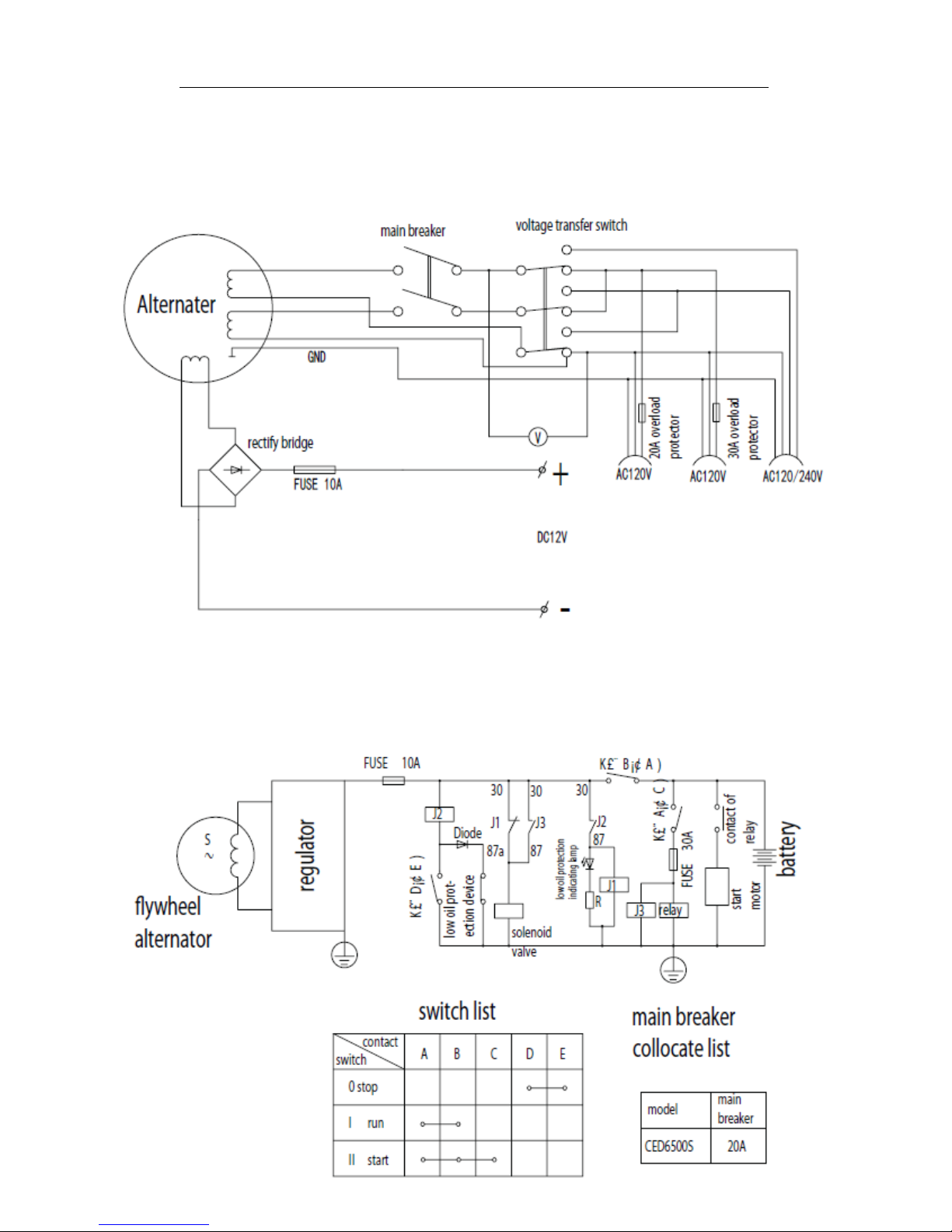

Figure 5-1 single-phase double voltage circuit diagram

19

Page 20

CIRCUIT DIAGRAM

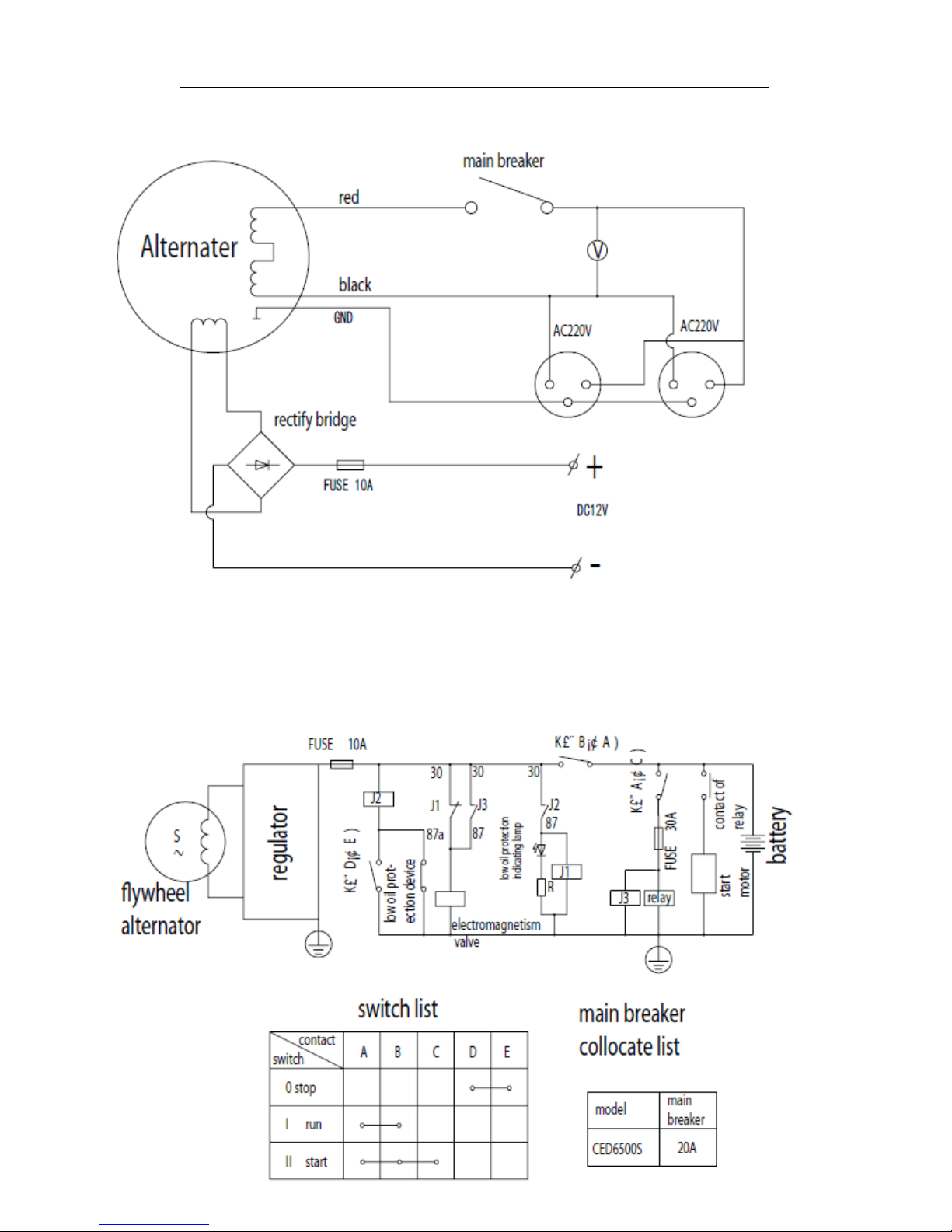

Figure 5-2 single-phase single voltage circuit diagram

20

Page 21

CALIFORNIA EMISSIONS CONTROL WARRANTY STATEMENT

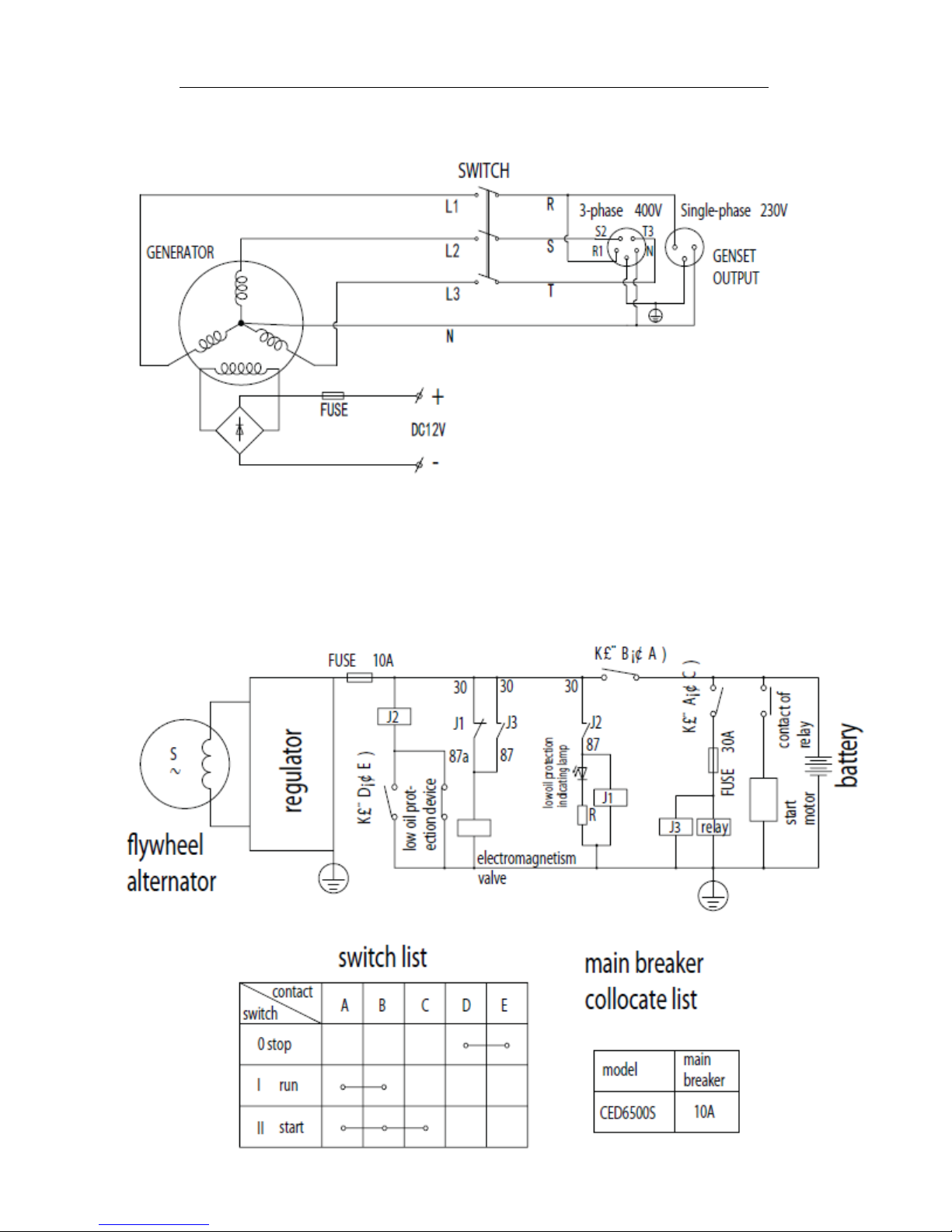

Figure 5-3 three-phase circuit diagram

21

Page 22

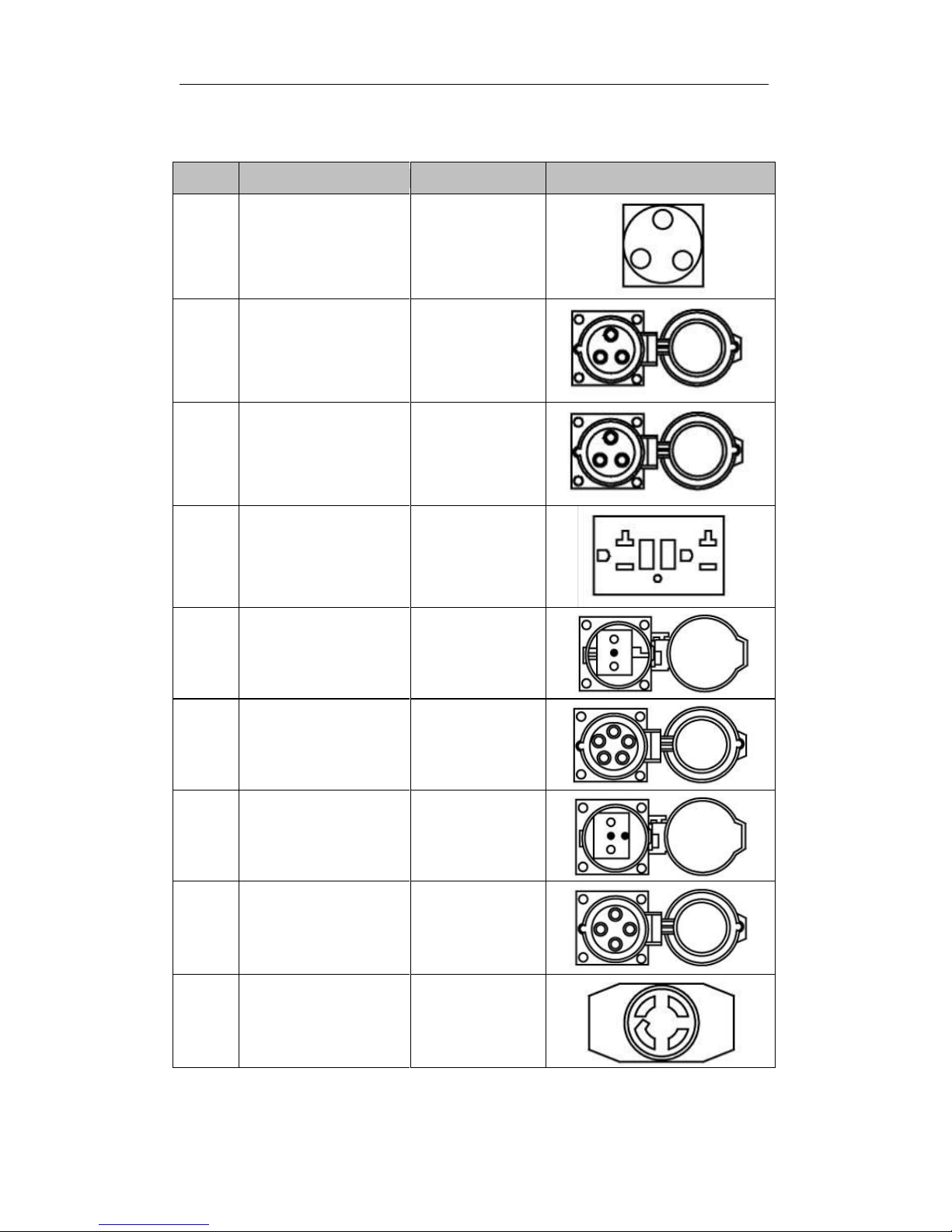

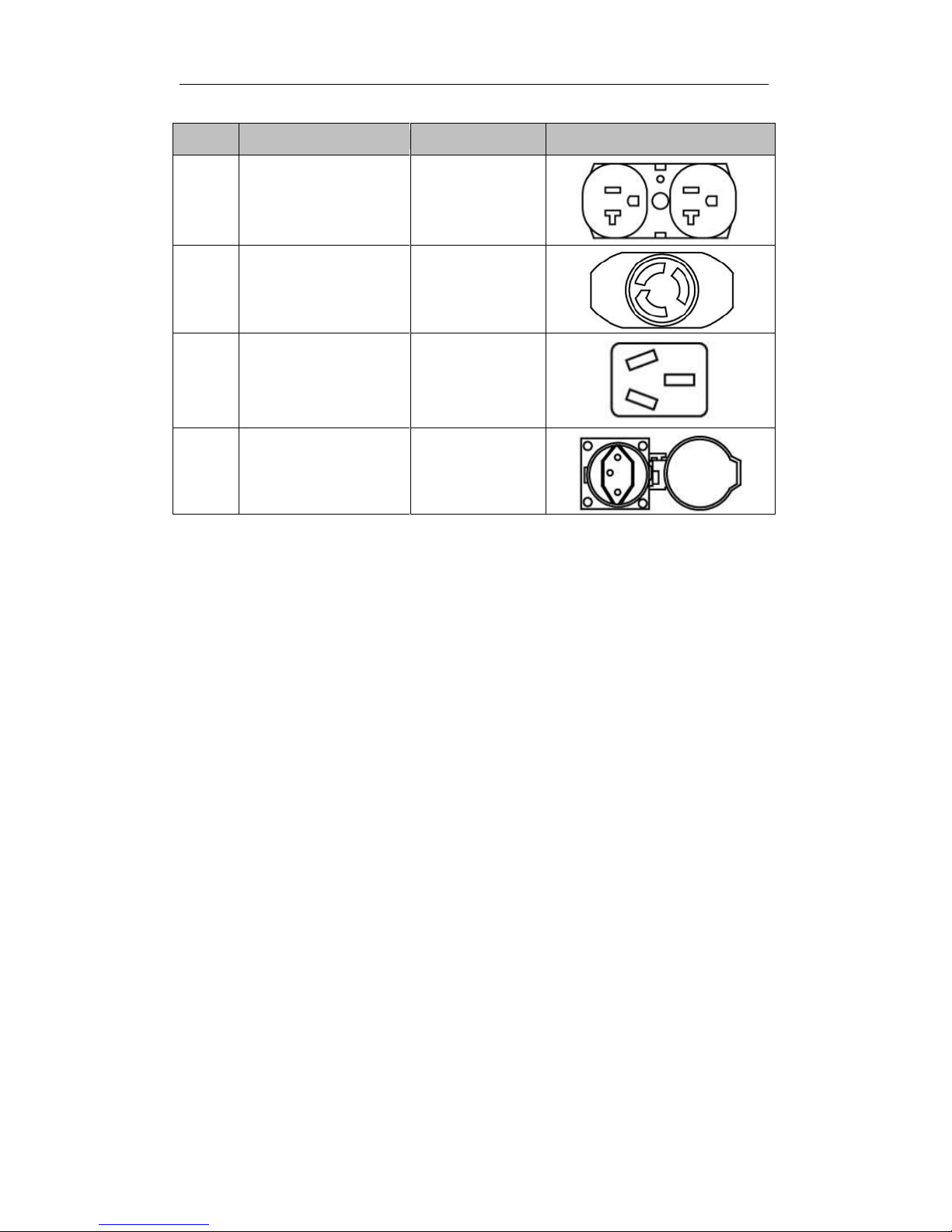

Appendix Ⅰ :Types of sockets

Code

Description

Specification

Picture

S01

S.A socket

25A, 250V

S02

British socket

32A, 240V

S03

British socket

16A, 240V

S04

Square American

type-socket

20A, 120V

S05

Germany socket

16A, 250V

S06

Three-phase five

holes socket

16A, 415V

S07

French socket

16A, 250V

S08

Three-phase four

holes socket

16A, 215V

S09

American type

4-hole unit loose

socket

30A, 250V

22

Page 23

Code

Description

Specification

Picture

S10

American double

socket

20A, 125V

S11

3-hole unit loose

socket

(UL-authentication

optional)

30A, 250V

S12

Australian socket

16A, 250V

S13

Swiss socket

10A, 250V

23

Page 24

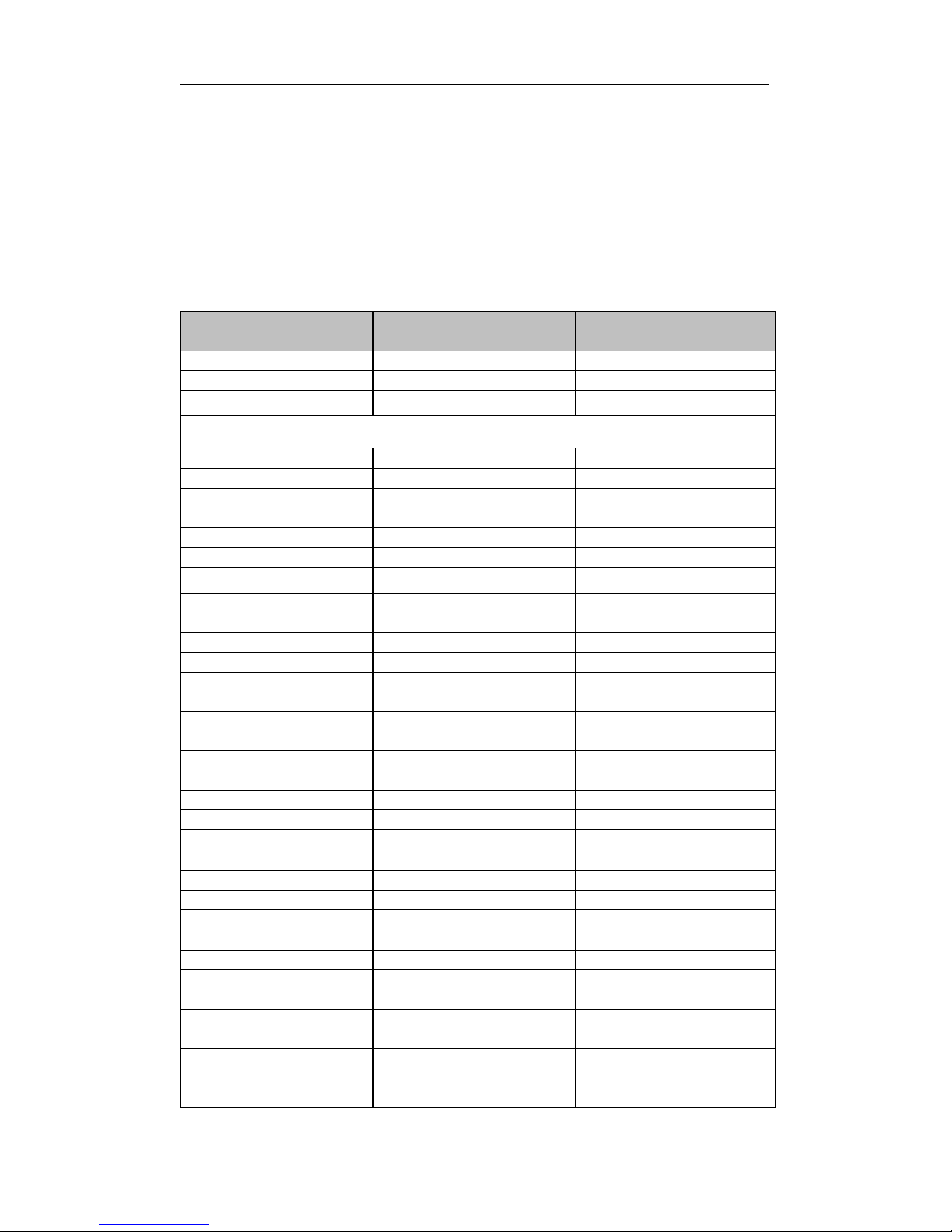

Appendix Ⅱ :General power list of

appliance

To select the correct size generator for your needs you should make a list of

which tools and/or appliances you intend to operate with your generator. The

chart below contains approximate wattages and should give you an idea of the

size generator you will need. After you make your list of devices to be used, (be

sure to consider starting wattages) you will add the total watts and select the

generator that can supply that amount of power.

House Hold

Running Wattage

Requirements

Starting Wattage

Requirements

Coffee Maker

1750

1750

Dishwasher

1450

1800

Electric Fry Pan

1300

1300

Electric Range

6 Inch Elements

1500

1500

8 Inch Elements

2100

2100

Microwave Oven 625

watts

625

800

Refrigerator or Freezer

700

2200

Toaster 2-slice

1050

1050

Toaster 4- Slice

1650

1650

Automatic Clothes

Washer

1150

2300

Clothes Dryer Gas

700

1800

Dehumidifier

650

800

Electric Blanket (queen

size)

650

800

Garage Door Opener

¼hp

550

1100

Garage Door Opener

1/3 hp

725

1400

Furnace Fan 1/8 hp

500

1000

Furnace Fan 1/6 hp

750

1500

Furnace Fan ¼ hp

900

1800

Furnace Fan 1/3 hp

1000

1800

Furnace Fan½hp

1200

1500

Hair Dryer

300 - 1500

300 - 1500

Clothes Iron

1200

1200

Lights

As Indicated

As Indicated

Radio

50 - 200

50 - 200

Well or Sump Pump

1/3 hp

750

1500

Well or Sump Pump

1/2 hp

1000

2000

Well or Sump Pump 1

hp

2300

4500

Color Television 13 to

300

300

24

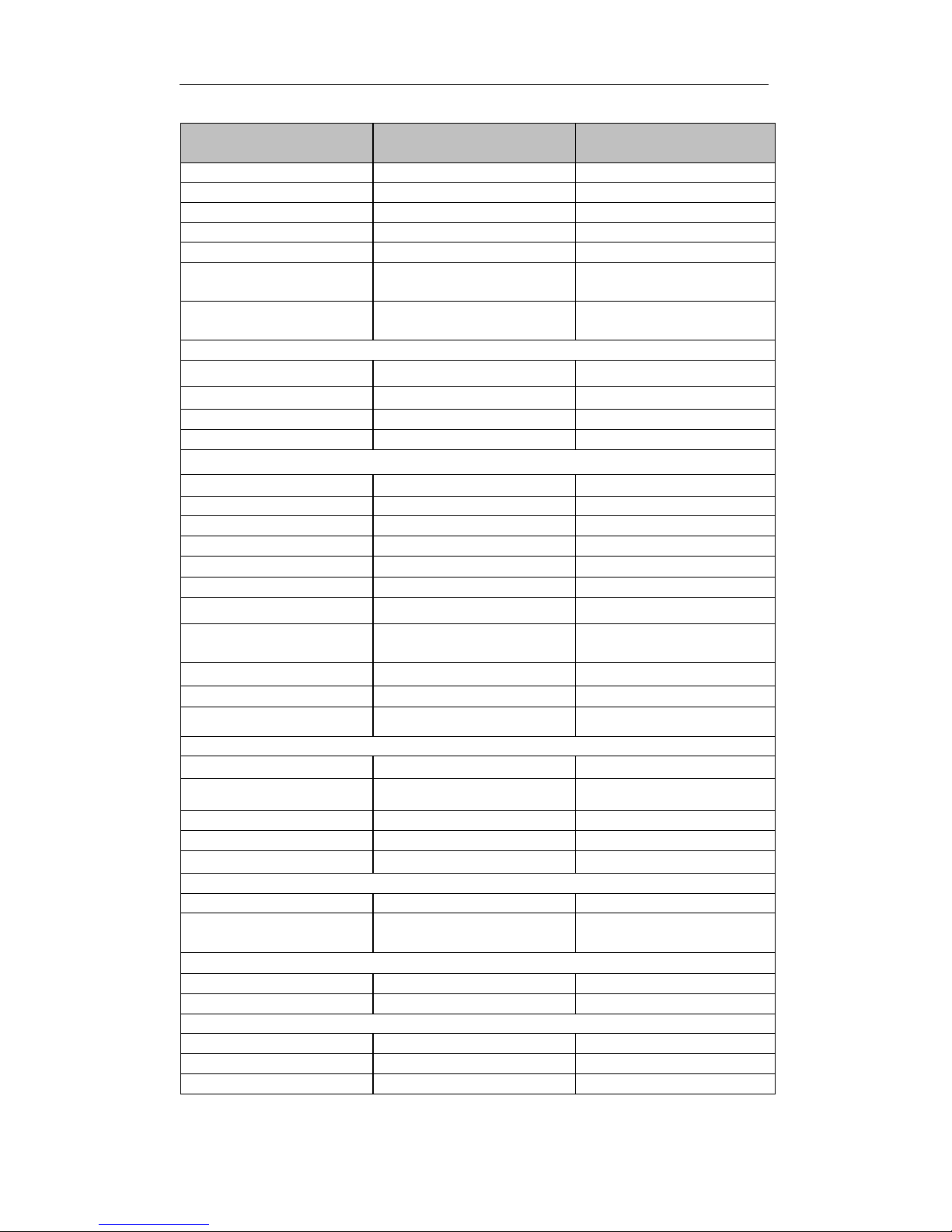

Page 25

House Hold

Running Wattage

Requirements

Starting Wattage

Requirements

32

VCR

50

50

Computer

150

150

Modem

25

25

Printer

100

100

Vacuum Cleaner

Upright

800

1100

Vacuum Cleaner

Canister

1100

1500

Central Air Conditioner

10.000 BTU

1500

2200

20.000 BTU

2500

3300

24.000 BTU

3800

4950

40.000 BTU

6000

7800

Air Compressor

½ hp

1000

2000

1 hp

1500

4500

1½hp

2200

6000

2 hp

2800

7700

Bench Grinder 6-inch

720

1000

Bench Grinder 8-inch

1400

2500

Bench Grinder 10-inch

1600

3600

Electric Cultivator 1/3

hp

700

1400

Electric Grass Trimmer

500

650

Drum Mixer ¼hp

700

1400

Mercury/Halogen

1000

1000

Floor Polisher

16-inch,¾hp

1400

3100

20-inch, 1hp

1600

4500

Hand Drill¼inch

350

350

Hand Drill 3/8 inch

400

400

Hand Drill½inch

600

600

Submersible

Water Pump 400gp

200

400

Water Pump

Centrifugal Type

500

650

Wet And Dry Vacuum

1.7 hp

900

900

2.5 hp

1300

1300

Saws

Worm Drive (chop saw)

1800

2600

Circular Saw 6½inch

800

1200

Circular Saw 7¼inch

1400

2300

25

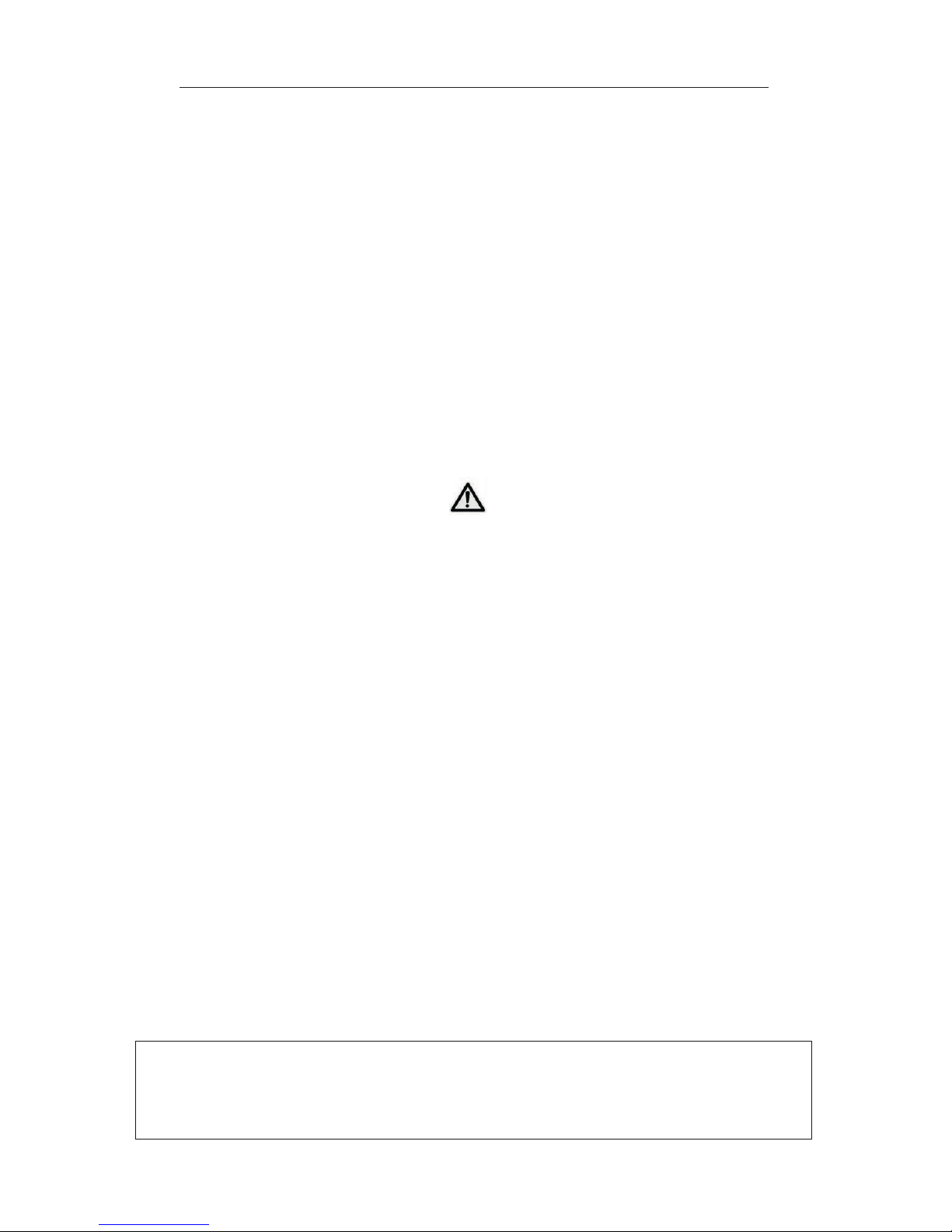

Page 26

House Hold

Running Wattage

Requirements

Starting Wattage

Requirements

Circular Saw 8 ¼ inch

1800

3000

Electric Chain Saw

1100

1400

Table Saw 9 inch

1500

3000

Table Saw 10 inch

1800

4500

Electric Welder 70 amp

2800

2800

Band Saw

1100

1400

Electric Fence, 25

miles

250

250

Stock Tank De-Icer

1000

1000

Grain Cleaner

650

1000

Portable Conveyer½hp

1000

2400

Grain Elevator¾hp

1000

2400

Milk Cooler

1100

2300

Mixer 3½Cubic Feet

¾hp

2800

7700

Milking Machine, 2 hp

1100

2300

26

Page 27

PREFAZIONE

PREFAZIONE

La ringraziamo per aver scelto i prodotti della nostra azienda.

I manuali la aiuteranno ad azionare e manutenzionare correttamente i

prodotti. La invitiamo a leggere attentamente i manuali prima di azionare i

prodotti, in questo modo i generatori potranno lavorare nelle condizioni

migliori e godere di una lunga vita operativa.

I consumatori noteranno che questo manuale potrebbe differire

leggermente dal prodotto reale, questo perché abbiamo realizzato dei

miglioramenti sui nostri prodotti. Anche

alcune immagini nel manuale

potrebbero differire leggermente dal prodotto reale. Il produttore si

riserva il diritto di effettuare delle modifiche in qualunque momento

senza preavviso e senza incorrere in obblighi.

La pregiamo di notare il seguente

avviso.

Qualora l’uso dei prodotti non sia conforme con i manuali, sussiste il rischio

di lesioni personali e decesso.

È pertanto OBBLIGATORIO azionare i prodotti solo dopo aver letto

attentamente i manuali.

27

PR INDUSTRIAL s.r.l.

Loc. Il Piano

CAP 53031, Casole D’Elsa (SI)

ITALIA

Page 28

TAVOLA DEI CONTENUTI

TAVOLA DEI CONTENUTI

Capitolo 1 Specifiche Te cniche e Dati… … … ….4

1-1 Specifiche tecniche e dati………………… …… ……………4

1-2 Parametri operativi di base…………………………………………..6

1-3 Ingombro e informazioni generali dei generatori ………………6

1-4 Nome delle parti e pannello di controllo .…………………………….7

Capitolo 2 Azionare il generatore diesel ……………………….....4

2-1 Regole di sicurezza generale per l’azionamento del generatore 8

2-2 Preparazione prima della messa in funzione………………………9

2-3 Controllare la messa in funzione del motore diesel ……………..13

2-4 Avviamento del gruppo generatore ………………………………..13

2-5 Messa in funzione corretta del gruppo generatore ………………..14

2-6 Caricare………………………………………………………………15

2-7 Arresto del generatore ………………………………………………16

Capitolo 3 Manutenzione…………………………………………………..17

3-1Programma di manutenzione .........................................................17

3-2 Conservazione per lunghi periodi di tempo ……………………...19

Capitolo 4 Risoluzione dei problemi ………………………………….21

4-1 Procedure di risoluzione dei problemi ……………………………...21

4-2 Domande e dubbi ………………………………………….….21

Capitolo 5 Diagramma di circuito …………………………………….23

Appendice ⅠTipi di prese……………………………………………………..26

Appendice ⅡElenco generale delle applicazioni ...…………………………28

28

Page 29

SPECIFICHE TECNICHE E DATI

1

CAPITOLO1 SPECIFICHE TECNICHE

E DATI

1-1 Specifiche tecniche e dati

Tipo

Articolo

PMD 5000s

PMD 5000s

Generatore

Genere

monofase

trifase

Frequenza(Hz)

50

60

50

60

Potenza erogata

(KVA)

4.2

4.5

4.2

4.5

Voltaggio (A.C)(V)

220V,230V,240V,110/220V,120/240V,

115/230V

400/230V,420/240V,380/220V,

127/200V

Modalità di eccitazione

Autoeccitazione di tipo brushless o

Regolatore automatico di tensione

(AVR)

Regolatore automatico di

tensione (AVR)

Rivoluzione (r/min)

3000

3600

3000

3600

Voltaggio (D.C)(V)

12

Corrente (D.C)(A)

7

Livello di emissioni

acustiche dB(A)/7m

(0-100%load)

70-74

Fattore di potenza

cosφ

1

0.8

Gradi d’isolamento F B

Motore Diesel

Modello di potenza

CF186F (E)

Genere

A 4 tempi monocilindro raffreddato ad aria a iniezione diretta

Potenza max.

(kW/rpm)

6.5

8.6

6.5

8.6

Alesaggio x corsa

(mm)

86×70

Dislocamento del

cilindro (ml)

406

Sistema di

raffreddamento

Raffreddato ad aria

Sistema di

lubrificazione

Spruzzata a pressione, lubrificazione di tipo duplex

Volume di olio

lubrificante (L)

1.65

Sistema d’avviamento

Avviamento elettrico

Carburante

Diesel

Gruppo

Volume di carburante

nella tanica (L)

14.5

Protezione di bassa

pressione dell’olio

Presente

Peso totale (kg)

186

Ingombro complessivo

(mm)

920×520×700

Nota: la potenza indicata è raggiunta solo dopo 30 ore di avviamento iniziale.

29

Page 30

SPECIFICHE TECNICHE E DATI

1-2 Parametri operativi di base

1-2.1 Alle condizioni date, il generatore produrrà la potenza

specificata nella tabella in basso.

Tabella 1

Altezza sul livello del mare (m)

Temperatura ambiente

RH

0

+60°F (+20 oC)

60%

<3280.8ft (<1000 m)

41 – 104°F (5-40°C)

90%

cyriellemillion

1-3 Ingombro e informazioni generali dei

generatori

Si prega di fare riferimento alle specifiche per la corretta

dimensione dei diversi modelli.

30

Page 31

SPECIFICHE TECNICHE E DATI

1-4 Nome delle parti e pannello di controllo

1-4.1 Nome delle parti

Coperchio del serbatoio

Pannello di controllo

Etichetta

Silenziatore

(interno)

Batteria (interna)

Motore (interno)

Ruota

Sportello

Coperchio

posteriore

Filtro dell’aria

(interno)

31

Page 32

AZIONARE IL GENERATORE DIESEL

1-4.2 Pannello di controllo

Pannello di controllo monofasico

Pannello di controllo trifasico

Spia di bassa

protezione

dell’olio (12V)

Voltmetro

99T1-300V

Connettore 7 contatti

Supporto 2P

dell’interruttore

Fusibile 10 A

Serracavo rosso

(107)

Serracavo nero

(107)

Bullone per

la messa a

terra

Presa 2P+T

230V 16A

Presa SCHUKO

230V 16A

Interruttore

dell’avviamento

elettrico

Spia di bassa

protezione

dell’olio (12V)

Voltmetro

99T1-300V

Connettore 7 contatti

Interruttore

dell’avviamento

elettrico

Supporto 2P

dell’interruttore

Fusibile 10 A

Serracavo nero

(107)

Serracavo rosso

(107)

Bullone per

la messa a

terra

Presa 2P+T

400V 16A

Presa 2P+T

230V 16A

32

Page 33

AZIONARE IL GENERATORE DIESEL

CAPITOLO 2 AZIONARE IL

GENERATORE DIESEL

2-1 Regole di sicurezza generale per

l’azionamento del gruppo generatore.

Per azionare il gruppo operatore in sicurezza, si prega di seguire

attentamente tutte le istruzioni fornite nel presente manuale. L'inosservanza delle

istruzioni potrebbe portare ad incidenti o danni all'attrezzatura.

2-1.1 Prevenzione degli incendi

Non utilizzare gasolio, cherosene o altri combustibili diversi dal diesel

leggero.

Tenere i carburanti infiammabili lontano dal generatore, poiché potrebbe

produrre scintille e dar fuoco ai gas.

Tenere il generatore diesel ad una distanza di almeno 1,5 metri dagli

edifici o da altra attrezzatura.

Azionare sempre il generatore diesel su una superficie piana.

2-1.2 Prevenzione dell’inalazione di gas di scarico.

Non inalare mai i gas di scarico emessi dal motore: contengono monossido di

carbonio tossico.

Non azionare mai il generatore in luoghi con scarsa ventilazione. Per azionare

questa apparecchiatura in locali chiusi, l’edificio dovrà necessariamente essere

dotato di un sistema di ventilazione adeguato che aspiri i gas di scarico.

2-1.3 Prevenzione di ustioni accidentali

Non toccare mai la marmitta e il suo rivestimento quando il motore diesel

è in funzione.

Non toccare mai la marmitta e il suo rivestimento dopo che il motore diesel

è stato usato, perché la marmitta resta calda a lungo.

2-1.4 Scossa elettrica e corto circuiti

Non toccare mai il generatore se questo è bagnato. Inoltre non toccare

mai il generatore con le mani bagnate.

Non azionare mai il generatore se le condizioni climatiche minacciano una

qualsivoglia precipitazione, come pioggia, neve o nebbia.

Per prevenire le scosse elettriche, il generatore dovrebbe essere messo a

terra. Fare riferimento alla fig. 2-1 prima di iniziare ad usare il generatore

elettrico.

Fig. 2-1

33

Page 34

AZIONARE IL GENERATORE DIESEL

NOTA

Quando si collegano i dispositivi al

generatore, assicurarsi che gli altri

dispositivi siano tarati a un livello

inferiore rispetto all'uscita del

generatore. Le prese del generatore non

vanno sovraccaricate oltre i limiti

regolati.

2-1.5 Altre istruzioni di sicurezza

Prima di azionare il generatore è raccomandabile che tutti gli operatori

sappiano come interrompere il circuito in caso di incidenti. Inoltre gli operatori

dovrebbero aver familiarizzato con tutti gli interruttori e le funzionalità del

generatore prima dell’uso. Quando si aziona il generatore, indossare delle

calzature antinfortunistiche e un abbigliamento idoneo. Tenere sempre bambini

e animali lontani dal generatore.

2-1.6 Batteria

Indossare una tuta di protezione quando si lavora con la batteria per

proteggere occhi, pelle e indumenti. Se si dovesse entrare in contatto con il

liquido elettrolitico, sciacquarsi immediatamente con acqua dolce. Inoltre, se il

liquido elettrolitico entra in contatto con gli occhi, sottoporsi immediatamente a

una visita medica.

2-2 Preparazione prima della messa in funzione

2-2.1 Scelta e trattamento del carburante

Utilizzare solo diesel leggero. In caso contrario sarà difficile avviare il

generatore.

Il carburante dovrebbe essere pulito e filtrato. Impedire l’ingresso di

polvere e acqua nel serbatoio per evitare di intasare i tubi del carburante e

gli ugelli dell'olio. Si potrebbe anche danneggiare la pompa di pressione.

Nota

È pericoloso far traboccare il serbatoio. Non superare mai l’asta di livello rossa

nel filtro.

Tipo

PMD 5000s

Il volume effettivo del serbatoio di

carburante:

14.5L

a. Dopo aver acquistato il carburante, porlo in un barile e farlo decantare per

3-4 giorni. In questo modo si depositeranno i granuli che altrimenti

otturerebbero i tubi del carburante.

b. 3-4 giorni dopo, inserire nella tanica metà asta di pompaggio del carburante

per non aspirare l’acqua e le impurità (che restano sul fondo del barile). Il

carburante contaminato accelera l’usura del sistema di alimentazione.

34

Page 35

AZIONARE IL GENERATORE DIESEL

NOTA

Non fumare mai vicino all’apertura del

serbatoio di carburante. Impedire che si

producano scintille vicino al carburante e

al serbatoio e non fare traboccare il

serbatoio. Dopo il rabbocco, stringere il

tappo del serbatoio.

2-2.2 Controllare e rabboccare l'olio del

motore

Accertarsi che il generatore si trovi su una

superficie piana e rimuovere l'asta di livello dai

motori. In caso contrario, il livello dell'olio che

viene mostrato sarà errato.

Controllare che il livello dell’olio si trovi tra il

limite massimo e il limite minimo. Se il motore è

nuovo o l’olio non è sufficiente, rabboccare il

motore con l’olio giusto (10W30).

Riporre l’asta di livello dell’olio nel foro per controllare il livello dell’olio.

Scegliere il giusto olio per il motore

L’olio del motore è il fattore più importante per determinare la vita operativa del

gruppo elettrogeno. Se si utilizza un olio di scarsa qualità o se non lo si cambia

regolarmente, il pistone e il cilindro si usureranno o s’ingripperanno in fretta.

Inoltre, la vita delle altre parti del motore, come i cuscinetti e le altre parti rotanti,

si accorcerà in maniera considerevole.

Asta di livello

Ogni 3 mesi o 200 ore

Intervallo per il cambio d’olio della macchina

Circa dopo 1 mese o 50 ore

35

Page 36

AZIONARE IL GENERATORE DIESEL

NOTA

Benché ci sia un sistema d’allarme che controlla la pressione bassa dell’olio, è

buona norma controllare la quantità d’olio presente nel motore. Se il livello

fosse troppo basso, rabboccare prima di avviare il motore.

Consigliamo di scaricare l’olio dal motore quando il motore diesel è ancora

caldo. Se il motore è freddo è più difficile scaricare tutto l'olio e alcune impurità

potrebbero restare all'interno del motore.

ATTENZIONE

NON rabboccare il motore con olio quando le macchine sono in funzione.

2-2.3 Controllare il filtro dell’aria

(1) Aprire il coperchio dei generatori, si

vedrà il gruppo del filtro.

(2) Allentare il dado ad alette del filtro

dell’aria, rimuovere il coperchio ed

estrarre il filtro dell’aria.

NOTA

Non lavare il filtro dell’aria con detergenti.

Cambiare il filtro dell’aria quando diminuiscono le prestazioni del motore o

se i gas di scarico hanno un brutto colore.

Non avviare mai il motore senza il filtro dell’aria installato, potrebbero

entrare oggetti estranei che danneggerebbero il motore.

(3) Dopo aver sostituito il filtro dell’aria, ricollocare il coperchio e stringere il

dado ad alette.

Se non s’installa immediatamente il filtro, la polvere nell’aria non sarà

riassorbita. In tal caso, consigliamo di bloccare il condotto dell’aria.

2-2.4 Controllare le condotte dell’olio

Un motore nuovo viene consegnato con l’olio e il carburante già scaricati.

Prima di avviare il motore, riempire il serbatoio di carburante e quello dell'olio.

Poi controllare che non ci siano bolle d’aria nel motore. In caso affermativo,

seguire la seguente procedura: allentare il dado di connessione tra la pompa

d’iniezione dell’olio e il tubo dell’olio e far sfiatare l’aria fino alla completa

eliminazione delle bolle. Infine ricollocare il dado di connessione e serrarlo.

2-2.5 Controllare i generatori

(1) Chiudere l’interruttore di potenza e disconnetterlo da ogni carico per non

provocare scosse elettriche, lesioni o morte.

Coperchio del filtro

36

Page 37

AZIONARE IL GENERATORE DIESEL

Knob handle

ATTENZIONE

Assicurarsi di chiudere l’interruttore di potenza.

Assicurarsi che i generatori siano messi a terra.

(2) Come utilizzare i generatori a doppio voltaggio

Spingere l’interruttore di voltaggio al voltaggio che s’intende usare.

ATTENZIONE

Assicurarsi che tutti i carichi siano sati disconnessi prima di avviare i

generatori. Altrimenti è molto pericoloso.

2-3 Controllare la messa in funzione del motore

diesel

2-3.1 Sistema d’allarme di bassa pressione.

I motori diesel sono dotati di un sensore d’allarme di bassa pressione che

spegne il motore se la pressione dell’olio scende troppo. Lo scopo di avere

questo sistema è assicurare che il motore non si blocchi. Se il livello dell'olio

nel motore è troppo basso, la temperatura dell'olio si alza troppo. Al contrario,

troppo olio rallenta il motore in maniera considerevole.

2-3.2 Come aprire il coperchio / sportello della scatola

(1) Aprire lo sportello della scatola: tirare la maniglia verso l’esterno e aprire.

Effettuare questi controlli quotidianamente.

(2) Allentare il bullone del coperchio esterno

del filtro dell’olio e del coperchio esterno

dell’ugello dell’olio, poi controllare il filtro

dell’aria.

(3) Controllare il coperchio esterno dell’ugello

dell’olio. Allentare il dado ad alette ed aprire

il coperchio esterno.

2-3.3 Rodaggio del motore

Quando si acquista un motore nuovo, è necessario rodarlo adeguatamente. Il

periodo di rodaggio è di circa 20 ore.

(1) Evitare il sovraccarico del motore quando è nuovo.

(2) Cambiare l’olio conformemente alle specifiche. In un motore nuovo, l’olio và

cambiato dopo circa 20 ore o tutti i mesi, mentre in un motore più vecchio l’olio

và cambiato ogni 100 ore o ogni tre mesi.

Il mancato rodaggio riduce la vita operativa del motore, la sua affidabilità e la

performance dei costi. In ultimo, anche la vita del generatore si accorcia.

Maniglia

37

Page 38

AZIONARE IL GENERATORE DIESEL

2-4 Avviamento del gruppo generatore

2-4.1 Avviamento.

(1) Assicurarsi che il generatore sia collocato su una SUPERFICIE PIANA O

UNIFORME. Se il motore s’inclina potrebbe fuoriuscirne del carburante.

(2) Disconnettere tutti i carichi elettrici dal generatore. Non avviare né arrestare

mai il generatore quando i dispositivi elettrici sono inseriti o accesi. In caso

contrario si possono generare dei corto circuiti e addirittura il guasto del

motorino d’avviamento.

(3) Girare la valvola del carburante su ON, altrimenti il carburante non sarà

sufficiente per avviare il generatore.

(4). Spingere la levetta di velocità in posizione “run”, in caso contrario il

generatore non si avvierà.

(5) Inserire la chiave di accensione in posizione “off”.

(6) Avviamento elettrico. Girare la chiave di accensione in posizione “start” e

aspettare che il motore si avvii, altrimenti sarà difficile da elettrizzare. (Se il

motore non si avvia entro cinque secondi, rilasciare la chiave e attendere per

almeno dieci secondi prima di effettuare un secondo tentativo. Se si continua

ad avviare il motore, questi si surriscalderà).

(7) Mentre il motore si scalda, muovere la chiave di accensione in posizione

“on”, altrimenti il carburante provocherà danni gravi.

2-4.2 Batteria

NOTA

Avviando lo starter troppo a lungo, la batteria potrebbe scaricarsi

eccessivamente e non fornire l’energia sufficiente ad un coretto avviamento del

motore.

Inoltre, quando il motore diesel è in funzione, è necessario lasciare la chiave in

posizione "ON".

NOTA IMPORTANTE

Tutte le quattro unità vengono dotate di batterie che non necessitano di

manutenzione. Non aggiungere acido di batteria.

2-5 Messa in funzione corretta del gruppo

generatore

2-5.1 Messa in funzione del motore diesel

1. Preriscaldare il motore diesel per 3 minuti a vuoto.

2. Prima controllare la spia di bassa pressione dell’olio sul pannello. Se la luce

è rossa, rabboccare l’olio.

3. Non regolare il bullone di regolazione del limite di velocità né il bullone di

regolazione del carburante. Questi bulloni sono stati configurati in ditta,

impostazioni diverse influiscono sulle prestazioni del motore.

38

Page 39

AZIONARE IL GENERATORE DIESEL

2-5.2 Controlli da effettuare durante il funzionamento del

motore

1. Controllare che non ci siano rumori anomali. Controllare spesso le giunzioni

dei condotti dell’olio, del carburante, dell’acqua e dell’aria per scoprire eventuali

perdite. In caso affermativo, eliminarle immediatamente per non causare danni

gravi.

2. Controllare che le prestazioni siano ottimali.

3. Controllare il colore dei gas di scarico (se sono troppo neri o troppo bianchi).

Qualora si riscontri una delle condizioni summenzionate, arrestare il motore e

scoprire la causa del problema. Se non si trovano problemi, contattare il

concessionario locale o il marchio della società più vicino.

2-6 Caricare

2-6.1 Connettere le cariche elettriche:

1. Collocare il motore in modo stabile e riscaldarlo per alcuni minuti dopo

l’avviamento.

2. Collegare e accendere nell’uscita di VOLTAGGIO CA desiderata le cariche

elettriche.

NOTA IMPORTANTE

NON collegare cariche trifase a un Generatore Diesel MONOFASE.

NON sovraccaricare il generatore.

Per prolungare la vita operativa del generatore e collegare correttamente le

applicazioni, raccomandiamo di seguire questi passaggi quando si aggiunge

carica elettrica:

3. Avviare il generatore SENZA CARICHE ELETTRICHE CONNESSE.

4. Far marciare il motore per alcuni minuti perché si STABILIZZI.

5. Collegare e accendere il primo pezzo. È preferibile collegare il pezzo prima

alla CARICA MAGGIORE.

6. Far stabilizzare il motore.

7. Collegare e accendere il secondo pezzo.

8. Far STABILIZZARE il motore.

9. Ripetere i passaggi 4 e 5 per ogni capacità durante l’aggiunta di cariche.

NOTA

Non avviare più di due dispositivi contemporaneamente. Ogni dispositivo

dovrebbe essere avviato da solo per evitare il sovraccarico del generatore.

Il generatore dovrebbe marciare a 3600 giri al minuto per raggiungere la

frequenza (60 Hz). La velocità del motore può essere regolata dal regolatore di

velocità.

39

Page 40

AZIONARE IL GENERATORE DIESEL

2-6.2 Uscita di elettricità

1. Aumentare i giri/minuto (girare la manopola di velocità al massimo) del

generatore per avere il massimo della potenza. In caso contrario, il

dispositivo regolatore automatico del voltaggio si ecciterà e, dopo un

periodo prolungato, potrebbe bruciare l'AVR. Per la velocità nominale del

generatore si prega di fare riferimento al Capitolo 1, punto 1-1 delle

specifiche tecniche e dati.

2. Osservare il puntatore del voltmetro, dovrebbe indicare il 5% del voltaggio

desiderato. Contemporaneamente portare l’interruttore in posizione GEN

(generatore). Il voltaggio CA della presa di alimentazione può essere in

uscita.

2-6.3 Caricare la batteria

1. Nello starter elettrico dei gruppi generatori, la batteria da 12V si ricarica

automaticamente attraverso il regolatore sul lato del motore mentre è in

funzione.

2. Se il generatore non viene utilizzato per periodi prolungati, la batteria

dovrebbe essere scollegata per evitare perdite d’energia della batteria.

3. Non collegare i terminali positivi e negativi della batteria

contemporaneamente. In questo modo si rischia di danneggiare la batteria e

causare gravi lesioni personali.

4. Non invertire le polarità durante l'attacco dei cavi alla batteria. In questo

modo si danneggerebbe sia la batteria che lo starter elettrico.

5. Quando si carica la batteria, questa produce gas infiammabili. Non fumare,

non provocare fiamme e scintille vicino alla batteria mentre si carica la

batteria perché si potrebbe provocare un incendio.

Per evitare le scintille durante la connessione dei cavi alla batteria, collegare

prima la batteria e poi il motore. Per scollegare i cavi della batteria, scollegare

prima il terminale motore del cavo.

2-7 Arresto del generatore

1. Per arrestare il generatore, rimuovere la carica elettrica.

2. Portare il contatore ad aria in posizione “off”, in caso contrario si verifica un

corto circuito.

3. Collocare la maniglia di velocità in posizione "RUN" e far marciare il motore

per 3 minuti dopo averlo scaricato. Non interrompere il motore diesel

immediatamente ma farlo raffreddare. Interrompendo improvvisamente il

motore si potrebbe alzare la temperatura in modo anomalo, bloccare l'ugello e

danneggiare il motore diesel.

40

Page 41

AZIONARE IL GENERATORE DIESEL

NOTA

1. Se non si riesce a interrompere il

motore con la carica, prima rimuovere

la carica e poi arrestare il motore.

2. Abbassare la maniglia del freno.

3. Se dotato di starter elettrico, girare

la chiave in posizione “Off”.

4. Portare la maniglia di velocità in

posizione "S".

4. Portare la chiave di accensione su “off”. I generatori si arresteranno.

5. Spostare la maniglia di velocità in posizione “stop” in modo da assicurare

l'interruzione del condotto del carburante.

6. Chiudere la valvola del carburante ma non bloccare il generatore chiudendo

il rubinetto del serbatoio qualora entrasse aria nel condotto del carburante

perché questo renderà più difficile il prossimo avviamento.

Maniglia

di

velocità

41

Page 42

MANUTENZIONE

CAPITOLO 3 MANUTENZIONE

3-1 Programma di manutenzione

Se si conserva il generatore in buono stato, gli si prolunga la vita operativa. È

necessario controllare ogni aspetto, compreso il motore diesel, il generatore, la

cabina di controllo e il telaio. Per le procedure di revisione, fare riferimento al

manuale d’istruzioni del relativo sottogruppo. In caso non si sia in possesso dei

predetti manuali, contattateci e ve ne invieremo uno.

Prima d’iniziare la manutenzione, assicurarsi che il motore diesel sia spento.

Fare riferimento alla tabella 3-1 per la corretta programmazione di

manutenzione.

Tabella 3-1. Programmazione di manutenzione per il gruppo generatore diesel

Scadenza

Pezzo

Tutti i giorni

Dopo 1

mese o

50 ore

Ogni 3 mesi o

200 ore

Ogni 6 mesi

o 400 ore

Una volta

all’anno o

ogni 1000

ore

Controllare e

rabboccare il

livello di

carburante

○Prima

dell’avviamento

Scaricare il

serbatoio

○

Controllare ed

eventualmente

rabboccare l’olio

nel motore

○

Pulire il filtro del

carburante

○

Controllare

eventuali perdite

di olio e

carburante

○dopo ogni

messa in

funzione

Controllare e

avvitare tutte le

parti fissate

○

●serrare il

bullone o la

testa del

cilindro

Controllare

l'iniettore

●

Controllare la pompa

ad iniezione

●

Controllare il

tubo del

carburante

●Cambiarlo

se

necessario

Controllare ed

eventualmente

rabboccare il

lubrificante nella

vaschetta di

recupero.

○Prima

dell’avviamento

Sostituire il

lubrificante

○la prima

volta

○la seconda

volta e quelle

successive

Pulire il filtro

dell’olio

○la prima

volta

○la seconda

volta e quelle

successive

Controllare il filtro

dell’aria

○la prima

volta

○la seconda

volta e quelle

successive

42

Page 43

MANUTENZIONE

Cambiare l’anima

del filtro dell’aria

Se danneggiato o macchiato, cambiarlo in tempo

Controllare ed

eventualmente

rabboccare il

livello del liquido

della batteria

○

Regolare il gioco

della valvola

d’ingresso e di

scarico

●la

prima

volta

●la seconda

volta e quelle

successive

Molare l’attacco

dell’ingresso e dello

scarico dell’aria

●

Cambiare l’anello

del pistone

●

Controllare la

spazzola elettrica e

l’anello scorrevole

●

Controllare la

resistenza

dell’isolamento

Il tempo d’interruzione è di oltre 10 giorni ○

Nota: il periodo di qualità dell'iniettore e della pompa d’iniezione è di 1500

ore o di due anni. Nella tabella,● significa che l’operazione richiede

attrezzi speciali o che i controlli possono essere realizzati dal

concessionario.

43

Page 44

MANUTENZIONE

Indicatore

Bullone di scarico

3-1.1 Cambio dell’olio del motore (ogni 100 ore)

Rimuovere il coperchio dell’olio. Rimuovere il

tappo di scarico dell’olio quando il motore è

ancora caldo. Fare attenzione all’olio caldo e al

motore caldo perché possono provocare ustioni. Il

bullone si trova nella parte inferiore del cilindro.

Dopo aver scaricato l’olio, ricollocare il bullone e

serrare, poi rabboccare con il carburante idoneo

fino al livello giusto.

3-1.2 Programma di manutenzione del filtro dell’aria

1. Pulire il filtro dell’aria ogni 6 mesi o dopo 500 ore di funzionamento.

2. Se necessario, cambiare il filtro.

3. Non utilizzare detergenti per pulire il filtro dell’aria.

NOTA

Non azionare mai il motore senza il filtro dell’aria. Potrebbe provocare gravi

danni al motore perché potrebbero entrare oggetti estranei nel sistema

d’ingresso. Cambiare sempre puntualmente il filtro dell’aria.

3-1.3 Manutenzione del filtro del carburante

1. Il filtro del carburante andrebbe pulito spesso per mantenere il

funzionamento del motore alle prestazioni massime.

2. Il periodo di tempo raccomandato per la pulizia del filtro del carburante è di 6

mesi o ogni 500 ore di funzionamento.

a. Per farlo, scaricare innanzitutto il carburante dal serbatoio.

b. Allentare le viti dal selettore del serbatoio e rimuovere il filtro dall’attacco.

Utilizzare il diesel per pulire il filtro del carburante. Inoltre, rimuovere l'iniettore

di carburante e pulirlo dei depositi di carbone. Il periodo di tempo consigliato

per farlo è ogni 3 mesi o 100 ore.

3-1.4 Tensione dei bulloni della testa del cilindro

I bulloni della testa del cilindro dovrebbero essere serrati conformemente alle

specifiche, fare riferimento al manuale del motore diesel per le specifiche e per

gli attrezzi speciali richiesti.

3-1.5 Controllo della batteria

Assicurarsi che l’acido della batteria sia pieno. Il motore utilizza una batteria

12V. A causa dei numerosi cicli d’inizio, l’acido della batteria può consumarsi.

Inoltre, prima del rabbocco, verificare che la batteria non sia danneggiata in

alcun modo. Aggiungere acqua distillata alla batteria durante il rabbocco.

Effettuare dei controlli sulla batteria una volta al mese.

44

Page 45

MANUTENZIONE

3-2 Conservazione per lunghi periodi di tempo

Se è necessario mettere via il generatore per lunghi periodi di tempo, si

dovrebbero realizzare le seguenti procedure.

1. Avviare il motore diesel per 3 minuti e poi interromperlo.

2. Quando il motore è ancora caldo, cambiare l'olio del motore con olio nuovo

di grado equivalente.

3. Per generatori con starter elettrico, premere la maniglia di decompressione e

avviare il motore per 2-3 secondi. Per farlo, portare l’interruttore dello starter su

“Start”. (Non avviare il motore diesel).

4. Pulire il motore e archiviarlo in un luogo asciutto.

45

Page 46

RISOLUZIONE DEI PROBLEMI

CAPITOLO 4 RISOLUZIONE DEI

PROBLEMI

4-1 Procedure di risoluzione dei problemi

Cause di malfunzionamento

Soluzione

Impossibile avviare il diesel.

Carburante insufficiente

Rabboccare il carburante

L’interruttore del carburante non

è su "OPEN".

Girare l’interruttore del carburante su

“OPEN”.

La pompa e l’ugello dell’alta

pressione non iniettano carburante

o la quantità iniettata è minore.

Smontare l’ugello e regolarlo sul banco

di prova.

La leva di controllo della velocità

non è su “RUN”.

Girare la leva di controllo su “RUN”.

Controllare il livello dell’olio di

lubrificazione.

La quantità standard di lubrificante

dovrebbe trovarsi tra la graduazione

alta “H” e la graduazione bassa “L”.

Non è veloce e potente nel tirare lo

starter reattivo.

Avviare il motore conformemente ai

requisiti delle “procedure di prima

messa in funzione”.

È presente sporcizia sull’ugello.

Pulire l’ugello.

L’accumulatore è privo di

elettricità.

Caricare l’accumulatore o cambiarlo.

Il generatore non genera elettricità

e non ha voltaggio di saldatura

L'interruttore principale (NFB) non

è acceso.

Girare la maniglia dell’interruttore

principale su “ON”.

La spazzola di carbone è usurato.

Il contatto è cattivo.

Cambiare la spazzola di carbone.

Il contatto della presa è cattivo.

Regolare il contatto della presa.

La rivoluzione nominale del motore

non viene raggiunta.

Far raggiungere la rivoluzione

nominale conformemente ai requisiti.

Il regolatore automatico AVR è

danneggiato.

Cambiarlo.

Il potenziometro di regolazione di

corrente per la saldatura elettrica è

danneggiato.

Cambiarlo.

Se dovessero ancora sussistere problemi, contattate il concessionario più

vicino o direttamente con la nostra società.

4-2 Domande e dubbi

1. Modello di generatore del motore diesel e il numero di serie del motore.

2. Stato di residenza.

3. Numero di ore di lavoro dell’attrezzatura e problema riscontrato.

4. Condizione dettagliata e momento in cui si è verificato il problema, in altre

parole, clima e atmosfera.

46

Page 47

DIAGRAMMA DI CIRCUITO

CAPITOLO 5 DIAGRAMMA DI CIRCUITO

Figura 5-1 diagramma di circuito a doppio voltaggio monofase

47

Page 48

DIAGRAMMA DI CIRCUITO

Figura 5-2 diagramma di circuito a singolo voltaggio monofase

48

Page 49

DIAGRAMMA DI CIRCUITO

Figura 5-3 diagramma di circuito trifase

49

Page 50

Appendice I: tipi di prese

Codice

Descrizione

Specifiche

Immagine

S01

presa S.A

25A, 250V

S02

Presa inglese

32A, 240V

S03

Presa inglese

16A, 240V

S04

Presa quadrata di

tipo americano

20A, 120V

S05

Presa tedesca

16A, 250V

S06

Presa trifase a

cinque fori

16A, 415V

S07

Presa francese

16A, 250V

S08

Presa trifase a

quattro fori

16A, 215V

S09

Presa americana a

quattro contatti

piatti

30A, 250V

50

Page 51

Codice

Descrizione

Specifiche

Immagine

S10

Doppia presa

americana

20A, 125V

S11

Presa a 3 contatti

piatti

(autenticazione UL

opzionale)

30A, 250V

S12

Presa australiana

16A, 250V

S13

Presa svizzera

10A, 250V

51

Page 52

Appendice II: Elenco generale di potenza

delle applicazioni

Per selezionare la dimensione corretta del generatore per ogni esigenza, è

necessario realizzare un elenco degli attrezzi e/o applicazioni che s’intende

azionare con il generatore. La tabella in basso contiene i watt approssimativi e

vuole fornire un’idea della dimensione del generatore necessario. Dopo aver fatto

un elenco di dispositivi da utilizzare (assicurarsi di considerare i watt iniziali)

aggiungere i watt totali e selezionare il generatore che può erogare quella

potenza.

Elettrodomestici

Potenza di lavoro

richiesta

Potenza iniziale

richiesta

Macchina del caffè

1750

1750

Lavapiatti

1450

1800

Friggitrice elettrica

1300

1300

Range elettrico

Elementi da 6 pollici

1500

1500

Elementi da 8 pollici

2100

2100

Microonde da 625 watt

625

800

Frigo o freezer

700

2200

Tostapane 2 fette

1050

1050

Tostapane 4 fette

1650

1650

Lavatrice automatica

1150

2300

Gas essiccatore di abiti

700

1800

Deumidificatore

650

800

Coperta elettrica

(matrimoniale)

650

800

Apriporta del garage ¼ hp

550

1100

Apriporta del garage 1/3 hp

725

1400

Ventola del forno 1/8 hp

500

1000

Ventola del forno 1/6 hp

750

1500

Ventola del forno ¼ hp

900

1800

Ventola del forno 1/3 hp

1000

1800

Ventola del forno ½hp

1200

1500

Phon

300 - 1500

300 - 1500

Ferro da stiro

1200

1200

Luci

Come da indicazioni

Come da indicazioni

Radio

50 - 200

50 - 200

Pompa per pozzi o per residui

1/3 hp

750

1500

Pompa per pozzi o per residui

1/2 hp

1000

2000

Pompa per pozzi o per residui

1 hp

2300

4500

TV a colori da 13 a 32

300

300

VCR

50

50

Computer

150

150

52

Page 53

Elettrodomestici

Potenza di lavoro

richiesta

Potenza iniziale

richiesta

Modem

25

25

Stampante

100

100

Aspirapolvere verticale

800

1100

Aspirapolvere con contenitore

1100

1500

Climatizzazione centralizzata

10.000 BTU

1500

2200

20.000 BTU

2500

3300

24.000 BTU

3800

4950

40.000 BTU

6000

7800

Compressore d’aria

½ hp

1000

2000

1 hp

1500

4500

1½hp

2200

6000

2 hp

2800

7700

Mola da banco 6 pollici

720

1000

Mola da banco 8 pollici

1400

2500

Mola da banco 10 pollici

1600

3600

Coltivatore elettrico 1/3 hp

700

1400

Tagliaerba elettrico

500

650

Miscelatore a tamburo ¼hp

700

1400

Mercurio/Alogena

1000

1000

Lucidatrice

16 pollici,¾ hp

1400

3100

20 pollici, 1hp

1600

4500

Menarola ¼ pollici

350

350

Menarola 3/8 pollici

400

400

Menarola ½ pollici

600

600

Macchina sommergibile

Pompa ad acqua 400gp

200

400

Pompa ad acqua di tipo a

centrifuga

500

650

Aspirapolvere e Aspiraliquidi

1.7 hp

900

900

2.5 hp

1300

1300

Seghe

Trasmissione a vite

(troncatrice)

1800

2600

Sega circolare 6½ pollici

800

1200

Sega circolare 7¼ pollici

1400

2300

Sega circolare 8 ¼ pollici

1800

3000

Segatrice elettrica a catena

1100

1400

Sega da tavolo 9 pollici

1500

3000

Sega da tavolo 10 pollici

1800

4500

Saldatrice elettrica 70 amp

2800

2800

53

Page 54

Elettrodomestici

Potenza di lavoro

richiesta

Potenza iniziale

richiesta

Sega a nastro

1100

1400

Recinzione elettrica, 25 miglia

250

250

Sbrinatore con serbatoio

1000

1000

Pulitore grani

650

1000

Trasportatore mobile ½hp

1000

2400

Elevatore per grani ¾hp

1000

2400

Raffreddatore di latte

1100

2300

Miscelatore 3½ Metri cubi

¾hp

2800

7700

Mungitrice, 2 hp

1100

2300

54

Page 55

PREFACIO

PREFACIO

Gracias por haber comprado los productos de nuestra empresa.

Los manuales le ayudarán a utilizar las máquinas y a llevar a cabo su

mantenimiento de manera correcta . Lea atentamente los manuales antes

de utilizar las máquinas . Así los generadores podrán funcionar en las

condiciones mejores prolongando su vida útil.

.Los usuarios podrían notar algunas diferencias en este manual

respecto al producto real, pero es algo debido a las mejoras hechas

en nuestros productos. Algunas de las imágenes

contenidas en este

manual también podrían ser ligeramente distintas del producto real.

El fabricante se reserva el derecho de llevar a cabo cualquier

modificación en cualquier momento sin previo aviso y sin incurrir en

ninguna obligación.

Fijarse en el siguiente símbolo de advertencia

.

Si las máquinas no se utilizan siguiendo las instrucciones contenidas en

estos manuales , podrían producirse heridas o incluso la muerte.

Por lo tanto, HAY que utilizar las máquinas solo después de haber

entendido completamente estos manuales.

55

PR INDUSTRIAL s.r.l.

Loc. Il Piano

CAP 53031, Casole D’Elsa (SI)

ITALIA

Page 56

ÍNDICE

ÍNDICE

Capítulo 1 Especificaciones y datos técnicos………………….1

1-1 Especificaciones y datos técnicos……………..……………………1

1-2 Parámetros de funcionamiento básico……….......………….……..2

1-3 Dimensiones y visión de conjunto generales de los

generadores...................................................................................2

1-4 Nombre de las partes y panel de mando……………………..…….3

Capítulo 2 Funcionamiento del generador diesel……….....4

2-1 Principales medidas de seguridad durante el funcionamiento del

generador……...............................................................................4

2-2 Preparación antes del uso………….....................……………..……5

2-3 Comprobación del funcionamiento del motor diesel………….…..8

2-4 Encendido del grupo generador……………...……………………..8

2-5 Funcionamiento correcto del grupo generador……………..……..9

2-6 Carga…………………………………………………………………10

2-7 Parada del generador………………………………………………11

Capítulo 3 Mantenimiento……………………………………………..12

3-1 Programas de mantenimiento……………………………………...12

3-2 Almacenamiento durante periodos de tiempo prolongados........13

Capítulo 4 Localización de averías……………………………….14

4-1 Procedimientos de localización de averías ..……………...14

4-2 Preguntas y dudas…………………………………………….….14

Capítulo 5 Diagrama del circuito………………………..…………….15

Apéndice ⅠTipo de enchufe……………………......…………………………..18

Apéndice ⅡLista general de la potencia de los aparatos….........…………20

56

Page 57

ESPECIFICACIONES Y DATOS TÉCNICOS

1

CAPÍTULO 1 ESPECIFICACIONES Y

DATOS TÉCNICOS