Page 1

Operator-Parts List Manual

Manuel de l’opérateur – Liste de pièces

Manual del operador – Lista de piezas

Industrial Series – ELECTRIC GENERATOR

Industrial Series – GÈNÈRATRICE ÉLECTRIQUE

Industrial Series – GENERADOR ELECTRICO

IMPORTANT – Please make certain that

persons who are to use this equipment

thoroughly read and understand these

instructions prior to operation.

IMPORTANT – Veiller à ce que toute personne

amenée à utiliser cet appareil lise

soigneusement ces instructions et les

comprenne avant de procéder à son utilisation.

IMPORTANTE – Favor de cerciorarse de que

toda persona que use el generador Coleman

Powermate lea y entienda todas las

instrucciones antes de la operación.

Record the model and serial numbers of your Generator below:

Model No._________________ Serial No.__________________

Inscrivez les numéros de modèle et de série du gènèratrice:

# modèle__________________ # de série ___________________

Tome nota de los números de serie y de modelo de su generador

No. de modelo ________________No. de serie ________________

enseguida:

HELPLINE 1-800-445-1805

© Coleman Powermate, Inc. 04/03 0056250.02 LFL

Page 2

TABLE OF CONTENTS

Safety and operation rules. . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Spark arresting muffler. . . . . . . . . . . . . . . . . . . . . . . . . . 4

Determining total wattage. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Operating voltage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Grounding the generator. . . . . . . . . . . . . . . . . . . . . . . . . 5

Lubrication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Fuel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Pre-start preparation. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Starting the engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Break-in procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Shutting the generator off. . . . . . . . . . . . . . . . . . . . . . . . 5

Power cord connection. . . . . . . . . . . . . . . . . . . . . . . . . . 5

Applying load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Major features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Circuit protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

AC features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

DC features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Battery Kit Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

TABLE DES MATIÈRES

Régles d’opération et de sécurité. . . . . . . . . . . . . . . . . . . . . 13

Silencieux pare-étincelles. . . . . . . . . . . . . . . . . . . . . . . . 14

Détermination de la puissance totale nécessaire. . . . . . . . . 14

Vérifier la tension. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Avant de mettre en marche. . . . . . . . . . . . . . . . . . . . . . . . . 15

Mise à la terre de la génératrice. . . . . . . . . . . . . . . . . . . 15

Lubrification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Carburant. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Préparatifs au démarrage. . . . . . . . . . . . . . . . . . . . . . . . 15

Démarrage du moteur. . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Rodage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Arrêt de la génératrice. . . . . . . . . . . . . . . . . . . . . . . . . . 16

Connexions du cordon d’alimentation. . . . . . . . . . . . . . . 16

Branchement des appareils. . . . . . . . . . . . . . . . . . . . . . 16

Caracteristiques principales. . . . . . . . . . . . . . . . . . . . . . . . . 17

Protection des circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . 17

AC features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DC features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Liste des pièces de la trousse de batteries. . . . . . . . . . . . . 17

Battery Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Low oil shutdown. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Infrequent service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Long term storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electric start wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Wiring diagram (Key switch on engine). . . . . . . . . . . . . . . . . 8

Idle control operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Idle control trouble shooting. . . . . . . . . . . . . . . . . . . . . . . . . . 9

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Exciting the generator. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Heat shield. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Draining the Oil. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Trouble Shooting the Generator. . . . . . . . . . . . . . . . . . . . . . 10

Installation Instructions of the Portability Kit. . . . . . . . . . . . . 11

Customer service information. . . . . . . . . . . . . . . . . . . . . . . . 12

Limited warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parts list. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-36

Parts drawing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-37

Installation de la batterie. . . . . . . . . . . . . . . . . . . . . . . . . 18

Niveau d’huile bas. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Usage peu fréquent. . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Remisage à long terme. . . . . . . . . . . . . . . . . . . . . . . . . . 18

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Câblage du démarreur électrique. . . . . . . . . . . . . . . . . . . . . 19

Entretien. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Excitation de la génératrice. . . . . . . . . . . . . . . . . . . . . . . 19

Écran de chaleur. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Vidage de l’huile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Fonctionnement de la commande du ralenti. . . . . . . . . . . . 20

Dépannage de la commande du ralenti. . . . . . . . . . . . . . . . 20

Dépannage de la Génératrice électrique. . . . . . . . . . . . . . . 21

Instructions de la trousse de transport. . . . . . . . . . . . . . . . . 22

Service clients. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Garantie limitée. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Liste des composants. . . . . . . . . . . . . . . . . . . . . . . . . . . 35-36

Diagramme des pièces. . . . . . . . . . . . . . . . . . . . . . . . . . 36-37

Reglas de seguridad y de funcionamiento. . . . . . . . . . . . . . 24

Silenciador apagachispas. . . . . . . . . . . . . . . . . . . . . . . . 25

Como determinar el vatiaje total. . . . . . . . . . . . . . . . . . . . . . 25

El requerimiento de voltaje. . . . . . . . . . . . . . . . . . . . . . . . . . 26

Antes de la operación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Puesta a tierra del generador. . . . . . . . . . . . . . . . . . . . . 26

Lubricación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Combustible. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Preparacion antes de arrancar. . . . . . . . . . . . . . . . . . . . 26

Arranque del motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Procedimiento de arranque inicial. . . . . . . . . . . . . . . . . 27

Apagado del generador. . . . . . . . . . . . . . . . . . . . . . . . . 27

Conexiones del cable. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Cómo aplicar una carga . . . . . . . . . . . . . . . . . . . . . . . . . 27

Características principales. . . . . . . . . . . . . . . . . . . . . . . . . . 28

Protección del circuito características CA. . . . . . . . . . . . 28

Características AC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Características CC. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Lista de partes para el equipo de batería. . . . . . . . . . . . . . . 29

2

INDICE

Batería Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Detencion por poca cantidad de aceite. . . . . . . . . . . . . 29

Servicio poco frecuente. . . . . . . . . . . . . . . . . . . . . . . . . 29

Almacenamiento a largo plazo. . . . . . . . . . . . . . . . . . . . 29

Cableado de arranque electrico. . . . . . . . . . . . . . . . . . . . . . 30

Instalación. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Diagrama de cableado basico. . . . . . . . . . . . . . . . . . . . . . . 30

Funcionamiento de control en vacio. . . . . . . . . . . . . . . . . . . 31

Deteccion de fallos de control en vacio. . . . . . . . . . . . . . . . 31

Mantenimiento. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Excitación del generador. . . . . . . . . . . . . . . . . . . . . . . . 31

Escudo de calor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Drenado de aceite. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Deteccion de Fallos de Generador. . . . . . . . . . . . . . . . . . . . 32

Instrucciones para el equipo portátil. . . . . . . . . . . . . . . . . . . 33

Servicio para los clientes. . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Garantía limitada. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Lista de componentes. . . . . . . . . . . . . . . . . . . . . . . . . . . 35-36

Dibujos de las partes. . . . . . . . . . . . . . . . . . . . . . . . . . . . 36-37

Page 3

cellars, excavations, and boat bilges. Air flow

the generator is running. Allow engine to cool

Do not refuel near open flames, pilot lights, or

SAFETY AND OPERATION RULES

3

Safety precautions are essential when any mechanical

equipment is involved. These precautions are necessary when

using, storing, and servicing mechanical equipment. Using this

equipment with the respect and caution demanded will

considerably lessen the possibilities of personal injury. If safety

precautions are overlooked or ignored, personal injury or

property damage may occur.

The following symbols shown below are used extensively

throughout this manual. Always heed these precautions, as

they are essential when using any mechanical equipment.

This warning symbol identifies specific

instructions or procedures which if not correctly

followed could result in personal injury or death.

This caution symbol identifies specific instructions

or procedures which, if not strictly observed, could

result in damage to, or destruction of equipment.

This unit was designed for specific applications. It should

not be modified and/or used for any application other than

which it was designed. If there are any questions regarding its

application, write or call Customer Service at 1-800-445-1805.

When using this product basic precautions should

always be followed, including the following:

1.Read this manual carefully - know your

equipment. Consider the applications, limitations,

and the potential hazards specific to your unit.

2.Equipment must be placed on a firm, supporting

surface.

3.Load must be kept within rating stated on

generator nameplate. Overloading will damage

the unit or shorten its life.

4.Engine must not be run at excessive speeds.

Operating an engine at excessive speeds

increases the hazard of personal injury. Do not

tamper with parts which may increase or

decrease the governed speed.

5.To prevent accidental starting, always remove the

spark plug or cable from the spark plug before

adjusting the generator or engine.

6.Units with broken or missing parts, or without

protective housing or covers, should never be

operated. Contact your service center for

replacement parts.

7.Units should not be operated or stored in wet or

damp conditions or on highly conductive locations

such as metal decking and steel work. Always

use rubber gloves and boots, and a ground

fault current interrupter if these conditions

may be present during use.

8.Keep the generator, tank and cap clean and free

of oil, mud and other foreign matter.

9.Extension cords, power cords, and all electrical

equipment must be in good condition. Never

operate electrical equipment with damaged or

defective cords.

10.Store the generator in a well ventilated area with

the fuel tank empty. Fuel should not be stored

near the generator.

11.Your generator should never be operated under

these conditions:

a.Change in engine speed.

b.Electrical output loss.

c.Overheating in connected equipment.

d.Sparking.

e.Damaged receptacles.

f.Engine misfire.

g.Excessive vibration.

h.Flame or smoke.

i.Enclosed compartment.

j.Rain or inclement weather.

12.Check the fuel system periodically for leaks or

signs of deterioration such as chafed or spongy

hose, loose or missing clamps, or damaged tank

or cap. All defects should be corrected before

operation. Clean up any or all spills immediately.

13.The generator should be operated, serviced, and

refueled only under the following conditions:

a.Good ventilation - avoid areas where vapors

may be trapped such as pits, basements,

and temperatures are important for air cooled

units. Temperatures should not exceed 100

degrees F (40 degrees C).

b.Dangerous exhaust gases should be piped

from enclosed areas. The engine exhaust

contains carbon monoxide, a poisonous,

odorless, invisible gas which, if breathed,

causes serious illness and possible death.

c.Refuel the generator in a well lighted

area. Avoid fuel spills and never refuel while

for two minutes prior to refueling.

d.

sparking electrical equipment such as power

tools, welders, and grinders.

e.The muffler and air cleaner must be installed

and in good condition at all times as they

function as flame arresters if backfiring

occurs.

f.Do not smoke near the generator.

English

Page 4

14.Do not wear loose clothing, jewelry, or anything

that maybe caught in the starter or other rotating

parts.

15.Unit must reach operating speed before electrical

loads are connected. Disconnect loads before

turning off engine.

DETERMINING TOTAL WATTAGE

In order to prevent overloading and possible damage to

your generator it is necessary to know the total wattage of the

connected load. To determine which tools and/or appliances

your generator will run follow these steps:

16.To prevent surging that may possibly damage

equipment, do not allow engine to run out of

fuel when electrical loads are applied.

17. When powering solid state equipment, a

Power Line Conditioner should be used to

avoid possible damage to equipment. (See

Caution Statement on this page.)

18.Do not stick anything through ventilating slots,

even when the generator is not operating. This

can damage the generator or cause personal

injury.

19.Before transporting the generator in a vehicle,

drain all fuel to prevent leakage that may occur.

20.Use proper lifting techniques when transporting

the generator from site to site. Improper lifting

techniques may result in personal injury.

21.To avoid burns, do not touch engine muffler or

other engine or generator surfaces which became

hot during operation.

22. Never disconnect components that help in the

scheduling of the maintance of the generator.

This would shorten the life of the generator.

SPARK ARRESTING MUFFLER

THIS PRODUCT IS NOT EQUIPPED WITH A SPARK

ARRESTING MUFFLER. If the product will be used around

flammable materials, such as agricultural crops, forests, brush,

grass, or other similar items, then an approved spark arrester

should be installed and is legally required in the State of

California. The California statutes requiring a spark arrester

are Sections 13005(b), 4442 and 4443. Spark Arresters are

also required on some U.S. Forest Service land and may also

be legally required under other statutes and ordinances. An

approved spark arrester is available from your Coleman

Powermate dealer, or may be ordered from Coleman

Powermate, Inc., P.O. Box 6001, Kearney, Nebraska 68848.

1-800-445-1805.

NOTE:Remember to clean the spark arrester screen

frequently to ensure the generator is operating at its best

performance.

1.Determine if you want to run one item or multiple items

simultaneously.

2.Check start and run wattage requirements for the items

you will be running by referring to the load’s nameplate or

by calculating it (multiply amps x volts = watts).

3.Total the start and run watts for each item. If the nameplate

only gives volts and amps, multiply volts x amps = watts.

1 KW = 1,000 watts.

NOTE: Allow 2 1/2 to 4 times the listed wattage for

starting equipment.

4.The generator’s start/surge and run/rated watts should

match or exceed the total number of watts required for the

equipment you want to run.

5.Always connect the heaviest load to the generator first,

then add other items one at a time.

6.Motorized appliances or tools require more than their rated

wattage for start up.

OPERATING VOLTAGE

CAUTION: Operating voltage and frequency

requirement of all electronic equipment

should be checked prior to plugging them into

this generator. Damage may result if the

equipment is not designed to operate within a

+/- 10% voltage variation, and +/- 3 hz

frequency variation from the generator name

plate ratings. To avoid damage, always have

an additional load plugged into the generator

if solid state equipment (such as a television

set) is used. A power line conditioner may

also be necessary for some solid state

applications.

Typical example of solid state equipment include:

Garage door openers

Kitchen appliances with digital displays

Televisions

Stereos

Personal computers

Quartz clocks

Copy machines

Telephone equipment

For more information, contact our Customer Service

Department at 1-800-445-1805.

4

English

Page 5

Pull on the starter rope with fast steady pull. As the engine

BEFORE OPERATION

5

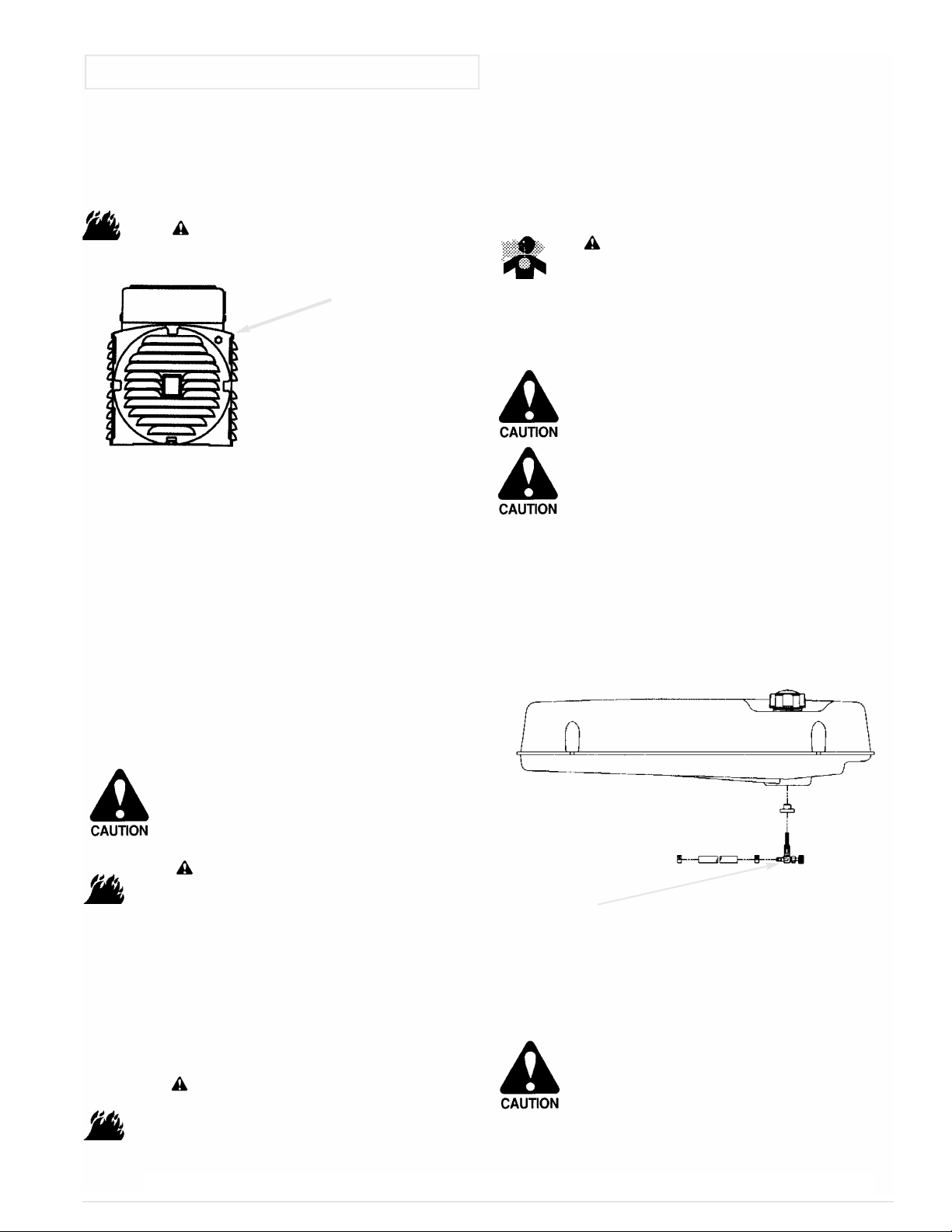

GROUNDING THE GENERATOR

Make sure that the generator is grounded to help prevent

accidental shock. A ground screw has been provided for this

purpose. Connect a length of heavy gauge wire between the

generator screw and an external ground source, such as a

water pipe or copper rod driven into the ground.

WARNING: Do not use a pipe carrying

combustible material as the ground source.

Ground Screw

STARTING THE ENGINE

1.Check oil level and fuel.

2.Disconnect all electrical loads from the unit.

3.Open fuel shut off valve.

4.Adjust choke as necessary.

5.Set the engine switch to the “ON" position.

6.

warms up, readjust the choke. On electric start models,

turn the key switch to “START”. Release key switch after

the engine starts.

WARNING: Provide adequate ventilation

for toxic exhaust gases and cooling air flow.

BREAK-IN PROCEDURE

Controlled break-in helps insure proper engine and

generator operation. Follow engine procedure outlined in

engine manual.

CAUTION: Do not apply heavy electrical load

during break-in period (the first two to three

hours of operations).

LUBRICATION

DONOT attempt to start this engine without filling the

crank case with the proper amount and type of oil. (See the

accompanying engine manual for this information.) Your

generator has been shipped from the factory without oil in the

crankcase. Operating the unit without oil can damage the

engine.

Note: To add oil to the unit a flexible, long necked

funnel, supplied with most models will be needed to reach

the Oil Fill. This funnel may be purchased through

Coleman Powermate. The Oil Fill is located on top of the

engine, (OHV) valve cover, battery side of the unit. Be sure

the oil drain plug is closed before adding the oil.

FUEL

Fill the tank with clean, fresh unleaded automotive

gasoline. Regular grade gasoline may be used provided a high

octane rating is obtained (at least 85 pump octane).

CAUTION: Do not overfill the tank. Keep

maximum fuel level 1/4 inch below the top of

the fuel tank. This will allow expansion in hot

weather and prevent overflow.

WARNING:Gasoline is very dangerous.

Serious injury may result from fire caused by

gasoline contacting hot surfaces.

CAUTION: Allow generator to run at no load

for five minutes upon each initial start-up to

permit engine and generator to stabilize.

SHUTTING THE GENERATOR OFF

1.Remove entire electrical load.

2.Let the engine run for a few minutes without load.

3.Move the engine switch to the “OFF” position. (Turn

the key switch to “OFF” on the electric start models).

4.Do not leave the generator until it has completely stopped.

5.Close the fuel shut off valve if the engine is to be put in

storage or transported.

6.If cover is used, do not install until unit has cooled.

Fuel Valve

1. Do not fill fuel tank with engine running.

2. Do not spill fuel while refilling tank.

3. Do not mix oil with gasoline.

PRE-START PREPARATION

Before starting the generator, check for loose or missing

parts and for any damage which may have occurred during

shipment.

WARNING: This generator must not be

operated without all factory installed heat

shields in place. Failure to comply may cause

the fuel tank to overheat and result in

personal injury from fire.

English

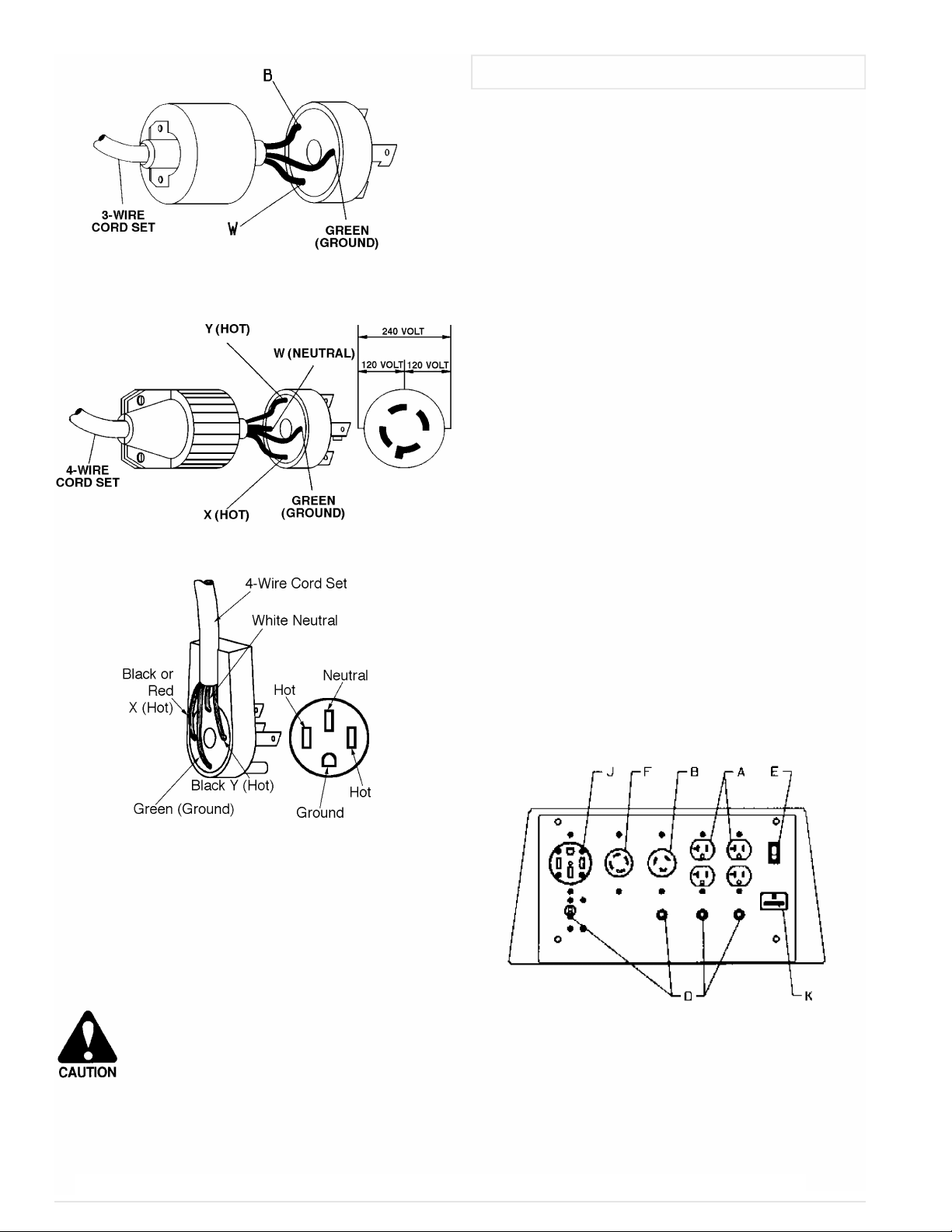

POWER CORD CONNECTIONS

Refer to the appropriate diagram for proper connection of

power cord wires to the plug terminals.

CAUTION: Insure that the power cord used is

well insulated and has a sufficient rating to

match that of the plug.

Page 6

120 volt 30 Amp Plug

120/240 Volts, 20 Ampere and 30 Ampere Plug

MAJOR FEATURES

A.120 V, 20 Ampere Duplex Receptacles

20 amps of current may be drawn from each of the duplex

receptacles. However, total power drawn must be kept

within nameplate ratings. These receptacles may be used

along with the twistlock receptacle provided the generator

is not overloaded.

B.120 Volt 30 Amp Twistlock Receptacle

You may draw a maximum of 30 amps or 3600 watts from

this receptacle. If other receptacles are used at the same

time, total power used must be kept within nameplate

rateings.

D.Circuit Breakers

The receptacles are protected by an AC circuit breaker.

(See Circuit Protection).

E.Idle Control Switch

Some models are equipped with an idle control switch.

(See Idle Control).

F.120/240 V 30 Amp Twistlock Receptacle

A maximum of 30 amps may be drawn from the 120/240

volt receptacle, provided it is the only receptacle used.

However, current must be limited to the nameplate rating.

If the 120/240 volt receptacle is used along with the 120

volt receptacle, the total load drawn must not exceed the

nameplate ratings.

120/240 Volt Heavy Duty Plug

APPLYING LOAD

This unit has been pretested and adjusted to handle its full

capacity. When starting the generator, disconnect all load.

Apply load only after generator is running. Voltage is regulated

via the engine speed adjusted at the factory for correct output.

Readjusting is not advised.

CAUTION: When applying a load, do not

exceed the maximum wattage rating of the

generator when using one or more

receptacles. Also, do not exceed the

amperage rating of any one receptacle.

J.240 Volt Heavy Duty Receptacle

This receptacle is rated at 50 amps but the current must be

limited to the nameplate rating. If this receptacle is used

along with the 120 volt receptacles, the total load drawn

must not exceed the nameplate ratings.

K.Hour Meter

The hour meter will help the user schedual the maintance

required to keep the unit in good working order.

6

English

Page 7

CIRCUIT PROTECTION

the plug. Then pull the starter until you feel the piston is on

, or

7

AC FEATURES

The receptacles are protected by an AC circuit breaker. If

the generator is overloaded or an external short circuit occurs,

the circuit breaker will trip. If this occurs, disconnect all

electrical loads and try to determine the cause of the problem

before attempting to use the generator again. If overloading

causes the circuit breaker to trip, reduce the load. NOTE:

Continuous tripping of the circuit breaker may cause

damage to generator or equipment. The circuit breaker may

be reset by pushing the button of the breaker.

DC FEATURES

The charging system of the unit is supplied by the

stater/alternator of the engne. 12 volts DC is constantly

charging the battery when the unit is running . Disconnecting

the battery will stop the charging of the battery.

Before charging a storage battery, check the electrolyte

fluid level in all the cells. (Sealed batteries do not require

checking). Add distilled water to each cell if necessary, to bring

the level back up to the manufacturer’s required level.

WARNING: Storage batteries give off

EXPLOSIVE hydrogen gas while charging. Do

not allow smoking, open flames, sparks, or

spark producing equipment in the area while

charging.

CAUTION: This battery charging system is

intended to recharge wieak batteries, not to

“boost start” vehicles.

Battery Installation

Coleman Powermate recommends a 12 v battery with at

least 235 cranking amps. Model U1L, Lawn and Garden

Battery. Place the battery in the position provided. Place the

spacers on the bolts, then place the bolts through the loops on

the Hold-Down bracket. Place the assembly over the battery

and place the bolts through the holes on the battery pan and

tighten down the Hold-Down assembly with the 1/4-20 nuts

provided.

Spacers may be removed depending on the battery height.

WARNING: Batteries contain sulfuric acid

(when filled). May contain explosive gasses.

Always abide by safety warnings provided

with the battery.

-Keep sparks, flame and cigarettes away.

-Hydrogen gas is generated during

charging and discharging.

-Always shield eyes, protect skin and

clothing when working near batteries.

Connect the Rd 8ga. battery lead to the positive battery

post and the black 8ga. battery to the negative battery post with

the bolts and nuts provided.

WARNING: Battery electrolyte fluid is

compressed of sulfuric acid that can be very

dangerous and cause severe burns. Do not

allow this fluid to contact eyes, skin, clothing,

etc. If contact or spillage does occur, flush the

area with water immediately.

BATTERY KIT PARTS LIST

ItemDescriptionQty.

A.*Bolt, 1/4-20X8”2

B.*Washer 1/42

C.*Spacer2

D. Hold Down bar (PN 0036525.02)1

E.*Nyloc nut, 1/4-202

*All parts are standard parts at your local hardware store.

LOW OIL SHUTDOWN

Some units are equipped with low oil shutdown. If the oil

level becomes lower than required, the generator set will

automatically shut off. This protects your generator set from

operating without proper lubrication.

If generator shuts off and the oil level is according to

specifications, check to see if generator is sitting at an angle

that forces oil to shift. Place on an even surface to correct this.

If engine fails to start, the oil level may not be sufficient to

deactivate low oil level switch. Be sure the sump is completely

full of oil.

INFREQUENT SERVICE

If the unit is used infrequently, difficult starting may result.

To eliminate hard starting, run the generator at least 30 minutes

every month. Also, if the unit will not be used for some time, it

is a good idea to drain the fuel from the carburetor and gas

tank.

LONG TERM STORAGE

When the generator set is not being operated or is being

stored more than one month, follow these instructions:

1.Replenish engine oil to upper level.

2.Drain gasoline from fuel tank, fuel line and carburetor.

3.Pour about one teaspoon of engine oil through the spark

plug hole, pull the recoil starter several times and replace

its compression stroke and leave it in that position. This

closes both the intake and exhaust valves to prevent the

inside of the cylinder from rusting.

4.Cover the unit and store in a clean, dry place that is well

ventilated away from open flame or sparks.

NOTE: The use of a fuel additive, such as STA-BIL

an equivalent, will minimize the formulation of fuel gum

deposits during storage. Such an additive may be added

to the gasoline in the fuel tank of the engine, or to the

gasoline in a storage container.

®

English

Page 8

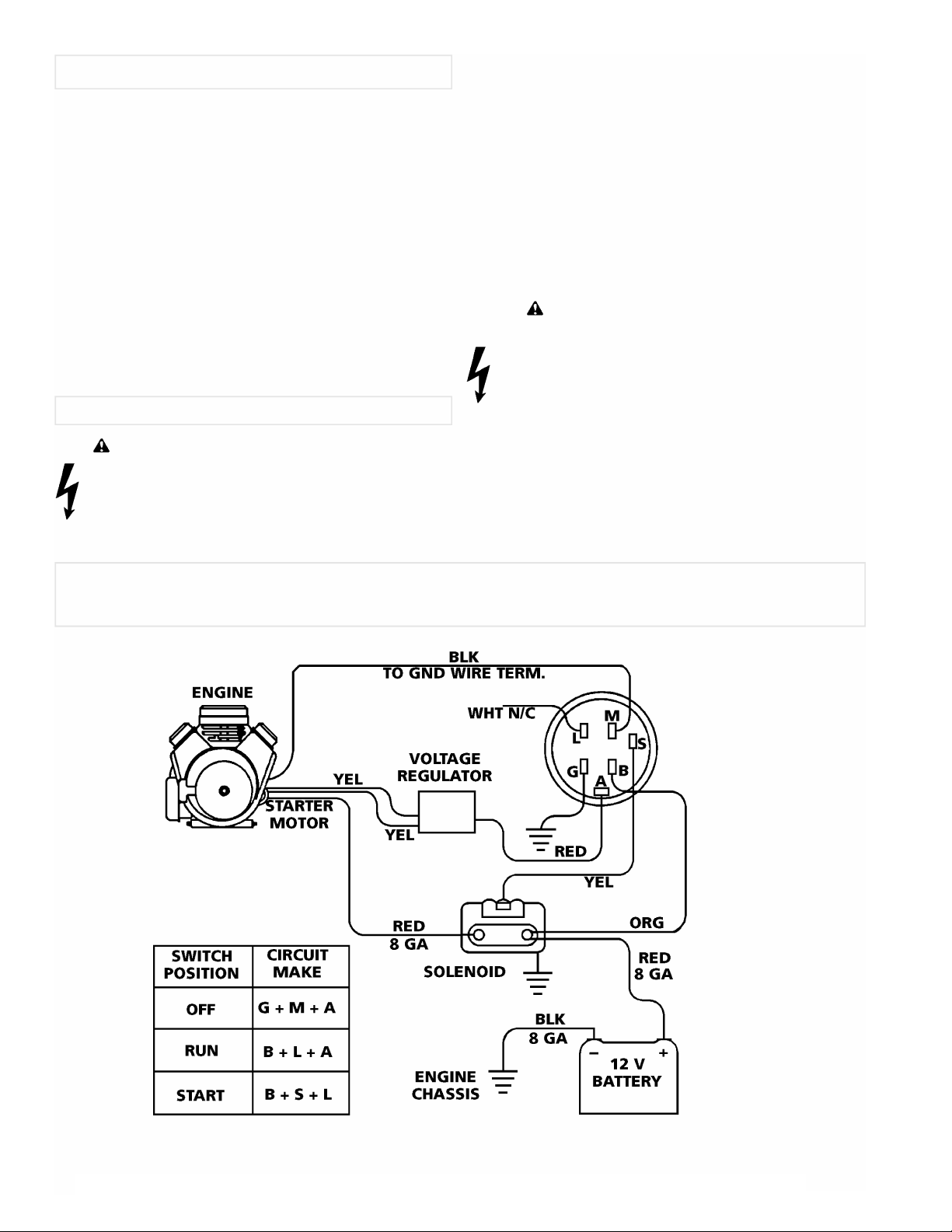

ELECTRIC START WIRING

The generator is equipped with electric start, refer to

FIGURE A

An “Off-On-Start” rotary key switch is provided on the recoil

end panel on some models. All necessary wiring is provided.

The battery is customer provided. #8 AWG (American Wire

Gauge) copper wire lead with ring terminals make battery

hookup quite simple.

Connect the lead hooked to the chassis to the negative (-)

battery terminal and the lead from the starter solenoid to the

positive (+) battery terminal with the appropriate bolts, lock

washers and nuts. The orange wire connected to the solenoid

and positive (+) battery terminal provides battery charging up to

16 amps.

Your engine may be equipped with a trickle charge system.

The 14 AWG (American Wire Gauge) red wire which comes

from the engine should be connected to the positive battery

terminal (see engine operator manual).

INSTALLATION

WARNING: To avoid possible personal injury or

equipment damage, a registered electrician or an

authorized service representative should perform

installation and all service. Under no circumstances

should an unqualified person attempt to wire into an

utility circuit.

To avoid backfeeding into utility systems, isolatin of the

residence electrical system is required.

Before temporary connection of the generator the

residence electrical system, turn off the main switch.

If your generator is to be used as a stand-by power source

in case of utility power failure, it should be installed by a

registered electrician and in compliance with all applicable local

electrical codes.

Proper use requires that a double throw transter switch be

installed bya licensed qualified electrician so that the building’s

electrical circuits may be safely switched between utility power

and the generator’s output, there by preventing backfeed into

the power utility’s electrical system.

WARNING: To avoid backfeeding into utility

systems, isolation of the residence electrical

system is required. Before temporary connection

of a generator to the residence electrical system

turn off the main switch. Before making permanent

connections a double throw transfer switch must

be installed. To avoid electrocution or property

damage, only a trained electrician should connect

generator to residence electrical system.

California law requires isolation of the residence

electrical system before connecting a generator to

residence electrical systems.

BASIC WIRING DIAGRAM

Electric Start Models (Models with Key Switch on Engine)

FIGURE A

8

English

Page 9

9

MAINTENANCE

IDLE CONTROL OPERATION

EXCITING THE GENERATOR:

NOTE: If your generator is a brushless unit please

contact your local service center or the Coleman

Powermate Service Department for assistance with

exciting your generator.

HEATSHIELD:

Inspect to ensure that all heat shields and heat deflectors

are intact and in place.

NOTE: Refer to the engine manufacturer's manual

for service and maintenance of the engine.

DRAINING THE OIL

Place a catch container underneath the oil drain. Push in,

turn and release the Quick Drain Plug. (Oil drainage will work

best if the oil is warm.)

The Idle Control circuit is designed to extend engine life

and improve fuel usage by slowing the engine down to

approximately 2000 RPM in a “No Load” condition. The noise

is also greatly reduced during this condition.

When power is required from the generator an electronic

control module automatically senses current flow in the

electrical outlet and allows the engine to return to full speed or

standard operating condition. Likewise, when the load is

removed, the generator will automatically return to the idle

condition after a 4-5 second delay.

A convenient switch is mounted in the control panel for

easy access and will disable the Idle Control circuitry when in

the off position.

NOTE: On the PM0610023 and the PC0610023 a 12V

battery must be installed in order for the idle control to

function. For the PM0612023 or PC0612023 a battery is

not required for the Idle control to work.

IDLE CONTROL TROUBLE SHOOTING

PROBLEMPOSSIBLE CAUSESOLUTION

Unit will not idle Control panel switch not onTurn to idle on position

Load plugged into receptacleUnplug load

Poor connection or faulty cordCheck & repair

Bad I.C. module; Bad electro-magnetReplace

or solenoids; Bad stator

Consult dealer

Unit idles even with load plugged in Load not heavy enoughTurn idle switch to off position

Increase load

Bad I.C. moduleReplace

Consult dealer

Unit tries to idle but won’t stay latched Electro-magnet or solenoid positionReset magnet or solenoid position for

incorrect2000 RPM idle speed

Consult dealer

Flapper bracket loose or bentTighten or straighten

Replace flapper. Readjust to 2000 RPM

Engine not running smoothlyAdjust carburetor

Consult dealer

English

Page 10

TROUBLE SHOOTING THE GENERATOR

PROBLEMPOSSIBLE CAUSESOLUTION

Alternator Excitation Failure.Low speed.Check rpm and set at nominal value.

Faulty capacitor. Check and replace.

Faulty windings.Check windings resistance.

High no-load voltage.Speed too high.Check and adjust rpm.

Capacitor with high capacity.Check and replace.

Low no-load voltage. Speed to low. Check and adjust rpm.

Faulty rotary diodes.Check and replace.

Breakdown in windings.Check winding resistance.

Capacitor with low capacity.Check and replace.

Proper no-load but low loaded voltage.Low loaded speed. Check and regulate rpm.

Load too big.Check and change.

Rotary diodes short-circuited.Check and replace.

Proper no-load but high loaded voltage.High speed in load condition.Check and regulate rpm.

Unstable voltage.Loose contacts.Check connections.

Change in engine speed.Check and regulate rpm.

Wont Start or run.Foreign debris in muffler.Check and clean muffler exhaust.

No gas.Add gas to tank.

Turn fuel valve on.

Spark pulg not connected. Connect apark plug wire.

Battery cable hooked up wrong.Check and change if necessary.

Air cleaner plugged.Check and clean or replace.

Tank Expansion.Fuel cap not venting.Check and replace cap.

10

English

Page 11

11

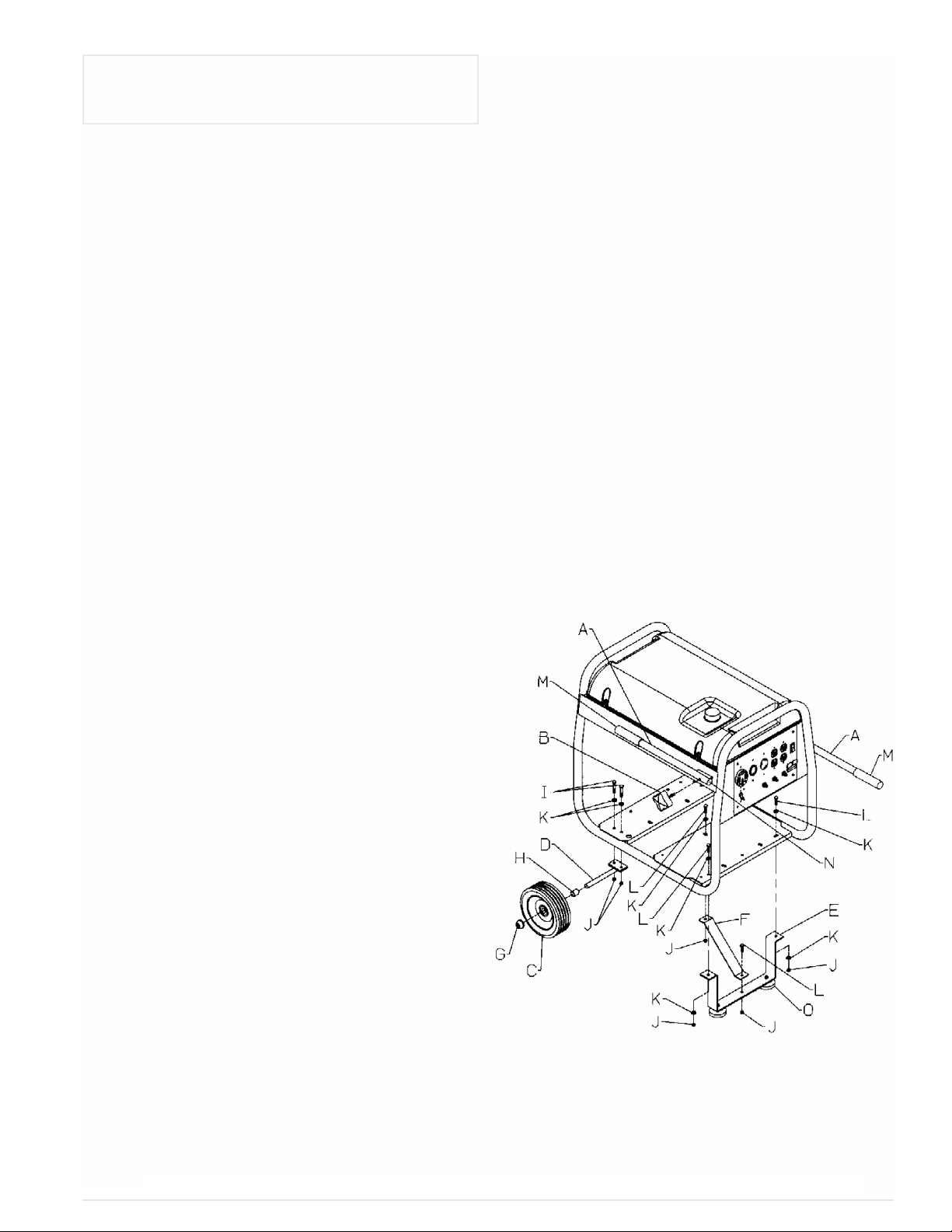

INSTALLATION OF THE

PORTABILITY KIT

Tools Required:

Hammer, 1/2” wrench, ratchet with a 1/2” socket, and

wood blocks.

Refer to the drawing for proper alignment of Foot bracket

and Wheel brackets.

Parts List

AHandle0056240

BKnob0062177

CWheel 0056236

DWheel Bracket0056406

EFoot Bracket0056237

FFoot Bracket Strap0056409

GAxle Cap0056444

HWheel Spacer0056445

IBolt 5/16-18X1.75”Note A

JNyloc Nut 5/16Note A

KFlat Washer 5/16Note A

LBolt 5/16-18X1”Note A

MHandle Grip0056239

NPlastic Cap0056030.01

ORubber Foot0008433

Foot bracket Installation

1. Block up opposite end of. the unit, about 8” high.

2. Add 5/16 washer to 1” bolts and place through holes

in the base pan.

3. Add foot bracket assy to bolts, add 5/16 nyloc nuts

and tighten securely.

4. Add support bracket from foot bracket to the base

pan. Secure in place with 1” bolts, washers and 5/16

nyloc nuts.

Handle Installation

1. Insert the threaded end of the knobs through the

holes in the handles.

2. Line up handle with knob to the side of the carrier and

place the threads into the holes at the handle location on

the carrier. Tighten securely.

CAUTION, DO NOT OVER TIGHTEN.

Note: Handles can be placed in both directions. Along

the carrier rails for storage and extended to move the

unit.

Note A: These are standard parts available at your

local hardware store.

Wheel Bracket & Wheel Installation

1. Block up end of generator , about 8” high, opposite

the fuel tank cap to install wheels and wheel bracket

assy.

2. Add 5/16 washer to the 1 3/4” bolts and insert

bolts/washers through the holes located in the base pan

of the carrier.

3. Place the wheel bracket through the bolts and add a

5/16 nyloc nut and tighten securely. (On the bottom side

of the pan in-between the holes will be a 1” square

brace, the wheel bracket will set on this brace).

4. Add wheel spacer to the axle.

5. Slide the wheel onto the axle until it is snug agaist the

spacer. The wheel is on correctly if there is

approximately a 1/2” gap between the carier tubing and

the side of the wheel . If it is less then 1/2” from the

carrier, turn the wheel over and reinstall. Align the

wheels parallel to the carrier tubing and tighten nuts

securly. To align correctly, the bolts holding the wheel

bracket may have to be loosened.

6. With a hammer, add the plastic cap on end of axle.

7. Repeat above instrucitons for the remaining wheel.

English

Page 12

SERVICE INFORMATION

CONTACT THE COLEMAN

POWERMATE CUSTOMER

SERVICE DEPARTMENT AT

LIMITED WARRANTY

(NOT VALID IN MEXICO)

This product is warranted by Coleman Powermate, Inc. to

the original retail consumer against defects in material and

workmanship for a period of two (2) years from the date of retail

purchase and is not transferable. This two year warranty

applies only to products used in consumer applications. If these

generators are used in a commercial application, then the

period of warranty coverage is limited to one (1) year from the

date of purchase.

1-800-445-1805

to obtain warranty service

information or to order

replacement parts or

accessories.

HOW TO ORDER REPLACEMENT PARTS

Even quality built equipment such as the Coleman

Powermate electric generator you have purchased, might need

occasional replacement parts to maintain it in good condition

over the years. To order replacement parts, please give the

following information:

1.Model No. and Serial No. and all specifications shown on

the Model No./Serial No. plate.

2.Part number or numbers as shown in the Parts List section

of this manual.

3. A brief description of the trouble with the generator.

NOTE: If replacement parts are required for the

engine, contact one of the engine manufacturer's service

centers.

Coleman Powermate, Inc.

4970 Airport Road

P. O. Box 6001

Kearney, NE 68848

Please complete and return the enclosed Customer

Information Card so that we can reach you in the unlikely event

a safety recall is needed. Return of this card is not required to

validate this warranty.

WHAT IS COVERED: Replacement parts and labor.

WHAT IS NOT COVERED: Transportation charges to

Coleman Powermate, Inc. for defective products.

Transportation charges to consumer for repaired products.

Brushes, rubber feet, and receptacles. Damages caused by

abuse, accident, improper repair, or failure to perform normal

maintenance. Power units or engines which are covered

exclusively by the warranties of their manufacturer. Sales

outside of the United States and Canada. Any other expense

including consequential damages, incidental damages, or

incidental expenses, including damage to property. Some

states do not allow the exclusion or limitation of incidental or

consequential damages, so the above limitation or exclusion

may not apply to you.

IMPLIEDWARRANTIES: Any implied warranties, including

the Implied Warranties of Merchantability and Fitness For A

Particular Purpose, are limited in duration to one (1) year from

the date of retail purchase. Some states do not allow

limitations on how long an implied warranty lasts, so the above

limitation may not apply to you.

HOW TO OBTAIN WARRANTY PERFORMANCE:

Replacement parts and service are available from Coleman

Powermate, Inc. Service Centers. Locate your nearest Service

Center by calling TOLL FREE 1-800-445-1805. In the unlikely

event a Service Center can not be located you may call

Coleman Powermate, Inc. for a return authorization number.

Any unit returned WITHOUT an authorization number will

be refused.

To the extent any provision of this warranty is prohibited by

federal, state, or municipal law, and cannot be preempted, it

shall not be applicable. This warranty gives you specific rights,

and you may also have other rights which vary from state to

state.

12

English

Page 13

utiliser des gants et des bottes en caoutchouc

ainsi qu’un interrupteur de circuit avec mise à

tuyau spongieux ou usé, une bride qui manque ou

Une bonne ventilation - évitez les endroits où

RÉGLES D’OPÉRATION ET DE SÉCURITÉ

13

Les mesures de sécurité sont des éléments essentiels

lorsqu’on parle d’équipement mécanique. Ces mesures sont

nécessaires lorsqu’on utilise, range, et fait l’entretien

d’équipement mécanique. Le fait d’utiliser cet équipement avec

le respect et les précautions voulues permettra de diminuer

considérablement les possibilités de blessures personnelles. Si

l’on ignore ou néglige les mesures de sécurité, des blessures

personnelles ou des dommages à la propriété peuvent s’en

suivre.

Les symboles suivants sont utilisés fréquemment dans

l’ensemble de ce manuel. Tenez toujours compte de ces

précautions car elles sont essentielles lorsque vous utilisez tout

équipement mécanique.

6.Un appareil dont les pièces sont cassées, auquel

il manque des pièces ou qui n’a pas de carter ou

de coquille protectrice ne doit en aucun cas être

utilisé. Contacter notre service après-vente pour

des pièces de rechange.

7.Ne pas faire fonctionner ou remiser l’appareil

dans un endroit humide ni sur une surface

mouillée, ni dans un endroit où il sera en contact

avec des surfaces conductrices telles que des

planchers ou armatures métalliques. Toujours

Ce symbole de danger identifie des instructions

ou des procédures précises qui peuvent éviter

des blessures personnelles ou même mortelles si

on les suit correctement.

Ce symbole de mise en garde identifie des

instructions ou des procédures précises qui

peuvent éviter, si on les observe, des dommages

ou la destruction de l’équipement.

Cet appareil est conçu pour des applications précises. Il ne

doit être ni modifié ni utilisé pour toute application autre que

celles pour lesquelles il a été conçu. Si vous avez des

questions quant aux applications, veuillez écrire ou

communiquer avec la compagnie. N’utilisez pas cet appareil

jusqu’à ce que vous ayez été avisé. Pour plus de

renseignements, communiquez avec le service à la clientèle au

1-800-445-1805.

Lorsque vous utilisez ce produit, certaines

précautions de base doivent être respectées, dont

les suivantes:

1. Lisez attentivement ce manuel - apprenez à

connaître votre équipement. Tenez compte

des applications, limites et dangers possibles

de votre appareil.

2.On doit placer l’équipement sur une surface

support solide.

3.La charge doit être dans les normes

spécifiées sur la plaque signalétique de la

génératrice. Toute surcharge abîme la

génératrice et en raccourcit la durée de vie

utile.

la masse si de telles conditions sont

présentes.

8.Garder la génératrice propre et libre de toute

huile, boue ou autre matière étrangère.

9.Les rallonges, les cordons d’alimentation et tout

appareil électrique doivent être en bon état. Ne

jamais faire fonctionner un appareil électrique

dont le cordon d’alimentation est abîmé ou

défectueux.

10.Ranger le nettoyeur haute pression dans un

endroit bien ventilé, réservoir d’essence vide. On

ne doit pas ranger l’essence près de la

génératrice.

11.Vous ne devez jamais utiliser votre nettoyeur

sous ces conditions:

a.Un changement de vitesse du moteur.

b.Perte de puissance électrique.

c.Surchauffe d’appareils connectés.

d.Jaillissement d’étincelles.

e.Prises endommagées.

f.Le moteur qui a des ratés.

g.Vibrations excessives.

h.Flammes ou fumée.

i.Compartiment fermé.

j.Pluie ou température défavorable.

12.Vérifier le système de carburant régulièrement

pour toute fuite ou signes de détérioration tels un

desserrée ou un réservoir ou couvercle

endommagé. On doit corriger ces problèmes

avant de faire fonctionner l’appareil. Nettoyer

immédiatement tout déversement.

4.Le moteur ne doit pas tourner à des vitesses

excessives car ceci augmente les risques de

blessures personnelles. Ne touchez pas aux

pièces ce qui pourrait augmenter ou réduire

la vitesse régulée.

5.Afin d’empêcher les démarrages imprévus,

toujours enlever la bougie ou le câble de la

bougie avant d’ajuster la génératrice ou le

moteur.

French

13.On ne doit faire fonctionner, réparer et faire le

plein que sous les conditions suivantes:

a.

les vapeurs peuvent être immobilisées

comme dans des fosses, sous-sols, caves,

trous et dans le fond d’un bateau. La

circulation de l’air et les températures sont

importantes pour les appareils refroidis par

air. Les températures ne devraient pas

dépasser 40 degrés C (100 degrés F).

Page 14

b.On doit canaliser les gaz d’échappement

dangereux vers l’extérieur de l’endroit de

travail. Les émanations du moteur

contiennent du monoxyde de carbone, un

gaz invisible, sans odeur et empoisonné

qui, si respiré, peut provoquer de sérieuses

maladies et même la mort.

c.Refaire le plein du nettoyeur haute pression

dans un endroit bien éclairé. Évitez les

débordements de carburant et ne refaites

jamais le plein lorsque le génératrice est en

marche.

d.Ne pas faire le plein près de flammes nues,

de veilleuses ou d’équipement électrique

projetant des étincelles comme les outils

électriques, les soudeuses et les meuleuses.

e.Le silencieux et le filtre à air doivent toujours

être en place et en bon état puisqu’ils jouent

le rôle de coupe-flammes s’il y a des ratés.

f.Ne pas fumer près de la génératrice.

14.Ne pas porter de vêtements amples, de bijoux ou

toute autre chose qui pourrait se prendre dans le

démarreur ou autres pièces rotatives.

15.La génératrice doit atteindre son régime de

fonctionnement avant que toute charge y soit

connectée. Débrancher toute charge avant

d’arrêter le moteur.

16.Afin d’empêcher les pointes de tension qui

pourraient endommager les appareils branchés

sur la génératrice, ne pas laisser le moteur

tomber en panne de carburant pendant que des

appareils sont branchés dessus.

17.Lorsque vous utilisez de l’équipement en solide,

vous devriez utiliser un protecteur de surtension

pour éviter d’endommager l’équipement. (Voir

Mise en garde en page 15).

18.Ne rien mettre dans les fentes d’aération, même

quand la génératrice n’est pas en marche. Ceci

pourrait l’abîmer ou provoquer des blessures.

19.Avant de transporter la génératrice dans un

véhicule, la vider de tout carburant afin

d’empêcher les fuites.

20.Pour transporter le générateur d’un site à l’autre,

utiliser les bonnes techniques de levage sinon

vous pourriez causer des blessures personnelles.

21.Pour éviter les brûlures, ne touchez pas au

silencieux du moteur ou à toute autre surface du

moteur ou du générateur qui se réchauffe durant

le fonctionnement.

22.Ne jamais débrancher une composante qui aide à

établir le calendrier d’entretien de la génératrice,

au risque de réduire la durée de vie de cette

dernière.

SILENCIEUX PARE-ÉTINCELLES

CET APPAREIL N’EST PAS DOTÉ D’UN SILENCIEUX

PARE-ÉTINCELLES. S’il doit être utilisé à proximité de

matériaux inflammables tels que récoltes, forêts, broussailles,

herbes ou autres, il est fortement recommandé d’installer un

pare-étincelles, par ailleurs obligatoire en Californie. Les

articles de la loi californienne relatifs à l’usage de pareétincelles sont les suivants : 13005(b), 4442 et 4443. L’usage

d’un pare-étincelles est également exigé sur certains des

territoires du service des Forêts américain et peut également

l’être par d’autres lois et règlements. Un pare-étincelles

homologué est disponible auprès de votre concessionnaire

Coleman Powermate ou peut être commandé à Coleman

Powermate, Inc., P. O. Box 6001, Kearney, Nebraska 68848.

Téléphone : 1-800-445-1805.

Remarque: Ne pas oublier de souvent nettoyer la grille

pare-étincelles pour assurer le meilleur rendement de la

génératrice.

DETERMINATION DE LA PUISSANCE

TOTALE NÉCESSAIRE

Pour déterminer quels outils et/ou quels appareils peuvent

fonctionner avec votre générateur, suivez ces étapes :

1.Déterminez si vous désirez faire fonctionner un ou

plusieurs appareils simultanément.

2.Vérifiez les exigences normales pour démarrer et faire

rouler les appareils voulus en vous reportant à la plaque

signalétique de charge ou en effectuant ce calcul

(multipliez les ampères x volts = watts).

3.Additionnez le nombre de watts de démarrage et de

fonctionnement de chaque appareil. Toutefois, la

plaque signalétique de l’équipement vous donnera des

chiffres de consommation d’électricité plus exacts. Si la

plaque ne vous donne que des volts et des ampères,

multipliez les volts x ampères = watts. 1KW = 1 000 watts.

REMARQUE : Prévoir 2 1/2 - 4 fois la puissance

indiquée pour la mise en marche de l’appareil.

4.Le nombre de watts de démarrage/surtension et de

fonctionnement/puissance nominale devrait concorder ou

dépasser le nombre total de watts requis pour

l’équipement que vous désirez faire fonctionner.

5.Branchez toujours d’abord la charge la plus lourde au

générateur, puis ajoutez les antres l’une à la fois.

6.Les appareils ou les outils à moteur exigent plus que leur

puissance indiquée pour le démarrage.

14

French

Page 15

Ceci permet l’expansion du carburant pendant

cette consigne peut entraîner la surchauffe du

appuyez sur le bouton installé sur la tête du générateur ou

pour éliminer les gaz d’échappement toxiques

VÉRIFIER LA TENSION

15

ATTENTION : Vérifier la tension et la

fréquence requises avant de brancher tout

équipement électronique sur la génératrice.

L’appareil peut se trouver endommagé s’il

n’est pas prévu pour fonctionner à une

tension égale à ± 10% et une fréquence égale

à ± 3 hz de celles indiquées sur la plaque

signalétique de la génératrice. Pour éviter

tout dommage, toujours brancher une charge

additionnelle sur la génératrice lorsqu’un

appareil à circuits intégrés (tel qu’un

téléviseur) est utilisé. Une varistance peut être

aussi nécessaire pour certaines applications,

dans le cas d’un ordinateur, par exemple. Une

varistance peut être aussi nécessaire pour

certaines applications de l’équipement en

solide.

Typique de l’équipement en solide incluyen:

Ouvres-portes de garage

Appareils de cuisine à affichers digital

Téléviseurs

Stéréos

Ordinateurs personnel

Pendules à quartz

Machines à photocopier

Équipement téléphonique

Pour plus de renseignements, contacter notre Service

Clients au 1-800-445-1805.

LUBRIFICATION

NE PAS essayer de faire démarrer ce moteur avant d’avoir

rempli le carter d’huile, en utilisant la quantité et le type d’huile

appropriés. (Ces renseignements sont fournis dans le manuel

du moteur ci-inclus.) La génératrice est expédiée de l’usine

avec le carter vide. Un moteur qui tourne sans huile dans le

carter peut se trouver détruit.

Remarque: Pour adouter de l’huile à l’appareil, utiliser

un entonnoir à long cou pour refoindre l’orifice de

remplissage d’huile, situé sur le dessus de moteur, au

couvercle des soupapes en tête, du côté de la batterie.

S’assurer de fermer le bouchon de vidange avant d’afouter

de l’huile.

CARBURANT

Remplir le réservoir d’essence automobile sans plomb

fraîche et libre de toute impureté. De l’essence ordinaire peut

être utilisée, à condition qu’elle ait un indice d’octane élevé (85

octane minimum).

ATTENTION : Ne pas trop remplir le réservoir.

Maintenir le niveau d’essence maximum à un

centimètre au-dessous du haut du réservoir.

les périodes de chaleur et empêche l’essence

de déborder.

DANGER : L’essence est un produit très

dangereux. Des blessures sérieuses peuvent

résulter des flammes produites par le contact

d’essence avec des surfaces très chaudes.

1. Ne pas mettre de l’essence dans le

réservoir quand le moteur est en marche.

2. Ne pas renverser d’essence lors du

remplissage du réservoir.

3. Ne pas mélanger de l’huile à l’essence.

AVANT DE METTRE EN MARCHE

MISE À LA TERRE DE LA GÉNÉRATRICE

Veiller à ce que la génératrice soit reliée à la terre pour

éviter les decharges électriques. Un ceillet de mise à la terre

est fourni à cet effet. Relier, à l’aide d’un fil de gros calibre,

l’oeillet de mise à la terre à une source extérieure de mise à la

terre telle qu’une conduite d’eau ou une tige de cuivre enfoncée

dans la terre.

DANGER : Ne pas utiliser une conduite

transportant un matériau combustible comme

source de mise à la terre.

Vis de masse

PRÉPARATIFS AU DÉMARRAGE

Avant de mettre la génératrice en marche, vérifier qu’il ne

manque aucune pièce, que toutes les pièces sont bien serrées

et que la génératrice n’a pas été abîmée pendant le transport.

DANGER : Ne pas faire fonctionner cette

génératrice sans les écrans de chaleur

montés en usine en place. Le non-respect de

réservoir de carburant et des blessures à la

suite de l’incendie ainsi provoqué.

DÉMARRAGE DU MOTEUR

1. Vérifiez le niveau d’huile et de carburant.

2. Débranchez toutes les charges électriques de l’appareil.

3.Ouvrez la vanne de fermeture de carburânt.

4.Réglez le doseur au besoin.

5. Réglez l’interrupteur du moteur en position “ON”.

6. Tirez sur la corde de lancement d’un coup rapide et sûr.

Lorsque le moteur se réchauffe, réglez à nouveau le

doseur. Pour les modèles à lancement électrique,

tournez l’interrupteur à clé à “DÉMARRER” selon votre

modèle. Après que le moteur démarre, relâchez

l’interrupteur à clé.

DANGER : Fournir une aération suffisante

French

et assurer le refroidissement du moteur.

Page 16

RODAGE

Un rodage bien mené aide à assurer le bon

fonctionnement du moteur et de la génératrice. Suivre les

recommandations données dans le manuel du moteur.

ATTENTION: Ne pas brancher un appareil

puissant sur la génératrice pendant la période

de rodage (les deux à trois premières heures

de fonctionnement).

ATTENTION : Laisser la génératrice

fonctionner cinq minutes sans aucun appareil

branché dessus au moment du démarrage

initial pour permettre au moteur et à la

génératrice de se stabiliser.

ARRÊT DE LA GÉNÉRATRICE

1. Retirez toute la charge électrique.

2. Laissez le moteur tourner quelques minutes sans charge.

3.Placez l’interrupteur du moteur en position “OFF”.

(Tournez l’interrupteur à clé à “ARRÊT” pour les modèles à

lancement électrique.)

4. Ne laissez pas le générateur jusqu’à ce qu’il soit

complètement arrêté.

5.Fermez la vanne de fermeture du carburant (s’il y en a

une) si le moteur doit être rangé ou transporté.

6. Si l’on utilise, un couvercle, ne l’installez pas jusqu’à ce

que l’appareil soit refroidi.

Fiche de 120 V et 30 A

Fiche de 120/240 V, 20 A et 30 A

Soupape de carburant

CONNEXIONS DU CORDON D’ALIMENTATION

Vous référer aux diagrammes appropriés pour relier les fils

du cordon d’alimentation aux bornes voulues de la fiche.

ATTENTION : Veiller à ce que le cordon

d’alimentation utilisé soit bien isolé et d’un

ampérage correspondant à celui de la fiche.

16

Fiche de 240 V, 50 A

BRANCHEMENT DES APPAREILS

Cette génératrice a été vérifiée et réglée pour fonctionner à

pleine capacité. Débrancher tout appareil qui y est relié avant

de la mettre en marche. Attendre qu’elle tourne avant de

commencer à brancher des appareils dessus. La tension est

réglée par la vitesse du moteur, qui a été ajustée à l’usine pour

assurer la puissance voulue. Il est déconseillé de la régler.

ATTENTION: Ne pas dépasser la puissance

nominale de la génératrice lorsqu’une ou

plusiers prises sont utilisées. De plus, ne pas

dépasser l’ampérage nominal d’une prise,

quelle qu’elle soit.

French

Page 17

17

batterie est prévu pour recharger les batteries,

(hydrogène) des batteries pendant qu’elles se

CARACTERISTIQUES PRINCIPALES

A.Prise double de 120 V, 15 A et 20 A

Cette prise double est câblée pour fournir 15 A/ 20 A. La

charge totale doit cependant rester dans les limites

indiquées sur la plaque signalétique. Ces prises peuvent

s’utiliser en conjonction avec la prise à verrouillage à

condition que la génératrice ne soit pas surchargée.

B.Prise à verrouillage de 120 V, 30 A

Cette prise fournit un maximum de 30 A. Si d’autres prises

sont utilisées en même temps que celle-ci, la charge totale

doit rester dans les limites indiquées sur la plaque

signalétique.

D.Disjoncteurs

Les boîtiers sont protégés par un disjoncteur de c.a.

(Voir Commande de ralenti)

E.Interrupteur de la commande de ralenti

Interrupteur de commande de ralenti certains modèles sont

dotés d’un interrupteur de commande de ralenti.

(Voir Commande de ralenti)

F.Prise à verrouillage de 120/240 V, 30 A

Cette prise de 120/240 V fournit un maximum de 30 A, à

condition que ce soit la seule utilisée. La charge totale doit

par ailleurs rester dans les limites indiquées sur la plaque

signalétique. Si la prise de 120/240 V est utilisée en

conjonction avec les prises de 120 V, la charge totale ne

doit pas dépasser les limites indiquées sur la plaque.

J.Boîtier résistant 120/240 volts

Ce boîtier a une valeur nominale de 50 A, mais le courant

doit être limité à la valeur de la plaque signalétique. Si ce

réceptacle est utilisé avec des boîtiers de 120 volts, la

charge totale ne doit pas dépasser les valeurs de plaque

signalétique.

K.Compteur d’heures.

Le compteur d’heures aide l’utilisateur à établir le

calendrier d’entretien pour maintenir l’appareil en bon

état.

REMARQUE : La génératrice ou les appareils branchés

dessus peuvent se trouver abîmés si le disjoncteur saute

continuellement. Appuyer sur le bouton du disjoncteur pour le

réenclencher.

DC FEATURES

Le système de charge de l’appareil est assuré par le

démarreur et l’alternateur du moteur. Une tension de 12 volts

c.c. charge sans cesse la batterie lorsque l’appareil fonctionne.

Le débranchement de la batterie met fin à sa charge.

ATTENTION: Ce système de recharge de

pas pour faire démarrer un véhicule dont la

batterie est insuffisamment chargée.

DANGER: Il se dégage un gas EXPLOSIF

rechargent. Ne pas permettre de fumer ni

autoriser la présence de flammes, étincelles

ou matériel produisant des étincelles à

proximité.

ATTENTION: L’électrolyte de la batterie

se compose d’acide sulfurique, un acide qui

peut être très dangereux et provoquer des

brûlures graves. Ne pas permettre le contact

de ce liquide avec les yeux, la peau, les

vêtements, etc. En cas de contact ou si du

liquide se trouve renversé, bien rincer à l’eau

tiède immédiatement.

LISTEDESPIÈCESDELATROUSSEDEBATTERIES

Ref.DescriptionQty.

A.*Boulon, 1.4-20 x 8”2

B.*Rondelles plates 2

C.*Entretoises2

D.Barre de retenue (PN 0036525.02)1

E.*Écrous nyloc 1/4-202

*Toutes les pièces sont standard et sont en vente à la

quincaillerie locale.

PROTECTION DES CIRCUITS

AC FEATURES

Les prises sont protégées par un disjoncteur alternatif. En

cas de surcharge ou de court-circuit extérieur, le disjoncteur

saute. Si cela se produit, débrancher tout appareil relié à la

génératrice et essayer de déterminer la cause du problème

avant d’essayer de la réutiliser. Si le disjoncteur saute en

raison d’une surcharge, réduire la charge.

French

Page 18

Installation de la Batterie

Coleman Powermate recommande une batterie de 12 V

fournissant au moins 235 A au démarrage. Batterie Lawn and

Garden modèle U1L. Placer la batterie à l’emplacement prévu.

Placer les entretoises sur les boulons, puis les boulons dans

les boucles de la barre de retenue. Placer l’assemblage sur la

batterie, insérer les boulons dans les trous du plateau de la

batterie et serrer la barre au moyen des écrous 1/4-20 fournis.

Il est possible d’enlever les entretoises, selon la hauteur de

la batterie.

ATTENTION: Les batteries

contiennent de l'acide sulfurique

(lorsqu'elles sont pleines). Elles peuvent

également produire des gaz explosifs.

Toujours observer les mesures de

sécurité recommandées par le fabricant.

3.Mettre environ une cuillerée à thé d’huile pour moteur dans

l’orifice des bougies, tirer sur le lanceur à plusieurs

reprises et remettre la bougie en place. Ensuite, tirer sur le

lanceur jusqu’à ce que le piston soit en position de

compression et le laisser dans cette position. Ceci ferme

les soupapes d’admission et d’échappement afin

d’empêcher l’intérieur du cylindre de rouiller.

4.Couvrir la génératrice et la remiser dans un endroit propre,

sec et bien aéré, loin de toute source de flamme ou

d’étincelles.

REMARQUE : L’usage d’un additif pour carburant tel

que STA-BIL® ou un produit équivalent limite la formation

de dépôts de calamine pendant l’entreposage. Ce genre

d’additif peut être ajouté à l’essence soit dans le réservoir

du moteur, soit dans le bidon d’essence.

-Ne pas fumer à proximité de batteries, les

garder à distance sûre de toute source

d'étincelles ou de flamme.

-De l'hydrogène est produit pendant la

décharge et la recharge de la batterie.

-Toujours protéger les yeux, la peau et les

vêtements lorsqu'on travaille à proximité

de batteries.

Brancher le fil rouge de calibre 8 de la batterie à la borne

positive et le fil noir de calibre 8 à la borne négative le la

batterie au moyen des boulons et des écrous fournis.

NIVEAU D’HUILE BAS

Certaines génératrices sont équipées d’un dispositif d’arrêt

en cas de niveau d’huile trop bas. Quand l’huile descend audessous du niveau limite, le voyant rouge clignote. Ce voyant

est monté sur le côté droit du boîtier du ventilateur. Si on

n’ajoute pas d’huile, la génératrice s’éteint automatiquement.

Ceci protège la génératrice en l’empêchant de fonctionner

quand la lubrification n’est plus adéquate.

Si la génératrice s’arrête mais qu’il y a suffisamment

d’huile, vérifier si elle se trouve sur un plan incliné, entraînant

l’accumulation d’huile à une extrémité de l’appareil. Si c’est le

cas, remettre la génératrice de niveau. Si elle ne démarre

encore pas, il est possible que le niveau d’huile ne soit pas

assez élevé pour couper le dispositif d’arrêt. Vérifier le voyant

indicateur de niveau d’huile tout en tirant sur le lanceur. Si le

voyant clignote, ajouter de l’huile. Veiller à ce que le carter soit

complètement rempli d’huile.

USAGE PEU FRÉQUENT

Si la génératrice est rarement utilisée, il est possible

qu’elle soit difficile à mettre en marche. Pour éliminer ce

problème, faire tourner la génératrice pendant au moins 30

minutes toutes les semaines. Par ailleurs, si elle ne doit pas

être utilisée pendant un certain temps, il est bon de vider le

carburateur et le réservoir de toute essence.

REMISAGE À LONG TERME

Si la génératrice n’est pas utilisée ou qu’elle est remisée

pendant plus d’un mois, procéder comme suit :

1. Remettre de l’huile jusqu’au repère supérieur.

INSTALLATION

DANGER : Pour éviter toute blessure et

tout dommage aux appareils, faire effectuer

l’installation électrique et toutes réparations

par un électricien licencié ou un spécialiste du

service après-vente agréé. En aucune

circonstance, une personne non qualifiée ne

doit-elle essayer de réaliser le câblage sur

l’installation électrique existante.

Pour éviter les retours de courant dans l’installation

électrique de la maison, il est nécessaire d’assurer son

isolation.

Avant d’effectuer la connexion temporaire de la génératrice

sur l’installation électrique de la maison, couper le courant à

l’interrupteur principal.

Si la génératrice est utilisée comme source auxiliaire en

cas de panne de courant, elle doit être installée par un

électricien qualifié et en conformité avec tous les codes locaux

applicables.

Pour que l’installation soit correcte, un commutateur de

transfert à deux directions doit être installé par un électricien

qualifié et licencié de façon à ce que les circuits électriques du

bâtiment puissent être commutés du secteur à la génératrice

sans danger, empêchant ainsi les retours de courant dans le

secteur.

DANGER : Pour éviter les retours de

courant dans le secteur, il est nécessaire

d’assurer l’isolation électrique de la maison.

Avant d’effectuer la connexion temporaire de

la génératrice sur l’installation électrique de la

maison, couper le courant à l’interrupteur

principal. Avant de réaliser des connexions

permanentes, installer un commutateur de

transfert à deux directions. Pour éviter toute

électrocution ou des dommages matériels,

faire connecter la génératrice à l’installation

électrique de la maison par un électricien

qualifié. Les lois californiennes exigent

l’isolation de l’installation électrique de la

maison avant d’y connecter une génératrice.

2. Éliminer toute essence du réservoir, de la conduite et du

carburateur.

18

French

Page 19

19

ENTRETIEN

EXCITATION DE LA GÉNÉRATRICE:

REMARQUE: Remplacer les balais uniquement avec

les balais de rechange spécifiés dans la liste des pièces

détachées. D’ autres balais peuvent paraître identiques

mais avoir des caraciéristiques mécaniques se électriques

complètement différentes.

ÉCRANS DE CHALEUR:

Vérifier que tous les écrans de chaleur et les déflecteurs

thermiques sont intacts et en place.

REMARQUE: Se référer au Manuel de l’utilisateur du

fabricant du moteur pour l’entretien et la réparation du

moteur.

Vidange de l’huile

Placer un récipient sous l’orifice de vidange d’huile.

Pousser, tourner et rettirer le bouchon de vidange. (La vidange

est plus facile lorsque l’huile est chaude.) S’assurer de

remettrele bouchon après la vidange de l’huile usageée.

CÂBLAGE DU DÉMARREUR

ÉLECTRIQUE

Si votre générateur est doté d’un démarreur électrique.

Consulter la figure A.

FIGURE A (Page 20)

Certains modèles sont dotés d’un interrupteur à clé rotatif

“Arrêt-Marche-Démarrer” sur le panneau latéral de recul. Tous

les fils nécessaires sont fournis tandis que le client doit fournir

la batterie. Les fils de cuivre #8 AWG (American Wire Gauge)

avec cosses circulaires facilitent le branchement de la batterie.

Branchez le fil du châssis à la cosse de batterie négative (-) et

le fil du solénoïde de démarrage à la cosse positive (+) à l’aide

des boulons, rondelles de blocage et écrous appropriés. Le fil

orange branché au solénoïde et la cosse positive (+)

permettent de charger la batterie jusqu’à 16 amps.

Votre moteur est équipé d’un système de charge

d’entretien. Le fil rouge #14 AWG (American Wire Gauge)

sortant du moteur doit être branché à la cosse positive de la

batterie (Voir le manuel de l’opérateur du moteur).

DIAGRAMME DE CÂBLAGE DE BASE

Modèles à démarrage électrique (Modèles à interrupteur à clé sur le moteur)

FIGURE A

French

Page 20

FONCTIONNEMENT DE LA

COMMANDE DU RALENTI

Le circuit de commande du ralenti est conçu pour prolonger la

durée de vie utile du moteur et en améliorer la consommation

de carburant en réduisant le régime à environ 2000 tours/mn

en condition «sans charge». Ceci assure également une forte

réduction du bruit.

Lorsque la production d’électricité doit reprendre, un

module de commande électronique «sent» le débit de courant

dans la prise de courant et permet au moteur de retourner à

son plein régime ou aux conditions de fonctionnement

normales. De même, lorsque la charge est retirée, la

génératrice se remet automatiquement au ralenti.

Un interrupteur monté sur le tableau de commande pour

plus de facilité d’accès coupe le circuit de commande du ralenti

lorsqu’il est mis en position éteinte.

DÉPANNAGE DE LA COMMANDE DU RALENTI

PROBLÉMECAUSE PROBABLE SOLUTION

La génératrice ne tourne pas au Le ralenti n’est pas allumé au tableAllumer le ralenti à l’interrupteur

ralenti de commande

Une charge est branchée sur la priseDébrancher la charge

Connexion ou cordon défectueuxVeerifier et réparer

Module de commande du ralentiRemplacer

défectueux; électro-aimant ou

solénoïde défectueus; statorConsulter le concessionnaire

défectueux

La génératrice tourne au ralenti La charge n’est pas assez importanteÉteindre le ralenti à l’interrupteur

même lorsqu’une charge est

branchée dessus Augmenter la charge

Module de commande du ralentiRemplacer

Consulter le concessionnaire

La génératrice veut tourner au Position de l’électroaimant ou duRégler la position de l’électro-aimant ou

ralenti mais n’y reste pas solénoïde incorrectedu solénoïde pour un 2000 t/mn

Consulter le concessionnaire

Le support du papillon des gaz a duSerrer ou redresser

jeu ou est tordu

Remplacer le pappillon des gaz.

Rerégler à un ralenti de 2000 t/mn

20

Le moteur ne fonctionne pas Régler le carburateur

correctement

Consulter le concessionnaire

French

Page 21

21

DÉPANNAGE DE LA GÉNÉRATRICE ÉLECTRIQUE

PROBLÉMECAUSE PROBABLESOLUTION

Panne d’excitation de l’alternateur.Basse Vitesse.Vérifier le régime et régler à la valeur

nominale.

Condensateur défectueux.Vérifier et replacer.

Enroulements deffectueux.Vérifier la résistance des.

enroulements.

Haute tension à vide.Trop grande vitesse.Vérifier et régler le régime.

Condensateur à haute capacité.Vérifier et replacer.

Basse tension à vide.Vitesse trop basse.Vérifier et régler le régime.

Diodes rotatives défectueuses.Vérifier et replacer.

Claquage des enroulements.Vérifier la résistance des.

Condensateur à basse capacité.Vérifier et replacer.

Bonne tension à vide, mais basse tension Basse vitesse sous charge.Vérifier et régler le régime.

sous charge.

Charge trop élevée.Vérifier et remplacer.

Court-circuit des diodes rotatives.Vérifier et replacer.

Débris dans le silencieux.Vérifier et nettoyer ou remplacer.

Bonne tension à vide, mais haute tension Haute vitesse sous charge.Vérifier et régler le régime.

sous charge.

Tension fluctuante.Connexions desserrées.Vérifier les connexions.

Changement du régime du moteur.Vérifier et régler le régime.

Ne démarre ou ne fonctionne pas.Débris dans le silencieux.Vérifier et nettoyer l’échappement du

silenciux.

Panne de carburant.Afouter du carburant dans le réservoir.

Ouvrir la vanne de carburant.

Bougie non connectée.Brancher le fil de la bougie.

Câble de la batterie mal installé.Vérifier et nettoyer ou remplacer.

Filtre à air bouchéVérifier it replacer

Dilatation du réservoir.Le bouchon de carburant ne laisse pas Vérifier et remplacer le bouchon.

l’air s’échapper.

French

Page 22

INSTALLATION DE LA TROUSSE

DE TRANSPORT

Outils nécessarires:

Marteau, clé de 1/2 po, clé à cliquets avec douille de 1/2 po et

blocs de bois.

Consulter le dessin pour bien aligner la ferrure de pied et les

ferrures de roue.

3. Ajouter la ferrure de pied aux boulons, poser des écrous à

frein élastique de 5/16 po et serrer à fond.

4. Ajouter une ferrure de soutien qui relie la ferrure de pied au

plateau. Fixer au moyen de boulons de 1 po, de rondelles et

d’écrous à frein e´lastique de 5/16 po.

Installation de la poignée.

1. Insérer l’extrémité filetée des boutons dans les trous des

poignées.

Liste des pièces

APoigné0056240

BBouton0062177