Page 1

PM0601350

02/07 0064645

ELECTRIC GENERATOR - GROUPE ELECTROGENE - GENERADOR ELECTRICO

Insert

Additif

Adición

Thank you for selecting a Coleman® Powermate®

Generator. The Coleman® Powermate® generator has

been made to supply reliable, portable electrical power

when utility power is not available. We hope you will

enjoy your new generator. Welcome to our worldwide

family of Coleman® Powermate® generator users.

Merci d'avoir choisi le groupe électrogène Coleman®

Powermate®. Ce groupe électrogène Coleman®

Powermate® a été conçu pour fournir le pouvoir

électrique, portatif et fiable quand le pouvoir d'utilité n'est

pas disponible. Nous espérons que votre groupe

électrogène vous donnera entière satisfaction. Bienvenue

dans la famille mondiale des utilisateurs de groupes

électrogènes Coleman® Powermate®.

Gracias por seleccionar un generador Coleman®

Powermate®. El generador Coleman® Powermate® ha

sido diseñado para proporcionar energía eléctrica

confiable y portátil cuando no hay servicio disponible de

energía pública. Esperamos que disfrute de su nuevo

generador. Bienvenido a nuestra familia de usuarios de

generadores Coleman® Powermate® a nivel mundial.

IMPORTANT – Please make certain that persons who are to use this equipment thoroughly read and

understand these instructions and any additional instructions provided prior to operation.

IMPORTANT - Prière de vous assurer que les personnes destinées à utiliser cet appareil ont pris soin d'en lire

et d'en comprendre le mode d'emploi ou les directives avant de le mettre en marche.

IMPORTANTE. Asegúrese que las personas que utilizarán este equipo lean y entiendan completamente estas

instrucciones y cualquier instrucción adicional proporcionada antes del funcionamiento.

Powermate Corporation

4970 Airport Road

P. O.Box 6001

Kearney, NE 68848

1-800-445-1805

1-308-237-2181

Fax 1-308-234-4187

www.powermate.com

www.powermate.com

Page 2

MAJOR GENERATOR FEATURES

*25 HP Subaru OHV engine

*Cast-iron cylinder sleeve

*Low oil sensor

*Receptacles on control panel

*Electric Start

*Idle control

*CordKeeper™

*8 gallon plastic fuel tank

*Spark arrester

*Portability Kit

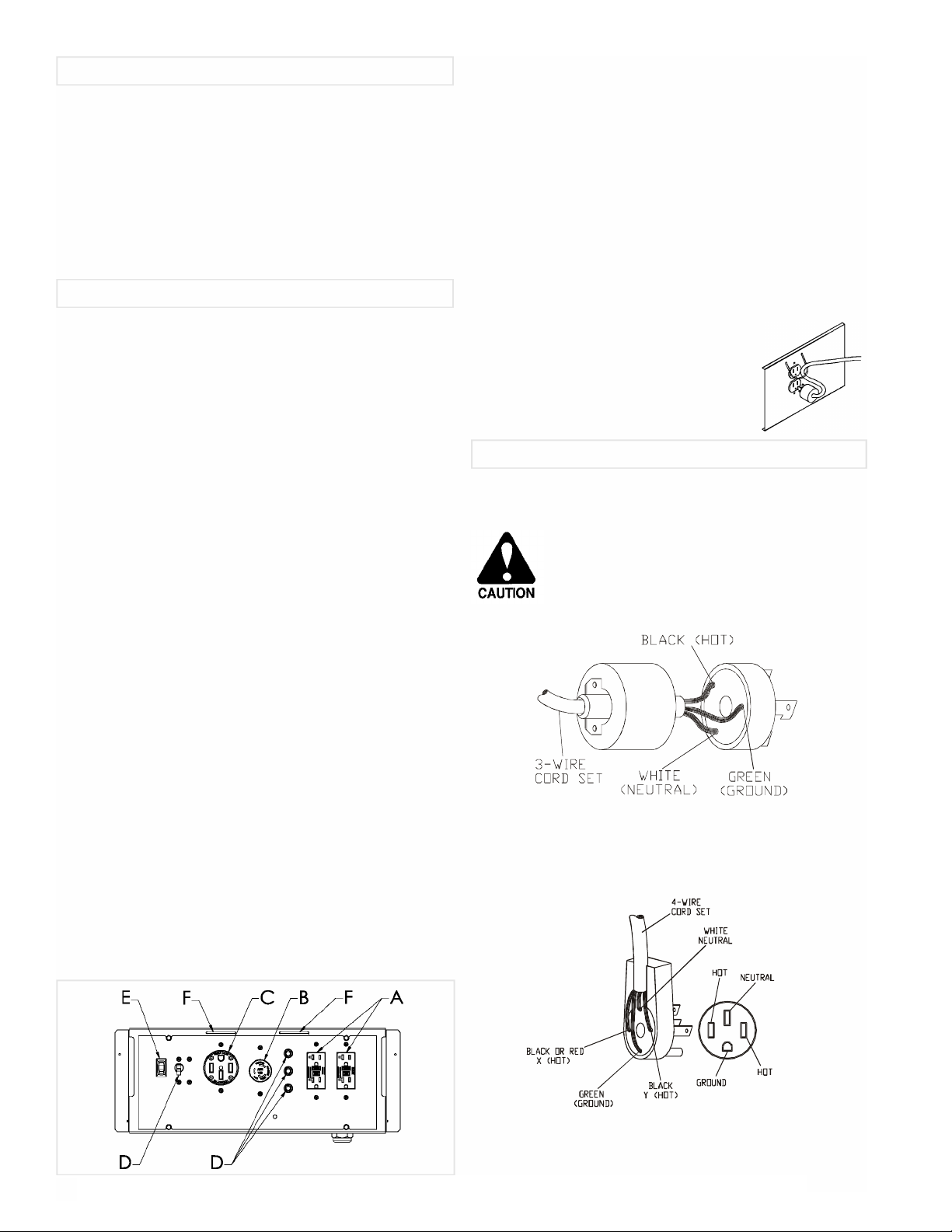

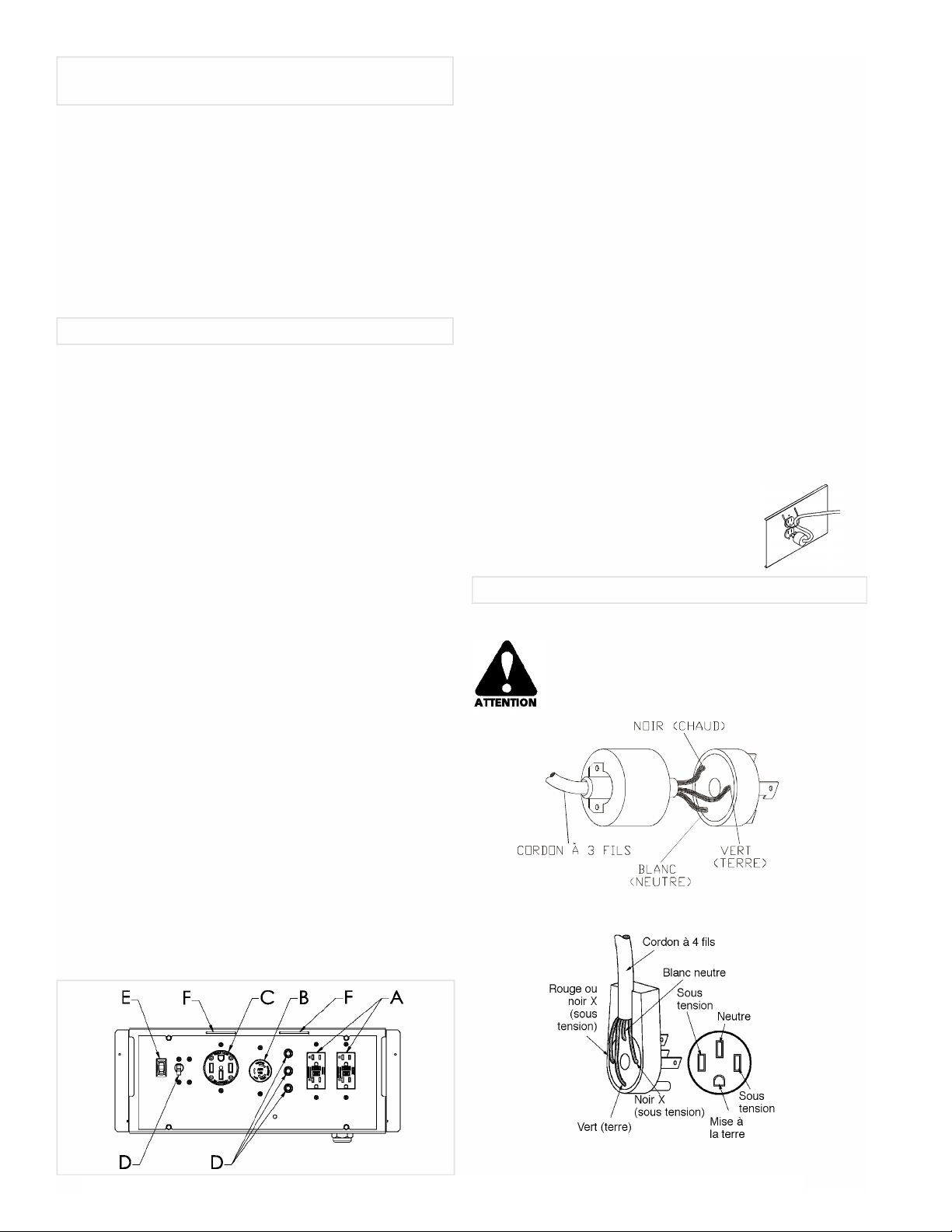

CONTROL PANEL

A.120 Volt GFCI Receptacle

Ground Fault Circuit Interrupter duplex receptacle is rated

so that a total of 20 amps may be drawn regardless of whether

both halves or just one receptacle is used. This receptacle may

be used along with other receptacles provided the generator is

not overloaded and total power drawn is kept within nameplate

ratings.

Ground Fault Circuit Interrupter

(Conforms to U.L 943, Class A and NEC requirements)

This device protects you against hazardous electrical

shock that may be caused if your body becomes a path through

which electricity travels to reach ground. This could happen

when you touch an appliance or cord that is “ live “ through

faulty mechanism, damp or worn insulation, etc.

The GFCI receptacle cannot be reset once tripped, unless

the generator is running and power is available to it. Test

regularly to assure proper operation.

E.Idle Control Switch

The Idle Control circuit is designed to extend engine life

and improve fuel usage by slowing the engine down to

approximately 2000 RPM in a “No Load” condition. The noise is

also greatly reduced during this condition.

When power is required from the generator an electronic

control module automatically senses current flow in the

electrical outlet and allows the engine to return to full speed or

standard operating condition. Likewise, when the load is

removed, the generator will automatically return to the idle

condition after a 4-5 second delay.

A convenient switch is mounted in the control panel for

easy access and will disable the Idle Control circuitry when in

the off position.

NOTE: A 12V battery must be installed in order for the

idle control to function.

F.CordKeeper™ Restraint

The CordKeeper™ restraint is a unique

feature used to prevent plugs from being

pulled out of the receptacles.

POWER CORD CONNECTIONS

Refer to the appropriate diagram for proper connection of

power cord wires to the plug terminals.

CAUTION: Insure that the power cord used is

well insulated and has a sufficient rating to

match that of the plug.

B.120 Volt, 30 Ampere Twistlock Receptacle

You may draw a maximum of 30 amps from this

receptacle. If other receptacles are used at the same time,

total power used must be kept within nameplate ratings.

C.120/240 Volt Heavy Duty Receptacle

This receptacle is rated at 50 amps but the current must be

limited to the nameplate rating. If this receptacle is used along

with the 120 volt receptacles, the total load drawn must not

exceed the nameplate ratings.

D.Circuit Breakers

The receptacles are protected by an AC circuit breaker. If

the generator is overloaded or an external short circuit occurs,

the circuit breaker will trip. If this occurs, disconnect all

electrical loads and try to determine the cause of the problem

before attempting to use the generator again. If overloading

causes the circuit breaker to trip, reduce the load. NOTE:

Continuous tripping of the circuit breaker may cause

damage to generator or equipment. The circuit breaker may

be reset by pushing the button of the breaker.

120 Volt 30 Amp Plug

120/240 Volt Heavy Duty Plug

2

English

Page 3

3

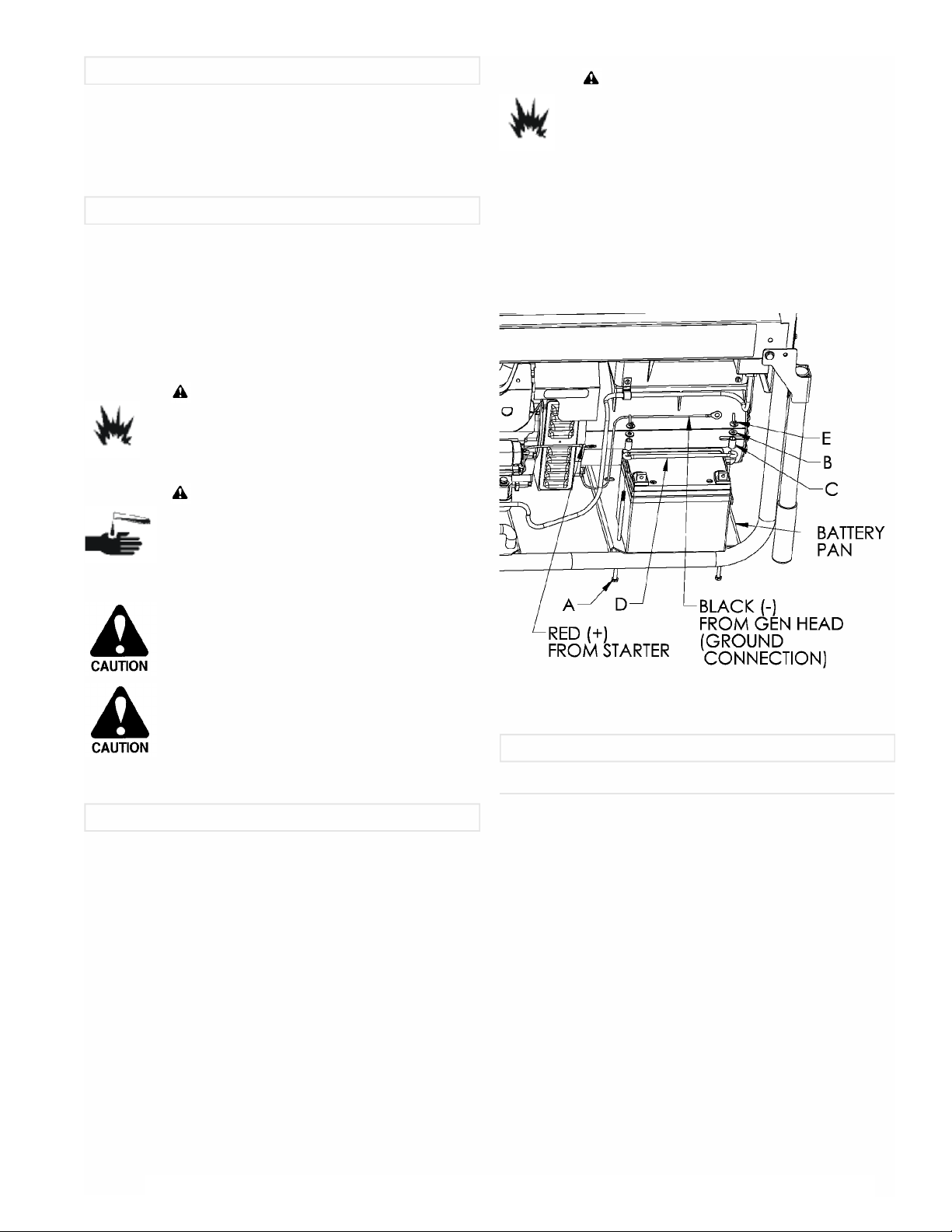

ELECTRIC START WIRING

The generator is equipped with electric start. An “Off-OnStart” rotary key switch is provided on the recoil end panel. All

necessary wiring is provided. The battery is provided. See

engine manual for wiring diagram (3A Charge Coil), and

additional information.

DC FEATURES

WARNING: Batteries contain sulfuric

acid (when filled). May contain explosive

gasses. Always abide by safety warnings

provided with the battery.

-Keep sparks, flame and cigarettes away.

-Hydrogen gas is generated during

charging and discharging.

-Always shield eyes, protect skin and

clothing when working near batteries.

The charging system of the unit is supplied by the

starter/alternator of the engine. 12 volts DC is constantly

charging the battery when the unit is running . Disconnecting

the battery will stop the charging of the battery.

Before charging a storage battery, check the electrolyte

fluid level in all the cells. (Sealed batteries do not require

checking). Add distilled water to each cell if necessary, to bring

the level back up to the manufacturer’s required level.

WARNING: Storage batteries give off

EXPLOSIVE hydrogen gas while charging. Do

not allow smoking, open flames, sparks, or

spark producing equipment in the area while

charging.

WARNING: Battery electrolyte fluid is

comprised of sulfuric acid that can be very

dangerous and cause severe burns. Do not

allow this fluid to contact eyes, skin, clothing,

etc. If contact or spillage does occur, flush

the area with water immediately.

CAUTION: This battery charging system is

intended to recharge weak batteries, not to

"boost start" vehicles. Do not overcharge

battery or leave battery unattended.

Connect the red 8 ga. battery lead to the positive (+)

battery post and the black 8 ga. battery to the negative (-)

battery post with the bolts and nuts provided.

CAUTION: Do not continue to charge a

battery that becomes hot or is fully charged.

BATTERY INSTALLATION

Powermate Corporation recommends a 12 V battery with

at least 235 cranking amps, Model U1L, Lawn and Garden

Battery.

1. Place the battery in the position provided.

2. Place the bolts through the holes on the battery pan.

3. Place the bolts through the loops on the Hold-Down bracket.

4. Place the spacers and washers on the bolts.

5. Tighten down the Hold-Down assembly with the 1/4-20 nuts

provided.

Note: Spacers may be removed depending on the battery

height.

BATTERY KIT PARTS LIST

ItemDescriptionQty.

A.*Bolt, 1/4-20 X 8”2

B.*Washer 1/42

C.*Spacer2

D. Hold Down bar (P/N 0036525.02)1

E.*Nyloc nut, 1/4-202

* These are standard parts available at your local hardware

store.

English

Page 4

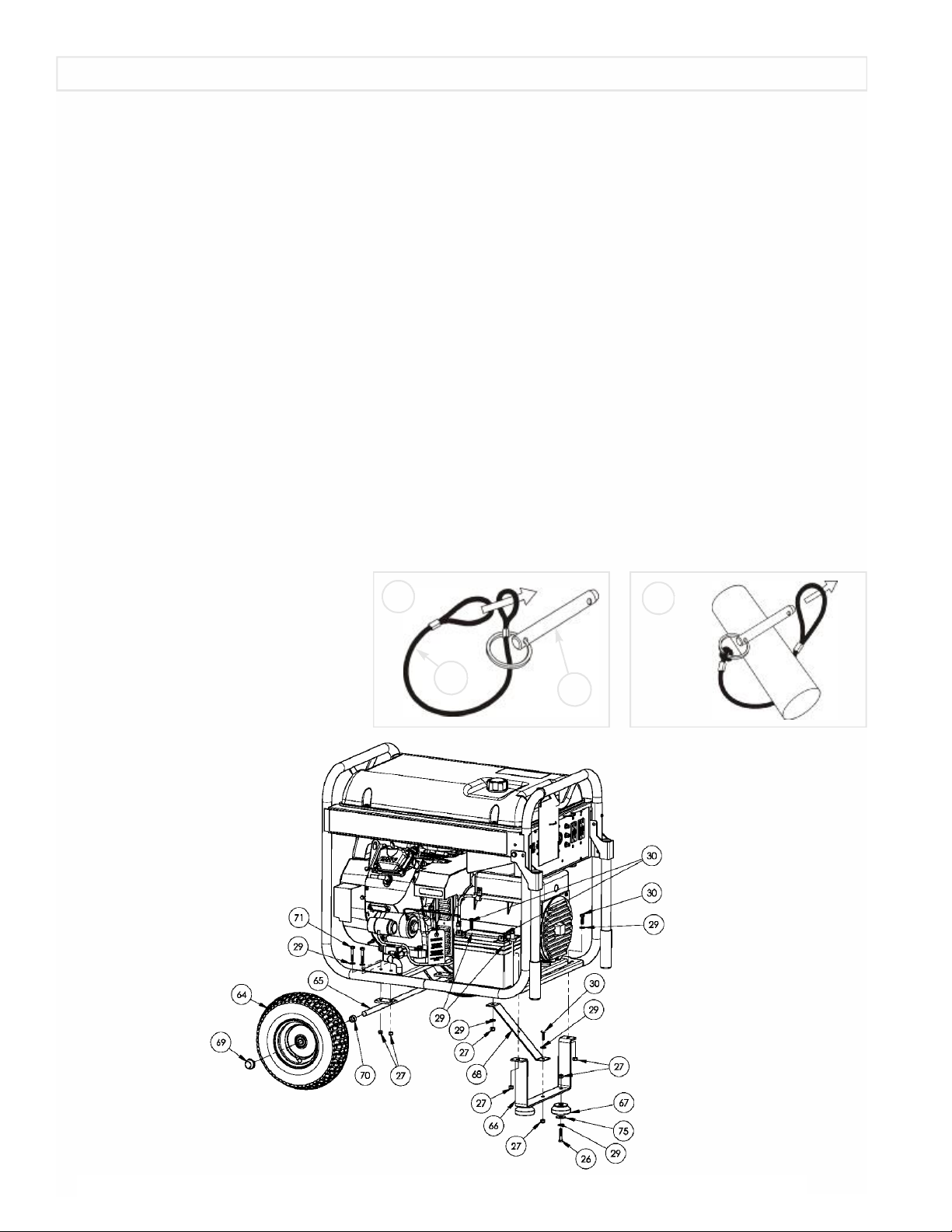

PORTABILITY KIT INSTALLATION

TOOLS REQUIRED: Hammer, 1/2” wrench, ratchet with a 1/2” socket, and wood blocks.

Refer to the drawing for proper alignment of Foot bracket and Wheel brackets.

Refer to the parts list on pages 15 and 16.

Wheel Bracket & Wheel Installation

1. Block up end of generator, about 8” high, opposite the fuel tank cap to install wheels and wheel bracket assy.

2. Add 5/16 washer (item 29) to the 1 3/4” bolts (item 71) and insert bolts/washers through the holes located in the base pan of

the carrier.

3. Place the wheel bracket (item 65) through the bolts and add a 5/16 nyloc nut (item 27) and tighten securely. (On the bottom

side of the pan in-between the holes will be a 1” square brace, the wheel bracket will set on this brace).

4. Add wheel spacer (item 70) to the axle.

5. Slide the wheel (item 64) onto the axle until it is snug against the spacer. The wheel is on correctly if there is approximately a

1/2” gap between the carrier tubing and the side of the wheel. If it is less then 1/2” from the carrier, turn the wheel over and

reinstall. Align the wheels parallel to the carrier tubing and tighten nuts securly. To align correctly, the bolts holding the wheel

bracket may have to be loosened.

6. With a hammer, add the plastic cap (item 69) on end of axle.

7. Repeat above instructions for the remaining wheel.

Foot bracket Installation

1. Block up opposite end of the unit, about 8” high.

2. Add 5/16 washer (item 29) to 1” bolts (item 30) and place through holes in the base pan.

3. Add foot bracket assembly (item 66) to bolts, add 5/16 nyloc nuts (item 27) and tighten securely.

4. Add support bracket (item 68) from foot bracket to the base pan. Secure in place with 1” bolts (item 30), washers (item 29)

and 5/16 nyloc nuts (item 27).

Locking Handle

1. Attach the lanyards (item 72) to the release

pins (item 73) and carrier as shown in the

illustration.

2. To lock the handle in the extended position,

align the holes in the handle brackets with the

holes in the carrier brackets and insert the

release pins.

1

72

73

2

4

English

Page 5

5

LIMITED WARRANTY

Warranty Coverage: Powermate Corporation (the Company) warrants to the original retail customer in North America that it will

repair or replace, free of charge, any parts found by the Company or its authorized service representative to be defective in

material or workmanship. This warranty covers the cost of replacement parts and labor for defects in material or workmanship.

Not Covered:

· Transportation charges for sending the product to the Company or its authorized service representative for warranty service,

or for shipping repaired or replacement products back to the customer; these charges must be borne by the customer.

· Engine is covered exclusively by a separate warranty from the engine manufacturer, included with the engine Manual.

· Damages caused by abuse or accident, and the effects of corrosion, erosion and normal wear and tear.

· Warranty is voided if the customer fails to install, maintain and operate the product in accordance with the instructions and

recommendations of the Company set forth in the owner's manual.

· The Company will not pay for repairs or adjustments to the product, or for any costs or labor, performed without the

Company's prior authorization.

Warranty Period: Two (2) years from the date of purchase on products used solely for consumer applications; if a product is

used for business or commercial applications, the warranty period will be limited to one (1) year from the date of purchase; if a

product is used for rental applications, the warranty period will be limited to ninety (90) days from the date of purchase. For

warranty service, the customer must provide dated proof of purchase and must notify the Company within the warranty period.

For warranty service: Call toll free 800-445-1805, or write to Powermate Corporation, Product Services, 4970 Airport

Road, P. O. Box 6001, Kearney, NE 68848.

EXCLUSIONS AND LIMITATIONS: THE COMPANY MAKES NO OTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED.

IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY DISCLAIMED. THE WARRANTY SERVICE DESCRIBED ABOVE IS THE EXCLUSIVE REMEDY

UNDER THIS WARRANTY; LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES IS EXCLUDED TO THE EXTENT

PERMITTED BY LAW.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do

not allow a disclaimer of implied warranties, or the exclusion or limitation of incidental and consequential damages, so the above

disclaimers and exclusions may not apply to you.

English

Page 6

CARACTÉRISTIQUES PRINCIPALES DU

GROUPE ELECTROGENE

*Moteur 25 HP Subaru OHV

*Chemise de cylindres en fonte

*Détecteur de bas niveau d'huile

*Prises sur tableau de commande

*Démarreur électrique

*Commande du ralenti

*CordKeeper™

*Réservoir de carburant en plastique d'une

contenance de 30.3 litres (8 gallons)

*Pare-étincelles

*Kit de transport

TABLEAU DE COMMANDE

A.Boîtier k’interrupteur de circuit en cas de fuite à la

terre 120 volts.

Le boîtier de prise double d’interrupteur de circuit en cas

de fuite à la terre a une valeur nominale telle qu’un total de 20

A peut être tiré indépendemment du boîtier utilisé (simple ou

demi). Ce boîtier puet être utilisé avec les autres boîtiers en

autant que le générateur n’est pas surchargé et que la

puisance totale reste dans la fourchette de valeurs indiquées

sur la plaque signalétique.

Interrupteur de circuit en cas de fuite à la terre

(conforme à U.L. 943, Catégorie A et ixigences NEC).

Cet appareil vous protège contre les dangers de chocs

électriques qui peuvent ítre causés si votre corps devient un

conduit pour l’électricité se rendant à la terre. Ceci peut se

produire si vous touchez u appareil ou un cordon qui est “sous

tension” suite à un mécanisme défectueux, un isolant usé ou

humide etc.

La prise à disjoncteur de fuite à la terre ne peut être

réenclenchée une fois qu'elle a été déclenchée, à moins que le

générateur ne soit en marche et qu'il soit alimenté. Effectuez

des essais périodiques pour vous assurer du fonctionnement

approprié.

saute. Si cela se produit, débrancher tout appareil relié au

groupe électrogène et essayer de déterminer la cause du

problème avant d’essayer de le réutiliser. Si le disjoncteur

saute en raison d’une surcharge, réduire la charge.

REMARQUE : Le groupe électrogène ou les appareils

branchés dessus peuvent se trouver abîmés si le

disjoncteur saute continuellement. Appuyer sur le bouton du

disjoncteur pour le réenclencher.

E.Interrupteur de la commande de ralenti

Le circuit de commande du ralenti est conçu pour

prolonger la durée de vie utile du moteur et en améliorer la

consommation de carburant en réduisant le régime à environ

2000 tours/mn en condition «sans charge». Ceci assure

également une forte réduction du bruit.

Lorsque la production d’électricité doit reprendre, un

module de commande électronique «sent» le débit de courant

dans la prise de courant et permet au moteur de retourner à

son plein régime ou aux conditions de fonctionnement

normales. De même, lorsque la charge est retirée, le groupe

électrogène se remet automatiquement au ralenti.

Un interrupteur monté sur le tableau de commande pour

plus de facilité d'accès. Il coupe le circuit de commande du

ralenti lorsqu’il est mis en position éteinte.

Remarque: Un 12V batterie être installée pour le

commande de ralenti pour fonctionner.

F.CordKeeper™ la Restriction

Le CordKeeper™ la restriction est un

dispositif unique qui empêche la fiche de

ressortir accidentellement d’une prise.

CONNEXIONS DU CORDON D’ALIMENTATION

Vous référer aux diagrammes appropriés pour relier les fils

du cordon d’alimentation aux bornes voulues de la fiche.

ATTENTION : Veiller à ce que le cordon

d’alimentation utilisé soit bien isolé et d’un

ampérage correspondant à celui de la fiche.

B.Prise à verrouillage de 120 V, 30 A

Cette prise fournit un maximum de 30 A. Si d’autres prises

sont utilisées en même temps que celle-ci, la charge totale doit

rester dans les limites indiquées sur la plaque signalétique.

C.Boîtier résistant 120/240 volts

Ce boîtier a une valeur nominale de 50 A, mais le courant

doit être limité à la valeur de la plaque signalétique. Si ce

réceptacle est utilisé avec des boîtiers de 120 volts, la charge

totale ne doit pas dépasser les valeurs de plaque signalétique.

D.Disjoncteurs

Les prises sont protégées par un disjoncteur alternatif. En

cas de surcharge ou de court-circuit extérieur, le disjoncteur

6

Fiche de 120 V et 30 A

Fiche de 240 V, 50 A

Français

Page 7

7

Ne pas fumer à proximité de batteries, les

CÂBLAGE DU DÉMARREUR ÉLECTRIQUE

Si votre générateur est doté d’un démarreur électrique.An

“Off-On-Start” rotary key switch is provided on the recoil end

panel. Un “Arrêt-Marche-Démarrer” le commutateur clé rotatif

est fourni sur le recule le panneau de fin. Tous les fils

nécessaires et la batterie sont fournis. Voir le manuel de

moteur pour installation éléctrique de diagramme (3A Bobine

de Charge), et l'information supplémentaire.

CARACTÉRISTIQUES DE CC

Le système de charge de l’appareil est assuré par le

démarreur et l’alternateur du moteur. Une tension de 12 volts

c.c. charge sans cesse la batterie lorsque l’appareil fonctionne.

Le débranchement de la batterie met fin à sa charge.

Avant de recharger une batterie, vérifiez le niveau de

liquide électrolytique dans tous les éléments. Ajoutez de l’eau

distillée à chaque élément, si nécessaire, pour ramener le

niveau à celui exigé par le fabricant.

AVERTISSEMENT: Il se dégage un gas

EXPLOSIF (hydrogène) des batteries pendant

qu’elles se rechargent. Ne pas permettre

de fumer ni autoriser la présence de flammes,

étincelles ou matériel produisant des

étincelles à proximité.

AVERTISSEMENT: Les batteries

contiennent de l'acide sulfurique

(lorsqu'elles sont pleines). Elles peuvent

également produire des gaz explosifs.

Toujours observer les mesures de

sécurité recommandées par le fabricant.

-

garder à distance sûre de toute source

d'étincelles ou de flamme.

-De l'hydrogène est produit pendant la

décharge et la recharge de la batterie.

-Toujours protéger les yeux, la peau et les

vêtements lorsqu'on travaille à proximité

de batteries.

Brancher le fil rouge de calibre 8 de la batterie à la borne

positive (+) et le fil noir de calibre 8 à la borne négative (-) le la

batterie au moyen des boulons et des écrous fournis.

AVERTISSEMENT: L’électrolyte de la

batterie se compose d’acide sulfurique, un

acide qui peut être très dangereux et

provoquer des brûlures graves. Ne pas

permettre le contact de ce liquide avec les

yeux, la peau, les vêtements, etc. En cas de

contact ou si du liquide se trouve renversé,

bien rincer à l’eau tiède immédiatement.

ATTENTION : Ce chargeur est destiné à la

recharge des batteries et non pas au

démarrage des véhicules en panne. Éviter de

charger la batterie à l'excès ou de la laisser

sans surveillance.

ATTENTION : Ne pas continuer de charger une

batterie chaude ou pleinement chargée.

INSTALLATION DE LA BATTERIE

Powermate Corporation recommande une batterie de 12 V

fournissant au moins 235 A au démarrage. Batterie Lawn and

Garden modèle U1L.

PLATEAU

DE LA

BATTERIE

NOIR (-) DE LA TETE

ROUGE (+) DU

DEMARREUR

DE GENERATEUR

(MISE À LA TERRE)

LISTE DES PIÈCES DE LA

TROUSSE DE BATTERIES

Ref.DescriptionQty.

A.*Boulon, 1/4-20 x 8”2

B.*Rondelles plates 2

C.*Entretoises2

D.Barre de retenue (P/N 0036525.02)2

E.*Écrous nyloc 1/4-202

1. Placer la batterie à l’emplacement prévu.

2. Insérer les boulons dans les trous du plateau de la batterie.

3. Placer les boulons dans les boucles de la barre de retenue.

4. Placer les entretoises et rondelles sur les boulons.

5. Serrer la barre au moyen des écrous 1/4-20 fournis.

Remarque: Il est possible d’enlever les entretoises, selon la

hauteur de la batterie.

Français

*Toutes les pièces sont standard et sont en vente à la

quincaillerie locale.

Page 8

L'INSTALLATION DE KIT DE TRANSPORT

OUTILS NÉCESSAIRES : Marteau, clé de 1/2 po, clé à cliquets avec douille de 1/2 po et blocs de bois.

Consulter le dessin pour bien aligner la ferrure de pied et les ferrures de roue.

Reportez-vous à la liste des pièces des pages 15 et 16.

Installation de la ferrure de roue et de la roue.

1. Mettre des cales d’environ 8 po de hauteur sous une extrémité de la génératrice, du côté opposé au bouchon du réservoir de

carburant pour poser les roues et les ferrures de roue.

2. Ajouter une rondelle de 5/16 po (article 29) aux boulons de 1 3/4 po (article 71) et insérer les assemblages dans les trous

situés dans la plaque du tuyau porteur.

3. Placer la ferrure de roue (article 65) sur les boulons et ajouter un écrou à frein élastique de 5/16 po (article 27) et serrer à

fond. (Une entretoise carrée de 1 po se trouve au fond du plateau entre les trous. La ferrure de roue s’appuie sur cette

entretoise.)

4. Ajouter une entretoise de roue (article 70) à l’essieu.

5. Poser la roue (article 64) sur l’essieu. Aligner les roues parralléles au tuyau porteur et serrer les écrous à fond. Pour obtenir

un bon alignement, desserrer les boulons qui fixent la ferrure de roue.

6. À l’aide d’un marteau, ajouter un chapeau de plastique (article 69) à l’extrémité de l’essieu.

7. Répéter la procédure pour l’autre roue.

Installation de la ferrure de pied

1. Mettre des cales d’environ 8 po de hauteur sous une extrémité de l’apareil.

2. Ajouter une rondelle de 5/16 po (article 29) aux boulons de 1 po (article 30) et poser l’assemblage dans les trous du

plateau.

3. Ajouter la ferrure de pied (article 66) aux boulons, poser des écrous à frein élastique de 5/16 po (article 27) et serrer à fond.

4. Ajouter une ferrure de soutien (article 68) qui relie la ferrure de pied au plateau. Fixer au moyen de boulons de 1 po

(article 30), de rondelles (article 29) et d’écrous à frein e´lastique de 5/16 po (article 27).

Poignee Verrrouillant

1. Attacher le lanyards (article 72) aux épingles

de relâchement (article 73) et le transporteur

selon l'illustration.

2. Pour verrouiller la poignée dans la

position étendue, aligner les trous dans les

support de poignée avec les trous dans les

support de transporteur et insérer les épingles

de relâchement.

1

72

73

2

8

Français

Page 9

La garantie est annulée si le client n'arrive pas à installer, garder et faire fonctionner le produit conformément aux directives et

GARANTIE LIMITÉE

9

Couverture limitée : Powermate Corporation (la compagnie) garantit au revendeur d'origine en Amérique du Nord qu'elle

réparera ou remplacera, sans frais, toutes les pièces que la compagnie ou que son représentant du service autorisé auront

déterminé comme étant défectueuses du point de vue du matériel ou de la fabrication. La garantie couvre les coûts de

remplacement des pièces et de main-d'œuvre pour tout défaut matériel ou de fabrication.

Ce qui n'est pas couvert :

· Les frais de transport pour envoyer le produit à la compagnie ou à son représentant du service autorisé pour effectuer le

travail couvert par la garantie, les frais d'expédition au client des produits réparés ou remplacés. Ces frais doivent être

assumés par le client.

· Le moteur est couvert exclusivement par une garantie distincte du fabricant du moteur. Cette garantie est incluse dans le

guide d'utilisation du moteur.

· Les dommages causés par un abus ou un accident, et les effets de la corrosion, de l'érosion ainsi que de l'usure normale.

·

aux recommandations de la compagnie formulées dans le guide d'utilisation.

· La compagnie ne paiera pas de réparation ou des ajustements au produit, ou pour les coûts ou main-d'œuvre, exécuté sans

l'autorisation préalable de la compagnie.

Période couverte par la garantie : Deux (2) ans à partir de la date d'achat sur les produits utilisés uniquement pour les

applications de consommateur. Si le produit est utilisé à des fins d'affaires ou commerciales, la période couverte par la garantie se

limite à un (1) an à partir de la date d'achat. Si le produit est utilisé comme équipement de location, la période couverte par la

garantie se limite à quatre-vingt-dix (90) jours à partir de la date d'achat. En ce qui concerne l'entretien couvert par la garantie, le

client doit présenter une preuve de la date d'achat et il doit aviser la compagnie au cours de la période couverte par la garantie.

Pour tout ce qui touche l'entretien couvert par la garantie : Composez sans frais le 1 800 445-1805, ou écrivez à

Powermate Corporation, Product Services, 4970 Airport Road, P. O. Box 6001, Kearney, NE 68848 É.-U.

EXCLUSIONS ET LIMITATIONS : LA COMPAGNIE NE PRÉSENTE AUCUNE AUTRE GARANTIE, EXPRESSE OU IMPLICITE.

LES GARANTIES IMPLICITES, INCLUANT LES GARANTIES DE QUALITÉ MARCHANDE ET DE CONFORMITÉ AUX

BESOINS SONT, PAR LA PRÉSENTE, ABANDONNÉES. L'ENTRETIEN COUVERT PAR LA GARANTIE DÉCRIT CI-DESSUS

EST UN RECOURS EXCLUSIF EN VERTU DE CETTE GARANTIE. LA RESPONSABILITÉ POUR DES DOMMAGES

ACCESSOIRES ET INDIRECTS EST EXCLUE JUSQU'À LA LIMITE AURORISÉE PAR LA LOI.

Cette garantie vous donne des droits spécifiques reconnus par la loi. Vous pouvez également bénéficier de certains autres droits,

lesquels varient d'une province (État) à l'autre. Certaines provinces (ou certains États) n'autorisent pas de clauses de renonciation

des garanties implicites ou de limites à l'égard de dommages accessoires ou indirects, ainsi, les clauses de renonciation et les

exclusions ci-dessus peuvent ne pas s'appliquer à vous.

Français

Page 10

CARACTERISTICAS PRINCIPALES DEL

GENERADOR

*Motor 25 HP Subaru OHV

*Manga de hierro fundido del cilindro

*El sensor del nivel bajo de aceite

*Receptáculos sobre el panel de control

*El arranque eléctrico

*Control en vacio

*CordKeeper™

*Tanque plástico de combustible con capacidad

de 30.3 litros (8 galones)

*Apagachispas

*Juego de transporte

PANEL DE CONTROL

A.Tomacorriente GFCI de 120 Voltios

El tomacorriente doble del interruptor accionado por corriente

de pérdida tierra tiene una especificación tal que se puede tomar

un total de 20 amperios indeferentemente a si se utilizan los dos

medios o sólo un tomacorriente. Este tomacorriente puede

utilizarse al mismo tiempo que los otros tomas siempre y cuando

no se tomada se mantenga dentro de las especificacciones de la

placa de identificación.

Interruptor de corriente de pérdida a tierra

(Se ajusta a los requisitos de U.L. 93, Clase A y NEC)

Este dispositivo lo protege contra una sacudida eléctrica

peligrosa que puede causarse cuando su cuerpo se convierte en

una senda por la cual la electricidad viaja para alcanzar la tierra.

Esto podría suceder cuando usted toca un aparato o la cuerda que

es “ vive “ por mecanismo defectuoso, aislamiento húmedo o

llevado, etc.

El receptáculo GFCI no se puede restablecer una vez se ha

puesto en marcha, a menos que el generador esté funcionando y

haya energía disponible hacia éste. Realice pruebas regularmente

para garantizar el funcionamiento correcto.

B.Receptáculo de cierre giratorio de 120 Voltios, 30 A

Puede extraerse un máximo de 30 amp desde este

receptáculo. Si se utilizan otros receptáculos al mismo tiempo, la

potencia total usada debe mantenerse dentro de los valores

nominales de la placa de identificación.

problema antes de usar el generador nuevamente. Si la

sobrecarga causa que salte el cortacircuitos, reduzca la carga.

NOTA: Si salta continuamente el cortacircuitos, se podría

dañar el generador o el equipo. El cortacircuitos puede

restaurarse pulsando el botón del cortacircuitos.

E.Llave de control de marcha en vacío

El circuito de control en vacío está diseñado para extender la

vida útil del motor y mejorar el uso de combustible, retardando el

motor hasta aproximadamente 2000 RPM en condiciones “sin

carga”. El ruido también se reduce mucho en estas condiciones.

Cuando se requiere potencia desde el generador, un módulo

de control electrónico automático detecta el flujo de corriente en el

tomacorriente eléctrico y permite que el motor vuelva a plena

velocidad o a condiciones de funcionamiento estándar. Del mismo

modo, cuando se retira la carga, el generador automáticamente

regresará a la condición de marcha en vacío después de un

retardo de 4 a 5 segundos.

Hay un interruptor muy conveniente montado en el panel de

control para lograr un acceso fácil. El mismo desactivará los

circuitos de control en vacío cuando está en la posición de

apagado.

NOTA: UNA batería 12V se debe instalar en la orden para

el control en vacío para funcionar.

F.CordKeeper™ Restricción

El CordKeeper™ restricción es una

característica exclusiva que se utiliza para

impedir que los tapones se salgan de los

receptáculos de 120 voltios.

CONEXIONES DEL CABLE

Consulte el diagrama correspondiente para ver la conexión

correcta de los cables eléctrico en las terminales del enchufe.

PRECAUCION: Asegúrese de que el cable

usado tenga un buen aislamiento y valores

nominales que coincidan con el enchufe.

C.Tomacorriente reforzado de 120/240 voltios

Este tomacorriente se clasifica como 50 amperios pero se

debe limitar la corriente a las especificaciones de la placa de

identificación. Si se utiliza este tomacorriente con un

tomacorriente de 120 voltios, el total de la carga tomada no

debe exceder las especificaciones de la placa de identificación.

D.Interruptor

Los receptáculos se protegen mediante un cortacircuitos de

CA. Si se sobrecarga el generador u ocurre un cortocircuito

externo, el cortacircuitos saltará. Si esto ocurre, desconecte

todas las cargas eléctricas y trate de determinar la causa del

10

Enchufe de 120 voltios y 30 amperios

Enchufe de 120/240 voltios y 50 amperios

Español

Page 11

El gas hidrógeno se genera durante la carga y

11

CABLEADO DE ARRANQUE ELECTRICO

Si su generador está equipado con encendido eléctrico.

Se provee de una llave giratoria “Off-On-Start” en el panel

trasero. Se provee de todos los cables necesarios. La batería

es provista. Vea manual de motor para alambrar esquema

(Rollo de Carga 3A), e información adicional.

CARACTERÍSTICAS CC

El sistema de carga de la undad se abastece por medio

del arrancador/alternador del motor. La batería se carga

constante con 12 VCD siempre que el motor esté funcionando.

Al desconectar la batería se detendrá la carga de la misma.

Antes de cargar una batería de almacenaje, verifique el

nivel de fluido electrolítico en todas las células. (Las baterías

selladas no requieren esta verificación). Agregue agua

destilada a cada célula, si fuera necesario, para traer el nivel

hasta el valor requerido por el fabricante.

ADVERTENICA: Las baterías de

almacenaje emiten gas hidrógeno EXPLOSIVO

al estar en carga. No permita que se fume ni la

existencia de llamas abiertas, chispas o

equipos que produzcan chispas en la zona al

estar en carga.

ADVERTENCIA: Las baterías contienen

ácido sulfúrico (cuando están llenas). Pueden

contener gases explosivos. Siempre deben

cumplirse las advertencias de seguridad

provistas con la batería.

-Mantenga alejadas las chispas, la llama y los

cigarrillos.

la descarga.

-Siempre proteja los ojos, la piel y la ropa al

trabajar cerca de las baterías.

Conecte la punta roja de calibre 8 de la batería al poste

positivo (+) de la misma y la punta negra de calibre 8 al poste

negativo (-). Para esto, utilice los pernos y las tuercas

suministrados.

ADVERTENCIA: El fluido electrolítico de

la batería está compuesto de ácido sulfúrico

que puede ser muy peligroso y causar

quemaduras graves. No permita que este

fluido entre en contacto con los ojos, la piel,

la ropa, etc. En caso de ocurrir un contacto o

un derrame, enjuague la zona con agua

inmediatamente.

PRECAUCION: Este sistema de carga de la

batería sirve para volver a cargar las baterías

débiles, y no para “arrancar por refuerzo” los

vehículos. No sobrecargue la batería o deje la

batería sin atención.

PRECAUCION: No continúe cargando una

batería que se ha quedado caliente o que esté

completamente cargada.

INSTALACIÓN DE LA BATERÍA

Powermate Corporation recomienda una batería de 12 V

con, por lo menos, 235 amps disponibles. El model U1L,

Batería Lawn and Garden.

1. Coloque la batería en la posición provista.

2. Pase los pernos a través de los orificios que se encuentran

en la base de la batería.

3. Coloque los pernos a través de lo lazos en la ménsula

sujetadora.

4. Coloque los espaciadores y arandelas en los pernos.

5. Apriete el montaje sujetador con las tuercas de 1/4-20

suministradas.

BASE DE

LA

BATERIA

NEGRA (-) DE LA

ROJA (+) EL

ARRANCADOR

CABEZA DEL

GENERADOR

(CONEXIÓN A TIERRA

LISTA DE PARTES PARA EL

EQUIPO DE BATERÁ

ArtículoDescriptionCantidad

A.*Perno 1/4-20 X 8”2

B.*Arandela, plana 1/42

C.*Espaciador2

D.Barra sujetadora (PN 0036525.02)1

E.*Tuerca, nyloc 1/4-202

*Todas las partes son estándar y puede encontrarlas en su

ferretería local.

Nota: Se pueden quitar espaciadores dependiendo de la altura

de la batería.

Español

Page 12

INSTALACION DEL JUEGO DE TRANSPORT

HERRAMIENTAS NECESARIAS: Martillo, llave de 1/2”, maneral con un dado de 1/2” y bloques de madera.

Consulte la lista de partes en las páginas 15 y 16.

Ménsula de la rueda e instalación de la rueda.

1. Bloquee el extremo del generador, alrededor de 8” de alto, que está en sentido opuesto al tapón del tanque de combustible

para instalar las ruedas y el montaje de la ménsula de rueda.

2. Coloque una arandela de 5/16 (artículo 29) a los pernos de 1 3/4” (artículo 71) e inserte los pernos y arandelas a través de

los oriticios localizados en la charola base del transportador.

3. Pase la ménsula de la rueda (artículo 65) a través de los prenos y coloque una tuerca nyloc de 5/16 (artículo 27); apriete

firmemente. (En el lado inferior de la charola, entre los orificios, hay un tirante de 1”, la rueda debe acomodarse en este

tirante).

4. Coloque un espaciador (artículo 70) para rueda al eje.

5. Acomode la rueda (artículo 64) en el eje. Alinee las ruedas para que queden paralelas a la tubería y apriete firmemente las

tuercas. Para alinear correctamente, tal vez sea necesario aflojar los pernos que sujetan la ménsula de la rueda.

6. Con un martillo, coloque el tapón de plástico (artículo 69) en el extremo del eje.

7. Repita las instrucciones anteriores para la rueda restante.

Instalación de la ménsula de pie.

1. Bloquee el extremo opuesto de la unidad, aproximadamente 8” de alto.

2. Coloque una arandela de 5/16 (artículo 29) a los pernos de 1” (artículo 30) e inserte a través de los orificios que están en

la charola base.

3. Coloque el ensamble de la ménsula de pie (artículo 66) en los pernos, ponga tuercas nyloc de 5/16 (artículo 27) y apriete

firmemente.

4. Coloque una ménsula de apoyo (artículo 68) desde la ménsula de pie hasta la charola de la base. Fíjela con pernos de 1”

(artículo 30),arandelas (artículo 29) y tuercas nyloc de 5/16 (artículo 27).

Manija que Cierra

1. Conecte los acoladores (artículo 72) a los

alfileres de la liberación (artículo 73) y el

portador como mostrado en la ilustración.

2. Para cerrar el manija en la posición extendida,

alinea los hoyos en los soporte del manija con

los hoyos en los soporte de transportador y

mete los alfileres de la liberación.

1

72

73

2

12

Español

Page 13

Daños ocasionados por el mal uso o por un accidente, y los efectos de la corrosión, la erosión, el desgaste y el uso normales.

13

GARANTIA LIMITADA)

Cobertura de la garantía: Powermate Corporation (la Compañía) garantiza al cliente minorista original en América del Norte,

que reparará o reemplazará, sin costo alguno, cualesquiera partes que la Compañía o cualquiera de sus representantes de

servicio autorizados encuentren defectuosas en sus materiales o en su fabricación. Esta garantía cubre el costo de partes de

reemplazo y mano de obra por defectos en materiales o en fabricación.

No están cubiertos:

· Costos de transporte por el envío del producto a la Compañía o a sus representantes de servicio autorizados por servicio de

garantías, o por el reenvío de los productos reparados o de reemplazo al consumidor; estos cargos los deberá cubrir el

cliente.

· El motor está cubierto exclusivamente por una garantía por separado por parte del fabricante del motor, que se incluye en el

Manual del motor.

·

· La garantía no será válida si el consumidor no instala, da mantenimiento y hace funcionar el producto de acuerdo con las

instrucciones y recomendaciones de la Compañía, descritas en el manual del usuario.

· La Compañía no pagará por reparaciones ni ajustes al producto, ni costos ni mano de obra, realizado sin la Compañía's la

autorización previa.

Período de garantía: Dos (2) años de la fecha de la compra en productos utilizados únicamente para aplicaciones de consumo;

si un producto se utiliza para usos comerciales o con fines de lucro, el período de garantía se limitará a un (1) año a partir de la

fecha de compra; si el producto se utiliza como equipo de arrendamiento, el período de garantía se limitará a noventa (90) días a

partir de la fecha de compra. Para obtener el servicio de garantía, el cliente debe proporcionar el comprobante de compra

fechado y debe notificar a la Compañía dentro del período de garantía.

Para el servicio de garantía: Llame sin costo al número 800-445-1805 o escriba a Powermate Corporation, Product

Services, 4970 Airport Road, P. O. Box 6001, Kearney, NE 68848 EE. UU.

EXCLUSIONES Y LIMITACIONES: LA COMPAÑÍA NO OTORGA NINGUNA OTRA GARANTÍA DE NINGÚN TIPO, EXPLÍCITA

O IMPLÍCITA. POR ESTE MEDIO SE RENUNCIA A LAS GARANTÍAS IMPLÍCITAS, INCLUYENDO GARANTÍAS DE

COMERCIABILIDAD O DE ADAPTABILIDAD PARA UN PROPÓSITO PARTICULAR. EL SERVICIO DE GARANTÍA DESCRITO

ANTERIORMENTE ES EL RECURSO EXCLUSIVO CUBIERO POR ESTA GARANTÍA; LA RESPONSABILIDAD CIVIL POR

DAÑOS INCIDENTALES Y CONSECUENTES SE EXCLUYEN EN LA MEDIDA EN QUE LA LEY LO PERMITA.

Esta garantía le otorga derechos legales específicos y también puede ser objeto de otros derechos que varían de estado a

estado. Algunos Estados no permiten la exención de responsabilidad de garantías implícitas o la exclusión o limitación de daños

incidentales o consecuentes, de manera que las exenciones y exclusiones de responsabilidades pueden no ser aplicables a

usted.

Español

Page 14

PARTS DRAWING / SCHEMA DES PIÈCES / DIAGRAMA DE PIEZAS

14

PM0601350

Page 15

15

PARTS LIST / LISTE DES PIÈCES / LISTA DE PIEZAS

REF.PARTDESCRIPTION DESCRIPTION DESCRIPCIÓNQTY

NO.NO.

10064486Carrier, assembly, fullEnsemble transportTransportador, conjunto1

20064598Panel, wired completeTableau compl. câbléPanel, abeado completo1

3Note CFuel tank AssemblyAssemb. complet du réservoirConjunto tanque1

4Note AEngine, 25hp Subaru MoteurMotor1

50057254Nut, hex flg 5/16-18Écrous 5/16-18 Tuerca, 5/16-1816

60056231Cap Fuel w/Gauge 6”Capuchon, réservoir Tapa combustible

d’essence1

70064607Assy, deflector Assemblage, déflecteurAssemb. déflecteur1

80056427Assy, Stator bracketPatte de fixation statorSoporte, estator1

90055620Washer, flat .42 x 1.5Rondelles platesArandela plana2

100062503MufflerSilencieuxSilenciador1

110064597Manifold, ExhaustSilencieux jointDescarga colector de escape1

120062498Muffler ClampSilencieux jointGrapa de silenciador1

13 0050941.01 Muffler BracketSilencieux fixationSoporte de silenciador.1

140052931Clamp, Vinyl J 1/2”CollierAbrazadera1

150006253Assy Wire Blk 8ga 17.25FilAlambre1

160006254Assy Wire Red 8ga 17.25FilAlambre1

17 1130564770 Oil Drain HoseBoyau de vidange d’huileManguera para drenar el

aceite6”

18Note BClamp hose worm SAE6Collier SAE6Abrazadera SAE61

190057747Fitting 3/8NPT x 1/2 barbRaccordAdaptador1

200057746Valve ball 3/8NPT M/FSoupapeVálvula1

210062499Fitting 3/8NPTF 14mm-MRaccordAdaptador1

220058618Screw, #10 x 1VisTornillo4

230049224Assembly, ground wireEns. fil de masse tresséConjunto, cable trenzado a tierra1

240053320Screw HWH #10-14 x .63VisTornillo4

250047864Screw HSW #10-32 x .5VisTornillo1

26Note BBolt HH 5/16-18 x 1.5BoulonPerno12

270048736Nut Nyloc 5/16-18Écrous nylocTuerca, nyloc10

28 0000919.01 Bolt whz 3/8-16 X 3/4Boulon whzPerno whz5

29Note BWasher, flat 5/16Rondelles platesArandela plana18

30Note BBolt HH 5/16-18 x 1BoulonPerno7

31Note BWasher, lock 5/16Contre-écrouArandela, de cierre7

320051094IsolatorSectionneurAislador7

33Note BWasher, star ext 5/16Rondelles à dentsArandela, estrella externa3

340065112Rotor, assemblyRotor, ensembleRotor, conjunto1

350062581DiodeDiodeDiode2

360065113Bolt, rotorBoulon, rotorPerno, rotor1

370065111Frame & Stator, 60 HzEncadrer et statorEncuadre y estator1

380065114Louvered Side PanelPanneau latéral à persiennesTablero lateral con rejillas2

390062584Capacitor, 40 mfd 500VCapaciteurCapacitor2

400062585Generator Head coverCouvercle de la tête de la Cubierta del cabezal del

génératricegenerador1

410056623Adapter, engineAdaptateur pour moteurAdaptador, motor1

420064729Fuel valve with filterRobinet de carburant avec Válvula combustible con filtro

filtre1

42A0062673Fuel bushingBague d’essenceBuje de combustible1

430049071Circuit Breaker 20ADisjoncteursCortacircuitos2

440049382Circuit Breaker 30ADisjoncteursCortacircuitos1

450056705Circuit Breaker 50A dualDisjoncteursCortacircuitos1

460062543I/C Module DCModule de commande du Módulo, control en vacío

ralenti1

470049291Strain ReliefRéducteur de tensionProtección contra tirones1

480050298Rocker SwitchInterrupteur à basculeInterruptor de balancín.1

490049352Washer, flat 5/16 WRondelles platesArandela plana2

510061393Nut, whz 8mmÉcrous whz 8mmTuerca whz 8mm4

520056813Bolt HH M8 x 18mmBoulon M8 x 18mmPerno M8 x 18mm2

530064890HandlePoignéeManija2

Page 16

PARTS LIST / LISTE DES PIÈCES / LISTA DE PIEZAS

REF.PARTDESCRIPTION DESCRIPTION DESCRIPCIÓNQTY

NO.NO.

550062495Grip, handlePoignéeEmpuñadura2

56Note BBolt HH 5/16-18 x 2.25BoulonPerno2

570062540Shield, heat

580057183Grommet 7/8 IDOeillet Arandela de cabo1

590064639Assy, wire harnessEnsemble, d'harnais de filConjunto de arreos de alambre1

62Note BBolt HH 5/16-18 x 1.25BoulonPerno1

630049279Bolt whz 5/16-18 X .50Boulon whzPerno whz2

640062507WheelRoueRueda2

650056406Wheel bracketFerrure de la roueMénsula de la rueda2

660056237Foot bracketFerrure de la piedMénsula de la pie1

670008433Foot, rubberPiedPie2

680056409Strap, foot bracketSangler, ferrure de la piedCorrea, ménsula de la pie1

690056444Cap, axleCapuchonTapa2

700062510Wheel spacerBague d’espacementEspaciador de la rueda2

71Note BBolt HH 5/16-18 x 1.75BoulonPerno4

720062174LanyardLanyardAcollador2

730059392Pin, releaseEpingle de relâchementAlfileres de la liberación2

740056680Filler Flootool FunnelEntonnoirEmbudo1

75Note BWasher, flat 7/16Rondelles platesArandela plana2

760063133VaristorVaristorVaristor2

Note A:

Powermate Corporation will not provide engines as replacement parts. Engines are covered through the engine manufacturer's warranty. Consult the accompanying

engine manual or contact our service department for assistance.

Note B:

These are standard parts available at your local hardware store.

Note C:

Contact your nearest Coleman® Powermate® Service Center for replacement fuel tanks.

WARNING: To avoid possible personal injury or equipment damage, a registered electrician or an authorized service representative should

perform installation and all service. Under no circumstances should an unqualified person attempt to wire into a utility circuit.

Electrical: For models approved for the City of Los Angeles, the ampacity of the phase conductors from the generator terminals to the first over current device shall not

be less than 115 percent of the nameplate rating of the generator.

Remarque A:

manuel du moteur inclus ou contacter notre département de service après-vente pour toute assistance.

Remarque B:

Remarque C:

Électricité: Pour les modèles a approuvé pour la ville de Los Angeles: La charge limite en ampères des fils de phase allant des bornes du groupe électrogène au

premier appareil en surcharge ne doit pas être inférieure à 115% de la puissance nominale indiquée sur la plaque des caractéristiques du groupe électrogène.

Nota A:

manual adjunto del motor o comuníquese con nuestro departamento de servicio para recibir ayuda al respecto.

Nota B:

Nota C:

Eléctricos:

nominal que aparece en la placa de identificación del generador en los modelos aprobados para la ciudad de Los Angeles.

Powermate Corporation ne fournit pas de moteurs dans ses pièces détachées. Les moteurs sont couverts par la garantie du fabricant de moteurs. Consulter le

Ces pièces sont des pièces standard disponibles en quincaillerie.

Pour commander un réservoir de rechange, contacter Centre de service Coleman® Powermate® le plus proche.

AVERTISSEMENT: Pour éviter toute blessure personnelle ou dommage à l’équipement, l’installation et tout entretien devralent être effectués par un

électricien qualifié ou un préposé au service autorisé. En aucun cas, une personne non-qualifiée ne devrait essayer de faire le raccord au circuit principal.

Powermate Corporation no proporcionará los motores como repuestos. Los motores están cubiertos por medio de la garantía del fabricante del motor. Consulte el

Estas son piezas estándar disponibles en su ferretería local.

Para hacer pedidos de tanques, localice el Centro de Servicio de Coleman® Powermate® más cercano.

ADVERTENCIA: Para evitar posibles lesiones físcas o daños materiales, es necesario que la instalación y todo el servicio sea realizado por un electricista

matriculado o representatnte de servicio autorizado. Bajo ninguna circunstancia debe permitirse que una persona que no está capacitad trate de

manipular cables dentro del circuito de servicio eléctrico.

El amperaje de los conductores de fase desde los terminales del generador al primer dispositivo de sobrecorriente no podrâ ser menor que 115 porciento del valor

Écran de chaleurPantalla para el calor1

16

Page 17

Limited Engine Warranty

Robin America, Inc., a division of Fuji Heavy Industries, Ltd. (herein "Robin"), warrants that each new engine sold by it will be free,

under normal use and service, from defects in material and workmanship for a period listed below from the date of sale to the original

condition of Robin's obligation under this Limited Warranty that Robin, directly or through one of its Distributors or Service Centers

authorized to service the particular engine involved, receive prompt notice of any warranty claim and that the engine or the part or parts

claimed to be defective be promptly delivered, transportation prepaid, to such Distributor or Service Center for inspection and repair. All

repairs qualifying under this Limited Warranty must be performed by Robin or one of its authorized Distributors or Service Centers.

Repair required because of prolonged storage including damage caused by old or contaminated fuel in the fuel tank, fuel lines

Repair required due to overheating. (Most often caused by overloaded or clogged or damaged or missing flywheel, fan, inlet air

Dirt or grit related wear caused by improper air cleaner maintenance (most often resulting in worn piston, piston rings,

Any engine that has been installed, repaired, or altered by anyone in a manner which in Robin's sole judgment adversely affects

17

for

Powermate Inc.

(Effective with engines purchased from Robin America, Wood Dale, IL, after November 15, 1993)

retail purchaser. Robin's obligation under this Limited Warranty shall be limited to the repair and replacement, at Robin's option, of any

part or parts which upon examination is/are found, in Robin's judgment, to have been defective in material or workmanship. It shall be a

WARRANTY PERIODS:

Robin Four-Cycle, Air-cooled, Gasoline EnginesLimited 3 years Warranty

The repair or replacement of any part or parts under this Limited Warranty shall not extend the term of the engine warranty beyond the

original term as set forth above.

LIMITATIONS AND EXCLUSIONS: This Limited Warranty shall not apply to:

1. Bent or broken crankshaft or resultant damage caused by vibration related to a bent or broken crankshaft. Also, damage caused

by loose engine mounting bolts or improper or imbalanced accessories or blades mounted to the crankshaft.

2.

or carburetor, sticky valves or corrosion and rust of engine parts.

3.

passages, cooling fins or air shrouds.)

4.

cylinders, valves, valve guides, carburetor or other internal components).

5. Broken or scored parts caused by low oil level, dirty or improper grade of oil

6. Engine tune-ups and normal maintenance service including, but not limited to, valve adjustment, normal replacement of service

items, fuel and lubricating oil, etc.

7. Any engine which has been subject to negligence, misuse, accident, mis-application or over-speeding.

8.

its performance or reliability.

9. Any engine which has been fitted with or repaired with parts or components not manufactured or approved by Robin which in

Robin's sole judgment adversely affects its performance or reliability.

10. Instances when normal use has exhausted the life of a component or an engine.

The customer is responsible for all transportation charges in connection with any warranty work.

Robin reserves the right to modify, alter or improve any engines or parts without incurring any obligation to modify or replace, any

engine or parts previously sold without such modification, alternation or improvement.

No person is authorized to give any other warranty or to assume any additional obligation on Robin's behalf unless made in writing and

signed by an officer of Robin.

THIS WARRANTY, AND ROBIN'S OBLIGATION HERE UNDER, ARE IN LIEU OF ANY OTHER

WARRANTIES OR OBLIGATIONS OF ANY KIND, EXPRESSED OR IMPLIED, INCLUDING ANY

WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. THERE ARE NO

WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HERE-OF. ROBIN SHALL IN

NO EVENT BE LIABLE FOR ANY CONSEQUENTIAL OR INCIDENTAL DAMAGES.

English

Page 18

NOTES – REMARQUES – NOTAS

18

Page 19

19

NOTES – REMARQUES – NOTAS

Page 20

4970 Airport Road

P. O. Box 6001

Kearney, NE 68848

1-800-445-1805

1-308-237-2181

Fax 1-308-234-4187

© 2007 Powermate Corporation. All rights reserved.

Coleman® and

Powermate ® is a registered trademark of Powermate Corporation.

© 2007 Powermate Corporation. Tous droits réservés.

Coleman® et

Powermate® est une marque déposée de Powermate Corporation.

© 2007 Powermate Corporation. Reservados todos los derechos.

Coleman® y

Powermate ® es una marca comercial registrada de Powermate Corporation.

are registered trademarks of The Coleman Company, Inc. used under license.

sont des marques déposées de The Coleman Company, Inc. utilisées sous licence.

son marcas comerciales registradas de The Coleman Company, Inc. utilizadas bajo licencia.

Loading...

Loading...