Page 1

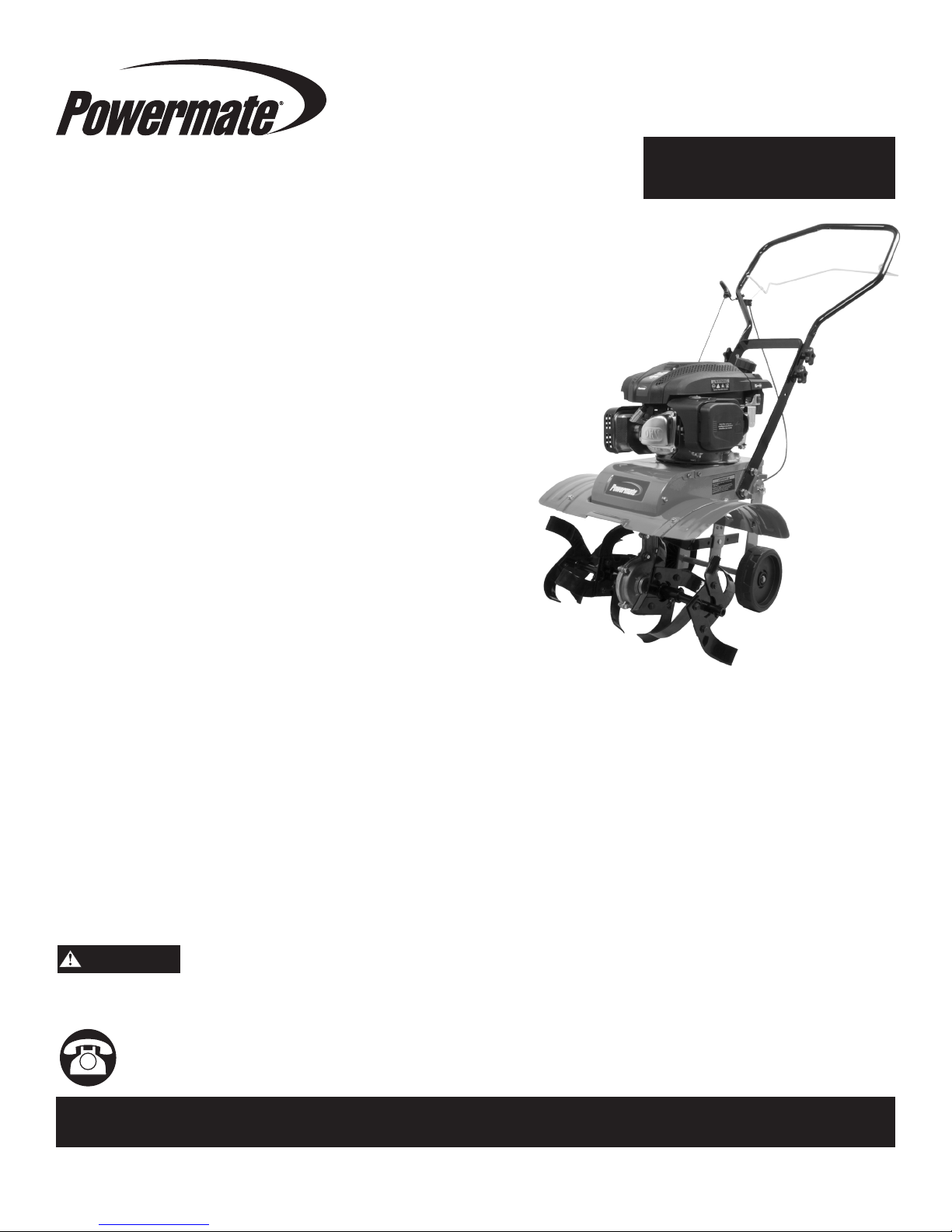

Operator’s Manual

Front Tine

Rotary Tiller

Look inside for:

Page

Safety Definitions 2

Important Safety Information 3-5

Product Specifications 6

Parts & Features 6

Safety Decals 7

Assembly 8-11

Engine Preparation 12

Operation 13-16

Maintenance 17-19

Technical Service 19

Troubleshooting 20

Warranty 21

MODEL No. PFTT142

IMPORTANT:

Thank you for purchasing this Powermate® Tiller.

This manual provides complete instructions for safely operating and maintaining your Tiller. Read and save these

instructions. Refer to this manual each time before using your Tiller.

Record the following for future reference:

Mfg. Date Code: ____________________

Date of Purchase: Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

Refer to the website for electronic manual and parts book.

www.powermateoutdoor.com

WARNING

Engine exhaust, some of its constituents, and certain product components contain or emit chemicals known to the State

of California to cause cancer and birth defects or other reproductive harm.

If you have a question or problem...

CALIFORNIA PROPOSITION 65 WARNING

CALL TOLL FREE: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

06/10/2016 Printed in China A203399

Page 2

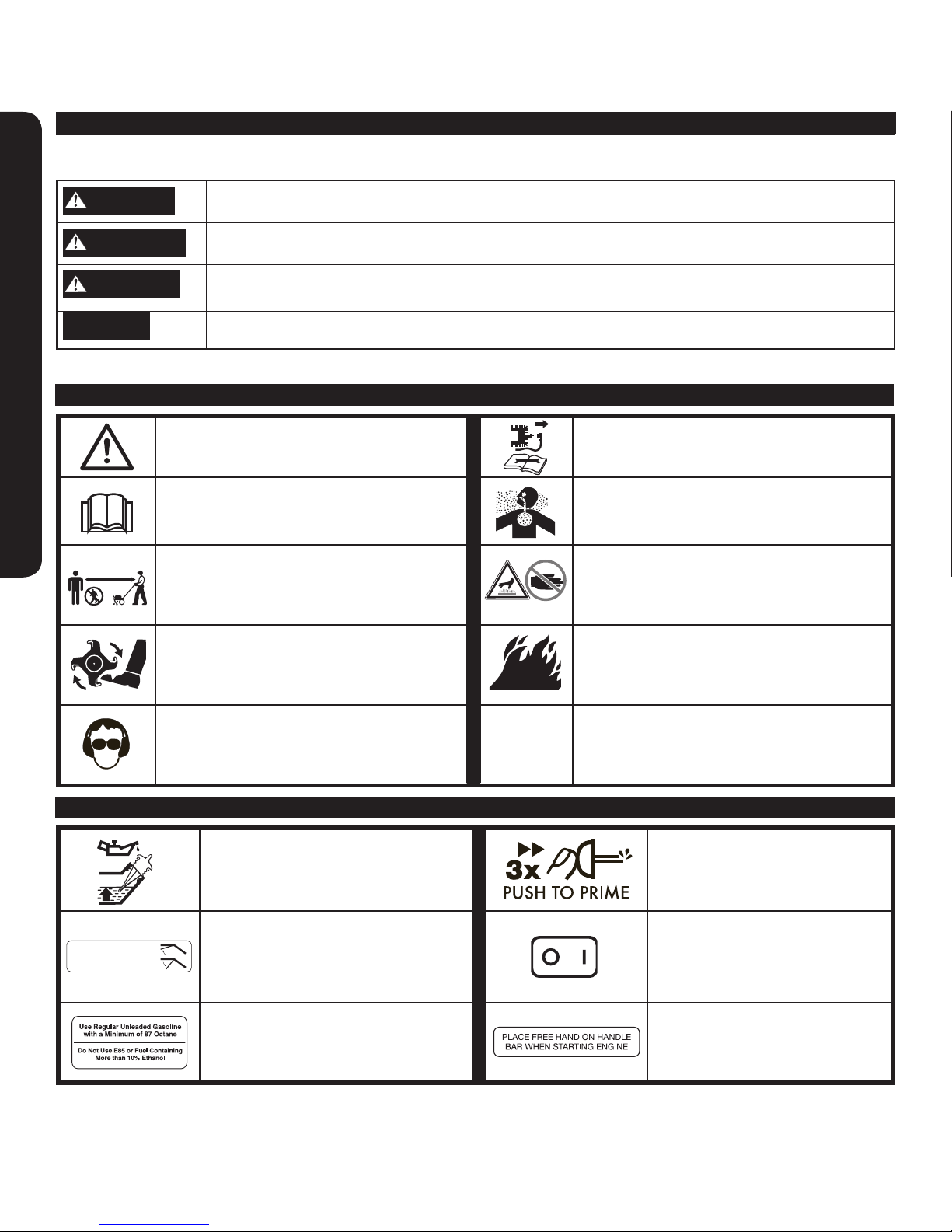

Safety Definitions

• Save these instructions

Safety Alert Symbols

Important Safety Information

The following symbols are used on the product and in this manual to alert the operator of potential safety hazards.

Read them carefully, and understand their meaning.

DANGER

WARNING

CAUTION

NOTICE

The following symbols may be found on your tiller. Carefully read and understand their meaning.

Safety Warning Symbols

Indicates WARNING, DANGER, or

CAUTION.

Read operator’s manual before operating

this machine. Failure to follow directions

could result in serious injury.

Do not use if children or bystanders are

present.

Rotating parts can cause serious injury.

Keep hands, feet and clothing away.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor/moderate

injury.

Indicates a practice not related to personal injury which, if not avoided, may result in property damage.

Disconnect spark plug wire when not in use

or before servicing, cleaning, or performing

maintenance on the unit.

Engine exhaust contains carbon monoxide,

an odorless and deadly gas. NEVER run unit

indoors or in a poorly ventilated area.

Do NOT touch hot muffler or cylinder. These

parts are extremely hot from operation and

may remain hot for a short time after operation.

To reduce risk of fire, clean spilled gas and

oil and keep unit free from debris. Gasoline is

extremely flammable. Allow machine to cool

before refueling

Wear eye protection complying with ANSI

Z87.1 and hearing protection.

Control and Operating Symbols

Oil Fill Location

Do Not Overfill. Add engine oil and

check quantity at this location

CLUTCH

CONTROL

ENGAGE

DISENGAGE

Clutch Lever

Lifting the lever engages the tines.

Do not use gasoline containing more

than 10% ethanol.

Push primer 3 times before starting

a cold engine.

ENG - 2Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

starting a hot engine, push only

once.

Ignition Switch

Move switch position to start/stop

engine.

Place free hand on handle bar

before pulling recoil starter handle

with other hand.

Important: For

Page 3

Important Safety Information

• Save all instructions

RESPONSIBILITY OF OPERATOR

1. Carefully read and follow these safety instructions. Failure to do so can result in serious injury.

2.

Know your product. Read and understand this manual before use. Compare the illustrations to unit. Learn location

and function of all controls. Thoroughly understanding the unit before use will result in the best performance and safety.

3. Follow all instructions when assembling the unit. If the unit was purchased in assembled condition, the operator must

check the unit carefully to make sure it was assembled according the instructions in the manual before use.

4. Regularly inspect the tiller. Make sure parts are not bent, damaged, or loose.

5. Use this equipment for its intended purpose only.

6. Operate the unit only with guards, shields, and other safety items in place and working correctly.

7. Service the unit only with authorized or approved replacement parts.

8. Complete all unit maintenance and adjustments according to the instructions in this manual.

Look for this symbol to point out important safety precautions. It means: “ Attention! Become Alert! Your Safety Is

Involved.”

WARNING

Engine Exhaust, some of its constituents, and certain vehicle components contain or emit chemicals known to the State

of California to cause cancer and birth defects or other reproductive harm.

WARNING

To prevent accidental starting when setting up, transporting, adjusting or making repairs, always disconnect spark plug

wire and put wire where it cannot contact the spark plug.

Important Safety Information

PREPARATION SAFETY

WARNING

• Read, understand, and follow all instructions on the machine and in this manual. Be thoroughly familiar with the

controls and the proper use of the tiller before starting. Know how to stop the engine quickly.

• Familiarize yourself with all the safety and operating decals on this equipment.

• Thoroughly inspect the area where the tiller is to be used and remove all foreign objects. Your equipment can propel

small objects at high speed causing personal injury or property damage. Stay away from breakable objects, such as

house windows, auto glass, greenhouses, etc.

• Check that all nuts and bolts are tight and equipment is in good condition before each use.

OPERATION SAFETY

• Never allow children or young teenagers to operate the tiller.

WARNING

• Keep area of operation clear of all bystanders, particularly small children and pets.

• Only allow responsible individuals, who are familiar with the instructions, to operate the tiller.

• Do not operate the tiller while under the influence of alcohol, drugs, or other medication which can cause drowsiness

or affect your ability to operate this machine safely.

• Do not use this machine if you are mentally or physically unable to operate the machine safely.

• Always wear ANSI compliant safety goggles or safety glasses with side shields when operating tiller to protect your

eyes from foreign objects, which can be thrown from the unit.

• Wear appropriate clothing such as a long sleeved shirt or jacket. Also wear long trousers or slacks. Do NOT wear

shorts. Do NOT wear loose clothing, which could get caught in this equipment.

• Always wear work gloves and sturdy footwear such as leather work shoes or short boots. These will protect ankles

and shins from small sticks, splinters, and other flying debris, and improve traction.

• It is advisable to wear protective headgear to protect against being struck by small flying particles, or being struck by

low hanging branches, twigs, or other objects, which may be unnoticed by the operator.

ENG - 3Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 4

Important Safety Information (Continued)

• Save all instructions

Important Safety Information

WARNING

• Do not put hands or feet near or under rotating parts.

• Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards

or traffic.

• Exercise caution to avoid slipping or falling. Always be sure of your footing; keep a firm hold on the handle and walk;

never run. Never operate the tiller at high transport speeds on slippery surfaces.

• Never operate the tiller without good visibility or light.

DANGER

• Do not run the engine indoors or inside a closed area. The exhaust fumes are dangerous, containing CARBON

MONOXIDE, an ODORLESS AND DEADLY GAS.

• Never leave the tiller unattended when the engine is running. Stop the engine and make sure all moving parts have

stopped. Remove the wire from the spark plug.

• Watch for holes, ruts, bumps, or other rough ground. Tall grass can hide obstacles.

• Always look behind and down and use caution when using reverse or pulling the tiller towards you.

• Never attempt to start the tiller unless both wheels are in the locked position. This acts as a brake for the tiller.

Always start the tiller on the level surface.

WARNING

• Disengage clutch lever and stop engine before leaving the tiller in operating position. Wait until the tines come to a

complete stop before removing debris or making any adjustments to the tiller.

• Do not attempt to till hard soil, till too deep or till at too fast a rate that can overload the tiller.

• If the tiller should start to vibrate abnormally, stop the engine, disconnect the spark plug wire and prevent it from

touching the spark plug. Check immediately for the cause. Vibration is generally a warning of trouble.

FUEL SAFETY

WARNING

• Gasoline is extremely flammable, and gasoline vapors can explode if ignited. Handle with care.

• Use an approved container.

• Check fuel supply before each use, allowing space for expansion as the heat of the engine and/or sun can cause fuel

to expand.

• Fill fuel tank outdoors with extreme care. Never fill fuel tank indoors.

• Never remove gas cap or add fuel with the engine running. Allow engine to cool a minimum of 2 minutes

before refueling.

• Do not smoke while refueling.

• After refueling, replace fuel tank cap securely and wipe up spilled fuel.

• Never store fuel or tiller with fuel in the tank inside a building where fumes may reach an open flame.

• Never fill gasoline containers or the tiller fuel tank inside of a vehicle or in a truck bed. Accidental electrical static dis

charge can ignite fuel vapors which could result in serious injury or death.

STORAGE SAFETY

•

Always refer to the operator’s manual instructions for important details if the tiller is to be stored for an extended period.

• Never store the tiller with fuel in the fuel tank inside a building where ignition sources are present such as water

heaters, space heaters, clothes dryers, etc.

• To reduce fire hazard, keep tiller free of grass, leaves, or other debris build-up.

• Allow the engine to cool before storing in any enclosure.

REPAIR, MAINTENANCE, AND ADJUSTMENT SAFETY

• After striking a foreign object, stop the engine. Remove the wire from the spark plug and keep the wire away from the

plug to prevent accidental starting. Thoroughly inspect the tiller for any damage. If damaged, have the equipment

repaired by a trained technician before restarting and operating.

ENG - 4Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 5

Important Safety Information (Continued)

• Save all instructions

WARNING

• Stop the engine before cleaning, repairing, or inspecting the unit. Make sure all moving parts have stopped. Let the

engine cool, disconnect the spark plug wire and move it away from the spark plug.

• Never attempt to make any adjustments while the engine is running except when specifically recommended by the

manufacturer.

• Keep the tiller in safe working condition. Check all fasteners at frequent intervals for proper tightness.

• When servicing or repairing the tiller, do not tip the machine over or up unless specifically instructed to do so in this

manual. Service and repair procedures can be done with the tiller in an upright position. Some procedures will be

easier if the machine is lifted on a raised platform or working surface.

• Use only original equipment or authorized replacement parts.

• Never tamper with safety devices. Check their proper operation regularly.

• Do not change the engine governor setting or over-speed engine.

• Clean and replace safety and instruction decals as necessary.

• To guard against engine over-heating, always have engine debris filter mounted and clean.

CHILDREN SAFETY

WARNING

• Tragic accidents can occur if the operator is not alert to the presence of children. Children are often attracted to the

tiller and the tilling activity.

• Keep children out of the tilling area and under the watchful care of a responsible adult.

• Never assume that children will remain where you last saw them.

• Be alert and turn tiller off if children enter the area.

• Before and while moving backwards, look behind and down for small children.

• Never allow children to operate the tiller.

• Use extra care when operating near blind corners, shrubs, trees, or other objects that may obstruct vision.

Important Safety Information

ENG - 5Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 6

Product Specifications

• Save all instructions

Unit Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . .89 lb (40 kg)

Tilling Width . . . . . . . . . . . . . . . . . . . . up to 21 in (53.3 cm)

Tilling Depths . . . . . . . . . . . . . . . . . . . . . . up to 8” (20.3 cm)

Tine Diameter . . . . . . . . . . . . . . . . . . . . . . . .11 in (27.9 cm)

Gasoline Type .......Regular Unleaded/87 Octane (min.)

Gasoline Capacity . . . . . . . . . . . . . . . . . . . . 1.0 US qt. (1 L)

Engine Oil Type (API SG-SL) . . . . . . . . . . . . . . . . . . . . . . . .

10W-30 is recommended for all service temperatures.

See page (11) for additional information.

Engine Oil Capacity . . . . . . . . . . . . . 15-1/2 US oz (450 ml)

Engine Type . . . . . . . . . . . . . . . . . . . . . . . . . . OHV 4-stroke

REFER TO ENGINE MANUAL FOR DETAILED ENGINE SPECS.

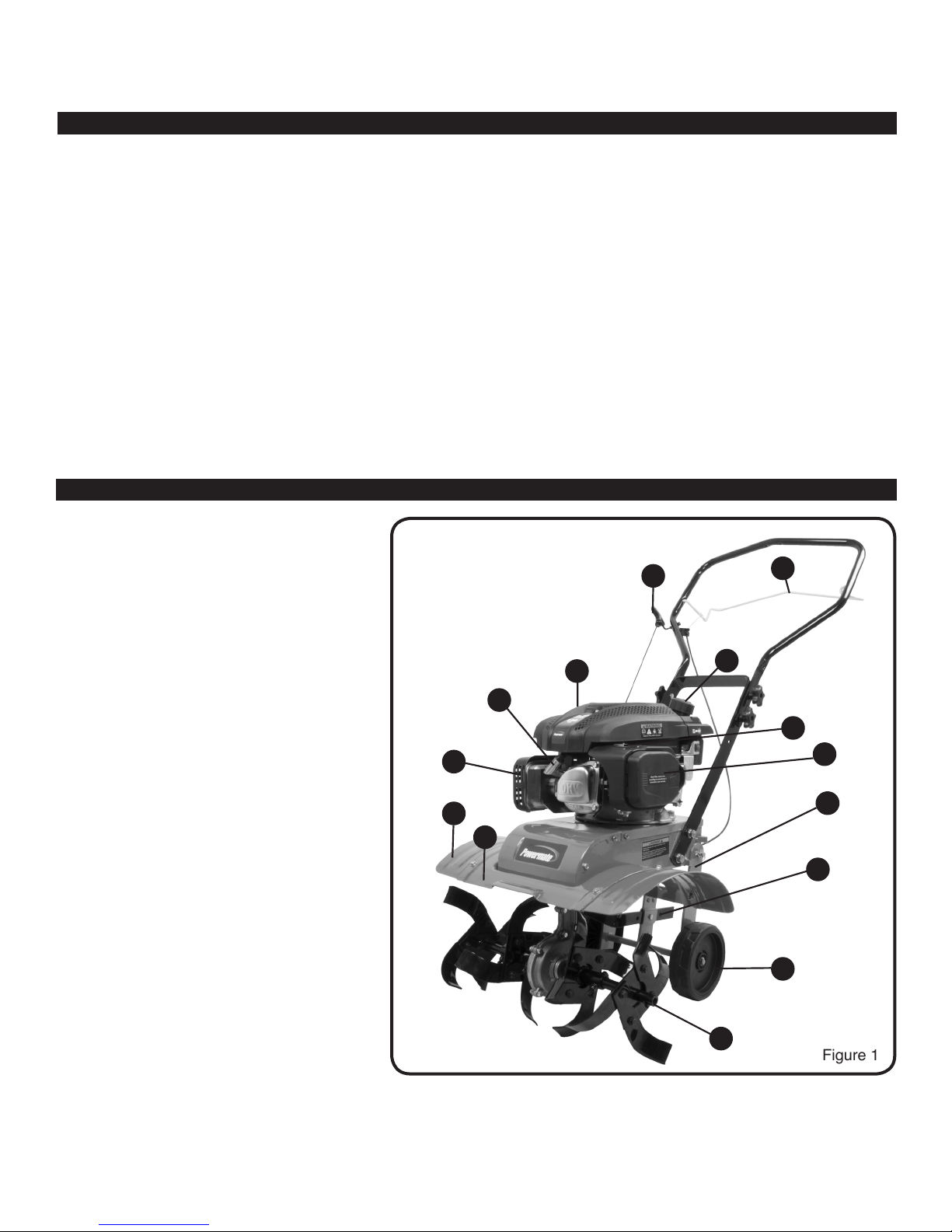

Parts & Features

1. Tines

2. Swing Plate

3. Wheels

4. Muffler

5. Air Filter

6. Recoil Starter Handle

7. Spark Plug / Spark Plug Wire

8. Drag Bar

9. Primer Bulb

10. Fuel Tank Cap

11. Oil Dipstick

12. Clutch Lever

13. Tine Shield

14. Outside Tine Shield

4

14

Engine Displacement . . . . . . . . . . . . . . . . . . . . . . . . . 150cc

Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3400 rpm

Torque Rating .... 5.75 ft-lbs gross torque per SAE J1940

Intake Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.006-0.008 in. (0.15-0.20 mm)

Exhaust Valve Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . .

0.006-0.008 in. (0.15-0.20 mm)

Spark Plug Gap ............0.020-0.028 in. (0.5-0.7 mm)

Spark Plug Type . . . . . . Torch K7RTC (Champion C7YCC)

Wheel Size . . . . . . . . . . . . . . . . . . . . . . . . . . .6.5” (16.5 cm)

12

9

5

2

13

6

11

7

10

8

3

1

Figure 1

ENG - 6Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 7

Safety Decals

• Save all instructions

This tiller has been designed and manufactured to provide

you with the safety and reliability you would expect from an

industry leader in outdoor power equipment manufacturing.

Although reading this manual and the safety instructions it

contains will provide you with the necessary basic knowledge

to operate this equipment safely and effectively, we have

placed several safety labels on the tiller to remind you of this

important information while you are operating the unit.

These important safety labels are illustrated and are shown

here to help familiarize you with the location and content to

the safety messages you will see as you perform normal tilling

operations. Please review these labels now. If you have any

questions regarding their meaning or how to comply with these

instructions, reread the complete safety instruction text on the

preceding pages, or contact your local dealer.

Should any of the safety labels become unreadable because of being worn, faded, or otherwise damaged during

the use of your tiller, please contact your local authorized

dealer to order replacement labels.

The safety labels are easily applied, and will act as a constant visual reminder to you and others who may use the

equipment. Following the safety instructions is necessary

for safe, effective operation of your tiller.

• Gasoline is flammable. Allow engine to cool at least 2 minutes

before refueling.

• Operation of this equipment may create sparks that can start

fires around dry vegetation. A spark arrestor may be required.

The operator should contact local fire agencies for laws or

regulations relating to fire prevention requirements.

ENG - 7Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 8

Assembly

• Save all instructions

Read and follow the assembly instructions. Do not discard any parts or materials until the unit is assembled.

References to the right or left side of the tiller are from the viewpoint of the operator’s position behind the tiller.

WARNING

Do not operate tiller if it is damaged or not completely and correctly assembled.

WARNING

Before doing any assembly or maintenance to the unit, remove the wire from the spark plug.

WARNING

Always wear ANSI compliant safety glasses with side shields while assembling the tiller.

The following components will be found in the carton.

Quantities shown in ( ).

1. (1) Tiller

2. (1) Upper Handle Assembly

3. (1) Lower Handle

4. (4) Tines

5. (1) Wheel Assembly

6. (1) Drag bar

7. (2) Outside Tine Shields

8. (1) Tiller Operator’s Manual

9. (1) Engine Manual

10. (1) Bottle of Engine Oil

11. (1) Parts bag containing the following

a. (4) M10 x 25 mm bolts, flat washers and lock washers for assembling lower handle.

b. (4) M8 x 25 mm saddle bolts and flat washers for assembling upper handle to lower handle.

c. (4) Handle knobs, for upper handle to lower handle.

d. (2) M8 x 50 mm bolts, (4) flat washers and (2) lock nuts for assembling outer tines.

e. (2) M10 x 50 mm bolts, (4) flat washers and (2) M10 locknuts for assembling inner tines.

f. (1) Pin, flat washer and hairpin cotter for drag bar.

g. (6) M6 x 16 bolts, lock nuts, and flat washers for installing outside tine shields.

h. (1) Rope guide with nylock nut.

i. (1) Cable Ties.

If you need assistance or find any parts missing, CALL

TOLL FREE: 1-800-737-2112.

How to Remove Tiller from Carton

A

1. Remove all parts and packaging components.

2. Use a utility knife to cut all 4 vertical edges and lay the side panels flat around the tiller.

3. Remove any remaining packaging.

ENG - 8Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 9

Assembly (Continued)

• Save all instructions

Assembly Instructions

B

The tiller comes assembled except for a few parts. The following instructions will help you complete the tiller assembly.

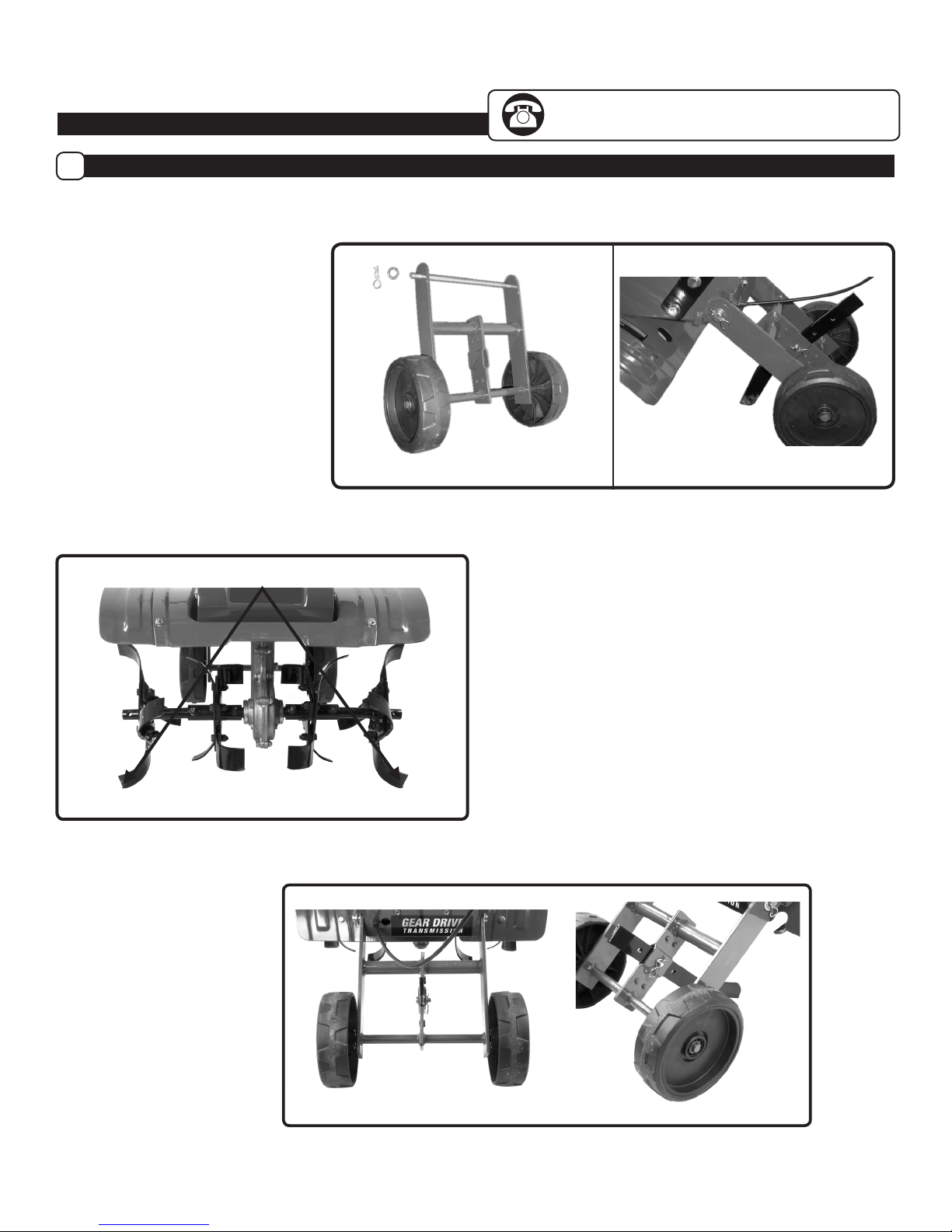

ATTACH THE WHEEL ASSEMBLY

TO THE FRAME

1. Install the wheel assembly to the

frame by removing a hairpin

cotter and at washer from

one end of pivot rod. Remove

rod. Align pivot holes in wheel

assembly to pivot holes in frame.

Install pivot rod and secure by

reinstalling at washer and

hairpin. (See Figure 2)

If you need assistance or find any parts missing, CALL

TOLL FREE: 1-800-737-2112.

Figure 2

Sharp edge of tine should face down to the ground.

INSTALL THE DRAG BAR

1. Insert the drag bar into the

bottom of the wheel bracket

assembly. (See Figure 4)

2. Insert the pin through the

bracket and the middle

hole of drag bar and secure

with flat washer and

hairpin cotter. (See Figure 4)

Figure 3

INSTALL THE TINES (See Figure 3)

1. Slide the tines onto the tine axle. Install the internal tines

first. Sharp edge of the front and top tines should face

down and forward to till the ground. Insert the

M10 x 50 bolt with lock nut provided to secure the

inside tines. Use one flat washer under the head of the

bolt and one under the locknut. Tighten securely.

2. For wide 21” tilling, install the outside tines in the way

that the long half of the tine tube faces towards the

inside tines. For narrow 16” tilling, install the outside

tines in a way that the short half tine tube faces towards

the inside tines.

3. Insert the M8 x 50 bolt with the locknut provided to

secure the outside tines. Use one flat washer under

the head of the bolt and one under the locknut.

Tighten securely.

Figure 4

ENG - 9Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 10

Assembly (Continued)

• Save all instructions

If you need assistance or find any parts missing, CALL

TOLL FREE: 1-800-737-2112.

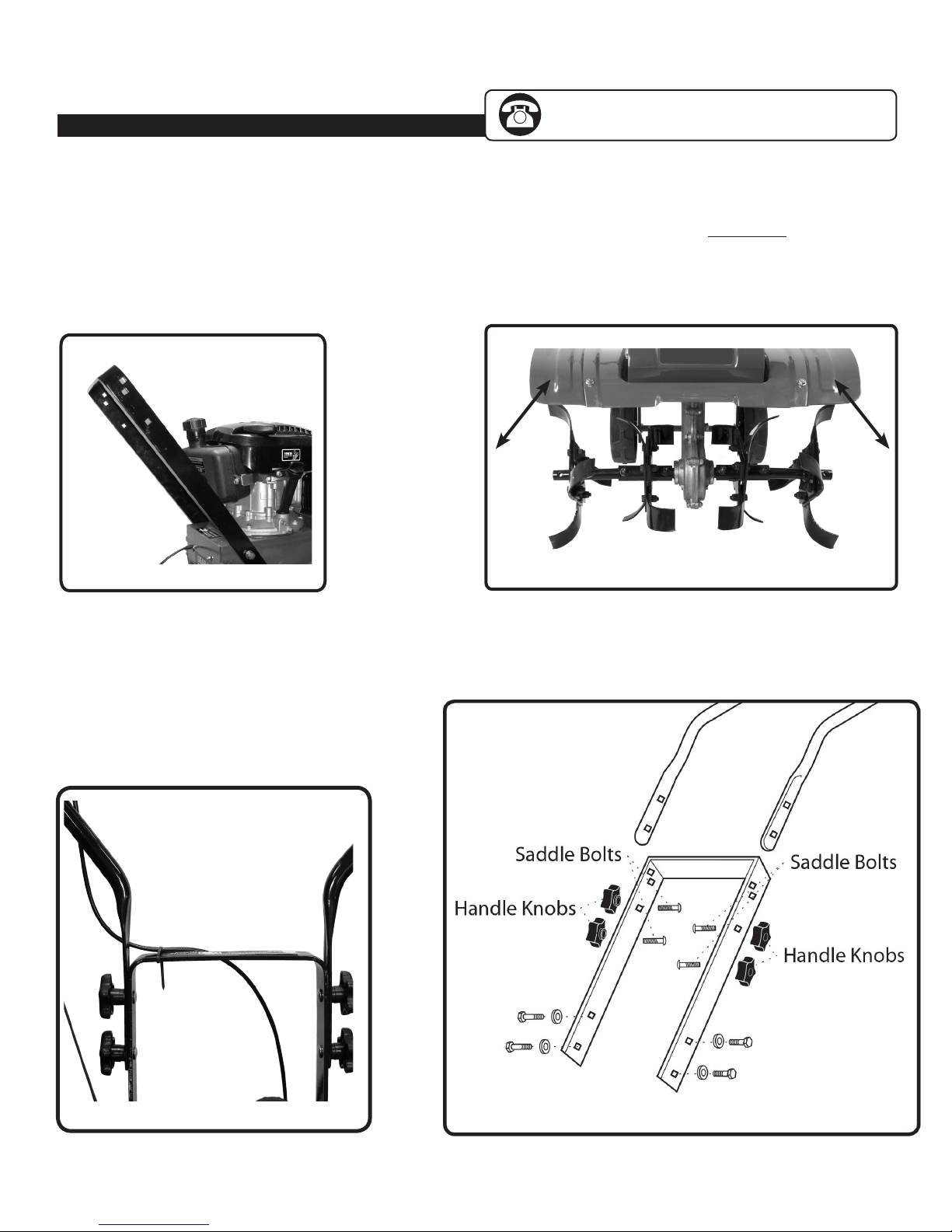

INSTALL LOWER HANDLE (See Figure 5)

1. Orient lower handle with upper square holes as

shown. Align lower handle holes with respective

holes in the frame and loosely install two M10 x

25 mm bolts, lock washers and flat washers on

each side.

2. Using a wrench, tighten bolts securely on

each side.

Figure 5

ATTACH UPPER HANDLE (See Figure 6,7)

1. Slide the upper handle down over the lower

handle and align the holes. Orient upper

handle so clutch lever is below handle.

2. Insert the saddle bolts into the holes as shown

and secure with at washers and handle knobs.

3. Tighten the handle knobs securely.

4. Using one cable tie, secure the control cable to

the handle as shown.

INSTALL THE OUTSIDE TINE SHIELDS (See Figure 8)

1. Each outside tine shield can be installed on

either side of the main tine shield.

2. Place the outside tine shield underneath the

main tine shield and align the holes.

3. Secure each outside tine shield to the main tine

shield with (3) M6 x 16 bolts washers and

lock nuts.

Figure 2

Figure 8

Figure 6

Figure 7

ENG - 10Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 11

Assembly (Continued)

• Save all instructions

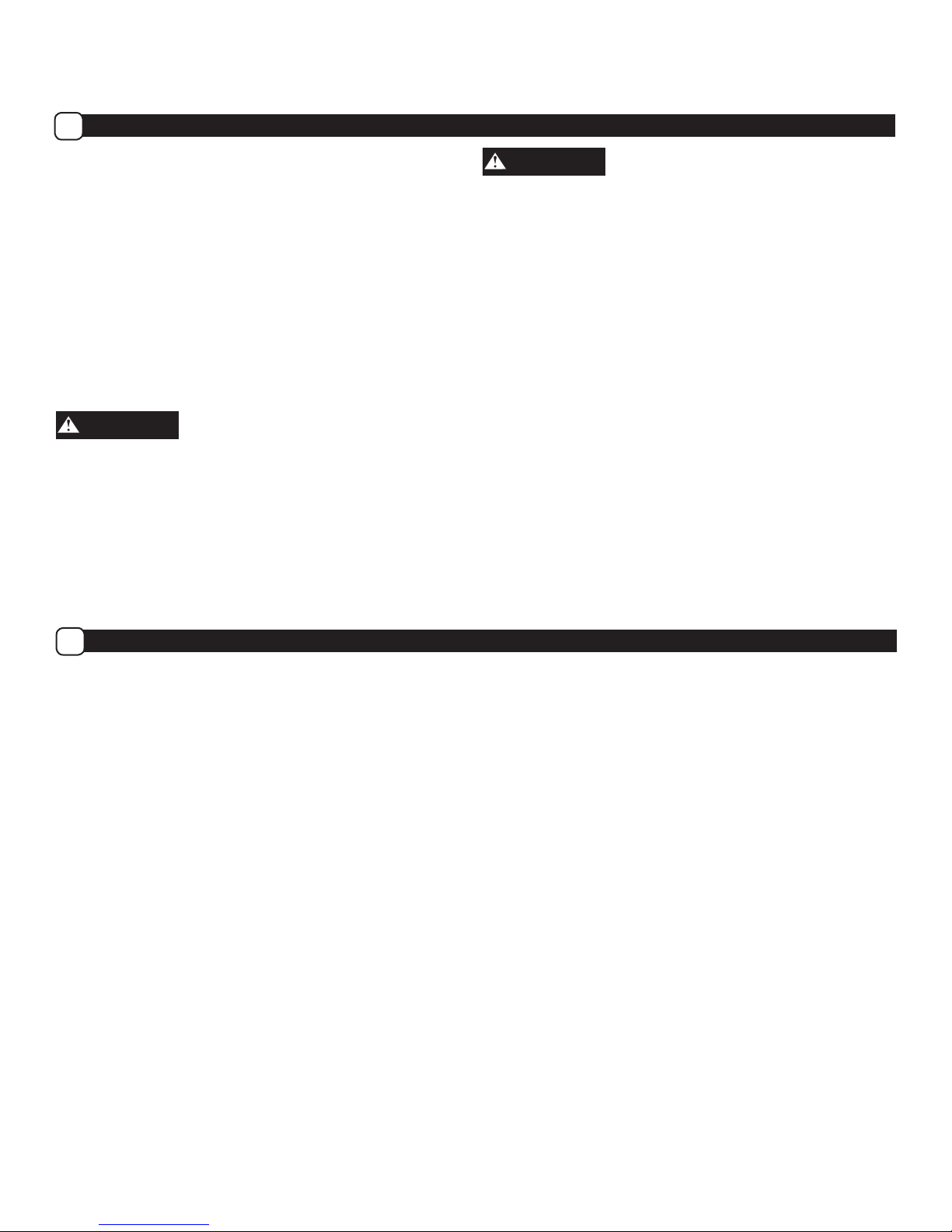

INSTALL THE ROPE GUIDE (See Figure 9)

1. Install the rope guide into the right hand

section of the upper handle as shown.

Install locknut and tighten securely. Pull

engine rope and route through the guide.

If you need assistance or find any parts missing, CALL

TOLL FREE: 1-800-737-2112.

Figure 9

ENG - 11Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 12

Engine Preparation

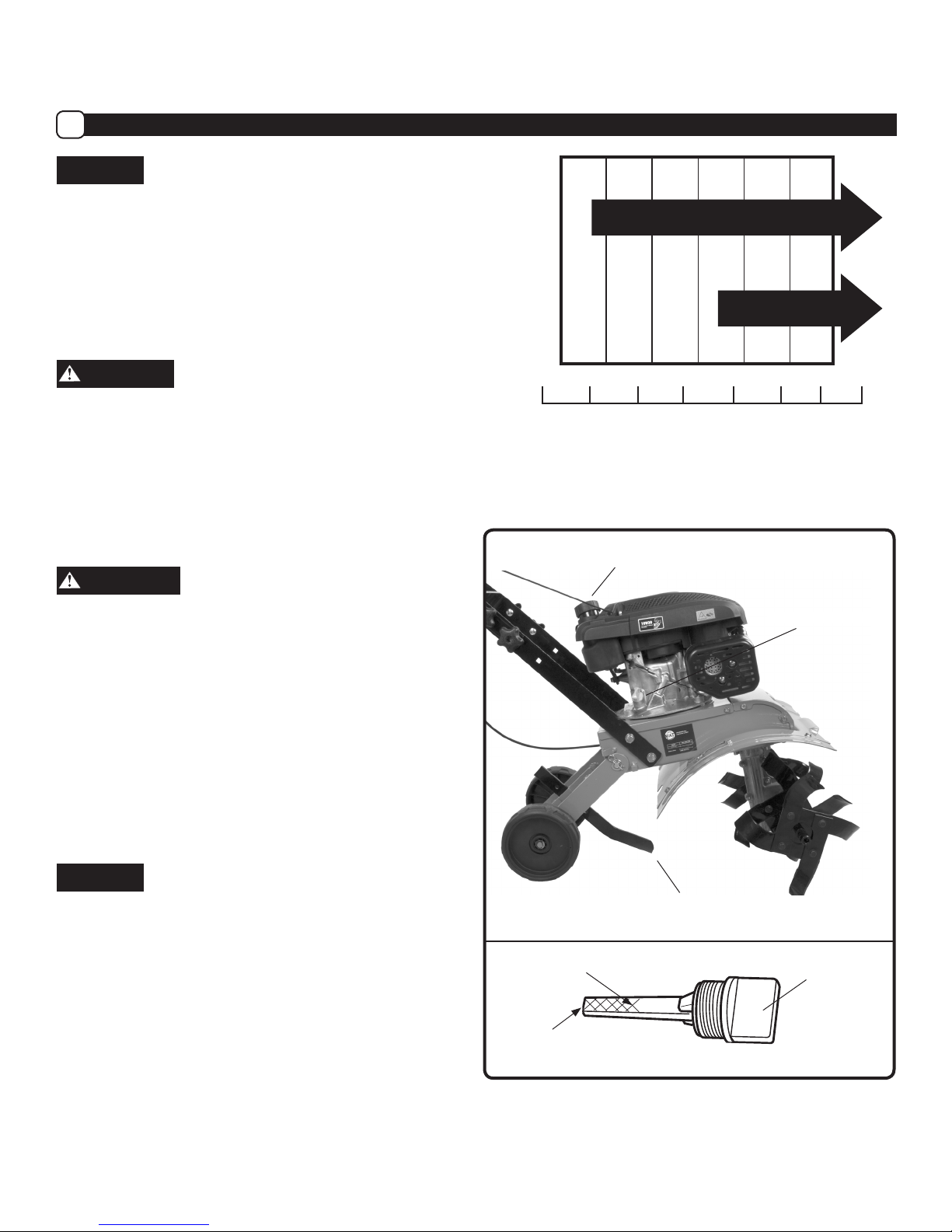

Ambient Service Temperature

• Save all instructions

Engine Oil

A

NOTICE

Engine shipped without oil. Failure to add oil will result in

serious engine damage.

A bottle of engine oil is included with your tiller. Refer

to the chart on the right for alternative oil types to use at

different temperatures. Always use a high quality detergent

oil classified “For Service, SG, SH, SJ” or higher. Do not

use special additives.

CAUTION

Always use recommended oil type. Using dirty oil or

incorrect oil type such as 2-stroke engine oil will damage

the engine.

NOTE: Engine Oil Capacity is 450 ml (15 1/2 US oz).

HOW TO CHECK OIL LEVEL AND FILL TO PROPER LEVEL

WARNING

Before checking oil, make sure engine is off, and spark

plug wire has been disconnected from spark plug.

SAE

TEMP

-20

0

-20-30 -10

Fuel Tank Cap

SAE 10W-30

20

0

*10W-30

40

SAE 30

60 80

2010

30

Oil Fill Cap/Dipstick

100° F

40° C

1. Place the tiller on a level surface and make sure the

drag bar is set.

(See Figure 10)

2. Remove the oil ll cap/dipstick and wipe with clean cloth.

3. Insert dipstick into ll spout but do NOT screw in.

Remove dipstick and check oil level.

4. When oil level is full, the oil will be at upper limit on dip

stick. If oil level is near or below the lower limit, oil must

be added. (See Figure 11)

5. Add oil slowly until the oil level reaches the upper limit

of the dipstick. Use a funnel or nozzle to reduce spillage.

NOTICE

Frequently check oil level while filling. DO NOT OVERFILL.

DO NOT UNDERFILL. Running engine at improper oil

level may seriously damage engine.

6. Replace and tighten dipstick.

7. Clean up any spilled oil.

NOTE: The transmission case comes from the factory with

the proper amount and type of lubricant.

Upper Limit

Lower Limit

Drag bar

Figure 10

Oil Fill Cap/

Dipstick

Figure 11

ENG - 12Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 13

Operation

• Save all instructions

Pre-Start Inspection

A

1. Make sure all safety guards are in place and all nuts and

bolts are secure.

2. Check oil level in engine crankcase. See your engine

manual for procedure and specications.

3. Inspect air cleaner for cleanliness. See your engine

manual for procedure.

4. Check the fuel supply. Fill the fuel tank no closer than 1

inch from top of tank to provide space for expansion.

See your engine manual for fuel recommendations.

5. Be sure spark plug wire is attached and spark plug is

tightened securely.

6. Examine underneath and around engine for signs of oil

or fuel leaks.

7. Inspect fuel hoses for tightness and fuel seepage.

8. Look for signs of engine damage.

9. Remove excessive debris from mufer area and

recoil starter.

10. Remove any debris from tines and tine shafts.

11. Move the tiller to the area of operation.

12. Check position of wheels swing plate should be in the

tilling mode position.

13. Check drag bar position.

CAUTION

Please do not start your tiller until you have read the

manual that came with your engine, and the sections in this

manual title controls, adjustments and safety. If you have

read these, follow the steps below to start your tiller. Always

perform this pre-start checklist before starting the engine.

WARNING

Gasoline is highly ammable and must be handled with

care. Never ll the tank when the engine is hot or running.

Always move outdoors to ll tank.

WARNING

Always keep hands and feet clear of rotating machine parts.

IMPORTANT: Engine is shipped from factory without oil. YOU

MUST ADD ENGINE OIL BEFORE STARTING ENGINE.

Start the Engine

B

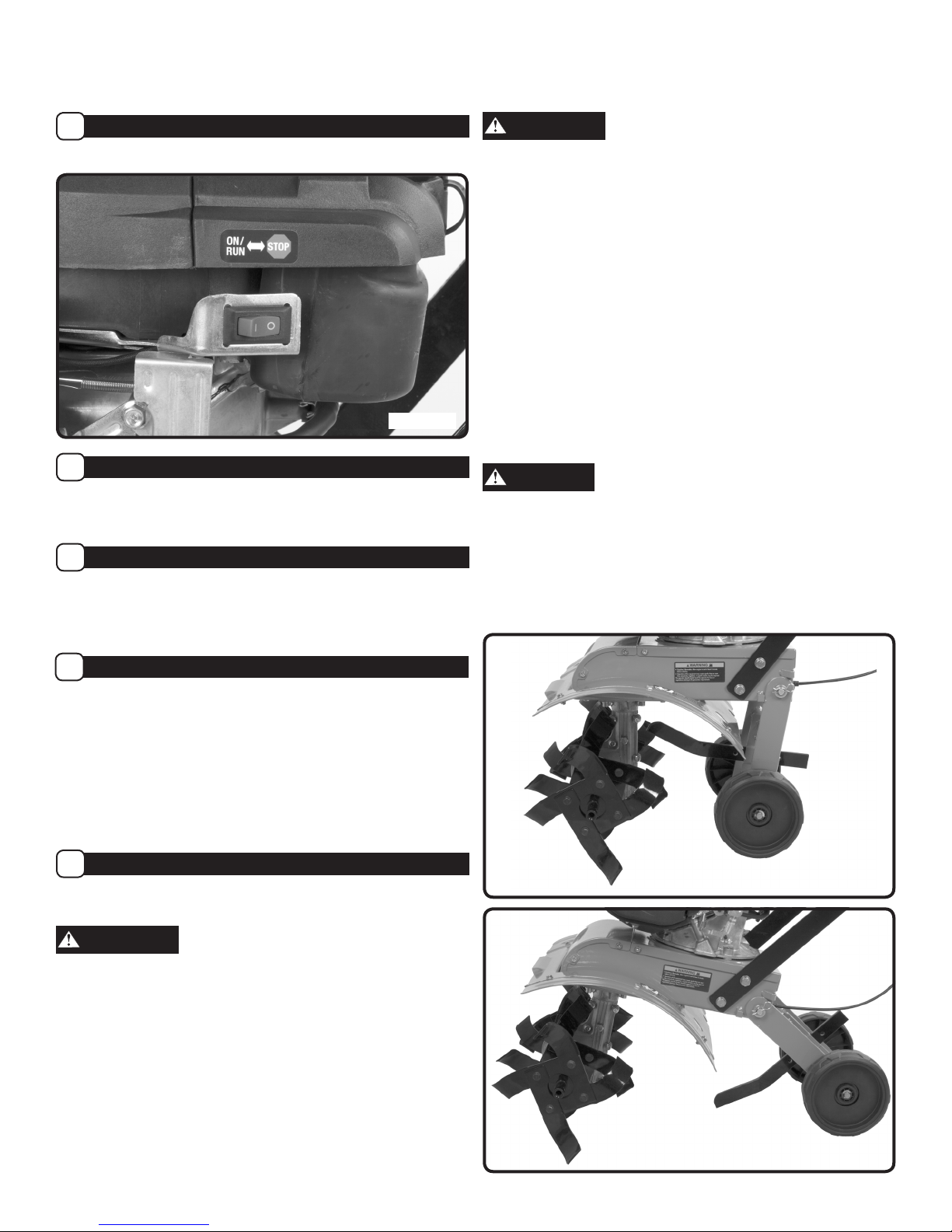

1. Press ON/OFF switch to ON position. (See Figure 12)

2. Push primer bulb 3 times. Wait 2 seconds between each push.

3. Place left hand on upper handle. (See Figure 13)

4. Grasp starter handle and pull out slowly, until you feel tension in the starter rope. (See Figure 13)

5. Pull rope with a rapid full arm stroke until engine starts.

6. Do not allow the starter rope to snap back. Let the starter rope slowly rewind.

Figure 12

Figure 13

ENG - 13Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 14

Operation (Continued)

• Save all instructions

Stop the Engine

C

1. Press ON/OFF switch to OFF position.

Figure 14

Operating Speed

D

This tiller is equipped with a fixed throttle that is set for

optimum tilling performance.

Shutting Down

E

To stop the engine at any time, release the clutch lever and

press ON/OFF switch to OFF position. To stop tines at any

time, release clutch lever.

WARNING

Temperature of mufer and nearby areas may exceed

150˚F. Avoid these areas.

Engine, transmission and surrounding parts become

extremely hot during normal use and CAN cause

serious burn injuries if touched before the engine has cooled.

Allow engine to cool completely before touching these

surfaces.

To stop tines at any time, release CLUTCH LEVER to

neutral position. Always release CLUTCH LEVER to neutral

position AND STOP THE ENGINE before adjusting the depth of

the drag bar.

If you do not know how to do these things, read the controls, adjustments and safety sections before proceeding

DANGER

IMPORTANT: Practice operating the controls and tiller with

tines out of ground before beginning to till. It is important

that you know how to use the tiller properly, keep control at

all times, stop the tines, and stop the engine if necessary. If

you do not know how to do these things, read the controls,

adjustments and safety sections before proceeding.

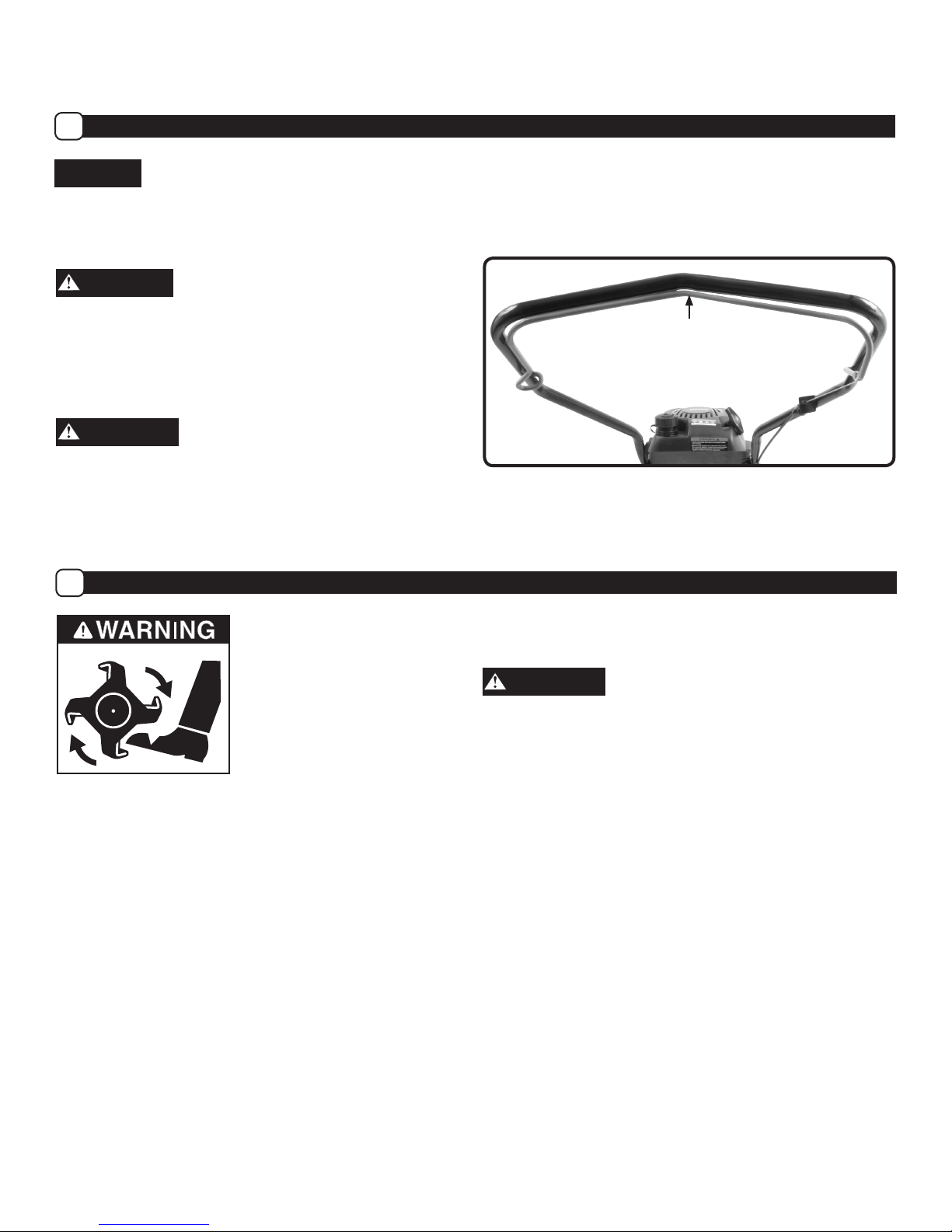

Transport Mode and Tilling Mode (See Figure 15 and 16)

F

Transport Mode

Fold the wheel under the engine for convenient transport.

NOTE: The drag bar must be in the middle or bottom hole

for transporting.

Tilling Mode

Unfold the wheel back for tilling operation.

Tilling

G

1. Adjust the drag bar to desired tilling depth.

WARNING

Lower the drag bar one hole at a time testing tiller

operation after each adjustment. Lowering drag bar down

too low can result in loss of control of tiller.

2. Pulling the clutch lever to the handle will engage the tines.

Figure 15

Figure 16

ENG - 14Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 15

Operation (Continued)

• Save all instructions

Clutch Lever

H

NOTICE

When tilling, always pull lever completely to the handle.

Failure to do so may result in excessive drive belt wear and

premature drive belt failure.

CAUTION

This information is provided here only to introduce the

controls. Do not start the engine at this time. Starting and

operating instructions are given on page 11. Please read

this section and all operating and safety instructions before

starting your tiller.

WARNING

Do not x the clutch lever in drive position by any other

means than manually using your hand. DO NOT tie or otherwise secure the lever in drive position.

• To stop the tines at any time release the clutch lever.

Adjustments

I

CLUTCH LEVER (See Figure 17)

Engage tines by pulling the clutch lever to the handle.

Releasing the lever stops the tines and brings the tiller to a

complete stop.

Lever Engaged

Figure 17

Engine should be off before adjusting any controls.

DRAG BAR (See Figure 2)

Tilling depth is controlled by the height of the drag bar. To

adjust tilling depth:

1. Remove pin.

2. Adjust the drag bar to position tines at chosen tilling depth.

3. Align hole in drag bar with hole in swing plate bracket and

replace pin.

Drag Bar Up = Shallower tilling.

Place the pin in the bottom hole of the drag bar for

shallowest tilling.

Drag Bar Down = Deeper tilling.

Place the pin in the top hole of the drag bar for deepest tilling.

NOTE: The drag bar must be in the middle or bottom hole for

transporting.

WARNING

Do not adjust tilling depth unless clutch lever is released and engine

is turned off.

ENG - 15Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 16

Operation (Continued)

• Save all instructions

Tilling Tips

J

• Tilling depth will vary with ground conditions.

• When beginning to till in unbroken ground or in extremely

hard soil, set the pin in the highest hole of the drag bar

(follow instructions under Tilling section). This will allow

for shallow tilling. With the drag stake in this position,

make several light passes over the area to be tilled. Reset

for deeper depths with successive passes.

• If tiller jumps or skids uncontrollably, lower the drag

stake by placing the pin in a higher hole. This will allow

for shallower tilling. Hold firmly to the handlebars to

control sudden lurches.

• If weeds, tall grasses, vines, or other materials clog or

jam the tines, reverse the tiller to unwind vegetation.

WARNING

Immediately release the clutch lever if the tines jam or you

strike a foreign object. With clutch lever in neutral position,

stop the engine. Disengage the spark plug wire. When

tines have stopped, remove foreign objects and check for

damage.

WARNING

Caution must be taken in selecting tilling depth. If you attempt to

till too deeply for soil conditions, that is, with the drag bar in too

high a position, loss of control could result.

When removing material from the tines, stop engine and

remove spark plug wire rst.

Cultivating Tips

K

If you plan to use your tiller for cultivating:

• Plant rows on 20" - 22" centers for ease of turning.

• Set the drag bar with the pin in one of the higher holes. This will allow for shallow cultivation necessary to

turn over weeds, and break up and aerate the soil.

ENG - 16Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 17

Maintenance

• Save all instructions

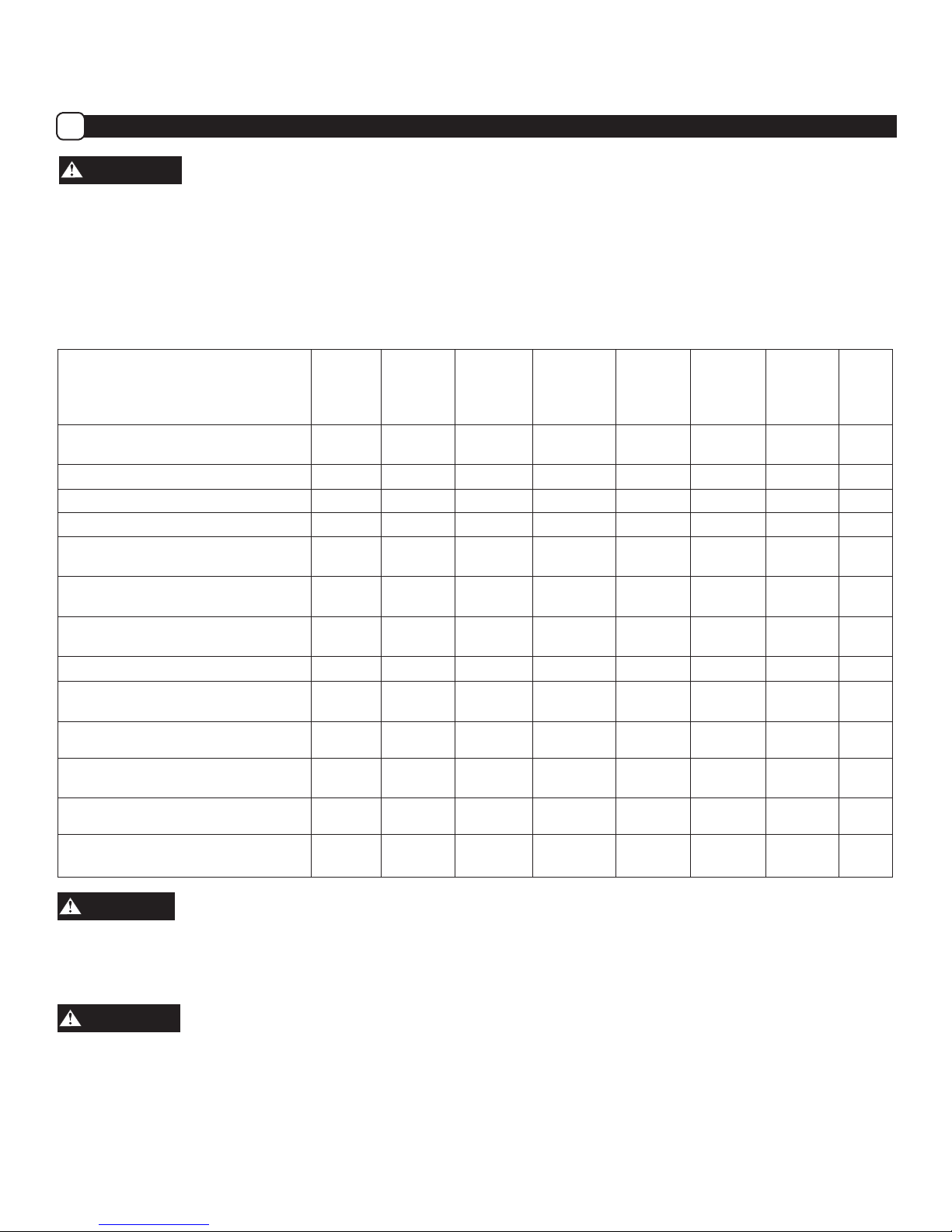

Maintenance Schedule

A

WARNING

Before performing any maintenance, turn engine off and remove the wire from the spark plug to prevent accidental starting

and serious injury.

IMPORTANT: The warranty on this tiller does not cover items that have been subjected to operator abuse or negligence. To

receive full value from the warranty, the operator must maintain the tiller as instructed in this manual, and only use genuine

replacement parts. The following table lists required periodic maintenance.

PERIODIC MAINTENANCE SCHEDULE TABLE

Service Records-

Fill in dates as you complete regular

service

Check Engine Oil Level,

Fill to Proper Level

Clean Debris From Unit √ √ √

Lubricate All Pivot Points √ √ √

Check Fasteners for Tightness √ √

Check Drive Belts

Replace if Necessary

Check Tines for Wear or Damage

Replace if Necessary

Check Fuel Line

Replace if Necessary

Lubricate Wheel Axles

Check Spark Plug

Replace if Necessary

Change Engine Oil √ √ √ √

Clean Air Filter

Replace if Necessary

Before

Each Use

√ √

After

Every

10 Hours

of Use

√ √

√ √

After

Every

25 Hours of

Use

√ √

√ √

√ √ √

√ √

After Every

50 Hours of

Use

After

Every

100 Hour

of Use

Before

Each

Season

Before

Storage

See

Note

Below

1

2,3

4

Replace Spark Plug √ √

Clean Combustion Deposits from

Cylinder, Piston, and Valves

CAUTION

IMPORTANT NOTES about Maintenance schedule

1. Re-check tightness of all fasteners after first 2 hours of initial use

2. Change engine oil after first 5-8 hours of initial use

3. Change oil every 25 hours

4. Clean air filter every 10 hours if operating under dusty conditions.

WARNING

Use only GENUINE replacement parts. Other parts may damage the unit or result in injury.

√

ENG - 17Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 18

Maintenance (Continued)

wire

tab

• Save all instructions

Servicing the Tiller

B

The following information will help you make the necessary

checks and perform the procedures required to follow the

normal care recommendations made for your tiller unit. If

you prefer, your local authorized dealer can make these

checks and perform the required procedures for you.

WARNING

To prevent accidental starting:

Engine must be turned off and cool, and spark plug wire

must be removed and secured from spark plug before

checking and adjusting engine or equipment.

CHANGE BELTS

1. Turn off engine. Engine must be cool completely before

proceeding.

2. Remove spark plug wire and secure from spark plug.

3. Remove the front belt cover.

• Remove the belt from the engine pulley:

- Remove the four engine plate-to-frame bolts.

- Slightly lift the engine and engine plate as an

assembly.

- Slide the belt free of the engine pulley.

- Remove the belt from the front pulley.

• Install new belt:

- Place belt around transmission pulley in groove.

- Place belt onto engine pulley in groove.

- Place backside of belt around idler pulley and belt

guides.

- Reinstall and tighten four engine plate bolts.

- Slowly pull engine rope and observe belt

movement to verify correct routing of belt.

- Reinstall front belt cover.

4. Attach spark plug wire.

5. Follow Operating Instructions- start the engine and

operate the clutch lever.

WARNING

The tines should not rotate with the engine running and the

drive lever not engaged.

Engine Maintenance

C

ENGINE MAINTENANCE

Refer to the engine manual included in your parts packet

for information on engine maintenance. Your engine

manual provides detailed information and a maintenance

schedule for performing the following tasks:

1. Check oil level before each use or after every 8 hours

of operation.

2. Change oil after first 5-8 hours of operation. Change oil

while engine is warm. Refill with new oil of

recommended grade.

3. Check spark plug yearly or every 25 hours of operation.

4. Service air cleaner.

5. Keep engine and parts clean.

6. Check engine and equipment often for loose nuts and

bolts, keep these items tightened.

CHECK OR FILL ENGINE CRANKCASE

IMPORTANT: Engine is shipped from factory without oil. You

must add engine oil before starting engine.

1. Add oil according to engine manual. Do not overfill.

Use a clean, high quality detergent oil. Do not mix oil

with gasoline. Oil level must be full. Check the oil level

by removing oil fill plug.

2. Always check oil level before starting engine. Refer to

engine manual for capacity and type of oil to use.

Maintenance

D

LUBRICATION

Proper lubrication of moving mechanical parts is critical for

proper care and maintenance. Oil the moving parts at 10

hour intervals using 30 weight oil.

CLEAN TINE AXLE SHAFT

1. Turn off engine. Engine must be cool.

2. Remove spark plug wire and secure from spark plug.

3. Tip the tiller backward. Block the tiller in position so that

it rests on the upper handle and the tines are exposed.

4. Remove all vegetation, string, wire, and other material

that may have accumulated on the axle between the

inside set of tines and the seal cover on the

transmission housing.

5. Tip the tiller back to a level position.

6. Replace spark plug wire.

ENG - 18Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 19

Maintenance (Continued)

• Save all instructions

How to Prepare for Storage

E

WARNING

Never store the tiller indoors with fuel in the fuel tank.

Never store in an enclosed, poorly ventilated area where

fumes could reach an open ame, a spark or a pilot light as

on a furnace, water heater or clothes dryer. Allow engine to

cool before storing unit.

WARNING

Do not remove gasoline while inside a building, near a re,

or while you smoke. Gasoline fumes can cause an explo-

sion or a re.

NOTE: A yearly checkup or tune-up at an authorized service

center will make sure that the tiller will provide maximum

performance for the next season.

When the tiller is put in storage for thirty days or more, the

following steps should be followed to make sure the tiller is in

good condition the next season.

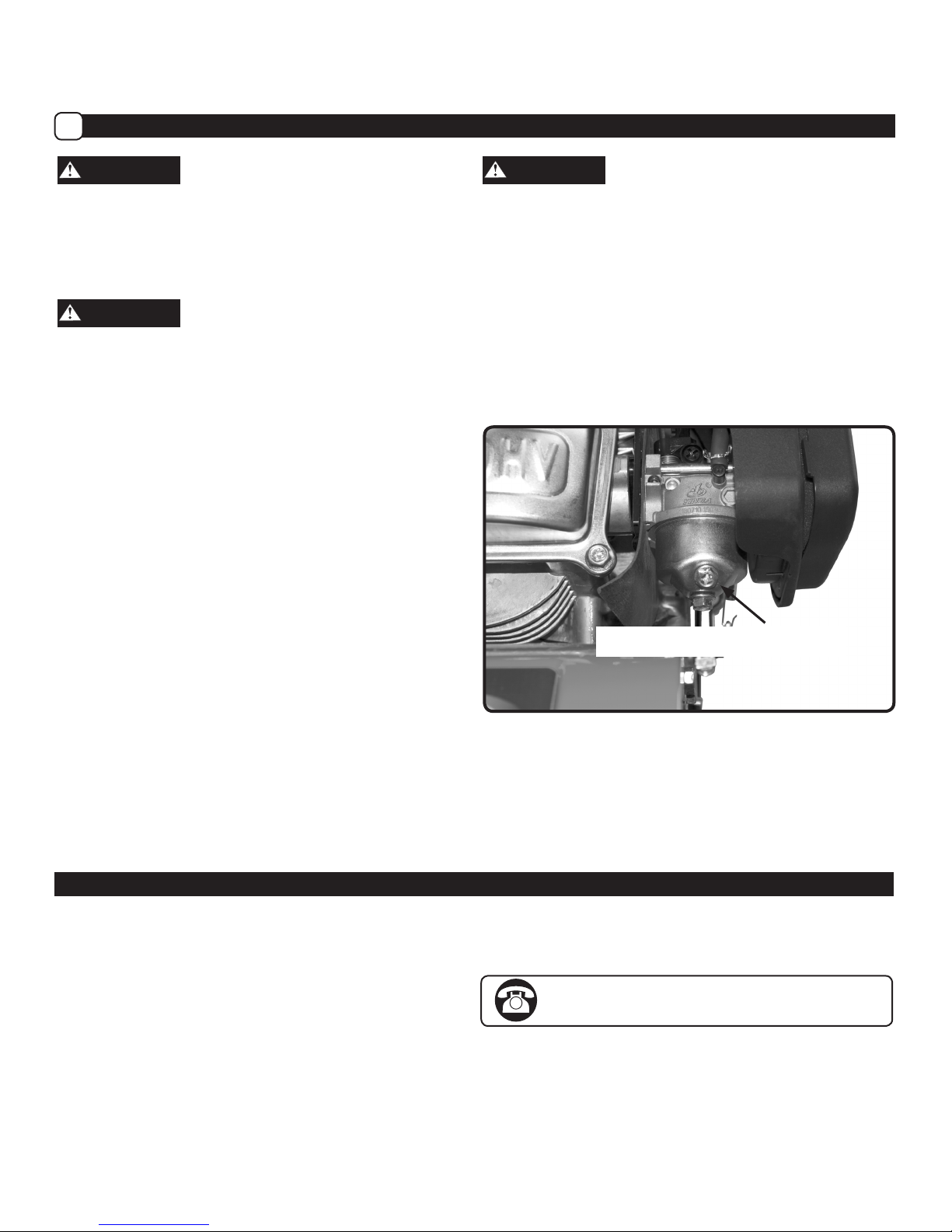

1. Let the engine run until it is out of gasoline. Remove

carburetor screw from bowl and drain fuel. Tilt unit

slightly to remove all fuel. Replace screw. (Figure 18)

2. Change the oil by following instructions under “How to

Change the Oil.”

3. Remove the spark plug from the cylinder. Pour one

ounce (1 oz liq. US / 30 ml) of oil into the cylinder.

Slowly pull the recoil-start handle so that the oil will

protect the cylinder. Install a new spark plug in the

cylinder. Pull starter handle slowly a few times to

distribute oil. Pull recoil handle slowly until resistance is

felt. This will close the cylinder valves.

WARNING

DO NOT attach spark plug wire to spark plug when

storing unit.

4. Clean tiller. Remove all dirt, leaves, debris, grease, etc.

from the tiller - including cylinder cooling fans, recoil

starter cover holes, under fuel tank, and under mufer.

5. Check the tiller for worn or damaged parts. Have

damaged parts replaced if necessary.

6. Tighten any loose hardware.

7. Apply lubrication as directed in Maintenance section.

8. Put the unit in a building that has good ventilation.

9. Cover the tiller with a breathing material.

Remove carburetor screw from

bowl and drain fuel. Replace screw.

Figure 18

Technical Service

You may have further questions about assembling, operating, or maintaining this TILLER. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

When contacting the Technical Service Department, have ready:

• Your Name

• Your Address

• Date Code on Product

• Your Phone Number

If you need assistance or have any questions, CALL

TOLL FREE: 1-800-737-2112.

ENG - 19Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 20

Troubleshooting

• Save all instructions

PROBLEM POSSIBLE CAUSE(S) SOLUTION(S)

Engine difficult to start 1. Out of fuel

2. Engine Switch Off

3. Engine is not primed

4. Spark plug wire disconnected

5. Fouled spark plug

6. Dirty Carburetor

7. Clogged air filter

8. Contaminated Fuel

Engine Problems

Engine smokes excessively

Engine runs very “rough”

Engine runs erratically

Engine cannot maintain full speed

Excessive vibration / noise 1. Loose parts

Tines will not rotate 1. Debris interfering with tines

Tines continue to rotate when

lever is not engaged

Engine will not stop Faulty switch Replace switch

Tines will not cut properly 1. Damaged or worn tines

Frequent engine stalling 1. Excessive tilling speed / depth

1. No Engine Oil

2. Engine oil not at proper level

3. Fouled spark plug

4. Clogged air filter

5. Contaminated Fuel

6. Carburetor out of adjustment

2. Engine problems (above)

2. Tines loose

3. Damaged drive belts

1. Damaged drive belts 1. Replace drive belts

2. Tines assembled incorrectly

2. Engine problems (above)

1. Add fresh fuel

2. Turn engine switch on

3. Push primer 3 times.

4. Attach spark plug wire to spark plug

5. Remove spark plug. Inspect. Replace if

necessary

6. Take unit to an authorized service center

for Carburetor cleaning

7. Remove and clean air filter

8. Drain fuel tank. Clean fuel tank. Fill with

fresh fuel

1. Add engine oil

2. Check engine oil. Add or drain engine oil if

necessary

3. Remove spark plug. Inspect. Replace if

necessary

4. Remove and clean air filter

5. Drain fuel tank. Clean fuel tank. Fill with

fresh fuel

6. Take unit to an authorized service center

for Carburetor adjustment

1. Tighten all fasteners

2. Refer to engine solutions (above)

1. Remove debris from around tines

2. Replace tine bolts and nuts

3. Replace drive belts

1. Replace tines

2. Refer to “Install the Tines” Section

1. Till at a moderate pace. Make multiple

passes.

2. Refer to engine solutions (above)

ENG - 20Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 21

Warranty

• Save all instructions

Powermate® ROTARY TILLER Limited Warranty

A

Always specify model number when contacting the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written

warranty. We make no other warranty, expressed or implied. MAT Engine Technologies, LLC warrants this Tiller and any parts thereof,

to be free from defects in material and workmanship for two years (90 days for commercial use or for reconditioned unit) from the date

of first purchase from an authorized dealer, provided that the product has been properly maintained and operated in accordance with

all applicable instructions. This warranty is extended only to the original retail purchaser. The bill of sales or proof of purchase must be

presented at the time a claim is made under this warranty. This warranty does not cover industrial or rental usage, nor does it apply to

parts that are not in original condition because of normal wear and tear, or parts that fail or become damaged as a result of misuse,

accident, lack of proper maintenance, tampering, or alteration. Exceptions to the standard warranty period would be normal wear items

such as cutting blades, string heads, earth auger blades, air filter, and spark plugs which are only covered for 60 days against defects

in material or workmanship. Travel, handling, transportation, and incidental costs associated with warranty repairs are not reimbursable under this warranty and are the responsibility of the owner. To the full extent allowed by the law of the jurisdiction that governs the

sale of the product, this express warranty excludes any and all other expressed warranties and limits the duration of any and all implied

warranties, including warranties of merchantability and fitness for a particular purpose to two years from the date of first purchase, and

MAT Engine Technologies, LLC’s liability is hereby limited to the purchase price of the product and MAT Engine Technologies, LLC

shall not be liable for any other damages whatsoever including indirect, incidental, or consequential damages. Some states do not allow limitation of how long an implied warranty lasts or an exclusion or limitation of incidental or consequential damages, so the above

limitation of damages may not apply to you. This warranty provides the original purchaser with specific rights.

For information regarding those rights, please consult the applicable state laws.

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL

60047

The Engine Emissions Control System Warranty is provided by the engine manufacturer, included with this product and administered by

MAT Engine Technologies, LLC.

If you have any questions regarding your warranty coverage,

you should contact METL customer service:

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

ENG - 21Questions? Call Toll Free at 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 22

Manuel de l’usager

Motobêche rotative

à dents avant

No. de modèle PFTT142

Retrouver à l’intérieur : Page

Définitions de sécurité 2

Importante information de sécurité 3-5

Spécifications du produit 6

Pièces et caractéristiques 6

Décalcomanies de sécurité 7

Assemblage 8-11

Préparation du moteur 12

Fonctionnement 13-16

Entretien 17-19

Service technique 19

Dépannage 20

Garantie 21

IMPORTANT :

Félicitations pour l’achat de votre motobêche Powermate®.

Ce manuel comprend les directives complètes pour assurer un fonctionnement et un entretien sécuritaires de votre

motobêche. Veuillez référer à ce manuel avant chaque usage de votre motobêche.

Veuillez noter les éléments suivants pour une référence future :

Code – Date de fabrication : __________

Date d’achat : Joignez une copie de votre reçu de caisse.

Numéro sans frais – service à la clientèle : 1-800-737-2112

Référez au site Web pour un manuel sous forme

électronique et un catalogue des pièces.

www.powermateoutdoor.com

AVERTISSEMENT

Les échappements de moteur, certains éléments constituants et certains composants de produit contiennent ou

émettent de produits chimiques reconnus par l’État de Californie pour causer le cancer, des anomalies congénitales ou

d’autres effets nuisibles sur la reproduction.

Si vous avez une question ou un problème...

AVERTISSEMENT - PROPOSITION 65 –CALIFORNIE

APPELEZ SANS FRAIS : 1-800-737-2112

CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE

06/10/2016 Imprimé en Chine A203398

Page 23

Définitions de sécurité

• Conservez ces directives

Symboles d’alerte de sécurité

Importante information de sécurité

Les symboles suivants sont utilisés sur le produit et dans ce manuel pour alerter l’opérateur de potentiels dangers

concernant la sécurité. Assurez-vous de les lire attentivement et de comprendre leur signification.

DANGER

AVERTISSEMENT

MISE EN GARDE

AVIS

Les symboles suivants peuvent se retrouver sur votre motobêche. Assurez-vous de les lire attentivement et de comprendre leur

signification.

Symboles d’avertissement de sécurité

Signale un AVERTISSEMENT, un DANGER

ou une MISE EN GARDE.

Veuillez lire le manuel de l’usager, avant de

faire fonctionner cet appareil. Le défaut de

suivre les directives pourrait provoquer de

sérieuses blessures.

Ne pas utiliser en présence d’enfants ou de

spectateurs.

Les dents rotatives peuvent causer de

sérieuses blessures. Maintenez les mains,

les pieds et les vêtements à l’écart.

Signale une situation imminente et dangereuse qui, si elle n’est pas évitée, entraînera la mort ou des

blessures graves.

Signale une situation potentiellement dangereuse susceptible, si elle n’est pas évitée, d’entraîner la mort

ou des blessures.graves.

Signale une situation potentiellement dangereuse susceptible, si elle n’est pas évitée, de causer des

blessures de mineures.

Indique une pratique qui n’est pas reliée à des blessures personnelles, mais qui, si elle n’est pas évitée,

peut entraîner des dommages matériels.

Débranchez le câble de bougie d’allumage

lorsqu’il n’est pas utilisé ou avant de

procéder à la réparation, au nettoyage ou à

l’entretien de cette unité.

Le gaz d’échappement contient du monoxyde

de carbone, un gaz inodore et mortel. Ne

JAMAIS faire fonctionner cette unité à

l’intérieur ou dans un espace mal ventilé.

Ne PAS toucher un tuyau d’échappement ou

un cylindre chaud. Ces pièces deviennent ex-

trêmement durant le fonctionnement et peuvent

demeurer ainsi pour une courte période de

temps après le fonctionnement.

Pour réduire le risque d’incendie, nettoyer

les déversements d’essence et d’huile et

maintenez l’unité libre de résidus. L’essence

est extrêmement inflammable. Laissez l’unité

refroidir avant de refaire le plein.

Symboles de contrôle et de fonctionnement

Emplacement de remplissage d’huile

Éviter un trop-plein. Ajoutez de l’huile

à moteur et vérifiez la quantité à cet

endroit.

CLUTCH

CONTROL

ENGAGE

DISENGAGE

Levier d‘embrayage

Le mouvement des dents s’engagera,

en soulevant le levier.

Ne pas utiliser d’essence contenant

plus de 10% d’éthanol.

Enfoncer l’ampoule d’amorce 3

fois avant de démarrer un moteur

froid.

Important : Pour démarrer un

FR - 2Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

moteur chaud, enfoncez une seule

fois.

Interrupteur de démarrage

Déplacer la position de

l’interrupteur pour démarrer/

arrêter le moteur

Placer la main libre sur le guidon

avant de tirer la poignée du

lanceur à rappel de l’autre main.

Page 24

Importante information de sécurité

• Conservez ces directives

RESPONSIBILITÉ DE PROPRIÉTAIRE

1. Veuillez lire et suivre cers directives de sécurité. Le défaut d’y adhérer pourrait provoquer de sérieuses blessures.

2. Apprenez à connaître votre produit. Veuillez lire et comprendre ce manuel avant l’usage. Comparez les illustrations

avec l’unité. Apprenez à connaître l’emplacement et le fonctionnement de tous les contrôles. De comprendre

complètement l’unité avant l’usage offrira plus de rendement et de sécurité.

3. Veuillez suivre toutes les directives lors de l’assemblage de l’unité. Si vous vous êtes procuré l’unité déjà assemblée,

l’opérateur doit vérifier l’unité attentivement pour s’assurer que celle-ci a été assemblée selon les directives du

manuel avant l’usage.

4. Vériez régulièrement la motobêche. Assurez-vous que les pièces ne sont pas repliées, endommagées ou desserrées.

5. N’utilisez cet appareil que pour l’objectif visé.

6. Faites fonctionner l’unité seulement lorsque les protecteurs et autres articles de sécurité sont bien en place et

fonctionnent adéquatement.

7. Réparez l’unité seulement avec des pièces autorisées ou approuvées.

8. Complétez tout l’entretien et les réglages de l’unité, selon les directives retrouvées dans ce manuel.

Recherchez ce symbole pour indiquer d’importantes mises en garde de sécurité. Il signifie : « Attention! Soyez attentif!

Votre sécurité est en jeu.»

AVERTISSEMENT

Les échappements de moteur, certains éléments constituants et certains composants de véhicule contiennent ou

émettent de produits chimiques reconnus par l’État de Californie pour causer le cancer, des anomalies congénitales ou

d’autres effets nuisibles sur la reproduction.

Importante information de sécurité

AVERTISSEMENT

Pour prévenir les mises en marche involontaires lors de la préparation, du transport, de réglages ou de réparations,

assurez-vous de toujours débrancher le câble de la bougie d’allumage et placez ce câble où il ne peut entrer en contact

avec la bougie.

SÉCURITÉ DURANT LA PRÉPARATION

AVERTISSEMENT

• Lisez, comprenez et suivez toutes les directives sur cet appareil et dans ce manuel. Familiarisez-vous complètement

avec les contrôles et l’usage approprié de la débrousailleuse avant de commencer. Apprenez à arrêter le moteur rapidement.

• Familiarisez-vous avec toutes les décalcomanies de sécurité et de fonctionnement sur cet appareil.

• Inspectez minutieusement l’espace où la débrousailleuse sera utilisée et retirez tous les corps étrangers. Votre appareil

peut projeter de petits objets à haute vitesse, pouvant provoquer des blessures ou des dommages matériels. Tenez-vous

loin d’objets cassants, tels : fenêtres de maison, vitres d’auto, serres, etc.

• Vérifiez que le levier de contrôle fonctionne adéquatement. Assurez-vous que le câble est libre et que le levier de

contrôle n’est pas endommagé.

SÉCURITÉ DURANT L’USAGE

• Ne permettez jamais à des enfants ou à de jeunes adolescents d’utiliser la motobêche.

AVERTISSEMENT

• Maintenez l’espace de travail exempt de spectateurs, surtout de jeunes enfants et d’animaux.

• Ne permettez qu’à des personnes responsables et familières avec les directives de faire fonctionner la motobêche.

• N’utilisez pas la motobêche lorsque sous l’influence d’alcool, drogues ou autre médication pouvant provoquer de la

somnolence ou affecter votre capacité à opérer cet appareil en toute sécurité.

• N’utilisez pas cet appareil si vous êtes mentalement ou physiquement inapte à opérer cet appareil en toute sécurité.

• En utilisant la motobêche, portez toujours des lunettes de sécurité conformes à ANSI ou des lunettes de sécurité

avec protecteurs latéraux, pour protéger vos yeux de corps étrangers pouvant être projetés de l’unité.

• Portez toujours des vêtements appropriés tels, une chemise à manches longues ou un gilet. Ne portez PAS de

culottes courtes. Ne portez PAS de vêtements amples, pouvant s’entremêler dans l’appareil.

FR - 3Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 25

Importante information de sécurité (Suite)

• Conservez ces directives

• Portez toujours des gants de travail et de robustes souliers, tels de bottes de travail en cuir ou des bottes courtes.

Importante information de sécurité

Ceux-ci protégeront les chevilles et le bas des jambes contre les petits morceaux de branchage, les éclats de

bois et autres débris volants et améliorera la traction.

• Il est recommandé de porter un casque protecteur pour protéger contre les petites particules volantes ou d’être heurté

par des branches basses ou autres objets passant inaperçus aux yeux de l’opérateur.

• Ne placez pas vos mains ni vos pieds près ou sous les pièces rotatives.

• Faites preuve d’extrême précaution durant le fonctionnement ou en traversant des entrées, passages ou chemins de

gravillons. Demeurez vigilants pour reconnaître les dangers cachés ou le trafic.

• Faites preuve de prudence pour éviter de glisser ou de tomber. Assurez-vous de votre stabilité; maintenez une bonne

prise sur le guidon et marchez; ne courez jamais. N’opérez jamais la motobêche à haute vitesse sur des surfaces

glissantes.

• N’utilisez jamais la motobêche sans avoir une bonne visibilité ou une bonne lumière.

DANGER

• Ne faites pas fonctionner le moteur à l’intérieur ou dans un espace fermé. Les gaz d’échappement sont dangereux et

contiennent du MONOXYDE DE CARBONE, un GAZ INODORE ET MORTEL.

• Ne laissez jamais la motobêche sans surveillance pendant que le moteur tourne. Arrêtez le moteur et assurez-vous

que toutes les pièces mobiles sont arrêtées. Débranchez le câble de la bougie d’allumage.

• Ouvrez l’œil pour la présence de trous, d’ornières, de buttes ou toute autre dénivellation de terrain. Les herbes hautes

peuvent cacher des obstacles.

• Regardez toujours derrière et vers le bas et usez de prudence en mode de marche arrière ou lorsque vous tirez la

motobêche vers vous.

• N’essayez jamais de démarrer la motobêche, à moins que les deux roues ne soient en position bloquée. Cette

méthode agit comme un frein pour la motobêche. Faites toujours démarrer la motobêche sur une surface unie.

AVERTISSEMENT

• Désengagez le levier d’embrayage et arrêtez le moteur, avant de laisser la motobêche en position de marche.

Attendez que les dents soient complètement arrêtées, avant de retirer des débris ou de faire quelque réglage à

la motobêche.

• Ne tentez pas de labourer un sol dur, ni de labourer trop profondément, ni de labourer à un rythme trop rapide,

pouvant surcharger la motobêche.

• Si la motobêche commence à vibrer de façon anormale, arrêtez le moteur, débranchez le câble de la bougie

d’allumage et assurez-vous qu’il n’entre pas en contact avec la bougie. Vérifiez immédiatement la cause.

Normalement une vibration représente un avertissement de problème.

SÉCURITÉ DE COMBUSTIBLE

AVERTISSEMENT

• L’essence est extrêmement inflammable et les vapeurs d’essence peuvent exploser si allumées. Manipulez avec soin.

• Utilisez un récipient approuvé.

• Vérifiez l’alimentation en combustible avant chaque usage, en laissant de l’espace pour l’expansion, car la chaleur du

moteur et /ou du soleil peut provoquer une expansion du combustible.

• Remplissez le réservoir de combustible à l’extérieur avec un soin extrême. Ne jamais remplir le réservoir de combustible

à l’intérieur.

• Ne jamais retirer le bouchon du réservoir de combustible, ni ajouter de combustible lorsque le moteur est en marche.

Laissez le moteur refroidir durant un minimum de 2 minutes, avant un ravitaillement.

• Ne fumez pas durant un ravitaillement.

• Après un ravitaillement, replacez fermement en place le bouchon du réservoir de combustible et essuyez tout

déversement de combustible.

• Ne rangez jamais de combustible ou le motobêche avec du combustible dans le réservoir dans un édifice où les

vapeurs pourraient rejoindre une flamme nue.

• Never fill gasoline containers or the tiller fuel tank inside of a vehicle or in a truck bed. Accidental electrical static dis

charge can ignite fuel vapors which could result in serious injury or death.

FR - 4Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 26

Importante information de sécurité (Suite)

• Conservez ces directives

SÉCURITÉ DE RANGEMENT

• Référez toujours aux directives énoncées dans le mode d’emploi relativement aux détails importants, si la motobêche

est entreposée durant une longue période de temps.

• N’entreposez jamais la motobêche avec de l’essence dans le réservoir, dans un édifice où pourraient se trouver des

sources d’ignition, telles que : chauffe-eau, chaufferette, sécheuse de linge, etc.

• Pour réduire les dangers d’incendie, maintenez le motobêche libre d’une accumulation de gazon, feuilles ou autres débris.

• Laissez le moteur refroidir avant de ranger l’unité dans tout espace fermé.

SÉCURITÉ POUR RÉPARATIONS, ENTRETIEN ET RÉGLAGES

• Après avoir frappé un objet, arrêtez le moteur. Débranchez le câble de la bougie d’allumage et placez-le où il ne peut

entrer en contact avec la bougie, pour prévenir les mises en marche involontaires. Vérifiez soigneusement la moto

bêche, pour détecter tout dommage. En présence de dommages, assurez-vous de faire réparer l’unité par un

technicien formé, avant de redémarrer et de réutiliser l’unité.

AVERTISSEMENT

• Arrêtez le moteur avant de procéder au nettoyage, à l’inspection ou à des réparations de l’unité. Assurez-vous que

toutes les pièces sont immobiles. Laissez refroidir le moteur, débranchez le câble de la bougie d’allumage et placez-le

où il ne peut entrer en contact avec la bougie.

• Ne tentez jamais de procéder à des réglages, lorsque l’unité fonctionne, sauf lorsque spécifiquement recommandé

par le fabricant.

• Maintenez la motobêche en condition sécuritaire de fonctionnement. Vérifiez toutes les attaches à intervalles fréquentes

pour assurer un serrage approprié.

• Lors de réparations ou d’entretien à la motobêche, ne basculez pas l’unité, à moins d’être spécifiquement instruit de

le faire dans le manuel. Les procédures de réparations ou d’entretien peuvent être exécutées lorsque la motobêche

est position usuelle. Certaines procédures seront plus faciles à exécuter, lorsque l’unité est soulevée sur une

plate-forme ou une surface de travail surélevée.

• Utilisez uniquement de l’équipement original ou des pièces de remplacement autorisées.

• Ne trafiquez jamais des dispositifs de sécurité. Vérifiez leur fonctionnement approprié de façon régulière.

• Ne changez pas la configuration du moteur; ne procédez pas à un réglage de surrégime de moteur.

• Nettoyez et remplacez les décalcomanies de sécurité et de directives, selon le besoin.

• Pour protéger contre la surchauffe du moteur, assurez-vous que le filtre à débris est propre et en place.

Importante information de sécurité

SÉCURITÉ DES ENFANTS

AVERTISSEMENT

• Des accidents tragiques peuvent survenir si l’opérateur n’est pas vigilant à la présence d’enfants. Les enfants sont

souvent attirés par le motobêche et le travail accompli.

• Maintenez les enfants à l’écart de la zone de travail et sous la surveillance d’un adulte responsable.

• Ne présumez jamais que les enfants demeureront à l’endroit où vous les avez vus la dernière fois.

• Soyez vigilant et arrêtez la motobêche à l’approche d’enfants dans la zone de travail.

• Avant et pendant que vous reculez, regardez derrière et vers le sol pour détecter la présence d’enfants.

• Ne permettez jamais à des enfants d’utiliser la motobêche.

• Soyez particulièrement prudent en utilisant l’unité près d’angles morts, arbustes, arbres ou autres objets pouvant

bloquer votre vision.

FR - 5Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 27

Spécifications du produit

• Conservez ces directives

Poids de l’unité . . . . . . . . . . . . . . . . . . . . . . . . .40 kg (89 lb)

Largeur de labourage . . . . . . . . . . Jusqu’à 53,3 cm (21 po)

Profondeurs de labourage . . . . . . . .Jusqu’à 20,3 cm (8 po)

Diamètre de dent . . . . . . . . . . . . . . . . . . . . . 27,9 cm (11 po)

Type d’essence . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Régulière sans plomb – indice d’octane 87 (min.)

Capacité d’essence . . . . . . . . . . . . . . . . 1litre (2.1 pinte US)

Type d’huile (API SG-SL) . . . . . 10W-30 est recommandée

pour toutes les températures de service.

Voir page 11 pour plus d’information.

Capacité d’huile moteur. . . . . . . . . . . 450 ml (15 1/2 oz US)

Type de moteur ............4 temps, à soupapes en tête

Cylindrée du moteur . . . . . . . . . . . . . . . . . . . . . . . . . 150 cc

Vitesse de moteur ................. 3400 tours / minute

Couple nominal ...... Couple brut de 7.79 Nm / 5.75 pi-lb

(Selon SAE J1940)

Jeu – Soupape d’admission . . . . . . . . . . . . . . . . . . . . . . . . .

0.006-0.08in. (0.15 -0.20 mm)

Jeu – Soupape d’échappement . . . . . . . . . . . . . . . . . . . . . .

0.006-0.008 in. (0.15-0.20 mm)

Écartement d’électrode – Bougie d’allumage . . 0.020-0.028

Modèle de bougie d’allumage . . . .Torch K7RTC (Champion

Grandeur de roue . . . . . . . . . . . . . . . . . . . 16,5 cm (6.5 po)

RÉFÉREZ AU MANUEL DU MOTEUR POUR OBTENIR LES SPÉCIFICATIONS DÉTAILLÉES DU MOTEUR.

Pièces et caractéristiques

1. Dents

2. Support de la tourelle

3. Roues

4. Silencieux

5. Filtre à air

6. Poignée de lanceur à rappel

7. Bougie d’allumage/Câble de bougie d’allumage

8. Barre de recouvrement

9. Ampoule d’amorce

10. Capuchon de réservoir d’essence

11. Jauge d’huile graduée

12. Levier d’embrayage

13. Protecteur de dents

14. Protecteur de dents extérieures

11

7

4

14

13

6

10

in. (0.5-0.7 mm)

C7YCC)

12

9

5

2

8

3

1

Figure 1

FR - 6Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 28

Décalcomanies de sécurité

• Conservez ces directives

Cette motobêche a été conçue et fabriquée pour vous offrir

la sécurité et la abilité à laquelle vous attendez, de la part

d’un chef de le industriel dans le domaine de la fabrication

d’équipement extérieur motorisé.

Même si la lecture de ce manuel et les directives de securité

qu’il contient vous procurera les connaissances de base pour

assurer le fonctionnement sécuritaire et efcace de cet appa-

reil, nous avons disposé plusieurs étiquettes de sécurité sur

la motobêche, pour rappeler ces renseignements importants

à l’usage de cet appareil.

Ces importantes étiquettes de sécurité sont illustrées pour

vous aider à vous familiariser avec l‘emplacement et le contenu des messages de sécurité vus durant les travaux normaux de labourage. Veuillez consulter ces étiquettes mainten-

ant. Si vous avez des questions quant à leur signication ou à

la façon de respecter des directives, lisez à nouveau le texte

complet des directives de sécurité des pages précédentes ou

contactez votre détaillant local.

Si jamais ces étiquettes devenaient illisibles parce qu’elles

sont usées, décolorées ou endommagées de quelque

façon, contactez votre détaillant autorisé local pour commander des étiquettes de remplacement.

Il est facile d’appliquer ces étiquettes de sécurité et elles

sauront agir comme constants rappels visuels pour vous et

tous les autres usagers de cet appareil. Suivre ces directives de sécurité est nécessaire pour assurer un fonc-

tionnement sécuritaire et efcace de votre motobêche.

• Gasoline is flammable. Allow engine to cool at least 2 minutes

before refueling.

• Operation of this equipment may create sparks that can start

fires around dry vegetation. A spark arrestor may be required.

The operator should contact local fire agencies for laws or

regulations relating to fire prevention requirements.

FR - 7Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 29

Assemblage

• Conservez ces directives

Veuillez lire et suivre les directives d’assemblage. Ne jetez aucune pièce ou matériaux jusqu’à ce que l’assemblage ne soit

complété. Les références faites à la droite ou à la gauche de la motobêche représentent le point de vue de la position de

l’opérateur, lorsqu’il est placé derrière la motobêche.

AVERTISSEMENT

-N’utilisez pas la motobêche si celle-ci est endommagée ou n’est pas complètement ou correctement assemblée.

-Avant de procéder à l’assemblage ou à l’entretien de l’unité, retirez le câble de la bougie d’allumage.

-Lors de l’assemblage de la motobêche, portez toujours des lunettes de sécurité conformes à ANSI avec protecteurs latéraux.

Vous trouverez les composants suivants dans la boîte.

Les quantités sont indiquées dans les ( ).

1. (1) Motobêche

2. (1) Assemblage de guidon supérieur

3. (1) Guidon inférieur

4. (4) Dents

5. (2) Roues

6. (1) Barre de recouvrement

7. (2) Protecteurs de dents extérieures

8. (1) Mode d’emploi de la motobêche

9. (1) Manuel du moteur

10. (1) Bouteille d’huile à moteur

11. (1) Sac de pièces contenant les articles suivants :

a. (4) Boulons m10 x 25 mm, rondelles plates et contre-écrous pour assembler le guidon inférieur.

b. (4) Boulons de selle m8 x 25 mm et rondelles plates pour assembler le guidon superieur au guidon inferieur

c. (4) Boutons de guidon, pour le guidon superieur et le guidon inferieur.

d. (2) M8 x 30 mm bolts, washers and locknuts for installing wheel axle

e. (2) boulons M10 x 50 mm, (4) rondelles plates et (2) contre-écrous M10 pour assembler les dents intérieures.

f. (1) Cheville, rondelle plate et goupille pour la barre de recouvrement.

g. (6) Boulons m6 x 16, contre-ecrous et rondelles plates pour installer les protecteurs de dents exterieures.

h. (1) Guide de corde avec ecrou nylock

i. (1) Attaches

Si vous avez besoin d’assistance ou devez trouver des pièces

manquantes, APPELEZ SANS FRAIS : 1-800-737-2112.

Comment retirer la motobêche de la boîte

A

1. Retirez toutes les pièces et les composants d’emballage.

2. Utilisez un couteau universel pour couper les 4 rebords verticaux et de déposer les panneaux latéraux à plat autour

de la motobêche.

3. Retirez tout l’excédent d’emballage.

FR - 8Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 30

Assemblage (Suite)

• Conservez ces directives

Directives d’assemblage

B

La motobêche est livrée préassemblée, sauf pour quelques pièces. Les directives suivantes vous aideront à compléter l’assemblage

de la motobêche.

FIXEZ L’ASSEMBLAGE DES

ROUES À LA STRUCTURE

1. Installez l’assemblage des roues

à la structure, en retirant la

goupille et la rondelle plate de

l’une des extrémités de la tige

de pivot. Retirez la tige. Alignez

les orices du pivot de

l’assemblage des roues

aux orices dans la structure.

Installez la tige de pivot et

xez-la en place, en réinstallant

la rondelle plate et la goupille.

Si vous avez besoin d’assistance ou devez trouver des pièces

manquantes, APPELEZ SANS FRAIS : 1-800-737-2112.

Figure 2

Sharp edge of tine should face down to the ground.

INSTALLEZ LA BARRE DE

RECOUVREMENT (Voir Illust.4)

1. Insérez la barre de

recouvrement dans la partie

inferieure de l’assemblage

du support des roues.

2. Insérez la goupille dans

le support et le trou du

milieu de la barre de

traînée et le fixer avec la

rondelle plate et la

goupille fendue.

Figure 3

NSTALLEZ LES DENTS (Voir Illust.3)

1. Glissez les dents sur l’essieu des dents. Installez les

dents intérieures en premier. Le rebord coupant des

dents avant et supérieures devrait être dirigé vers le bas

et vers l’avant pour labourer le sol. Resserrez le boulon

M8 x 50 avec le contre-écrou, pour bien fixer en place

les dents intérieures.

2. Pour un labourage large de 53, 3 cm / 21 po, installez

les dents extérieures de telle façon à ce que la partie

longue de la tubulure soit dirigée vers les dents

intérieures. Pour un labourage étroit de 40,6 cm /

16 po, installez les dents extérieures de telle façon à

ce que la partie courte de la tubulure soit dirigée vers

les dents intérieures.

3. Resserrez le boulon M8 x 50 à l’aide du contre-écrou

fourni, pour fixer les dents extérieures.

Figure 4

FR - 9Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 31

Assemblage (Suite)

• Conservez ces directives

Si vous avez besoin d’assistance ou devez trouver des pièces

manquantes, APPELEZ SANS FRAIS : 1-800-737-2112.

INSTALLEZ LE GUIDON INFÉRIEUR (Voir Illust. 5)

1. Alignez les orifices du guidon inférieur aux

orifices respectifs dans la structure et

sans les resserrer, installez deux boulons

m10 x 25 mm, rondelles de blocage et

rondelles plates de chaque côté.

2. À l’aide d’une clé, resserrez fermement les

boulons de chaque côté.

Figure 5

INSTALLEZ LE GUIDON SUPÉRIEUR (Voir Illust. 6,7)

1. Glissez le guidon supérieur sur le guidon inféri

eur et alignez les orices.

2. Insérez la boulons de selle dans les orices tel

qu’illustré et xez-les en place à l’aide des bou

tons de guidons.

3. Resserrez fermement les boutons de guidons.

4. L’utilisation d’un collier de serrage, xer le câble

de commande à la poignée comme indiqué.

INSTALLEZ LES PROTECTEURS DE DENTS

EXTÉRIEURES (Voir Illust.8)

1. Chaque protecteur de dents extérieures peut être

installé de n’importe quel côté du protecteur principal

de dents.

2. Placez le protecteur de dents extérieures

en-dessous du protecteur principal de dents et

alignez les orifices.

3. Fixez chaque protecteur de dents extérieures au

protecteur principal de dents, à l’aide de (3) boulons

m6 x 16, rondelles et contre-écrous.

Figure 2

Figure 8

Figure 6

Figure 7

FR - 10Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2016 MAT Engine Technologies, LLC

Page 32

Assemblage (Suite)