Page 1

Look inside for:

Page

Safety Definitions 1

Important Safety Information 2-3

Product Specifications 4

Parts & Features 4

Assembly 5-6

Operation 7-8

Maintenance 9

Storage 9

Troubleshooting 10

Technical Service 10

Warranty 1

1-16

Spanish 18-33

12/16/2010 Printed in China A201016

Operator’s Manual

GASOLINE POWERED CULTIVATOR

43cc, 2 Cycle

IMPORTANT:

Thank you for purchasing this Powermate® Cultivator.

Read and understand all warnings and instructions in this manual before using this machine. Improper use of equipment

can cause severe injury or death. Keep this manual for future reference.

Record the following for future reference:

Mfg. Date Code : _________________

Date of Purchase: Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

KEEP THIS MANUAL FOR FUTURE REFERENCE

MODEL No.S

PCV43

PCVR43

For Occasional Use Only

If you have a question or problem...

CALL TOLL FREE: 1-800-737-2112

Refer to the website for electronic manual and parts book.

www.powermate.com

Page 2

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

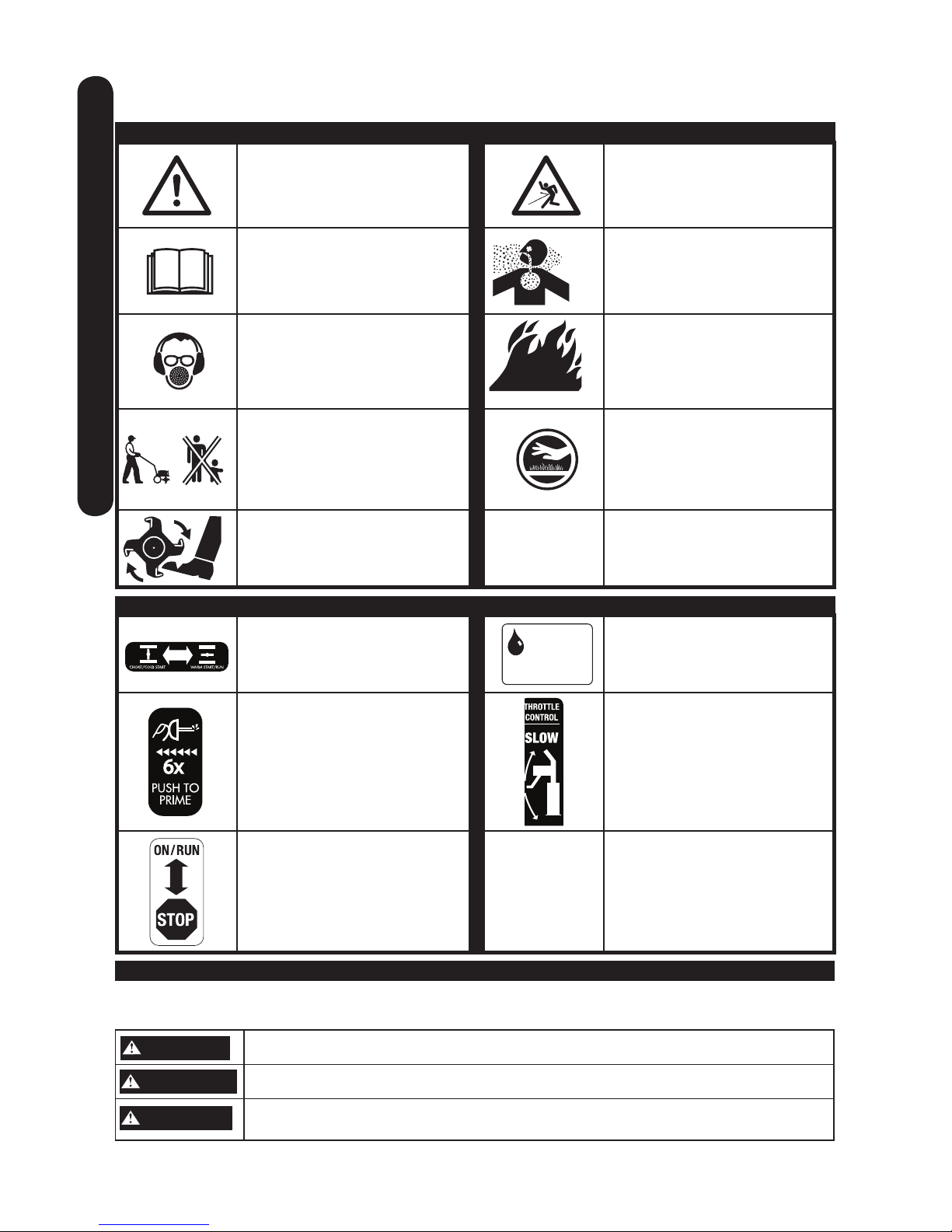

Indicates WARNING, DANGER, or

CAUTION.

This equipment can throw small objects

at high speed causing personal injury.

Inspect area where used and remove

all foreign objects.

Read operator’s manual before

operating this machine. Failure to

follow directions could result in serious

injury.

Engine exhaust contains carbon

monoxide, an odorless and deadly gas.

NEVER run unit indoors or in a poorly

ventilated area.

Always wear eye protection that meets or

exceeds the requirements of ANSI Z87.1.

Wear hearing protection.

Wear breathing protection.

To reduce risk of fire, clean spilled gas

and oil and keep unit free from debris.

Gasoline is extremely flammable. Allow

machine to cool completely before

refueling.

Do not use if children or bystanders

are present.

Extremely hot surface. Do not touch

a hot muffler, gear box or cylinder,

you may get burned. These parts get

extremely hot from operation and

remain hot for a short time after the unit

is turned off.

Keep hands, feet, and clothing away

from rotating tines. Contact with

rotating tines may result in serious

injury.

Safety Definitions

• Save all instructions

Safety Warning Symbols:

Control and Operating Symbols:

Choke Control:

Run/Warm Start

Choke/Cold Start

Fuel Mixture

40:1

Unleaded Gas: 2 Cycle Oil

Caution: Do Not Use Gas

Mix with More Than 10%

Methanol or Ethanol

Fuel Mixture:

40:1

(Unleaded Gas : 2 Cycle Oil)

Fuel Primer:

Press 6 times.

Throttle Control:

SLOW

FAST

Ignition Switch:

ON/RUN

OFF/STOP

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury

or equipment/property damage

DANGER

CAUTION

WARNING

The information listed below should be read and understood by the operator. We utilize the symbols below to allow the

reader to recognize important information about their safety.

Safety Alert Symbols

1

Important Safety Information

Page 3

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC 2

Before Operating Cultivator

1. READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE OPERATING CULTIVATOR. Be thoroughly familiar with

the controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

WARNING

Read and follow all warnings and safety instructions. Failure to do so can result in serious injury to you or bystanders.

2. Avoid Dangerous Environments

a. Do not operate cultivator while under the influence of alcohol, medications, or drugs.

b. Do not operate cultivator when you are tired.

c. Do not use this cultivator if you are mentally or physically unable to operate safely.

3. Inspect cultivator for damaged parts, and make sure all fasteners and guards are in place and secure. Replace any

damaged parts.

4. Dress properly when operating cultivator.

a. Always wear heavy long pants, boots, gloves, and a long-sleeve shirt.

b. Do not wear loose clothing or jewelry that can get caught in the moving parts of the cultivator.

c. Always wear gloves and substantial foot wear when working outside.

d. Always wear protective hair covering to contain long hair.

5. Always wear a face or dust mask if operation is dusty.

6. Always wear eye protection that meets or exceeds the requirements of ANSI Z87.1.

7. Always wear hearing protection which meets or exceeds ANSI standards.

8. Thoroughly inspect the area where the cultivator is to be used and remove all foreign objects.

9. Keep the area of operation clear of all persons, particularly small children, and pets.

WARNING

Your equipment can throw small objects at high speed causing personal injury or property damage.

10. Never allow children to operate the equipment. Never allow adults to operate the equipment without proper

instruction.

11. Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property,

and themselves.

WARNING

Engine exhaust from this product contains chemicals known to the State of California to cause cancer or birth defects, or

other reproductive harm.

Important Safety Information

• Save all instructions

While Operating Cultivator

1. Stay alert. Use common sense. Watch what you are doing.

2. Do not operate cultivator if it is damaged or not securely and fully assembled.

3. Never operate the cultivator without good visibility or light.

4. Never operate the machine without proper guards, plates, or other safety protective devices in place.

5. Keep all part of your body away from the rotating tines. Do not put hands or feet near or under rotating parts.

6. Keep children and pets away.

7. Use only for jobs explained in this manual. Do not use cultivator for any job except that for which it is intended.

8. Maintain your balance and proper footing at all times. Do not overload the machine capacity by attempting to till too deep.

9. After striking a foreign object, stop the engine, remove the wire from spark plug, thoroughly inspect the machine for

any damage, and repair the damage before restarting and operating the machine.

10. Never leave the machine unattended. Stop the engine when leaving the operating position.

11. Stop the engine before unclogging the tines, and when making any repairs, adjustments, and inspections.

12. Be careful when tilling in hard ground. The tines may catch in the ground and propel the cultivator forward. If this

occurs, let go of the handles and do not restrain the machine.

13. Use extreme caution when reversing or pulling the machine towards you.

14. Do not force cultivator. It will do the job better and with less likelihood of a risk of injury at the rate for which it was

designed.

DANGER

Never start or run the unit inside a closed room or building; breathing exhaust fumes can kill.

16. Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards

or traffic.

17. Exercise caution to avoid slipping or falling.

18. If the unit should start to vibrate abnormally, stop the engine and check immediately for the cause. Vibration is generally

a warning sign of trouble.

19. Never operate the machine at high transport speeds on hard or slippery surfaces.

20. Start the engine carefully according to instructions and with feet well away from the tines.

21. Never pick up or carry a machine while the engine is running.

Important Safety Information

Important Safety Information

Page 4

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Important Safety Information (Continued)

• Save all instructions

3

While Operating Cultivator (cont.)

CAUTION

Prolonged exposure to vibrations through use of gasoline powered hand tools could cause blood vessel or nerve damage

in fingers, hands, and joints of people prone to circulation disorders or abnormal swellings. Extensive use in cold weather

has been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of

strength, change in skin color or texture, or loss of feeling in the fingers, hands, or joints, discontinue the use of this tool

and seek medical attention.

Fuel Safety

1. Mix and pour fuel outdoors WHERE THERE ARE NO SPARKS OR FLAMES.

2. Use a container approved for gasoline.

3. Do not smoke or allow smoking near fuel or the cultivator.

4. Avoid spilling fuel or oil. Wipe up all fuel spills.

5. Move at least 10 feet (3 meters) away from fueling site before starting engine. Do not refuel a hot engine. Do not refuel

a running engine.

6. Stop engine and allow to cool before removing fuel cap. Remove fuel cap slowly.

7. Never store engine with fuel in the tank indoors. Fuel and fuel vapors are highly flammable.

8. Replace all fuel tank and container caps securely.

Maintenance & Storage of Cultivator

1. Stop the engine, and disconnect the spark plug before servicing, cleaning, or performing maintenance on the unit.

Never attempt to make any adjustments while the engine is running.

2. Maintain cultivator with care. Inspect cultivator periodically. Keep machine, attachments, and accessories in safe

working condition. If cultivator is not working properly or damaged, have it repaired by a qualified service center.

3. Check for misalignment of moving parts, binding of moving parts, broken parts, and any other condition that may affect

its operation. Check shear bolts, engine mounting bolts, and other bolts at frequent intervals for proper tightness to be

sure the equipment is in safe working condition.

4. Keep guards in place and in working order.

5. A guard or other part that is damaged should be properly repaired or replaced by a qualified service center.

6. Use only genuine Powermate® replacement parts and accessories. Use of any non-Powermate® parts or

accessories could lead to injury, damage the unit, and void your warranty.

7. Do not remove or modify any parts. Removing or modifying parts could lead to injury, damage the machine and will

void the warranty.

8. Keep handles dry, clean, and free from oil and grease.

9. Allow engine to cool and empty the fuel tank before storing or transporting in vehicle. Use up remaining fuel in the

carburetor by starting the engine and letting it run until it stops. If the fuel tank has to be drained, do it outdoors.

10. When not in use, store cultivator indoors in a dry location. Store cultivator above the reach of children or in a locked

area out of the reach of children.

11. Store unit and fuel in area where fuel vapors cannot reach sparks or open flames from water heaters, electric motors

or switches, furnaces, etc.

12. Always refer to the operator’s manual for important details if the cultivator is to be stored for an extended period.

13. Follow manufacturer’s recommendations for safe loading, unloading, transport, and storage of machine.

Important Safety Information

Page 5

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Engine .................... 43 cc, 2 cycle, Full-Crank

Idle Speed ....................... 2,800-3,000 RPM

Tilling Width ................................ 7”-10”

Tilling Depth .............................. Up to 5”

Fuel Tank Capacity.................... 28 oz (840 ml)

Fuel Type .......

Unleaded Gasoline – 87 Octane or higher

2-Cycle Oil Type........

2-Cycle Oil that meets or exceeds

. . . . . . . . . . . . . . . . . . . . . . . . . . .

JASO – FC Specifications

Fuel Mixture ................

40:1 (Gasoline: 2-Cycle Oil)

Spark Plug ................. NHSP LD L6, NGK BM6A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CHAMPION - CJ8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . or equivalent

Net Weight ...........................33 lbs (15 kg)

Product Specifications

• Save all instructions

Parts & Features

4

6

5

4

2

8

1

3

15

1. Ignition Switch 7. Tines 13. Air Filter Cover

2. Upper Handle 8. Recoil Starter Handle 14. Throttle Trigger

3. Middle Handle 9. Fuel Tank 15. Muffler

4. Lower Handle 10. Spark Plug 16. Drag Stake

5. Front Carry Handle 11. Fuel Primer Bulb 17. Detent Pin

6. Engine 12. Choke 18. Transport Wheels

9

7

14

18

11

12

13

16

17

10

Page 6

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Parts Included with Cultivator

• Middle Handle (1)

• Upper Handles (2)

• Wing nuts and bolts (4 ea.)

• Spark Plug Wrench & Rod (1)

• Cable Ties (3)

• Operator’s Manual (1)

• 3.2 oz bottle of 2-Cycle engine oil (1)

* Wrench (1)

Do not operate cultivator if it is damaged or not securely and fully assembled.

If you need assistance or find any parts

missing, CALL TOLL FREE: 1-800–737-2112

Assembly

• Save all instructions

5

WARNING

How to Unpack Cultivator from Carton

1. Remove all parts and packing components.

2. Use a utility knife to cut all 4 vertical edges. Lay the side panels flat around the cultivator.

3. Remove inner components and packaging.

CAUTION

Use care when removing parts not to damage any cables or wires that are attached to the parts.

4. Roll the unit out from the carton, and place on a hard level surface.

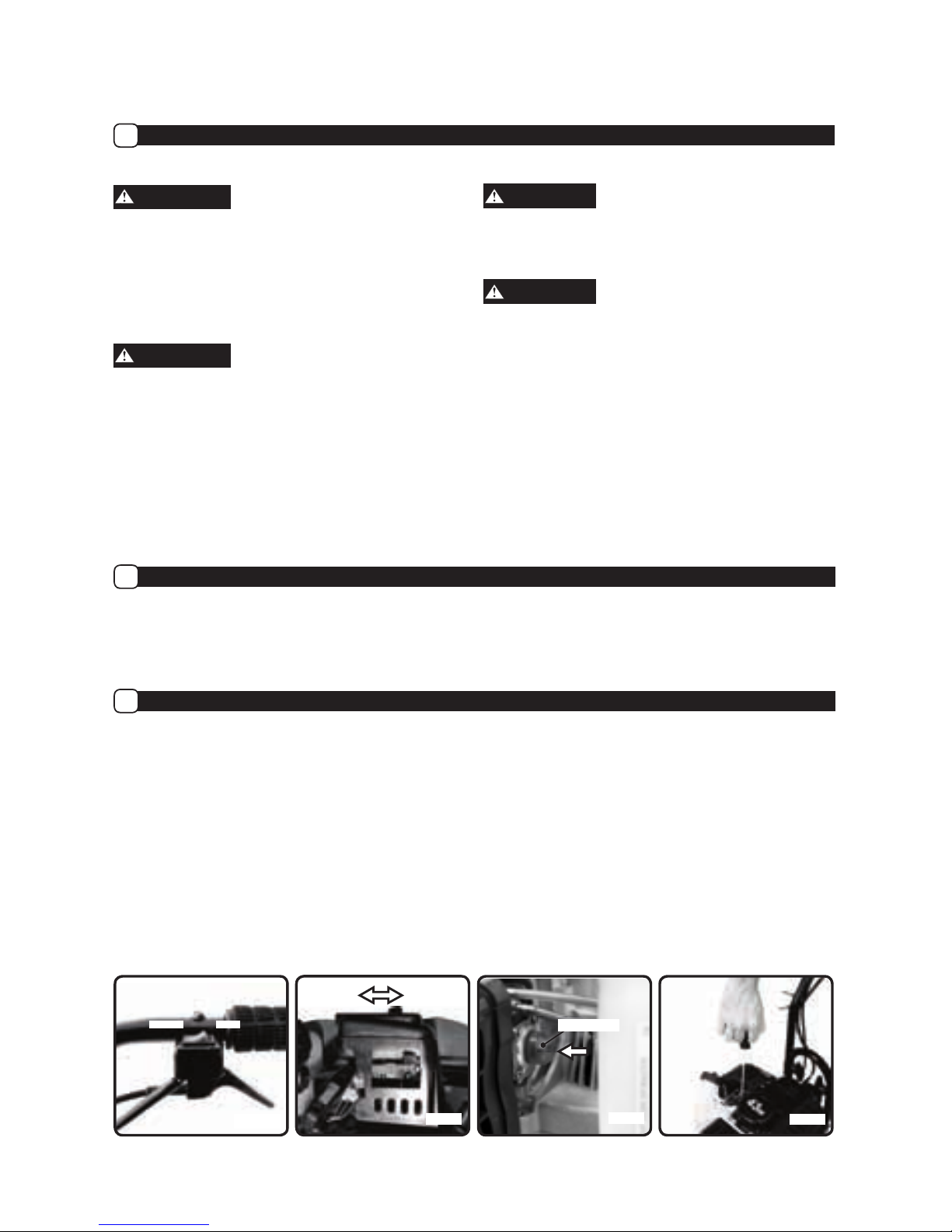

Fig. 2

Drag stake

pointed down

Detent Pin

1. Place the cultivator upright with tines and wheels on a hard level surface. Wheels should be set in the lowest position.

WARNING

Do NOT place the cultivator on a high surface where it can fall and cause property damage or personal injury.

2. Assemble the middle handle to the lower handle with the 2 bolts and wing nuts. Refer to Figure 1. Firmly hand-tighten

the wing nuts.

3. Attach the upper handles to the middle handle using the two remaining bolts and wing nuts. Refer to Figure 1.

4. Assemble the ignition switch and throttle trigger to the right upper handle with the screw. Use included wrench. See

Figure 1.

5. Make sure the ignition wire is connected to both the ignition switch (on the upper handle) and the engine. Make sure

the wires are connected at the white connection terminal.

6. Use the cable ties to secure the throttle cable and ignition wire to the handles.

7. The drag stake is shipped with the point facing upwards. To use for cultivating, remove detent pin, and turn the drag

stake upside down so the point faces downward. Re-insert the detent pin. Refer to Figure 2.

How to Assemble the Handles and Drag Stake

Fig. 1

Lower

Handle

Middle Handle

Left Upper

Handle

Right Upper

Handle

Wingnut

Bolt

Cable

Ties

Ignition

Wire

Throttle Wire

Screw

Ignition Switch

Throttle

Trigger

Page 7

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

6

Assembly (Continued)

• Save all instructions

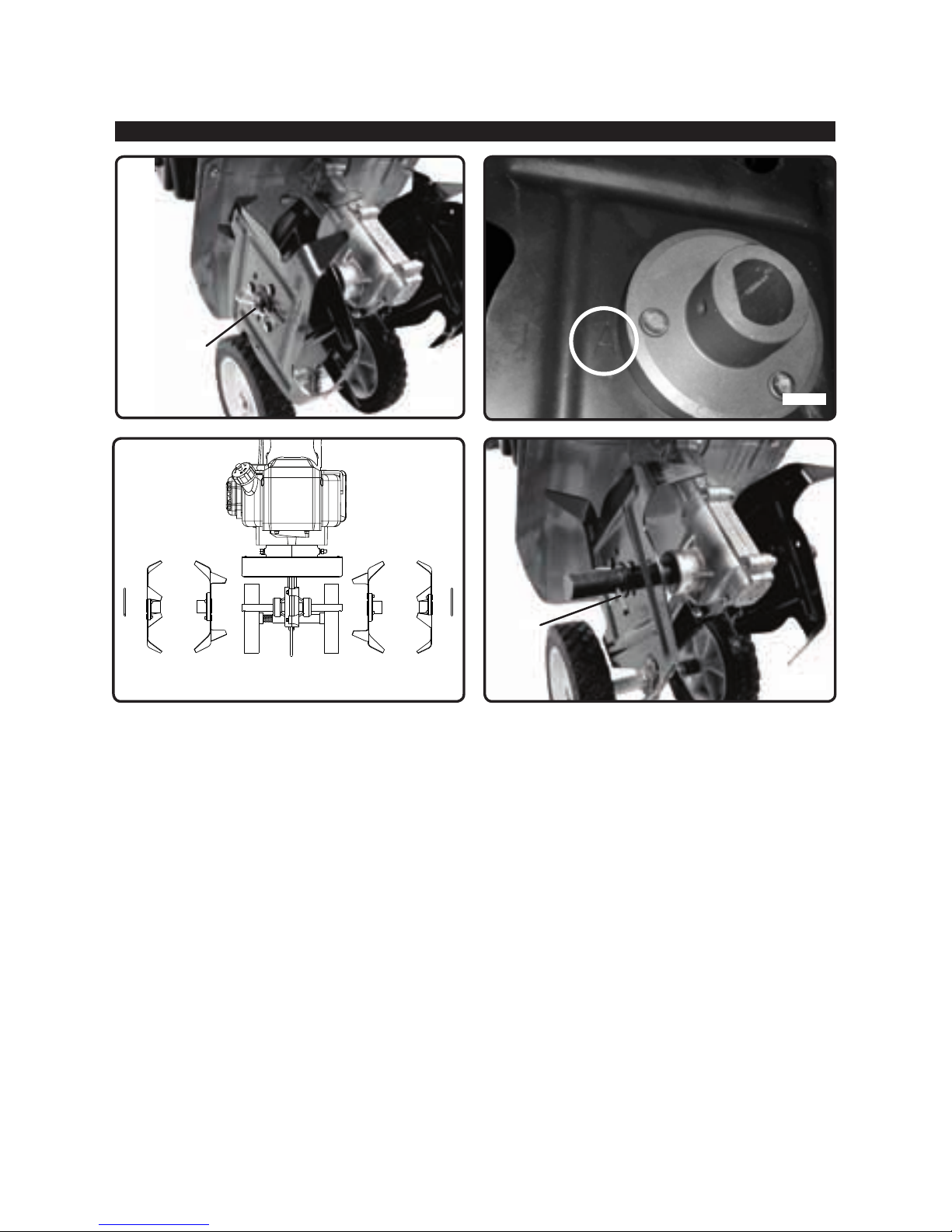

To Remove Tines

1. Remove the pins from each end of the tine shaft. Refer

to Figure 3.

2. Slide the four tines off the tine shaft.

To Install Tines

The 4 different tines are labeled “A”, “B”, “C”, and “D”. Refer

to Figure 4a for the location of the label.

For a 10” tilling width:

1. Assemble the tines as shown in Figure 4b. Make sure

the collars of the tines are facing each other.

2. Insert the pins into the holes at each end of the tine shaft

to lock the tines into place. See Figure 3.

For a 7” tilling width:

1. Only assemble tines B and C (the two inside tines). Do

not assemble tines A and D (the two outside tines).

Refer to figure 4b.

2. Insert the pins into the INSIDE holes of the tine shaft to

lock the tines into place. See Figure 5.

How to Assemble the Tines

Fig. 3

Pin

Fig. 5

Fig. 4a

D C BA

Fig. 4b

Pin

Page 8

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Before Starting Engine:

A

Adding Fuel to Cultivator:

B

1. Stop engine and allow it to cool before refueling.

2. Place the unit upright on the ground or on a sturdy bench and wipe and any debris from around the fuel cap.

3. Remove fuel cap slowly and use a funnel to pour the mixture into the tank, and replace the fuel cap.

4. Avoid spilling fuel or oil. Wipe up all fuel spills.

5. Move at least 10 feet (3 meters) away from fueling site before starting engine.

Operation

• Save all instructions

7

Fig. 6 Fig. 9

Fig. 7

COLD START

RUN/WARM

START

Fig. 8

PRIMER BULB

Mixing Fuel / 2-Cycle Oil

WARNING

Do not smoke or allow smoking near fuel or the cultivator.

Mix and pour fuel outdoors WHERE THERE ARE NO

SPARKS OR FLAMES.

The 2-cycle engine on your cultivator requires that fuel and

2-cycle engine oil need to be pre-mixed before adding to

the fuel tank.

WARNING

Always mix the gasoline and 2-cycle oil in a container

approved for gasoline. Never mix fuel directly in the engine

fuel tank.

Use fresh unleaded gasoline with an octane rating of 87 or

higher and less than 10% ethanol or methanol.

Use 2-cycle oil that meets or exceeds JASO – FC

specifications and is intended for mixing at a fuel to oil

ratio of 40:1.

CAUTION

Use of incorrect gasoline such as diesel fuel or gasoline

containing more than 10% ethanol or methanol will damage

the cultivator engine and void your warranty.

CAUTION

Use of incorrect oil, such as automotive oil, 2-cycle marine

outboard oil, or any oil other than specified oil will damage

the cultivator engine and void your warranty.

To mix the fuel and 2-cycle oil, follow instructions on 2-cycle

oil container for mixing fuel. Mix gasoline and 2-cycle oil

at a ratio of 40:1. A mixture with a 40:1 ratio is obtained

by mixing 1 gallon (4 liters) of gasoline with 3.2 ounces of

oil (95 ml). After adding oil to gasoline, shake container

momentarily to ensure proper mixing.

IMPORTANT: Mix only enough fuel for your immediate

needs. Do not store pre-mixed fuel.

Starting Engine:

C

Starting a Cold Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘cold start’ position.

(See Figure 7)

4. Press the primer bulb slowly 6 times. (See Figure 8)

5. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

6. Pull the recoil starter handle sharply until the engine

starts and runs

7. After engine starts and runs for 10-15 seconds, move

choke lever to “run/ warm start” position. (See Figure 7)

Starting a Warm Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘run/ warm start’ position.

(See Figure 7)

4. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

5. Pull the recoil starter handle sharply until the engine

starts and runs.

ON/RUN STOP

Page 9

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Operation (Continued)

• Save all instructions

Engine Break-In Period:

H

8

During the first ten (10) hours of use, use the slowest engine speed which allows for effective cutting and avoid operation

at high engine speeds for extended periods of time.

This will maximize the life and performance of your cultivator’s engine. Maximum power will be achieved after the first ten

(10) hours of engine operation.

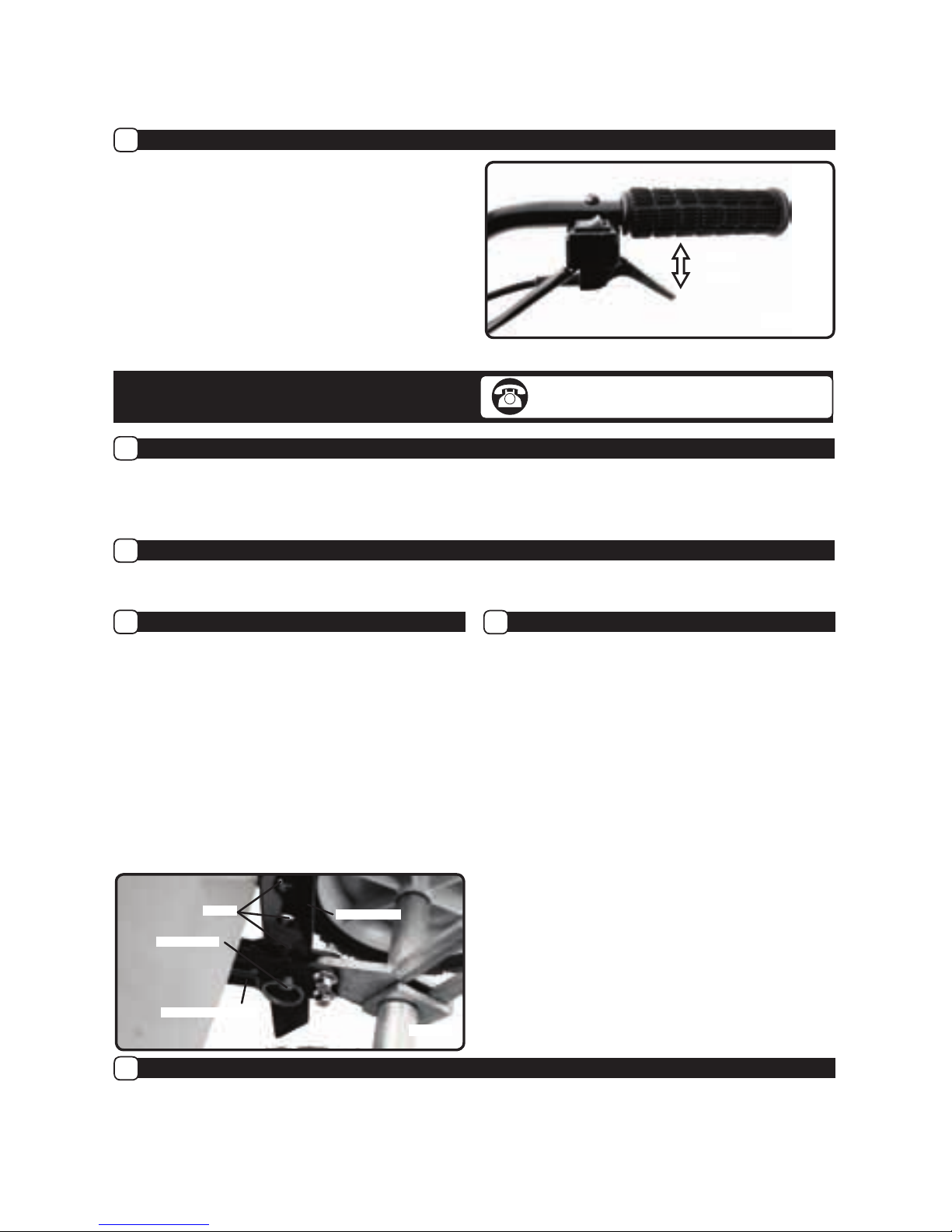

Fig. 11

The drag stake adds resistance when cultivating which

makes the unit easier to control. It also can be adjusted to

change the depth of cultivating. To adjust the drag stake

position, follow the steps below and refer to Figure 11:

1. Remove the detent pin

2. Slide the stake to the desired position, aligning the hole

in the stake with the holes in the support bracket

3. Insert the detent pin through the holes to secure the

drag stake.

Note: For the deepest cultivating depth, set the drag stake

in its lowest position. This will give the greatest resistance

and allow for the deepest depth.

Adjusting the Drag Stake Position:

F

1. Loosen knob.

2. Move the wheels up or down.

NOTE: the upper position is for cultivating, the lower

position is for transport

3. Tighten knob securely after adjusting the wheels to the

desired height.

Adjusting the Wheel Height:

G

Starting Engine (Continued):

C

Adjusting Engine Speed:

D

If the unit still doesn’t start, refer to the

TROUBLESHOOTING section of this manual or:

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

Starting a Flooded Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the ON position.

3. Move the choke lever to the ‘run/ warm start’ position.

(see Figure 7)

4. Hold the throttle trigger fully depressed in fast position.

(See Figure 10)

5. Pull the recoil starter handle repeatedly until engine

starts and runs. This could require pulling the recoil

starter handle many times, depending on how badly the

unit is flooded.

6. If the engine still does not start, allow the unit to sit for

about 15 minutes, and repeat steps 1-5.

Note: this cultivator is equipped with a centrifugal clutch, so the tines will not turn until the engine speed is increased.

To increase the engine speed, lift up on the throttle trigger. (See Figure 10)

To slow the engine down, slowly release the throttle trigger. Completely releasing the throttle lever will return the engine to

idle and will stop the tines from rotating.

1. Release the throttle trigger and allow the engine to idle for a few moments. (See Figure 10)

2. Push and hold the ignition switch to the ‘stop’ position. (See Figure 6)

Stopping the Engine:

E

Fig. 10

FAST

SLOW

Drag stake

Detent Pin

Holes

Support Bracket

Page 10

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Turn off ignition switch, and disconnect the spark plug before performing maintenance except for carburetor adjustments.

Reconnect the spark plug wire after the service is done.

WARNING

Maintenance

• Save all instructions

Air Filter

A

Your cultivator has been equipped with two (2) foam air

filters inside the air filter housing to prevent dirt and debris

from entering the engine.

Accumulated debris and dust in the air filter will reduce

engine performance, increase fuel consumption, and

increase the risk of damage. Inspect the air filters frequently

for dust and debris build-up, and clean the air filters

every 5 hours of operation (more frequently in dusty/dirty

conditions).

Both air filters should be cleaned by following these

instructions:

1. Before removing air filter cover, brush away any loose dirt

or debris on and around the filter cover.

2. Remove the screw securing the air filter cover. See

Figure 13.

3. Remove and clean foam filter.

• Light surface dust can readily be removed by

tapping the filter.

• Heavy deposits should be washed out in soap and

water. Squeeze out any remaining water and allow

the filter to completely dry.

WARNING

Never clean filter in gasoline or other flammable solvents.

4

. Add a drop of thin oil to the filter and replace it.

9

Fig. 13

Spark Plug

B

Inspect the spark plug after every 10-15 hours of use; adjust spark plug gap and replace spark plug as necessary. Replace

spark plug every year to maintain engine performance and easy starting.

To inspect or replace the spark plug:

1. Remove the insulated spark plug boot.

2. Use the spark plug wrench to remove the spark plug, by turning counter-clockwise.

3. Visually inspect the spark plug for cracks or damage. If damaged, replace spark plug with a recommended replacement

(see “Product Specifications”).

4. Clean carbon deposits. If excessive carbon build up, replace spark plug.

5. Adjust the spark plug gap to 0.024 – 0.028 in. (0.6 - 0.7mm).

6. Install the spark plug finger tight in the cylinder head, and then tighten firmly with the spark plug wrench.

7. Re-install the insulated spark plug boot.

Storage

1.

Allow engine to cool and empty the fuel tank before

storing or transporting in vehicle. Use up remaining fuel in

the carburetor by starting the engine and letting it run until

it stops.

2. When not in use, store cultivator indoors in a dry

location. Store cultivator above the reach of children or

in a locked area out of the reach of children.

3. Store unit and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

4. When preparing the cultivator for storage or when

cultivator will not be used for 30 days or more:

a. Empty fuel tank and use up remaining fuel in the

carburetor by starting the engine and letting it run

until it stops.

b. Inspect and clean the cultivator thoroughly.

c. Lightly oil all external metal surfaces.

d. Remove the spark plug, place a few drops of

2-cycle engine oil into the cylinder. Pull the recoil

starter several times to distribute the oil. Replace

the spark plug.

e. Inspect and clean air filter as required.

Page 11

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

PROBLEM POSSIBLE CAUSE(S) SOLLUTION(S)

Engine will not start. 1.

Ignition Switch in the “OFF” position.

2. Engine flooded.

3. Fuel Tank empty.

4. Spark Plug not firing.

5. Fuel not reaching carburetor.

6. Carburetor requires adjustment.

1. Move ignition switch to the ON position.

2. See Starting a Flooded Engine in

OPERATION section.

3. Fill tank with correct fuel mixture.

4. Replace Spark Plug.

5. Check for kinked or split fuel line; repair

or replace.

6. Contact a qualified service center.

Engine will not accelerate, lacks

power or stalls.

1.

Fuel not reaching carburetor.

2. Air filter dirty.

3. Spark plug fouled.

4. Carburetor requires adjustment.

5. Carbon build-up on muffler outlet

screen.

6. Compression low.

1. Check for kinked or split fuel line; repair

or replace.

2. Clean air filter.

3. Clean or replace spark plug

4. Contact a qualified service center.

5. Contact a qualified service center.

6. Contact a qualified service center.

Engine smokes excessively. 1. Fuel mixture incorrect.

2. Air filter dirty.

3. Carburetor requires adjustment.

4. Choke lever in the CHOKE/COLD

START position.

1. Empty Fuel Tank and refill with correct fuel

mixture.

2. Clean or replace air filter.

3. Contact a qualified service center.

4. Rotate choke lever to the RUN/WARM

START position.

Engine runs hot. 1. Fuel mixture incorrect.

2. Spark Plug incorrect.

3. Carburetor requires adjustment.

4. Carbon build-up on muffler outlet

screen.

1. See Mixing Fuel / 2-Cycle Oil in

OPERATION section.

2. Replace with correct Spark Plug.

3. Contact a qualified service center.

4. Contact a qualified service center.

Engine will not idle properly. 1. Carburetor requires adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Contact a qualified service center.

2. Contact a qualified service center.

3. Contact a qualified service center.

Troubleshooting

• Save all instructions

You may have further questions about assembling, operating, or maintaining this cultivator. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

Technical Service

10

When contacting the Technical Service Department, have

ready:

• Your Name

• Your Address

• Your Phone Number

• Model Number of Product

• Date of Purchase (include copy of receipt for written requests)

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

Page 12

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Warranty

• Save all instructions

Always specify model number when contacting the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard

written warranty. We make no other warranty, expressed or implied.

MAT Engine Technologies, LLC

warrants this Cultivator

and any parts thereof, to be free from defects in material and workmanship for two years (90 days for reconditioned unit) from

the date of first purchase from an authorized dealer, provided that the product has been properly maintained and operated in

accordance with all applicable instructions. This warranty is extended only to the original retail purchaser. The bill of sales or

proof of purchase must be presented at the time a claim is made under this warranty. This warranty does not cover commercial,

industrial, or rental usage, nor does it apply to parts that are not in original condition because of normal wear and tear, or parts

that fail or become damaged as a result of misuse, accident, lack of proper maintenance, tampering, or alteration. Travel,

handling, transportation, and incidental costs associated with warranty repairs are not reimbursable under this warranty and

are the responsibility of the owner. To the full extent allowed by the law of the jurisdiction that governs the sale of the product,

this express warranty excludes any and all other expressed warranties and limits the duration of any and all implied warranties,

including warranties of merchantability and fitness for a particular purpose to two years from the date of first purchase, and

MAT

Engine Technologies, LLC’s

liability is hereby limited to the purchase price of the product and

MAT Engine Technologies,

LLC

shall not be liable for any other damages whatsoever including indirect, incidental, or consequential damages. Some states

do not allow limitation of how long an implied warranty lasts or an exclusion or limitation of incidental or consequential damages,

so the above limitation of damages may not apply to you. This warranty provides the original purchaser with specific rights.

For information regarding those rights, please consult the applicable state laws.

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

This MAT Engine Technologies, LLC (

METL

) outdoor power equipment engine complies with the emissions regulations of:

Powermate® Model No. Regulatory Agency

PCV43

PCVR43

United States Environmental Protection Agency (“U.S. EPA”) and State of California

To the extent there is any conflict between this Emissions Control Warranty and the

METL

Limited Warranty, this Emissions Control

Warranty shall apply except where the

METL

Limited Warranty may provide a longer warranty period.

YOUR WARRANTY RIGHTS AND OBLIGATIONS

State of California:

The California Air Resources Board and MAT Engine Technologies, LLC (METL) are pleased to explain the emissions

control system warranty on your 2009 small off-road engine (SORE). In California, new SOREs must be designed, built

and equipped to meet the State’s stringent anti-smog standards. METL must warrant the emissions control system on

your SOREs for the periods of time listed below provided there has been no abuse, neglect or improper maintenance of

your SOREs.

11

Powermate® CULTIVATOR Limited Warranty

A

Federal and California Emissions Control Warranty Statement

B

Page 13

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

In other areas of the Unites States, your outdoor power equipment engine must be designed, built and equipped so as

to conform at the time of sale to U.S. EPA emissions standards for small off-road spark ignition engines at or below 19

kilowatts.

Warranty (Continued)

• Save all instructions

Other U.S States / Territories:

All of the United States:

Your emission control system may include parts such as the carburetor or fuel-injection system, fuel lines, the ignition

system, and catalytic converter. Also included may be hoses, belts, clamps, connectors and other emission-related

assemblies.

Where a warrantable condition exists, METL will repair your small off-road engine at no cost to you including diagnosis,

parts and labor.

Manufacturer’s Warranty Coverage:

The emissions control system is warranted for two years. If any emissions-related part on your engine is defective, the part

will be repaired or replaced by METL.

Owner’s Warranty Responsibilities:

• As the SORE owner, you are responsible for the performance of the required maintenance listed in your owner’s manual.

METL recommends that you retain all receipts covering maintenance on your SORE, but METL can not deny warranty

solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

• As the SORE owner, you should however be aware that METL may deny your warranty coverage if your SORE or a part

has failed due to abuse, neglect, improper maintenance or unapproved modifications.

• You are responsible for presenting your SORE to a distribution center or service center authorized by METL as soon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty

coverage, you should contact METL customer service:

12

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

Page 14

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Warranty (Continued)

• Save all instructions

Defects Warranty Coverage:

METL warrants to the original purchaser and each subsequent purchaser that the small off-road engine (SORE) (1) has

been designed, built and equipped so as to conform with all applicable regulations; and (2) is free from defects in materials

and workmanship that cause the failure of a warranted part to conform with those regulations as may be applicable to the

terms and conditions stated below.

(a) The warranty period begins on the date the engine is first purchased. The warranty period is two years.

(b) Subject to certain conditions and exclusions as stated below, the warranty on emissions related parts is as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in your Operator’s Manual

is

warranted for the warranty period stated above. If the part fails during the period of warranty coverage, the part will

be repaired or replaced by METL according to Subsection (4) below. Any such part repaired or replaced under

warranty will be warranted for the remainder of the period.

(2) Any warranted part that is scheduled only for regular inspection in your Operator’s Manual

is warranted for the

warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining

warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in your Operator’s Manual

is

warranted for the period of time before the first scheduled replacement date for that part. If the part fails before the

first scheduled replacement, the part will be repaired or replaced by METL

according to Subsection (4) below.

Any such part repaired or replaced under warranty will be warranted for the remainder of the period prior to the first

scheduled replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions herein must be performed at a

warranty station at no charge to the owner.

(5) Notwithstanding the provisions herein, warranty services or repair will be provided at all of our distribution centers

that are franchised to service the subject engines.

(6) The engine owner must not be charged for diagnostic labor that leads to the determination that a warranted part is

in fact defective, provided that such diagnostic work is performed at a warranty station.

(7) METL

is liable for damages to other engine components proximately caused by a failure under warranty of any

warranted part.

(8) Throughout the engine warranty period stated above, METL

will maintain a supply of warranted parts sufficient to

meet the expected demand for such parts.

(9) Any replacement part may be used in the performance of any warranty maintenance or repairs and must be

provided without charge to the owner. Such use will not reduce the warranty obligations of METL.

(10) Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of

any non-exempted add-on or modified parts by the original or subsequent purchaser will be grounds for disallowing

a warranty claims. METL will not be liable to warrant failures of warranted parts caused by the use of a non exempted add-on or modified part.

(

11) The manufacturer issuing the warranty shall provide any documents that describe that warranty procedures or

policies within five working days or requested by the Air Resources Board.

13

Page 15

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Warranty (Continued)

• Save all instructions

Emission Warranty Parts List:

The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such

warranty coverage if METL demonstrates that the engine has been abused, neglected, or improperly maintained, and that

such abuse, neglect, or improper maintenance was the direct cause of the need for repair or replacement of the part. That

notwithstanding, any adjustment of a component that has a factory installed, and properly operating, adjustment limiting

device is still eligible for warranty coverage. The following emissions warranty parts list is covered.

(1) Fuel Metering System:

(a) Gasoline carburetor assembly and its internal

components (if so equipped)

(b) Fuel filter (if so equipped)

(c) Carburetor gaskets

(d) Fuel pump (if so equipped)

(2) Air Induction System including:

(a) Intake pipe/manifold

(b) Air cleaner

(3) Ignition System including:

(a) Spark plug

(b) Ignition module/coil

(4) Catalytic Muffler Assembly (if so equipped) including:

(a) Muffler gasket

(b) Exhaust manifold

(5) Crankcase Breather Assembly including:

(a) Breather connection tube.

(6) Miscellaneous items Used in Above Systems including:

(a) Switches

(b) Hoses, belts, connectors, and assemblies.

14

Page 16

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Warranty (Continued)

• Save all instructions

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and METL are pleased to explain the evaporative emission control system’s warranty

on your 2009 model year small off-road engine (SORE). In California, new SOREs must be designed, built and equipped

to meet the State’s stringent anti-smog standards. METL must warrant the evaporative emission control system on your

SOREs for the period of time listed below provided there has been no abuse, neglect or improper maintenance of your

SOREs.

Your evaporative emission control system may include parts such as: carburetors, fuel tanks, fuel lines, fuel caps, valves,

canisters, filters, vapor hoses, clamps, connectors, and other associated components.

Manufacturer’s Warranty Coverage:

This evaporative emission control system is warranted for two years. If any evaporative emission-related part on your

equipment is defective, the part will be repaired or replaced by METL.

Owner’s Warranty Responsibilities:

• As the SORE owner, you are responsible for performance of the required maintenance listed in your owner’s manual.

METL recommends that you retain all receipts covering maintenance on your SOREs, but METL can not deny warranty

solely for the lack of receipts.

• As the SORE owner, you should however be aware that METL may deny you warranty coverage if your SOREs or a part

have failed due to abuse, neglect, or improper maintenance or unapproved modifications.

• You are responsible for presenting your SOREs to distribution center or service center authorized by METL as soon as

the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty

coverage, you should contact METL customer service:

15

California Evaporative Emission Control Warranty Statement

C

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

Page 17

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Warranty (Continued)

• Save all instructions

Defects Warranty Coverage:

(a) The warranty period begins on the date the engine is purchased.

(b) General Evaporative Emissions Warranty Coverage. The engine must be warranted to the ultimate purchaser and

any subsequent owner that the evaporative emission control system when installed was:

(1) Designed, built, and equipped so as to conform with all applicable regulations; and

(2) Free from defects in materials and workmanship that causes the failure of a warranted part for a period of two years.

(c) The warranty on evaporative emissions-related parts will be interpreted as follows:

(1) Any warranted part that is not scheduled for replacement as required maintenance in the written instructions must

be warranted for the warranty period defined in subsection (b) (2).

If any such part fails during the period of warranty coverage, it must be repaired or replaced by METL

issuing

the warranty. Any such part repaired or replaced under the warranty must be warranted for a time not less than the

remaining warranty period.

(2) Any warranted part that is scheduled only for regular inspection in the written instructions must be warranted

for the warranty period defined in subsection (b) (2). A statement in such written instructions to the effect of “repair

or replace as necessary” will not reduce the period of warranty coverage. Any such part repaired or replaced under

warranty must be warranted for a time not less than the remaining warranty period.

(3) Any warranted part that is scheduled for replacement as required maintenance in the written instructions must be

warranted for the period of time prior to the first scheduled replacement point for that part. If the part fails prior to the

first scheduled replacement, the part must be repaired or replaced by METL Any such part repaired or replaced under

warranty must be warranted for a time not less than the remainder of the period prior to the first scheduled

replacement point for the part.

(4) Repair or replacement of any warranted part under the warranty provisions of this article must be performed at no

charge to the owner at a warranty station.

(5) Notwithstanding the provisions of subsection (4) above, warranty services or repairs must be provided at

distribution centers that are franchised to service the subject engines or equipment.

(6) The owner must not be charged for diagnostic labor that leads to the determination that a warranted part is in fact

defective, provided that such diagnostic work is performed at a warranty station.

(7) Throughout the evaporative emission control system’s warranty period set out in subsection (b) (2), METL

issuing

the warranty must maintain a supply of warranted parts sufficient to meet the expected demand for such parts.

(8) Manufacturer approved replacement parts must be used in the performance of any warranty maintenance or

repairs and must be provided without charge to the owner. Such use will not reduce the warranty obligations of the

manufacturer issuing the warranty.

(9) The use of any add-on or modified parts will be grounds for disallowing a warranty claim made in accordance with

this article. The manufacturer issuing the warranty will not be liable under this Article to warrant failures of warranted

parts caused by the use of an add-on or modified part.

(10) METL

issuing the warranty shall provide any documents that describe the warranty procedures or policies within

five working days of request by the Executive Officer.

(1) Fuel Tank.

Evaporative Emission Warranty Parts List:

16

Page 18

Page 19

Contenido:

Página

Definiciones de seguridad 18

Información importante sobre seguridad 19-20

Especificaciones del producto 21

Piezas y características 21

Montaje 22-23

Puesta en marcha y funcionamiento 24-25

Mantenimiento 26

Almacenamiento 26

Diagnóstico y resolución de problemas 27

Servicio técnico 27

Garantía 28-33

12/16/2010 Printed in China A201016

Manual de operación

MOTOAZADA A GASOLINA

Cilindrada: 43 cm³,

2 ciclos

IMPORTANTE:

Gracias por comprar esta motoazada Powermate®.

Leer y entender todas las advertencias e instrucciones en este manual antes de usar esta máquina. El uso indebido del

equipo puede causar lesiones graves o la muerte. Guardar este manual para referencia futura.

Anotar lo siguiente para referencia futura:

Código de fecha de fabricación: ____

Fecha de compra: adjuntar una copia del recibo de venta.

Número gratuito para el consumidor: 1-800-737-2112

GUARDAR ESTE MANUAL PARA REFERENCIA FUTURA

Modelo Nro.

PCV43

PCVR43

Solo para uso ocasional

Si se tienen preguntas o problemas...

LLAMAR AL NÚMERO TELEFÓNICO GRATUITO: 1-800-737-2112

Consultar el sitio web para obtener una copia electrónica del

manual y del catálogo de piezas.

www.powermate.com

Page 20

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Definiciones de seguridad

• Guardar todas las instrucciones

Símbolos de advertencia sobre seguridad:

Símbolos de control y operación:

Control del estrangulador:

Marcha / arranque en caliente

Estrangulador / arranque en frío

Fuel Mixture

40:1

Unleaded Gas: 2 Cycle Oil

Caution: Do Not Use Gas

Mix with More Than 10%

Methanol or Ethanol

Mezcla de combustible:

40:1

(Gasolina sin plomo: Aceite para

motores de dos tiempos)

Cebador de combustible:

Oprimirlo 6 veces.

Control del regulador:

LENTA

FRÁPIDA

Interruptor de encendido:

ON/RUN (ENCENDIDO / MARCHA)

OFF/STOP (APAGADO / PARAR)

PELIGRO

Indica una situación inminentemente peligrosa que, de no evitarse, producirá la muerte o

lesiones graves.

ADVERTENCIA

Indica una situación potencialmente peligrosa que, de no evitarse, podría causar la muerte o

lesiones graves.

CUIDADO

Indica una situación potencialmente peligrosa que, de no evitarse, podría causar lesiones de

leves a moderadas o daños materiales o al equipo.

El operador debe leer y entender la información que aparece abajo. Para señalar al lector información importante sobre

su propia seguridad, el manual utiliza los símbolos siguientes:

Símbolos de alerta sobre seguridad

18

Información importante sobre seguridad

Indica ADVERTENCIA, PELIGRO o

CUIDADO.

Este equipo puede lanzar objetos

pequeños a gran velocidad y causar

lesiones personales. Inspeccionar el

área en que se va a utilizar y retirar todo

objeto extraño.

Leer el manual de operación antes de

utilizar esta máquina. El no seguir las

directrices podría conducir a lesiones

graves.

Los gases de escape contienen

monóxido de carbono, un gas inodoro

y letal. JAMÁS hacer funcionar la

unidad en espacios interiores o en

áreas con ventilación deficiente.

Siempre usar protección ocular que

cumpla o supere los requisitos de la

norma ANSI Z87.1.

Utilizar protección auditiva.

Utilizar protección respiratoria.

Para reducir el riesgo de incendio,

limpiar el combustible y aceite

derramados y mantener la unidad

libre de residuos. La gasolina es

sumamente inflamable. Dejar que la

máquina enfríe antes de reabastecerla

de combustible.

No utilizar la motoazada ante niños o

circunstantes.

Mantener las manos, los pies y la

indumentaria alejados de las azadas

rotativas. El contacto con las azadas

rotativas puede causar lesiones

graves.

Superficie sumamente caliente. No tocar el silenciador, la caja de engranajes o el cilindro después

de operar la motoazada: éstos podrían causarle quemaduras. Estas piezas alcanzan temperaturas

sumamente altas y permanecen calientes durante un período de tiempo corto después de apagarse la

unidad.

Page 21

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC 19

Antes de operar la motoazada

1. LEER Y ENTENDER TODAS LAS INSTRUCCIONES ANTES DE OPERAR LA MOTOAZADA. Familiarizarse

completamente con los controles y el uso apropiado del equipo. Saber cómo parar la unidad y desengranar los

controles rápidamente.

ADVERTENCIA

Leer y seguir todas las advertencias e instrucciones de seguridad. El hacer caso omiso de esta directriz puede conducir

a lesiones graves del operador o de circunstantes.

2. Evitar entornos peligrosos

a. No operar la motoazada bajo la influencia de alcohol, medicamentos o fármacos.

b. No operar la motoazada al estar cansado.

c. No utilizar esta motoazada si no se es capaz, mental o físicamente, de operarla de manera segura.

3. Inspeccionar la motoazada para determinar si hay piezas averiadas; asegurarse de que todos los sujetadores y

protecciones estén en posición y seguros. Reemplazar toda pieza averiada.

4. Vestir indumentaria apropiada al operar la motoazada.

a. Siempre usar pantalones largos gruesos, botas, guantes y camisa de manga larga.

b. No vestir indumentaria holgada o joyería que pudiera atorarse en las piezas móviles de la motoazada.

c. Siempre usar guantes de trabajo y calzado robusto al trabajar al aire libre.

d. En caso de tener el cabello largo, mantenerlo recogido dentro de un gorro protector.

5. Siempre usar una máscara para la cara o contra el polvo si la operación genera mucho polvo.

6. Siempre usar protección ocular que cumpla o supere los requisitos de la norma ANSI Z87.1.

7. Siempre usar protección auditiva que cumpla o supere los requisitos de las normas ANSI.

8. Inspeccionar completamente el área en que se va a utilizar la motoazada y retirar todo objeto extraño.

9. Mantener el área de trabajo libre de personas (particularmente niños pequeños) y mascotas.

ADVERTENCIA

Este equipo puede lanzar objetos pequeños a gran velocidad y causar lesiones personales o daños materiales.

10. Jamás permitir que niños operen la motoazada. Jamás permitir a adultos operar el equipo sin la debida instrucción

de uso.

11. Téngase en cuenta que el operador o usuario es responsable por accidentes o riesgos causados a otras personas, a

la propiedad de éstas y a sí mismo.

ADVERTENCIA

Los gases de escape del motor de este producto contienen sustancias químicas que, consta al Estado de California,

producen cáncer y malformaciones congénitas u otros daños reproductivos.

Información importante sobre seguridad

• Guardar todas las instrucciones

Durante la operación de la motoazada

1. Mantenerse alerta. Aplicar el sentido común. Prestar atención a lo que se está haciendo.

2. No operar la motoazada si ésta está dañada o no montada de manera segura o completa.

3. Jamás operar la motoazada sin buena visibilidad o iluminación.

4. Jamás operar la máquina sin dispositivos de protección, placas u otros dispositivos protectores de seguridad

instalados.

5. Mantener todas las partes del cuerpo alejadas de las azadas rotativas. No colocar las manos ni los pies cerca de

piezas rotativas o bajo éstas.

6. Mantener alejados a niños y mascotas.

7. Utilizarla sólo para las labores explicadas en este manual. No usar la motoazada para ninguna otra labor que no sea

para la cual está prevista.

8. Mantener el equilibrio y un apoyo firme de los pies en todo momento. Para evitar sobrecargar la máquina, no intentar

un labrado demasiado profundo.

9. Después de golpear un objeto extraño, parar el motor, desconectar el cable de la bujía, inspeccionar la máquina para

determinar si ha sufrido daños y reparar dichos daños antes arrancarla y utilizarla nuevamente.

10. Jamás dejar la máquina desatendida. Parar el motor al dejarse la posición de operación.

11. Parar el motor antes de desobstruir las azadas, y asimismo, al reparar, ajustar o inspeccionar la unidad.

12. Tener cuidado al labrarse suelo duro. Las azadas podrían atorarse en el suelo e impulsar la motoazada hacia adelante.

Si esto ocurriera, soltar las empuñaduras y no restringir la máquina.

13. Tener sumo cuidado al retroceder o tirar de la máquina hacia sí mismo.

14. No forzar la motoazada. Ésta realizará un mejor trabajo y con menos probabilidad de un riesgo de lesión cuando se

la utiliza conforme al régimen para el cual se la diseñó.

PELIGRO

Jamás arrancar o tener en marcha la unidad dentro de una habitación o edificio cerrado; la inhalación de los gases de

escape puede causar la muerte.

Información importante sobre seguridad

Información importante sobre seguridad

Page 22

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Información importante sobre seguridad (Continuación)

• Guardar todas las instrucciones

20

Durante la operación de la motoazada (cont.)

16. Tener sumo cuidado al operar la motoazada sobre accesos, andenes o caminos con grava; o bien, al cruzarlos.

Mantenerse alerta por peligros ocultos o circulación de vehículos.

17. Tener cuidado para no deslizarse o caerse.

18. Si la motoazada comenzara a vibrar anormalmente, parar el motor y buscar la causa inmediatamente. Generalmente,

la vibración indica problemas.

19. Jamás operar la motoazada a velocidades altas de transporte sobre superficies duras o resbaladizas.

20. Arrancar el motor cuidadosamente según las instrucciones y con los pies alejados de las azadas.

21. Jamás levantar o cargar una máquina mientras el motor esté en marcha.

CUIDADO

La exposición prolongada a vibraciones a través de herramientas mecánicas manuales podría causar daños en los

vasos sanguíneos o a los nervios en los dedos, las manos y en las articulaciones de personas propensas a trastornos

circulatorios o inflamaciones anormales. Se ha relacionado el uso extensivo en clima frío con daños a los vasos

sanguíneos de personas normalmente saludables. Si ocurrieran síntomas como entumecimiento, dolor, pérdida de fuerza,

cambio en el color o la textura de la piel o pérdida de sensación en los dedos, las manos o las articulaciones, descontinuar

el uso de esta herramienta y buscar atención médica.

Manejo seguro del combustible

1. Mezclar y verter el combustible en espacios exteriores DONDE NO HAYAN CHISPAS NI LLAMAS.

2. Utilizar un contenedor aprobado para gasolina.

3. No fumar ni permitir fumar cerca del combustible o de la motoazada.

4. Evitar derrames de combustible o aceite. Enjugar todo derrame de combustible.

5. Mover la motoazada al menos 3 metros (10 pies) del sitio de abastecimiento de combustible antes de arrancar el

motor. No reabastecer de combustible un motor caliente. No reabastecer de combustible un motor en marcha.

6. Parar el motor y dejarlo enfriar antes de retirar la tapa del combustible. Retirar la tapa del combustible lentamente.

8. Jamás almacenar en espacios interiores la motoazada con combustible en el tanque. La gasolina y los vapores de

gasolina son sumamente inflamables.

9. Colocar nuevamente las tapas del tanque y del contenedor de manera segura.

Mantenimiento y almacenamiento de la motoazada

1. Parar el motor y desconectar la bujía antes de dar servicio técnico, limpiar o dar mantenimiento a la unidad. Jamás

intentar ajuste alguno mientras el motor esté en marcha.

2. Dar mantenimiento esmerado a la motoazada. Inspeccionar la motoazada periódicamente. Mantener la máquina y

sus accesorios en condiciones de funcionamiento seguro. Si la motoazada no está funcionando correctamente o está

averiada, acúdase a un centro de servicio calificado para que la reparen.

3. Revisar la unidad para determinar si hay piezas móviles desalineadas, piezas móviles atascadas, piezas rotas o

cualquier otra condición que pudiera afectar su funcionamiento. Revisar el apriete de los pernos de seguridad, los

pernos de montaje del motor y otros pernos a intervalos frecuentes para asegurarse de que el equipo esté en

condiciones de funcionamiento seguras.

4. Mantener todos los protectores instalados y en buenas condiciones.

5. Un centro de servicio calificado debe reparar o reemplazar todo dispositivo de protección u otra pieza dañada.

6. Utilizar únicamente piezas de repuesto y accesorios Powermate® genuinos. El uso de cualquier pieza o accesorio que

no sea Powermate® puede conducir a lesiones, daños a la unidad e invalidar la garantía.

7. No retirar ni modificar ninguna pieza. El retiro o modificación de piezas podría conducir a lesiones, daños a la

motoazada e invalidará la garantía.

8. Mantener los asideros secos, limpios y libres de aceite y grasa.

9. Dejar que el motor enfríe para vaciar el tanque de combustible antes de almacenar o transportar la motoazada en

un vehículo. Arrancar el motor y dejarlo marchar hasta que pare al agotarse el combustible en el carburador. Si se ha

de drenar el tanque de combustible, hacerlo al aire libre.

10. Cuando no esté en uso, almacenar la motoazada en un espacio interior seco. Almacenar la motoazada a una altura

inalcanzable por niños o en un área bajo llave, fuera del alcance de niños.

11. Almacenar la unidad y el combustible en un área donde los vapores del combustible no puedan llegar a chispas o

llamas abiertas de calentadores de agua, motores o interruptores eléctricos, hornos, etc.

12. Siempre consultar el manual de operación para obtener información importante pormenorizada si se va a guardar la

motoazada durante un período de tiempo prolongado.

13. Seguir las recomendaciones del fabricante para la carga, descarga, transporte y almacenamiento seguros de la máquina.

Información importante sobre seguridad

Page 23

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Motor ................... Cilindrada: 43 cm3, 2 ciclos,

cigüeñal completo apoyado en ambos extremos

Velocidad de marcha en vacío ......... 2800 a 3000 rpm

Anchura de labrado ................... 178 a 254 mm

Profundidad de labrado ................ Hasta 127 mm

Capacidad del tanque de combustible............840 ml

(28 onzas fluidas)

Tipo de combustible ...

Gasolina sin plomo, de 87 octanos o

superior

Aceite para motores de dos tiempos ..................

Aceite para motores de 2 tiempos que cumple o supera las

especificaciones JASO - FC

Mezcla de combustible.............................

40:1 (gasolina: aceite para motores de dos tiempos)

Bujía ...................... NHSP LD L6, NGK BM6A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CHAMPION - CJ8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . o equivalente

Peso neto .............................15 kg (33 lb)

Especificaciones del producto

• Guardar todas las instrucciones

Piezas y características

21

6

5

4

2

8

1

3

15

1. Interruptor de encendido 7. Azadas 13. Cubierta del filtro de aire

2. Asidero superior 8. Empuñadura del arrancador de retroceso 14. Gatillo del regulador

3. Asidero intermedio 9. Tanque de combustible 15. Silenciador

4. Asidero inferior 10. Bujía 16. Estaca de arrastre

5. Asidero frontal para transporte 11 . Bulbo de cebado de combustible 17. Pasador de detención

6. Motor 12. Estrangulador 18. Rueda de transporte

9

7

14

18

11

12

13

16

17

10

Page 24

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Piezas incluidas con la motoazada

• Asidero intermedio (1)

• Asideros superiores (2)

• Tuercas de orejetas y pernos (4 de c/u)

• Llave de bujía y varilla (1)

• Ataduras para cables (3)

• Manual de operación (1)

• Envase de aceite para motores de dos tiempos, 3.2 onzas (1)

• Llave (1)

ADVERTENCIA

No operar la motoazada si ésta está dañada o no montada de manera segura o completa.

Si se necesita ayuda o hacen falta piezas,

LLAMAR GRATUITAMENTE AL: 1-800-737-2112

Montaje

• Guardar todas las instrucciones

22

Cómo sacar la motoazada de la caja

1. Sacar todas las piezas y componentes del embalaje.

2. Cortar las cuatro esquinas verticales con una cuchilla multiuso. Colocar los costados de la caja sobre el piso, alrededor

de la motoazada.

3. Retirar todos los componentes internos y el embalaje.

CUIDADO

Tener cuidado al sacar piezas para no dañar ningún cable o alambre instalado en las piezas.

4. Rodar la unidad para sacarla de la caja y colocarla en una superficie plana y sólida.

Fig. 2

Estaca de

arrastre

orientada

hacia abajo

Pasador de

detención

1. Colocar la motoazada en posición vertical, con las azadas y las ruedas sobre una superficie dura a nivel. Se deben

colocar las ruedas en la posición más baja.

ADVERTENCIA

Do NOT place the cultivator on a high surface where it can fall and cause property damage or personal injury.

NO colocar la motoazada en una superficie elevada de donde pueda caer y causar daños materiales o lesiones

personales.

2. Instalar el asidero intermedio en el asidero inferior con los dos pernos y tuercas de orejeta. Véase la Figura 1. Apretar

firmemente, a mano, las tuercas de orejeta.

3. Instalar los asideros superiores en el asidero intermedio con los dos pernos y tuercas de orejeta restantes. Véase la Figura 1.

4. Con el tornillo, montar el interruptor de encendido y el gatillo del regulador en el asidero superior derecho. Utilizar la

llave incluida. Véase la Figura 1.

5. Asegurarse de que el cable de encendido esté conectado al interruptor de encendido (en el asidero superior) y al motor.

Asegurarse de que los cables estén conectados al borne de conexión blanco.

6. Asegurar con las ataduras para cables el cable del regulador y el cable de encendido a los asideros.

7. La estaca de arrastre se envía con la punta orientada hacia arriba. Para labrado, retirar el pasador de detención e

invertir la posición vertical de la estaca de arrastre para que la punta esté orientada hacia abajo. Reinsertar el pasador

de detención. Véase la Figura 2.

Cómo armar los asideros y la estaca de arrastre

Fig. 1

Asidero

inferior

Asidero intermedio

Asidero

superior

izquierdo

Asidero superior

derecho

Tuerca de

orejetas

Perno

Ataduras

para

cables

Ignition

Wire

Cable del

regulador

Tornillo

Cable de

encendido

Gatillo del

regulador

Page 25

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

23

Montaje (Continuación)

• Guardar todas las instrucciones

Para sacar las azadas

1. Retirar los pasadores de cada extremo del eje de azadas.

Véase la Figura 3.

2. Deslizar las cuatro azadas para sacarlas del eje de azadas.

Para instalar las azadas

Las cuatro azadas están rotuladas «A», «B», «C» y «D».

Véase la Figura 4a para determinar la ubicación de la

etiqueta.

Para una anchura de labrado de 254 mm (10”):

1. Instalar las azadas como se muestra en la Figura 4b.

Asegurarse de que las bridas de las azadas estén una

frente a otra.

2. Insertar los pasadores en los agujeros en ambos

extremos del eje de azadas para asegurar las azadas

en posición. Véase la Figura 3.

Para una anchura de labrado de 178 mm (7”):

1. Sólo montar las azadas B y C (las dos azadas internas).

No montar las azadas A y D (las dos azadas externas).

Véase la Figura 4b.

2. Insertar los pasadores en los agujeros INTERNOS del

eje de azadas para asegurar las azadas en posición.

Véase la Figura 5.

Cómo montar las azadas

Fig. 3

El pasador

Fig. 5

Fig. 4a

D C BA

Fig. 4b

El pasador

Page 26

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Antes de arrancar el motor:

A

Cómo agregar combustible a la motoazada:

B

1. Parar el motor y dejarlo enfriar antes de reabastecerlo de combustible.

2. Colocar la unidad en posición vertical sobre el terreno o sobre un banco de trabajo robusto y enjugar todo despojo

alrededor de la tapa de combustible.

3. Retirar la tapa de combustible lentamente y usar un embudo para verter la mezcla en el tanque; luego, colocar la tapa

nuevamente.

4. Evitar derrames de combustible o aceite. Enjugar todo derrame de combustible.

5. Mover la motoazada al menos 3 metros (10 pies) del sitio de abastecimiento de combustible antes de arrancar el motor.

Puesta en marcha y funcionamiento

• Guardar todas las instrucciones

24

Fig. 6 Fig. 9

Fig. 7

ARRANQUE

EN FRÍO

MARCHA /

ARRANQUE

EN CALIENTE

Fig. 8

BULBO DE

CEBADO

Mezcla de combustible con aceite para motores de

dos tiempos

ADVERTENCIA

No fumar ni permitir fumar cerca del combustible o de la

motoazada. Mezclar y verter el combustible en espacios

exteriores DONDE NO HAYAN CHISPAS NI LLAMAS.

El motor de dos tiempos de la motoazada precisa que se

mezcle el combustible con aceite para motores de dos

tiempos antes de agregarlo al tanque de combustible.

ADVERTENCIA

Siempre mezclar la gasolina y el aceite de dos tiempos

en un contenedor aprobado para gasolina. Jamás mezclar

combustible directamente en el tanque del motor.

Utilizar gasolina fresca sin plomo, de 87 octanos o superior

y menos de 10% de etanol o metanol.

Utilizar aceite para motores de dos tiempos que cumpla

o supere las especificaciones JASO - FC, previsto para

mezclar el combustible con el aceite en una proporción

de 40:1.

CUIDADO

El uso de gasolina incorrecta, tal como combustible diesel o

gasolina que contenga más de un 10% de etanol o metanol,

dañará el motor de la motoazada y anulará la garantía de

ésta.

CUIDADO

El uso de aceite incorrecto, tal como aceite automotriz,

aceite para motores fuera de borda de dos tiempos, o

cualquier otro aceite distinto del especificado dañará el

motor de la motoazada y anulará la garantía de ésta.

Para mezclar el combustible y el aceite para motores de dos

tiempos, seguir las instrucciones en el contenedor del aceite

para motores de dos tiempos sobre cómo mezclarlo con

combustible. Mezclar la gasolina y el aceite de dos tiempos

en una proporción de 40:1. Una mezcla con una proporción

40:1 se obtiene al mezclar 4 litros (1 galón) de gasolina con

95 ml (3.2 onzas) de aceite. Después de agregar aceite a

la gasolina, agitar el contenedor momentáneamente para

asegurar una mezcla apropiada.

IMPORTANTE: Mezclar únicamente suficiente combustible

para las necesidades inmediatas. No almacenar combustible

premezclado.

Arranque del motor:

C

Cómo arrancar el motor en frío

1. Colocar la motoazada sobre una superficie plana.

2. Mover el interruptor de encendido a la posición de

encendido («ON»). (Véase la Figura 6)

3. Mover la palanca del estrangulador a la posición «COLD

START» («ARRANQUE EN FRÍO»). (Véase la Figura 7)

4. Oprimir el bulbo de cebado, lentamente, seis veces.

(Véase la Figura 8)

5. Empuñar el arrancador de retroceso con la mano

derecha y sujetar la motoazada con la mano izquierda.

(Véase la Figura 9)

6. Tirar de la empuñadura del arrancador de retroceso

rápidamente hasta que el motor arranque y se ponga en

marcha.

7. Después de que el motor arranque y esté en

marcha durante 10 a 15 segundos, mover la palanca

ENCENDIDO/

MARCHA

PARAR

del estrangulador a la posición «RUN/WARM START»

(«MARCHA / ARRANQUE EN CALIENTE». (Véase la

Figura 7)

Cómo arrancar el motor en caliente

1. Colocar la motoazada sobre una superficie plana.

2. Mover el interruptor de encendido a la posición de

encendido («ON»). (Véase la Figura 6)

3. Mover la palanca del estrangulador a la posición «Marcha

/ Arranque en caliente». (Véase la Figura 7)

4. Empuñar el arrancador de retroceso con la mano derecha

y sujetar la motoazada con la mano izquierda. (Véase la

Figura 9)

5. Tirar de la empuñadura del arrancador de retroceso

rápidamente hasta que el motor arranque y se ponga en

marcha.

Page 27

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

Operation (Continuación)

• Guardar todas las instrucciones

Período de desarrollo del motor:

H

25

Durante las primeras diez (10) horas de uso, utilizar la velocidad más baja del motor que permita un labrado eficaz, y

asimismo, evitar la operación del motor a altas velocidades durante períodos de tiempo prolongados.

Esto maximizará la vida útil y el rendimiento del motor de la motoazada. Se logrará la máxima potencia después de las

primeras diez (10) horas de operación del motor.

Fig. 11

La estaca de arrastre añade resistencia al labrado, lo cual

facilita el control de la unidad. También se la puede ajustar

para cambiar la profundidad de labranza. Para ajustar la

posición de la estaca de arrastre, seguir los pasos que

aparecen a continuación y consultar la Figura 11:

1. Retirar el pasador de detención.

2. Deslizar la estaca de arrastre hacia la posición deseada

y alinear el agujero en la estaca con los agujeros en el

soporte de apoyo.

3. Insertar el pasador de detención a través de los agujeros

para asegurar la estaca de arrastre.

Nota: Para la profundidad máxima de labranza, fijar

la estaca de arrastre en la posición más baja. Dicha

configuración ofrece resistencia máxima y produce la mayor

profundidad de labranza.

Cómo ajustar la posición de la estaca de arrastre:

F

1. Aflojar la perilla.

2. Mover las ruedas hacia arriba o hacia abajo.

NOTA: la posición superior es para labrar; la inferior para

transporte.

3. Después de ajustar las ruedas a la altura deseada,

apretar la perilla de manera segura.

Cómo ajustar la altura de las ruedas:

G

Starting Engine (Continued):

C

Cómo ajustar la velocidad del motor:

D

Si la unidad aún no arranca, consúltese la sección

DIAGNÓSTICO Y RESOLUCIÓN DE PROBLEMAS

de este manual o:

Si se necesita ayuda o se tienen preguntas,

LLAMAR GRATUITAMENTE AL: 1-800-737-2112

Cómo arrancar un motor ahogado

1. Colocar la motoazada sobre una superficie plana.

2. Mover el interruptor de encendido a la posición de

encendido («ON»).

3. Mover la palanca del estrangulador a la posición «Marcha

/ Arranque en caliente». (Véase la Figura 7)

4. Mantener el gatillo completamente accionado en la

posición FAST («RÁPIDA»). (Véase la Figura 10)

5. Tirar de la empuñadura del arrancador de retroceso

repetidamente hasta que el motor arranque y se ponga en

marcha. Esto podría hacer necesario tirar de la empuñadura

del arrancador de retroceso muchas veces, dependiendo

de cuán ahogada esté la unidad.

6. Si el motor aún no arranca, dejar la unidad en reposo

durante aproximadamente 15 minutos; luego, repetir los

pasos del 1 al 5.

Nota: esta motoazada está equipada con un embrague

centrífugo; así, las azadas no giran sino hasta que se

aumenta la velocidad del motor.

Para aumentar la velocidad del motor, apretar el gatillo del

regulador. (Véase la Figura 10)

Para disminuir la velocidad de marcha del motor, soltar

lentamente el gatillo del regulador. Al soltarse completamente

la palanca del regulador el motor vuelve a la marcha en

vacío y las azadas dejan de rotar.

1. Soltar el gatillo del regulador y dejar que el motor marche en vacío momentáneamente. (Véase la Figura 10)

2. Oprimir y retener el interruptor de encendido en la posición «STOP» («PARAR»). (Véase la Figura 6)

Cómo parar el motor:

E

Fig. 10

FAST

SLOW

Drag stake

Detent Pin

Holes

Support Bracket

Page 28

¿Preguntas? Llamar gratuitamente al 1-800-737-2112 Copyright © 2011 MAT Engine Technologies, LLC

ADVERTENCIA

Colocar el interruptor en la posición de apagado («OFF») y desconectar la bujía antes de efectuar labores de

mantenimiento, excepto por ajustes al carburador. Reconectar el cable de la bujía al completarse el servicio.

Mantenimiento

• Guardar todas las instrucciones

Filtro de aire

A

Para limpiar ambos filtros de aire se deben seguir las

instrucciones siguientes: