Page 1

Look inside for:

Page

Safety Definitions ......................2-3

Important Safety Information .............3-4

Product Specifications ...................5

Parts & Features .......................5

Assembly ............................6-7

Operation ............................8-9

Maintenance.......................... 10

Storage.............................. 10

Troubleshooting ...................... 11

Technical Service ..................... 11

Warranty............................. 12

08/03/2018 Printed in China A203970

Operator’s Manual

GASOLINE POWERED

CULTIVATOR

43CC, 2 CYCLE

Model No. PCV43.2

Record the following for future reference:

Mfg. Date Code:________________

Date of Purchase: ____________ Attach a copy of your sales receipt.

Consumer Toll Free Number: 1-800-737-2112

Refer to the website for electronic manual and parts book.

www.powermateoutdoor.com

IMPORTANT:

Thank you for purchasing this Powermate® Cultivator.

This manual provides complete instructions for safely operating, and maintaining your Cultivator. Read and save

these instructions. Refer to this manual each time before using your Earth Auger.

CONTAINS LEAD. May be harmful if eaten or chewed. May generate dust containing lead. Wash hands after use.

Keep out of reach of children.

This product can expose you to chemicals including lead, which is known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information go to www.P65Warnings.ca.gov.

KEEP THIS MANUAL FOR FUTURE REFERENCE

If you have a question or problem...

CALL TOLL FREE: 1-800-737-2112

WARNING

WARNING

Page 2

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 2

Safety Definitions

• Save all instructions

Important Safety Information

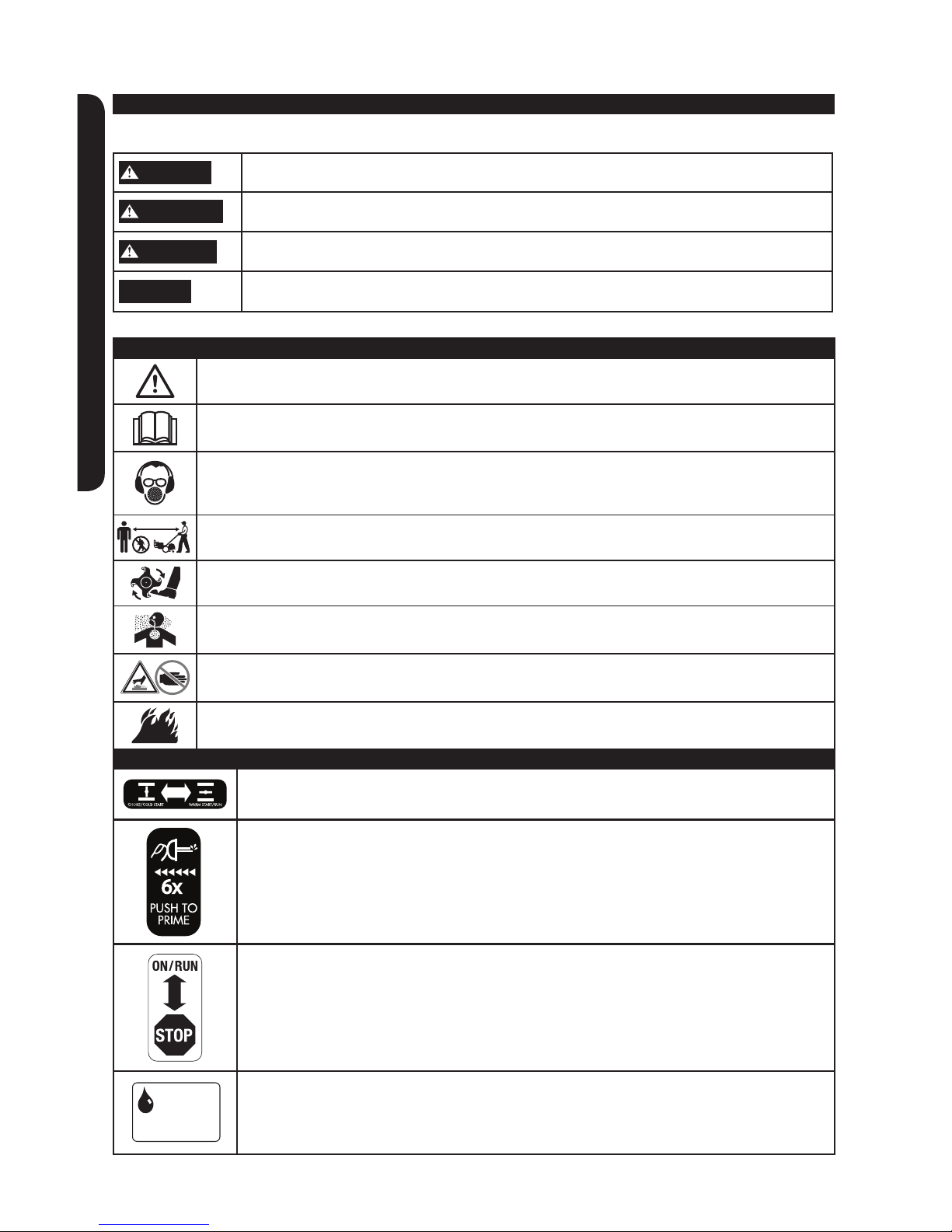

The following symbols may be found on your cultivator. Carefully read and understand their meaning.

Look for this symbol to point out important safety precautions. It means: Attention! Become Alert!

Your Safety Is Involved.

Read operator’s manual before operating this machine. Failure to follow directions could result in

serious injury.

Always wear eye protection that meets or exceeds the requirements of ANSI Z87.1. Wear hearing

protection. Wear breathing protection.

Do not use if children or bystanders are present.

Keep hands, feet, and clothing away from rotating tines. Contact with rotating tines may result in

serious injury.

Engine exhaust contains carbon monoxide, an odorless and deadly gas. NEVER run unit indoors

or in a poorly ventilated area.

Extremely hot surface. Do not touch a hot muffler, gear box or cylinder, you may get burned. These

parts get extremely hot from operation and remain hot for a short time after the unit is turned off.

To reduce risk of fire, clean spilled gas and oil and keep unit free from debris. Gasoline is

extremely flammable. Allow machine to cool completely before refueling.

DANGER

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

WARNING

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

NOTICE

Indicates a practice not related to personal injury which, if not avoided, may result in

property damage.

The information listed below should be read and understood by the operator. We utilize the symbols below to allow

the reader to recognize important information about their safety.

Safety Alert Symbols:

Choke Control:

Choke/Cold Start • Warm Start/Run

Fuel Primer:

Press 6 times.

Ignition Switch:

ON/RUN

OFF/STOP

Fuel Mixture

50:1

Unleaded Gas: 2 Cycle Oil

Caution: Do Not Use Gas

Mix with More Than 10%

Methanol or Ethanol

Fuel Mixture:

50:1

(Unleaded Gas : 2 Cycle Oil)

Safety Warning Symbols:

Control and Operating Symbols:

Page 3

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 3

Safety Definitions (Continued)

• Save all instructions

Important Safety Information

• Save all instructions

Important Safety Information

Before Operating Cultivator

NOTE: READ AND UNDERSTAND ALL INSTRUCTIONS BEFORE OPERATING CULTIVATOR. Be thoroughly familiar with the

controls and the proper use of the equipment. Know how to stop the unit and disengage the controls quickly.

WARNING

Read and follow all warnings and safety instructions. Failure to do so can result in serious injury to you or bystanders.

1. Avoid Dangerous Environments

a. Do not operate cultivator while under the influence of alcohol, medications, or drugs.

b. Do not operate cultivator when you are tired.

c. Do not use this cultivator if you are mentally or physically unable to operate safely.

2. Inspect cultivator for damaged parts, and make sure all fasteners and guards are in place and secure. Replace any

damaged parts.

3. Dress properly when operating cultivator.

a. Always wear heavy long pants, boots, gloves, and a long-sleeve shirt.

b. Do not wear loose clothing or jewelry that can get caught in the moving parts of the cultivator.

c. Always wear gloves and substantial foot wear when working outside.

d. Always wear protective hair covering to contain long hair.

4. Always wear a face or dust mask if operation is dusty.

5. Always wear eye protection that meets or exceeds the requirements of ANSI Z87.1.

6. Always wear hearing protection which meets or exceeds ANSI standards.

7. Thoroughly inspect the area where the cultivator is to be used and remove all foreign objects.

8. Keep the area of operation clear of all persons, particularly small children, and pets.

9. Never allow children to operate the equipment. Never allow adults to operate the equipment without proper instruction.

10. Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their property,

and themselves.

While Operating Cultivator

1. Stay alert. Use common sense. Watch what you are doing.

2. Do not operate cultivator if it is damaged or not securely and fully assembled.

3. Never operate the cultivator without good visibility or light.

4. Never operate the machine without proper guards, plates, or other safety protective devices in place.

5. Keep all parts of your body away from the rotating tines. Do not put hands or feet near or under rotating parts.

6. Keep children and pets away.

7. Use only for jobs explained in this manual. Do not use cultivator for any job except that for which it is intended.

8. Maintain your balance and proper footing at all times. Do not overload the machine capacity by attempting to till too deep.

9. After striking a foreign object, stop the engine, remove the wire from spark plug, thoroughly inspect the machine for any

damage, and repair the damage before restarting and operating the machine.

10. Never leave the machine unattended. Stop the engine when leaving the operating position.

11. Stop the engine before unclogging the tines, and when making any repairs, adjustments, and inspections.

Control and Operating Symbols: (Continued)

Throttle Control:

SLOW

FAST

Page 4

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 4

While Operating Cultivator (Continued)

12. Be careful when tilling in hard ground. The tines may catch in the ground and propel the cultivator forward. If this

occurs, let go of the handles and do not restrain the machine.

13. Use extreme caution when pulling the machine towards you.

14. Do not force cultivator. It will do the job better and with less likelihood of a risk of injury at the rate for which it was designed.

DANGER

Never start or run the unit inside a closed room or building; breathing exhaust fumes can kill.

15. Exercise extreme caution when operating on or crossing gravel drives, walks, or roads. Stay alert for hidden hazards

or traffic.

16. Exercise caution to avoid slipping or falling.

17. If the unit should start to vibrate abnormally, stop the engine and check immediately for the cause. Vibration is generally

a warning sign of trouble.

18. Never operate the machine at high transport speeds on hard or slippery surfaces.

19. Start the engine carefully according to instructions and with feet well away from the tines.

20. Never pick up or carry a machine while the engine is running.

CAUTION

Prolonged exposure to vibrations through use of gasoline powered hand tools could cause blood vessel or nerve damage

in fingers, hands, and joints of people prone to circulation disorders or abnormal swellings. Extensive use in cold weather

has been linked to blood vessel damage in otherwise healthy people. If symptoms occur such as numbness, pain, loss of

strength, change in skin color or texture, or loss of feeling in the fingers, hands, or joints, discontinue the use of this tool

and seek medical attention.

Fuel Safety

1. Mix and pour fuel outdoors WHERE THERE ARE NO SPARKS OR FLAMES.

2. Use a container approved for gasoline.

3. Do not smoke or allow smoking near fuel or the cultivator.

4. Avoid spilling fuel or oil. Wipe up all fuel spills.

5. Move at least 10 feet (3 meters) away from fueling site before starting engine. Do not refuel a hot engine.

Do not refuel a running engine.

6. Stop engine and allow to cool before removing fuel cap. Remove fuel cap slowly.

7. Never store engine with fuel in the tank indoors. Fuel and fuel vapors are highly flammable.

8. Replace all fuel tank and container caps securely.

Maintenance & Storage of Cultivator

1. Stop the engine, and disconnect the spark plug before servicing, cleaning, or performing maintenance on the unit.

Never attempt to make any adjustments while the engine is running.

2. Maintain cultivator with care. Inspect cultivator periodically. Keep machine, attachments, and accessories in

safe working condition. If cultivator is not working properly or damaged, have it repaired by a qualified service center.

3. Check for misalignment of moving parts, binding of moving parts, broken parts, and any other condition that

may affect its operation. Check shear bolts, engine mounting bolts, and other bolts at frequent intervals for

proper tightness to be sure the equipment is in safe working condition.

4. Keep guards in place and in working order.

5. A guard or other part that is damaged should be properly repaired or replaced by a qualified service center.

6. Use only genuine Powermate® replacement parts and accessories. Use of any non-Powermate® parts or

accessories could lead to injury, damage the unit, and void your warranty.

7. Do not remove or modify any parts. Removing or modifying parts could lead to injury, damage the machine

and will void the warranty.

8. Keep handles dry, clean, and free from oil and grease.

9. Allow engine to cool and empty the fuel tank before storing or transporting in vehicle. Use up remaining fuel

in the carburetor by starting the engine and letting it run until it stops. If the fuel tank has to be drained, do it outdoors.

10. When not in use, store cultivator indoors in a dry location. Store cultivator above the reach of children or in a

locked area out of the reach of children.

11. Store unit and fuel in area where fuel vapors cannot reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

12. Always refer to the operator’s manual for important details if the cultivator is to be stored for an extended period.

13. Follow manufacturer’s recommendations for safe loading, unloading, transport, and storage of machine.

Important Safety Information (Continued)

• Save all instructions

Page 5

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 5

Engine ..................... 43 cc, 2 cycle, Full-Crank

Idle Speed ......................... 2,800-3,000 RPM

Tilling Width ................................. 7”-10”

Tilling Depth ............................... Up to 5”

Fuel Tank Capacity..................... 28 oz (840 ml)

Fuel Type ........

Unleaded Gasoline – 89 Octane or higher

Full Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . .8,000-9,000 RPM

2-Cycle Oil Type.........

2-Cycle Oil that meets or exceeds

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

JASO – FC Specifications

Fuel Mixture .................

50:1 (Gasoline: 2-Cycle Oil)

Spark Plug ...................NHSP LD L6, NGK BM6A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CHAMPION - CJ8

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . or equivalent

Net Weight ............................33 lbs (15 kg)

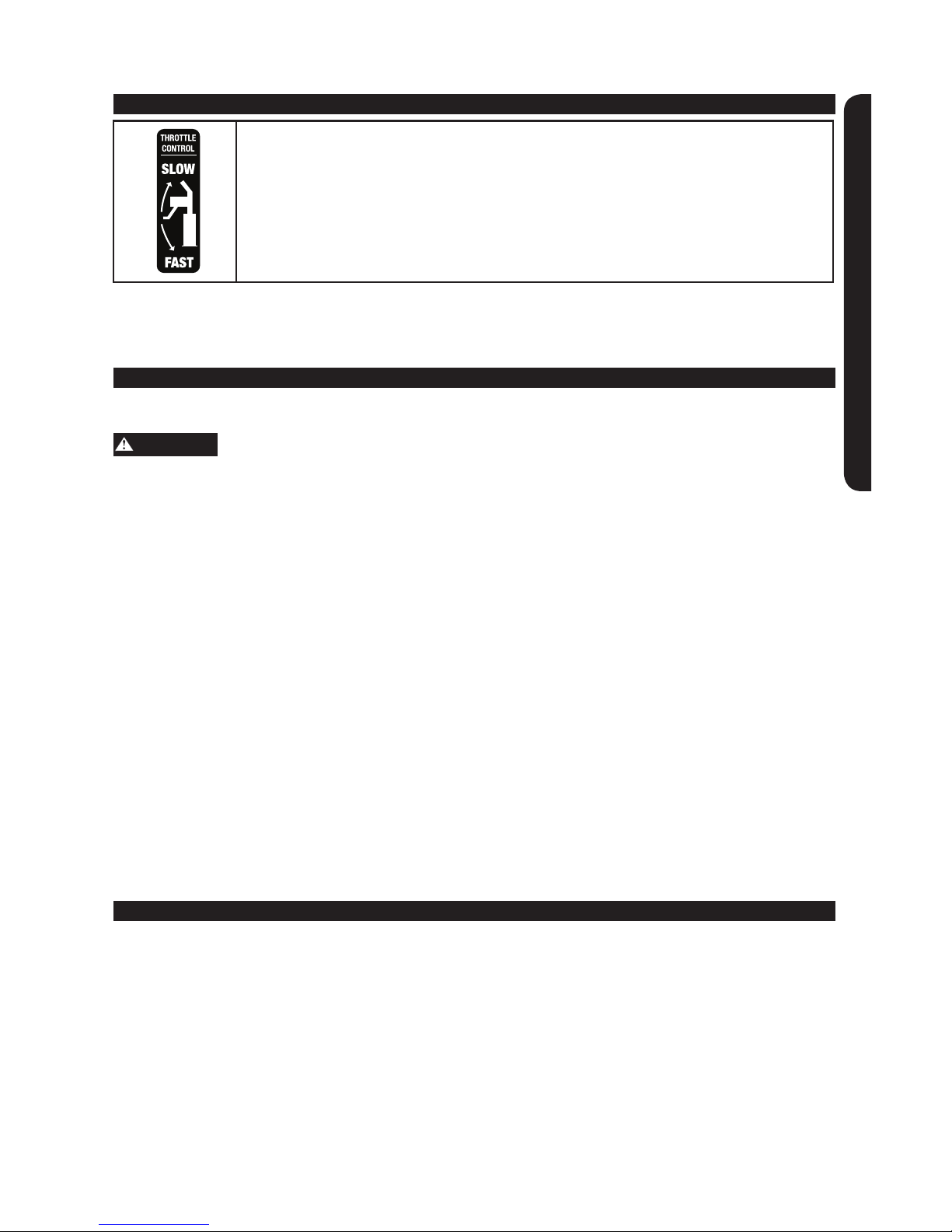

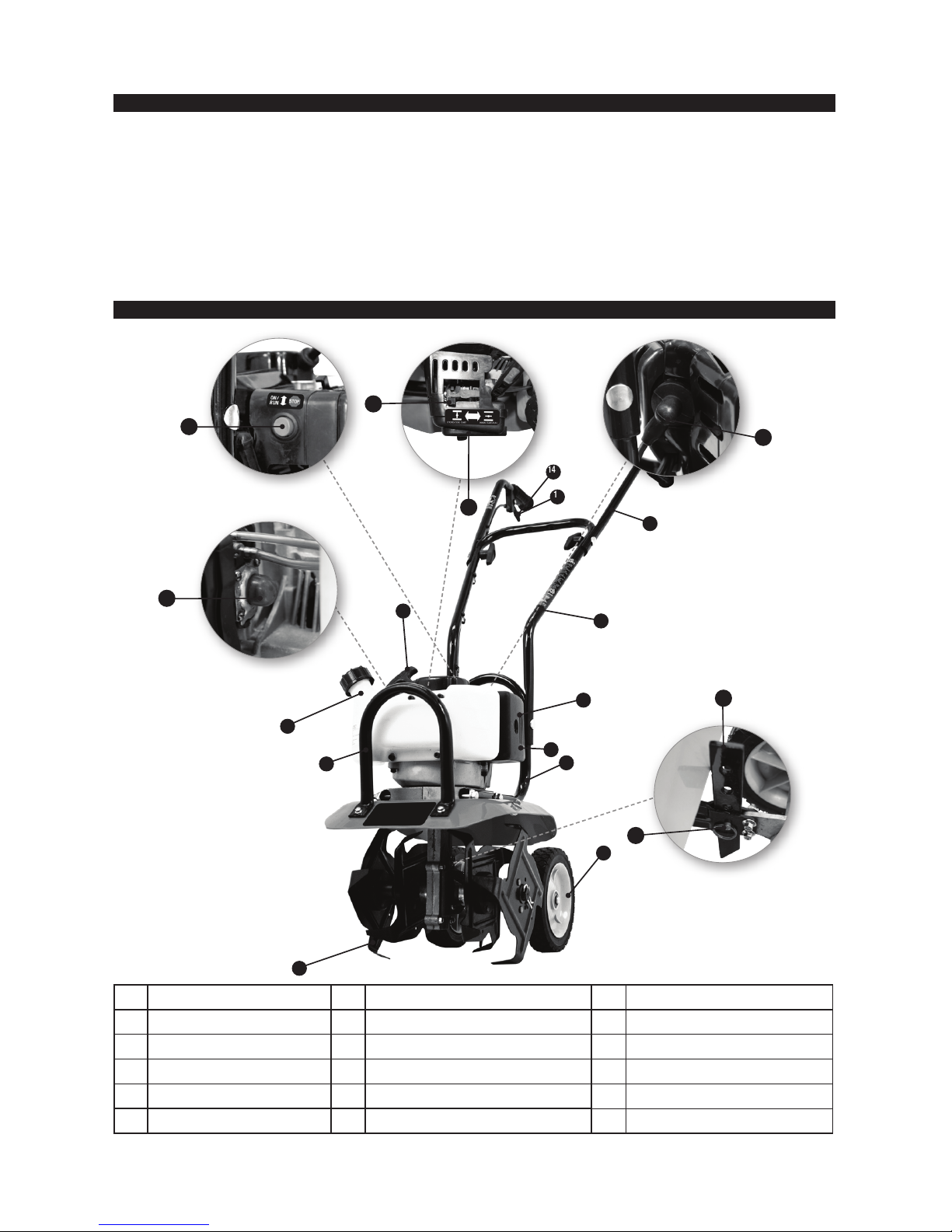

1. Ignition Switch 7. Tines 13. Air Filter Cover

2. Upper Handle 8. Recoil Starter Handle 14. Throttle Trigger

3. Middle Handle 9. Fuel Tank 15. Muffler

4. Lower Handle 10. Spark Plug 16. Drag Stake

5. Front Carry Handle 11. Fuel Primer Bulb 17. Detent Pin

6. Engine 12. Choke 18. Transport Wheels

Product Specifications

• Save all instructions

Parts & Features

6

5

4

1

15

9

7

14

18

8

2

3

1

11

13

12

10

16

17

Page 6

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 6

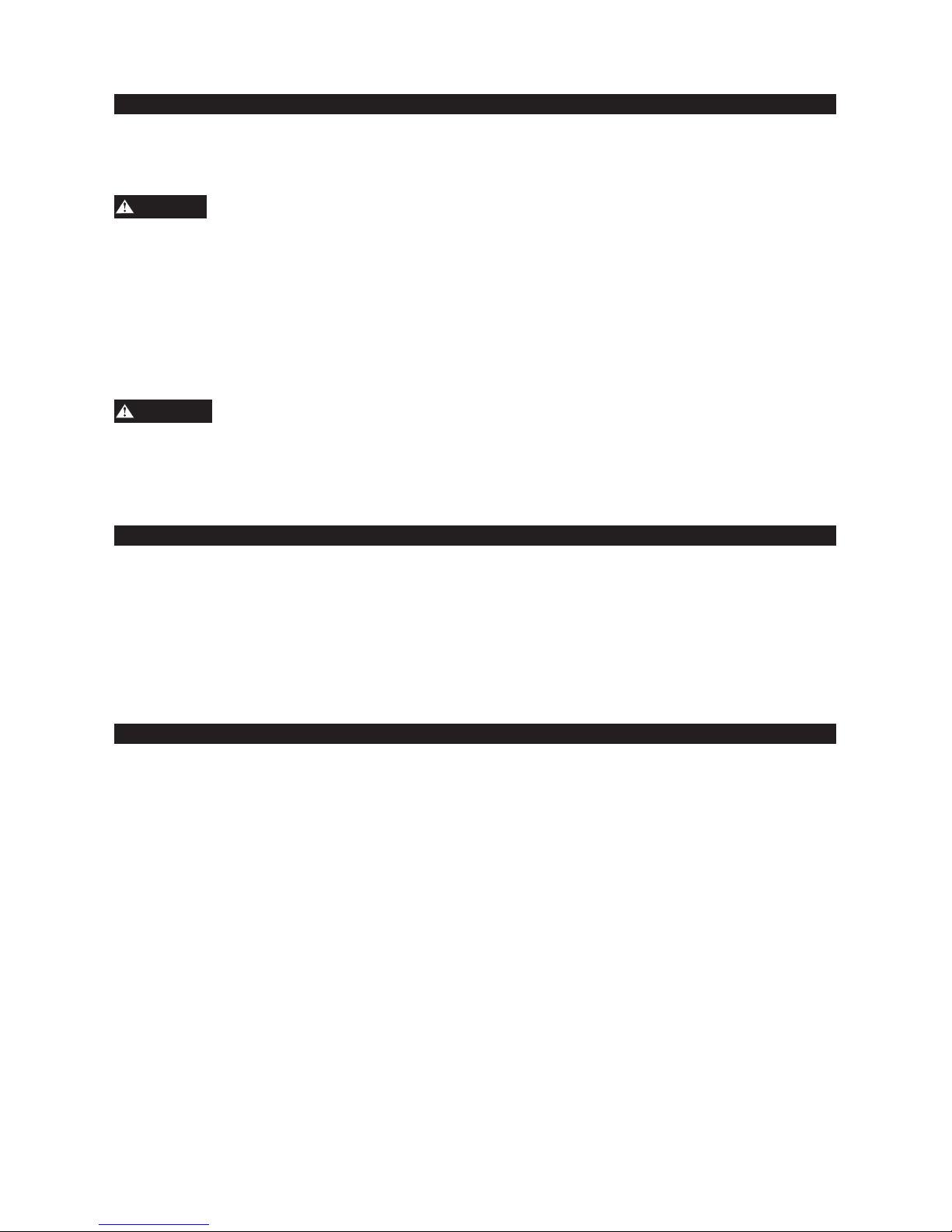

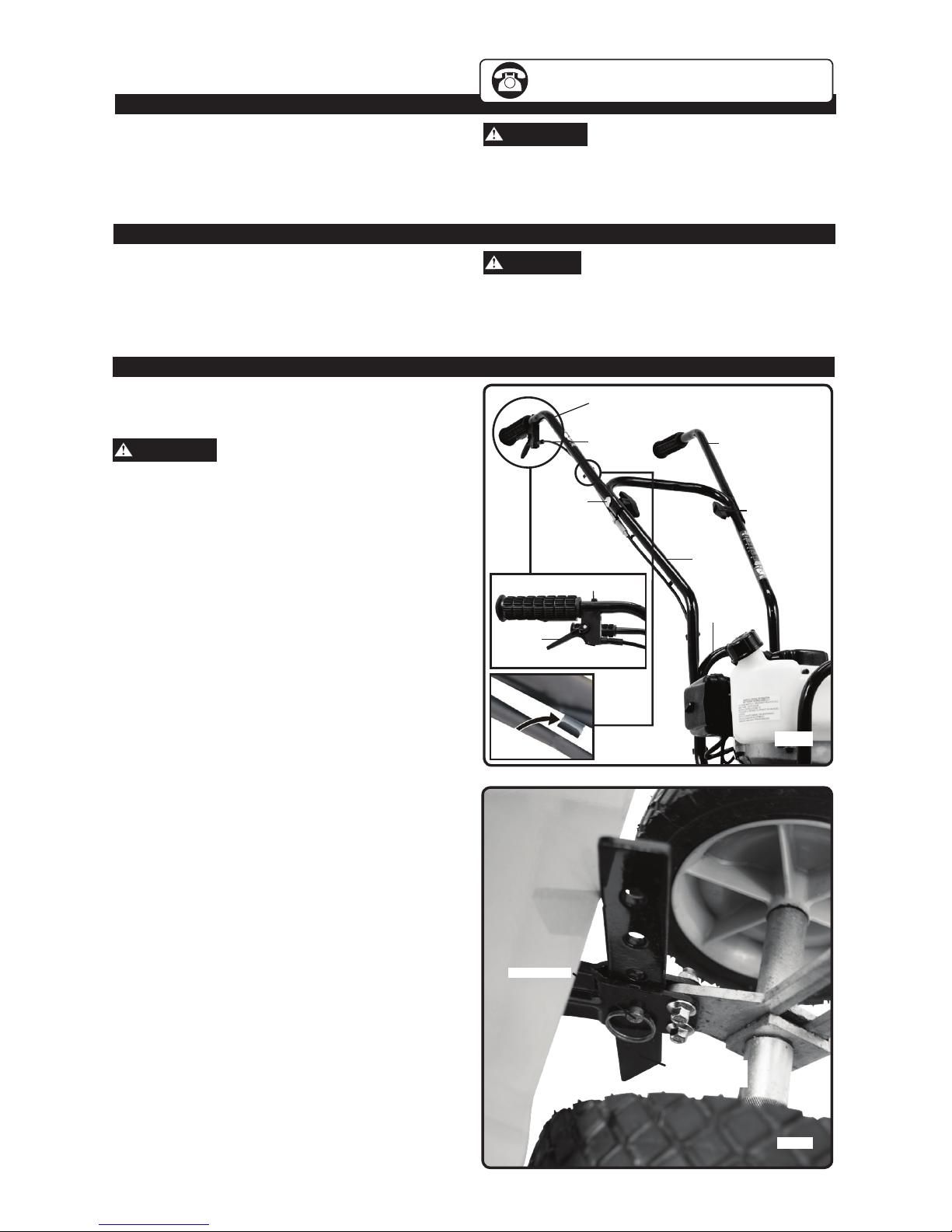

Fig. 2

Drag stake

pointed down

Detent Pin

Assembly

• Save all instructions

Parts Included with Cultivator

• Middle Handle (1)

• Upper Handles (2)

• Wing nuts and bolts (4 ea.)

• Cable Ties (3)

• Operator’s Manual (1)

• 2.6 fl. oz US bottle of 2-Cycle engine oil (1)

How to Unpack Cultivator from Carton

1. Remove all parts and packing components.

2. Use a utility knife to cut all 4 vertical edges. Lay the side

panels flat around the cultivator.

3. Remove inner components and packaging.

Fig. 1

Lower

Handle

Middle

Handle

Left Upper

Handle

Right Upper

Handle

Wingnut

Bolt

Throttle

Wire

Screw

Throttle

Trigger

If you need assistance or find any parts missing,

CALL TOLL FREE: 1-800–737-2112

WARNING

Do not operate cultivator if it is damaged or not securely and

fully assembled.

CAUTION

Use care when removing parts not to damage any cables or

wires that are attached to the parts.

4. Roll the unit out from the carton, and place on a hard

level surface.

How to Assemble the Handles and Drag Stake

1. Place the cultivator upright with tines and wheels on

a hard level surface. Wheels should be set in the

lowest position.

WARNING

Do NOT place the cultivator on a high surface where it can

fall and cause property damage or personal injury.

2. Assemble the middle handle to the lower handle with the

2 bolts and wing nuts. Refer to Figure 1. Firmly hand tighten the wing nuts.

3. Attach the upper handles to the middle handle using the

two remaining bolts and wing nuts. Refer to Figure 1.

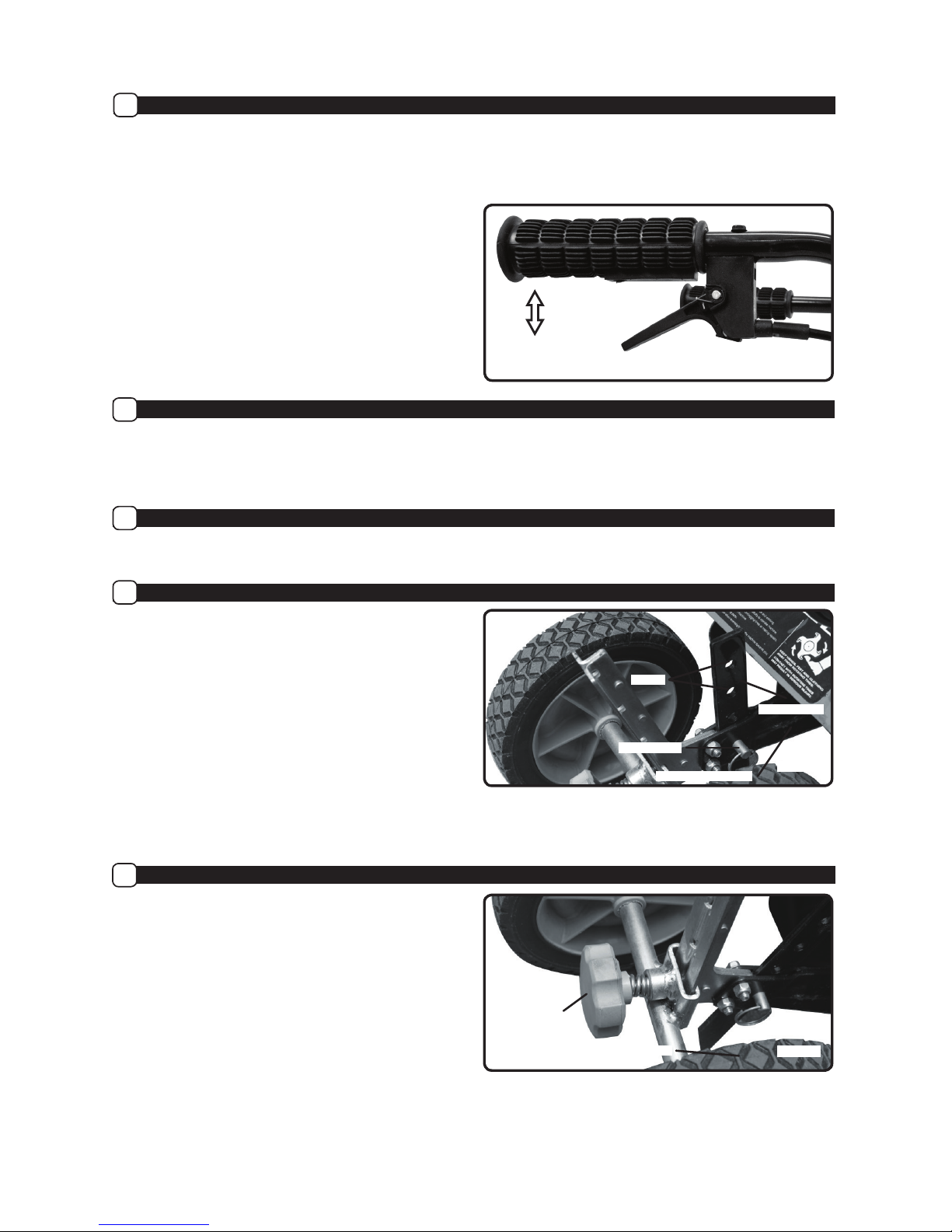

4. Assemble the throttle trigger to the right upper handle with

the screw. Use included wrench. See Figure 1.

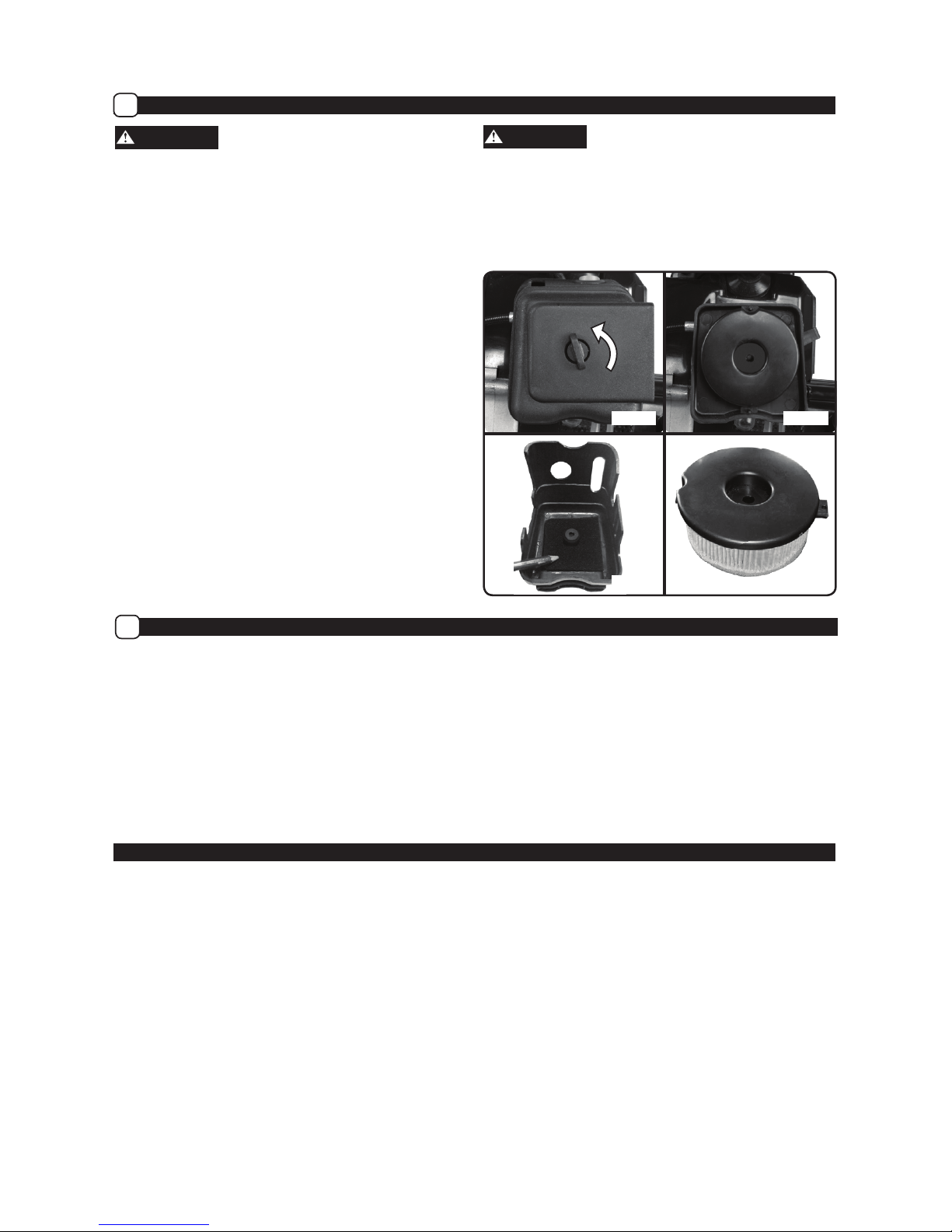

5. The drag stake is shipped with the point facing upwards.

To use for cultivating, remove detent pin, and turn the

drag stake upside down so the point faces downward.

Re-insert the detent pin. Refer to Figure 2.

6. Secure the throttle cable to the handle with FIVE

retaining clips already mounted to the handle. Refer to

Figure 1.

NOTE: Use the metal retaining clips to secure the throttle

cable, while use cable tie only to secure the ignition wire.

Page 7

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 7

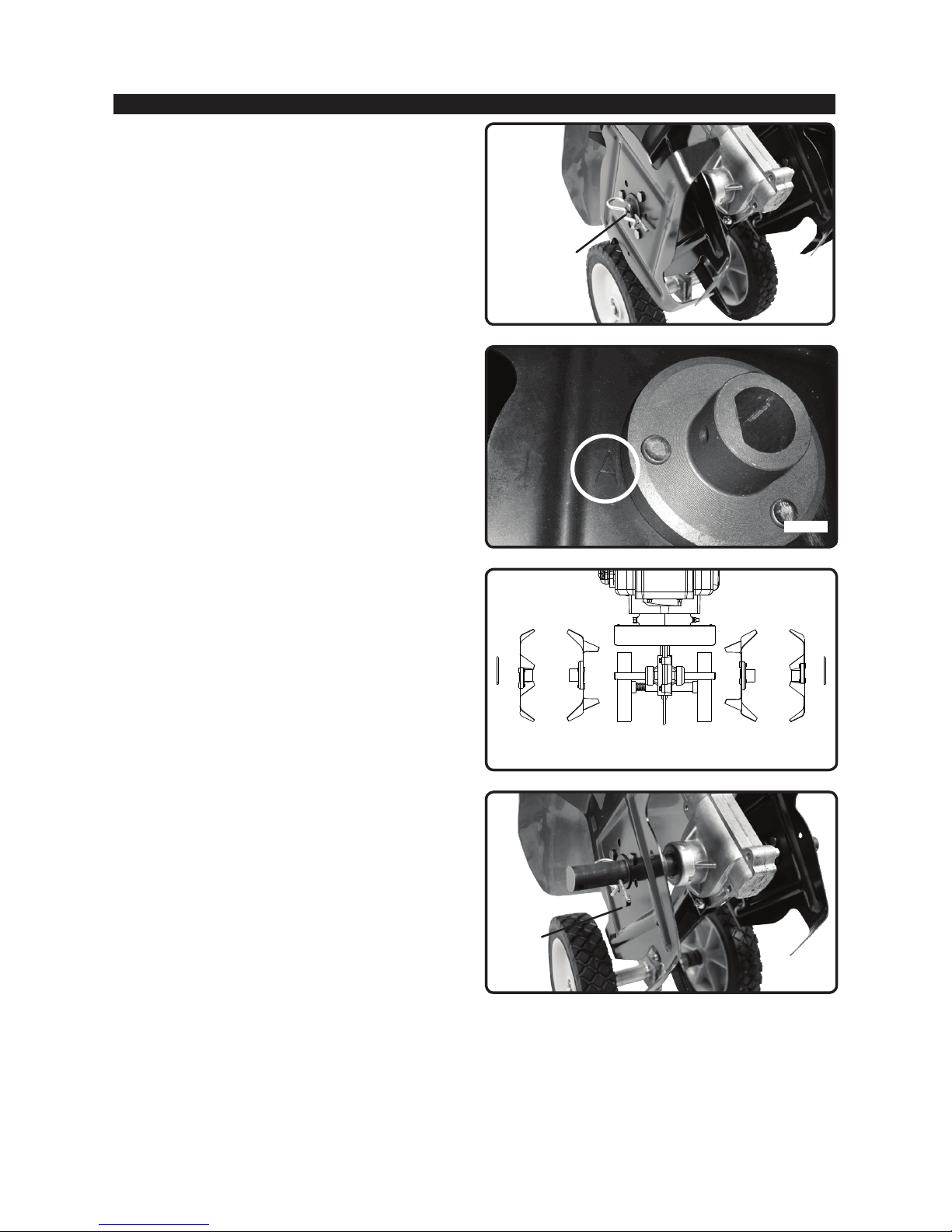

To Remove Tines:

1. Remove the pins from each end of the tine shaft. Refer

to Figure 3.

2. Slide the four tines off the tine shaft.

To Install Tines:

The 4 different tines are labeled “A”, “B”, “C”, and “D”. Refer

to Figure 4a for the location of the label.

For a 10” tilling width:

1. Assemble the tines as shown in Figure 4b. Make sure

the collars of the tines are facing each other.

2. Insert the pins into the holes at each end of the tine

shaft to lock the tines into place. See Figure 3.

For a 7” tilling width:

1. Only assemble tines B and C (the two inside tines). Do

not assemble tines A and D (the two outside tines).

Refer to figure 4b.

2. Insert the pins into the INSIDE holes of the tine shaft to

lock the tines into place. See Figure 5.

Fig. 3

Pin

D C B A

Fig. 4b

Fig. 4a

Fig. 5

Pin

Assembly (Continued)

• Save all instructions

How to Assemble the Tines

Page 8

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 8

1. Stop engine and allow it to cool before refueling.

2. Place the unit upright on the ground or on a sturdy

bench and wipe away any debris from around the

fuel cap.

Fig. 9

Fig. 7

COLD START

RUN/WARM

START

Fig. 8

PRIMER BULB

Operation

• Save all instructions

Before Starting the Engine

A

Mixing Fuel / 2-Cycle Oil

WARNING

Do not smoke or allow smoking near fuel or the cultivator.

Mix and pour fuel outdoors WHERE THERE ARE NO

SPARKS OR FLAMES.

The 2-cycle engine on your cultivator requires that fuel and

2-cycle engine oil need to be pre-mixed before adding to

the fuel tank.

WARNING

Always mix the gasoline and 2-cycle oil in a container

approved for gasoline. Never mix fuel directly in the engine

fuel tank.

Use fresh unleaded gasoline with an octane rating of 89 or

higher and less than 10% ethanol.

Use 2-cycle oil that meets or exceeds JASO – FC

specifications and is intended for mixing at a fuel to oil ratio

of 50:1. We recommend the continuous use of a 2 cycle fuel

additive/stabilizer to counteract the effects of ethanol.

These additives also prolong the shelf life of gasoline.

NOTICE

Use of incorrect gasoline such as diesel fuel or gasoline

containing more than 10% ethanol or methanol will damage

the cultivator engine and void your warranty.

NOTICE

Use of incorrect oil, such as automotive oil, 2-cycle marine

outboard oil, or any oil other than specified oil will damage

the cultivator engine and void your warranty.

To mix the fuel and 2-cycle oil, follow instructions on 2-cycle

oil container for mixing fuel. Mix gasoline and 2-cycle oil

at a ratio of 50:1. A mixture with a 50:1 ratio is obtained

by mixing 1 gallon (4 liters) of gasoline with 2.6 ounces of

oil (77 ml). After adding oil to gasoline, shake container

momentarily to ensure proper mixing.

IMPORTANT: Mix only enough fuel for your immediate needs. Do

not store pre-mixed fuel.

Adding Fuel to Cultivator

B

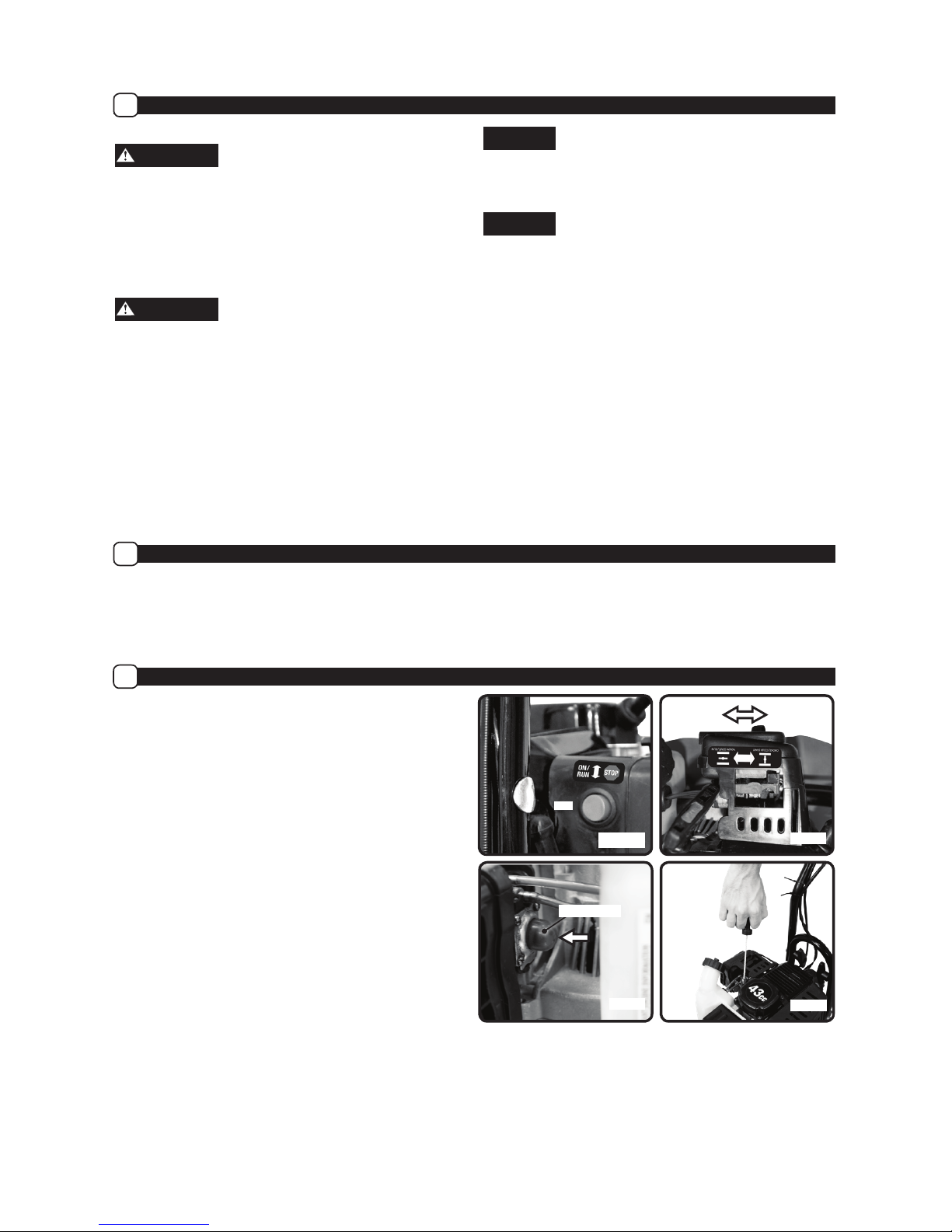

Starting the Engine

C

Starting a Cold Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘cold start’ position.

(See Figure 7)

4. Press the primer bulb slowly 6 times. (See Figure 8)

5. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

6. Pull the recoil starter handle sharply until the engine

starts and runs

7. After engine starts and runs for 10-15 seconds, move

choke lever to “run/ warm start” position. (See Figure 7)

Starting a Warm Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the “on” position. (See Figure 6)

3. Move the choke lever to the ‘run/ warm start’ position.

(See Figure 7)

4. Grab the recoil starter handle with your right hand, and

support the cultivator with your left hand. (See Figure 9)

5. Pull the recoil starter handle sharply until the engine

starts and runs.

Fig. 6

ON

3. Remove fuel cap slowly and use a funnel to pour the

mixture into the tank, and replace the fuel cap.

4. Avoid spilling fuel or oil. Wipe up all fuel spills.

5. Move at least 10 feet (3 meters) away from fueling site

before starting engine.

Page 9

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 9

Starting a Flooded Engine

1. Place the cultivator on a flat surface.

2. Move the ignition switch to the ON position.

3. Move the choke lever to the ‘run/ warm start’ position.

(see Figure 7)

4. Hold the throttle trigger fully depressed in fast position.

(See Figure 10)

5. Pull the recoil starter handle repeatedly until engine

starts and runs. This could require pulling the recoil

starter handle many times, depending on how badly the

unit is flooded.

6. If the engine still does not start, allow the unit to sit for

about 15 minutes, and repeat steps 1-5.

NOTE: This cultivator is equipped with a centrifugal clutch, so the tines will not turn until the engine speed is increased.

To increase the engine speed, lift up on the throttle trigger. (See Figure 10) To slow the engine down, slowly release the

throttle trigger. Completely releasing the throttle lever will return the engine to idle and will stop the tines from rotating.

1. Release the throttle trigger and allow the engine to idle

for a few moments. (See Figure 10)

Fig. 10

FAST

SLOW

Fig. 11

Drag stake

Detent Pin

Holes

Support Bracket

Fig. 12

Knob

Wheels

Operation (Continued)

• Save all instructions

Starting the Engine (Continued)

C

Adjusting Engine Speed

D

Stopping the Engine

E

Adjusting the Drag Stake Position

F

The drag stake adds resistance when cultivating which

makes the unit easier to control. It also can be adjusted to

change the depth of cultivating. To adjust the drag stake

position, follow the steps below and refer to Figure 11:

1. Remove the detent pin

2. Slide the stake to the desired position, aligning the hole

in the stake with the holes in the support bracket

3. Insert the detent pin through the holes to secure the

drag stake.

NOTE: For the deepest cultivating depth, set the drag stake in

its lowest position. This will give the greatest resistance and

allow for the deepest depth.

Adjusting the Wheel Height

G

1. Loosen knob.

2. Move the wheels up or down.

NOTE: The upper position is for cultivating, the lower position

is for transport

3. Tighten knob securely after adjusting the wheels to the

desired height.

NOTE: If the unit still doesn’t start, refer to the

TROUBLESHOOTING section of this manual or: If you

need assistance or have any questions, CALL TOLL FREE:

1-800–737-2112

.

2. Move the ignition switch to the ‘stop’ position.

(See Figure 6)

Page 10

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 10

Inspect the spark plug after every 10-15 hours of use;

adjust spark plug gap and replace spark plug as necessary.

Replace spark plug every year to maintain engine

performance and easy starting.

To inspect or replace the spark plug:

1. Remove the insulated spark plug boot.

2. Use the spark plug wrench to remove the spark plug, by

turning counter-clockwise.

Maintenance

• Save all instructions

Air Filter

A

WARNING

Turn off ignition switch, and disconnect the spark plug before

performing maintenance except for carburetor adjustments.

Reconnect the spark plug wire after the service is done.

Your cultivator has been equipped with two (2) air filters

inside the air filter housing to prevent dirt and debris from

entering the engine.

Accumulated debris and dust in the air filters will reduce

engine performance, increase fuel consumption, and

increase the risk of damage to the engine. Inspect the air

filters frequently for dust and debris build-up, and clean the

air filters every 5 hours of operation (more frequently in dusty/

dirty conditions).

Both air filters should be cleaned by following these

instructions:

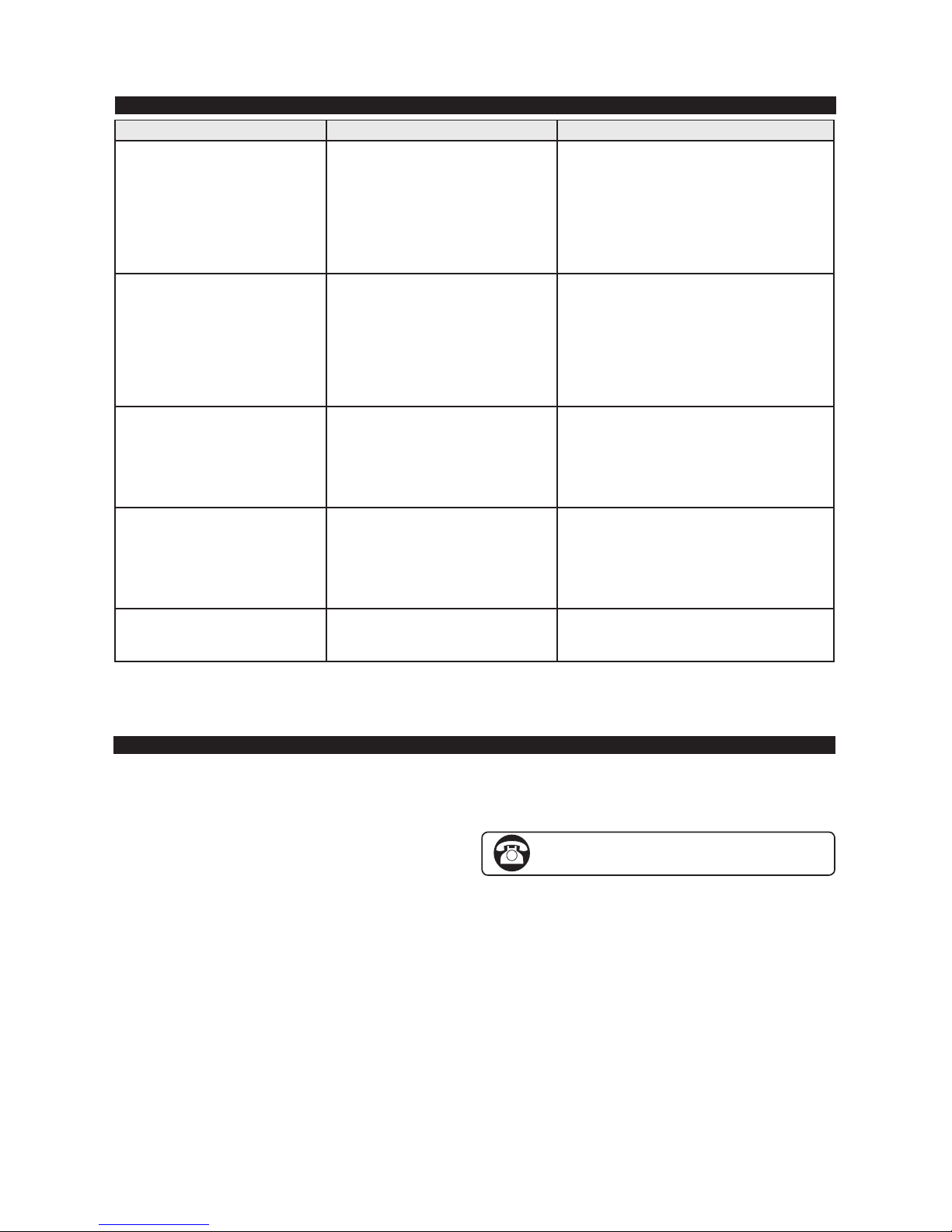

1. Before removing air filter cover, brush away any loose

dirt or debris on and around the filter cover.

2. Remove the screw securing the air filter cover. (Fig 13)

3. Remove and clean foam filter. (Fig 15)

• Light surface dust can readily be removed by

tapping the filter.

• Heavy deposits should be washed out in soap and

water. Squeeze out any remaining water and allow

the filter to completely dry.

Spark Plug

B

Storage

To prevent fuel gum deposits and corrosion in the unit’s

carburetor and fuel system, it is highly recommended to use

a fuel additive/stabilizer formulated for ethanol fuels. Follow

the stabilizer manufacturer’s instructions. Run the engine at

least 5 minutes after adding stabilizer.

1.

Allow engine to cool and empty the fuel tank before

storing or transporting in vehicle. Use up remaining fuel in

the carburetor by starting the engine and letting it run until

it stops.

2. When not in use, store cultivator indoors in a dry

location. Store cultivator above the reach of children or

in a locked area out of the reach of children.

3. Store unit and fuel in area where fuel vapors cannot

reach sparks or open flames from water heaters, electric

motors or switches, furnaces, etc.

4. When preparing the cultivator for storage or when

cultivator will not be used for 30 days or more:

a. Empty fuel tank and use up remaining fuel in the

carburetor by starting the engine and letting it run

until it stops. Squeeze primer bulb several times to

purge fuel from carburetor.

b. Inspect and clean the cultivator thoroughly.

c. Lightly oil all external metal surfaces.

d. Remove the spark plug, place a few drops of

2-cycle engine oil into the cylinder. Pull the recoil

starter several times to distribute the oil. Replace

the spark plug.

e. Inspect and clean air filter as required.

WARNING

Never clean filter in gasoline or other flammable solvents.

4. Add a drop of thin oil to the filters and replace it.

5. Remove the paper air filter element.(Fig 16) Clean filter

by gently tapping it on a flat surface. Replace if

very dirty.

6. Reassemble the filter element and the air filter cover.

3. Visually inspect the spark plug for cracks or damage.

If damaged, replace spark plug with a recommended

replacement (see “Product Specifications”).

4. Clean carbon deposits. If excessive carbon build up,

replace spark plug.

5. Adjust the spark plug gap to 0.024 – 0.028 in.

(0.6 - 0.7mm).

6. Install the spark plug finger tight in the cylinder head,

and then tighten firmly with the spark plug wrench.

7. Re-install the insulated spark plug boot.

Fig. 13 Fig. 14

Fig. 16Fig. 15

Page 11

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 11

PROBLEM POSSIBLE CAUSE(S) SOLLUTION(S)

Engine will not start. 1.

Ignition Switch in the “OFF” position.

2. Engine flooded.

3. Fuel Tank empty.

4. Spark Plug not firing.

5. Fuel not reaching carburetor.

6. Carburetor requires adjustment.

1. Move ignition switch to the ON position.

2. See Starting a Flooded Engine in

OPERATION section.

3. Fill tank with correct fuel mixture.

4. Replace Spark Plug.

5. Check for kinked or split fuel line; repair or

replace.

6. Contact a qualified service center.

Engine will not accelerate, lacks

power or stalls.

1.

Fuel not reaching carburetor.

2. Air filter dirty.

3. Spark plug fouled.

4. Carburetor requires adjustment.

5. Carbon build-up on muffler outlet

screen.

6. Compression low.

1.

Check for kinked or split fuel line; repair or

replace.

2. Clean air filter.

3. Clean or replace spark plug

4. Contact a qualified service center.

5. Contact a qualified service center.

6. Contact a qualified service center.

Engine smokes excessively. 1. Fuel mixture incorrect.

2. Air filter dirty.

3. Carburetor requires adjustment.

4. Choke lever in the CHOKE/COLD

START position.

1. Empty Fuel Tank and refill with correct fuel

mixture.

2. Clean or replace air filter.

3. Contact a qualified service center.

4. Rotate choke lever to the RUN/WARM

START position.

Engine runs hot. 1. Fuel mixture incorrect.

2. Spark Plug incorrect.

3. Carburetor requires adjustment.

4. Carbon build-up on muffler outlet

screen.

1. See Mixing Fuel / 2-Cycle Oil in

OPERATION section.

2. Replace with correct Spark Plug.

3. Contact a qualified service center.

4. Contact a qualified service center.

Engine will not idle properly. 1. Carburetor requires adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Contact a qualified service center.

2. Contact a qualified service center.

3. Contact a qualified service center.

You may have further questions about assembling, operating, or maintaining this cultivator. If so, you can contact our

Technical Service Department at 1-800-737-2112 (English only).

You may also write to:

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

If you need assistance or have any questions, CALL

TOLL FREE: 1-800–737-2112

Troubleshooting

• Save all instructions

Technical Service

When contacting the Technical Service Department, have ready:

• Your Name

• Your Address

• Your Phone Number

• Model Number of Product

• Date of Purchase (include copy of receipt for written requests)

Page 12

Questions? Call Toll Free at 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

ENG - 12

Always specify model number when contacting the factory.

We reserve the right to amend these specifications at any time without notice. The only warranty applicable is our standard written

warranty. We make no other warranty, expressed or implied.

MAT Engine Technologies, LLC

warrants this Cultivator and any

parts thereof, to be free from defects in material and workmanship for two years from the date of first purchase from an authorized

dealer, provided that the product has been properly maintained and operated in accordance with all applicable instructions. This

warranty is extended only to the original retail purchaser. The bill of sales or proof of purchase must be presented at the time a

claim is made under this warranty. This warranty does not cover commercial, industrial, or rental usage, nor does it apply to parts

that are not in original condition because of normal wear and tear, or parts that fail or become damaged as a result of misuse,

accident, lack of proper maintenance, tampering, or alteration. Travel, handling, transportation, and incidental costs associated with

warranty repairs are not reimbursable under this warranty and are the responsibility of the owner. To the full extent allowed by the

law of the jurisdiction that governs the sale of the product, this express warranty excludes any and all other expressed warranties

and limits the duration of any and all implied warranties, including warranties of merchantability and fitness for a particular purpose

to two years from the date of first purchase, and

MAT Engine Technologies, LLC’s

liability is hereby limited to the purchase

price of the product and

MAT Engine Technologies, LLC

shall not be liable for any other damages whatsoever including indirect,

incidental, or consequential damages. Some states do not allow limitation of how long an implied warranty lasts or an exclusion or

limitation of incidental or consequential damages, so the above limitation of damages may not apply to you. This warranty provides

the original purchaser with specific rights.

For information regarding those rights, please consult the applicable state laws.

METL Corporate Office - CORRESPONDENCE ONLY

ATTN: Technical Service – METL

6700 Wildlife Way

Long Grove, IL 60047

The Engine Emissions Control System Warranty is provided by the engine manufacturer, included with this product and

administered by MAT Engine Technologies, LLC.

Warranty

• Save all instructions

Powermate® CULTIVATOR Limited Warranty

A

If you have any questions regarding your warranty

coverage, you should contact METL customer service:

If you need assistance or have any questions,

CALL TOLL FREE: 1-800–737-2112

Page 13

Retrouver à l’intérieur :

Page

Définitions de sécurité ..................2-3

Importante information de sécurité.........3-5

Spécifications du produit .................5

Pièces et caractéristiques ................6

Assemblage ..........................7-8

Fonctionnement .......................9-10

Entretien ............................. 11

Rangement........................... 12

Dépannage .......................... 12

Service technique . . . . . . . . . . . . . . . . . . . . 13

Garantie ............................. 13

Veuillez noter les éléments suivants pour une référence future :

Code – Date de fabrication :____________

Date d’achat : __________Joignez une copie de votre reçu de caisse.

Numéro sans frais – service à la clientèle : 1-800-737-2112

Référez au site Web pour un manuel sous forme électronique et un catalogue des

pièces. www.powermateoutdoor.com

IMPORTANT :

Nous vous remercions d’avoir acheté cette motobineuse Powermate®

Veuillez lire et comprendre tous les avertissements et directives dans ce manuel, avant de faire fonctionner cet

appareil. Un usage inapproprié de cet appareil peut causer de sérieuses blessures ou la mort. Conservez ce

manuel pour référence ultérieure.

CONTIENT DU PLOMB. Peut être dangereux si avalé ou mâché. Peut produire de la poussière à teneur en plomb.

Lavez-vous les mains après l’utilisation. Gardez hors de la portée des enfants.

Ce produit peut vous exposer à des produits chimiques, y compris le plomb qui est reconnu par l’état de la Californie

comme pouvant causer le cancer, des anomalies congénitales ou d’autres dommages aux fonctions reproductrices.

Pour obtenir des renseignements supplémentaires, allez sur www.P65Warnings.ca.gov.

CONSERVEZ CE MANUEL POUR RÉFÉRENCE FUTURE

Si vous avez une question ou un problème...

APPELEZ SANS FRAIS : 1-800-737-2112

08/03/2018 Imprimé en Chine A203970

Manuel de l’usager

MOTOBINEUSE À ESSENCE

43 CC, 2 TEMPS

No. de modèle PCV43.2

AVERTISSEMENT

AVERTISSEMENT

Page 14

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 2

Définitions de sécurité

• Conservez ces directives

Importante information de sécurité

Les symboles suivants peuvent être trouvés sur votre cultivateur. Lire attentivement et comprendre leur signification.

Recherchez ce symbole qui indiquera d’importantes mises en garde de sécurité, relativement aux

risques de blessures. Il signifie :

“ Attention! Soyez attentifs! Votre sécurité est en jeu.”

Veuillez lire le manuel de l’usager, avant de faire fonctionner cet appareil. Le défaut de suivre les directives pourrait provoquer de sérieuses blessures.

Toujours porter une protection oculaire rencontrant ou excédant les exigences ANSI Z87.1. Porter

une protection auditive. Porter une protection respiratoire.

Ne pas utiliser en présence d’enfants ou de spectateurs.

Maintenir les mains, les pieds et les vêtements à l’écart des dents rotatives. Un contact avec dents

rotatives pourrait se solder par de sérieuses blessures.

Le gaz d’échappement du moteur contient du monoxyde de carbone, un gaz inodore et mortel. Ne

JAMAIS faire fonctionner cette unité à l’intérieur ou dans un espace mal ventilé.

Surface extrêmement chaude. Ne touchez pas un tuyau d’échappement, un multiplicateur de

vitesse ou un cylindre chaud, vous pourriez vous brûler. Ces pièces deviennent extrêmement

chaudes durant le fonctionnement et peuvent demeurer ainsi pour une courte période de temps

après avoir fermé l’unité.

Pour réduire le risque d’incendie, nettoyer les déversements d’essence et d’huile et maintenir l’unité

libre de résidus. L’essence est extrêmement inflammable. Laissez l’unité refroidir avant de refaire

le plein.

DANGER

Signale une situation imminente et dangereuse qui, si elle n’est pas évitée, entraînera la

mort ou des blessures graves.

AVERTISSEMENT

Signale une situation potentiellement dangereuse susceptible, si elle n’est pas évitée,

d’entraîner la mort ou des blessures.graves.

MISE EN GARDE

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, peut entraîner

des blessures légères ou modérées.

Indique une pratique non liée à des blessures qui, si elle n’est pas évitée, peuvent entraîner

des dommages matériels.

Les symboles suivants sont utilisés sur le produit et dans ce manuel pour alerter l’opérateur de potentiels dangers

concernant la sécurité. Assurez-vous de les lire attentivement et de comprendre leur signification.

Symboles d’avertissement de sécurité

Contrôle de l’étrangleur :

Démarrage en marche / à chaud (Run/Warm Start)

Démarrage avec étrangleur / à froid (Choke/Cold Start)

Ampoule d’amorce pour carburant :

Comprimez 6 fois.

Interrupteur d’allumage :

MARCHE (ON)

ARRÊT (OFF)

Fuel Mixture

50:1

Unleaded Gas: 2 Cycle Oil

Caution: Do Not Use Gas

Mix with More Than 10%

Methanol or Ethanol

Mélange de carburant :

50:1

(Essence sans plomb : Huile à 2 temps)

Symboles d’avertissement de sécurité

Symboles de contrôle et de fonctionnement

AVIS

Page 15

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 3

Définitions de sécurité

• Conservez ces directives

Importante information de sécurité

• Conservez ces directives

Importante information de sécurité

Avant de Faire Fonctionner la Motobineuse

NOTA : Familiarisez-vous complètement avec les contrôles et l’usage approprié de l’appareil. Apprenez à arrêter l’unité et

désengagez les contrôles rapidement.

AVERTISSEMENT

Lisez et suivez tous les avertissements et les directives de sécurité. Le défaut de suivre cette procédure pourrait provoquer de

sérieuses blessures à vous-même et aux spectateurs.

1. Évitez les environnements dangereux.

a. N’opérez pas la motobineuse lorsque vous êtes sous l’influence d’alcool, de médicaments d’ordonnance ou de drogues.

b. N’opérez pas la motobineuse lorsque vous êtes fatigué.

c. N’utilisez pas cette motobineuse si vous êtes mentalement ou physiquement inapte à opérer cet appareil en toute sécurité.

2. Vérifiez la motobineuse pour détecter la présence de pièces endommagées. Assurez-vous que toutes les attaches et les

dispositifs de sécurité sont bien fixés en place. Au besoin, remplacez les pièces endommagées.

3. Portez des vêtements adéquats à l’usage de la motobineuse.

a. Portez toujours des pantalons longs, bottes, gants et une chemise à manches longues.

b. Ne portez pas de vêtements amples ou des bijoux pouvant se coincer dans les pièces mobiles de la motobineuse.

c. Portez toujours des gants et de robustes souliers, lors de travail à l’extérieur.

d. Portez toujours une coiffe protectrice pour contenir les cheveux longs.

4. Portez toujours un masque facial ou anti-poussière, si l’opération est poussiéreuse.

5. Portez toujours une protection oculaire qui rencontre ou excède les exigences ANSI Z87.1.

6. Portez toujours une protection auditive, rencontrant ou excédant les normes ANSI.

7. Vérifiez avec soin la zone où la motobineuse sera utilisée et retirez tous les corps étrangers.

8. Maintenez la zone de travail exempte de spectateurs, surtout de jeunes enfants et d’animaux.

9. Ne laissez jamais les enfants opérer cet appareil. Ne laissez jamais des adultes opérer cet appareil sans les directives

appropriées.

10. Souvenez-vous que l’opérateur ou l’usager est responsable des accidents ou des dangers envers les autres personnes,

leurs biens et eux-mêmes.

Durant le Fonctionnement de la Motobineuse

1. Demeurez vigilant. Utilisez le bon sens. Prenez garde à ce que vous faites.

2. N’utilisez pas la motobineuse si celle-ci est endommagée ou si elle n’est pas assemblée complètement et de façon sécuritaire.

3. N’utilisez jamais la motobineuse sans avoir une bonne visibilité ou une bonne lumière.

4. N’utilisez jamais l’appareil sans vous assurer que les protecteurs, plaques et autres dispositifs de sécurité sont bien en place.

5. Maintenez toutes les parties de votre corps à l’écart des dents rotatives. Ne placez pas les mains ou les pieds près ou

sous les pièces rotatives.

6. Maintenez les enfants et les animaux à l’écart.

7. Utilisez-la uniquement pour effectuer des travaux décrits dans ce manuel. N’utilisez pas cette motobineuse à d’autres

fins que celles pour lesquelles elle a été conçue.

8. Maintenez votre équilibre et tenez-vous bien campé en tout temps. Assurez-vous de ne pas surcharger la capacité de

l’appareil, en tentant de labourer trop profondément.

9. Après avoir frappé un objet, arrêtez le moteur, débranchez le câble de la bougie d’allumage, vérifiez soigneusement

l’appareil pour détecter tout dommage et réparez le dommage avant de redémarrer et d’utiliser à nouveau l’appareil.

Symboles de contrôle et de fonctionnement (Suite)

Contrôle de l’accélérateur :

LENT

RAPIDE

Page 16

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 4

10. Ne laissez jamais l’appareil sans surveillance. Arrêtez le moteur, en laissant la position d’opération.

11. Arrêtez le moteur avant de débloquer les dents et lorsque vous effectuez des réparations, réglages et inspections.

12. Soyez prudent en labourant un sol durci. Les dents pourraient se bloquer dans le sol et projeter la motobineuse vers

l’avant. Si une telle situation se produit, relâchez les guidons et ne tentez pas de retenir l’appareil.

13. Faites preuve de prudence extrême, en tirant l’appareil vers vous.

14. Ne forcez pas la motobineuse. Celle-ci offrira un meilleur rendement et ce, avec moins de risque de blessures,

lorsqu’elle est utilisée au rythme pour lequel elle a été conçue.

DANGER

Assurez-vous de ne jamais démarrer ou faire fonctionner l’unité à l’intérieur d’une pièce fermée ou d’un édifice ; respirer

les émanations de l’échappement peuvent tuer.

15. Faites preuve d’extrême précaution, en faisant fonctionner et en traversant des entrées, passages ou chemins de gravillons.

Demeurez vigilants pour reconnaître les dangers cachés ou le trafic.

16. Soyez vigilants pour éviter de glisser ou de tomber

17. Si l’unité commence à vibrer de façon anormale, arrêtez le moteur et vérifiez immédiatement la cause. Normalement une

vibration représente un avertissement de problème.

18. Ne faites jamais fonctionner cet appareil à vitesse rapide sur des surfaces dures et glissantes.

19. Faites démarrer le moteur avec soin, en suivant les directives et en maintenant les pieds bien à l’écart des dents.

20. Assurez-vous de ne jamais soulever ni transporter un appareil, lorsque le moteur est en marche.

MISE EN GARDE

Une exposition prolongée à des vibrations lors de l’usage d’outils motorisés à essence peut causer des dommages aux

vaisseaux sanguins et aux nerfs des doigts, des mains et des articulations des personnes sujettes à des désordres de

circulation ou à des enflures anormales. Un usage intensif par temps froid a été relié à des dommages aux vaisseaux

sanguins, auprès de personnes normalement en santé. Si des symptômes comme l’engourdissement, douleur, perte de

force, changement de couleur ou de texture de peau ou encore, une perte de sensibilité des doigts, des mains ou des

articulations, cessez l’utilisation de cet outil et consultez un médecin.

Manipulation Sécuritaire - Carburant

1. Mélangez et versez le carburant à l’extérieur, OÙ IL N’Y A PAS D’ÉTINCELLES, NI DE FLAMMES NUES.

2. Utilisez un contenant approuvé pour l’essence.

3. Assurez-vous de ne pas fumer, ni de permettre de le faire près de carburants ou de la motobineuse.

4. Évitez de renverser du carburant ou de l’huile. Essuyez tous les déversements de carburant.

5. Déplacez-vous à au moins 3 m (10 pi) à l’écart du point de remplissage, avant de démarrer le moteur.

Ne remplissez pas un moteur chaud. Ne remplissez pas un moteur en marche.

6. Arrêtez le moteur et laissez refroidir, avant de retirer le bouchon de réservoir. Retirez lentement le bouchon de réservoir.

7. Ne rangez jamais à l’intérieur un moteur ayant du carburant dans le réservoir. Le carburant et les vapeurs de

carburant sont hautement inflammables.

8. Replacez fermement tous les bouchons de réservoir et de contenant de carburant.

Entretien et Rangement de la Motobineuse

1. Arrêtez le moteur et débranchez la bougie d’allumage avant de procéder au nettoyage, à l’inspection ou à des

réparations de l’unité. Ne tentez jamais d’effectuer des réglages lorsque le moteur est en marche.

2. Prenez grand soin de la motobineuse. Vérifiez l’unité périodiquement. Conservez l’appareil, les attachements

et accessoires en bon état de fonctionnement. Si la motobineuse ne fonctionne pas adéquatement ou est

endommagée, assurez-vous de la faire réparer dans un centre de service qualifié.

3. Vérifiez pour détecter un alignement défectueux ou un coincement des pièces mobiles, des pièces brisées

et toute autre condition qui pourrait en affecter le fonctionnement. Vérifiez les boulons de cisaillement, boulons

de montage du moteur et autres boulons à intervalles fréquents pour un serrage approprié et vous assurer que

l’appareil est en bon état de fonctionnement.

4. Maintenez les dispositifs de protection en place et en bon ordre de fonctionnement.

5. Un dispositif de protection ou toute pièce endommagée devrait être réparée ou remplacée correctement dans

un centre de service qualifié.

6. Utilisez uniquement des pièces de rechange et accessoires originaux Powermate®. L’utilisation de pièces

de rechange et accessoires autres que Powermate®, pourrait provoquer des blessures, endommager l’unité et

annuler votre garantie.

7. Assurez-vous de ne pas retirer, ni de modifier quelque pièce. Le fait de retirer ou de modifier quelque pièce

pourrait provoquer des blessures, endommager la souffleuse et annulera la garantie.

8. Assurez-vous de conserver les guidons secs, propres et libres d’huile et de graisse.

Importante information de sécurité (Suite)

• Conservez ces directives

Importante information de sécurité

Durant le Fonctionnement de la Motobineuse (Suite)

Page 17

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 5

Moteur ... 43 cc, 2 temps, vilebrequin à double roulement

Vitesse au ralenti . . . . . . . . . . . . . . 2,800-3,000 tours/minute

Largeur de labourage . . . . . . . . . . . . . . . De 17,7 à 25,4 cm

Profondeur de labourage. . . . . . . . . . . . . . . Jusqu’à 12,7 cm

Capacité du réservoir de carburant . . 840 ml (28 oz liq US)

Type de carburant . . . . . . . . . . . . . . . .

Essence sans plomb –

indice d’octane de 89 ou plus

Plein régime . . . . . . . . . . . . . . . . . . . . 8,000-9,000 tours/minute

Type d’huile – 2 temps . . . . . .

Huile à 2 temps rencontrant ou

excédant les spécifications JASO – FC

Mélange de carburant . . . . . .

50:1 (Essence : Huile à 2 temps)

Bougie d’allumage . . . . . . . . . . . . . NHSP LD L6, NGK BM6A

CHAMPION - CJ8

ou équivalent

Poids net . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 kg (33 lbs)

Importante information de sécurité (Suite)

• Conservez ces directives

Spécifications du produit

• Conservez ces directives

Entretien et Rangement de la Motobineuse (Suite)

9. Laissez le moteur refroidir et videz le réservoir de carburant, avant de le ranger ou le transporter dans un

véhicule. Utilisez le carburant restant dans le carburateur, en démarrant le moteur et en le laissant fonctionner,

jusqu’à ce qu’il s’arrête. Si le réservoir de carburant requiert un drainage, assurez-vous de l’effectuer à l’extérieur.

10. Lorsqu’elle n’est pas en usage, rangez la motobineuse à l’intérieur à un endroit sec. Rangez la motobineuse

au-dessus de la portée des enfants ou dans un endroit sous clé, hors de la portée des enfants.

11. Rangez l’unité et le carburant à un endroit où les émanations de carburant ne peuvent rejoindre des étincelles

ou des flammes nues, provenant de chauffe-eau, moteurs ou interrupteurs électriques, fournaises, etc.

12. Référez toujours au manuel de l’usager concernant des détails importants, su vous devez ranger la

motobineuse durant une période de temps prolongée.

13. Suivez les recommandations du fabricant concernant la sécurité du chargement, déchargement, transport et

rangement de l’appareil.

Page 18

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 6

1. Interrupteur d’allumage 7. Dents 13. Couvercle de filtre à air

2. Guidon supérieur 8. Poignée du lanceur à rappel 14. Levier de l’accélérateur

3. Guidon intermédiaire 9. Réservoir de carburant 15. Silencieux

4. Guidon inférieur 10. Bougie d’allumage 16. Barre de recouvrement

5. Poignée avant de transport 11. Ampoule d’amorce pour carburant 17. Cheville de sécurité

6. Moteur 12. Étrangleur 18. Roues de transport

Pièces et caractéristiques

6

5

4

1

15

9

7

14

18

8

2

3

1

11

13

12

10

16

17

Page 19

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 7

Fig. 2

Barre de

recouvrement

pointée vers le bas

Cheville de

sécurité

Assemblage

• Conservez ces directives

• Guidon intermédiaire (1)

• Guidons supérieurs (2)

• Boulons et écrous à ailettes (4 de chaque)

• Attaches en plastique pour câbles (3)

• Manuel de l’usager (1)

• Bouteille d’huile à moteur à 2 temps -

(77 ml / 2.6 oz liq US)(1)

AVERTISSEMENT

N’utilisez pas la motobineuse si celle-ci est endommagée ou

incomplètement et incorrectement assemblée.

Comment déballer la motobineuse

1. Retirez toutes les pièces et les composants d’emballage.

2. Utilisez un couteau universel pour couper les 4 rebords

verticaux. Déposez les panneaux latéraux à plat autour

de la motobineuse.

3. Retirez tous les composants internes et l’emballage.

Fig. 1

Guidon

inférieur

Guidon

intermédiaire

Guidon

supérieur

gauche

Guidon supérieur droit

Écrou à

ailettes

Boulon

Câble de

l’accélérateur

Vis

Levier de

l’accélérateur

Pièces incluses avec la motobineuse

Si vous avez besoin d’assistance ou devez trouver des

pièces manquantes, APPELEZ SANS FRAIS :

1-800-737-2112.

MISE EN GARDE

En retirant les pièces, prenez soin de ne pas endommager les

câbles ou fils attachés aux pièces.

4. Déplacez l’unité en la roulant hors de l’emballage et placez-

la sur une surface dure et unie.

Comment assembler les guidons et la barre de recouvrement

1. Placez la motobineuse équipée de ses dents et roués

sur une surface dure et unie. Les roues devraient être

installées dans la position la plus basse.

AVERTISSEMENT

Ne placez PAS la motobineuse sur une surface élevée, où

elle pourrait tomber et causer des dommages matériels ou

des blessures.

2. Joignez le guidon intermédiaire au guidon inférieur, à

l’aide des 2 boulons et écrous à ailettes. Voir la

Figure 1. Resserrez fermement à la main les écrous

à ailettes.

3. Joignez les guidons supérieurs au guidon intermédiaire,

à l’aide des 2 autres boulons et écrous à ailettes. Voir la

Figure 1.

4. Fixez l’interrupteur d’allumage et le levier de

l’accélérateur au guidon supérieur droit, à l’aide d’une

vis. Utilisez la clé incluse. Voir la Figure 1.

5. La barre de recouvrement est expédiée avec l’extrémité

pointue dirigée vers le haut. Afin de l’utiliser pour

labourer, retirez la cheville de sécurité et retournez la

barre de recouvrement à l’envers, de façon à ce qu’elle

soit dirigée vers le bas. Insérez la cheville à nouveau.

Voir Figure 2.

6. Fixez le câble de l’accélérateur au guidon, à l’aide des

CINQ attaches déjà installées sur le guidon. Voir

Figure 1.

REMARQUE: Utilisez les attaches métalliques pour fixer

le câble de l’accélérateur et les attaches en plastique

seulement pour fixer le câble d’allumage.

Page 20

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 8

Pour retirer les dents :

1. Retirez les goupilles fendues, chacune située aux

extrémités de l’arbre des dents. Voir la Figure 3.

2. En les glissant, retirez les quatre dents de l’arbre des dents.

Pour installer les dents :

Les 4 unités de dents sont différentes et sont identifiées

“A”, “B”, “C” et “D”. Référez à la Figure 4a pour retrouver

l’emplacement de l’identification.

Pour une largeur de labourage de 25,4 cm :

1. Assemblez les dents, tel qu’illustré à la Figure 4b.

Assurez-vous que les collets des dents se font face.

2. Insérez une goupille fendue à chaque extrémité de

l’arbre des dents, pour bien bloquer les dents en place.

Voir Figure 3.

Pour une largeur de labourage de 17,7 cm :

1. Assemblez uniquement les dents B et C (les deux dents

intérieures). N’assemblez pas les dents A et D (les deux

dents extérieures). Référez à la Figure 4b.

2. Insérez une goupille fendue dans chaque orifice

INTÉRIEUR de l’arbre des dents, pour bien bloquer les

dents en place. Voir Figure 5.

D C B A

Fig. 4b

Goupille

fendue

Fig. 3

Fig. 4a

Fig. 5

Goupille

fendue

Assemblage (Suite)

• Conservez ces directives

Comment assembler les dents

Page 21

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 9

Fig. 9

Fig. 7

DÉMARRAGE

À FROID

MARCHE /

DÉMARRAGE

À CHAUD

Fig. 8

AMPOULE

D’AMORCE

Fonctionnement

• Conservez ces directives

Avant de démarrer le moteur

A

Mélange essence / huile à 2 temps

AVERTISSEMENT

Assurez-vous de ne pas fumer, ni de permettre de fumer

près de carburants ou de la motobineuse. Mélangez

et versez le carburant à l’extérieur, OÙ IL N’Y A PAS

D’ÉTINCELLES, NI DE FLAMMES NUES.

Le moteur à 2 temps de votre motobineuse exige d’abord

un prémélange d’essence et d’huile à moteur à 2 temps,

avant de l’ajouter dans le réservoir à carburant.

AVERTISSEMENT

Mélangez toujours l’essence et l’huile à 2 temps dans un

contenant approuvé pour l’essence. Ne mélangez jamais le

carburant directement dans le réservoir à carburant.

Utilisez de l’essence sans plomb fraîche, ne contenant pas

plus de 10% d’éthanol et possédant un indice d’octane

89 ou plus. Utilisez toujours une huile à 2 temps, rencontrant

ou excédant les spécifications JASO – FC et destiné pour

un mélange d’essence et d’huile à un ratio 50:1. Nous

recommandons l’utilisation continue d’un additif/stabilisateur de

carburant à 2 cycles pour contrebalancer les effets de l’éthanol.

Ces additifs prolongent également la durée de vie de l’essence.

AVIS

L’usage de carburant inapproprié comme le combustible

diesel ou de l’essence contenant plus de 10% d’éthanol ou

de méthanol endommagera le moteur de la motobineuse et

annulera la garantie.

AVIS

L’usage d’huile inappropriée, comme l’huile pour

automobiles ou d’huile à 2 temps pour moteur hors-bord

ou toute autre d’huile autre que le type d’huile spécifié

endommagera le moteur de la motobineuse et annulera la

garantie.

Pour mélanger le carburant à l’huile à 2 temps, suivez les

directives sur le contenant d’huile à 2 temps pour mélanger

le carburant. Mélangez l’essence et l’huile à 2 temps à

un ratio 50:1. Un mélange possédant un ratio 50:1 est

obtenu en mélangeant 3,8 litres (1 gallon US) d’essence

et 77 ml (2.6 oz liq. US) d’huile. Après avoir ajouter l’huile

à l’essence, brassez le contenant pour quelques instants,

pour assurer l’homogénéité du mélange.

IMPORTANT : Mélangez seulement la quantité nécessaire

pour subvenir à vos besoins immédiats. Ne rangez pas en un

carburant prémélangé.

Démarrage du moteur

C

Fig. 6

MARCHE

Démarrage de moteur à froid

1. Placez la motobineuse sur une surface unie.

2. Déplacez l’interrupteur d’allumage, en position de

marche (ON) (Voir Figure 6)

3. Déplacez le levier de l’étrangleur, en position de

démarrage à froid (cold start) (Voir Figure 7)

4. Comprimez lentement l’ampoule d’amorce 6 fois

(Voir Figure 8)

5. Empoignez fermement la poignée du lanceur à rappel

de la main droite et stabilisez la motobineuse de la main

gauche (Voir Figure 9)

6. Tirez la poignée de lanceur à rappel fermement, jusqu’à

ce que le moteur démarre et fonctionne.

7. Après avoir démarré et laissé fonctionner le moteur

pendant 10-15 secondes, déplacez le levier de

l’étrangleur en position de “ marche / démarrage à

chaud “ (run/warm start). (Voir Figure 7)

Démarrage de moteur à chaud

1. Placez la motobineuse sur une surface unie.

2. Déplacez l’interrupteur d’allumage, en position de

marche (ON) (Voir Figure 6)

3. Déplacez le levier de l’étrangleur, en position de

démarrage marche / démarrage à chaud “ (run/warm start)

(Voir Figure 7)

1. Arrêtez le moteur et laissez-le refroidir, avant de

procéder au remplissage.

2. Placez la motobineuse en position normale sur le sol ou

sur un banc solide et essuyez tout débris se trouvant

autour du bouchon de réservoir.

3. Retirez lentement le bouchon de réservoir et utilisez

Ajout de carburant à la motobineuse

B

un entonnoir pour verser le mélange dans le réservoir et

replacez le bouchon de réservoir.

4. Évitez de renverser du carburant ou de l’huile. Essuyez

tous les déversements de carburant.

5. Déplacez-vous à au moins 3 m (10 pi) à l’écart du point

de remplissage, avant de démarrer le moteur.

4. Empoignez fermement la poignée du lanceur à rappel

de la main droite et stabilisez la motobineuse de la main

gauche (Voir Figure 9)

5. Tirez la poignée de lanceur à rappel fermement, jusqu’à

ce que le moteur démarre et fonctionne.

Page 22

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 10

Démarrage de moteur noyé

1. Placez la motobineuse sur une surface unie.

2. Déplacez l’interrupteur d’allumage, en position de

marche (ON)

3. Déplacez le levier de l’étrangleur en position de “marche

/ démarrage à chaud“ (run/warm start) (Voir Figure 9)

4. Maintenez une pression complète sur le levier de

l’accélérateur en position rapide (Voir Figure 10)

5. Tirez la poignée de lanceur à plusieurs reprises,

jusqu’à ce que le moteur démarre et se mette en

marche. Il est possible que plusieurs tentatives soient

requises, dépendant à quel point le moteur est noyé.

6. Si le moteur ne démarre toujours pas, laissez l’unité

reposer pendant environ 15 minutes et répétez les

étapes 1 à 5.

REMARQUE : Cette motobineuse est équipée d’un embrayage à commande centrifuge, de façon à ce que les dents ne

tourneront pas avant que la vitesse du moteur ne soit augmentée.

Pour augmenter la vitesse du moteur, comprimez le levier de l’accélérateur. (Voir Figure 10)

Pour réduire la vitesse du moteur, relâchez lentement le levier de l’accélérateur. Si le levier est complètement relâché, le

moteur retournera à une vitesse au ralenti et les dents cesseront de tourner.

1. Relâchez le levier d’accélération et laissez tourner le

moteur au ralenti pendant quelques instants.

(Voir Figure 10)

Fig. 10

RAPIDE

LENT

Fig. 11

Barre de

recouvrement

Cheville de sécurité

Orifices

Support

Fig. 12

Bouton de

serrage

Roues

Fonctionnement (Suite)

• Conservez ces directives

Démarrage du moteur (suite)

C

Réglage de la vitesse du moteur

D

Arrêter le moteur

E

Réglage de la position de la barre de recouvrement

F

La barre de recouvrement ajoute un élément de résistance

lors du labourage, facilitant le contrôle de l’unité. Celle-ci

peut également être réglée pour modifier la profondeur du

labourage. Pour régler la position de la barre de recouvrement,

observez les étapes suivantes et référez à la Figure 11 :

1. Retirez la cheville de sécurité

2. Déplacez la barre vers la position désirée, en alignant

l’orifice de la barre aux orifices du support.

3. Insérez la cheville de sécurité à travers les orifices, pour

bien fixer en place la barre de recouvrement.

REMARQUE : Pour la profondeur la plus accentuée, réglez

la barre de recouvrement à la position la plus basse. Cette

procédure offrira la plus grande résistance et la profondeur

la plus accentuée.

Réglage de la hauteur des roues

G

1. Relâchez le bouton de serrage.

2. Déplacez les roues vers le haut ou vers le bas.

REMARQUE : La position supérieure sert au labourage et la

position inférieure sert au transport

3. Resserrez le bouton après avoir réglé les roues à la

hauteur désirée.

REMARQUE : Si l’unité ne démarre toujours pas, consultez la

section du COIN-DÉPANNAGE de ce manuel ou : Si vous

avez besoin d’assistance ou si vous avez des questions,

APPELER SANS FRAIS : 1-800-737-2112.

2. Déplacez et maintenez l’interrupteur d’allumage en

position d’arrêt (stop). (Voir Figure 6)

Page 23

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 11

Vérifiez la bougie d’allumage après chaque période de

10-15 heures d’usage; réglez l’écartement d’électrode de

la bougie d’allumage et remplacez la bougie d’allumage au

besoin. Remplacez la bougie d’allumage à chaque année,

pour maintenir le rendement du moteur et en faciliter le

démarrage.

Pour vérifier ou remplacer la bougie d’allumage :

1. Retirez le couvre-borne isolé de la bougie d’allumage.

2. Utilisez la clé de bougie d’allumage pour retirer la

bougie, en tournant dans le sens contraire des aiguilles

d’une montre.

3. Inspectez visuellement la bougie d’allumage pour

détecter la présence de fendillement ou de dommages.

Entretien

• Conservez ces directives

Filtre à air

A

AVERTISSEMENT

Placez l’interrupteur d’allumage en position d’arrêt (OFF)

et débranchez la bougie d’allumage avant de procéder à

l’entretien, sauf pour les réglages de carburateur. Rebranchez

la bougie d’allumage après avoir complété l’entretien.

Pour prévenir l’entrée de poussière et de débris entrent

dans le moteur, votre motobineuse est équipée de deux (2)

filtres à air en mousse, à l’intérieur du boîtier du filtre à air.

La poussière et les débris accumulés dans les filtres à

air réduiront le rendement du moteur, augmenteront la

consommation de carburant et le risque de dommages pour

le moteur. Vérifiez les filtres à air fréquemment pour détecter

une accumulation de poussière et les débris et nettoyez-les à

chaque période de 5 heures d’usage (plus fréquemment sous

des conditions poussiéreuses/sales).

Les deux filtres à air devraient être nettoyés, en observant

les directives suivantes :

1. Avant de retirer le couvercle de filtre à air, dégagez

toute trace de saleté et de débris sur le couvercle de

filtre et autour.

2. Retirez la vis fixant en place le couvercle de filtre à air.

(Figure 13)

3. Retirez et nettoyez les filtres en mousse. (Figure 13)

• Une légère poussière de surface peut être retirée

rapidement en cognant légèrement les filtres.

• Nettoyez les dépôts plus lourds à l’aide d’eau

savonneuse. Retirez l’excédent d’eau et laissez

sécher les filtres complètement.

Bougie d’allumage

B

AVERTISSEMENT

Ne nettoyez jamais les filtres à l’aide d’essence ou d’autres

solvants inflammables.

4. Ajoutez une goutte d’huile légère aux filtres et replacez-les.

5. Retirez l’élément en papier du filtre à air. (Fig. 16)

Nettoyez le filtre en le tapotant doucement sur une

surface plane. Remplacez-le s’il est très sale.6.

Remplacez l’élément filtrant et le couvercle du filtre à air.

6. Remettez l’élément du filtre et le couvercle du filtre à air

en place.

Si elle est endommagée, remplacez-la à l’aide

d’une pièce de rechange recommandée (voir les

Spécifications de Produit).

4. Nettoyez les dépôts de carbone. S’il y a une

accumulation excessive de carbone, remplacez la

bougie d’allumage.

5. Assurez-vous que l’écartement de la bougie d’allumage

mesure 0.6-0.7 mm (0.024-0.028 po).

6. Insérez la bougie d’allumage à la main dans la culasse

et resserrez-la fermement, à l’aide de la clé pour bougie

d’allumage.

7. Réinstallez le couvre-borne isolé de la bougie

d’allumage.

Fig. 13 Fig. 14

Fig. 16Fig. 15

Page 24

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 12

PROBLÈME CAUSE(S) POSSIBLE(S) SOLUTION(S)

Le moteur ne démarre pas. 1. L’interrupteur d’allumage est en

position d’arrêt (OFF).

2. Moteur noyé.

3. Réservoir de carburant vide.

4. Aucun feu dans la bougie d’allumage.

5. Le carburant n’atteint pas le

carburateur.

6. Le carburateur requiert un réglage.

1. Déplacez l’interrupteur d’allumage vers la

position de marche (ON).

2. Consultez le démarrage de moteur noyé

à la section FONCTIONNEMENT.

3. Remplissez le réservoir avec le mélange

approprié de carburant.

4. Remplacez la bougie d’allumage.

5. Vérifiez pour détecter une conduite de

carburant pliée ou fendue ; réparez ou

remplacez.

6. Contactez un centre de service qualifié.

Le moteur n’accélère pas, manque

de puissance ou tombe en panne.

1. Le carburant n’atteint pas le

carburateur.

2. Filtre à air vicié.

3. Bougie d’allumage encrassée.

4. Carburateur requiert un réglage.

5. Accumulation de carbone sur la

grille de sortie du silencieux.

6. Basse compression.

1. Vérifiez pour détecter une conduite de

carburant pliée ou fendue ; réparez ou

remplacez.

2. Nettoyez le filtre à air.

3. Clean or replace spark plug

4. Contactez un centre de service qualifié.

5. Contactez un centre de service qualifié.

6. Contactez un centre de service qualifié.

Le moteur fume excessivement. 1. Mélange de carburant incorrect.

2. Filtre à air vicié.

3. Carburateur requiert un réglage.

4. Levier d’étrangleur en position de

démarrage à froid (CHOKE/COLD

START).

1. Videz le réservoir de carburant et

remplissez avec le avec le mélange approprié

de carburant.

2. Nettoyez ou remplacez le filtre à air.

3. Contactez un centre de service qualifié.

4. Déplacez le levier de l’étrangleur en

position “ marche / démarrage à chaud “

(RUN / WARM START).

Le moteur surchauffe. 1. Mélange de carburant incorrect.

2. Bougie d’allumage inadéquate.

3. Carburateur requiert un réglage.

4. Accumulation de carbone sur la

grille de sortie du silencieux.

1. Consultez le mélange d’essence / huile à

2 temps à la section FONCTIONNEMENT.

2. Remplacez par une bougie d’allumage

appropriée.

3. Contactez un centre de service qualifié.

4. Contactez un centre de service qualifié.

Le moteur ne tourne pas

correctement au ralenti.

1. Carburateur requiert un réglage.

2. Joints d’étanchéité de vilebrequin usés.

3. Basse compression.

1. Contactez un centre de service qualifié.

2. Contactez un centre de service qualifié.

3. Contactez un centre de service qualifié.

Dépannage

• Conservez ces directives

Rangement

Pour empêcher les dépôts de gomme d’essence et la corrosion dans le carburateur et le circuit de carburant de

l’appareil, il est fortement recommandé d’utiliser un additif/

stabilisateur de carburant conçu pour les carburants à

l’éthanol. Suivez les instructions du fabricant du stabilisa-

teur. Laissez tourner le moteur pendant au moins 5 minutes

après avoir ajouté le stabilisateur.

1. Laissez le moteur refroidir et videz le réservoir de carbu

rant, avant de le ranger ou le transporter dans un véhicule.

Faites démarrer le moteur et laissez-le fonctionner,

jusqu’à ce qu’il s’arrête, pour utiliser le carburant restant

dans le carburateur.

2. Lorsqu’elle n’est pas en usage, rangez la motobineuse

à l’intérieur à un endroit sec. Rangez-la au-dessus de la

portée des enfants ou dans un endroit sous clé, hors de

la portée des enfants.

3. Rangez l’unité et le carburant à un endroit où les

émanations de carburant ne peuvent rejoindre des

étincelles ou des flammes nues provenant de chauffe-eau,

moteurs ou interrupteurs électriques, fournaises, etc.

4. Lors de la préparation de la motobineuse pour le

rangement ou que celle-ci ne sera pas utilisée pour 30

jours ou plus :

a. Videz le réservoir de carburant et faites démarrer

le moteur et laissez-le fonctionner, jusqu’à ce qu’il

s’arrête, pour utiliser le carburant restant dans le

carburateur. Pressez la poire d’amorçage plusieurs

fois pour purger le carburant du carburateur.

b. Vérifiez et nettoyez la motobineuse complètement.

c. Huilez légèrement toutes les surfaces métalliques

extér eures.

d. Retirez la bougie d’allumage, placez quelques

gouttes d’huile à moteur à 2 temps dans le cylindre.

Tirez à plusieurs reprises la poignée de lanceur

à rappel, pour distribuer l’huile. Replacez la bougie

d’allumage.

e. Vérifiez et nettoyez les filtres à air, selon le besoin.

Page 25

Questions? Appelez sans frais à : 1-800-737-2112 Copyright © 2018 MAT Engine Technologies, LLC

FR - 13

Spécifiez toujours le numéro de modèle en contactant l’usine.

Nous nous réservons le droit de modifier ces spécifications en tout temps sans préavis. La seule garantie applicable est notre

garantie régulière écrite. Nous n’offrons aucune autre garantie, expresse ou implicite. MAT Engine Technologies, LLC garantit que

cette motobineuse et toute autre pièce constituante sera libre de tout défaut relatif aux matériaux et à la main-d’œuvre, pendant

une période de deux ans, à partir de la date du premier achat auprès d’un concessionnaire autorisé, à condition que le produit ait

été entretenu et opéré adéquatement, selon les directives applicables. Cette garantie est accordée seulement à l’acheteur original

au détail. Le contrat de vente ou la preuve d’achat doit être présenté au moment où une réclamation est faite au titre de la garantie.

Cette garantie ne couvre pas un usage commercial, industriel ou locatif; elle ne couvre pas non plus les pièces qui ne sont pas

dans leur condition originale, due à l’usure normale ou des pièces qui sont défectueuses ou qui deviennent endommagées, suite

à un mauvais usage, accident, manque d’entretien approprié, modification ou altération. Les frais de déplacement, manutention,

transport et autres frais additionnels associés aux réparations sous garantie ne sont pas remboursables sous cette garantie et

demeurent la responsabilité du propriétaire. Dans la mesure autorisée par la loi de la juridiction régissant la vente de ce produit,

cette garantie expresse exclut toutes les autres garanties expresses et limite la durée de toutes les garanties implicites, incluant les

garanties de qualité marchande ou d’adaptation à un usage particulier à une période de deux ans, à partir de la date du premier

achat et par la présente, MAT Engine Technologies, LLC ne sera en aucun cas tenu responsable de quelque dommage que ce

soit, incluant les dommages indirects, accessoires ou consécutifs. Certains états / provinces ne permettent pas la limitation de la

durée d’une garantie implicite ou l’exclusion ou la limitation des dommages accessoires ou consécutifs ; ainsi les limitations ci-haut

mentionnées relatives aux dommages pourraient ne pas s’appliquer à vous. Cette garantie confère à l’acheteur original des droits

juridiques spécifiques.

Pour obtenir plus d’information au sujet de ces droits, veuillez consulter les lois applicables selon l’état / province.

METL - CORRESPONDANCE SEULEMENT

ATT’N: Service technique– METL

6700 Wildlife Way

Long Grove, IL 60047

La garantie du système de contrôle des émissions est fournie par le fabricant du moteur et est incluse avec ce produit et administrée

par MAT Engine Technologies, LLC.

Garantie

• Conservez ces directives

Garantie limitée pour motobineuse Powermate®

A

SI VOUS AVEZ DES QUESTIONS AU SUJET DE LA

COUVERTURE DE VOTRE GARANTIE, VOUS DEVRIEZ

CONTACTER LE SERVICE A LA CLIENTELE DE METL

Si vous avez besoin d’assistance ou si vous

avez des questions, APPELER SANS FRAIS :

1-800-737-2112.

Vous pourriez avoir d’autres questions au sujet de l’assemblage, du fonctionnement ou de l’entretien de cette motobineuse.

Dans ce cas, vous pouvez contacter notre département de service technique au 1-800-737-2112 (Anglais seulement).

Vous pouvez également nous écrire :

METL - CORRESPONDANCE SEULEMENT

ATT’N: Service technique– METL

6700 Wildlife Way

Long Grove, IL 60047

Service technique

En contactant le département de service technique, ayez en

main :

• Votre nom

• Votre adresse

• Votre numéro de téléphone

• Numéro de modèle du produit

• Date de l’achat(inclure une copie de votre reçu pour les