Power Integrations TNY380PNG, TinySwitch-PK Datasheet

TNY375-380

TinySwitch-PK Family

www.powerint.com May 2007

Energy-Efcient, Off-Line Switcher With

Enhanced Peak Power Performance

®

Output Power Table

Product

3

230 VAC ± 15% 85-265 VAC

Adapter

1

Open

Frame

2

Peak Adapter

1

Open

Frame

2

Peak

TNY375 P 8.5 W 15 W 16.5 W 6 W 11.5 W 12.5 W

TNY376 P 10 W 19 W 22 W 7 W 15 W 17 W

TNY377 P 13 W 23.5 W

28 W

8 W 18 W 23 W

TNY378 P 16 W 28 W 34 W 10 W 21.5 W 27 W

TNY379 P 18 W 32 W 39 W 12 W 25 W 31 W

TNY380 P 20 W 36.5 W 45 W 14 W 28.5 W 35 W

Table 1. Output Power Table.

Notes:

1. Minimum continuous power in a typical non-ventilated enclosed adapter

measured at +50 °C ambient. Use of an external heatsink will increase power

capability.

2. Minimum continuous power in an open frame design (see Key Applications

Considerations).

3. Packages: P: DIP-8C. Available as lead free (with N suffix). See Part Ordering

Information.

Product Highlights

Lowest System Cost with Enhanced Flexibility

Simple ON/OFF control, no loop compensation needed

Unique Peak Mode feature extends power range without

increasing transformer size

Maximum frequency and current limit boosted at peak loads

Selectable current limit through BP/M capacitor value

Higher current limit further extends maximum power in open

frame applications

Lower current limit improves efficiency in enclosed adapter

applications

Allows optimum TinySwitch-PK choice by swapping devices

with no other circuit redesign

Tight I2f parameter tolerance reduces system cost:

Maximizes MOSFET and magnetics power delivery

ON time extension – typically extends low line regulation range/

hold-up time to reduce input bulk capacitance

Self-biased: no bias winding required for TNY375-376; winding

required for TNY377-380

Frequency jittering reduces EMI filter costs

Optimized pin out eases pcb/external heatsinking

Quiet source-connected heatsink pins for low EMI

Enhanced Safety and Reliability Features

Accurate hysteretic thermal shutdown with automatic recovery

provides complete system level overload protection and

eliminates need for manual reset

Auto-restart delivers <3% maximum power in short circuit and

open loop fault conditions

Output overvoltage shutdown with optional Zener

Line undervoltage detect threshold set using a single optional

resistor

Very low component count enhances reliability and enables

single sided printed circuit board layout

High bandwidth provides fast turn on with no overshoot and

excellent transient load response

Extended creepage between DRAIN and all other pins improves

field reliability

EcoSmart®– Extremely Energy Efficient

Easily meets all global energy efficiency regulations

No-load <170 mW at 265 VAC without bias winding, <60 mW

with bias winding

ON/OFF control provides constant efficiency down to very light

loads – ideal for mandatory CEC efficiency regulations and 1 W

PC standby requirements

Applications

Applications with high peak-to-continuous power demands –

DVDs, set-top decoders, active speakers (e.g. PC audio),

audio amplifiers, modems, photo printers

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

Description

TinySwitch-PK incorporates a 700 V MOSFET, oscillator, highvoltage switched current source, current limit (user selectable),

and thermal shutdown circuitry. A unique peak mode feature

boosts current limit and frequency for peak load conditions. The

boosted current limit provides the peak output power while the

increased peak mode frequency ensures the transformer can be

sized for continuous load conditions rather than peak power

demands.

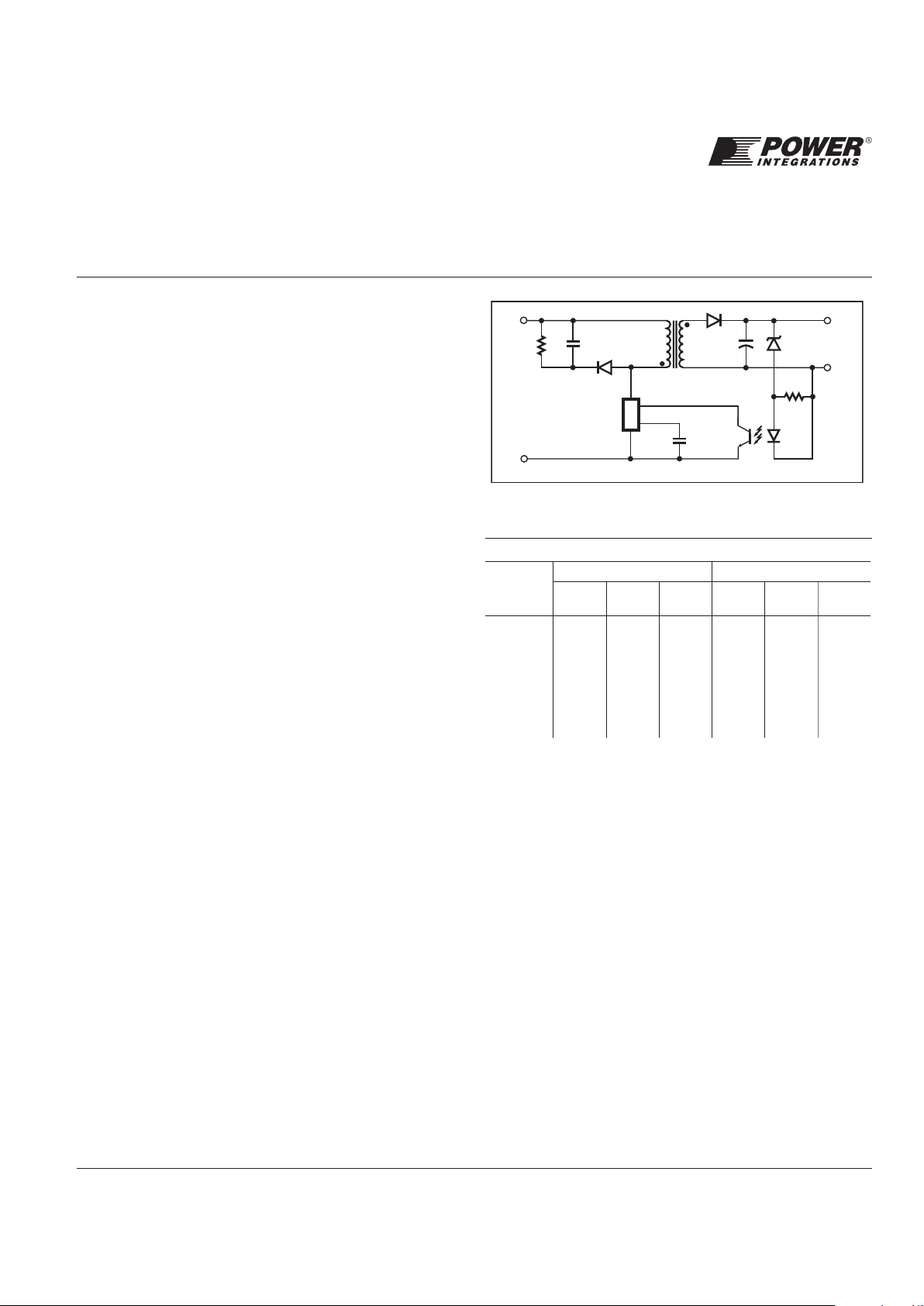

PI-4266-010906

Wide-Range

HV DC Input

D

S

EN/UV

BP/M

+

-

+

-

DC

Output

TinySwitch-PK

Figure 1. Typical Standby Application.

Rev. A 05/07

2

TNY375-380

www.powerint.com

Pin Functional Description

DRAIN (D) Pin:

This pin is the power MOSFET drain connection. It provides

internal operating current for both start-up and steady-state

operation.

BYPASS/MULTI-FUNCTION (BP/M) Pin:

This pin has multiple functions:

It is the connection point for an external bypass capacitor for

the internally generated 5.85 V supply.

It is a mode selector for the current limit value, depending on

the value of the capacitance added. Use of a 0.1 mF

capacitor results in the standard current limit value. Use of a

1 mF capacitor results in the current limit being reduced to

that of the next smaller device size (TNY376-380). Use of a

10 mF capacitor results in the current limit being increased to

that of the next larger device (TNY377-379).

It provides a shutdown function. When the current into the

bypass pin exceeds 7 mA, the device latches off until the

BP/M voltage drops below 4.9 V, during a power down or

when a line undervoltage is detected. This can be used to

provide an output overvoltage function with a Zener diode

connected from the BP/M pin to a bias winding supply.

1.

2.

3.

ENABLE/UNDERVOLTAGE (EN/UV) Pin:

This pin has dual functions: enable input and line undervoltage

sense. During normal operation, switching of the power

MOSFET is controlled by this pin. MOSFET switching is

terminated when a current greater than a threshold current is

drawn from this pin. Switching resumes when the current being

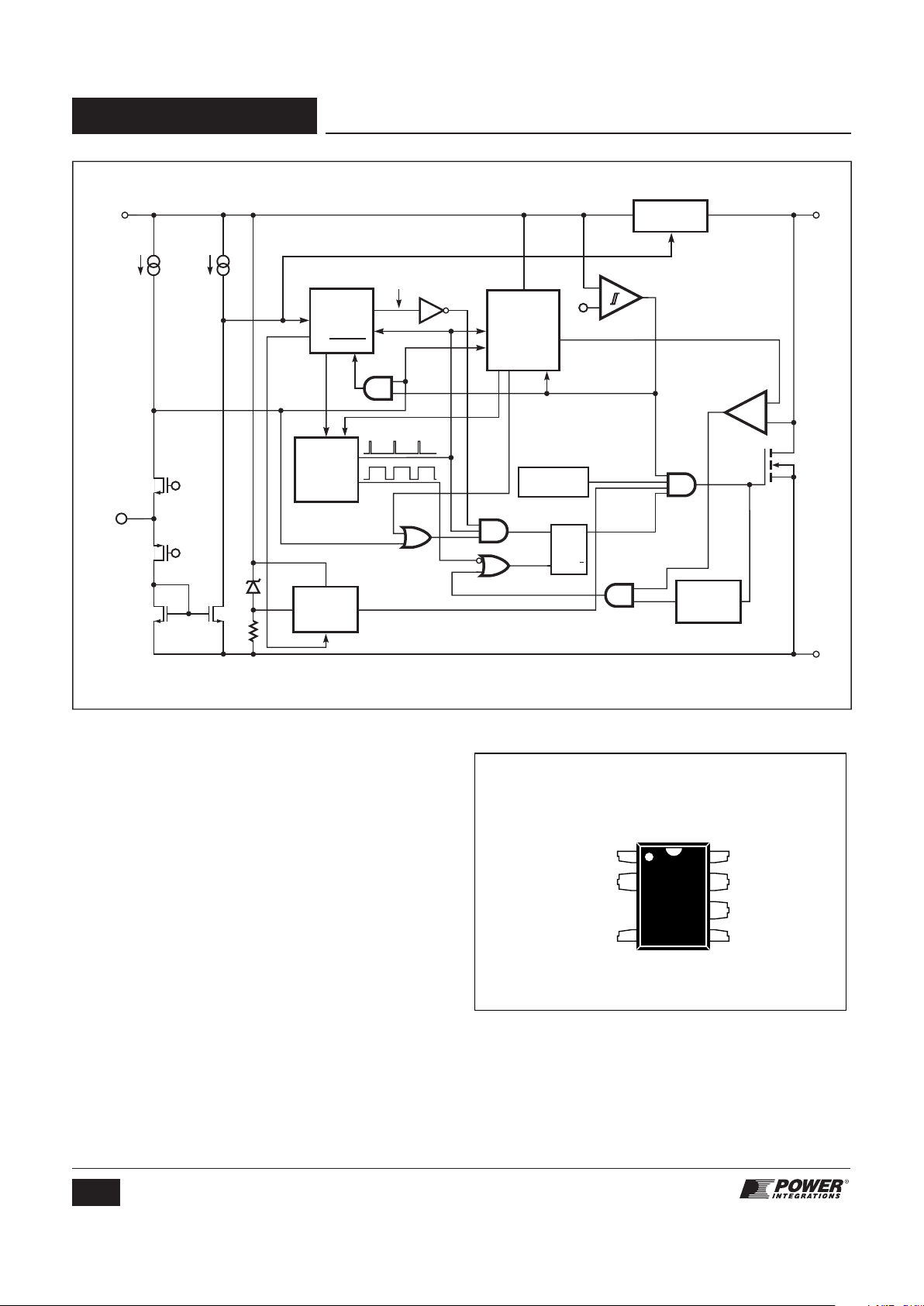

PI-4550-121406

CLOCK

OSCILLATOR

5.85 V

4.9 V

SOURCE

(S)

SRQ

DC

MAX

BYPASS/

MULTI-FUNCTION

(BP/M)

+

-

V

I

LIMIT

FAULT

PRESENT

CURRENT LIMIT

COMPARATOR

ENABLE

LEADING

EDGE

BLANKING

THERMAL

SHUTDOWN

+

-

DRAIN

(D)

REGULATOR

5.85 V

BYPASS PIN

UNDER-VOLTAGE

1.0 V + V

T

ENABLE/

UNDER-

VOLTAGE

(EN/UV)

Q

115 mA 25 mA

LINE UNDER-VOLTAGE

RESET

AUTORESTART

COUNTER

JITTER 2X

1.0 V

6.4 V

BYPASS

CAPACITOR

SELECT AND

CURRENT

LIMIT STATE

MACHINE

OVP

LATCH

RESET

Figure 2 Functional Block Diagram.

PI-4348-032806

D

S

BP/M

S

S

EN/UV

P Package (DIP-8C)

8

5

7

1

4

2

S

6

Figure 3. Pin Configuration.

Rev. A 05/07

3

TNY375-380

www.powerint.com

pulled from the pin drops to less than a threshold current. A

modulation of the threshold current reduces group pulsing.

The threshold current is between 75 mA and 115 mA.

The EN/UV pin also senses line undervoltage conditions

through an external resistor connected to the DC line voltage.

If there is no external resistor connected to this pin,

TinySwitch-PK detects its absence and disables the line undervoltage function.

SOURCE (S) Pin:

This pin is internally connected to the output MOSFET source

for high voltage power return and control circuit common.

TinySwitch-PK Functional Description

TinySwitch-PK combines a high voltage power MOSFET switch

with a power supply controller in one device. Unlike

conventional PWM (pulse width modulator) controllers, it uses a

simple ON/OFF control to regulate the output voltage.

The controller consists of an oscillator, enable circuit (sense and

logic), current limit state machine, 5.85 V regulator, BYPASS/

MULTI-FUNCTION pin undervoltage, overvoltage circuit, and

current limit selection circuitry, over-temperature protection,

current limit circuit, leading edge blanking, and a 700 V power

MOSFET. TinySwitch-PK incorporates additional circuitry for

line undervoltage sense, auto-restart, adaptive switching cycle

on-time extension, and frequency jitter. Figure 2 shows the

functional block diagram with the most important features.

Oscillator

The typical oscillator frequency is internally set to an average of

264 kHz (at the highest current limit level). Two signals are

generated from the oscillator: the maximum duty cycle signal

(DC

MAX

) and the clock signal that indicates the beginning of

each cycle.

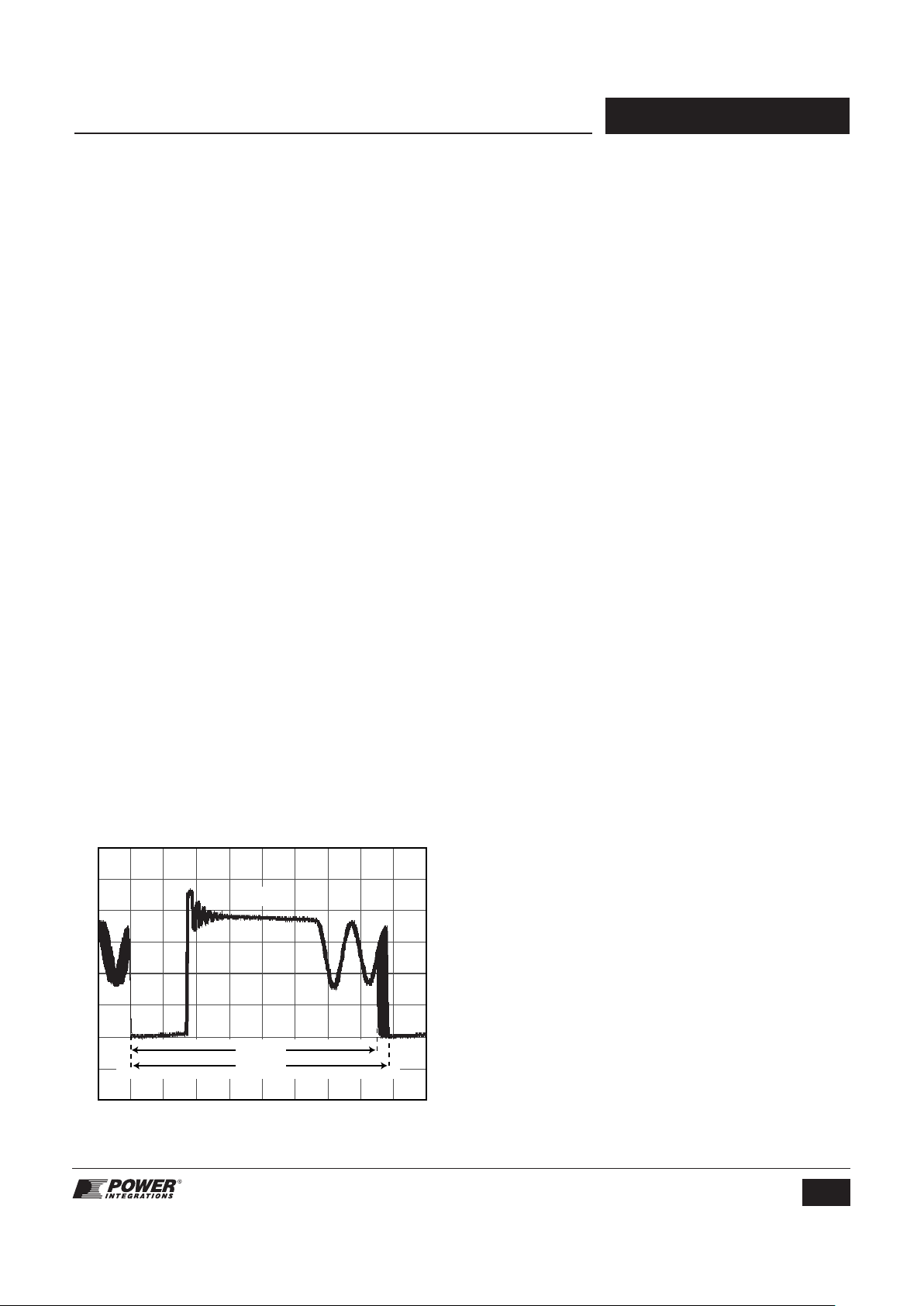

The oscillator incorporates circuitry that introduces a small

amount of frequency jitter, typically ±3% of the oscillator

frequency, to minimize EMI emission. The modulation rate of

the frequency jitter is set to 1 kHz to optimize EMI reduction for

both average and quasi-peak emissions. The frequency jitter

should be measured with the oscilloscope triggered at the

falling edge of the DRAIN waveform. The waveform in Figure 4

illustrates the frequency jitter with an oscillator frequency of

264 kHz.

Enable Input and Current Limit State Machine

The enable input circuit at the EN/UV pin consists of a low

impedance source follower output set at 1.2 V. The current

through the source follower is limited to 115 mA. When the

current out of this pin exceeds the threshold current, a low logic

level (disable) is generated at the output of the enable circuit

until the current out of this pin is reduced to less than the

threshold current. This enable circuit output is sampled at the

beginning of each cycle on the rising edge of the clock signal. If

high, the power MOSFET is turned on for that cycle (enabled). If

low, the power MOSFET remains off (disabled). Since the

sampling is done only at the beginning of each cycle,

subsequent changes in the EN/UV pin voltage or current during

the remainder of the cycle are ignored. When a cycle is

disabled, the EN/UV pin is sampled at 264 kHz. This faster

sampling enables the power supply to respond faster without

being required to wait for completion of the full period.

The current limit state machine reduces the current limit by

discrete amounts at light loads when TinySwitch-PK is likely to

switch in the audible frequency range. The lower current limit

raises the effective switching frequency above the audio range

and reduces the transformer flux density, including the

associated audible noise. The state machine monitors the

sequence of enable events to determine the load condition and

adjusts the current limit level accordingly in discrete amounts.

Under most operating conditions (except when close to noload), the low impedance of the source follower keeps the

voltage on the EN/UV pin from going much below 1.2 V in the

disabled state. This improves the response time of the

optocoupler that is usually connected to this pin.

5.85 V Regulator and 6.4 V Shunt Voltage Clamp

The 5.85 V regulator charges the bypass capacitor connected

to the BYPASS pin to 5.85 V by drawing a current from the

voltage on the DRAIN pin whenever the MOSFET is off. The

BYPASS/MULTI-FUNCTION pin is the internal supply voltage

node. When the MOSFET is on, the device operates from the

energy stored in the bypass capacitor. Extremely low power

consumption of the internal circuitry allows the TNY375 and

TNY376 to operate continuously from current taken from the

DRAIN pin. A bypass capacitor value of 0.1 mF is sufficient for

both high frequency decoupling and energy storage.

In addition, there is a 6.4 V shunt regulator clamping the

BYPASS/MULTI-FUNCTION pin at 6.4 V when current is

provided to the BYPASS/MULTI-FUNCTION pin through an

external resistor. This facilitates powering of TinySwitch-PK

externally through a bias winding as required for TNY377-380.

Powering the TinySwitch-PK externally in this way also

decreases the no-load consumption to well below 50 mW.

600

0 2.5 5

272 kHz

256 kHz

V

DRAIN

Time (µs)

PI-4539-120406

500

400

300

200

100

0

Figure 4. Frequency Jitter.

Rev. A 05/07

4

TNY375-380

www.powerint.com

BYPASS/MULTI-FUNCTION Pin Undervoltage

The BYPASS/MULTI-FUNCTION pin undervoltage circuitry

disables the power MOSFET when the BYPASS/MULTIFUNCTION pin voltage drops below 4.9 V in steady state

operation. Once the BYPASS/MULTI-FUNCTION pin voltage

drops below 4.9 V in steady state operation, it must rise back to

5.85 V to enable (turn-on) the power MOSFET.

Over Temperature Protection

The thermal shutdown circuitry senses the die temperature.

The threshold is typically set at 142 °C with 75 °C hysteresis.

When the die temperature rises above this threshold, the power

MOSFET is disabled and remains disabled, until the die

temperature falls by 75 °C, at which point it is re-enabled. A

large hysteresis of 75 °C (typical) is provided to prevent

overheating of the PC board due to a continuous fault condition.

Current Limit

The current limit circuit senses the current in the power

MOSFET. When this current exceeds the internal threshold

(I

LIMIT

), the power MOSFET is turned off for the remainder of that

cycle. The current limit state machine reduces the current limit

threshold by discrete amounts under medium and light loads.

The leading edge blanking circuit inhibits the current limit

comparator for a short time (t

LEB

) after the power MOSFET is

turned on. This leading edge blanking time has been set so

that current spikes caused by typical capacitance and

secondary-side rectifier reverse recovery time will not cause

premature termination of the switching pulse.

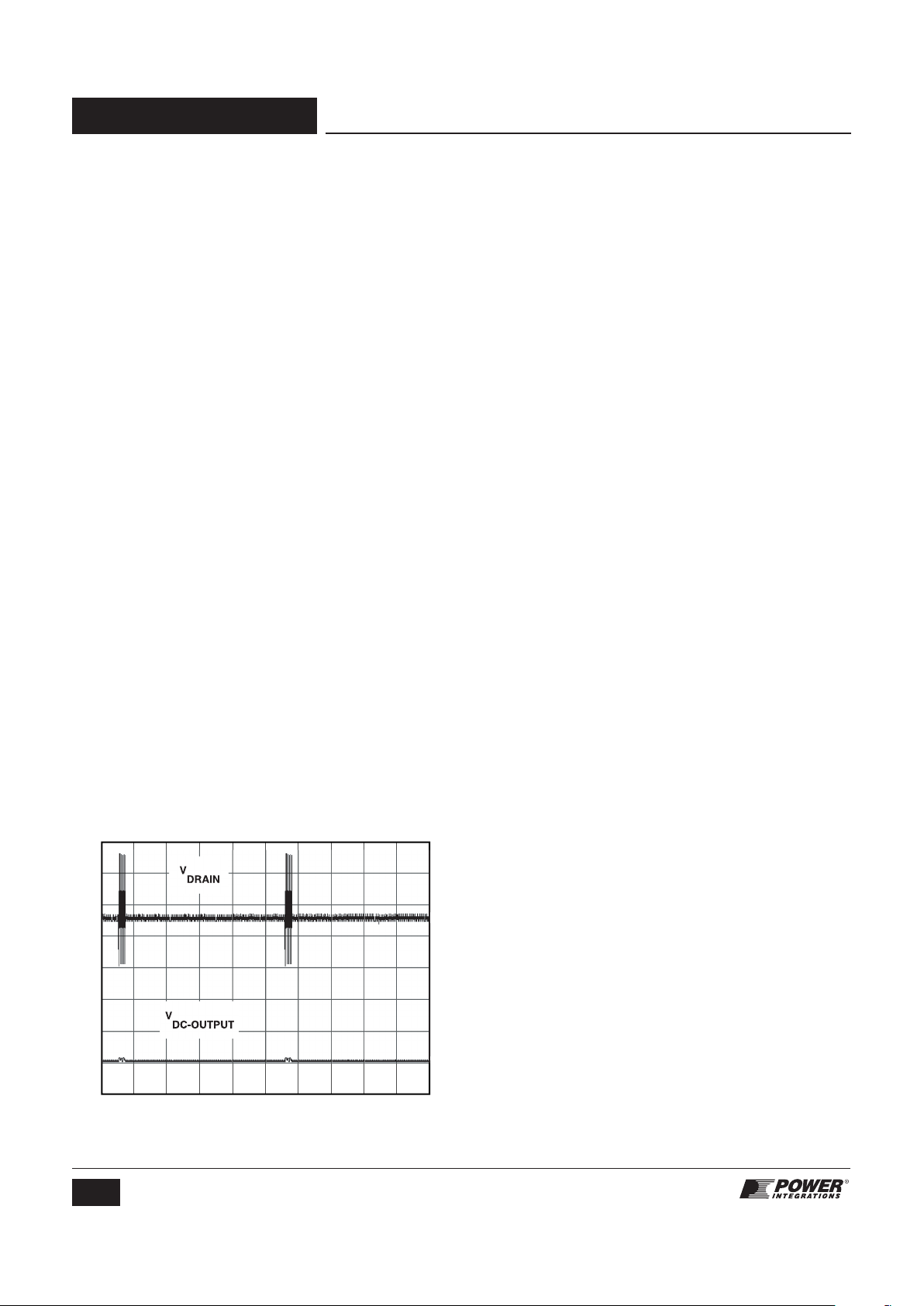

Auto-Restart

In the event of a fault condition such as output overload, output

short circuit, or an open loop condition, TinySwitch-PK enters

into auto-restart operation. An internal counter clocked by the

oscillator is reset every time the EN/UV pin is pulled low. If the

EN/UV pin is not pulled low for 8192 switching cycles

(or 32 ms), the power MOSFET switching is normally disabled

for 1 second (except in the case of line undervoltage condition,

in which case it is disabled until the condition is removed). The

auto-restart alternately enables and disables the switching of

the power MOSFET until the fault condition is removed.

Figure 5 illustrates auto-restart circuit operation in the presence

of an output short circuit.

In the event of a line undervoltage condition, the switching of

the power MOSFET is disabled beyond its normal 1 second

until the line undervoltage condition ends.

Adaptive Switching Cycle On-Time Extension

Adaptive switching cycle on-time extension keeps the cycle on

until current limit is reached, instead of prematurely terminating

after the DC

MAX

signal goes low. This feature reduces the

minimum input voltage required to maintain regulation, typically

extending hold-up time and minimizing the size of bulk

capacitor required. The on-time extension is disabled during

the startup of the power supply, and after auto-restart, until the

power supply output reaches regulation.

Line Undervoltage Sense Circuit

The DC line voltage can be monitored by connecting an

external resistor from the DC line to the EN/UV pin. During

power-up or when the switching of the power MOSFET is

disabled in auto-restart, the current into the EN/UV pin must

exceed 25 mA to initiate switching of the power MOSFET.

During power-up, this is accomplished by holding the BYPASS/

MULTI-FUNCTION pin to 4.9 V while the line undervoltage

condition exists. The BYPASS/MULTI-FUNCTION pin then rises

from 4.9 V to 5.85 V when the line undervoltage condition goes

away. Once MOSFET switching is enabled, the DC line voltage

is ignored unless the power supply enters auto-restart mode in

the event of a fault condition. When the switching of the power

MOSFET is disabled in auto-restart mode and a line undervoltage condition exists, the auto-restart counter is stopped.

This stretches the disable time beyond its normal 1 second until

the line undervoltage condition ends.

The line undervoltage circuit also detects when there is no

external resistor connected to the EN/UV pin (less than ~1 mA

into the pin). In this case the line undervoltage function is

disabled.

TinySwitch-PK Operation

TinySwitch-PK devices operate in the current limit mode.

When enabled, the oscillator turns the power MOSFET on at the

beginning of each cycle. The MOSFET is turned off when the

current ramps up to the current limit or when the DC

MAX

limit is

reached (applicable when On-Time Extension is disabled).

Since the highest current limit level and frequency of a

TinySwitch-PK design are constant, the power delivered to the

load is proportional to the primary inductance of the transformer

and peak primary current squared. Hence, designing the

supply involves calculating the primary inductance of the

transformer for the maximum output power required. If the

TinySwitch-PK is appropriately chosen for the power level, the

current in the calculated inductance will ramp up to current limit

before the DC

MAX

limit is reached.

PI-4320-030106

0

1000 2000

Time (ms)

0

5

0

10

100

200

300

V

DRAIN

V

DC-OUTPUT

Figure 5. Auto-Restart Operation.

Rev. A 05/07

5

TNY375-380

www.powerint.com

Enable Function

TinySwitch-PK senses the EN/UV pin to determine whether or

not to proceed with the next switching cycle. The sequence of

cycles is used to determine the current limit. Once a cycle is

started, it always completes the cycle (even when the EN/UV

pin changes state halfway through the cycle). This operation

results in a power supply in which the output voltage ripple is

determined by the output capacitor, amount of energy per

switch cycle, and the delay of the feedback.

The EN/UV pin signal is generated on the secondary by

comparing the power supply output voltage with a reference

voltage. The EN/UV pin signal is high when the power supply

output voltage is less than the reference voltage.

In a typical implementation, the EN/UV pin is driven by an

optocoupler. The collector of the optocoupler transistor is

connected to the EN/UV pin, and the emitter is connected to

the SOURCE pin. The optocoupler LED is connected in series

with a Zener diode across the DC output voltage to be

regulated. When the output voltage exceeds the target

regulation voltage level (optocoupler LED voltage drop plus

Zener voltage), the optocoupler LED will start to conduct,

pulling the EN/UV pin low. The Zener diode can be replaced by

a TL431 reference circuit for improved accuracy.

ON/OFF Operation with Current Limit State Machine

The internal clock of the TinySwitch-PK runs at all times. At the

beginning of each clock cycle, it samples the EN/UV pin to

decide whether or not to implement a switch cycle, and based

on the sequence of samples over multiple cycles, it determines

the appropriate current limit. At high loads, the state machine

sets the current limit to its highest value. With TinySwitch-PK,

when the state machine sets the current limit to its highest

value, the oscillator frequency is also doubled, providing the

unique peak mode operation. At lighter loads, the state

machine sets the current limit to reduced values. At these lower

current limit levels, the oscillator frequency returns to the

standard value.

At near maximum load, TinySwitch-PK will conduct during

nearly all of its clock cycles (Figure 6). At slightly lower load, it

will “skip” additional cycles in order to maintain voltage

regulation at the power supply output (Figure 7). At medium

loads, more cycles will be skipped, the current limit will be

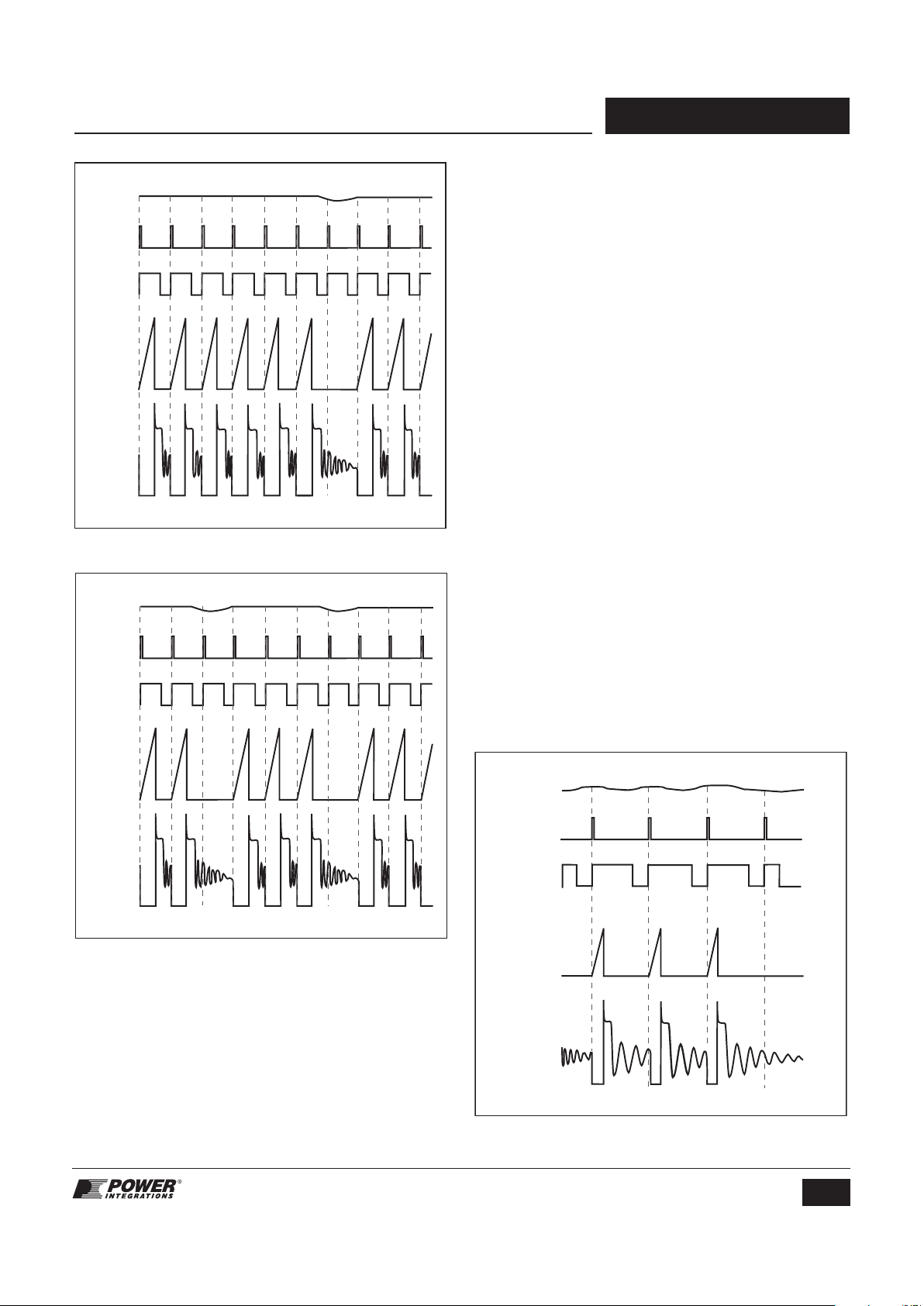

V

DRAIN

V

EN

CLOCK

DC

DRAIN

I

MAX

PI-2749-082305

V

DRAIN

V

EN

CLOCK

DC

DRAIN

I

MAX

PI-2667-082305

Figure 6. Operation at Near Maximum Loading (f

OSC

264 kHz).

Figure 7. Operation at Moderately Heavy Loading (f

OSC

264 kHz).

PI-4540-050407

V

DRAIN

V

EN

CLOCK

DC

DRAIN

I

MAX

Figure 8. Operation at Medium Loading (f

OSC

132 kHz).

Rev. A 05/07

6

TNY375-380

www.powerint.com

PI-4541-042507

V

DRAIN

V

EN

CLOCK

D

DRAIN

I

MAX

Figure 9. Operation at Very Light Load (f

OSC

132 kHz).

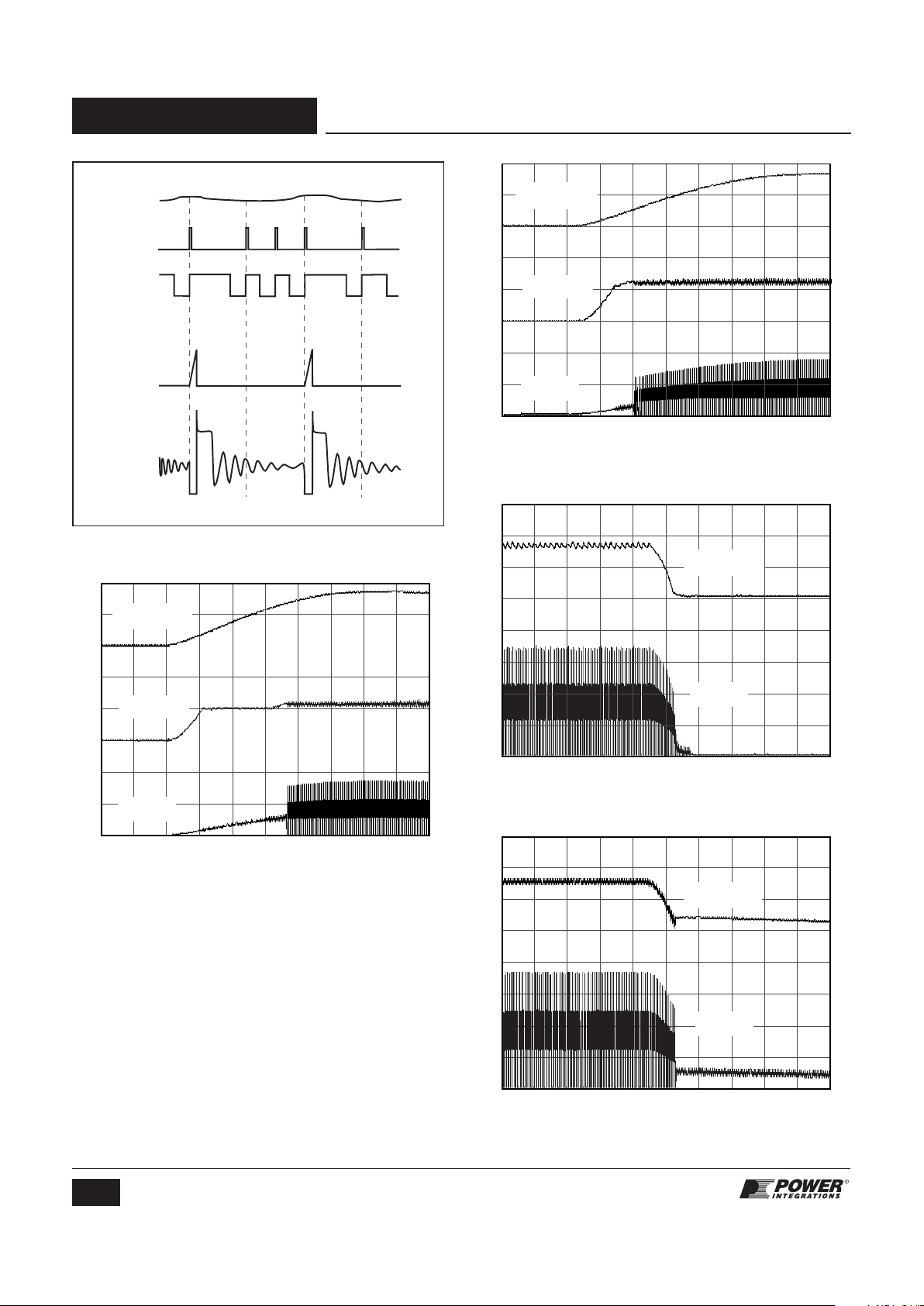

0

1 2

Time (ms)

0

200

400

5

0

10

0

100

200

PI-2383-030801

V

DC-INPUT

V

BYPASS

V

DRAIN

PI-2381-1030801

0

1 2

Time (ms)

0

200

400

5

0

10

0

100

200

V

DC-INPUT

V

BYPASS

V

DRAIN

PI-2348-030801

0

.5 1

Time (s)

0

100

200

300

0

100

200

400

V

DC-INPUT

V

DRAIN

PI-2395-030801

0

2.5 5

Time (s)

0

100

200

400

300

0

100

200

V

DC-INPUT

V

DRAIN

Figure 10. Power-up With Optional External UV Resistor (4 MW) Connected

to EN/UV Pin.

Figure 11. Power-up Without Optional External UV Resistor Connected

to EN/UV Pin.

Figure 12. Normal Power-down Timing (Without UV Resistor).

Figure 13. Slow Power-down Timing With Optional External (4 MW) UV Resistor

Connected to EN/UV Pin.

Loading...

Loading...