Page 1

IN

AOTION

SEMICONDUCTORS

The General Electric

signed for

power

C444

switching

and

C445 Silicon Controlled Rectifiers are de-

at

high frequencies. These are all-diffused Press-

Pak devices employing the field-proven interdigitated amplifying gate system.

FEATURES:

..

Interdigitated gate

structure

to

maximize high frequency current switching

capability.

Fully characterized for

..

High

di/dt

ratings.

..

High dv/dt capability

Guaranteed maximum

..

Rugged hermetic glazed ceramic package having 1" creepage path.

operation

with

turn-off

'"

~

w

~

'"

~

z

~

n:

::J

u

W

II-

'"

'?

z

0

'"

w

'"

u.

in inverter applications.

selections available.

time

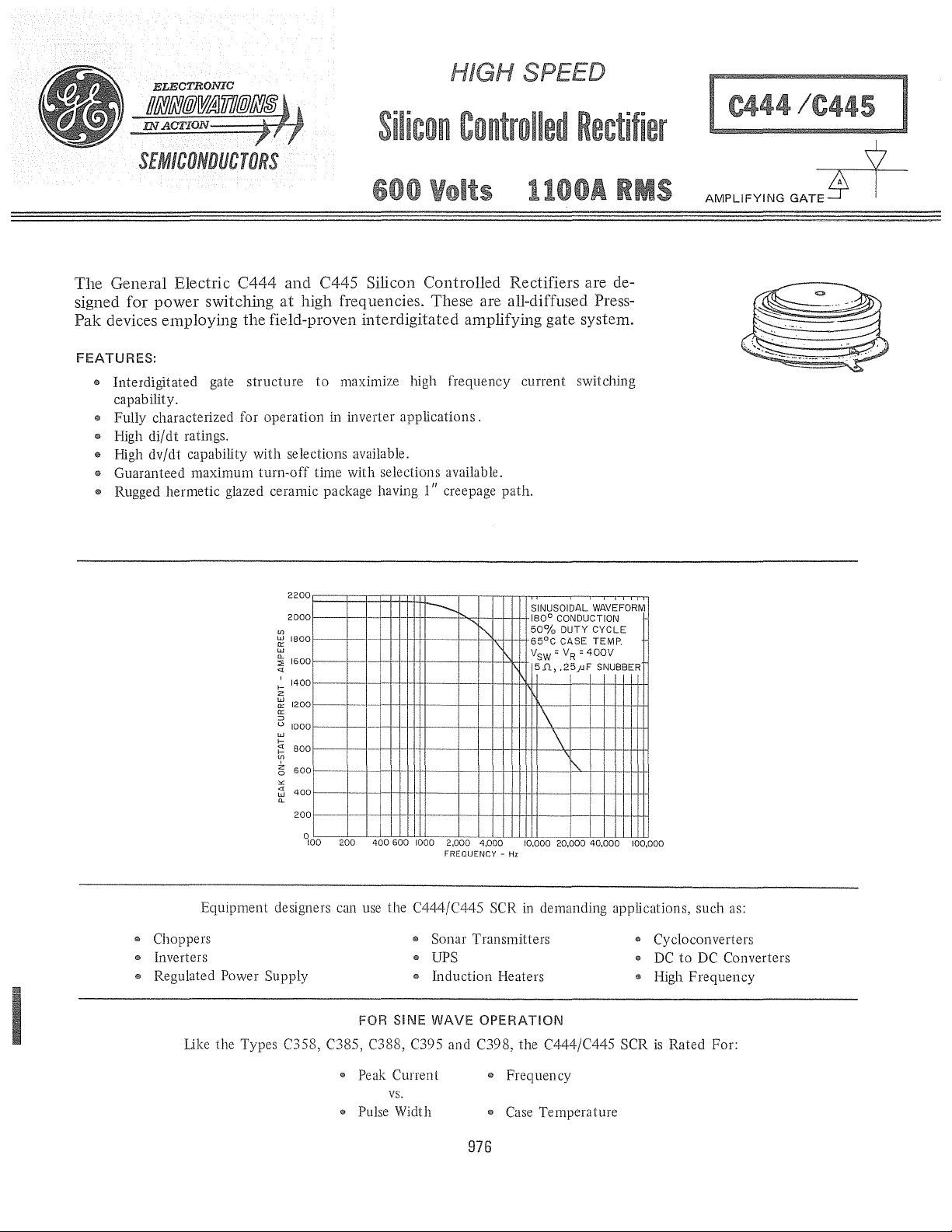

2200

2000

1800

1600

1400

1200

!----

1000

800

600

400

200

with

selections available.

c--L

-

I

--

0-

SINUSOIDAL

180°

CONDUCTION

50%

65°C

vsw

5Jl.,

= vR =

.25jJF

t\

-~

WAVEFORM

DUTY CYCLE

CASE TEMP.

400V

SNUBBER

- -

f'....

t-

~oo

200

400

600

1000

2,000

4,000

10,000

20,000

FREQUENCY

- Hz

40,000

100,000

AMPLIFYING

GAT*

I

Equipment designers

" Choppers

" Inverters

" Regulated Power Supply

Uke

the Types C358, C385, C388, C395 and C398,

C~U1

use the C444/C445 SCR in demanding applications, such as:

" Sonar Transmitters

€I

UPS

" Induction Heaters

FOR SINE WAVE OPERATION

" Peak Current

" Frequency

the

C444/C445 SCR

" Cycloconverters

..

DC

to

" High

is

Rated For:

vs.

" Pulse Width

" Case Tempera lure

976

DC Converters

Frequency

Page 2

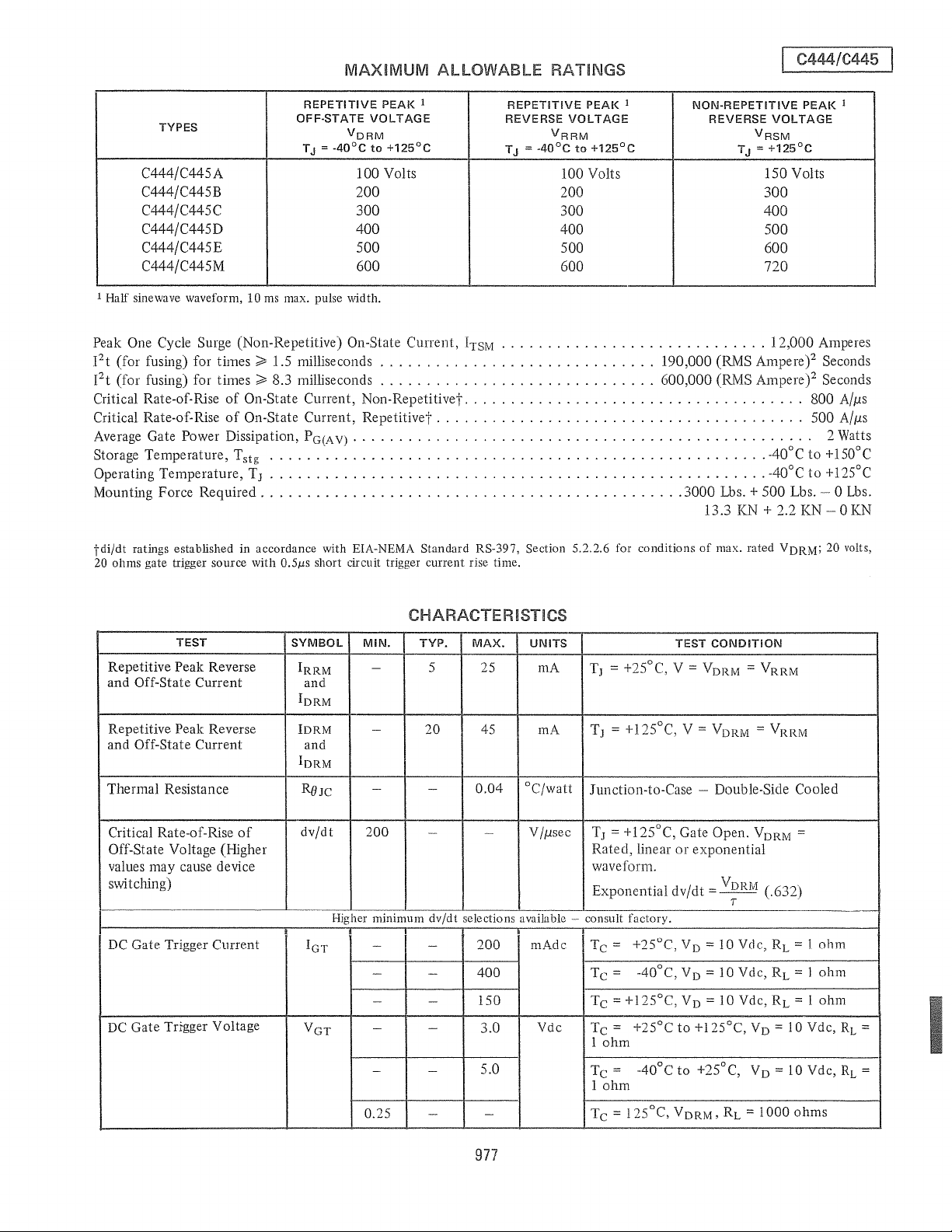

MAXIMUM

ALLOWABLE RATINGS

C444/C445

TYPES

C444/C445A

C444/C445B

C444/C445C

C444/C445D

C444/C445E

C444/C445M

1 Half

sinewave

Peak One Cycle Surge

I2t

(for

et

(for

Critical Rate-of-Rise

Critical Rate-of-Rise

Average

Storage

Operating

Mounting

tdi/dt

ratings established

20

ohms gate trigger source with

waveform,

fusing)

fusing)

Temperature,

for

for

Gate

Power

Temperature,

Force

Required

times;;;'

times;;;'

of

of

Dissipation,

REPETITIVE

OFF-STATE

TJ = -40°C to +125°C

10

ms

max.

pulse width.

(Non-Repetitive)

1.5

milliseconds

8.3

milliseconds

On-State

On-State

T

stg

T

in

accordance with

Current,

Current,

PG(A

V)

.....................................................

......................................................

J

..............................................

O.51.ls

short circuit trigger current rise time.

PEAl<

VOLTAGE

V

ORM

100

Volts

200

300

400

500

600

On-State

..............................

..............................

Non-Repetitivet

Repetitivet

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

EIA-NEMA

1

Current,

........................................

Standard RS-397, Section 5.2.2.6 for conditions

REPETITIVE

REVERSE

TJ = -40°C

[TSM

.............................

.....................................

VOLTAGE

V

RRM

to

100

200

300

400

500

600

PEAl<

+125°C

Volts

1

NON-REPETITIVE

REVERSE

190,000

600,000

3000

of

(RMS

(RMS

Lbs. +

13.3

max. rated

V

RSM

TJ

= +125°C

150

300

400

500

600

720

Ampere)2

Ampere)2

. AO°C

AO°C

500

KN +

PEAl<

VOLTAGE

Volts

12,000

Amperes

Seconds

Seconds

800

500

..

to

+lS0°C

to

+12SoC

Lbs. 0 Lbs.

2.2

KN

-OKN

VDRM;

20

1

A/ps

Alps

2 Watts

volts,

TEST

Repetitive

and

Repetitive

and

Thermal

Critical Rate-of-Rise

Off-State Voltage

values

switching)

I DC

DC

Peak

Off-State

Peak

Off-State

Resistance

may

Gate

Trigger

Gate

Trigger

Current

Current

cause device

Reverse

Reverse

of

(Higher

Current

Voltage

SYMBOL

IRRM

and

IDRM

IDRM

and

IDRM

R(jJC

dv/dt

i

lGT

V

GT

ISTICS

MIN.

-

-

-

200

Higher

minimum dv/dt selections available consult factory.

i I

-

- -

-

TYP.

20

MAX.

5 25 rnA

45

-

0.04

200

400

150

3.0

UNITS

DC/watt

-

V

I

mAde

rnA

/psec

Vdc

=

+25°C,

T

J

T

=

+l2SoC,

J

Junction-to-Case

T

=

+l25°C,

J

Rated,

linear

waveform.

Exponential

ITn

=

+2SoC, V

-,-

-40°C,

Tc

=

Tc = +125°C,

+2SoC

Tc

=

1

ohm

TEST

CONDITION

V = V

DRM

V = V

DRM

- Double-Side

Gate

Open.

or

exponential

dv/elt = V

= 10

D

V

=

10

D

V

=

10

D

to

+125°C,

= V

DRM

T

Vdc,

Vdc,

Vdc,

= V

V

DRM

(.632)

V

D

RRM

RRM

Cooled

=

RL = J

RL = 1

RL = 1

= 10

ohm

ohm

ohm

Vdc,

RL

--

=

- -

0.25

5.0

-

-

_40°C

Tc

=

1

ohm

Tc = 125°C,

to

V

+25°C,

DRM

, RL =

V

D

1000

= 10

ohms

Vdc,

RL

=

977

Page 3

C444/C445

Peak

On-State

TEST

Voltage

SYMBOL

V

TM

MIN.

-

TYP.

-

MAX.

2.5

R

UNITS

Volts

Tc

==

+25°C,

cycle ~ .01%

TEST

ITM

CONDITION

==

2000

Amps.

peak.

Duty

Conventional

mutated

(with

Turn-Off

Reverse Voltage)

C444

C445

Conventional

mutated

(with

Turn-Off

Feedback

C444

C445

tConsult

(J)

w

0:

w

"-

"

'"

I-

Z

w

0:

!5

u

w

l-

i'!

'f'

z

o

'"

w

'"

"-

10,000

I

1,000

factory for

-...;

J---

~

~

Circuit

Circuit

Diode)

I,

!'----j-...

~OOO

F-20,OOO

25,000

Com-

Time

Com-

Time

maximum

~,OOO

tq

-

tq

(diode)

-

-

turn-off

time.

SiNE

,oj-',o-zt=i=t

"-

"-

1"'-

'"

~2,500i'...

5,000

i'!,000

,,-;O-Ij>

Sf'

)'..400

-

-

15

25

10

20

t

t

CURRENT

<S;o-

\

~I\ID

l'

60

/1sec

/1sec

RATING

(1)

Tc==+125°C

(2)

ITM = 500

(3)

VR ==

( 4)

V

DRM

(5)

Rate-of-Rise

voltage =

(6)

Communication

(7)

Repetition

(8)

Gate

volts,

(1)

Tc

(2)

(3)

( 4)

(5)

==

ITM

VR =

VDRM

Rate-of-Rise

voltage

(6)

Commutation

(7)

Repetition

(8)

Gate

volts,

50

Volts

Reapplied

200

bias

during

100

ohms

+125°C

==

500

l.5

Volts

Reapplied

==

200

bias

during

100

ohms

Amps.

min.

of

V//1sec

rate

==

Amps.

of

V//1sec

di/dt

rate

==

reapplied

(linear)

di/dt

==

25 Amps/J1sec

I pps.

turn-off

reapplied

(linear)

==

25 Amps//1sec

I pps.

turn-off

off-state

interval

off-state

interval

= 0

= 0

10

0

10

1.

MAXIMUM

CURRENT

(J)

W

0:

W

"-

"

'"

I-

Z

W

0:

0:

::J

u

w

I-

<{

I-

'f'

z

0

<{

'"

w

"-

100

PULSE BASEWIDTH

ALLOWABLE

VS. PULSE WIDTH

10.000

r--

"-

r--

1.000

100

r--.

-

Vsw'400

6A

••

l!!lp.f

T)

:1l!t5"C

liAS E400V

10

-...;

1,000

-".S

PEAK ON-STATE

(Tc

==

65°C)

"-

"-

I'-..

"-

'"

"",

~

~

~

~

[-"1'

"-

"-

""-..1

.05

100 1,000

PULSE BASE WIDTH

3.

ENERGY

PER

10,000

"-

~

.25

-".S

PULSE FOR

PULSES

100L-

~ATT-SECOND

"-

"

~

""

"I

".5

978

__

L-~~LLLUL-

10

2.

MAXIMUM

CURRENT

PER PULSE

"-

20

~

~

I~

i'-

~

,2.5

10,000

SINUSOIDAL

__

100

PULSE BASEWIDTH

ALLOWABLE

VS.

NOTES:

(Pertaining

Current

Switching

1.

2. Reverse

3.

R-C

4.

Double-side

5. See

~-L-L~LUJ-

1,000

PEAK ON-STATE

PULSE WIDTH

to

Sine

and

Ratings)

Snubber/5.o.,

chart

Trapezoidal

voltage ~ 400

voltage ~ 400

cooled.

for

required

-".S

.25/1f

__

(Tc

-L~-L~~

==

90°C)

volts.

volts.

gate

drive.

10,000

Wave

Page 4

TRAPEZOI

I-

z

W

0::

0::

=>

()

w

I-

«

I-

(f)

,

z

o

f----+--+-+-+-+++++----+-

«

'"

f----+--+-+-+-+++++----+-

w

CL

100L-_~-L-L~~~-~-~~~~~-L-~~LL~

10

PULSE

4.

MAXIMUM

CURRENT

10000

(f)

W

0::

W

CL

2

«

I-

z

W

0::

0::

=>

()

w

I-

«

I-

(f)

Z

0

«

'"

f----+_-+-4-~~+_--+_

w

CL

-f!t+H--j-

WAVE CURRENT

+dild!

= 100AlfLS,

V sw =

400V,

VR

TeASE = 65°C

100

BASE

WIDTH

ALLOWABLE

VS. PULSE

+dildt

Vsw

VR::;400V

5!l

::;

400V

-}JS

PEAK ON-STATE

WIDTH

= 100AlfLS,

=

400V,

5!l,

-di/dt

• 100A/fLS

, .25fLF

HH-+t+H

(TC = 65°C)

-dild!

• 100AlfLS

.25fLF

+-~~+r

C444/C445

10000

5'0

100

10

5.

MAXiMUM

CURRENT

10000rsQW~~WE~1lE====

1=

SQUARE

WAVE

+di/d!

(f)

W

0::

W

CL

2

«

,

I-

Z

W

0::

0::

:

looo~~~!~~m~~

~

(f)

,

z

o

«

'"

w

CL

100L-_~-L-L~~~

-di/d!

Vsw = 400V

5!l,

.25fLF +-1-1-1:++

VR::;

400V

TJ

= 125"C

~

10

6.

ENERGY

= 100A/fLS

= 100A/fLS

100

PULSE

BASE

WIDTH

-}JS

ALLOWABLE

VS. PULSE

__

PULSE

BASE

PEAK ON-STATE

WIDTH

WIDTH

-}JS

PER PULSE VS. PEAK

ANI.) PULSE

WIDTH

(TC = 90°C)

CURRENT

10000

979

Page 5

I C444/C445

10,000

<J)

w

a:

w

n.

:lE

<!

,

I-

Z

~

1,000

a:

::J

u

W

I<!

l-

I{'

Z

o

0

10

0

7.

1000

800

o

600

o

500

(L

-z

~

oJ

400

«

~

(fJ

x

300

:::;;

0

a::

W

en

200

150

100

lj'125'C

1.0

MAXIMUM

~

----

L

/

/

/

I/TJ'25'C

II--

2.0

ON-STATE

VOLTAGE

ON-STATE

!-----

./

L

/

/

3.0

- VOLTS

CHARACTERISTICS

4.0

---

--

I

~

...

~

5.0

W

0

2

<!

0

W

(L

;;

.J

.0

I

<!

:::;;

0:

W

J:

l-

I-

Z

W

iii

z

<!

0:

I-

V

V

8.

l/

TRANSIENT

VV

./

.01

V

V

.1

TIME

- SECONDS

THERMAL

t-

J.,.

DOUBLE SIDE COOLING

I

IMPEDANCE _

10

100

JUNCTION-TO-CASE

.-

10

I

1.5

9. SUB-CYCLE SURGE

ON-STATE

50

<J)

t::J

!?20

,

~

w

<!J

<!

I-

10

6

>

w

I-

/

/

"

<!J

5

Z

2

fo--

I

k

~

./

~5'C

125'C

V

V

./

.2

INSTANTANEOUS GATE CURRENT -

PULSE WIDTH

CURRENT

v

v,v

1'"

~~

'"

/40'C

V

5 I

10

V

3 4 5 6 7 8 9

IMSECI

(NON-REPETITIVE)

2

AND

1

t

RATING

J:'-,.,

~

1:-

4

"',s>

~C'

r-

"

--

1'1'i'=J-

~

"I~<,;U'

1:

"'"

$0-

20

<

2$

I

0

oS

~1'

"'U'<,;

"',s>~

1'U'

C'

~4

S.

~-1J::.....

......-

-I-

-I-i"...

V

AMPERES

11.

I

l.sc

'*--U'

if<:<1

I

1'

1'U'

01,o:<1.j-

'-

,.--

GATE

"0

~~

if<

:<1"r

<'0

1,o:<1.j-1'

.....

TRIGGER

AND

U'

f--'

I

II

:<11';.0

01l

:<1.j-

f'

10

NOTES:

1. The locus of possible DC trigger points lies

2.

3.

10

CHARACTERISTICS

POWER

RATINGS

10~

10.

boundaries

Al~e~

__

~~~~~~

I

REVERSE

TYPICAL

RECOVERED CHARGE (125°C)

shown

at

T p = rectangu lar gate

20V-20n

rate of

is

circuit

the

current

minimum

long-term repetitive

with

20V-20n

gate source.

__ ~ __

10

DI/DT

various case

current

L-LJ~~L-

-AMPERES/MICROSECOND

temperatures.

pulse width.

gate source load line when

rise> 1 00

anode

Amp/psec. Maximum

di/dt = 500

__

~-L-L~~~

100

outside

Amps/psec.

1,000

the

980

Page 6

OUTLINE

DRAWING

C444/C445

MOUNTING

When the Press-Pak

ance with the following general instructions, a reliable and

low thermal interface will result.

1.

Check each mating surface for nicks, scratches, flatness

and surface finish. The heat dissipator mating surface

should be flat within .0005 inch/inches and have a

face finish

2.

It

is

of

recommended

with nickel or tin.

will oxidize

resistance.

is

assembled to a heat sink

in

accord-

63 micro-inches.

that

the heat dissipator be plated

Bare

aluminum or copper surfaces

in

time resulting in excessively high thermal

sur-

SYM

MIN.

A

B

C

0

E

F

G

H

J

I(

L

M

N

p

Q

R

S

T

12.200 12.360

U

DECIMAL

INCHES

MAX.

.240

.110

.245

.186

.060

2.200

.011

.030

.056 .060

1.000 1.065

.030

.130

1.300

.067

.137

.260

.130

.191

.075

1.430

1.065

2.500

.019

.130 .762

.096

.150

1.345

2.150

.083

.153

METRIC

M.M.

MIN.

55.88

309.9 313.9

MAX.

.762

3.302

3.480

6.604

3.302

4.851

1.905

36.32

27.051

63.50

3.483

3.302

27.05

2.438

3.810

34.16

54.61

2.11

3.886

6.096

2.794

6.223

4.724

1.524

2.794

1.422 1.524

25.40

33.02

1.702

HEAT DISSIPATORS

3.

Sand each surface lightly with 600 grit paper just prior

to

assembly. Clean

SF1l54,

200 centistoke viscosity) or silicone

(GE G322L or Dow Corning

Clean

off

and apply again

will adversely affect the electrical and thermal

resistances.)

4. Assemble with the specified mounting force applied

through a self-leveling, swivel connection. The force

has

to

be evenly distributed over the full area. Center

holes on

both

locating purposes only.

top

and

off

and apply silicon oil

DC

3, 4, 340 or 640).

as

a thin film. (A thick film

bottom

of

the

Press-Pale

(GE

grease

are

for

981

I

Loading...

Loading...