Page 1

High

Speed

145.73

11/77

The A398 series

Fast

1500 Volts

is

General Electric's highly reliable, all-diffused, Press-Pak,

Recovery

Rectifier

400A

Avg

400 ampere, fast recovery, silicon rectifier diode. These diodes are designed

for use

necessity. These diodes provide a superior combination

in

high frequency applications

or

where a fast recovery diode

of

speed, blocking

is

voltage capability and soft recovery, which is required in such demanding

applications

as:

• Inverter Feedback Diode

• Free Wheeling Diode

• High Frequency Rectification

• Low EMI Power Supplies

FEATURES:

ED

+175°C Operating

ED

Published Current Ratings Up

ED

Soft

Recovery With Low Recovery Charge • Rugged Glazed Ceramic Hermetic Package

Junction

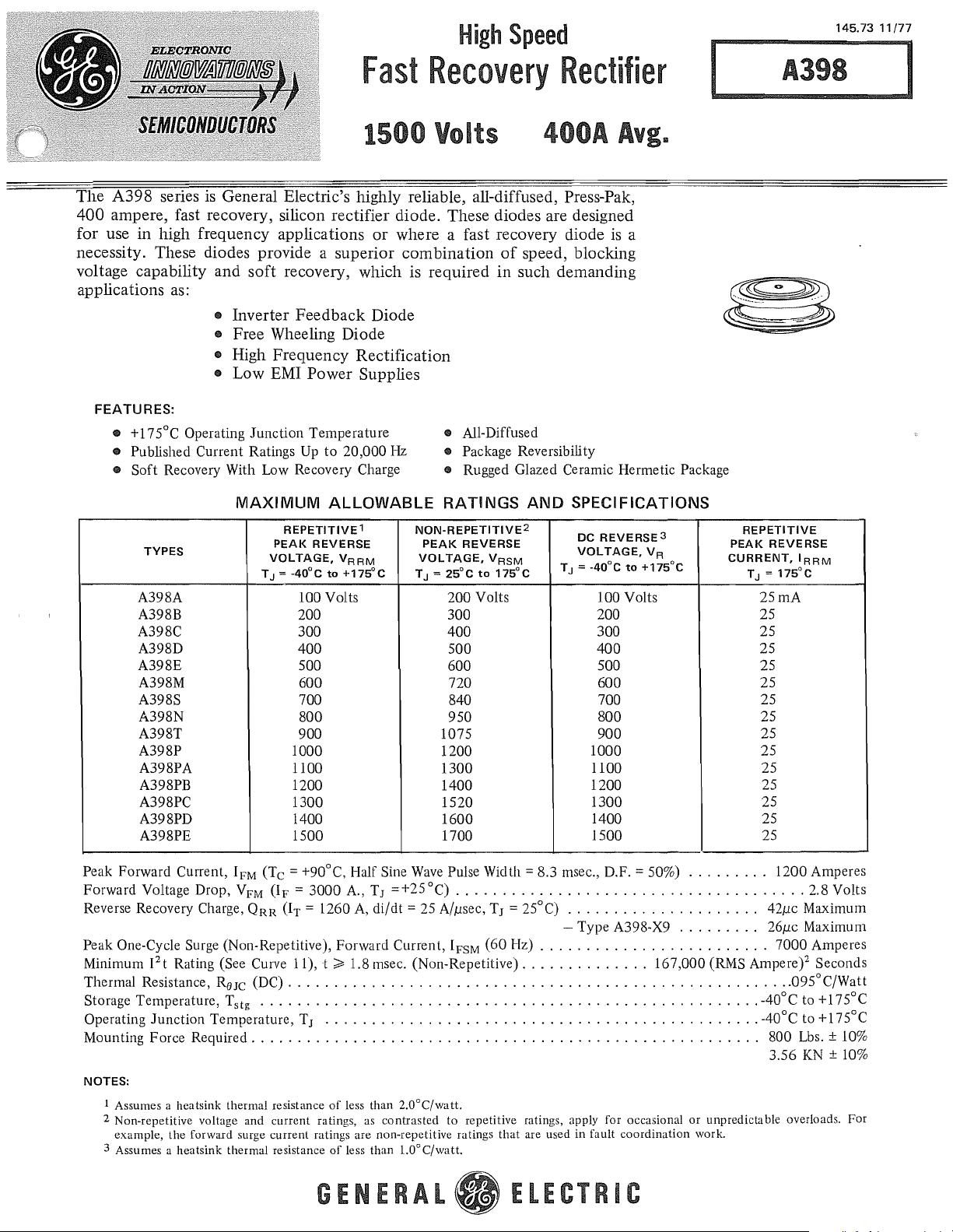

MAXIMUM

REPETITIVE

TYPES

A39SA 100 Volts

A39SB

A39SC

A39SD

A39SE 500

A39SM

A39SS 700

A39SN

A39ST

A39SP 1000

A39SPA 1100

A39SPB

A39SPC

A39SPD 1400

A39SPE

PEAK

VOLTAGE,

TJ = -40°C

200 300

300

400

600

SOO

900

1200

1300

1500

Temperature

to

20,000 Hz

ALLOWABLE RATINGS

1

REVERSE

V

RRM

to

+175°C

• All-Diffused

ED

Package Reversibility

NON-REPETITIVE2

PEAK

REVERSE

VOL

TAGE,

V

TJ =

25°C

200

400

500

600

720

S40

950

1075

1200

1300

1400

1520

1600

1700

RSM

to

175°C

Volts 100 Volts

AND

SPECIFICATIONS

DC

REVERSE3

VOLTAGE,V

T

= -40°C

J

200

300 25

400

500 25

600 25

700

SOO

900

1000

1100

1200

1300

1400

1500 25

to

a

+175°C

R

..

A398

··~·~·o

........

,

.••

,.

.'

-..;.::-.~".

B

REPETITIVE

PEAK

REVERSE

CURRENT,

TJ =

IRRM

175°C

25mA

25

25

25

25

25

25

25

25

25

25

IFM

(Tc

Peak Forward Current,

Forward Voltage Drop, V

Reverse Recovery Charge,

Peak One-Cycle Surge (Non-Repetitive), Forward Current, I

Minimum

Thermal Resistance,

Storage Temperature, Tstg ,

Operating

Mounting Force Required

NOTES:

1 Assumes a heatsink thermal resistance

2 Non-repetitive voltage and current ratings, as contrasted to repetitive ratings, apply for occasional

3 Assumes a heatsink thermal resistance

1

Junction

example,

2

t Rating (See Curve 11), t ~ I.S

ROJe

Temperature, T

the

forward surge current ratings are non-repetitive ratings that are used in fault

= +90°C, Half Sine

(IF

=

FM

QRR

(DC),

..... , ..

3000

(IT

=

....

.... , ... , ...

J

A., TJ =+25°C)

1260

A,

, . _ ,

,.,"

, . , . ,

of

less than

of

less

GENERAL

Wave

Pulse Width = S.3 msec., D.F. = 50%) . , , . , . ,

, . ' , , ,

di/dt

= 25 A//lsec, TJ = 25°C) , , , , . ,

, ,

FSM

..

msec. (Non-Repetitive)

..

_ , , , , , . , . ,

' , ,

.........

•.•.•....•.

... , ...

2.0°C/watt.

than

1.00 C/watt.

(60

.....

, . , . ,

,

......

, ,

.... , ...

.. , ....

Hz) _ . , , , ,

.......

, , . , ,

ELECTRIC

-

.. , ...

_ . , • ,

, ' , , . , ,

, . ,

.. , ..

Type

...

,

....

.....

, , . _ , , ,

.............

...

A39S-X9

, , . , _ ' . ,

_ , , , , _ ,

coordination

, . ' . , . , . , , . ,

, ,

..

, . , , , ,

....

..... , ..

, .

167,000

.....

..........

(RMS

.....

, ,

,

or

unpredictable overloads, For

work,

..

.....

.,

42/lc Maximum

. . .

..

26/lc Maximum

Ampere?

, ,

....

....

_40°C to +175°C

.. , ..

_40°C to +175°C

, .

,.

SOO

3.56 KN

1200

Amperes

2,S Volts

7000

Amperes

Seconds

_095°C/Watt

Lbs. ± 10%

± 10%

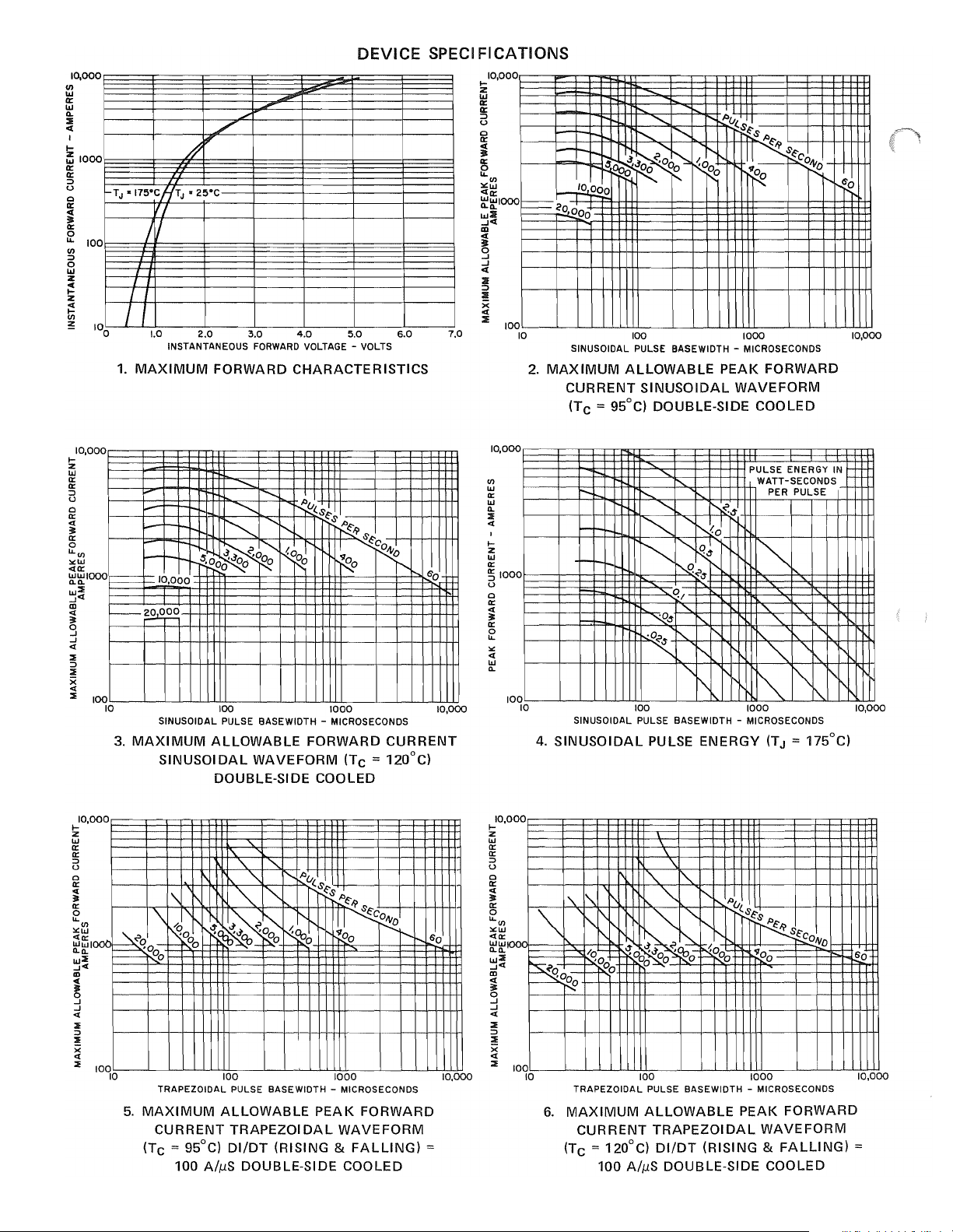

Page 2

10,000

Ul

W

0:

W

0..

::IE

<

I

I-

~

1000

0:

0:

::J

U

o

0:

;

0:

~

100

Ul

::J

o

W

Z

~

Z

~

;!:

I-T

•

J

/ I

1.

I I

.4

175'CHT

'/

•

J

/1

1.0

INSTANTANEOUS

MAXIMUM

/

/'

,.-

25'C

2.0

FORWARD

3.0

FORWARD

4.0

VOLTAGE - VOLTS

CHARACTERISTICS

DEVICE

5.0

SPECIFICATIONS

10,000

I-

Z

w

0:

0:

::J

U

o

0:

;

~

Ul

><w

<0:

~~Iooo

w:l!

..J<

m

;

o

..J

..J

<

~

!

X

<

6.0

7.0

::IE

100

-

-<0000

10

r--

,

t"--I'-

~o

,0

"u(,

PEAK

..........

-

.........

-

1

~d.l

_'DODO

2.

MAXIMUM

e90~

SINUSOIDAL PULSE BASE WIDTH - MICROSECONDS

CURRENT

["-.,

~

......

~o~

t"--

100

ALLOWABLE

SINUSOIDAL

(TC = 95°C) DOUBLE-SIDE COOLED

$~$

I"h::

"~~

1I1

~COl\to-

"~

1000

",

FORWARD

WAVEFORM

6'0

10,000

10,000

I-

Z

W

0:

0:

::J

U

o

0:

;

0:

o

U,Ul

><w

<0:

i---

~~Iooo

w::E

..J<

m

<

I---~~

:=

o

..J

..J

<

::Ii

::J

::Ii

X

<

::Ii

100

10

3.

10,00 I-0

Z

W

0:

0:

::J

U

o

0:

;

0:

o

U,

Ul

><w

<0::

000

~qo-

~~I

I "

w::E

..J<I

m

l

..J

..J

<

:IE

::J

:IE

X

<I

::Ii

100

10

.........

........

.............

""-

d

-

r.Aoo~'o~

-10,000

SINUSOIDAL PULSE BASE WIDTH - MICROSECONDS

MAXIMUM

",-"",

100

ALLOWABLE

SINUSOIDAL

..,f;U(,$

~$

I"--

-(0

0

r--9

FORWARD

WAVEFORM

1K-9

I

~

1000

DOUBLE-SIDE COOLED

I'\.

'\.

"-

I'--

'\..

1\

1\

\

00

TRAPEZOIDAL PULSE BASE WIDTH MICROSECONDS

5.

MAXIMUM

CURRENT

(Tc

-t

/0

"

~o

'~~~~

-~O

ALLOWABLE

= 95°C)

~~

""

100

TRAPEZOIDAL

DliDT

"u($

r-...

'"

"<.00

_

....

0

PEAK

(RISING &

~$

"~~

U

'100

1000

WAVEFORM

100 AiMS DOUBLE-SIDE COOLED

$

~~o

I"--

CURRENT

(Tc

= 120°C)

$~C~

FORWARD

FALLING)

--..

6'0

10,000

60

=

10,000

10,000

Ul

W

0:

W

0..

::IE

<

I

I-

Z

W

0::

~IOOO

u

o

0::

<

:=

0::

~

><

<

W

0..

100

10

4.

10,

000

I-

Z

W

0::

0::

::J

U

o

0::

<

3t

0:

o

u'Ul

><w

<0::

Ww

0..0..

w::IE

..J<I

m

~r-

~

..J

..J

<

:IE

::J

::!!

x

<

::Ii

100

10

PULSE ENERGY IN

r--.....

-

-I-

'-I-

'"

""

~

'-t.d

"

I""~

i'-.

'1",

-t

"~-t

i'-

'1,

""

"'-

I---:

~-t

,0",

~

r-.....

"-

i'

"

"'\.

SINUSOIDAL PULSE BASEWIDTH - MICROSECONDS

SINUSOIDAL

100

PULSE

'"

1000

ENERGY

'\

I"\..

"\..

r---..

I'\.

~

'00-

6.

'\

\.

~\

f'.

/0L-

p.:O

r--~O

--!2

TRAPEZOIDAL PULSE BASEWIDTH - MICROSECONDS

MAXIMUM

CURRENT

(TC

= 120°C)

"\..

""'\.."

-t~~~~~

o

00

100

ALLOWABLE

"u($

,~

,

I 0

::::?.o0o

0

1000

PEAK

TRAPEZOIDAL

DliDT

(RISING &

100 AiMS DOUBLE-SIDE COOLED

WATT-SECONDS_

PER PULSE

~

"'\.

" "

"-

"-

'"

~

"""

~

"00

WAVEFORM

0..

(TJ = 175°C)

~

$~cOIV

FORWARD

FALLING)

'\."

10,000

60

10,000

=

Page 3

DEVICE

SPECIFICATIONS

10,000

en

IIJ

a:

1&1

Q.

::II

oil(

•

I-

Z

1&1

a:

§ 1000

o

o

a:

oil(

31

~

'"

'"

~

100

i'

"-

I'

10

1.0

TRAPEZOIDAL PULSE

7.

TRAPEZOIDAL

(RISING & FALLING)

d./dl

t-tA

--T~

IRM

Ie'"

j

O.

75

- - - -

I I

{R~~l

- - - -

_f--

~

.I

o

1.0

REVERSE

9.

RECOVERED

TYPICAL

PULSE

ENERGY

........

i'..

f'

f"\.

DIIDT

"-

'l"-

IN

I"

I"-

,

'"

'r--

1"-"

r-..

........

1'\

'"

'1/

f'

"-fZ~,$

III

i'

III

~,$

~O

'1,$

WATT-SECONDS

PER PULSE

'"

"-

"-

r"..

f'

~

~"

100

f'

BASEWIDTH

PULSE

= 100

{d,/dtlREC

--l<t-tB~

-

I

I

:'

-:-.

':;"~ACTOR=

~

tA

'"

"

1000

'"

-.

MICROSECONDS

ENERGY

AlpS

(TJ = 175°C)

I

-

i--

-

-

10

CHARGE-OR

"S"

FACTOR VERSUS

CHARGE (TJ = 175°C)

100 1000

(RECl

I"

COULOMBS

RECOVERY

10.000

en

1000

I1D

~

...J

~

g

a:

o

i 100

•

IIJ

!

%

o

o

:t!

10

~

I&!

I

1.0

!:

~

I

W

U

Z

g

W

0-

;!

-'

I

~

O.

0:

W

J:

..

..

z

w

in

z

..

0:

..

)

.0

./

8.

V-

.00)

10.

e

V

REVERSE dildt -

TYPICAL

FOR

PARTS

GRAPH

L.--

.....

.0)

TRANSIENT

-

....-

LA~

\"

REVERSE

o

di/dl

I IIII1I I

10

AMPERES

RECOVERED CHARGE (TJ = 175°C)

SUPPLIED

8 REPRESENTS A

CHARG

VIA

E

(TJ=~1750C)

DOU

100

PER

MICROSECOND

A398·X9

MAXIMUM

BlE

SIDE

"'""

0.1

TIME IN SECONDS

THERMAL

JUN CTI ON-TO-CASE

).0

IMPEDANCE

0"

.S~

~~Rlt

PART

NUMBER,

RECOVERED

COOLED

10

IFM~t

1000A

40b1

200A

1000

4oo

T

t'::.;

-.-L

-,-25,000

,000

N

300.0ool-----t----I---I---I--+--+--+-t--+--I--+-f-+-I

ill"'250.0001-----t----I---+---I--+--+--+-t--+--+--+-f-+-I

lOa:o

~

\l:~

200,000t===t===f==f=i=~==j=trH-ti1i

!;{~[;J

a:

J,

'"

150.00011-----+----l----l---I1-+-+--+--+-+---l--+-l--~

Ha:

100.000)L-

!z

20.000

w'"

~~~

<t::JW

UCL

W

CL

::';

W

1O<t

a:

iii

I

..--L-5,000

__

--L

__

--L._--L._L-...L.....L--L--L.....L--L........l_L...-.l--l

1--

151000

r--

10,000

9,000

8,000

7,000

6,000

I

11. SUB-CYCLE SURGE FORWARD

FOLLOWING

AND

--

---

1.5

2

PULSE BASEWIDTH - MILLISECONDS

2

1

t

RATING

RATED

I--

2.5:3

VERSUS PULSE

LOAD

r-..

4 5 6 7 8 9

CURRENT

TIME

CONDITIONS

F

..L

t

10

/-:;-----,

! I \ \

f/

\.'

E

1

t

I!

OUTLINE

R-DIA.

S-

.--

--..

...........

DEEP

\\

,'::=-::::::/

/ /

o

~

c-rrt

~~P~

=t-11

SEATING

FLAT WITHIN

.001 TOTAL 1.03MM

DRAWING

SYM

A

-

B

C

D

E

F

PLANES

R

S

J

TABLE OF DIMENS)ONS

Conversion Tuble

i .060

I -

I .017

.145

.083

METRIC

MIN.

18.89

40.64

2.79

.33

3.42

l.70 i 21

MAX.

11

!

:41.9

3.68

i

._-

DECIMAL

INCHES MM

MIN·IMAX.

.744\.752

-r-

.030

.5151 .565 13.08

1.600 1.656

.110

.031

.1351

067 i

.43

Page 4

When

SUGGESTED

the Press-Pak

MOUNTING

is

assembled to a heat sink in accord-

METHODS FOR PRESS-PAKS TO

ance with the following general instructions, a reliable and

low thermal resistance interface will result:

1.

Check each mating surface for nicks, scratches, flatness

and surface fmish. The heat dissipator mating surfaces

should be flat within

face finish

It

2.

is

of

recommended that the heat dissipator be plated

with nickel, tin,

faces will oxidize

63

.0005 inch/inch and have a sur-

micro-inches.

or

silver. Bare aluminum

in

time resulting in excessively high

or

copper sur-

thermal resistance.

HEAT

DISSIPATORS

3. Sand each surface lightly with 600 grit paper just prior

to

assembly. Clean

off

and apply silicone oil (GE

SF 1154 200 centistoke viscosity) or silicone grease

(GE G322L or Dow Corning

off

Clean

and apply again as a

3, 4, 340

thin

film. (A thick fIlm

or

640).

DC

will adversely affect the electrical and thermal

reSistances.)

4. Assemble with the specified mounting force applied

through a self-leveling, swivel connection. The force has

to be evenly distributed over the full area. Center holes

both

top

and

on

bottom

of

the Press-Pak are for locat-

ing purposes only.

MOUNTING

THE A398, ONE-HALF INCH PRESS-PAK USING THE SERIES 1000 CLAMP

CLAMP FEATURES:

II

Hardened Steel Pivot insuring constant pressure in

rugged applications over long periods.

II

One-piece phenolic insulator

gives

added 1/2" creep

distance.

II

Use

of

special Force Indicator

for torque wrenches, inaccurate

Gauge

"flex"

eliminates need

gauges and

guesswork.

II

Various bolt lengths available

to

accommodate most

mounting situations.

..

No

loose parts to complicate assembly.

II

Stiffening brace to reinforce heat sink available upon

request.

MOUNTING

PROCEDURE:

With the semiconductor positively located in place on the

heatsink(s), place the clamp in position with the bolts

through the holes

1.

Refer to SCR Manual, Fifth Edition for Preparation

in

the heatsink(s), and proceed

as

follows:

Mounting the Press-Pak SCR, 18.2.7.

2. Tighten the nuts evenly until finger tight.

3. Tighten each

1/2 turn, using a

7/16

socket wrench

bolt

on the bolt heads.

4.

Place the Force Indicator Gauge firmly against the

springs,

as

shown on the Outline Drawing,

so

that

both

ends and the middle are in solid contact with the

springs. The holes

of

the gauge will then indicate the

spring deflection, or force; correct mounting force

indicated when the holes coincide.

of

is

II

Single-side cooling terminal available upon request.

II

Positive, non-binding swivel action.

To

Calibrate Force Gauge:

If

the gauge

wear or damage, check it on a flat surface

is

suspected

~

of

being

to-

0.300*·010

out

of

calibration due

as

SERIES

1000

to

shown below.

Examples:

Less

than

Tighten

ly

Yo

turn

until

points

SEMICONDUCTOR

ELECTRONICS

nuts

rated

PARK,

force.

alternate-

at a time

coincide.

PRODUCTS

SYRACUSE.

Correct

Force

DEPARTMENT

N. Y 1:'3201

Holes

Lined Up

Excessive

en

nuts

and

NEVER

spring

ing

friction

false readings. Always

start

force

off

the

at

G

ENE

try

will

Step

force.

start

to

by

nuts,

1.

Loos-

over.

adjust

back-

spring

produce

-

R

'It

E • E U E

TRUE

FLAT

(OR

-rrr~~rr~~~rr~7T~~~

STRAIGHT

SURFACE

EDGE)

If the points are not 0.300 ± .010 apart, calibrate the gauge

by filing the

bottom

C'f

contact points.

~

RIC

.

(In

~anada~·

Canadian

OutSide

•

Bldg.

#7,

the

U.S.A

Mall

.•

and

Drop

General

Canada,

49,

Electric.

by:

Semiconductor

Electronics

PRINTED

~=

Company,

Park,

Syracuse,

IN

""

LId.,

products

U.S.A.

= '"

Toronto,

Department,

N.

Y.

13201)

~'"

Onto

Page 5

5.2

A398

Condensed Electrical and Thermal Characteristics and Ratings

~

~109.1

JEDECTYPE

GETYPE

SPECIFICATIONS

(1

Max. average forward

IFM(AV)

V

RM

IFM

(Surge)

I2t

T

J

ReJc

V

FM

QRLREC)

tIT

V

F

ReJc

Package Outline No.

Maximum Stud Torque (In-Lbs/N-M)

Max Mounting Force (Lbs/Kn)

Expanded Electrical Characterization, see page:

Tc = (DC)

(Rep)

Max. repetitive peak reverse voltage (V)

Max. peak one cycle, non-recurrent .

.

surge current

@ max. rated load conditions (A)

Max. non-repetitive for 1.5 msec (A2sec)

Operating junction temperature range

Max. thermal resistance,

junction-to-case (DC/W)

Max. peak forward voltage drop @ rated

I

FrAV

@Tc = (DC)

Reverse recovered charge @,rated TJ (p.c)

Reverse recovery time @ rated TJ (p.s)

Max. forward

voltage drop

for the current

range:

Transient thermal(2)

resistance for

time: F

(1

phase operation) 50 Hz.

)

(1

phase operation)

(I)

phase operation)

300

60

Hz.

(DC)

IMIN(A)

IMAX(A)

A

B

C

D

TM1N(S)

TMAX(S)

G

TO

RECTIFIERS

450

AMPERES

300

68

50-800

5000

5500 7000

95000

-40to175

0.3 .15

1.2 1.4

68

-

- -

100

6000 8000

-.607

.378 .2393

.00081 .0005

-.05

.001 .001

.01

.128 .072

.431 .24

324 109.1

15/1.7

152

400

145

100-1500

6600

82000

-40

to 200

144

-

100

- .1115

-.0244

.01

-

800/3.56

157

324

400 400

110 90 65

100-1500 100-1500

4800

5000

51000

-40

to 125

.095 .095

1.75

25

70

2.8

20

7000 9000 5000

.2337

.1446 .18 .165

.0004 .0004

-.0055

.001 .001 .001

.01 .01 .01

.072 .072

.24

109.1 109.1 183

-

800/3.56 800/3.56 2000/8.9

158

6500

7000 7400

170000

-40

to 175

1.7 2.65

25 65

15

1.5 5

10

-.02

-.0005

.24

- -

160

450

1600-2600

7000

98000

-40

to 150

.06

230

200

.24

.00067

.01

.29

.61

165

(l)Voltage Drop Model: V F

(2)Transient Thermal Resistance Model: ReJc

= A + B . LN(I) + C . I + DVI

/

=

F·

to

114

Loading...

Loading...