Variable Speed Drive

Programming and Software Manual

Variable Speed Drive

Programming and Software Manual

Edition: June 2016

SD50MTSW01EI Rev. E

SD500

POWER ELECTRONICS

2

POWER ELECTRONICS

SD500

3

Edition June 2016

This publication could present technical imprecision or misprints. The information here included will be

periodically modified and updated, and all those modifications will be incorporated in later editions.

To consult the most updated information of this product you might access through our website

www.power-electronics.com where the latest version of this manual can be downloaded.

WARNING

This symbol means improper operation may results in serious personal

injury or death.

CAUTION

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present. Maintenance

operation should be done by qualified personnel

Identifies potential hazards under certain conditions. Read the message and

follow the instructions carefully.

Identifies shock hazards under certain conditions. Particular attention should

be given because dangerous voltage may be present.

SAFETY SYMBOLS

Always follow safety instructions to prevent accidents and potential hazards from occurring.

SD500

POWER ELECTRONICS

4

Revisions

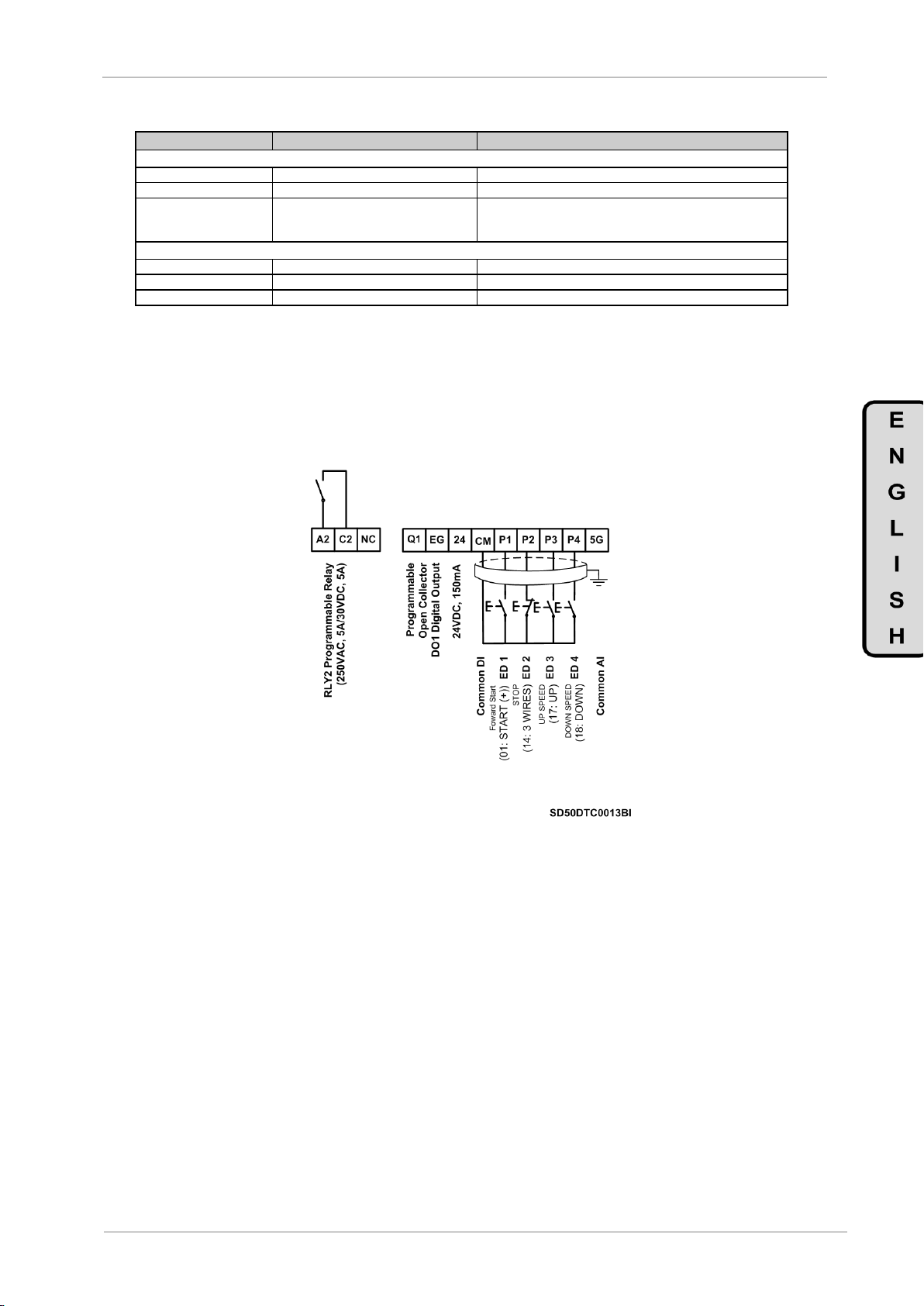

Date Revision Description

25 / 01 / 2011 A First Edition. Version SW 1.0

28 / 02 / 2011 B SW 1.1 Update

24 / 05 / 2011 C SW 1.2 Update

20 / 05 / 2013 D SW 2.0 Update

07 / 06 / 2016 E SW 2.3 Update

The equipment and technical documentation is updated periodically. Power Electronics reserves the right to modify totally or partially the

content within the present manual without notification.

POWER ELECTRONICS

SD500

INDEX

5

INDEX

SAFETY INSTRUCTIONS ........................................................................................................... 8

1. DISPLAY AND CONTROL KEYPAD UNIT .......................................................................... 12

1.1. Keypad Unit Description ............................................................................................. 12

2. STATUS MESSAGES .......................................................................................................... 15

2.1. Status Messages List ................................................................................................. 15

3. STATUS AND VISUALIZATION SCREENS ........................................................................ 16

3.1. Screens SV.1 – Motor Visualization ........................................................................... 16

3.2. Screens SV.2 – Drive Visualization ............................................................................ 17

3.3. Screens SV.3 – External Visualization ....................................................................... 17

3.4. Screens SV.4 – Internal Visualization ........................................................................ 17

3.5. Screens SV.5 – PID Visualization .............................................................................. 17

3.6. Screens SV.8 – Pump Macro Visualization ................................................................ 18

4. PROGRAMMING PARAMETER DESCRIPTION ................................................................. 19

4.1. Group 1 – G1: Options Menu ..................................................................................... 19

4.2. Group 2 – G2: Nameplate .......................................................................................... 21

4.3. Group 3 – G3: References ......................................................................................... 22

4.4. Group 4 – G4: Inputs .................................................................................................. 23

4.5. Group 5 – G5: Acceleration and Deceleration Ramps ............................................... 27

4.6. Group 6 – G6: PID Control ......................................................................................... 29

4.7. Group 7 – G7: Start / Stop Mode Configuration ......................................................... 30

4.8. Group 8 – G8: Outputs ............................................................................................... 33

4.9. Group 9 – G9: Comparators ....................................................................................... 36

4.10. Group 10 – G10: Limits .............................................................................................. 37

4.11. Group 11 – G11: Protections ..................................................................................... 39

4.12. Group 12 – G12: Auto Reset ...................................................................................... 42

4.13. Group 13 – G13: Fault History ................................................................................... 42

4.14. Group 14 – G14: Multi-references .............................................................................. 44

4.15. Group 15 – G15: Inch Speeds ................................................................................... 45

4.16. Group 16 – G16: Skip Frequencies ............................................................................ 45

4.17. Group 17 – G17: External Brake ................................................................................ 46

4.18. Group 18 – G18: ENCODER ..................................................................................... 46

4.19. Group 19 – G19: Fine Tuning .................................................................................... 47

4.20. Group 20 – G20: Communication Buses .................................................................... 50

4.21. Group 25 – G21: Pump Control ................................................................................. 51

5. MODBUS COMMUNICATION .............................................................................................. 55

5.1. Introduction……………………………………………………………………………………. 55

5.2. Specifications…………… ........................................................................................... 55

5.3. Installation………….. .................................................................................................. 56

5.4. RS485 Modbus Communication Protocol .................................................................. 58

5.5. Address List ..................................................................................................... 58

6. FAULT MESSAGES. DESCRIPTION AND ACTIONS ........................................................ 71

6.1. Description of Fault List .............................................................................................. 71

6.2. Procedure for Fault Solutions ..................................................................................... 72

7. COMMONLY USED CONFIGURATIONS ............................................................................ 75

7.1. Start / Stop Commands and Speed Reference by Keypad ........................................ 75

7.2. Start / Stop Commands by Terminals and Speed Reference by

7.3. Start / Stop Commands by Terminals and Speed Reference by

7.4. Start / Stop Commands by Terminals and Seven Speed References

7.5. Control of the Main Pump 1 and Auxiliary Pump 2, Seven References

8. CONFIGURATION REGISTER ............................................................................................ 86

Analogue Input . ………………………………………………………………………… 75

Buttons……………………………………………………………………………………….. 78

and 15 Selectable by Digital Inputs ............................................................................ 80

by Screen (Underload) ............................................................................................... 83

SD500

POWER ELECTRONICS

6

SAFETY INSTRUCTIONS

Do not remove the cover while the power is applied or the unit is in operation.

Otherwise electric shock could occur.

Do not run the drive with the front cover removed.

Otherwise you may get an electric shock due to the high voltage terminals or exposure of charged

capacitors.

Do not remove the cover except for periodic inspections or wiring, even if the input power is not

applied. Otherwise you may access the charged circuits and get an electric shock.

Wiring and periodic inspections should be performed at least 10 minutes after disconnecting the

input power and after checking the DC Link voltage is discharged with a meter (below 30VDC).

Otherwise you may get an electric shock.

Operate the switches with dry hands.

Otherwise you may get an electric shock.

Do not use cables with damaged insulation.

Otherwise you may get an electric shock.

Do not subject the cables to abrasions, excessive stress, heavy loads or pinching.

Otherwise, you may get an electric shock.

SAFETY INSTRUCTIONS

IMPORTANT!

Read this manual carefully to maximise the performance of this product and to ensure its safe

use.

In this manual, safety messages are classified as follows:

WARNING

POWER ELECTRONICS

SD500

SAFETY INSTRUCTIONS

7

Install the drive on a non-flammable surface. Do not place flammable material nearby.

Otherwise fire could occur.

Disconnect the input power if the drive gets damaged.

Otherwise it could result in a secondary accident or fire.

After the input power is applied or removed, the drive will remain hot for a couple of minutes.

Touching hot parts may result in skin burns.

Do not apply power to a damaged drive or to a drive with parts missing even if the installation is

complete.

Otherwise you may get an electric shock.

Do not allow lint, paper, wood chips, dust, metallic chips or other foreign matter into the drive.

Otherwise fire or accident could occur.

RECEPTION

The SD500 is carefully tested and perfectly packed before leaving the factory.

In the even of transport damage, please ensure that you notify the transport agency and POWER

ELECTRONICS: 902 40 20 70 (International +34 96 136 65 57) or your nearest agent, within

24hrs from receipt of the goods.

UNPACKING

Make sure model and serial number of the variable speed drive are the same on the box, delivery

note and unit.

Each variable speed drive is supplied with a SD500 technical manual.

RECYCLING

Packing of the equipments should be recycled. For this, it is necessary to separate different

materials included (plastic, paper, cardboard, wood, ...) and deposit them on proper banks.

Waste products of electric and electronic devices should be selectively collected for their correct

environmental management.

EMC

According to EN 61800-3 the frequency inverter is not intended to be used in low voltage public

network which supplies in domestic premises. Radio frequency interference is expected in such a

network.

With additional activities (e. g. EMC-Filter) it is possible to use these devices in the “Firs

environment” according to EN 61800-3 Category C2.

CAUTION

WARNINGS

SD500

POWER ELECTRONICS

8

SAFETY INSTRUCTIONS

SAFETY

Before operating the drive, read this manual thoroughly to gain and understanding of the unit. If

any doubt exists then please contact POWER ELECTRONICS, (902 40 20 70 / +34 96 136 65

57) or your nearest agent.

Wear safety glasses when operating the drive with power applied and the front cover is

removed.

Handle the drive with care according to its weight.

Install the drive according to the instructions within this manual.

Do not place heavy objects on the drive.

Ensure that the mounting orientation is correct.

Do not drop the drive or subject it to impact.

The SD500 drives contain static sensitive printed circuits boards. Use static safety procedures

when handling these boards.

Avoid installing the drive in conditions that differ from those described in the Technical

Characteristics section.

CONNECTION PRECAUTIONS

To ensure correct operation of the drive it is recommended to use a SCREENED CABLE for the

control wiring.

For EMERGENCY STOP, make sure supply circuitry is open.

Do not disconnect motor cables if input power supply remains connected. The internal circuits of

the SD500 Series will be damaged if the incoming power is connected and applied to output

terminals (U, V, W).

It is not recommended to use a 3-wire cable for long distances. Due to increased leakage

capacitance between conductors, over-current protective feature may not operate correctly.

Do not use power factor correction capacitors, surge suppressors, or RFI filters on the output

side of the drive. Doing so may damage these components.

Always check whether the DC Link LED is OFF before wiring terminals. The capacitors may

hold high-voltage even after the input power is disconnected. Use caution to prevent the

possibility of personal injury.

TRIAL RUN

Verify all parameters before operating the drive. Alteration of parameters may be required

depending on application and load.

Always apply voltage and current signals to each terminal that are within levels indicated within

this manual. Otherwise, damage to the drive may result.

POWER ELECTRONICS

SD500

SAFETY INSTRUCTIONS

9

OPERATION PRECAUTIONS

When the Auto Restart function is enabled, keep clear of driven equipment, as the motor will

restart suddenly after a fault is reset.

The “STOP / RESET” key on the keypad is active only if the appropriate function setting has been

made. For this reason, install a separate EMERGENCY STOP push button that can be operated

at the equipment.

If a fault reset is made with the reference signal still present then a restart will occur. Verify that it

is permissible for this to happen, otherwise an accident may occur.

Do not modify or alter anything within the drive.

Before programming or operating the SD500 Series, initialise all parameters back to factory

default values.

EARTH CONNECTION

The drive is a high frequency switching device and leakage current may flow. Ground the drive to

avoid electrical shock. Use caution to prevent the possibility of personal injury.

Connect only to the dedicated ground terminal of the drive. Do not use the case or the chassis

screw for grounding.

When installing, grounding wire should be connected first and removed last.

The earth cable must have a minimal cross sectional area that meets local country electrical

regulations.

Motor ground must be connected to the drive ground terminal and not to the installation’s ground.

We recommend that the section of the ground connection cable should be equal or higher than

the active conductor.

Installation ground must be connected to the drive ground terminal.

SD500

POWER ELECTRONICS

10

DISPLAY AND CONTROL KEYPAD UNIT

LED

COLOR

FUNCTION

ON

Yellow

Switched on indicates the equipment is powered.

RUN

Green

Switched on indicates the motor receives voltage from the SD500.

FAULT

Red

Flashing indicates the equipment is in fault.

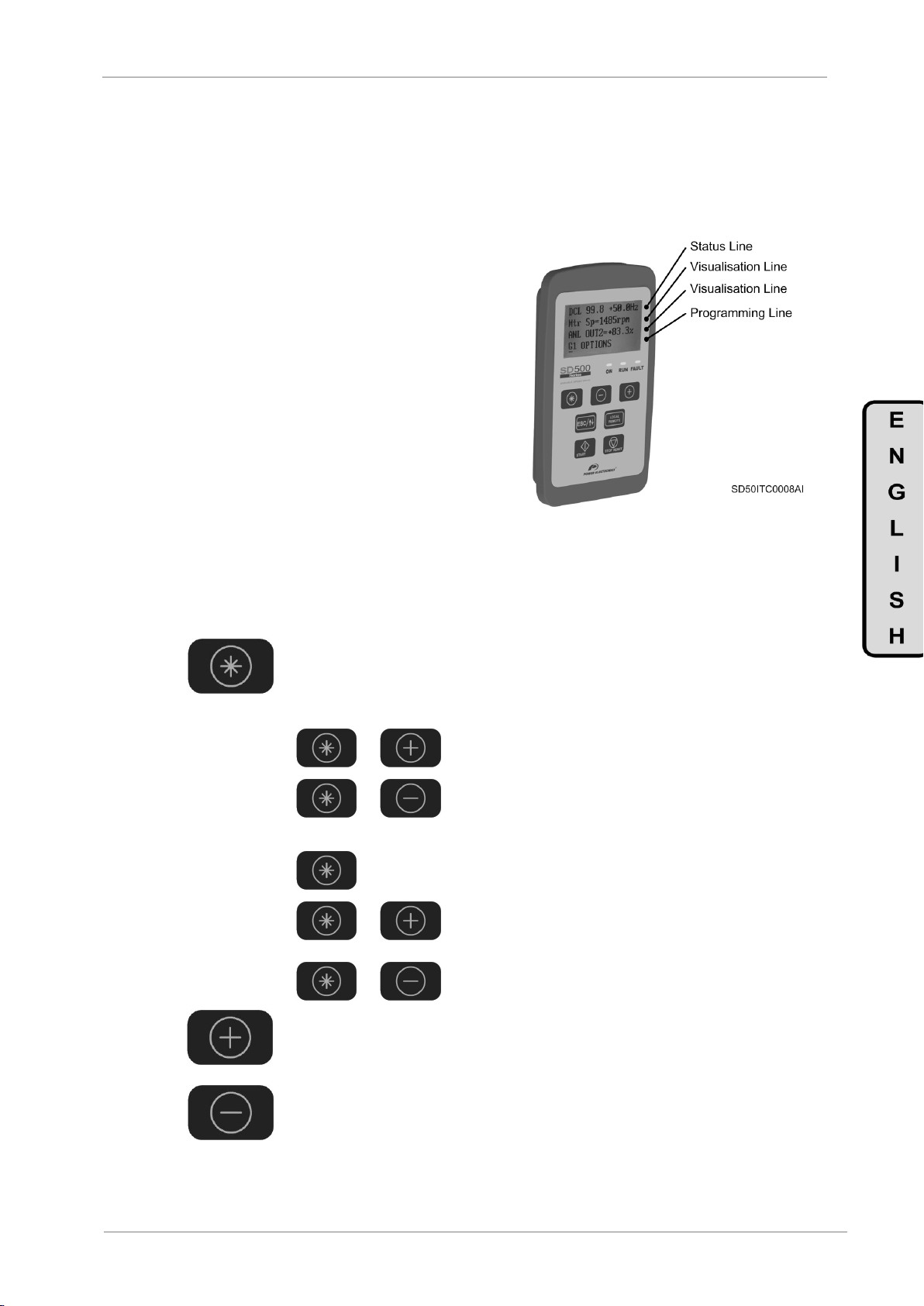

1. DISPLAY AND CONTROL KEYPAD UNIT

1.1. Display and Keypad Unit Description.

The SD500 membrane display is a removable display for remote installation, as shown in the

illustration. The display integrates three LEDs indicating the drive operating status, an LCD display

screen with 4 lines of 16 characters and control keypad and setting parameters.

.

Figure 1.1 Display and Keypad Unit

1.1.1. LED Status Indicators.

Leds show at any time and simply for the user, if the SD500 is powered, provides output voltage

or a fault has taken place.

Figure 1.2 Display Status

POWER ELECTRONICS

SD500

DISPLAY AND CONTROL KEYPAD UNIT

11

1.1.2. Alphanumeric LCD Display Screen.

The SD500 display counts with a four-line LCD screen with sixteen characters per line (16x4).

Each line has different functions.

Status Line: Is the upper line.

Always present and shows the SD500 status

(RUN, STP, etc…).

It also shows the motor output current and speed.

It is not configurable by the user.

Display Line 1: Second screen line.

Always present and allows the user to select the

different variables within the display menu.

It is configurable by the user.

Display Line 2: Third screen line.

Always present and allows the user to select the

different variables within the display menu.

Programming Line: The lower line

The user can view and set the different SD500

parameters

Figure 1.3 Display lines detail

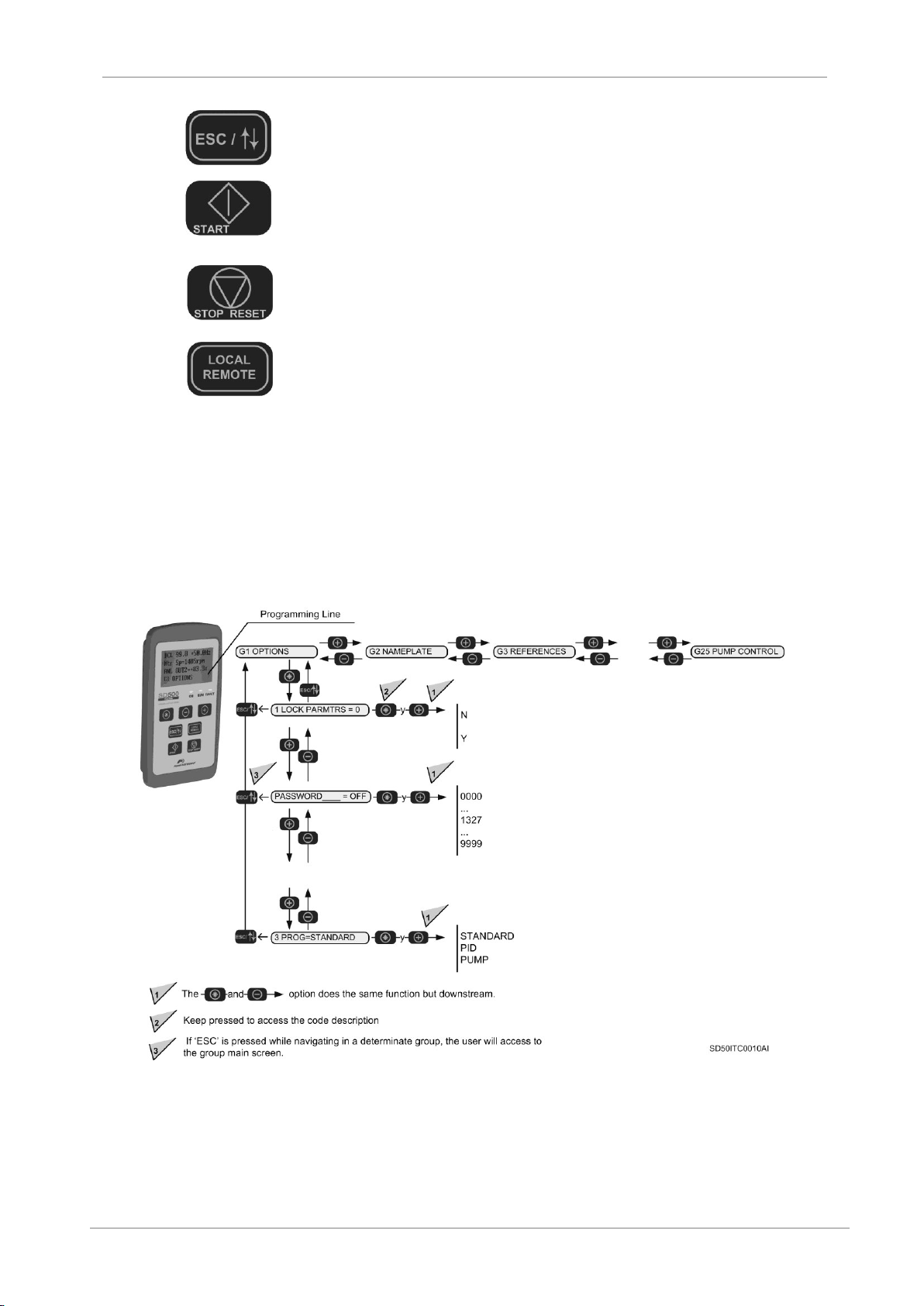

1.1.3. Control Keypad

The keypad items have different function depending on their individual or combined use:

Authorise to enter into a parameter group to access the subgroups. In case a

group does not have subgroups, the access would be straight to the group

parameters.

Modifying numeric parameters:

Modifying parameter numbered options:

Scroll through the parameter groups. Within a parameter group, it is possible to

browse the different parameters in ascending order. It also allows setting

(increase) the value of configurable parameters.

Same function than the previous key. However, downstream. It also allows

setting (decrease) the value of configurable parameters.

Y Pressed simultaneously the value is increased.

Y Pressed simultaneously the value is decreased.

Pressing this key, the user will have access to the option

extended description.

Y Pressed simultaneously is possible to pass the

different codes in ascending order.

Y Pressed simultaneously is possible to pass the

different codes in descending order.

SD500

POWER ELECTRONICS

12

DISPLAY AND CONTROL KEYPAD UNIT

Pressing for a 2 second period (approximately), the cursor changes within the

different lines configurable by the user. It also allows to exit from a menu

location to a previous one.

Pressing this key, the drive starts if it is configured in local control mode (check

equipment configuration). This button will only operate whenever the equipment

is configured in local control mode.

Pressing this key stops the drive if it is running. In case the equipment is at

fault, pressing this button will reset the drive whenever the fault conditions have

disappeared. This button will only work when the equipment is configured in

local control.

Pressing this key, the drive will change from remote mode to local mode and

vice versa. To activate this key functionality, the parameter [G1.12 ENB/DIS

L/R] must be set to ‘E’ (Enabled). Pressing the key once, the drive switches to

be controlled locally so the start command and the speed reference must be set

in the display. The symbol “►” appears in the status line showing that the

display is in local mode. Pressing the key again, the drive switches to remote

mode, communications mode, or PLC mode, depending on the drive previous

configuration. Also, the symbol “►” disappears from the status line of the

display.

Note: There must be an elapsed time of two seconds between keystrokes for

changes to take effect.

The following figure shows a programming example, indicating the previous explication.

Figure 1.4 Parameters navigation example

POWER ELECTRONICS

SD500

STATUS MESSAGES

13

Screen

Name

Description

FLT

Fault trip

The drive is in fault state

DCB

DC Brake

The SD500 has injected DC current to stop the motor.

STP

Stopping

The drive is decreasing the output frequency due to a stop order.

DCL

Decelerating

The drive is decreasing the output frequency. The motor is decreasing its

speed, it is decelerating.

ACL

Accelerating

The drive is increasing the output frequency. The motor is increasing its

speed, its accelerating.

RUN

Running

The drive is operating at reference speed. The motor will keep the introduced

speed. Operating in nominal rate.

RDY

Ready

The drive is ready for commissioning.

2. STATUS MESSAGES

The upper line of the display corresponds to the status line. In this line we can see the equipment status,

motor mean current consumption (A), and motor speed (Hz). Always visible in the display screen and it

can not be modified by the user.

Figure 2.1 Description of the Status Line

Note: The user can access to the displayed information in the status line through the Modbus communication. Consult

section “Modbus Communication”.

2.1. Status Messages List

SD500

POWER ELECTRONICS

14

STATUS AND VISUALIZATION SCREENS

Screen

Units

Description

Mtr I out=0.0

MTR O/P current

A

Shows the current running through the motor, corresponding to the second field of the status line

OFF 0.0A +0.0Hz

Mtr Freq= 0.00Hz

Motor Frequency

Hz

Shows the motor frequency

Mtr Sp= 0rpm

Motor Speed(rpm)

rpm

Shows the motor speed in rpm

Mtr FBSp=+0rpm

MTR FBK Speed

rpm

Shows the motor encoder speed. The value will be only shown if an encoder board has been

installed in the drive.

Mtr Vout=0V

MTR O/P voltage

V

Shows the motor voltage

Mtr Pow = 0.00kW

MTR O/P power

kW

Shows the motor instantaneous power consumption

Mtr Torqe = 0.0%

MTR O/P torque

% Motor torque

Shows the torque applied to the motor.

EncMon= 0 Hz (*)

Hz

Shows the encoder speed in terms of motor frequency.

PulMo = 0 kHz (*)

kHz

Shows the encoder speed in terms of encoder pulses.

3. STATUS AND VISUALIZATION SCREENS

These screens show all time the SD500 input and output (signals and dynamic parameters) status. Display

lines are lines 2 and 3. Anyway, the user can select in each line the parameter to visualise.

In order to select a parameter, the user must place the cursor in lines 2 and 3 pressing during 2 seconds,

ESC /

. so that the cursor will jump from one line to the other. Once located in lines 2 and 3, the user

can navigate as done in the programming line (line 4) and visualise the selected parameter. Once the

parameter has been chosen, it is saved in the display memory. This way, when the display is powered, it

will show the last selected parameter in lines 2 and 3.

By the use of these two lines the user can choose a parameter to see and obtain further information in a

simple and easy way.

Figure 3 Display Lines Description

3.1. Screens SV.1 – Motor Visualization

(*) Available if parameter G19.1.1 =VECTOR

POWER ELECTRONICS

SD500

STATUS AND VISUALIZATION SCREENS

15

Screen

Units

Description

Bus vol= 528V

Bus voltage

VDC

Shows the DC voltage measured in the driver bus.

Temperature=27ºC

Temperature

ºC

Shows the internal temperature of the drive.

Screen

Units

Description

ANLG IN1 = +0.0V

A|1 Monitor

V

Shows the Analogue Input 1 mean value.

ANLG IN2 = +0.0mA

A|2 Monitor

mA

Shows the Analogue Input 2 mean value.

DigI= 00000000

Dig I/P Status

-

Shows the activation or rest status of the Digital Inputs, from left to right ED8 to ED1.

ANL OUT1 = 0.0%

Anl Out1 Monitor

%

Shows the value of the Analogue Output 1.

ANL OUT2 = 0.0%

Anl Out2 Monitor

%

Shows the value of the Analogue Output 2.

DOstatus= 0-00

Dig Output status

-

Shows the status of the digital outputs in the following order: SD1-Relay2 Relay1.

Screen

Units

Description

Inv.Power=

Inv.Power

kW

Shows the drive capacity in kW

Inv. S/W

Inv.SW

0x103

Shows the last software version installed in the drive Ex. 0x103 v1.03

SW Disp=

Display Rev Num

1.2_0_0

Shows the last software version installed in the display.

Screen

Units

Description

S=0.0% F=0.0%

Set- Fdb PID

%

Shows the PID set point value of the analogue PID (left) and the sensor value that sends the

feedback signal (right).

PID Out=+0.00%

PID Out

%

Shows the t PID Output

3.2. Screens SV.2 – Drive Visualization

3.3. Screens SV.3 – External Visualization

3.4. Screens SV.4 – Internal Visualization

3.5. Screens SV.5 – PID Visualization

This display group appears when the parameter [G1.3 PROG] has been set to the PID option.

SD500

POWER ELECTRONICS

16

STATUS AND VISUALIZATION SCREENS

Screen

Units

Description

S=0.0% F=0.0%

Set-Fdb PID

%

Shows the PID reference value of the analogue PID (left) and the sensor value that sends the

feedback signal (right).

Sal PID=+0.00%

PID OUTPUT

%

Shows the PID output.

No Bmb Ma=0

Num Pumps on

-

Shows the number of pumps running

Screen

Units

Description

1 MREF1= 10.00%

Multireference1

%

When operating with a single local reference in PID mode, use the value set [SV8.4.1 MREF1]

The speed applied in each case will depend on the activation status of the digital inputs

configured with the following options:

[G4.1.8 ED6 = ′MRefPID-H′]

[G4.1.9 ED7 = ′MRefPID-M′]

[G4.1.10 ED8 = ′MRefPID-L′]

The assignment is done as shown on the following table:

DIGITAL OUTPUTS

REFERENCE PID

ED6=00

ED7=00

ED8=00

0 0 X

G25.1.1 ‘M_Ref1’

0 X 0

G25.1.2 ‘M_Ref2’

0 X X

G25.1. ‘M_Ref3’

X 0 0

G25.1.4 ‘M_Ref4’

X 0 X

G25.1.5 ‘M_Ref5’

X X 0

G25.1.6 ‘M_Ref6’

X X X

G25.1.7 ‘M_Ref7’

2 MREF2= 20.00%

Multireference2

%

3 MREF3= 30.00%

Multireference3

%

4 MREF4= 40.00%

Multireference4

%

5 MREF5= 50.00%

Multireference5

%

6 MREF6= 50.00%

Multireference6

%

7 MREF7= 50.00%

Multireference7

%

3.6. Screens SV.8 – Pump Macro Visualization

This display group is shown when the parameter [G1.3 PROG] is set as the ‘PUMPS’ option.

3.6.1. Subgroup SV8.4 – References

In order to facilitate access to the configuration of different references, this display group is

programmable. Its function is the same as the parameter group [G25.1 References] found on the

pump application program.

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

17

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 LOCK PARMTRS= N

Lock Parameters

G1.1 / Parameters

lock N Y

Enables a total lockage of the SD500 parameters. This lockage is

enabled after introducing on screen [G1.1b] a password.

DESCRIPTION

FUNCTION

N=NO

Lock is disabled

Y=YES

Only screen [G1.1 Lock Parameters] can

be modified.

NO

PASSWORD= 0

Lock Password

G1.1b/ Access

Password

OFF,

0000 to 9999

Enables a password entrance to lock the parameters and prevent non

authorised modifications within the configuration.

When [G1.1 LOCK PARMTRS'] Y is selected, this screen appears

automatically.

Unlock: In [G1.1 = S] set N NO. The screen PASSWORD=0 will

appear.

YES

ERRPWD= XXXX

Password Clue

G1.1c / Unlock

recovery clue

0000 to 9999

Provides information for the lock code recovery:

Unlock password = (XXXX/2)-3.

YES

4. PROGRAMMING PARAMETER DESCRIPTION

The various parameters found in the SD500 are arranged in functional groups (G1, G2, G3,…). To access

the screens or subgroups found on a lower level press the key. Once the parameter has been

accessed, it may show a numeric value or an option list.

Figure 4.1 Programming Line Detail

The next section shows the screen lists and the different configuration options.

4.1. Group 1 – G1: Options Menu

SD500

POWER ELECTRONICS

18

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

2LOCK SCRENS= N

ViewLock Screens

G.1.2 / Screen

Lock N Y

Allows the user to lock the access to the different SD500 parameter

groups, excluding the [G1] parameter group. This lockage is enabled after

introducing on screen [G1.2b] a password

DESCRIPTION

FUNCTIÓN

N=NO

No, lockage is not active.

Y=YES

Screen lock is active.

NO

PASSWORD = 0

Enter Password

G1.2b/ Password

OFF,

0000 to 9999

Allows the user to introduce a password to lock the screen display.

When on screen [G1.2 LOCK SCRENS], Y is selected, this screen will

appear automatically.

Unlock: In [G1.2=′Y] set N NO. The screen PASSWORD= 0 appears.

YES

ERRORWD= XXXX

Clue

G1.2c / Unlock

recovery

password

0000 to 9999

Provides the information for the lock code recovery:

Unlock Password = (XXXX/2)-3.

YES

3 PROG= STANDARD

Program Select

G1.3 / Program

activation

STANDARD

PID

PUMP

Select additional functions.

When PID is selected, the drive is in PID control mode. This mode

parameter setting is done in group [G6 ‘PID Control’]. Thus, new

functionality will be available in some parameters such as Digital Inputs in

group [G4], and visualization group [SV5 ‘PID Visualization’].

When PUMP is selected, an extended available function will appear for

the pump control [G25].

The screen group [G25] will remain hidden while the pump program is

defused. Furthermore, another available configuration options relative to

the pump control found in other parameters will not appear, as well as the

multi-reference parameters [G14] due to the fact that those settings will

be carried out from group G25. The visualization group [SV8 ‘Pump

Macro Visualization’] is displayed

NO

4 LANGUA= ENGLISH

Languag selection

G1.4 / Language

display

ENGLISH

Shows the users operating language.

NO

5 INITIALIZE= NO

Parameter Init

G1.5 / Default

values initialisation

NO

YES

Initialise the parameters to reset the factory default settings.

DESCRIPTION

FUNCTION

NO

No parameter has been initialised

YES

All parameters have been initialised

NO

6 UPLOAD= N

Eloader Upload

G1.6 / Save

display

parameters

N

Y

Save the complete drive parameter configuration

NO

Upload STS=

Upload Status

G1.6b / Uploading

parameter status

0 to 100%

Show the parameter uploading process

NO

7 DOWNLOADM= N

Eloader Download

G1.7 /

Downloading

parameters

N

Y

Recovery of the parameter complete configuration previously saved in the

memory

NO

DownloadSts=

Download Status

G1.7b /

Downloading

parameter status

0 to 100%

Show the parameter downloading process from the memory.

NO

8 Changed Para= N

ViewChangedParam

G1.8 / Changed

parameter display

N

Y

Show the parameters that have changed their values from their default

value. This way, the user can identify which parameters have changed

and the parameters adjusted to the default value are hidden.

Note: Enabling this function may cause the display to run slowly. Use this

functionality only when needed.

YES

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

19

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

9 ADMIN PW= 0

Admin_Serv PWD

G1.9 / Software

Administration

0 to 65535

Restricted for internal use.

YES

10 LCDContra= 60

Display Contrast

G1.10 / Set

display contrast

0 to 63

Enables the display contrast set.

YES

11 FAN= Run

FAN Control

G1.11 / Drive Fan

Control

DuringRun

Always ON

Temp Ctrl

The user will be able to decide the drive fan operating mode.

OPTION

FUNCTION

DuringRun

The drive fans will connect with the start command and

disconnect three minutes after the drive stops.

Always

ON

The fans are permanently working whenever the drive

is powered.

Temp Ctrl

The fan will connect at 51ºC and disconnect below

47ºC.

YES

12 ENB/DIS L/R=D

Enb/Ds Key Lc/Re

G1.12 / LOCAL /

REMOTE key

enabling

D

E

The user will be able to enable or disable the operation of the LOCAL /

REMOTE key of the display:

OPTION

FUNCTION

D=DISABLED

LOCAL / REMOTE key is disabled.

E=ENABLED

LOCAL / REMOTE key is enabled.

Note: For further information about the operation of this key go to section

‘1.1.3 Control Keypad’.

NO

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 ACi/pVolt= 380V

AC Input Volt

G2.1.1 / Input

Voltage

170 to 230V

320 to 480V

In order to set the input voltage.

Note: The default setting value and this parameter range will vary

depending on the drive supply voltage:

220V220

400V380

YES

2 I/P Freq= 50Hz

Input Frequency

G2.1.2 / Input

frequency

50 – 60Hz

In order to set the input frequency. If the user changes from 50Hz to

60Hz, the parameters related to the frequency (or rpm) defined in a value

greater than 50Hz will change to 60Hz.

However, if the frequency is changed from 60Hz to 50Hz, the parameters

related to the frequency (or rpm) defined in a value lower than 60Hz will

change to 50Hz.

NO

3 TrimPwr%= +100%

Trim Power %

G2.1.3 / Power

display setting

70 to 130%

Set the output power display, increasing its value if it is lower than

expected or otherwise reducing it to coincide with the real value.

YES

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 MTRPWR= 0.0kW

[1]

Motor Power

G2.2.1 / Motor

rated Power

0.2 to 185kW

Set the power to motor rated values in accordance with the nameplate.

Note: When this parameter is changed, parameters [G2.2.2 MTR CUR],

[G2.2.3 NOLOADC] and [G2.2.4 MTR VOLT] are automatically modified.

NO

2 MTR CUR= 0.0A

[1]

Motor Current

G2.2.2 / Motor

rated current

1.0 to 200.0A

Set the motor nominal current in accordance with the nameplate.

Note: The value of this parameter will be automatically configured when

setting parameter [G2.2.1 MOTRPWR].

NO

3 NOLOADC= 0.0A

[1]

No load Current

G2.2.3 / No load

current

0.5 to 200A

Set the current measured of the motor at rated frequency without load. If

difficulties found when measuring the current without load, this setting

should be between 30% and 50% of the motor nameplate rated current.

Note: The value of this parameter will be automatically configured when

setting parameter [G2.2.1 MOTRPWR].

NO

4.2. Group 2 – G2: Nameplate

4.2.1. Subgroup 2.1 – G2.1: Drive Parameters

Note: If all of these values are not introduced correctly, the SD500 would not work properly. Whenever the motor

nameplate offers multiple options or the star-delta coil configuration can be altered make sure to introduce the data

correctly in accordance with its configuration.

4.2.2. Subgroup 2.2 – G2.2: Motor Parameters

SD500

POWER ELECTRONICS

20

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

4 MTR VOLT= 0V

Motor Voltage

G2.2.4 / Motor

nominal voltage

180 to 480V

Set the motor rated voltage according to its nameplate.

Note: The value adjusted in this parameter will be automatically set to 0V

when changing the value of parameter [G2.2.1 MTRPWR]. Be careful of

setting the motor rated voltage after changing the motor power

parameter.

NO

5 POLE Number= 4

[1]

POLE Number

G2.2.5 / Motor

Poles

2 to 48

Set the number of poles in the motor according to its nameplate.

NO

6 ADJTSPD= 100.0%

FineAdjustSpeed

G2.2.6 / Fine

speed setting

0.1 to 6000%

Set the motor fine rated speed in accordance with the nameplate.

YES

7 EFICIENC= +85%

[1]

Efficiency

G2.2.7 / Motor

Efficiency

70 to 100%

Set the motor efficiency according to its nameplate.

NO

8 MTR FRC = 50.00Hz

Motor Frequency

G2.2.8 / Motor

frequency

30 to 400Hz

Set the motor frequency to rated value according to its nameplate.

NO

9 MTRCOOL=SELF

Motor Cooling

G2.2.9 / Motor

cooling

SELF

FORCED

Sets the drive with the motor characteristics to control. Provides

information for the thermal electric protection based on the motor thermal

model.

OPTIÓN

FUNCTION

SELF

Motor Self cooling

FORZAD

Motor with forced cooling

YES

Screen / Default Value

Name / Description

Range

Function

Set on

RUN

1 REF1 SP= LOCAL

Speed Reference 1

G3.1 / Speed

Reference Source 1

LOCAL

AI1

AI2

AI3

AI4

MDBUS

COMMS

PLC

Select the speed reference source associated with each control mode:

- The reference source [G3.1 ‘REF1 SP’] is associated with the main

control model [G4.1.1 ‘CONTRL MODE 1’].

- The reference source 2 [G3.2 ‘REF2 SP’] is associated with the

alternative control mode [G4.1.2 ‘CONTRL MODE 2’].

OPTION

FUNCTION

LOCAL

The reference will be introduced by the use of the

keypad and set on [G3.3LOCAL].

AI1

The reference will be introduced through the Analogue

Input 1.

AI2

The reference will be introduced through the Analogue

Input 2.

AI3

The reference will be introduced through the Analogue

Input 3.

Note: This option is only available if the I/O expansion

board has been installed.

AI4

The reference will be introduced through the Analogue

Input 4.

Note: This option is only available if the I/O expansion

board has been installed.

MDBUS

The reference will be installed by the use of MODBUS

communications.

COMMS

The reference will be installed by the use of the optional

communications board installed in the drive.

Note: This option is only available if any of the

communication boards have been installed.

PLC

The reference will be introduced through a

programmable Logic Controller.

Note: This option is only available if the optional PLC

board has been installed.

Note: In case an unavailable option is selected, the parameter will return

to the previously selected option.

NO

2 REF2 SP= LOCAL

Alt Speed Ref

G3.2 / Speed

Reference Source 2

NO

3 LCLSP= 0.00Hz

Local Speed

G3.3 / Local Speed

Reference

[G19.2.5]

to [G10.1]

The user can set the motor spinning speed value whenever the speed

reference has been set as LOCAL.

YES

[1] Value that depends on the drive rated current.

Note: If all of these values are not introduced correctly, the SD500 would not work properly. Whenever the motor

nameplate offers multiple options or the star-delta coil configuration can be altered, make sure to introduce the data

correctly in accordance with its configuration.

4.3. Group 3 – G3: References

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

21

Screen / Default Value

Name / Description

Range

Function

Set on

RUN

4 REF1 TQ = LOCAL (*)

G3.4 / Torque

Source Reference 1

LOCAL

AI1

AI2

AI3

AI4

MDBUS

COMMS

PLC

Allows to select supply 1 or supply 2 of the torque reference:

OPTION

FUNCTION

LOCAL

Reference will be introduced through keyboard and

will be adjusted in G3.6 ‘Local Torque Reference’.

AI1

The reference will be introduced through the analog

input 1.

AI2

The reference will be introduced through the analog

input 2.

AI3

The reference will be introduced through the analog

input 3.

AI4

The reference will be introduced through the analog

input 4.

MDBUS

The reference will be introduced through Modbus.

COMMS

The reference will be introduced through the

communications.

PLC

The reference will be introduced through PLC.

NO

5 REF2 TQ = LOCAL (*)

G3.5 / Torque

Source Reference 2

NO

6 LclTQ = 0 % (*)

G3.6 / Local Torque

Reference

-180 to

180%

Allows the user to set the torque value of the motor if the torque reference

source has been adjusted to “LOCAL”

YES

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 CONTROL MODE1= 1

Control Mode 1

G4.1.1 / Main

Control Mode

LOCAL

REMOTE

MODBUS

COMMS

PLC

The user is able to set the main control mode to order the command

functions (Start/Stop, Reset, …).

OP.

DESCRIP.

FUNCTION

0

LOCAL

The drive is controlled from the keypad.

1

REMOTE

The drive is controlled from the control

terminals.

3

MODBUS

The drive is controlled through the

communications bus, integrated in the

equipment.

4

COMMS

The drive control is carried out by the use of

any of the optional communication boards.

Note: This option is only available if any of the

communication boards have been installed.

5

PLC

The drive control is carried out through a

programmable Logic Controller.

Note: This option is only available if the

optional PLC board has been installed.

Note: In case an unavailable option is selected, the parameter will return

to the previously selected option.

NO

2 CONTROL MODE2= 1

Alt Ctrl Mode

G4.1.2 /

Alternative Control

Mode

LOCAL

REMOTE

MODBUS

COMMS

PLC

Enables the user to set the secondary control mode to order the

command functions ( Start, Stop, Reset…)

The control mode 2 will enable exclusively through digital inputs.

Therefore, set any of these to [15 CTR/REF 2]. When the input is

active, it will operate in the auxiliary control mode, inhibiting the main

mode.

OP.

DESCRIP.

FUNCTION

0

LOCAL

The drive is controlled from the keypad.

1

REMOTE

The drive is controlled from the control

terminals.

3

MODBUS

The drive is controlled through the

communications bus, integrated in the

equipment.

4

COMMS

The drive control is carried out by the use of

any of the optional communication boards.

Note: This option is only available if any of the

communication boards have been installed.

5

PLC

The drive control is carried out through a

programmable Logic Controller.

Note: This option is only available if the

optional PLC board has been installed.

Note: In case an unavailable option is selected, the parameter will return

to the previously selected option.

NO

4.4. Group 4 – G4: Inputs

4.4.1. Subgroup 4.1 – S4.1: Digital I/P

(*) Available if parameter G19.1.1 =VECTOR

SD500

POWER ELECTRONICS

22

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

3 DI1= START (+)

Digital I/P 1

G4.1.3 /

Multifunction

Digital Input 1

Configuration

NONE

MRefPID-H

MRefPID-M

MRefPID-L

START (+)

START (-)

RESET

EXT TRIP

DIS START

INCH 1

SPEED-L

SPEED-M

SPEED-X

XCEL-L

XCEL-M

3 WIRE

CTR/REF 2

UP

DOWN

RESERVED

POT CLEAR

AnalogHLD

PIDOPLoop

RESERVED

Pre-Excit

Speed/Torque

ASR GAIN2

ASR P/PI

ThermalIn

INCH (+)

INCH (-)

Tq OFFSET

Digital Inputs configuration for individual use.

OPTION

FUNCTION

None

Not programmed entry.

MRefPID-H

High Bit for the PID multireference. See [Group 14 –

′Multi-references′] (NO).

Note: This option is only available for Digital Input 6.

MRefPID-M

Medium Bit for the PID multireference. See [Group

14 – ′Multi-references′] (NO).

Note: This option is only available forDigital Input 7.

MRefPID-L

Low Bit for the PID multireference. See [Group 14 –

′Multi-references′] (NO).

Note: This option is only available for Digital Input 8.

START (+)

In order to command the ‘Direct Start’ order through

the selector (NO). This option will not work if there is

any digital input programmed as ‘3 WIRE’, ‘UP’, or

‘DOWN’.

START (-)

In order to command the ‘Inverse Start order through

the selector (NO). This option will not work if there is

any digital input programmed as ‘3 WIRE’, ‘UP’, or

‘DOWN’.

RESET

In order to command the ‘Reset’ order through

digital inputs. (NO)

EXT TRIP

Allows an extreme fault generation in order to stop

the drive through digital inputs (NO). Is advisable to

invert the digital input logic configured as Extreme

Fault and set it as contact (NC). See parameter

[G4.1.16].

DIS START

In order to stop the drive removing the motor output

power supply forcing a stop by inertia. (NO)

INCH 1

In order to enable the speed reference programmed

in [G15.1 ′InchFq′]. (NO)

SPEED-L

[1]

Bit 0 speed reference. Allows selecting the multiple

preconfigured speed references. See [Group 14 –

′Multi-references′] (NO)

SPEED-M

[1]

Bit 1 speed reference. Allows selecting the multiple

preconfigured speed references. See [Group 14 –

′Multi-references′] (NO)

SPEED-H

[1]

Bit 2 speed reference. Allows selecting the multiple

preconfigured speed references. See [Group 14 –

′Multi-references′] (NO)

SPEED-X

[1]

Bit 3 speed reference. Allows selecting the multiple

preconfigured speed references. See [Group 14 –

′Multi-references′] (NO)

XCEL-L

Bit 0 for alternative acceleration ramps. Allows the

selection of the multiple preconfigured

acceleration/deceleration ramps. See [Subgroup

5.16 – ‘Alternative Ramps’]

XCEL-M

Bit 1 for alternative acceleration ramps Allows the

selection of the multiple preconfigured

acceleration/deceleration ramps. See [Subgroup

5.16 – ‘Alternative Ramps’]

3 WIRE

‘Speed through Buttons’ function’.

Example:

DI1 = 1 START(+) (NO)

DI2 = 14 3 WIRE (NC)

DI3 = 17 UP (NO)

DI4 = 18 DOWN (NO)

This way, the DI1 button orders to start and the DI2

orders to stop. The DI3 and DI4 buttons allow the

user to increase or decrease the speed.

CTR/REF 2

Enables the alternative control mode programmed in

[G4.1.2. ′Alt Ctrl Mode′] (NO).

[1]

Available if [G1.3 PROG=STANDARD]

Note: Continues on the following page.

NO

4 DI2= START(-)

Digital I/P 2

G4.1.4 /

Multifunction

Digital Input 2

Configuration

5 DI3= DIS START

Digital I/P 3

G4.1.5 /

Multifunction

Digital Input 3

Configuration

6 DI4= EXT TRIP

Digital I/P 4

G4.1.6 /

Multifunction

Digital Input 4

Configuration

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

23

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

7 DI5= SPEED-L

[1]

Digital I/P 5

G4.1.7 /

Multifunction

Digital Input 5

Configuration

NONE

MRefPID-H

MRefPID-M

MRefPID-L

START (+)

START (-)

RESET

EXT TRIP

DIS START

INCH 1

SPEED-L

SPEED-M

SPEED-X

XCEL-L

XCEL-M

3 WIRE

CTR/REF 2

UP

DOWN

RESERVED

POT CLEAR

AnalogHLD

PIDOPLoop

RESERVED

Pre-Excit

Speed/Torque

ASR GAIN2

ASR P/PI

ThermalIn

INCH (+)

INCH (-)

Tq OFFSET

Note: Previous page continuation.

DESCRIPTION

FUNCTION

UP

Assigns to the digital input the function of increasing

the speed reference by the use of a button(NO). The

reference limits will be the ones set on [G.10 LIMITS].

DOWN

Assigns to the digital input the function of decreasing

the speed reference by the use of a button(NO). The

reference limits will be the ones set on [G.10 LIMITS].

RESERVED

-

POT CLEAR

Deletes the speed reference memory set with

motorized potentiometer. This way, even if parameter

[G4.18 ‘SaveMot Frq’] is set as ‘YES’, when restarting

the drive, the drive will operate depending on the

established reference in [G3.3 ‘LOCAL’].

AnalogHLD

Allows set a speed reference from an analog input to

the value present at the activation time. When this

digital input is active, the drive will ignore any change

produced in the analog input reference (NO).

PIDOPLoop

Allows disabling the PID function. When it is disabled,

the control PID will be resumed.

Note: This option must be used when the PID

reference is set by analogue input. If PID reference is

set by display, use option ‘INCH1’.

RESERVED

-

Pre-Excit

Enables the motor pre-excitation activation, before

start. The user can adjust this functionality in

parameters [G7.1 ‘START’], [G7.12 ‘DCSt T’] and

[G7.13 ‘DC Curr’].

Speed/Torque(*)

Allows setting speed mode (NO) or torque mode (NC).

ASR GAIN2(*)

Allows changing the gain of the speed controller to

[G19.3.7] after [G19.3.10].

ASR P/PI (*)

Allows disabling the Integral gain of the speed

controller (NC).

Thermalln

Assigns the over temperature trip function when a

PTC sensor is connected to a digital input. Therefore,

the PTC should be connected between a digital input

and the common terminal. Furthermore, this input

should be configured as (NC) in the parameter

[G4.1.16 - ′DCTy′] and the overheat protection must

be enabled in parameter [G11.23 ‘OvHM’].

INCH (+)

In order to define the direct starting fix speed

reference to the one set in parameter [G15.1 -′InchFq′]

INCH (-)

In order to define the direct starting fix speed

reference to the one set in parameter [G15.1 -′InchFq′]

Tq OFFSET(*)

In order to activate the Tq OFFSET option.

Parameters are configured in screens [G10.8.6] to

[G10.8.8].

NO

8 DI6= SPEED-M

[1]

Digital I/P 6

G4.1.8 /

Multifunction

Digital Input 6

Configuration

9 DI7= SPEED-H

[1]

Digital I/P 7

G4.1.9 /

Multifunction

Digital Input 7

Configuration

10 DI8= INCH 1

Digital Input 8

G4.1.10 /

Multifunction

Digital Input 8

Configuration

14 DIOnF= 10ms

DI On Filter

G4.1.14 / Digital

Input activation

delay

0 to 10000ms

In order to set the delay time when activating the digital input. In case any

variation occurs within a smaller time gap, the input will remain disabled.

YES

15 DIOffF= 3ms

DI Off Filter

G4.1.15 / Digital

Input

deactivation

delay

0 to 10000ms

In order to set the delay time when disabling a digital input. In case any

variations occur within a smaller time gap, the input will remain enabled.

YES

16 DCTy= 00000000

DiContactType

G4.1.16 / Digital

input contact

type selection

00000000

to

XXXXXXXX

Allows defining the digital inputs as usually opened contactors (NO). or

usually closed (NC)

OPTION

FUNCTION

0

Contact normally open (NO)

X

Contact normally closed (NC)

The assignment order is DI1, DI2, …, DI8 starting from the bit placed

farthest to the right.

NO

17 DiScan= 1ms

Di Scan Time

G4.1.17 /

Multireference

delay time

1 to 5000ms

In order to set how much time must pass to refresh the digital inputs

configured as multireference.

NO

18 SaveMot Frq= N

Save motpot freq

G4.1.18 / Save

operating

frequency

motorised

Potentiometer

NO

YES

Save automatically the speed reference defined by the motorised

potentiometer.

YES

[1]

These parameters default values depends on the program mode set in [G1.3 PROG].

(*) Available if parameter G19.1.1 =VECTOR

SD500

POWER ELECTRONICS

24

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 An1PT= 0-10v

Ain1PolarityType

G4.2.1 / Analog

Input Mode

Selection

0-10V

-/+10V

The user is able to select between the single-pole or bipolar analog input

mode.

OPTION

FUNCTION

0-10V

Single-pole of 0-10V

10V

Bipolar of 10V

In addition to change this parameter, the user should ensure that the

analog input wiring is correct as shown in the Hardware and Installation

Manual.

NO

2 Ain1LPF= 10ms

Ain1LPF

G4.2.2 / Low

Pass Filter for

Analog Input 1

0 to

10000ms

Enables the setting of the time response against a change produced in the

speed reference, so that it can reduce the speed fluctuation due to

unstable signs or noise. This results that the response becomes slower.

YES

3 A1MnV= +0.00V

Ain1 Min V

G4.2.3 / Analog

Input 1 Minimum

Range

0 to [G4.2.5]

In order to define the minimum voltage for the analog input 1 according to

the connected sensor characteristics.

YES

4 A1MnRf= +0.00%

An1MxV

G4.2.4 / Analog

Input 1 Minimum

Range Speed

0 to 100.00%

The user is able to set the speed reference corresponding to the analog

input 1 minimum range. It corresponds to the minimum voltage level set in

[G4.2.3 ‘Ain1LPF’]. It is configured to introduce the speed reference

through the analog input. The value is a percentage of the frequency

adjusted in parameter [G4.2.12 ‘MxFqA’].

YES

5 A1MxV= +10.00V

Ain1 Max V

G4.2.5 / Analog

Input 1 Maximum

Rage

[G4.2.3] to

10.00V

Defines the maximum voltage for the analog input 1, according to the

connected sensor characteristics.

YES

6 A1MxR= +100.00%

Ain1 Max Ref

G4.2.6 / Analog

Input 1 Maximum

Range Speed

0 to 100.00%

The user is able to set the speed reference corresponding to the analog

input 1 minimum range. It corresponds to the minimum voltage level set in

[G4.2.5 ‘A1MxV’]. It is configured to introduce the speed reference through

the analog input. The value is a percentage of the frequency adjusted in

parameter [G4.2.12 ‘MxFqA’].

YES

7 An1NgMn=+0.00V

[1]

Ain1 neg min V

G4.2.7 / Analog

Input 1 Negative

Minimum Range

-10.00 to 0V

Defines the negative minimum voltage for the analog input 1, according to

the connected sensor characteristics.

YES

8 A1MnR= +0.00%

[1]

Ain1 Neg Min Ref

G4.2.8 / Analog

Input 1 Minimum

Negative Range

-100.00 to

0%

The user is able to set the speed reference corresponding to the analog

input 1 minimum negative range. Is corresponds to the minimum voltage

level set in [G4.2.7 ‘An1NgMn’]. It is configured to introduce the speed

reference through the analog input. The value is a percentage of the

frequency adjusted in parameter [G4.2.12 ‘MxFqA’].

YES

9 A1MxR= -10.00V

[1]

Ain1 Neg MaxV

G4.2.9 / Analog

Input 1 Maximum

Negative Range

-10.00 to 0V

Defines the maximum negative voltage for the analog input 1 according to

the connected sensor characteristics.

YES

10 A1MxR= -100.00

[1]

Ain1Neg Max Ref

G4.2.10 / Analog

Input 1 Maximum

Negative Range

Speed

-100.00 to

0%

The user is able to set the speed reference corresponding to the analog

input 1 maximum negative range. It corresponds to the maximum voltage

level set in [G4.2.8 ‘A1MnR’]. It is configured to introduce the speed

reference through an analog input. The value is a percentage of the

frequency adjusted in parameter [G4.2.12 ‘MxFqA’].

YES

11 A1DeLI= 0.04%

Ain1 Discre Lv

G4.2.11 / Analog

Input 1

Quantification

Level

0.04 to 10%

The user is able to set the analog input 1 quantification level. It is used

when too much noise is present within the analog input signals. The

quantification value is defined as the analog input 1 maximum percentage

value. For example, if the input maximum value is 10V and the

quantification level is 1%, the frequency will change in 0.05Hz (when the

maximum frequency is 50Hz), in 0.1V intervals. As the input voltage

increases or decreases, the output frequency will differ, removing the

fluctuation effect within the analog input value.

NO

12 MxFqA= 50.00Hz

Max Freq Ang Inp

G4.2.12 /

Maximum

frequency at

analogue input

[G19.2.5] to

[G10.1]

The user is able to set the operating frequency of the drive at the maximum

voltage input of the analogue input.

YES

4.4.2. Subgroup 4.2 – S4.2: Analog Input 1

[1]

Available if the Analog Input 1 is configured as bipolar (10V) in parameter [G4.2.1 EA1Md = 1].

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

25

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 Ain2LPF= 10ms

Ain2LPF

G4.3.1 / Low Pass

Filter for Analog

Input 2

0 to 10000ms

Enables the setting of the time response against a change produced in

the speed reference, so that it can reduce the speed fluctuation due to

unstable signs or noise. This results that the response becomes slower.

NO

2 A2MnC= 4.00mA

Ain2 Min C

G4.3.2 / Analog

Input 2 Minimum

Range

0 to 20.00mA

In order to define the minimum current for the analog input 2 according to

the connected sensor characteristics.

YES

3 A2MnR= +0.00%

Ain2 Min Ref

G4.3.3 / Analog

Input 1 Minimum

Range Speed

0 to 100.00%

The user is able to set the speed reference corresponding to the analog

input 2 minimum range. It corresponds to the minimum voltage level set

in [G4.3.2 ‘A2MnC’]. It is configured to introduce the speed reference

through the analog input. The value is a percentage of the frequency

adjusted in parameter [G4.3.7 ‘MxFqA’].

YES

4 A2MxC= 20.00mA

Ain2 Max Curr

G4.3.4 / Analog

Input 2 Maximum

Range

4 to 20.00mA

Defines the maximum current for the analog input 2, according to the

connected sensor characteristics.

YES

5 A2MxR= +100.00%

Ain2 Max Ref

G4.3.5 / Analog

Input 2 Maximum

Range Speed

0 to 100.00%

The user is able to set the speed reference corresponding to the analog

input 2 maximum range. It corresponds to the maximum current level set

in [G4.3.4 ‘A2MxC’]. It is configured to introduce the speed reference

through the analog input. The value is a percentage of the frequency

adjusted in parameter [G4.3.7 ‘MxFqA’].

YES

6 A2DeLl= 0.04%

Ain2 Dze Level

G4.3.6 / Analog

Input 2

Quantification

level

0.04 to 10%

Same function as the quantification parameter shown in [G4.2.11

‘A1DeLl‘].

NO

7 MxFqA= 50.00Hz

Max Freq Ang Inp

G4.3.7 / Maximum

frequency at

analogue input

[G19.2.5] to

[G10.1]

The user is able to set the operating frequency of the drive at the

maximum voltage input of the analogue input.

YES

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 ACC1= 20.0s

Acc Ramp

G5.1 /

Acceleration

Ramp 1

0 to 600.0s

The user is able to set the acceleration ramp 1. The established setting

within the parameter is the time required to reach the maximum

frequency value, starting form 0Hz.This ramp will be set according to the

process necessities.

SI

2 DECEL1= 30.0s

Decel Ramp

G5.2 /

Deceleration

Ramp 1

0 to 600.0s

The user is able to set the deceleration ramp 1. The established setting

within the parameter is the time required to reach the maximum

frequency value, starting form 0Hz.This ramp will be set according to the

process necessities.

SI

4 RmpT= MaxFreq

Ramp T Mode

G5.4 / Type of

Acceleration

Ramp

MaxFreq

FrqDelta

Enables the acceleration ramp settings:

OPTION

FUNCTION

MaxFreq

Allows accelerating or decelerating with the same

ramp based on the maximum frequency,

independently from the operating frequency.

FrqDelta

Allows defining the accelerating/decelerating time

which will reach the next speed reference when

working at constant speed.

NO

5 AccPn= Linear

Acc Pattern

G5.5 /

Acceleration

Pattern

LINEAR

S CURVE

In order to set the type of acceleration depending on the application:

OPTION

FUNCTION

LINEAR

The output frequency is constant and increases/

decreases linearly.

S CURVE

Used in applications which require a soft

acceleration/deceleration, such as lifting loads. The S

curve index can be set from parameters

[G5.7 – G5.10]

NO

4.4.3. Subgroup 4.3 – S4.3: Analog Input 2

4.5. Group 5 – G5: Acceleration and Deceleration Ramps

SD500

POWER ELECTRONICS

26

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

6 DecPn= Linear

Dec Pattern

G5.6 /

Deceleration

Pattern

LINEAR

S CURVE

Allows the setting of the same functions found in parameter [G5.5

‘AccPn’]

NO

7 AcSSrt= +40%

Acc S Start

G5.7 / S Curve

Acceleration

Starting Ramp

1 to 100%

The user is able to set the curve whenever the acceleration/deceleration

pattern is defined as S curve. It is used to set the S curve curvilinear

relation when starting the acceleration.

NO

8 AccSEnd= +40%

Acc S End

G5.8 / S-Curve

Acceleration

Ending Ramp

1 to 100%

The user is able to set the curve’s ramp once the

acceleration/deceleration pattern has been defined as S Curve. It is used

to set the S Curve curvilinear relation when ending the acceleration.

NO

9 DeISSrt= +40%

Dec S Start

G5.9 / S- Curve

Deceleration

Starting Ramp

1 to 100%

The user is able to set the curve whenever the acceleration/deceleration

pattern is defined as S curve. It is used to set the S curve curvilinear

relation when starting the deceleration.

NO

10 DecSEnd=+40%

Dec S End

G5.10 / S-Curve

Decelerating

Ending Ramp

1 to 100%

The user is able to set the curve’s ramp once the

acceleration/deceleration pattern has been defined as S Curve. It is used

to set the S Curve curvilinear relation when ending the deceleration.

NO

11 AccDWF= 5.00Hz

Acc Dwell Freq

G5.11 /

Acceleration

Frequency Pause

[G19.2.5] to

[G10.1]

During the acceleration process, the drive will pause at this frequency,

keeping it constant during a period of time set in parameter

[G5.12 – ′AccDWT′].

NO

12 AccDWT= 0.0s

Acc Dwell Time

G5.12 /

Acceleration Time

Pause

0 to 60s

During the acceleration process, this parameter allows to set during how

long the drive will operate at the constant frequency set in parameter

[G5.11 - AccDWF′].

NO

13 DecDWF= 5.00Hz

FDec Dwell Freq

G5.13 /

Deceleration

Frequency Pause

[G19.2.5] to

[G10.1

During the deceleration process, the drive will pause at this frequency

value, remaining constant during the period of time established in

parameter [G5.14 – ′DecDWT′].

NO

14 DecDWT= 0.0s

Dec Dwell Time

G5.14 /

Deceleration Time

0 to 60.0s

During the deceleration process, this parameter allows to set how long

will the drive be operating at the constant frequency set in parameter

[G5.13 - ′DecDWF′].

NO

15 TDedFll= 3.0s

Fault decal time

G5.15 / Fault

Deceleration Time

0 to 600.0s

To proceed with the deceleration time settings, whenever a fault occurs.

YES

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 ACC2= 20.0s

Acc Ramp 2

G5.16.1 /

Alternative

Acceleration

Ramp 2

0 to 600.0s

This parameter allows up to three alternative acceleration/deceleration

ramps. The main acceleration/deceleration ramps can be set in

parameters [G5.1 ‘ACC1’] and [G5.2 ‘DECEL1’].

The alternative ramps will be enabled by means of the digital inputs,

configured as multiple acceleration/deceleration references. See

parameters [G4.1.3] to [G4.1.10].

To proceed with their use, the user must select the digital inputs which

control the alternative ramps setting them as ‘XCEL-L and XCEL-M.

The setting is carried out by assigning a time value to each of the

parameters within the [G5.16.1] to [G5.16.6] groups.

The following table link the configured digital inputs as Alternative Ramps

with the selected acceleration/deceleration:

PARM.

DESCRIP

DIGITAL. I:

START/STOP

DIGITAL.I.

ACC/DEC

STOP(+)

START(-)

M

B

G5.1

ACC1 1 0 0 0

G5.2

DECEL1 0 1 0 0

G5.16.1

ACC2 1 0 0 X

G5.16.2

DEC2 0 1 0 X

G5.16.3

ACC3 1 0 X 0

G5.16.4

DEC3 0 1 X 0

G5.16.5

ACC4 1 0 X X

G5.16.6

DEC4 0 1 X X

Note: 0: Disabled y X: Enabled.

YES

2 DEC2= 20.0s

Decel Ramp 2

G5.16.2 /

Alternative

Deceleration

Ramp 2

0 to 600.0s

3 ACC3= 30.0s

Acc Ramp 3

G5.16.3 /

Alternative

Acceleration

Ramp 3

0 to 600.0s

4 DEC3= 30.0s

Decel Ramp 3

G5.16.4 /

Alternative

Deceleration

Ramp 3

0 to 600.0s

5 ACC4= 40.0s

Acc Ramp 4

G5.16.5 /

Alternative

Acceleration

Ramp 4

0 to 600.0s

6 DEC4= 40.0s

Decel Ramp 4

G5.16.6 /

Alternative

Deceleration

Ramp 4

0 to 600.0s

4.5.1. Subgroup 5.16 – S5.16: Alternative Ramps

POWER ELECTRONICS

SD500

PROGRAMMING PARAMETER DESCRIPTION

27

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 SEL REF= MREF

Select Reference

G6.1 / Source

Selection to

introduce the set

point

MREF

AI1

AI2

AI3

AI4

MODBUS

COMMS

PLC

The user is able to select the source to introduce the PID regulator

reference.

OPTION

FUNCTION

MREF

PID reference introduced by keypad. The different

references are set in parameter [Group 14

MULTIREFERENCES]

AI1

PID reference introduced through Analog Input 1

AI2

PID reference introduced through Analog Input 2

AI3

PID reference introduced through Analog Input 3

Note: This option is only available if the I/O expansion

board has been installed.

AI4

PID reference introduced through Analog Input 4

Note: This option is only available if the I/O expansion

board has been installed.

MODBUS

PID reference introduced through integrated Modbus

communications

COMMS

PID reference introduced through communications of any

of the optional communication boards.

Note: This option is only available whenever any of the

optional communication boards have been installed.

PLC

PID reference introduced through the equipments

programmable logic controller

Note: This option is only available whenever the PLC

optional board has been installed.

Note: Whenever an unavailable option is selected, the parameter will

return to the previously selected option.

NO

2 SEL FBK= AI1

Select Feedback

G6.2 / Source

Selection to

Introduce the

Feedback Signal

AI1

AI2

AI3

AI4

MODBUS

COMMS

PLC

In order to select the source this will introduce the feedback to close the

control loop.

OPTION

FUNCTION

AI1

Feedback signal through the Analog Input 1

AI2

Feedback signal through the Analog Input 2

AI3

Feedback signal through the Analog Input 3

Note: This option is only available whenever the I/O

expansion board has been installed.

AI4

Feedback signal through the Analog Input 4

Note: This option is only available whenever the I/O

expansion board has been installed.

MODBUS

Feedback signal through the equipment integrated

Modbus communications

COMMS

Feedback signal through communications of any of the

optional communication boards.

Note: This option is only available whenever any of the

optional communication boards have been installed.

PLC

Feedback signal through a programmable logic controller

Note: This option is only available whenever the PLC

optional board has been installed.

Note: Whenever an unavailable option is selected, the parameter will

return to the previously selected option.

NO

3 GainKp= +50.0%

Gain Kp

G6.3 / PID

Regulator Gain

0 to 1000.0%

In order to set the value of the proportional gain controller. This value

should be increased, whenever a greater control response is needed,

Note: Increasing too much this value can cause a greater system

instability

YES

4 INTEGRL= 10.0s

PID Integral

G6.4 / PID

Regulator

Integrating Time

0 to 200.0s

Set the regulator integration time. In case greater precision is needed,

increase this value.

Note: Increasing this value may slow down the system.

YES

5 T Der= 0ms

PID Differential

G6.5 / PID

Regulator

Differential Time

0 to 1000ms

Set the regulator differential time. Whenever a greater response is

needed, this value can be increased.

Note: Increasing too much this value can cause a precision loss.

YES

4.6. Group 6 – G6: PID Control

This configuration group allows adjusting the PID control of the drive. To enable this control mode it is

necessary to adjust parameter [G1.3 ‘PROG’] as ‘PID’.

SD500

POWER ELECTRONICS

28

PROGRAMMING PARAMETER DESCRIPTION

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

6 MxSL= +50.00Hz

Max Speed LIM

G6.6 / PID Upper

Frequency Limit

From [G6.8]

to 300Hz

Set the upper limit at the PID output

YES

7 MnSL= 0.00Hz

Min Speed Lim

G6.7 / PID Lower

Frequency Limit

From -300.00

to [G6.7] Hz

Set the lower limit at the PID output

YES

8 INVERT PID= N

Invert PID

G6.8 / PID Output

Inverting N Y

In order to invert the drive PID output.

OPTION

FUNCTION

N=NO

The PID regulator answers in normal mode. This means,

when the feedback value is greater than the reference

signal, the speed will be reduced. Whenever the

feedback is lower than the reference signal, the speed

will be increased.

Y=YES

The PID regulator responds in inverted mode. Therefore,

whenever the feedback value is higher than the

reference signal, speed will be increased. However,

whenever the feedback is lower than the signal reference

value, speed will be decreased.

NO

9 OutSc= +100.0%

Out Scale

G6.9 / PID Output

Scale

0.1 to

1000.0%

To set the PID regulator output magnitude.

NO

Screen / Default Value

Name /

Description

Range

Function

Set on

RUN

1 START= RAMP

Start Mode

G7.1 / Start Mode

RAMP

DCSTART

Define the motor start

OPT.

FUNCTION

RAMP

The drive will start applying a frequency ramp to the

motor.

DCSTART

Allows accelerating after having stopped the motor by

the use of the DC Brake. It can also be used after a

normal brake whenever some torque is needed after

opening the external brake.

To configure this option, see parameters [G7.12

‘DCSt T’] and [G7.13 ‘DC Curr’].

NO

2 StrDly= 0.00s

Start Delay

G7.2 / Start Delay

Time

0 to 100.00s

Provides the delay setting from the moment the drive receives the start

order until the start begins. After receiving the start order, the drive will

wait until the delay time to start has passed.

NO

3 STOP= RAMP

Stop Mode

G7.3 / Stop Mode 1

RAMP

DC BRAKE

SPIN

POW BRKE

Select the drives main stop mode. This value should be adequate for

each application.

OPT.

FUNCTION

RAMP

The drive will stop applying a frequency ramp to stop

the motor.

DC BRAKE

The drive will apply DC to stop the motor. To

configure this option, see parameters from [G7.14

‘PreDC T’] to [G7.17 ‘DCBk F’].

SPIN

The drive will cut the motor output supply, stopping