Page 1

Poulan PRO /

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

SM132

For Occasional Use Only

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENOIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en le-

siones graves.

AVERTISSEMENT:

Lire le manuel d'instructions et bien respecter tousles avertisse-

ments et toutes les instructions de s6curite. Tout defaut de le

faire pourrait entraTner des blessures graves.

Electrolux Home Products, Inc.

1030 Stevens Creek Road

Augusta, GA 30907

The Electrolux Group. The worlds No.l choice.

KITCHEN, CLEANING AND OUTDOOR APPUANCES COMBINED

Copyright "_2004 Electrolux Home Products, Inc 530164890 11/19/04

Page 2

WARNING: When using gardening

appliances, basic safety precautions must al-

ways be followed to reduce the risk of fire and

serious injury. Read and follow all instruc-

tions.

This power unit can be dangerous! Operator is

responsible for following instructions and warn-

ings on unit and in manual. Read entire instruc-

tion manuat before using unit! Be thoroughIy fa-

miliar with the controls and the proper use of the

unit. Restrict the use of this unit to persons who

have read, understand, and will follow the

instructions and warnings on the unit and in the

manual. Never allow children to operate this

unit.

INSTRUCTION SAFETY INFORMATION

MANUAL ON THE UNIT

A

dBbDANGER: Never use blades or flail-

ing devices, This unit is designed for line trim-

mer use only, Use of any other accessories or

attachments wilt increase the risk of injury,

Q©O

A

WARNING: Trimmer line throws ob-

jects violently. You and others can be blinded/in-

jured, Wear eye and leg protection, Keep body

parts clear of rotating line.

Eye Protection

/ Hazard 7one

lm* Boots

Keep children, bystanders, and animals 50 feet

(15 meters) away, Stop unit immediately if ap-

proached.

if situations occur which are not covered in

this manual, use care and good judgment. If

you need assistance, contact your authorized

service dealer or call 1-800-554-6723,

OPERATOR SAFETY

• Dress properly. Always wear safety

glasses or similar eye protection when op-

erating, or performing maintenance, on

your unit (safety glasses are available).

Eye protection should be marked Z87.

• Alwayswear faceor dust mask if operation

is dusty.

• Always wear heavy, long pants, long sleeves,

boots, and gloves. Wearing safety leg guards

is recommended.

• Always wear foot protection. Do not go

barefoot or wear sandals. Stay clear of

spinning line.

• Secure hair above shoulder length. Secure

or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc.

They can be caught in moving parts.

• Being fully covered also helps protect you

from debris and pieces of toxic plants

thrown by spinning line.

• Stay Alert. Do not operate this unit when

you are tired, ill, upset or under the influ-

ence of alcohol, drugs, or medication.

Watch what you are doing; use common

sense.

• Wear hearing protection.

• Never start or run inside a closed room or

building. Breathing exhaust fumes can kill

• Keep handles free of oil and fuel.

UNIT / MAINTENANCE SAFETY

• Disconnect the spark plug before perform-

ing maintenance except carburetor adjust-

ments,

• Look for and replace damaged or loose

parts before each use. Look for and repair

fuel leaks before use. Keep in good working

condition.

• Reptace trimmer head parts that are

chipped, cracked, broken, or damaged in

any other way before using the unit.

• Maintain unit according to recommended

procedures. Keep cutting line at proper

length.

• Use only 0.080" (2 mm) diameter Poulan

PRO_) brand replacement line. Never use

wire, rope. string, etc.

• install required shield properly before using

the unit. Use only specified trimmer head;

make sure itis properly installed and securely

fastened.

• Make sure unit is assembled correctly as

shown in this manual.

• Make carburetor adjustments with lower

end supported to prevent line from contact-

ing any object.

• Keepothersawaywhen makingcarburetor

adjustments.

• Use only recommended Poulan PRO ¢ ac-

cessories and replacement parts.

• Have all maintenance and service not ex-

plained in this manual performed by an au-

thorized service dealer.

FUEL SAFETY

• Mix and pour fuel outdoors.

• Keep away from sparks or flames.

• Use a container approved for fuel.

• Do not smoke or allow smoking near fuel or

the unit.

• Avoid spilling fuel or oil. Wipe up all fuel

spills.

• Move at least 10 feet (3 meters) away from

fueling site before starting engine.

• Stop engine and allow to cool before re-

moving fuel cap.

• Always store gasoline in a container ap-

proved for flammable liquids.

2

Page 3

CUTTINGSAFETY

_ WARNING: Inspect the area before

each use. Remove objects (rocks, broken

glass, nails, wire, etc.) which can be thrown

by or become entangled h_ line. Hard objects

can damage the trimmer head and be thrown

causing serious injury.

• Use only for trimming, scalping, mowing and

sweeping. Do not use for edging, pruning or

hedge trimming.

• Keep firm footing and betance. Do not over-

reach.

• Keep alt parts of your body away from muffler

and spinning Hne. Keep engine below waist

level. A hot muffler can cause serious bums.

• Cut from your teff to your right. Cutting on

right side of the shield will throw debris away

from the operator=

• Use only in daylight or good artificial light.

• Use only for jobs explained in this manual.

TRANSPORTING AND STORAGE

• Allow engh_e to cool before storing or trans-

porting in vehicle.

• Emptythe fueItank before storing or trans-

porting the unit. Use up fuel left in the carbu-

retor by starting the engine and tetth_g it run

until it stops.

• Store unit and fuel in areawhere fuelvapors

cannot reach sparks or open flames from

water heaters, etectric motors or switches,

furnaces, etc.

• Store unit so line limiter blade cannot acci-

dentally cause injury, The unit can be hung

by the shaft.

• Store unit out of reach of children,

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or ab-

normal swellings. Pro;onged use in cold

weather has been linked to blood vessel dam-

age in otherwise healthy people. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek med-

ical attention, An anti-vibration system does

not guarantee the avoidance of these prob-

lems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical condition and the condi-

tion of this toot,

SPECIAL NOTICE: This unit is equipped

with a temperature limiting muffler and spark

arresting screen which meets the require-

ments of California Codes 4442 and 4443. All

U.S. forest land and the states of California,

idaho, Maine, Minnesota, New Jersey, Ore-

gon, and Washington require by law that

many internal combustion engines be

equipped with a spark arresting screen. Ifyou

operate in a locale where such regulations ex-

ist, you are legally responsible for maintaining

the operating condition of these parts. Failure

to do so is a vio;ation of the law. For normal

homeowner use, the muffler and spark arrest-

ing screen will not require any service. After

50 hours of use, we recommend that your

muffler be serviced or repiaced by an autho-

rized service dealer.

dDbWAHNINL_: If received assembted,

repeat alt steps to ensure your unit is properly

assembled and all fasteners are secure.

Examine parts for damage. Do not use dam-

aged parts.

NOTE: If you need assistance or find parts

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fuel or oil residue on muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

ADJUSTING THE HANDLE

WAR NIN G: When adjusting the assist

handle, be sure it remains above the safety label

and below the mark or arrow on the shaft.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an upright

position; retighten wing nut,

ATTACHING SHIELD

,_ WARNING: The shield must be prop-

erly installed. The shield provides partial protec-

tion to the operator and others from the risk of

thrown objects, and is equipped with a line limit-

er blade which cuts excess line to the prober

length. The line limiter blade (on underside of

shield) is sharp and can cut you.

For proper orientation of shield, see KNOW

YOUR TRIMMER illustration in OPERATION

section,

1. Remove wing nut from shield,

2. Insert bracket into slot as shown,

3. Pivot shield until bolt passes through hole

in bracket.

4. Securely tighten wing nut onto bolt,

Slot Wing Nut

Shield

PIVOT

Bracket

Page 4

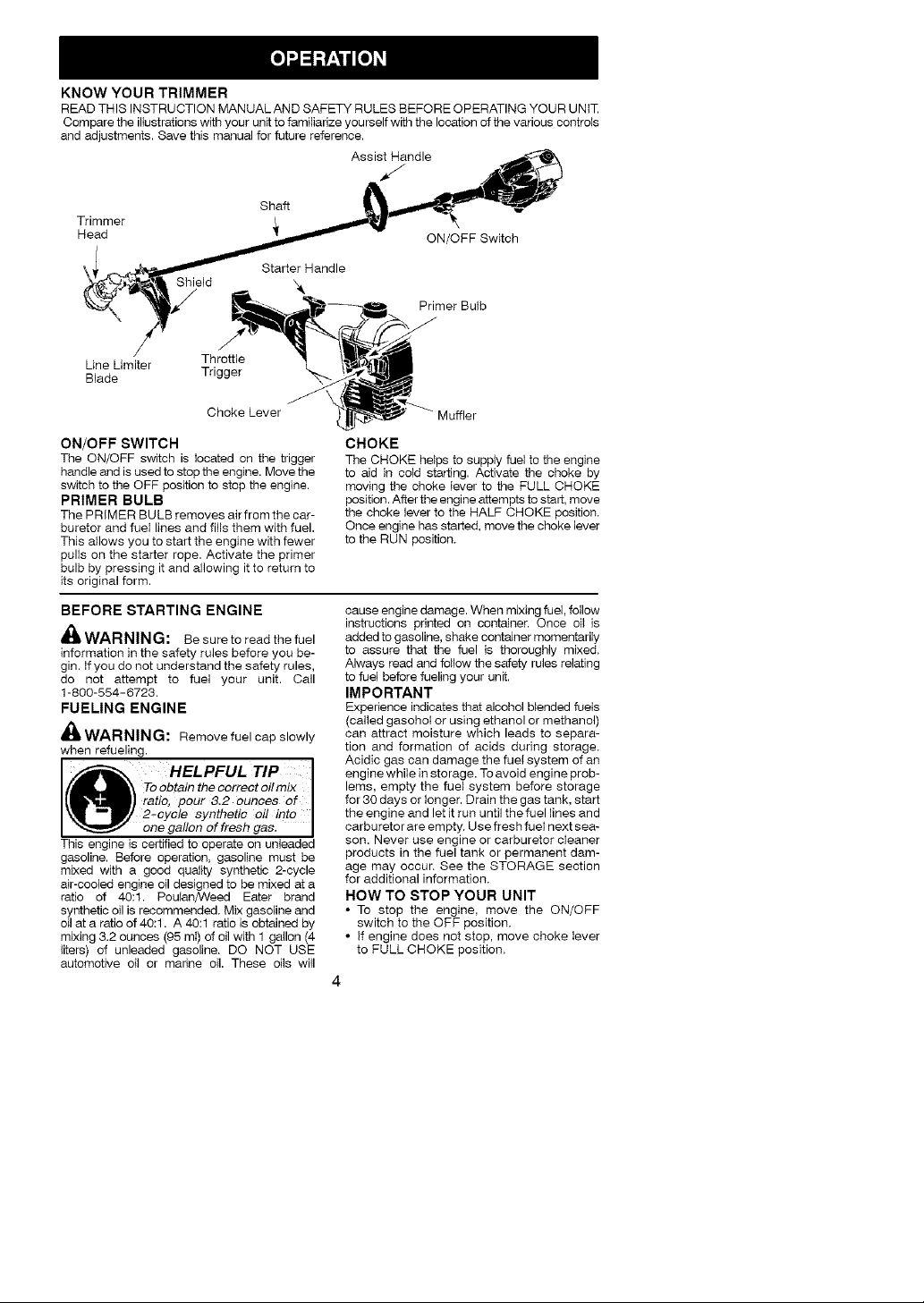

KNOWYOURTRIMMER

READTHIS INSTRUCTION MANUALAND SAFETY RULESBEFORE OPERATINGYOUR UNIT

Compare the iliustrationswith your unit to familiarize yourself with the location of the various controls

and edjustrnents. Save this manual for future reference.

Assist Handle

/

Shaft

Trimmer

Head

Starter Handle

Shield

Line Umiter Throttle

Blade Trigger

ON/OFF Switch

Primer Bulb

Choke Lever

ON/OFF SWITCH

The ON/OFF switch is located on the trigger

handle and is used to stop the engine. Move the

switch to the OFF position to stop the engine.

PRIMER BULB

The PRIMER BULB removes air from the car-

buretor and fueI lines and fills them with fuel.

This atlows you to start the engine with fewer

pulis on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original form.

BEFORE STARTING ENGINE

_ WARNING: Be sure to read the fuel

information in the safety rules before you be-

gin. If you do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723.

FUELING ENGINE

_ WARNING: Remove fuel cap slowly

when refueling.

HELPFUL TIP I

\ To obtain th e correct oilmix I

ratio, pour 8.2 ounces of I

• 2-cycle synthetic oil into I

one gallon of fresh gas. I

This engine

gasoline. Before operation, gasoline must be

mixed with a good quality synthetic 2-cycle

air-cooled engine oil designed to be mixed at a

ratio of 40:1. Poulan/Weed Eater brand

synthetic oil is recommended, Mix gasoline and

oil at a ratio of 40:1. A 40:1 ratio is obtained by

mixing 3.2 ounces (95 mI) of oil with 1 gallon (4

liters) of unleaded gasoline, DO NOT USE

automotive oil or marine oil. These oils will

is certified to operate on unleaded

Muffler

CHOKE

The CHOKE he_ps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position. After the engine attempts to start, move

the choke lever to the HALF CHOKE position,

Once engine has started, move the choke lever

to the RUN position,

cause engine damage. When mixing fuel, follow

instructions printed on container. Once oil is

added to gasoline, shake container momentarily

to assure that the fuel is thoroughly mixed,

Always read and follow the safety rules relating

to fuel before fueling your unit.

IMPORTANT

Experience indicates that alcohol blended fuels

(called gasohot or using ethanol or methanol)

can attract moisture which leads to separa-

tion and formation of acids during storage,

Acidic gas can damage the fuel system of an

engine white in storage. To avoid engine prob-

lems, empty the fuel system before storage

for 30 days or tonger. Drain the gas tank, start

the engine and let it run until the fuel lines and

carburetor are empty, Use fresh fuel next sea-

son. Never use engine or carburetor cleaner

products in the fuel tank or permanent dam-

age may occur, See the STORAGE section

for additional information,

HOW TO STOP YOUR UNIT

• To stop the engine, move the ON/OFF

switch to the OFF position,

• If engine does not stop, move choke lever

to FULL CHOKE position,

Page 5

ON/OFFSwitch

HOW TO START YOUR UNIT

_WARNING: The trimmer head will

turn while starting the engine. Avoid any con-

tact with the muffler. A hot muffler can cause

serious burns.

HELPFUL TIP I

!f your engine still does not

I stait after foflowing these I

instructions, please Carl

1-800-554-6728.

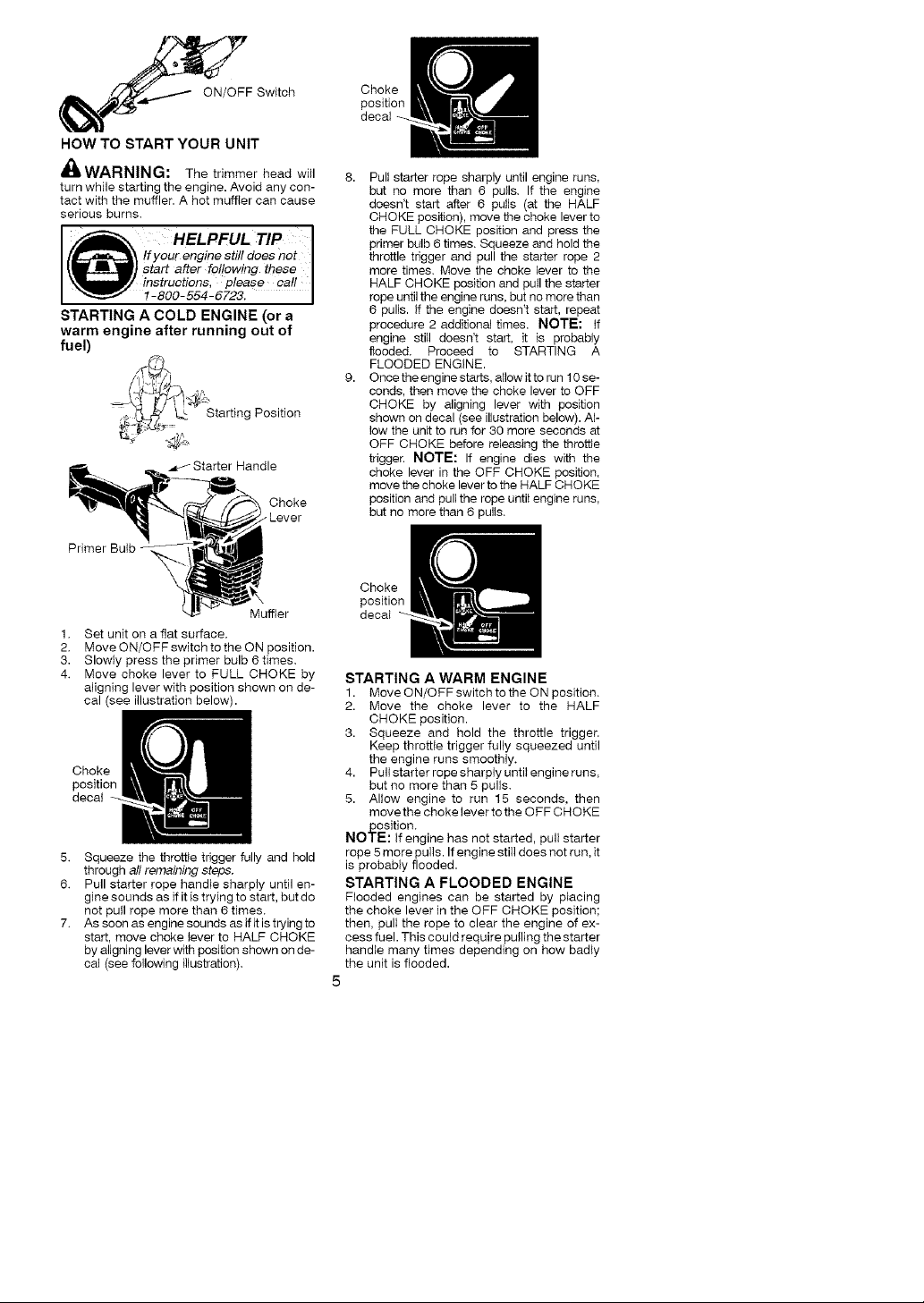

STARTING A COLD ENGINE (or a

warm engine after running out of

fuel)

,_ Starting Position

Choke

_Lever

Primer Bulb

Muffler

1,

Set unit on a flat surface.

2.

Move ON/OFF switch to the ON position.

3.

Slowly press the primer bulb 6 times.

4.

Move choke lever to FULL CHOKE by

aligning lever with position shown on de-

cal (see illustration below).

Choke

position

decat

5. Squeeze the throttle trigger fully and hold

through all remaining steps,

6. Pull starter rope handle sharply until en-

gine sounds as if it is trying to start, but do

not pull rope more than 6 times.

7. As soon as engine sounds as ifit is trying to

start, move choke lever to HALF CHOKE

by aligning lever with position shown on de-

cal (see following illustration).

Choke

position

decal

8. Pull starter rope sharply until engine runs.

but no more than 6 pulls. If the engine

doesn't start after 6 pulls (at the HALF

CHOKE position), move the choke lever to

the FULL CHOKE position and press the

primer bulb 6 times. Squeeze and hold the

throttle trigger and pull the starter rope 2

more times. Move the choke lever to the

HALF CHOKE position and pull the starter

rope until the engine runs. but no more than

6 pulis, if the engine doesn't start, repeat

procedure 2 additional times. NOTE: if

engine still doesn't start, it is probably

flooded. Proceed to STARTING A

FLOODED ENGINE.

9. Once the engine starts, allow itto run 10 se-

conds, then move the choke lever to OFF

CHOKE by aligning lever with position

shown on decal (see illustration below). AF

tow the unit to run for 30 more seconds at

OFF CHOKE before releasing the throttle

trigger. NOTE: If engine dies with the

choke lever in the OFF CHOKE position.

move the choke lever to the HALF CHOKE

position and pull the rope until engine runs.

but no more than 6 pulls.

Choke

position

decal

STARTING A WARM ENGINE

1. Move ON/OFF switch to the ON position.

2. Move the choke lever to the HALF

CHOKE position.

3. Squeeze and hold the throttle trigger.

Keep throttle trigger fully squeezed until

the engine runs smoothly.

4. Pull starter rope sharply until engine runs.

but no more than 5 pulls.

5. Allow engine to run 15 seconds, then

movethe choke lever to the OFF CHOKE

position.

NOTE: if engine has not started, pull starter

rope 5 more pulls. If engine still does not run. it

is probably flooded.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the choke lever in the OFF CHOKE position;

then, pull the rope to clear the engine of ex-

cess fuel. This could require pulling the starter

handle many times depending on how badly

the unit is flooded.

5

Page 6

If theunitstilldoesn'tstart,referto

TROUBLESHOOTINGTABLEor call

1-800-554-6723.

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operated for longer than 1 minute at full

throttle.

OPERATING POSITION

ALWAYS WEAR: _._ Eye protection

Long pant_.

Heavy shoes

Out from your left to your right.

A

44, WAR NIN G: Alwaysweareye protec-

tion. Never lean over the trimmer head.

Rocks or debris can ricochet or be thrown into

eyes and face and cause blindness or other

serious injury.

De net run the engine at a higher speed than

necessary. The cutting line will cut efficiently

when the engine is run at less than full throttle.

At lower speeds, there is less engine noise and

vibration. The cutting line will last longer and will

be tess likely to 'Weld" onto the spool.

Always release the throttie tdgger and allow the

engine to return to idle speed when not cutting.

To stop engine:

• Release the throttle trigger.

• Move the ON/OFF switch to the OFF posi-

tion.

TRIMMER LINE ADVANCE

The trimmer line will advance approximately 2

inches (5 cm) each time the bottom of the

trimmer head is tapped on the ground with the

engine running at full throttle.

The most efficient line length is the maximum

length allowed by the line limiter. Always keep

the shield in place when the tool is being oper-

ated.

To advance line:

• Operate the engine at full throttle.

• Holdthetrimmerhead paralieltoandabove

the grassy area.

• Tap the bottom of the trimmer head lightly on

the ground one time. Approximately 2 inches

(5 cm) of line will be advanced with each tap.

Always tap the trimmer head on a grassy area.

Tapping on surfaces such as concrete or as-

phalt can cause excessive wear to the trimmer

head. If the line is worn down to 2 inches (5 cm)

or less, more than one tap will be required to ob-

tain the most efficient line length.

A

WARNING: use only0,080" (2mm)

diameter line. Other sizes of line will not ad-

vance properly and can cause serious injury.

Do not use other materials such as wire,

string, rope, etc. Wire can break off during

cutting and become a dangerous missile that

can cause serious injury.

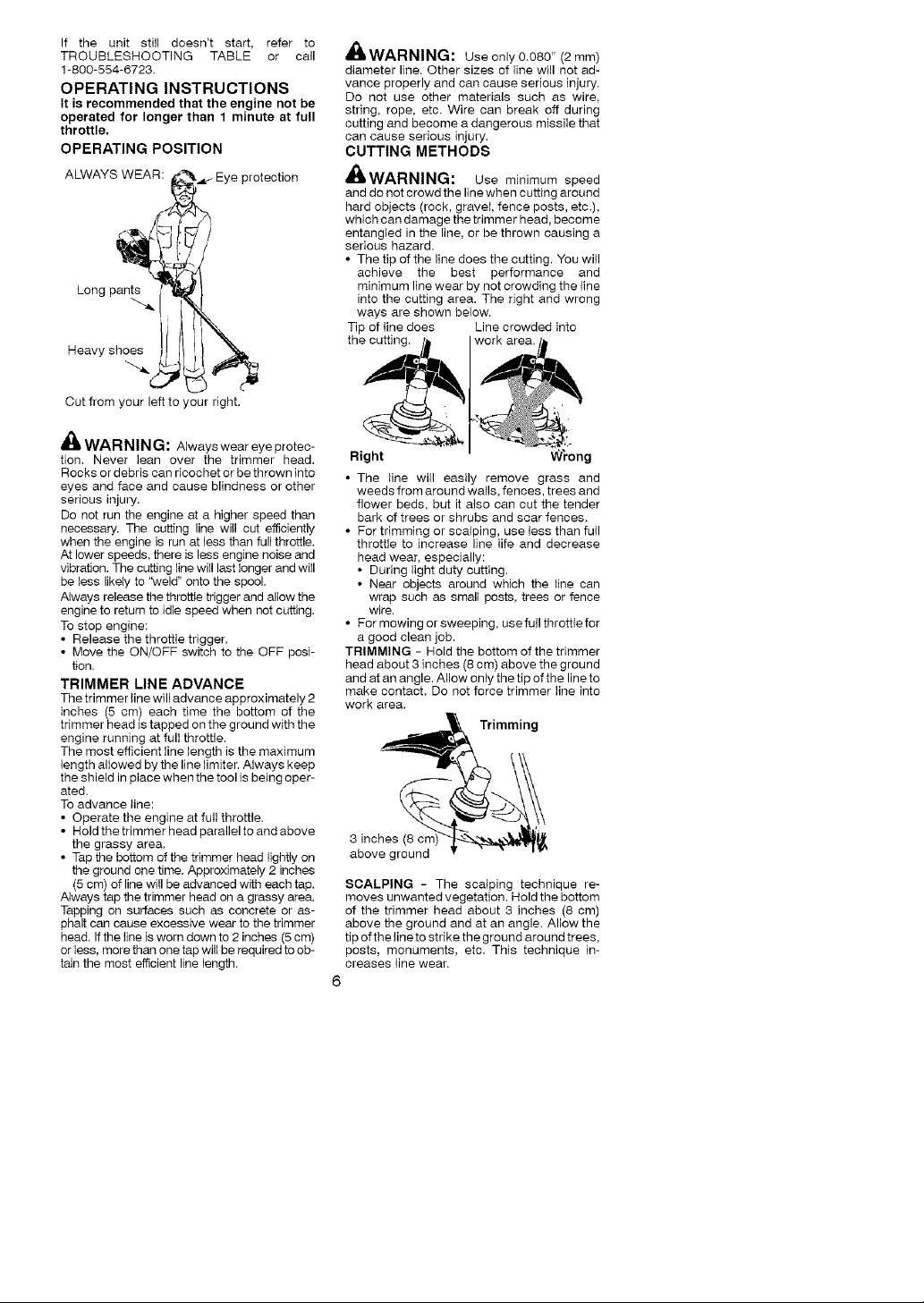

CUTTING METHODS

'_L,WARNING: Use mh_imum speed

and do not crowd the line when cutting around

hard objects (rock, graveI, fence posts, etc.),

which can damage the trimmer head, become

entangled in the Ih_e, or be thrown causing a

serious hazard.

• The tip of the line does the cutting. You will

achieve the best performance and

minimum line wear by not crowding the line

into the cutting area. The right and wrong

ways are shown below.

Tip of iine does Line crowded into

the cutth_g.

Right W_'ong

• The line will easily remove grass and

weeds from around wails, fences, trees and

flower beds, but it also can cut the tender

bark of trees or shrubs and scar fences.

• For trimming or scalping, use less than full

throttle to increase line life and decrease

head wear, especially:

• During light duty cutting.

• Near objects around which the line can

wrap such as small posts, trees or fence

wire.

• Formowingorsweeping, usefullthrottlefor

a good clean job.

TRIMMING - Hold the bottom of the trimmer

head about 3 inches (8 cm) above the ground

and at an angle. Allow only the tip of the line to

make contact. De net force trimmer line into

work area.

Trimming

3 inches (8 crr

above ground

SCALPING - The scalping technique re-

moves unwanted vegetation. Hold the bottom

of the trimmer head about 3 inches (8 cm)

above the ground and at an angle. Allow the

tip of the lineto strike the ground around trees,

posts, monuments, etc. This technique in-

creases line wear.

6

Page 7

Scalping

MOWING - Your trimmer is ideal for mowing

in places conventional lawn mowers cannot

reach. In the mowing position, keep the line

parallel to the ground. Avoid pressing the

head into the ground as this can scalp the

ground and damage the tool.

Mowing

SWEEPING - The fanning action of the rotat-

ing line can be used for a quick and easy

clean up. Keep the line parallel to and above

the surfaces being swept and move the tool

from side to side.

Sweeping

4E_W/-XHNIN_: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments.

HELPFUL TIP

_ IMPORTANT: Hav e all

fh_l_ll_X, repairs other than the rec-

I_ _ _ ommended maintenance

_1_ .,_/ described in the instruction

",_I_ _Vj" manual performed by an

If any dealer other than an authorized

Service dealer performs work On the

product, Electrolux Home Products,

Inc., may not pay for repairs under war-

ranty. It is your responsibility to maintain

and perform general maintenance.

CHECK FOR LOOSE

FASTENERS AND PARTS

• Spark Plug Boot

• Air Filter

• Housing Screws

• Assist Handle Screw

• Debris Shield

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

• ON/OFF Switch - Ensure ON/OFF switch

functions properly by moving the switch to

the OFF position. Make sure engine stops;

then restart engine and continue.

• Fuel Tank - Discontinue use of unit if fuel

tank shows signs of damage or leaks.

authorized service dealer.

• Debris Shield - Discontinue use of unit if

debris shield is damaged.

INSPECT AND CLEAN UNIT AND DE-

CALS

• After each use. inspect complete unit for

loose or damaged parts. Clean the unit and

decals using a damp cloth with a mild deter-

gent.

• Wipe off unit with a clean dry cloth.

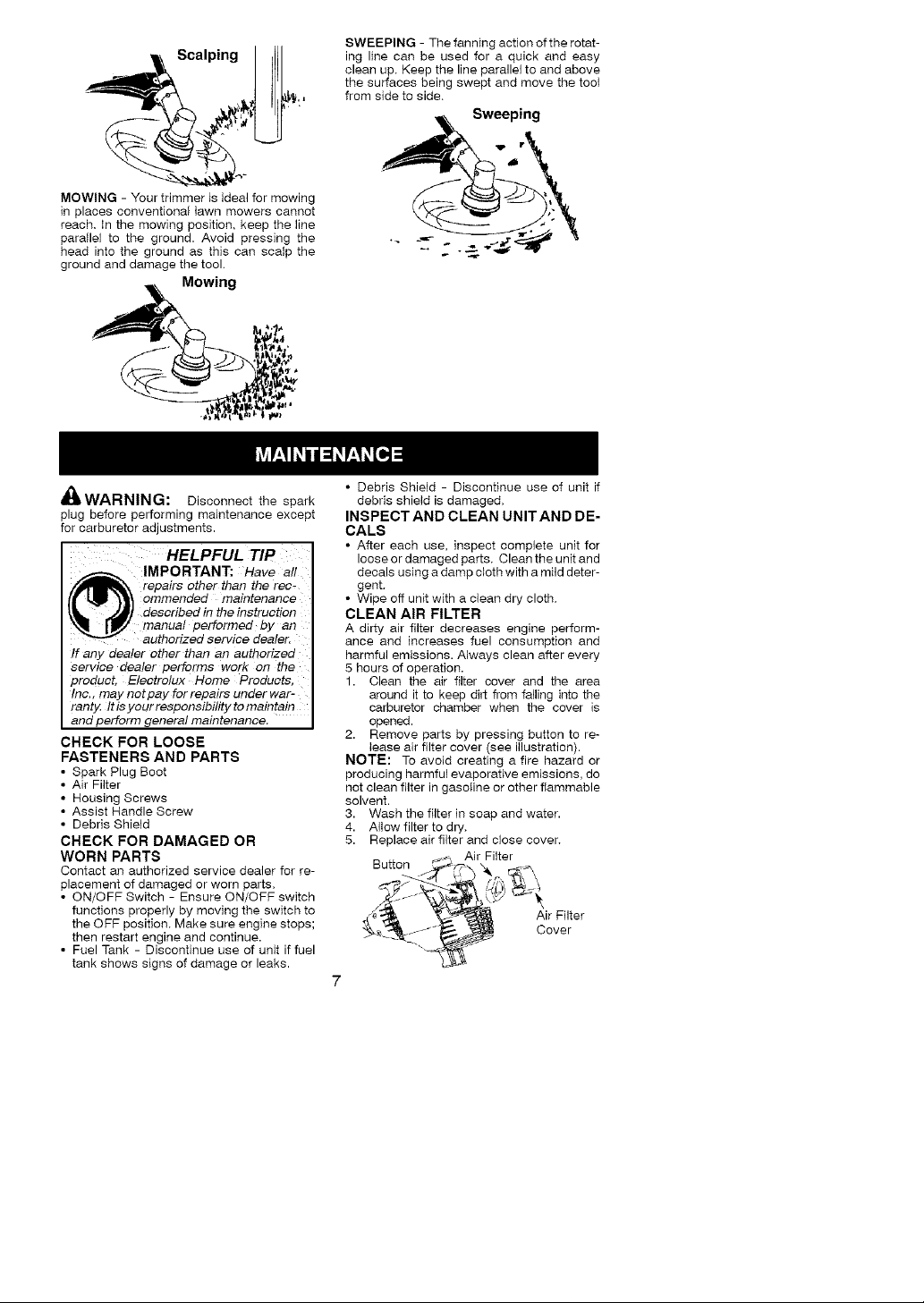

CLEAN AIR FILTER

A dirty air filter decreases engh_e perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the air filter cover and the area

around it to keep dirt from falling into the

carburetor chamber when the cover is

opened.

2. Remove parts by pressing button to re-

lease air filter cover (see illustration).

NOTE: To avoid creating a fire hazard or

producing harmful evaporative emissions, do

not clean filter in gasoline or other flammable

solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace air filter and close cover.

Button _-, _. _,

_'_ _ Cover

_>_ Air Filter

"_X-_ Air Filter

Page 8

MUFFLER AND SPARK ARREST-

ING SCREEN

WARNING: The muffler on this prod-

uct contains chemicals known to the State of

California to cause cancer.

As your unit is used, carbon deposits build up

on the muffler and spark arresting screen.

For normal homeowner use, however, the

muffler and spark arresting screen wilt not re-

quire any service. After 50 hours of use, we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Set

spark plug gap at 0.025 inch (0.6 mm). Igni-

tion timing is fixed and nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and

discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench.

4. Reinstall the spark plug boot.

REPLACING THE LINE

1. Remove spool by firmly pulling on tap

button.

2. Clean entire surface of hub and spool.

3. Replace with a pre-wound spool, or cut two

lengths of 12-1/2 feet of 0.080" (2 mm) di-

ameter Poulen PRO ¢ brand line.

_IWARNING: Never use wire. rope,

string, etc.. which can break offand become a

dangerous missile.

4. Insert ends of the lines about 1/2 inch (1

cm) into the small holes on the inside of

spool.

/7- ? ,

/f )'/l_ Holes

Line exit holes Line in Notch

\

_, Line in Notch

Hub

5. Wind the line evenly and tightly onto the

spool. Wind in the direction of the arrows

found on the spool.

6. Push the lines into the notches, leaving 3

to 5 inches (7 - 12 cm) unwound.

7. Insert the lines into the the exit holes in

the hub as shown in the illustration.

8. Align the notches with the line exit holes.

9. Push spoo_ into hub until it snaps into

place.

10. Pull the lines extending outside of the hub

to release the lines from the notches.

REPLACING THE TRIMMER HEAD

1. Align t_o_ein the dust cup with the hoie in

the side of the gearbox by rotating the

dust cup.

Insert a small screwdriver into aligned

holes. This will keep the shaft from turning

while removing and installing the trimmer

head.

Screwdriver__

3. While hoiding the screwdriver in position,

remove trimmer head by turning clock-

wise.

4. Thread replacement trimmer head onto

the shaft by turning counterclockwise.

Tighten until secure.

5. Remove the screwdriver.

CARBURETOR ADJUSTMENT

WARNING: Keepothers away when

making idle speed adjustments. The trimmer

head will be spinning during this procedure,

Wear your protective equipment and observe

all safety precautions.

The carburetor has been carefully set at the

factory, Adjustments may be necessary ifyou

notice any of the following conditions:

• Engine will not idle when the throttle is

released.

Make adjustments with the unit supported so

the cutting attachment is off the ground and

will not make contact with any object. Hold

the unit by hand while running and making ad-

justments. Keep all parts of your body away

from the cutting attachment and muffler.

Idle Speed Adjustment

Allow engine to idle, Adjust speed until engine

runs without stalling (idle speed toe slow),

• Turn idle speed screw clockwise to increase

engine speed if engine stalls or dies.

• Turn idle speed screw counterclockwise to

decrease engine speed,

Page 9

Cover

AirFilter_d

IdleSpeed

Screw

Ifyourequirefurtherassistanceorareunsure

aboutperformingthisprocedure,contactan

authorizedservicedealeror call

1-800-554-6723.

,tA

_"mWARNING: Perform the following

steps after each use:

• Allow engine to cool before storing or trans-

porting.

• Store unit and fuel h_awell ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

• Store unit with all guards in place. Position

unit so that any sharp object cannot acci-

dentally cause injury.

• Store unit and fuel well out of the reach of

children.

SEASONAL STORAGE

Prepare unit for storage at end of season or if

it will not be used for 30 days or more.

If your unit is to be stored for a period of time:

• Clean the entire unit before lengthy

storage.

• Store in a clean dry area.

• Lightly oil external metal surfaces.

FUEL SYSTEM

Under FUELING ENGINE in the OPERA-

TION section of this manual, see message la-

beled IMPORTANT regarding the use of ga-

sohol in your engine.

Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits

during storage. Add stabilizer to the gasoline

in the fuel tank or fue_ storage container. Fol-

low the mix instructions found on stabilizer

container. Run engine at least 5 minutes after

adding stabilizer.

HELPFUL TIP I

_el_ oitmixture theoilwillsepa-

_ rate from the gas.

m_) We recommend that you I

_ shake the gas can weekly

ENGINE

• Remove spark plug and pour 1 teaspoon of

40:1,2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

• Replace spark plug with new one of recom-

mended type and heat range.

• Clean air filter.

• Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts,

• At the beginning of the next season, use

only fresh fuel having the proper gasoline to

oil ratio.

OTHER

• Do not store gasoline from one season to

another.

• Replace your gasoline can if it starts to rust.

During storage of your gas/ I

to insure proper blending of I

the gas and oil. I

Page 10

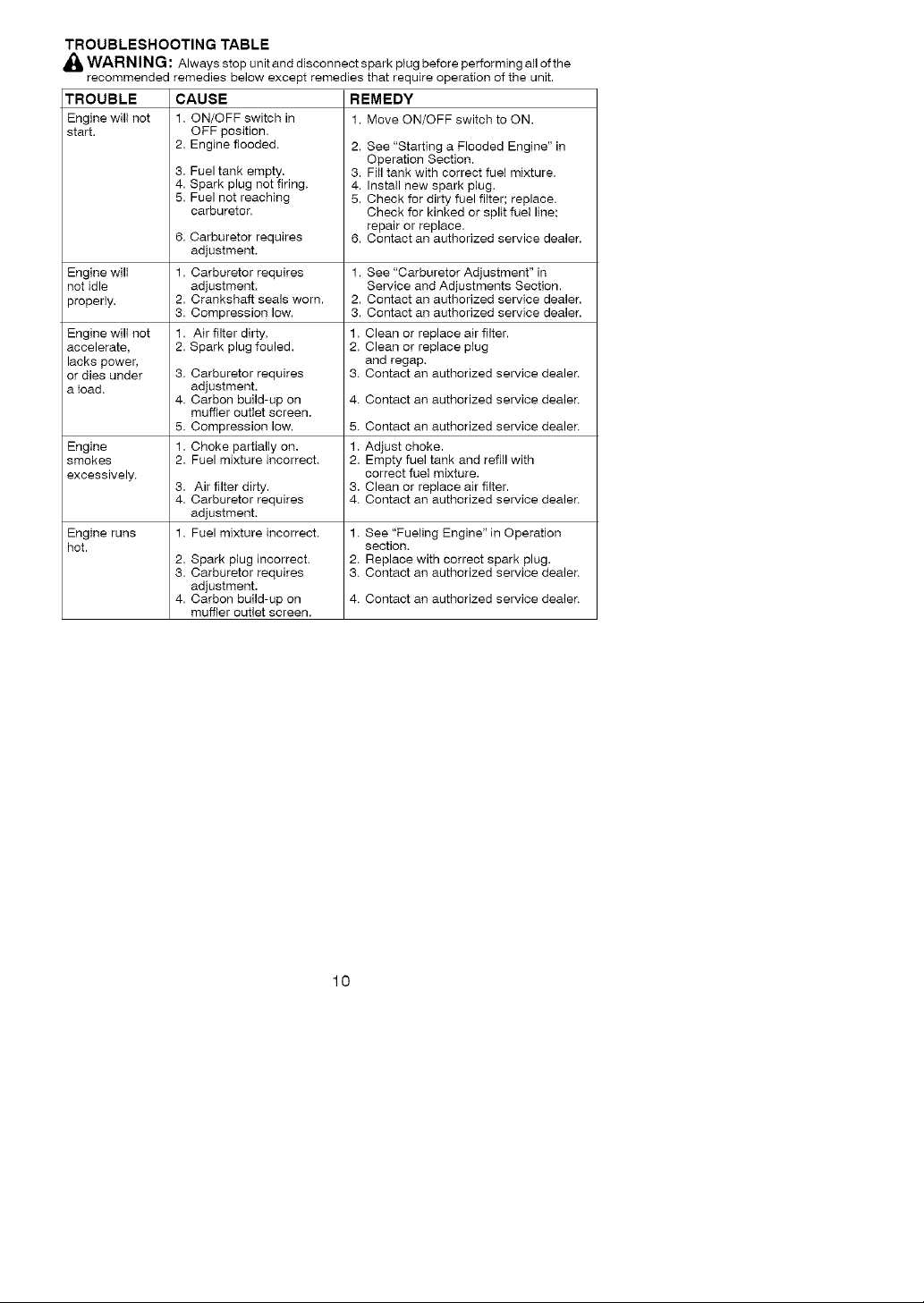

TROUBLESHOOTING TABLE

_l WARN IN : Always stop unit anddisconnect spark plugbefore performing allofthe

G

recommended remedies below except remedies that require operation of the unit.

TROUBLE

Engine will not

start.

Engine will

not idle

properly.

Engine wilt not

accelerate,

lacks power,

or dies under

a load,

Engine

smokes

excessively,

Engine runs

hot.

CAUSE

1. ON/OFF switch in

OFF position.

2. Engine flooded,

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Carburetor requires

adjustment.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffter outIet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffier outIet screen.

REMEDY

1. Move ON/OFF switch to ON.

2. See "Starting a Flooded Engine" in

Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact an authorized service dealer.

1. See "Carburetor Adjustment" in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1.

See "Fueting Engine" in Operation

section.

2.

Replace with correct spark plug.

3.

Contact an authorized service dealer.

4.

Contact an authorized service dealer.

10

Page 11

ELECTROLUX HOME PRODUCTS, INC.,

warrants to the original purchaser that each

new Poulan PRO@ brand gasoline toot or at-

tachment is free from defects in material and

workmanship and agrees to repair or replace

under this warranty any defective gasoline

product or attachment as follows from the

originat date of purchase.

2 YEARS- Parts and Labor, when used for

household purposes.

90 DAYS - Parts and Labor, when used for

commercial, professional, or income produc-

ing purposes.

30 DAYS - Parts and Labor, if used for rental

purposes.

This warranty is not transferable and does not

cover damage or liability caused by improper

handling, improper maintenance, or the use

of accessories and/or attachments not spe-

cifically recommended by ELECTROLUX

HOME PRODUCTS, INC., for this tool. Addi-

tionally, this warranty does not cover tune-

ups, spark plugs, filters, cutting line, or rotat-

ing head parts that will wear and require

replacement with reasonable use during the

warranty period, This warranty does not coy-

er predelivery setup or normal adjustments

explained in the instruction manual.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EX-

PRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITA-

TIONS ON HOW LONG AN IMPLIED WAR-

RANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CON-

SEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATIONS OR EXCLUSION MAY NOT

APPLY TO YOU.

The policy of ELECTROLUX HOME PROD-

UCTS, INC., is to continuously improve its

products. Therefore, ELEOTROLUX HOME

PRODUCTS, INC., reserves the right to

change, modify, or discontinue models, de-

signs, specifications, and accessories of all

products at any time without notice or obliga-

tion to any purchaser.

YOUR WARRANTY RIGHTS AND OBUGA-

TIONS: The U.S, Environmental Protection

Agency, California Air Resources Board, and

ELECTROLUX HOME PRODUCTS, INC., are

pleased to explain the emissions control system

warranty on your year 2002-2004 small off-

road engine, in California, all small off-road en-

gines must be designed, built, and equipped to

meet the State's stringent anti-smog standards.

ELECTROLUX HOME PRODUCTS, INC.,

must warrant the emission control system on

your small off-road engine for the periods of

time listed below provided there has been no

abuse, neglect, or improper maintenance of

your small off-road engine. Your emission con-

trol system includes parts such as the carbure-

tor and the ignition system, Where a warrant-

able condition exists, ELECTROLUX HOME

PRODUCTS, INC,, will repair your smail off-

road engine engine at no cost to you, Expenses

covered under warranty include diagnosis,

parts and labor. MANUFACTURER'S WAR-

RANTY COVERAGE: if any emissions related

part on your engine (as listed under Emissions

Control Warranty Parts List) is defective or a de-

fect in the materials or workmanship of the en-

gine causes the failure of such an emission re-

iated part, the part will be repaired or replaced

by ELECTROLUX HOME PRODUCTS, INC.

OWNER'S WARRANTY RESPONSlBIU-

TIES: As the small off-road engine engine own-

er, you are responsible for the performance of

the required maintenance listed in your instruc-

tion manual. ELECTROLUX HOME PROD-

UCTS, INC., recommends that you retain all re-

ceipts covering maintenance on your small

off-road engine, but ELECTROLUX HOME

PRODUCTS, INC., cannot deny warranty sole-

ly for the lack of receipts or for your failure to en-

sure the peffon-nance of all scheduled mainte-

nance. As the small off-road engine engine

owner, you should be aware that ELECTRO-

LUX HOME PRODUCTS, INC., may deny you

warranty coverage ifyour small off-road engine

engine or a part of it has failed due to abuse, ne-

glect, improper maintenance, unapproved mod-

ifications, or the use of parts not made or ap-

proved by the original equipment manufacturer.

You are responsible for presenting your small

off-road engine to an ELECTROLUX HOME

PRODUCTS, INC., authorized repair center as

soon as a problem exists. Warranty repairs

should be completed in a reasonable amount of

time, not to exceed 30 days. If you have any

questions regarding your warranty rights and re-

sponsibilities, you should contact your nearest

authorized service center or call ELECTRO-

LUX HOME PRODUCTS, INC., at

1-800-554-6723. WARRANTY COM-

MENCEMENT DATE: The warranty period be-

gins on the date the small off-road engine is

purchased. LENGTH OF COVERAGE: This

warranty shall be for a period of two years from

the initial date of purchase. WHAT IS COV-

ERED: REPAIR OR REPLACEMENT OF

PARTS. Repair or replacement of any war-

ranted part will be performed at no charge to the

owner at an approved ELECTROLUX HOME

PRODUCTS, iNC,, servicing center, if you

have any questions regarding your warranty

11

Page 12

rights and responsibilities, you should contact

your nearest authorized service center or call

ELECTROLUX HOME PRODUCTS, INC., at

1-800-554-6723. WARRANTY PERIOD: Any

warranted part which is not scheduled for re-

placement as required maintenance, or which is

scheduled only for regular inspection to the ef-

fect of "repair or replace as necessary" shall be

warranted for 2 years. Any warranted part which

is scheduled for replacement as required main-

tenance shall be warranted for the period of time

up to the first scheduled replacement point for

that part. DIAGNOSIS: The owner shall not be

charged for diagnostic labor which leads to the

determination that a warranted part is defective

if the diagnostic work is performed at an ap-

proved ELECTROLUX HOME PRODUCTS,

INC., servicing center. CONSEQUENTIAL

DAMAGES: ELECTROLUX HOME PROD-

UCTS, IND., may be liable for damages to other

engine components caused by the failure of a

warranted part stiff under warranty. WHAT IS

NOT COVERED: All failures caused by abuse,

neglect, or improper maintenance are not cov-

ered. ADD-ON OR MODIFIED PARTS: The

use of add-on or modified parts can be grounds

for disallowing a warranty claim. ELECTRO-

LUX HOME PRODUCTS, INC., is not liable to

cover failures of warranted parts caused by the

use of add-on or modified parts. HOW TO FILE

A CLAIM: If you have any questions regarding

your warranty rights and responsibilities, you

should contact your nearest authorized service

center or caII ELECTROLUX HOME PROD-

UCTS, INC., at 1-800-554-6723. WHERE TO

GET WARRANTY SERVICE: Warranty ser-

vices or repairs shall be provided at all ELEC-

TROLUX HOME PRODUCTS, INC., service

centers. Call: 1-800-554-6723. MAINTE-

NANCE, REPLACEMENT AND REPAIR OF

EMISSION RELATED PARTS: Any ELEC-

TROLUX HOME PRODUCTS, INC., approved

replacement part used in the performance of

any warranty maintenance or repair on emis-

sion related parts will be provided without

charge to the owner ifthe part is under warranty.

EMISSION CONTROL WARRANTY PARTS

LIST: Carburetor, Ignition System: Spark Plug

(covered up to maintenance schedule), Ignition

Module, Muffler including catalyst. MAINTE-

NANCE STATEMENT: The owner is responsi-

ble for the performance of all required mainte-

nance as defined in the instruction

manu-

al.

The information on the product label indicates to which standard your engine is certified.

Example: (Year) EPA Phase I or Phase II and/or CALIFORNIA.

41 I GI I 81 1

This engine is certified to be emissions compliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

12

Page 13

ADVERTENClA:AI usar cualquier

herramienta de fuerza de jardineria, deberAn ob-

servarse precauciones bAsicas de seguirdad en

todo momento para reducir el riesgo de incendio

y graves heridas. Lea y cumpla con todas las

instrucciones.

iEsta herramienta de fuerza puede ser peli-

grosa! Cabe al usuario le responsabilidad de

cumplir con todas las advertencias e instruc-

ciones, iLea el manual de instrucciones en su

totalidad antes de usar el aparato! Este com-

pletamente familiarizado con los controIes y

con eI uso correcto del aparato. Umite el uso

de este aparato a aquellas personas que hay-

an leido y comprendido, y que vayan a ob-

edecer, todas las advertencias e h_struc-

ciones tanto en el aparato como en el manual.

No permita nunca a los ni(_os que usen este

aparato.

MANUAL DE INFORMACION

INSTRUCCIONES DE SEGURIDAD

A

PELIGRO: Nunca use cuchillas nidis-

positivos desgranadores. El aparato fue dis-

eifiado para ser usado exclusivamente como

cortodora de linea. El uso de cualquier otro

pieza o accessorio incrementarA el petigro de

heridas.

DEL APARATO

Q

_ADVERTENClA: La linea de eorte

arroja objetos violentamente. Usted, at igual

que otras personas, puede quedar ciego o

herido. Use anteojos de seguridad y protec-

cion en las piernas. Mantenga todas las

partes del cuerpo alejadas de la linea girante.

Use anteojos de seguridad

Mantenga a los niSos, los espectadores y aei-

males a una distancia minima de 15 metros

(50 pies). Pare el motor inmediatamente si al-

guien se le acerca.

Si acontece alguna situaci6n no prevista en este

manual, tenga cuidado y use buen criterio. Si ne-

cesita ayuda, entre en contacto con su distribui-

dot autorizado del servicio o Ilame al

1-800-554-6723.

SEGURIDAD DEL USUARIO

• Vistase apropiadamente. Siempre use an-

teojos de seguridad o similar protecci6n

para los ojos cuando use o de mantenimien-

to a este aparato (anteojos de seguridad

est#tn disponiMes). La proteccion para los

ojos debe estar marcada Z87.

• Siempre utilize mascarilla para ta cara o

mascarilla a prueba de polvo si se va a tra-

bajar en condiciones donde hay polvo.

• Siempre utilize pantalones pesados y lar-

gos, mangas largas, botas y guantes. Se re-

comienda el uso de pantorrilleras de seguri-

dad.

• Siempre utilize protecci6n para los pies. No

trabaje descalzo ni en sanda)ias. Evite la

linea girante.

• Mantenga el cabello por encima de los hom-

bros, atandolo para tal efecto si es necesa-

rio. No use ropa suelta ni ropa con corbatas,

tiras, borlas, etc. que cuelgan libremente.

Pueden enredarse en las piezas en movi-

miento.

• Siesta completament tapado, estar#t mas

protegido de los escombros y pedazos de

plantas t6xicos arrojados per la lieea gi-

rante.

• Mantengase alert& No haga use del apara-

to estando cansado, enfermo, trastornado o

bajo ta influencia del alcohol, de drogas o de

remedios. Vigile bien Io que est#t haciendo;

use del sentido comt_n.

• Use protecci6n de oidos.

• Nunca ponga el aparato en marcha ni Io

deje en marcha dentro de un recinto cerra-

do. Respirar los vapores del combustible Io

puede matar.

• Mantenga las manijas libres de aceite y de

combustible.

SEGURIDAD DEL APARATO Y EN

EL MANTENIMIENTO

• Desconecte la bujia antes de hacer cualqui-

er mantenimiento menos los ajustes al car-

burador.

• Inspeccione el aparato y cambie las piezas

daSadas o flojas antes de cada uso. Repare

toda fuga de combustible antes de usar el

aparato. Mantenga el aparato en buenas

condiciones de use.

• Cambie todas las piezas del cabezal que

estee descantilladas, resquebrajadas, que-

bradas o da{_adas de cualquier otro modo,

antes de usar el aparato.

• Haga el mantenimiento del aparato de

acuerdo a los procedimientos recomend-

ados. Mantenga la linea de corte el largo

aprodiado.

• Use soIamente linea de diametro 2 mm (0,080

de pulgada) de la marca Poulae PRO ®. Nun-

ca use alambre, soga, hilo, etc.

• Instale ta protector requerida antes de usar

su aparato. Use la bobina especificada.

AsegOrese que la bobina este correcta-

mente instalada y este bien fijo.

13

Page 14

• AsegQrese que el aparato este correcta-

mente armado como se muestra en el

manual.

• Haga los ajustes al carburador con el cabe-

zal apoyado de modo que ta linea no pueda

tocar nada.

• Mantenga alejadas a las demas personas

siempre que haga ajustes al carburador.

• Use exclusivamente los accesorios y repues-

tos Poulan PRO ¢ recomendados.

• Todo servicio y mantinimiento no explicado

en este manual debera ser efectuado por un

distribuidor autorizado del servicio.

SEGURIDAD CON EL COMBUSTIBLE

• Mezcle y vierta el combustible al aire libre.

• Mantengalo alejado de las chispas y de las

llamas.

• Use recipiente aprobado para el combus-

tible.

• No fume ni permita que se fume cerca de1

combustible ni del aparato ni mientras este

este en uso.

• Evite derramar e} combustible o el aceite.

Umpie rode el combustib}e derramado.

• AIAjese a per Io menos 3 metros (10 pies)

de1lugar de abastecimiento antes de poner

en marcha el motor.

• Pare el motor y permita que se enfrie el apa-

rato antes de retirar la tapa del tanque.

• AlmacAne siempre combustible en un reci-

piente aprobado para los liquidos inflama-

bles.

SEGURIDAD AL CORTAR

_ ADVERTENOIA: InsFeccione et

Area antes de cada use. Retire los objetos (pie-

dras, vidrio roto, ciavos, alambre, etc.) que se

puedan enredar en la linea o que esta pueda ar-

rojar. Los objetos duros pueden da(_ar el cabezal

y este los puede arrojar, causando graves heri-

das.

• Use el aparato exclusivamente para recortar,

para cortar cesped y para barrer. No _o use

para cortar bordes, para podar ni para recortar

sere.

• Mantenga el equi_ibrio, con los pies en una

superficie estable. No se extienda demasia-

do.

• Mantenga todas las partes del cuerpo aleja-

das de la iinea girante y dei silenciador.

Mantenga el motor por debajo del nivel de la

cintura. El silenciador puede causar graves

quemaduras cuando esta caiiente.

• Corte siempre de izquierdaa derecha. Sise

corta con la linea del lado derecho del protec-

tor, los escombros volaran en sentido opuesto

al usuario.

• Use el aparato t_nicamente de dia o en iuz

artificial fuerte.

• Utilice el aparato solamente para ias tareas

explicadas en este manual.

TRANSPORTE Y ALMACENAMIENTO

• Espere que el motor se enfrie y fije bien el

aparato antes de quardarlo o de transpor-

tado en un vehicuio.

• Vacie el tanque de combustible antes de guar-

dar el aparato o de transportarIo. Consuma

todo el combustible restante en el carburador

poniendo el motor en marcha y dejandolo en

marcha hasta que le motor se pare solo.

• Guarde el aparato y el combustible en un lu-

gar donde los vapores del combustible no

puedan alcanzar chispas ni llamas prove-

nientes de los termotanques, los motores o

interruptores elActricos, los calefactores

centrales, etc.

• Guarde el aparato de modo que el cuchilla

limitadora de linea no pueda causar heridas

accidentales. Se puede coigar el aparato

pot ia caja el eje de propulsion.

• Guarde el aparato fuera del alcance de los

nti_os.

AVlSO SPECIAL: El estar expuesto alas

vibraciones a traves del uso prolongado de

herramientas de fuerza a gasolina puede cua-

sar daf_os a los vasos sanguineos o a los ner-

vios de los dedos, las manos y ias coyunturas

en aquellas personas que tienen propensidad

a los trastornos de la circulaciAn o alas hin-

chazones anormales. El uso prolongado en

tiempo frio ha sido asociado con da(fos a los

vasos snaguineos de personas que por otra

parte se encuentran en perfecto estado de sa-

lud. Si ocurren sintomas tales como el entu-

mecimiento, el dolor, la fatta de fuerza, los

cambios en el color o la textura de la piel o falta

de sentido en los dedos, ias manos o ias coy-

unturas, deje de usar esta maquina inmedia-

tamente y procure atenciAn medica. Los siste-

mas de anti-vibraciAn no garantizan que se

eviten tales problemes. Los usuarios que ha-

cen uso continuo y prolongando de las herra-

mientas de fuerza deben fiscalizar atenta-

mente su estado fisico y el estado del aparato.

AVlSO ESPECIAL: Su aparato viene equi-

pada con silenciador limitador de temperatura y

con rejilia antichispa que cumpla los requisitos

de los Codigos de California 4442 y 4443. Todas

las tierras forestadas federales, mas los estados

de California, Idaho, Maine, Minnesota, Nueva

Jersey, Washington y Oregon, requieren por ley

que muchos motores de combustiAn interna es-

tan equipados con rejilla antichispa. Si usted el

aparato en un estado y otra Iocalidad donde ex-

isten tales reglamentos, usted tiene la responsa-

bilidad juridica de mantener estas piezas en cor-

recto estado de funcionamiento. De io contrario,

estara en infraccion de ia ley. Para el uso normal

del due5o de la casa, el silenciador y la rejilla

antichispa no requeriran ningLin servicio.

Despues de 50 horas de uso, recomendamos

que ai silenciador se ie de servicio o sea

substituido por un distribuidor autodzado del ser-

vicio.

14

Page 15

4"LADVERTENClA: Si recibio el apa-

rato ya armado, repita todos los pasos para

asegurar que el mismo se encuentre correcta-

mente armado y que todos los fijadores se en-

cuentren bien ajustados.

Examh_e 1aspiezas para verificar que no haya

da{_os. No use piezas daSadas.

AVlSO: Si necisita ayuda, si faltan piezas o

si hay piezas da[_adas, 1lame al nOmero

1-800-554-6723.

Es normal escuchar que el filtro de combstiMe

golpetee en el tanque vacio.

Es normal encontrar residuos de aceite o de

gasolh_a en el silenciador, debido a los ajustes

al carburador y a las pruebas efectuadas pot

el fabricante.

AJUSTE DEL MANGO

_ADVERTENOIA: AI ajustar laman-

go auxiliar, asegOrese que este se mantenga

sobre la etiqueta de seguridad y debajo la

marca o la flecha en el eje.

1. Afloje la tuerca mafiposa en el mango.

2. Gire el mango en posici6n vertical. Vuelva

a apretar la tuerca mariposa firmemente.

INSTALACION DE LA PROTECTOR

,_ ADVERTENCIA: El protector deb-

er#. ser instalado correctamente. El protector

provee protecci6n parcial hacia el usuafio y

otras personas contra el riesgo de los objetos

arrojados, y viene equipado con un cuchiHa

limitadora de linea que corta el exceso de

line& El cuchilla limitadora de tinea (en la

parte h_ferior del protector) es filoso y puede

cortar. Para conseguir la orientaci6n apropiada

para el protector, vea la ilustraci6n CONOZCA

SU APARATO que se encuentra en la secci6n

de USO.

1. Remueva latuerca mariposade la protec-

tor.

2. Introduzca el soporte dentro de la ranura

como se muestra.

3. Haga girar la protector basra que eltorniF

Io pase a traves del hueco en el soporte.

4. Apriete firmemente la tuerca mariposa en

el tornillo.

Ranura de alas

Protector

tuerca en forma

PIVOTE Caja de

engranajes

CONOZCASUAPARATO

LEA ESTE MANUAL DE INSTRUCCIONES Y LAS REGLAS DE SEGURIDAD ANTES DE

PONER EL APARATO EN MARCHA. Compare las ilustraciones con su aparato para familiari-

zarse con la ubicacion de los diversos controles y ajustes. G uarde este manuat para uso futuro.

Mango Auxiliar

J

Eje

Cabezal de Corte '_

Protector x_

Cuchilla Gatillo Acelerador

Umitadora

de Linea

Palanca del

Cebador

Mango de la Cuerda ON/OFF

de Arranque

15

Interruptor

Bombeador

Silenciador

Page 16

INTERRUPTOR ON/OFF

Se usa el interruptor ON/OFF para detener el

motor. Coloque el interruptor ON/OFF en laposi-

ci6n OFF para detener el motor.

BOMBEADOR

El BOMBEADOR retira el mire de el carbura-

dory de las lineas de combustible y las Ilena

de mezcla de combustible, permiti_,ndole pon-

er el motor en marcha con menos tirones de la

cuerda de arranque. Accione el bombeador

oprimiendolo y luego dejando que este re-

cobre su forma original

ANTES DE PONER EN MARCHA EL

MOTOR

,_ ADVERTENCIA: Lea atentamente

la informaci6n sobre el combustible en laas

reglas de seguridad antes de comenzar. Si no

comprende las reglas de seguridad, no intente

abastecer el aparato de combustible. Llame al

nQmero 1-800-554-6723.

ABASTECIMIENTO DEL MOTOR

_ ADVERTENCIA: Remueva la tapa

del tanque de combustible lentamente al rea-

bastecer combustible.

INFORMAOION UTIL ]

Para obtonor la proporcidn I

correcta de mezcla de I

aceite vierta 8,2 onzae de I

aceite sintetico de 2 ciclo s I

Este motor est& habilitado para funcionar con

gasolina sin plomo. Antes de comenzar con el

uso, se deber& mezclar la gasolina con un

aceite de sintetico de buena calidad para mo-

tores de 2 tiempos enfriados a aire. Recomen-

damos el aceite de sintetico de la marca Pou-

lan/Weed Eater. Mezcle la gasolina con eI

aceite en la proporci6n 40:1. Se obtiene una

proporci6n de 40:1 mezctando 3,2 onzas (95

ml) de aceite con cada gal6n (4 litros) de gaso-

lina sin plomo. NO USE aceite para au-

tom6viles ni para barcas. Estos aceites

daffar&n el motor. AI mezclar el combustible,

siga las instrucciones impresas en el reci-

piente. Una vez haya afiadido el aceite a la ga-

soiina, agite al recipiente brevemente para

asegurar que el combustible este completa-

mente mezclado. Siempre lea y siga las

instrucciones de seguridad que tienen que ver

con el combustible antes de abastecer el apa-

rato.

IMPORTANTE

La experiencia indica que los combustible

mezclados con alcohol (los Ilamados gasohol

o los que contienen etanol o metanol) pueden

atraer la humedad, Io que puede causar la se-

paracion y la formacion de &.cidos durante el

almacenaje. La gasolina acida puede dai_ar el

sistema de combustible deI motor durante el

almacenaje. Para evitar problemas con el mo-

dentro de gaeotina fresca. J

CEBADOR

El CEBADOR ayuda a suministrar combus-

tible al motor para facilitar el arranque cuando

el motor est&. frio. Acione el cebador coiocan-

do la palanca en la posici6n FULL CHOKE.

Despues que el motor intente arrancar, mue-

va la palanca del cebador a la posicion HALF

CHOKE. Despues que el motor se haya

puesto en marcha, ponga la palanca de1 ceba-

dor en la posicion RUN.

tor, deber_, vaciarse el sistema de combus-

tible antes de almacenar el aparato por 30

dims o mb.s. Vacie el tanque de combustible,

ponga el motor en marcha y d6jelo en marcha

hasta que las lineas de combustible y el car-

burador queden vacios. Use combustible

fresco para la pr6xima temporada. Nunca use

productos de limpieza de motor o carburador

en el tanque de combustible ya que de hacerla

puede provocar daf_os permanentes. Vea la

secci6n de ALMACENAJE para informaci6n

adicional.

PARA DETENER EL MOTOR

• Para detener el motor, mueva el interruptor

ON/OFF a la posici6n OFR

• Si el motor no se detiene, mueva la palanca

det cebador a la posici6n FULL CHOKE.

Interruptor

ON/OFF

PARA PONER EN MARCHA

EL MOTOR

_bADVERTENCIA: El cabezal de

corte girar&, mientras se este intentando poner

en marcha et motor. Evite el hacer ningL_n tipo

de contacto con el silenciador. Un silenciador

caliente podria provocar quemaduras de gra-

vedad sise toca.

_ INFORMACION UTIL I

Si el motor de su aparato I

no se pusiera en marcha I

despu#s de haber seguido

estas instrucciones, flam e

PARA ARRANCAR CON MOTOR

FRIO (o motor caliente despues de

quedar sin combustible)

al 1-800-554-5723.

16

Page 17

Mango de la Cuerda

de Arranque

Palanca

del

Cebador

Bombeador

1. Ponga el aparato en una superficie plana.

2. Mueva el interruptor ON/OFF a la posi-

ci6n ON.

3. Optima tentamente el bombeador 6

veoes.

4. Mueva la palanca dei cebador a FULL

CHOKE alineando la palaeca en la posici6n

mostrada en la etiqueta (yea la iiustraci6n

abajo).

Etiqueta

muestra

la

posici6n

de1

cebador

5. Apdete y sujete el gatillo durante todos Ice

paeoe siguientee.

6. Tire firmemente det mango de ta cuerda

de arranque hasta que el motor suene

como s ieste intentando arrancar, pero no

tire de la cuerda m_.s de 6 veces.

7. Tan pronto como el motor suene como si

fuera a arrancar, mueva la palanca del ce-

bador a HALF CHOKE alineando la palan-

ca en la posici6n mostrada en la etiqueta

Etiqueta

muestra

la

posici6n

de1

cebador

Tire firmemente dei mango de ia cuerda

de arranque hasta que el motor arranque,

pero no mas de 6 tirones. Si el motor no

arranca despues del sexto tir6n de la

cuerda de arranque (con ia palanca de1

cebador en la posici6n HALF CHOKE),

mueva la paianca del cebador a la posi-

ci6n FULL CHOKE y oprima el bombea-

dot 6 veces. Apriete y sostenga et gatillo

acelerador y tire de la cuerda de arranque

otras 2 veces. Mueva la palanca dei ceba-

Silenciador

dora la posicion HALF CHOKE y tire de la

cuerda de arranque hasta que el motor se

ponga en marcha, pero no mas de 6

veces. Si el motor no arranca, repita el

procedimiento de arranque otras 2 veces

adicionales. AVISO: Si el motor no ar-

ranca, probablemente se encuentre aho-

gado. Proceda con la secci6n ARRAN-

QUE DE MOTOR AHOGADO.

g,

Una vez que el motor arranca, permita

que el motor marche por 10 segundos,

luego mueva la palanca del cebador a

OFF CHOKE alineaedo la palanca en la

posici6n mostrada en la etiqueta (vea la

ilustraci6n abajo). Permita que el motor

marcha por 30 segundos con la palanca

del cebador en la posicion OFF CHOKE

antes de soltar el gatillo acelerador.

AVISO: Si el motor se apaga con la pa-

lanca del cebador en la posici6n OFF

CHOKE, mueva la palanca a la posici6n

HALF CHOKE y tire de la cuerda de ar-

ranque hasta que el motor se ponga en

marcha, pero no mas de 6 tirones.

Etiqueta

muestra

la

posici6n

del

cebador

PARA ARRANCAR CON EL MOTOR

CALIENTE

1. Mueva el interruptor ON/OFF a ta posi-

ci6n ON.

2. Mueva la palanca del cebador a la posi-

ci6n HALF CHOKE.

3. Oprima y sostenga el gatillo acelerador.

Mantenga el gatillo totaimente oprimido

hasta que el motor marche sin problemas.

4. Tire firmemente del mango de la cuerda

de arranque hasta que el motor se ponga

en marcha, pero no mb.s de 5 tirones.

5. Permita que el motor marche por 15 segun-

dos, entonces mueva la palaeca del ceba-

dora la posicion OFF CHOKE.

AVISO: Si el motor no arranca, tire de la cuer-

da otras 5 veces. Si el motor no arranca, pro-

babiemente este ahogado.

ARRANQUE DE MOTOR AHOGADO

Lors motores ahogados pueden ponerse en

marcha moviendo la palanca del cebador a la

posici6n OFF CHOKE; luego, tirede lacuerda

para aclarar el exceso de combustible. Esto

podr_t requerir que se tire del mango de la

cuerda muchas veces dependiendo cuan

ahogado se encuentre el motor.

Si el aparato sigue sin ponerse en marcha,

vea la TABLA DIAGNOSTICA o Ilame al

nt_mero 1-800-554-6723.

17

Page 18

INSTRUCCIONESDE USO

Se recomienda que no opere el motor pot

mas de un minuto a la velocidad maxima.

POSIClON DE USO

USE SIEMPRE: PretecciAn

Pantalones

Largos _ (

Zapatos

Gruesos

Corte izquierda a derecha.

_ADVERTENCIA: Usesiemprepro-

tecciAn para los ojos. Nunca se inclh_e por en-

cima del cabezal. La linea puede arrojar o

hacer rebotar piedras o desechos hacia los

ojos y la cara, pudieedo causar la perdida de

la vista u otras graves heridas.

No haga marchar el motor a revoluciones mas

altas que las necesarias. La linea de corte cor-

tara de una forma mAs eficiente sin que el motor

este acelerado a fondo. A revoluciones mas ba-

jas, habrA menos ruido y menor vibraciAn del

motor. La linea de corte durara mAs tiempo y

tendrA menor probabilidad de"fundirse" en la bo-

bina.

Siempre que no se halle cortando, suelte el

gatillo acelerador y permita que el motor vuel-

va a marcha tent&

Para detener el motor:

• Sueite el gatiHo acelerador.

• Mueva el interrupter ON/OFF a la posiciAn

ON.

AVANCE DE LA LINEA DE CORTE

La linea de corte avanza aproximadameete 5

cm (2 pulgadas) cada vez que se toca eI cabe-

zal contra el suelo con el motor acelerado a

fondo.

EI largo mas eficiente de la linea es el largo

mbximo permitido per el limitador de

linea.Siempre mantenga ia cubierta protectora

en su lugar siempre que el aparato este en uso.

Para avanzar la lieea:

• Acelere el motor a fondo.

• Sostenga el cabezal paralelo al suelo, por en-

cima de un Area con cesped.

• Toque el cabezal de corte contra el suelo le-

vemente una vez. Con cada toque, la linea

avanzarA aproximadamente 5 cm (2 pulga-

das).

Toque el cabezal contra el sueto siempre en

un Area con cesped. Si se hace tocar contra

superficies como el cemento o el asfalto, el

cabezal podria sufrir desgaste excesivo.

Si la linea se ha gastado y cuenta con 5 cm (2

pulgadas) o menos, hara falta mAs de un toque

para obtener el largo de lieea mas eficiente.

de ojos

'_ADVERTENCIA: Use Qnicamente

iinea con diAmetro de 2 mm (0,080 de pulgada).

Las lineas de otros diArnetros no avanzarAn de-

bidamente y pueden causar graves heridas. No

use otros materiales, tales, como el alambre, el

hilo, la cuerda, etc. El alambre se puede quebrar

al cortar, convirtiendose en un misil muy peligro-

so y causando heridas de gravedad.

METODOS DE CORTE

'_ADVERTENCIA: Use lavelocidad

minima y no acerque el aparato demasiado al

cortar cerca de objetos solidos (piedra, graviF

la, postes, etc.): estos pueden daAar el cabe-

zal, pueden enredarse en la linea o la lieea los

puede arrojar violentamente al aire, causando

serio peligro.

• La punta de la linea es la que corta. Se con-

seguirA mejor rendimiento y el minimo des-

gaste si no se mete la tieea dentro del mate-

riai que se estA cortando. La ilustraciAn a

continuacion muestra la forma correcta e in-

oorreota de oortar.

La punta de la linea La linea esta metida

es la que corta, dentro del material

Correcta Incorre'cta

• La linea retira f&cilmente el cAsped y las malas

hierbas de alrededor de paredes, cercados,

Arboles y macizos de flores; pero tambien es

capaz de cortar la corteza tierna de arboles y

arbustos y de marcar las cercas.

• Para recortar o escalpar, use el aparato sin

acelerar a fondo, para incrementar la vida

Otilde la linea y disminuir el desgaste dei ca-

bezal, especialmente:

• AI hacer trabajos livianos.

• Cerca de objetos con los cuales la linea se

puede enredar, como son los postes o

Arboles de poco diametro y el alambre de

las oercas.

• Paracortarcespedybarrer, acelereel motora

fondo para Iograr un buen trabajo de Iimpieza.

PARA REOORTAR - Sostenga el cabezal

unos 8 cm (3 pulgadas) del suelo yen Angulo.

Unicamente la punta de ta linea deberA hacerel

contacto con el materiaI a cortar. No meta la

linea deetro del Area que se estA cortaedo.

Para Recortar

8 cm (3 pulga-

das) del suelo

18

Page 19

PAPA ESCALPAR - La t6cnica de1 ascalpa-

do retira la vegetaci6n no deseada abajo a la

tierra. Sostenga el cabezal unos 8 cm (3 pul-

gadas) del suelo yen angulo. Deje que la

punta de la linea go_pee contra el suelo cerca

de los arboles, los postes, los monumentos,

etc. Esta tecnica incrementa el desgaste de la

linea.

Para Escalpar

PAPA CORTAR CESPED - Este parato es

idea1 para cortar cesped en lugares donde las

cortadoras convencionales no Ilegan. En po-

sici6n de cortar cesped, mantenga la lieea pa-

ralela al suelo. Evite presioear el cabezal con-

tra el suelo, ya que de hacerlo podria escalpar

la vegetacion y da_ar el aparato.

Para Cortar Cesped

PAPA BARRER - Se puede usar la acci6n

ventiladora de la linea girante para barrer rApida

y f_tcilmente un Area determinada. Mantenga la

linea paralela al suelo directamente encima de

las superficies que se quiera barrer y meuva el

aparato de un lado al otro rapidamente.

Para Barter

_ADVERTENCIA: Desconecte la

buj[a antes de hacer cualquier mantenimiento,

con la excepcion de los ajustes al carburador.

INFORMACION UTIL

IMPORTANTE: Permita

que toda reparaal6n que no

i sea el mantenimiento te-

l comendado en el manual

de instrucalones sea efec-

tuada pot un distribuidor

Si un distdbuidor NO autorizado efec-

tuara cualqaler trabajo en el producto,

Electrolux Home Products, inc., no pa-

gara reparaciones bajo ta garantia. Es su

reeponeabilidad el mantener y efectuar el

mantenimiento general del producto.

VERIFIQUE QUE NO HAYA FIJA-

DOPES NI PIEZAS SUELTAS

• Cubierta de _aBujia

• Filtro de Aire

• Tornillos de la Caja

• Tornillo del Mango Auxiliar

• Protector

VERIFIQUE QUE NO HAYA PIEZAS

DANADAS O GASTADAS

Entre en contacto con el distribuidor autoriza-

do del servicio para el reemplazo de piezas

dal_adas o desgastadas.

autorizado dal servicio.

• Interruptor ON/OFF - AsegOrese de que el

interruptor ON/OFF este funcionando cor-

rectamente coloc_tndoio en la posici6n O FR

AsegOrese de que ei motor se haya deteni-

do por completo, luego, ponga el motor en

marcha nuevamente y continQe.

• Tanque de Combustible - Deje de usar el

aparato si hay se[_ales de daSos o perididas

en el tanque de combustible.

• Protector - Deje de usar el aparato si el pro-

tector esta daSado.

INSPECCIONE Y LIMPIE EL APARA-

TO Y SUS PLACAS

• Despues de que cada uso, inspeccione la

aparato completa para saber si hay piezas

flojas o dal_adas. Limpie eI aparato y las

placas usando un trapo hLimedo con un de-

tergente suave.

• Seque el aparato usando un trapo seco y

limpio.

LIMPIE EL FILTRO DEL AIRE

Los fi_tros de aire sucios disminuyen la vida

t_tily el rendimiento del motor e iecrementan el

cons umo de combustible y de emiciones noci-

vas. Umpie siempre el filtro de aire despues

de cada 5 horas de uso.

1. Limpie la tapa del filtro de aire y el area aF

rededor de la tapa para evitar que caiga

suciedad o desechos en el carburador

cuando se abre la tapa.

2. Remueva las piezas presionando el bot6n

para aflojar la tapa del filtor de aire (vea la

ilustracion).

19

Page 20

AVISO: Para evitar peligro de incendio y de

emiciones evaporativas nocivas, no limpie el

filtro de aire con gasoliea ni cualquier otro sol-

vente inflamable.

3. Umpie el filtro con agua y jab6n.

4. Permita que elfiltro se seque.

5. lestaie el filtro de aire y cierra la tapa.

Boton

SILENCIADOR Y LA REJILLA ANTI-

CHISPAS

Filtro de aire

Tapa det

Fiitro de Aire

_.ADVERTENCIA: Elsilenciader en

este producto contiene 1assubstancias quimi-

casque el estado de California reconoce

oomo oausantes de cancer.

A medida que se use el aparato, el silenciador

y la rejilla aetichispas se van carbonizando.

Para el uso normal dei dueSo de la casa, sin

embargo, el silenciador y la rejilla antichispa no

requeriran ningOn servicio. Despues de 50

horas de use, recomendamos que al siienciador

se le de servicio o sea substituido pot un distri-

buidor autorizado de1servicio.

CAMBIE LA BUJIA

Debera cambiarse la bujia anualmente para

asegurar que el motor arranque facilmente y

tenga un mejor rendimeinto. Ajuste la separa-

cion de los electrodos a0,6 mm (0,025 de pul-

gada). El encendido es fijo e inalterable.

1. Gire y saque la cubierta de la bujia.

2. Retire ta bujia det cilindro y desechela.

3. C_tmbiela per una bujia Champion RCJ-6Y

y ajuste firmemente la bujia nueva con una

Ilave de cubo de 19 mm (3/4 de pulgada).

4. Instale nuevamente la cubierta de la

bujia.

REEMPLAZO DE LA LINEA DE

CORTE

1. Retire la bobina tirando de_bot6n detoque

firmemente.

2. Umpie por entero la superficie del cubo y

de la bobina.

3. Reemplace la bobina por una previa-

mente enrollada, o corte dos pedazos de

aproximadamente 3,8 metros (t2-1/2

pies) de largo de linea de 2 mm (0.080 de

pulgada) de la marca Poulan PRO ®.

_ ADVERTENCIA: Nunca use

alambre, cuerda, hilo, etc., los cuales pueden

romperse y convertirse en proyectiles peligro-

SOS.

4. letroduzca tas puntas de la linea, alrede-

dorde 1 cm (1/2 puigada), dentro deI hue-

cos pequeSo que se encuentra en la parte

interior de la bobina.

Bobina _ /_/,_ _ _ Huecos

_S/,_/ ' Peque(Sos

Huecos de salida de la linea

Linea dentro de la muesca

J' Linea dentro de ia muesca

Cube

5. Enrolle la Iinea en la bobina de forma pa-

reja y ajustada. Enrolle la linea en la direc-

ci6n en que apuntan tas flechas que se

encuentran en la bobina.

6. Introduzca la linea dentro de las mues-

cas, dejando de 7 a 12 cm (3 a 5 puiga-

das) sin enrollar.

7. Introduzca la lineas dentro de los huecos

de salida en el cubo como se muestra en

la ilustraci6n.

8. Alinee las muescas con el los huecos de

salida de la linea.

9. Presione la bobina dentro del cubo hasta

que esta encaje en su lugar.

10. Tire de la lineas que se extiende fuera del

cubo para soitarla de ia muescas.

REEMPLAZO DE LA CABEZAL DE

CORTE

1. Haga girar el taza para el poivo para ha-

cer coincidir el orificio con el otro orificio

situado a un lado del cajetin de

engranajes.

2. Introduzca un destornillador pequeSo por

los orificios confrontados. Esto previene

que el eje gire mientras usted remueva y

instale el cabezal de corte.

Dest_

3. Sujete el destomiltador en su posici6n y

remueva el cabezal de corte dando vuelta a

la derecha.

4. Enrosque et cabezat de rempiazo en el eje

dando vuelta a la izquierda. Apriete

firmemente.

5. Remueva el destornillador.

20

Page 21

AJUSTE AL CARBURADOR

'i_ ADVERTENCIA: Mantenga a etras

personas atejadas de la zona en donde se en-

cuentre haciendo ajustes de marcha tenta. EI

cabezal de corte se mantendrA girando du-

rante este procedimiento. Use su equipo pro-

tector y observe todas las precauciones de

seguridad.

El carburador ha sido ajustado cuidadosa-

mente en la fabrica. Posiblemente sea nece-

sario hacer ajustes si se nota cuaiquiera de

las siguientes condiciones:

• El motor no funcionaenmarchalentacuan-

do se suelta el acelerador.

Haga los ajustes sosteniendo el equipo de

rnanera que el accesorio de oorte se en-

cuentre alejado del sueto y no haga contacto

con ning0n objeto. Sostenga el aparato man-

ualmente rnientras el motor se encuentre en-

cendido y mientras usted se encuentre ha-

ciendo los ajustes. Mantenga todas las partes

de su cuerpo alejadas de los accesorios de

corte y del silenciador.

Marcha Lenta

Deje el motor en marcha lenta. Ajuste las re-

voluciones hasta que el motor se mantenga

en marcha sin calarse (la marcha lenta es de-

masiado lenta).

• Gire e_tornil]o de marcha _enta hacia la dere-

cha para aumentar tas revoluciones si el mo-

tor se ahoga o se para.

• Gire el torni]lo de marcha lenta hacia la iz-

quierda para reducir las revoluciones.

Tapa de1

Filtro de

Aire

Tornillo de

Ajuste de

la Marcha

Lenta

Si requiriera ayuda adicional o no se sintiera

seguro al desempe[far este procedimiento,

entre en contacto con el distribuidor autoriza-

do dei servicio o Ilame al 1-800-554-6723.

_ ADVERTENCIA: Realice los

siguientes pasos despues de cada uso:

• Permita que eI motor se enfrie antes de

guardarlo o transportarlo.

• Guarde et aparato yet combustible en un lu-

gar bien ventilado donde los vapores deI

combustible no puedan entrar en contacto

con chispas ni llamas abiertas provenientes

de clentadores de agua. motores o interrpu-

tores electricos, calefactores centrales, etc.

• Guardeelaparatocontodos tosprotectores

en su lugary coloquelo de modo que las pie-

zas cortantes no puedan causar heridas por

accidente.

• Guarde el aparato y el combustible en un lu-

gar completamente fuera del alcance de los

nitros.

ESTACIONAL ALMACENAJE

Prepare el aparato para almacenado al final

de latemporada o si no Iova a usar por mAs de

30 dims.

Siva a aimacenar el aparato durante un perio-

do largo de tiempo:

• Limpie el aparato por completo antes del al-

macenaje.

• Almacene en un Area limpia y seca.

• Aplique una peque[_a cantidad de aceite a

las superficies extemas metAlicas.

SISTEMA DE COMBUSTIBLE

Vea el mensaje marcado como IMPOR-

TANTE, que se refiere al uso de combustibles

con mezcla de alcohol en su aparato, en la

seccion de USO, bajo ABASTECIMIENTO

DEL MOTOR. Los estabiHzadores de com-

bustible son una aiternativa aceptable para

minimizar la formaci6n de depositos de goma

durante el almacenaje.

ASada estabilizador a la gasolina en eltanque

de combustible o en el recipiente para atma-

cenar el mismo. Siga las instrucciones de

mezcla que se encuentran impresas en el ee-

vase. Ponga el motor en marcha y dejelo en

marcha por unos 5 minutos despues de hab-

erie puesto estabilizador.

I INFORMACION UTIL

MOTOR

• Retire la bujia y vierta una cucharadita de