Poulan PPG6000, 2006-08 Owner's Manual

Portable Electric Generator

Service Manual

Model: PPG6000

Contents

Chapter 1 General Information…………………………………………….. 3-7

General Description of Generator…………………………………. 3

Safety Information…………………………………………………… 4

Model Parameters…………………………...………………………. 5

Maintenance and Adjusting Data……………..……………………. 5-7

Chapter 2 Maintenance of the Generator Set………………………………8

2.1 Maintenance of Starting System……………………………….. 8-10

2.2 Maintenance of Lubrication System…………………………… 10-11

2.3 Maintenance of Inlet System…………………………………… 12-13

2.4 Maintenance of Fuel System………………..………………… 13-14

2.5 Maintenance of Exhaust System……………………………… 14-15

2.6 Maintenance of Ignition System……………………………….. 16-17

2.7 Maintenance of Generator………………………………………18-20

2.8 Maintenance of Cylinder Head and Valve……………………. 20-24

2.9 Maintenance of Crankcase, Crankshaft and Camshaft……... 25-28

2.10 Maintenance of Connecting Rod, Piston and Cylinder…….. 29-31

2.11 Electrical System ………...................................................... 32

2.12 Wiring Diagram…………………………………………………. 33

Chapter 3 Trouble Shooting…................................................................. 34

3.1 General…………………………………………………………… 34

3.2 Hard Starting…………………………………………………….. 35

3.3 Ignition System……………………………………………………35

3.4 Generator Power Flow Chart…………………………………… 36

3.5 Electrical Troubleshooting Stator……………………………… 37

3.6 General Troubleshooting……………………………………….. 38

Chapter 4 Exploded View and Bill of Materials (BOM)………………….. 39

4.1 Exploded Views………………………………………………… 39-42

4.2 Bill of Materials (BOM)………………………………………….. 42-50

Chapter 1 General Information

PPG6000 Generator is equipped with a single cylinder, 4 stroke, forced air-cooled, OHV 25° slant,

internal combustion engine. It is equipped with an electronic ignition system and is tuned to meet all

EPA and California Emissions Requirements.

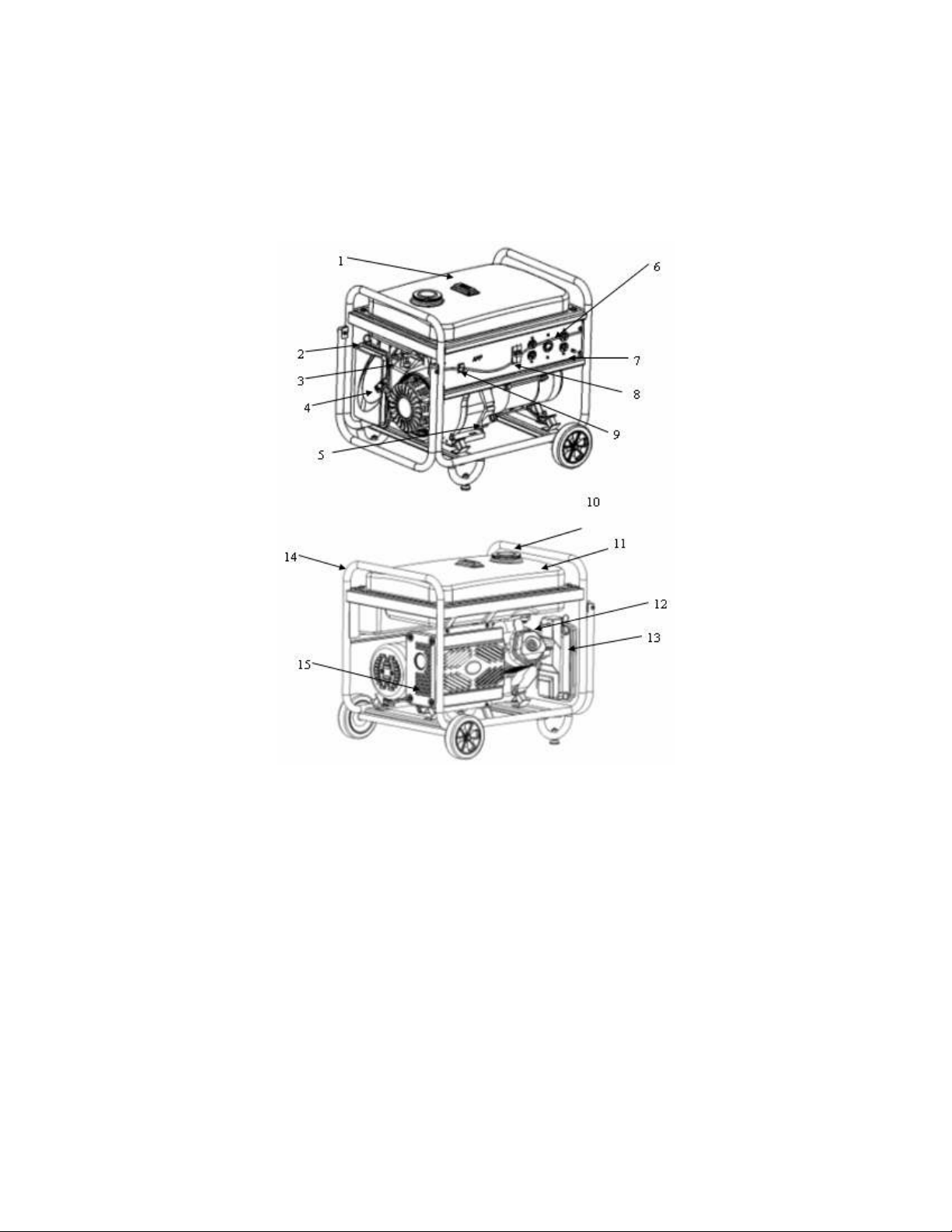

General Description:

1. Gas Tank

2. Choke

3. Fuel Shut Off

4. Pull Starter

5. Oil Dipstick

6. 120 Volt Outlet

7. Ground

8. Circuit Breaker

9. On Off Switch

10. Gas Cap

11. Gas Tank

12. Valve Cover

13. Air Filter

14. Frame

15. Muffler

Figure 1.1

Safety Information:

This symbol is known as the safety alert symbol and points out safety instructions that can lead

to injury or death.

Attention:

Please read and understand this manual

and the safety information prior to

starting the Generator.

Danger: Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Warning: Indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

Caution: Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

SAFETY INSTRUCTIONS

This generator is designed to supply electrical power. Please read and understand all of the safety instructions

and warning labels associated with this generator.

1) Do not operate indoors.

2) Generator must be on a flat stable surface. Surface slope not to exceed 4 degrees.

3) Operate in a well-lit and ventilated area.

4) Do not operate in moist or wet conditions including the surrounding ground.

5) The generator should be a minimum of 3 feet away from all combustible materials and should not be used

around hazardous materials.

6) Operating at a gas or natural gas filling station is forbidden.

7) Do not touch muffler or cylinder during or after operation. They are hot.

8) No smoking when filling the gas tank.

9) Do not overflow gas tank. Fill the tank to 1 inch below the top neck to allow for gas expansion. Ensure the

ventilation hole in the gas cap is not plugged with foreign matter such as dirt or leaves.

10) The engine should be shut off for at least 2 minutes before adding gas or oil.

11) Do not open the gas tank or oil reservoir while the engine is running.

12) Be mindful of the danger, warning and caution labels on the generator.

13) Keep away from children. Children should be kept at a minimum of 6 feet away from the generator at all

times.

14) In a normal situation the generator should be shut off using the instructions found on the front panel label.

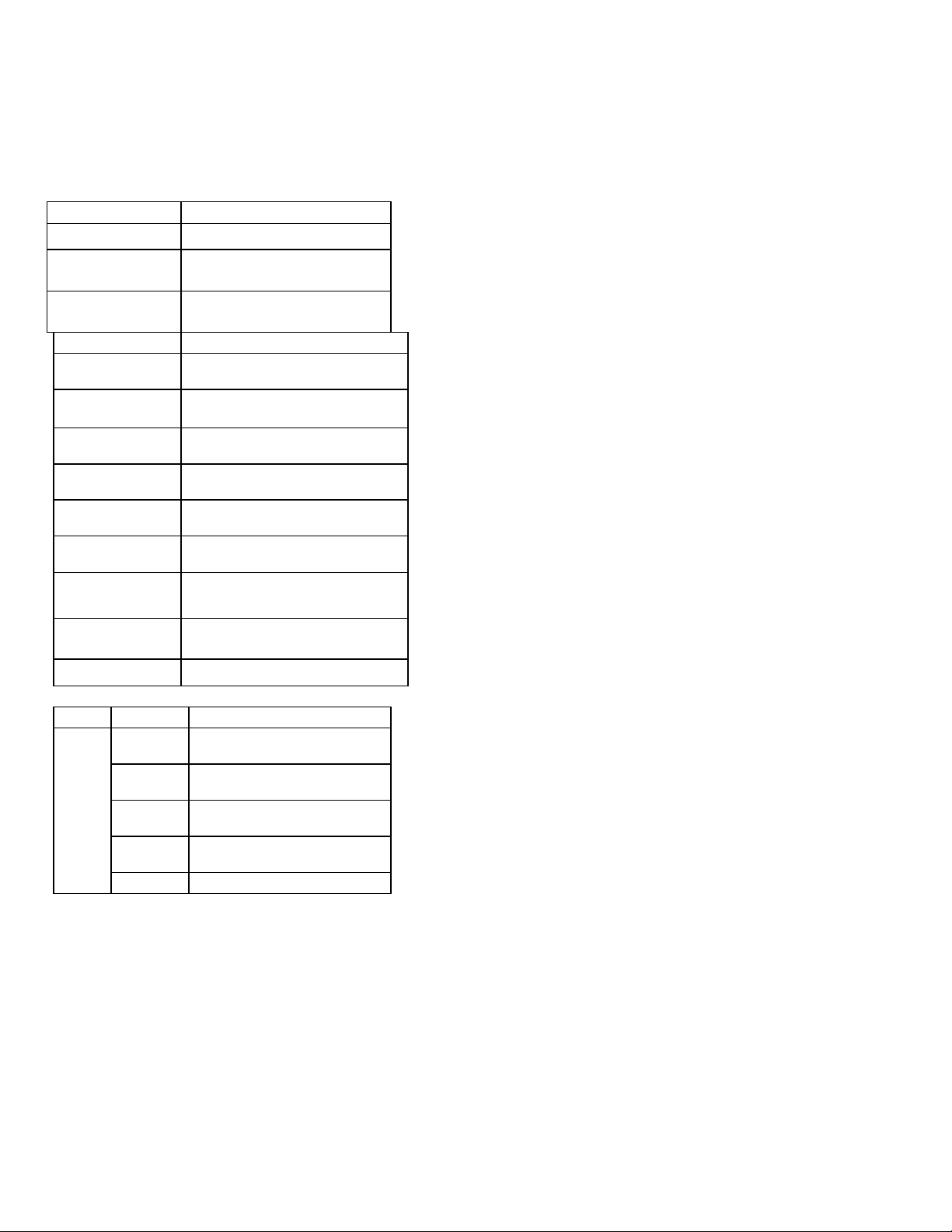

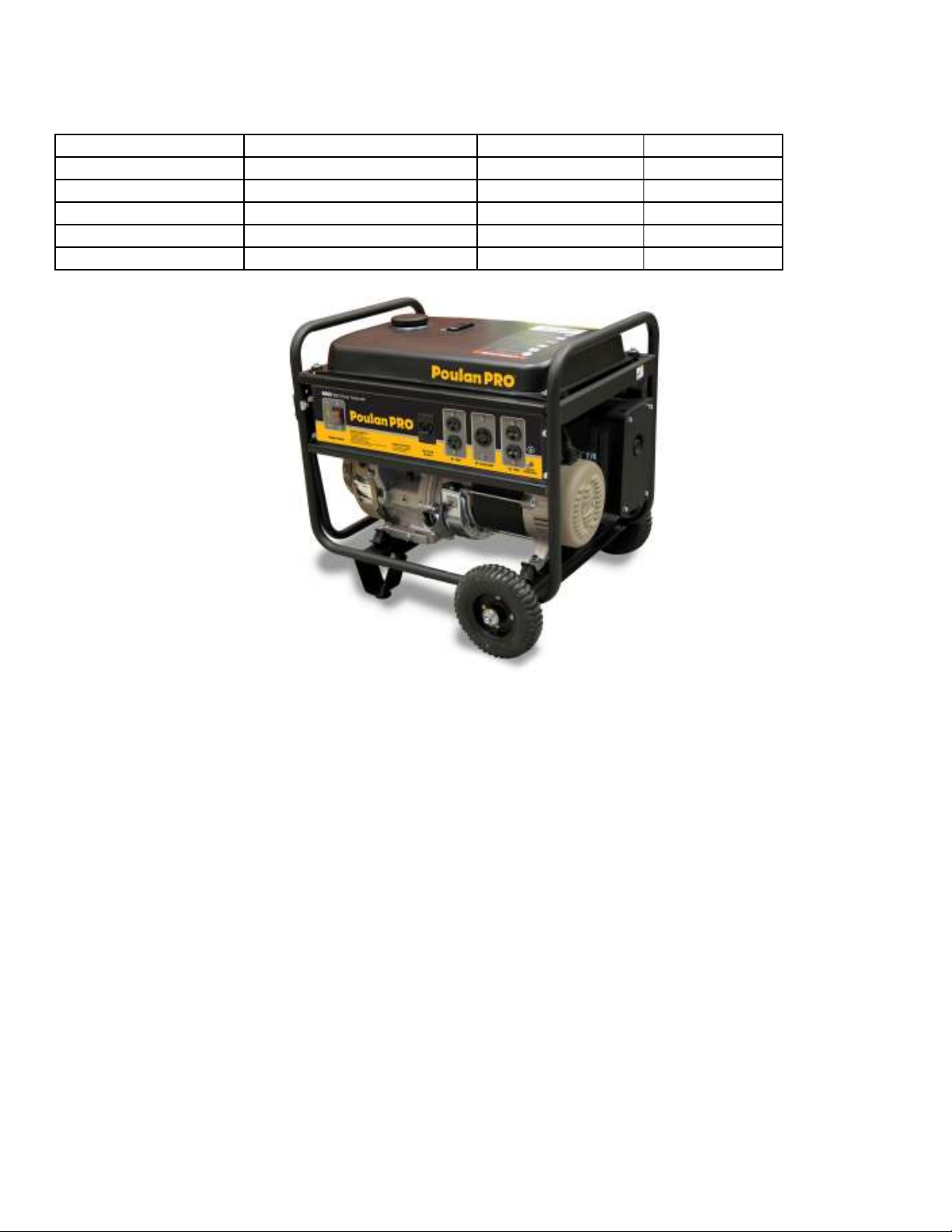

Specifications

PPG6000

Dimension/Weight Engine

Model PPG6000

LxHxW - Inches

26.8x20x21.3

Net Weight, Box Incl.

Gross Weight, Full of

Fuel

Model OHV13H

Engine Type

Cylinder discharge

capacity

Bore x Stroke

Cooling System

Ignition System

Spark Plug

Engine Oil Volume

Fuel Volume)

Compression Ratio

Model

Rated

Voltage

Rated

Frequency

Rated

Current

185lb

220lb

4-stroke, overhead valve, cylinder tilt 25°

389 cc

88x64 mm

Forced Air Cooling

Transistor Magnet Ignition

NGK, BP6ES

1.1Qt

6.6 Gallon

8.0:1

PPG6000

120V / 240V

60HZ

27.2A

Rated Output

Max Output

6.0KW

6.3KW

834KPa@600RPM

Generator

Tolerance Parameters

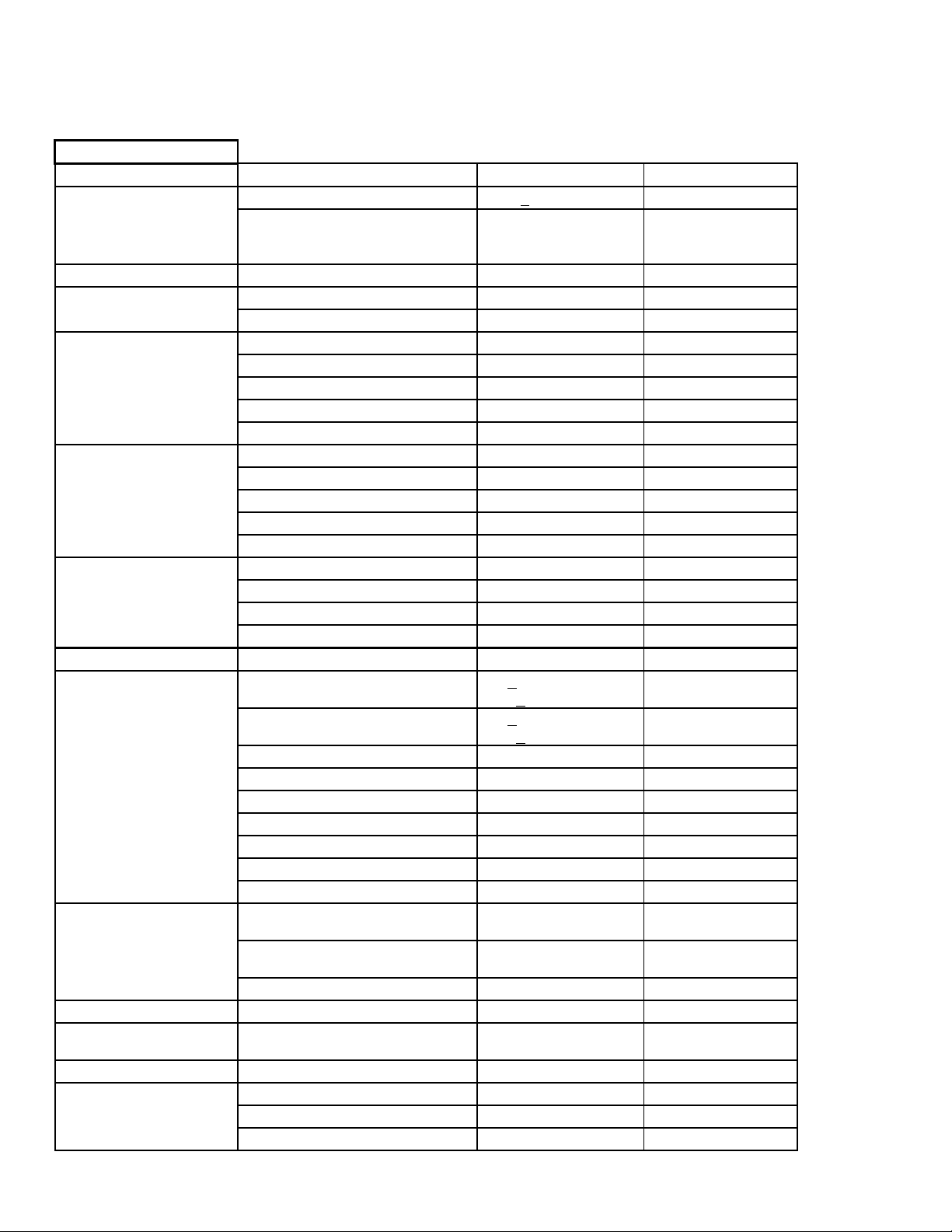

Parts Item Standard Extreme Max/Min

Cylinder

Crankshaft

Crankshaft case cover

spark plug

spark plug capacity

Maintenance and Adjusting Data

Max Speed

Cylinder Pressure

Cylinder bore diameter

Warpage

Valve bushing

Outside Diameter of piston skirt

Gap of piston and cylinder

Inside diameter of piston pin hole

Outside diameter of piston pin

Clearance of piston and piston pin hole

Flank clearance of Piston ring

Closed gap of the first and second ring

Closed gap of the oil ring

Width of the first ring

Width of the oil ring

Small end diameter

Large end diameter

Large end clearance

Large end flank clearance

Crankshaft pin outside diameter

Intake valve adjusted clearance

Exhaust valve adjusted clearance

Intake valve stem diameter

Exhaust valve stem diameter

Valve guide inside diameter

Clearance of intake valve and guide

Clearance of exhaust valve and guide

Valve seat width

Spring free length

Intake valve cam height

Exhaust valve cam height

Camshaft collar

Camshaft hole

Spark plug gap

Resistance

Resistance of primary coil

Resistance of secondary coil

Air Gap

3750+ 150, No Load

588-

85-120PSI@600PSI

88.00mm, 3.465" 88.17mm, 3.471"

.10mm, .004"

6.60mm, .260" 6.75mm, .2657"

87.985mm, 3.464" 87.85mm, 3.459"

.015-.052mm, .001" .12mm, .005"

20.002mm, .787" 20.042mm, .789"

20.00mm, .787" 19.95mm, .785"

.002-.014mm, .0006" .08mm, .003"

.030-.060mm, .002" .15mm, .006"

.20-.40mm, .012" 1.0mm, .039"

.20-.70mm, .002" 1.0mm, .039"

2.0mm, .079" 1.75mm, .069"

2.8mm, .110" 2.7mm, .106"

20.005mm, .7876" 20.07mm, .790"

36.025mm, 1.418" 36.070mm, 1.420"

.040-.066mm, .002" .12mm. .005"

.1-.7mm, .019" 1.0mm, .039"

35.985mm, 1.4167" 35.93mm, 1.4146"

.15+.02mm,

.006+.001"

.20+.02mm,

.008+.001"

6.59mm, .259" 6.44mm, .253"

6.55mm, .258" 6.40mm, .252"

6.60mm, .260" 6.66mm, .262"

.010-.037mm, .001" .10mm, .004"

.050-.077mm, .002" .12mm, .005"

1.1mm, .043" 2.0mm, .079"

39.0mm, 1.535" 37.5mm, 1.476"

32.44-32.60mm,

1.279"

31.94-32.10mm,

1.260"

15.984mm, .6292" 15.92mm, .6268"

16.0mm, .6299" 16.05mm, .6318"

0.7-0.8mm, .027.031"

7.5-12.5K ohms

.8-1.0 ohms

5.9-7.5 ohms

.4+.2mm, .016+.007"

-

-

32.24mm, 1.269"

31.74mm, 1.249"

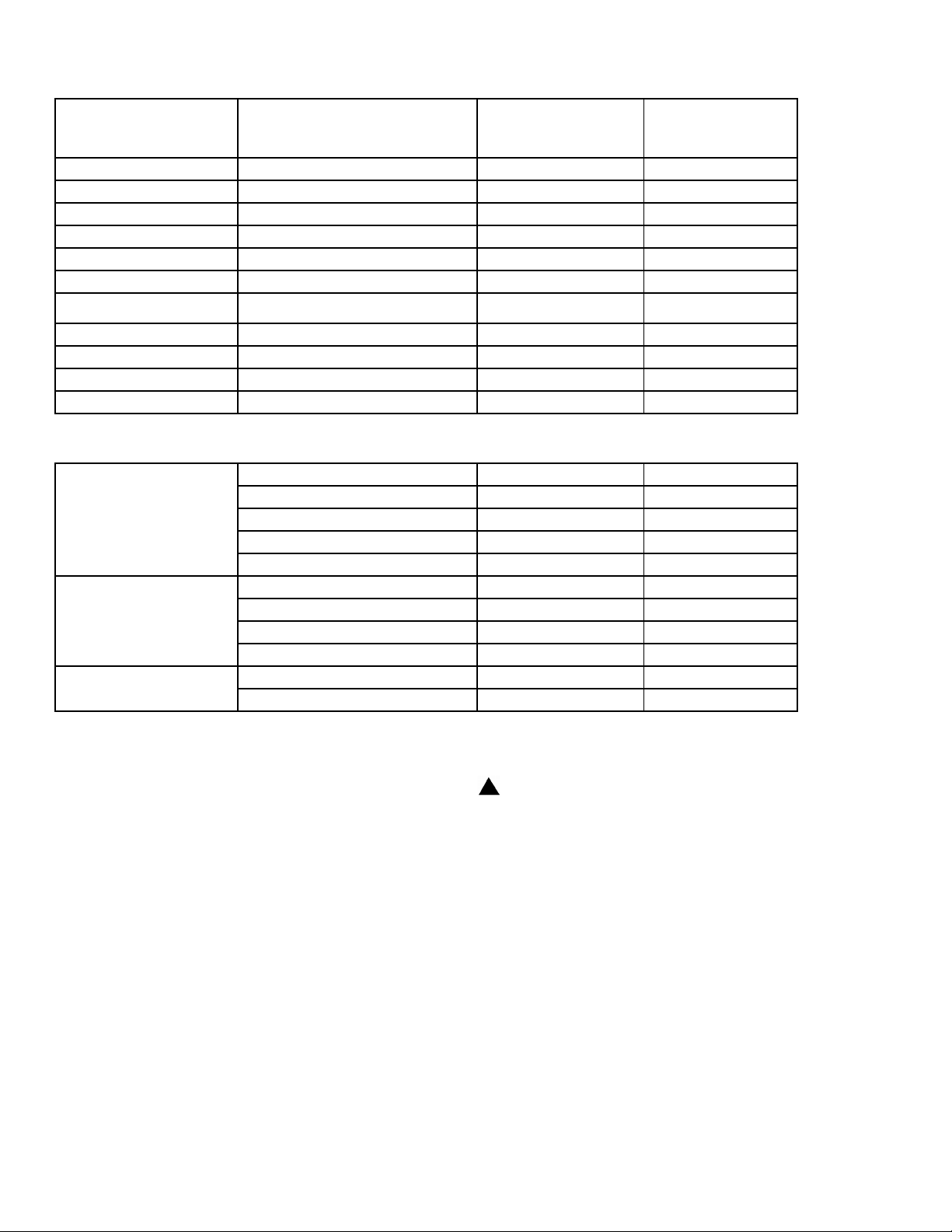

Torque Values

Torque Torque

Connecting rod bolt

Cylinder head bolt

Flywheel nut

Rocker shaft nut

Rocker shaft bolt

Fuel switch connecting nut

Exhaust pipe connecting

nut/bolt

Air filter bolts

Air filter nut

Drain plug

Rotor bolt

Standard Torque Values

M8X1.25(special bolt)

M10X1.25

M16X1.5(special nut)

M6X.5

M8X1.25(special bolt)

M10X1.25

M8X1.25

M6X1.0

M6X1.0

M12X1.25

M10X210

M5

M6

M8

M10

M12

M6

M8

M10

M12

M5

M6

N/m

14 124

34 300

113 *83 ft*lbf

10 88

24 212

10 88

24 212

7.5 66

8.5 75

23 203

44 389

5 44

10 88

24 212

37 327

55 487

12 106

26 230

34 300

59 522

4 35

9 79

in*lbf *except

where note

Fitting Directions:

1. When fitting the piston in the cylinder the mark “ ” on the piston top must be aimed to the intake

valve direction (upper).

2. When fitting the piston rings on the piston the “R,N’ mark on the first and second ring must be

upwards, and the gap of all three rings should be 120° apart.

3. The timing marks on the gears must be matched to each other.

Generator Information

Area

Main Winding

Field Winding

Exciter Winding

Main Winding

Carbon Brush length

Item Standard Service Limit

Resistance .2 ohms

Resistance 52-62 ohms

Resistance 1.2 ohms

Resistance .4 ohms

Length .9mm, .354" 5mm, .197"

EPA and Engine Serial Number are located on the panel side of the generator in the location shown.

Chapter 2 Maintenance of the Generator Set

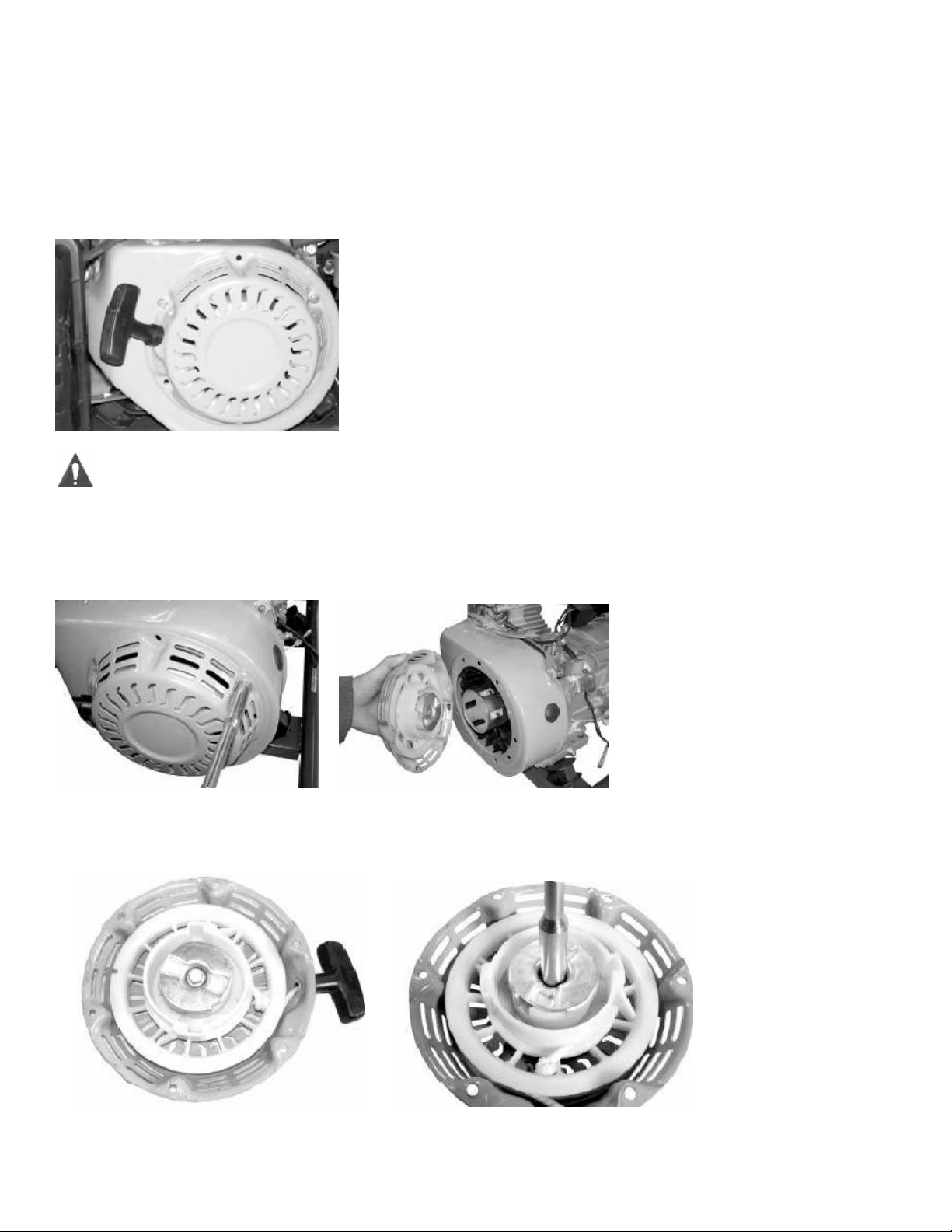

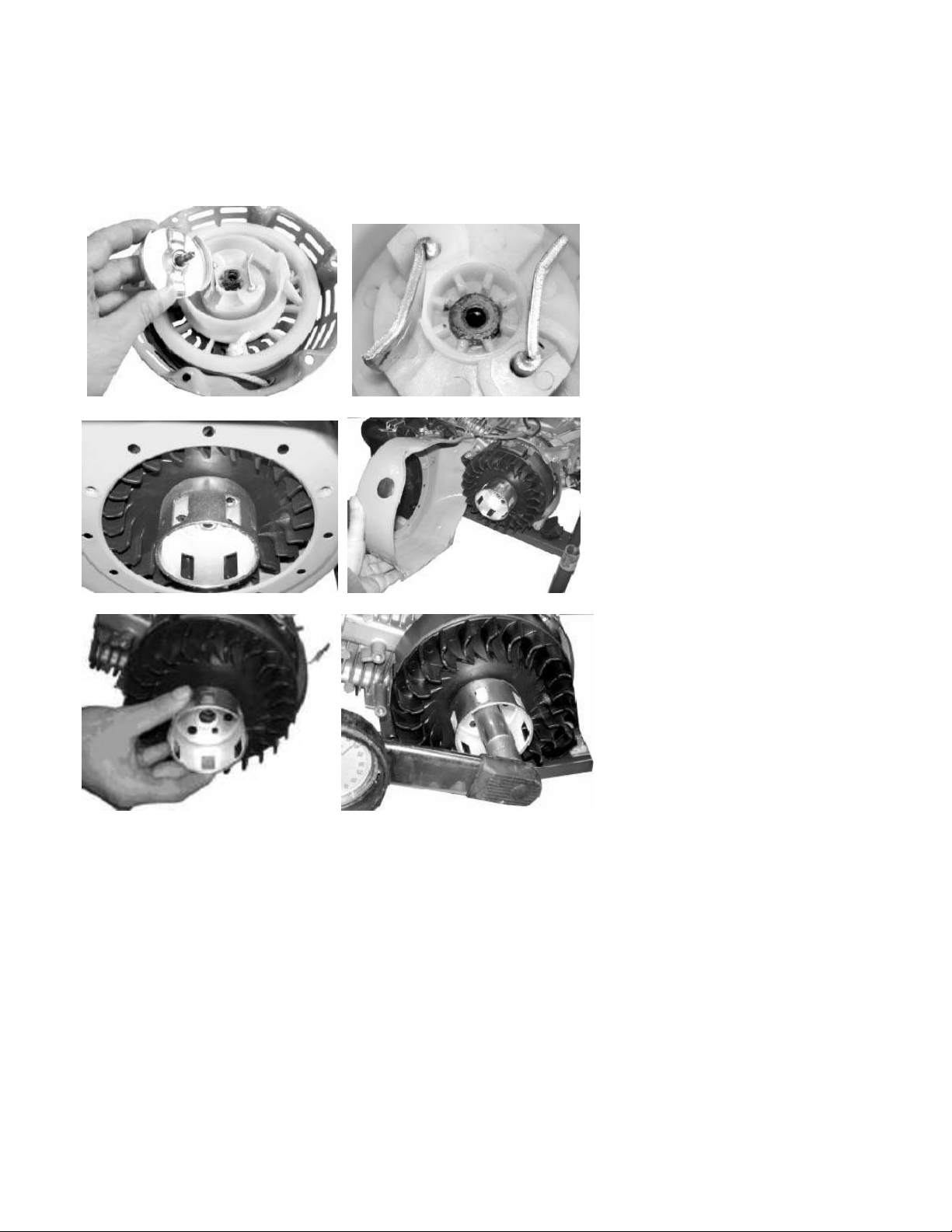

2.1 Maintenance of the Manual Starting System

The integral configuration of the starting device is shown below. Check the condition of the starter.

Replace if damaged.

There is a spring inside the starter device that is under stress. Wear safety goggles and watch

for flying debris when it is removed.

Remove the perimeter bolts to remove the starter housing.

Check the condition of the starter system. Replace any broken or damaged parts as follows:

1. Inspect the rope for abrasions. Replace as necessary.

2. Dismantle the starter pawl guide bolt with a socket.

3. Remove the pawls and pawl spring.

4. Visually inspect all parts.

5. Inspect the flute of the starting draw wheel.

6. Remove the shroud from the engine for inspection of the fan blades.

7. Replace parts as necessary.

2.2 Maintenance of the Lubrication System

Chose the oil type according to the local temperature of operation.

Use Four-stroke engine oil. SE, SF or equivalent to SG grade oil (SAE-30). When temp is below

50°F SAE 10W30 is recommended. SAE 5W-30 is recommended when temp is below 5°F.

1. It is best to change the engine oil when the engine is warm. This allows the oil to flow better for

a complete drain.

2. Drain the oil from the cylinder block by removing the plug at the base of the engine.

3. Check the condition of the dipstick and o-ring seal.

4. Replace the drain plug.

5. Fill with oil. See specifications in section 1.1 (parameters) for amount to add.

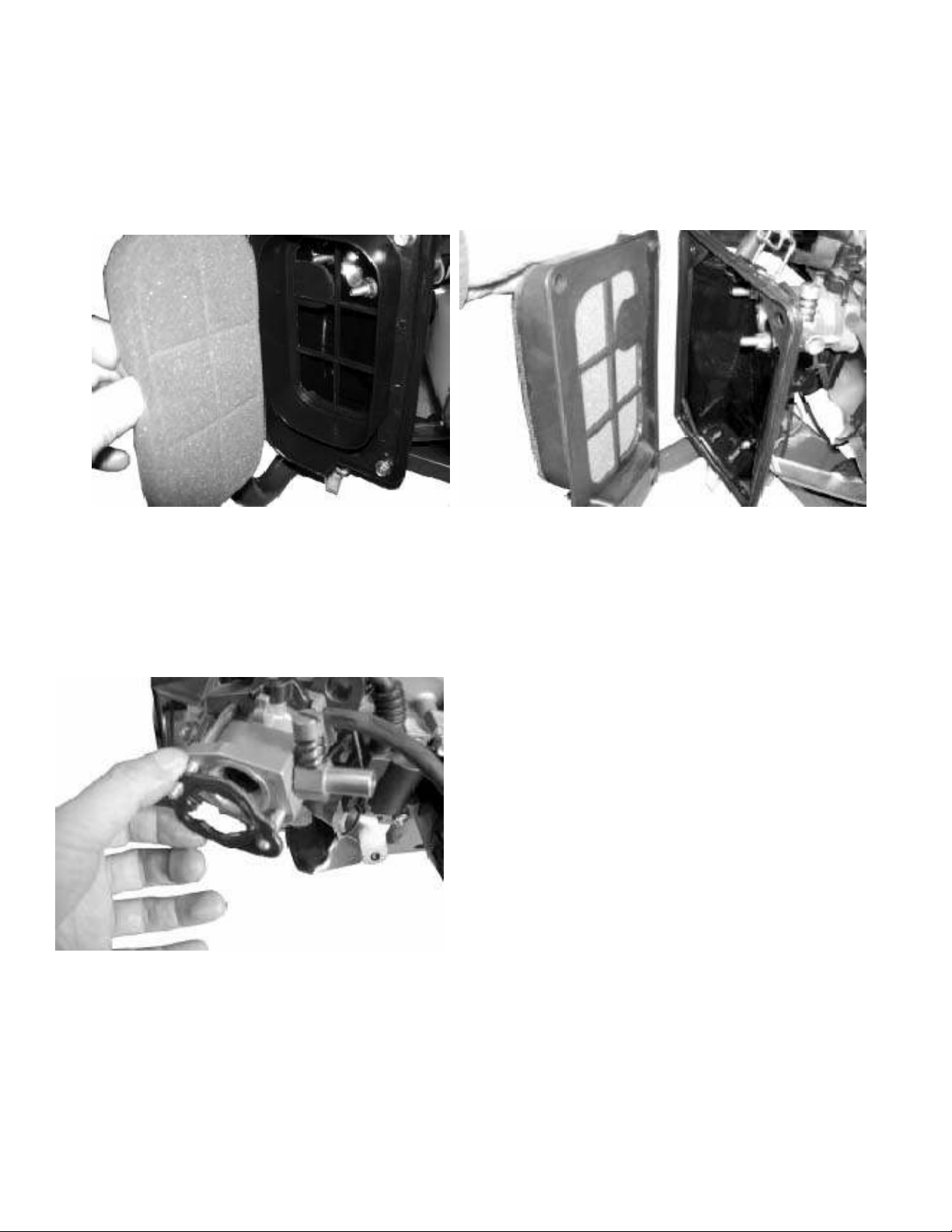

2.3 Maintenance of the Inlet system

1. Remove the air cleaner outer cover by releasing the latches at the top and bottom.

2. Remove the air cleaner element (foam pad). Replace as necessary.

Never use gasoline, low-burning point solvent, acid or alkaline to clean the element. Use

detergent only!

Cleaning the element (foam pad)

Dip the element in the detergent and wring it out. Apply motor oil and wring out excess oil. Install

element.

3. Remove the plastic inner housing by removing the six nuts around the perimeter.

4. Remove the enclosure by removing the two nuts inside the enclosure and one on the

backside.

5. Remove the carburetor gasket and choke mechanism. Some models may not have automatic

chokes and the choke mechanism will not need to be removed. It is built onto the carburetor in

this case.

6. Remove the lines to the carburetor and remove the carburetor.

2.4 Maintenance of Fuel System

1. Remove the bowl of the fuel cock.

2. Remove the screen inside the fuel cock.

3. Remove the fuel cock.

4. Pull out the screen inside the tank.

5. Clean or replace both screens and reassemble.

Loading...

Loading...