Poulan 530164284, PPB1838, PPB1634 User Manual

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

For Occasional Use Only

R

ENGLISH ESPAÑOL

PPB1634

PPB1838

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones graves.

AVERTISSEMENT:

Lirelemanueld’instructionsetbienrespectertouslesavertissements et toutes les instructions de sécurité. Tout défaut de le

faire pourrait entraîner des blessures graves.

Electrolux Home Products, Inc.

250 Bobby Jones Expressway

Augusta, GA 30907

CopyrightE2003 Electrolux Home Products, Inc.

530164284

11/14/03

FRANÇAIS

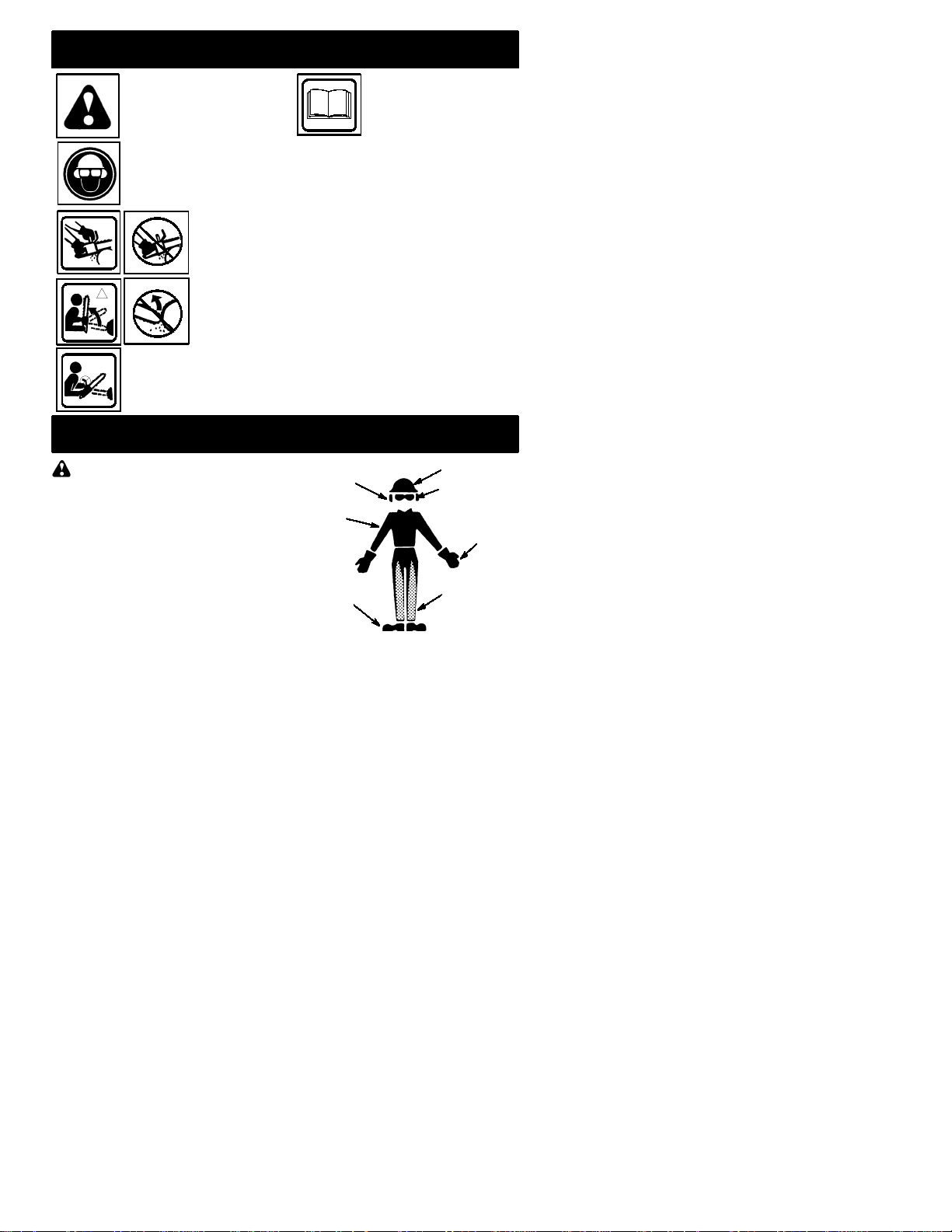

IDENTIFICATION OF SYMBOLS

WARNING!

saw can be dangerous! Careless or improper use cancause

serio us or evenfatal injury.

Alwayswearappropriateearprotection,eye protectionand headprotection.

XX_

Measuredmaximum kickback value withoutchain brakefor thebar

and chain combination on the label.

This chain

Always use two hands when operatingthe chain saw.

WARNING!

should be avoided; tip contact may cause the guide bar to

movesuddenlyupwardandbackward,whichmay causeserious injury.

SAFETY RULES

WARNING:

spark plug wire and place wirewhereitcannot contact spark plug to preventaccidental

starting when setting up, transporting, adjusting or making repairs except carburetor

adjustments.

Becauseachain saw is a high-speedwoodcutting tool, special safety precautionsmust

beobserved to reduce the risk of accidents.

Careless or improper use of this tool can

cause serious injury.

PLAN AHEAD

Read this manual carefully until you com-

S

pletely understand and can follow all safety

rules, precautions, and operating instructions before attempting to use the unit.

Restrict the use ofyoursaw to adult users

S

who understand and can follow safety

rules, precautions, and operating instructions found in this manual.

Wear protective gear. Always use steel-

S

toed safety footwear with non-slip soles;

snug-fitting clothing; heavy-duty, non-slip

gloves; eye protection such as non-fogging, vented goggles or face screen; an

approvedsafety hardhat;andsoundbarriers (ear plugs or mufflers) to protect your

hearing. Regular users should havehearing checked regularly as chain saw noise

can damage hearing. Secure hair above

shoulder length.

Always disconnect

Read and understand the

instruction manual before

using the chain saw.

Contactingtheguidebar tip with any object

Hearing

Protection

Snug

Fitting

Clothing

Safety

Shoes

Keepall parts of your body away from the

S

chain when the engine is running.

Keepchildren, bystanders, and animals a

S

minimum of 30 feet(10meters)awayfrom

the work area. Do not allow other people

or animals to be near the chain saw when

starting or operating the chain saw.

Do not handle or operate a chain saw when

S

you are fat igued,ill, or upset,or if you have

taken alcohol, drugs, or medication. You

must be ingoodphysical condition andmentally alert. Chain saw work is strenuous. If

you have any condition that might be aggravated by strenuous work, check with your

doctor before operating a chain saw.

Safety Hat

Eye

Protection

Heavy Duty

Gloves

Safety Chaps

2

Carefullyplanyour sawingoperation inad-

S

vance. Donot startcuttinguntil youhavea

clearworkarea,secure footing,and, if you

are felling trees,a planned retreat path.

OPERATE YOUR SAW SAFELY

Donotoperatea chain sawwithonehand.

S

Serious injury to the operator, helpers, bystanders or any combination of thesepersons may result from one-handed operation. A chain saw is intended for

two-handed use.

Operatethe chain saw onlyinawell-venti-

S

lated outdoor area.

Do not operate saw from a ladder or in a

S

tree.

Makesurethe chainwill notmake contact

S

with any object while starting the engine.

Never try to start the saw when the guide

bar is in a cut.

Do not put pressure onthesawattheend

S

of the cut. Applying pressure can cause

you to lose control when the cut is completed.

Stop the engine before setting the saw

S

down.

Do not operate a chain saw that is dam-

S

aged, improperly adjusted, or not completely and securely assembled. Always

replace bar, chain, hand guard, or chain

brakeimmediately ifitbecomesdamaged,

broken or is otherwise removed.

With the engine stopped, hand carry the

S

chain saw with the muffleraway fromyour

body, and the guide bar and chain to the

rear,preferably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKINGORDER

Haveallchainsaw service performed bya

S

qualified service dealerwith the exception

of theitems listed in the maintenance sectionof thismanual. Forexample,ifimpropertoolsareusedtoremoveorhold theflywheelwhen servicing theclutch, structural

damage to the flywheel can occur and

cause the flywheel to burst.

Make certain the saw chain stops moving

S

when the throttle trigger is released. For

correction, refer to CARBURETOR ADJUSTMENTS.

Never modify your saw in any way.

S

Keepthe handles dry,clean, andfreeofoil

S

or fuel mixture.

Keep fuel and oil caps, screws, and fas-

S

teners securely tightened.

UseonlyPoulanPRORaccessoriesand

S

replacement parts as recommended.

HANDLE FUEL WITH CAUTION

Do not smoke while handlingfuel or while

S

operating the saw.

Eliminate all sources of sparks or flamein

S

the areas where fuel is mixed or poured.

Thereshouldbe nosmoking,openflames,

orworkthat couldcausesparks. Allowengine to cool before refueling.

Mix and pour fuel in an outdoor area on

S

bare ground; store fuel in a cool, dry,well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills beforestartingsaw.

Move at least 10 feet (3 meters) from fuel-

S

ing site before starting engine.

Turn the engine off and let saw cool in a

S

non-combustible area, not on dry leaves,

straw,paper, etc. Slowly remove fuel cap

and refuel unit.

Storetheunit andfuelinanareawherefuel

S

vapors cannot reach sparks or open

flamesfromwaterheaters, electric motors

or switches, furnaces, etc.

KICKBACK

WARNING:

can result in serious injury.

backward,upwardorsuddenforwardmotion

of the guide bar occurring when the saw

chainneartheuppertip oftheguidebarcontacts any object such as a log or branch, or

when the wood closes in and pinches the

sawchainin thecut. Contactinga foreignobject in the wood can also result in loss of

chain saw control.

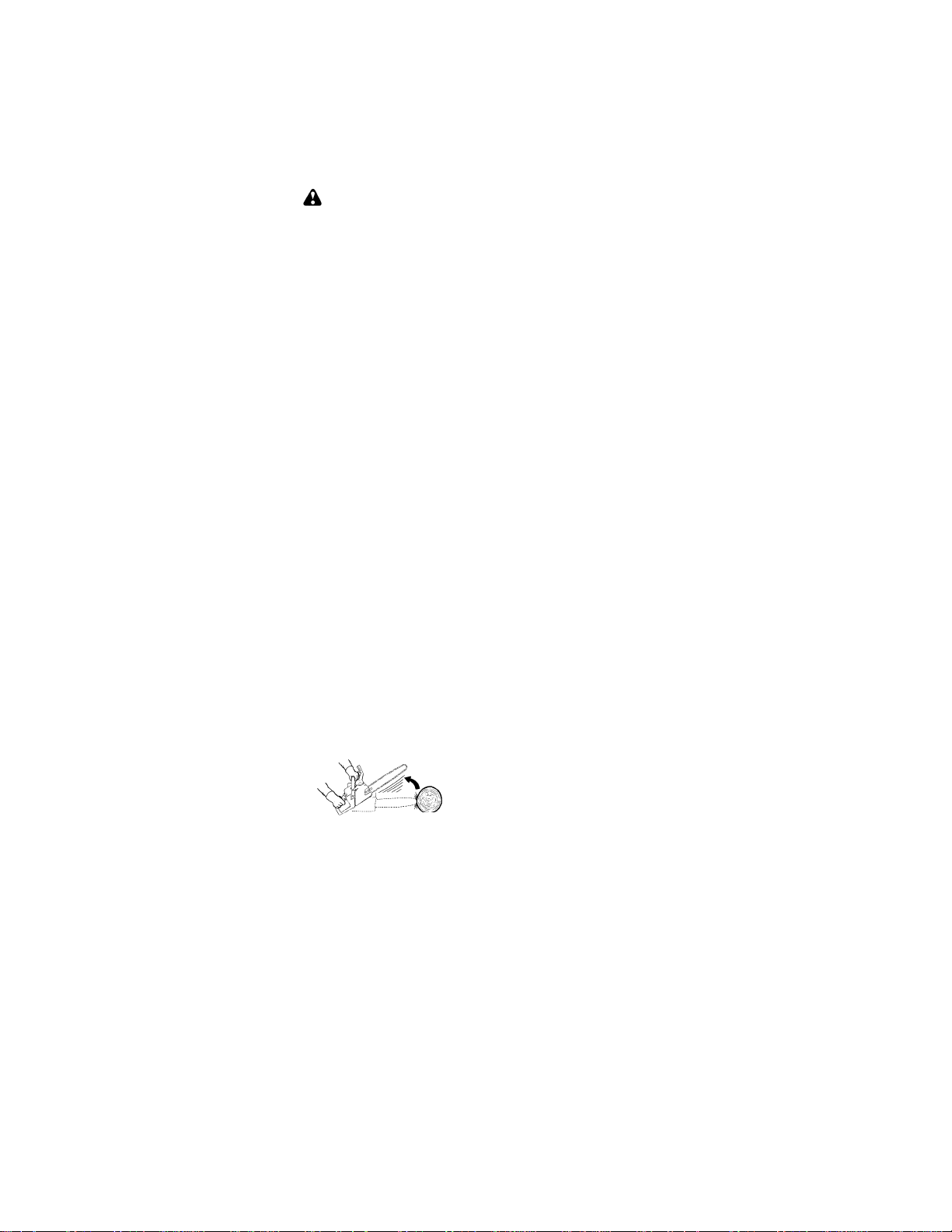

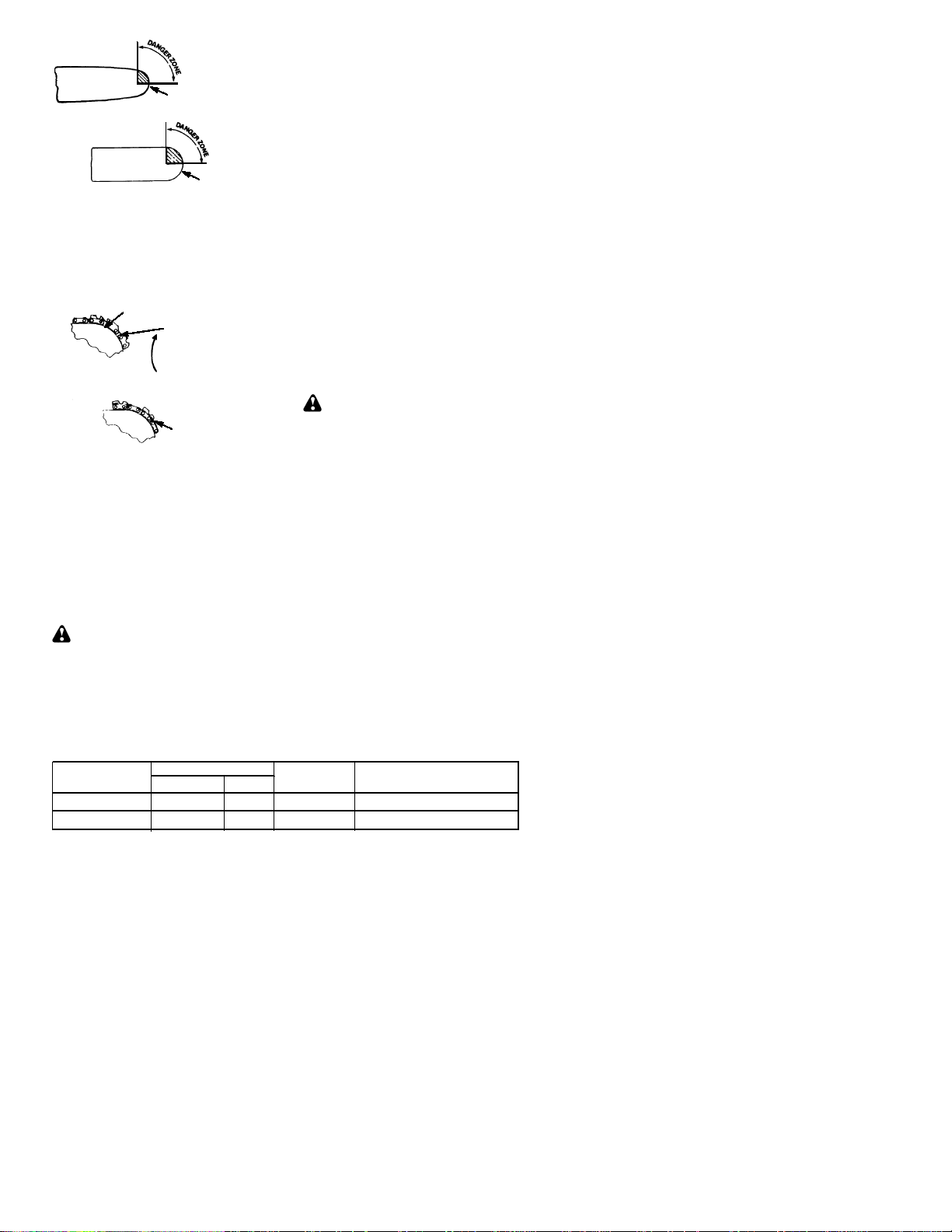

RotationalKickback

S

moving chain contacts anobjectat the upper tip of the guide bar. This contact can

cause the chain to dig into the object,

which stops the chain for an instant. The

result is a lightning fast, reverse reaction

which kicks the guide bar up and back toward the operator.

Pinch-Kickback

S

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

sawtomovein theoppositedirectionofthe

chain rotation. The saw is driven straight

back toward the operator.

can occur when the moving chain

Pull-In

S

contacts a foreign object in the wood in the

cut alongthebottom of the guide bar and the

sawchainis suddenlystopp ed. Thissudde n

stopping pulls the saw forward and away

from theoperatorand could easily cause the

operator to lose control of the saw.

Avoid Pinch--Kickback:

Be extremely aware of situations or ob-

S

structions thatcancausematerial topinch

the top of or otherwise stop the chain.

Do not cut more than one log at a time.

S

Do not twist the saw as the bar is with-

S

drawn from an undercut when bucking.

AvoidPull--In:

Always begin cutting with theengine atfull

S

speedandthe saw housing againstwood.

Use wedges made of plastic or wood.

S

Never use metal to hold thecut open.

Avoid kickback which

Kickback

canoccurwhen the

can occur when the the

Kickback Path

is the

3

Avoid Obstructions

Clear The Working Area

REDUCETHE CHANCE OF

KICKBACK

Recognize that kickback can happen.

S

With a basic understanding of kickback,

you can reduce the element of surprise

which contributes to accidents.

Neverletthemovingchaincontactanyob-

S

ject at the tip of the guide bar.

Keep the working area free from obstruc-

S

tionssuchasothertrees,branches,rocks,

fences, stumps, etc. Eliminate or avoid

any obstruction that your saw chain could

hit while you are cutting. When cutting a

branch, do not let the guide bar contact

branch or other objects around it.

Keep your saw chain sharp and properly

S

tensioned. A loose or dull chain can increase the chance of kickback occurring.

Follow manufacturer’s chain sharpening

andmaintenanceinstructions. Check tension at regular intervals with the engine

stopped, never with the engine running.

Make sure the chain brake nuts are securely tightenedaftertensioningthechain.

Begin andcontinuecuttingat full speed. If

S

the chain is moving at a slower speed,

thereisgreaterchance of kickback occurring.

Cut one log at a time.

S

Use extreme caution when re-entering a

S

previous cut.

Do not attempt cuts starting with the tip of

S

the bar (plunge cuts).

Watch for shifting logs or otherforcesthat

S

could close a cut and pinch or fall into

chain.

Use the Reduced--Kickback Guide Bar

S

and Low--Kickback Chain specified for

your saw.

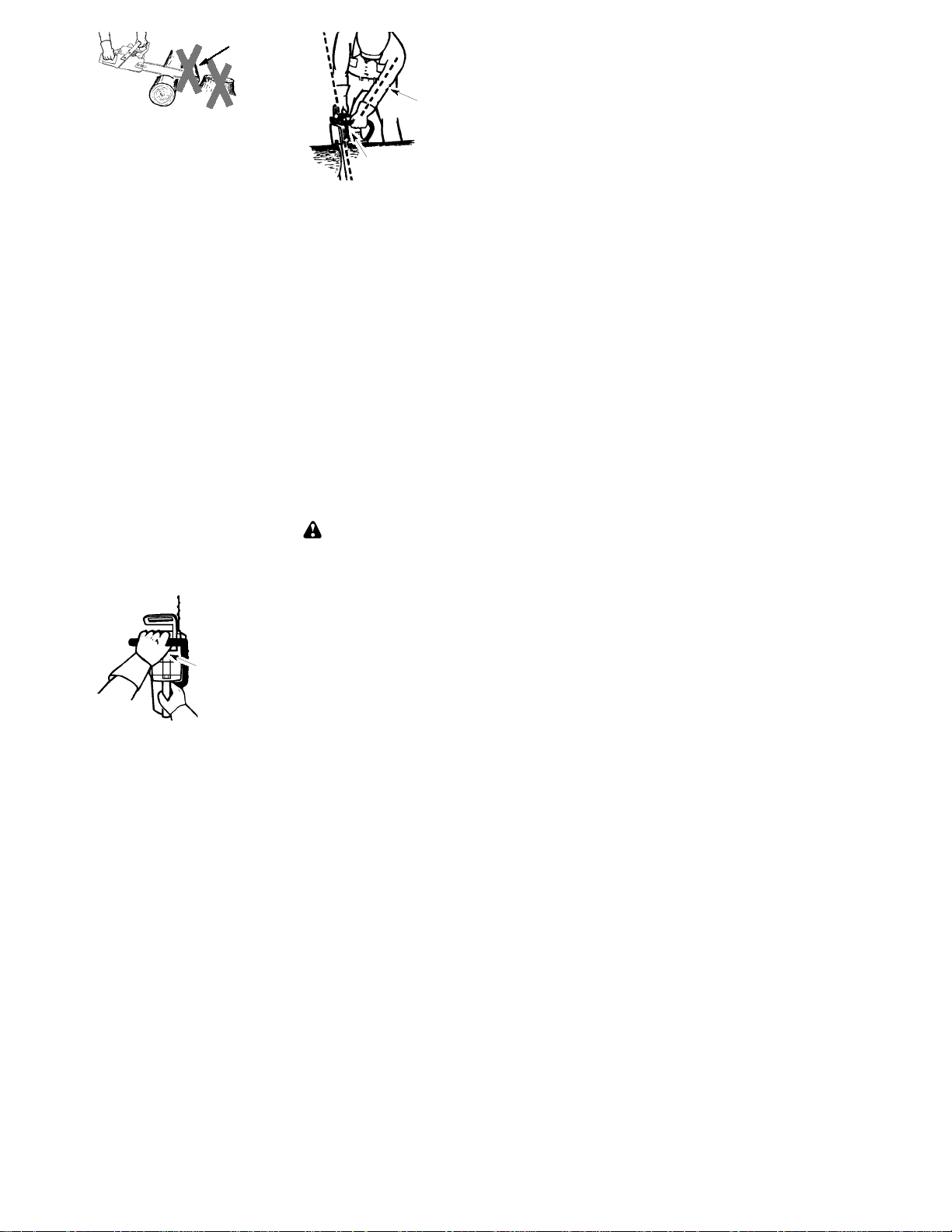

MAINTAIN CONTROL

Stand to the

left of the saw

Thumb on

underside of

handlebar

Never reverse

hand positions

Elbow locked

Thumb on underside of

handlebar

Keepa good,firm griponthesawwithboth

S

hands when the engine is running and

don’tletgo. A firm gripwillhelpyoureduce

kickback and maintain control of the saw.

Keep the fingers of your left hand encircling and your left thumb under the front

handlebar. Keep your right hand completely around the rear handle whether

yourareright handedorlefthanded. Keep

your left arm straight with the elbow

locked.

Position your lefthandonthefront handle-

S

bar so it is in a straight line with your right

hand on the rear handle when making

bucking cuts. Never reverse right andleft

hand positions for any type of cutting.

Standwithyourweightevenlybalancedon

S

both feet.

Stand slightly to the left side of the saw to

S

keep your body from being in a direct line

with the cutting chain.

Do not overreach. Youcould be drawn or

S

thrown off balance and lose control of the

saw.

Donot cutaboveshoulderheight. It isdiffi-

S

cult to maintain control of saw above

shoulder height.

KICKBACKSAFETY FEATURES

WARNING:

are included on your saw to help reducethe

hazard of kickback; however, such features

will not totally eliminate this danger. As a

chainsawuser,donotrelyonlyonsafetydevices. You must follow all safety precautions, instructions, and maintenance in this

manual to help avoid kickback and other

forces which can result in serious injury.

Reduced--Kickback Guide Bar, designed

S

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced--Kickback Guide Bar

hasbeendemonstrated tosignificantly reducethenumberand seriousness of kickbacks when tested in accordance with

safety requirements for gasoline powered

chain saws as set by ANSI B175.1.

The following features

4

Reduced Kickback Symmetrical Guide Bar

Small Radius Tip

Symmetrical G uide Bar

Low--Kickback Chain, designed with a

S

contoured depth gauge and guard link

which deflect kickback force and allow

woodto graduallyrideintothe cutter .Low-Kickback Chain has met kickback performance requirements when tested on a

representative sample of chain saws below 3.8 cubic inch displacement specified

in ANSI B175.1.

Low---Kickback

Chain

Not a Low ---Kickback Chain

Front Hand Guard, designed to reduce the

S

chance ofyourleft handcontacting thechain

if your hand slips off the front handlebar.

Position of front and rear handlebars, de-

S

signedwithdistancebetweenhandlesand

“in-line” with each other. The spread and

“in-line” position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kickback occurs.

CHAIN BRAKE AND CKA ANGLE

Chain Brake,designedto stopthechain in

S

the event of kickback.

WARNING:

RESENT AND YOU SHOULD NOT ASSUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A KICKBACK. Kickback is a lightning fast action

which throws the bar and rotating chain back

and up toward the operator. Kickback can be

Contoured Depth Gauge

Large Radius Tip

Elongated Guard Link

Deflects

kickback force

and allows wood

to gradually ride

into cutter

Can Obstruct Material

WE DO NOT REP-

caused by allowing contact of the bar tip in the

danger zone with any hard object. Kickback

canalsobecausedbypinchingthesawchain

along the top of the guide bar. This actionmay

push the guide bar rapidly back toward theoperator. Either of these events may cause you

to losecon trol of thesawwhichcould resultin

serious injury or even death. DO NOT RELY

UPON ANY OF THE DEVICES BUILT INTO

YOUR SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced--kickback guide bars

and low--kickback saw chains reduce the

chance and magnitude of kickback and are

recommended. Your saw has a low kickback

chain and bar as original equipment. Repairs

on a chain brake should be made by an authorized servicing dealer. T ake your unit to the

place of purchase if purchased from a servicing dealer, or to the nearest authorized master

service dealer.

Tipcont a ctinsomecasesmaycausealight-

S

ning fast reverse REACTION, kicking guide

bar up and back toward operator.

Pinching the saw chain along the top of the

S

guide bar may push the guide bar rapidly

back toward the operator.

Either of these reactions may cause you to

S

lose control of the saw which could result in

serious injury. Do not rely exclusively upon

devices builtint oyour saw.

WARNING:

angle (CKA) listed onyoursaw andlisted in the

CKA table below represents angle of kickback

your bar and chain combinations will have

when tested in acco r d ance with CSA (Canadian Standards Association) and ANSI standards. When purchasing replacement bar and

chain, considerations should be given to the

lower CKA values. Lower CKA values represent safer angles to the user, higher values indicate more angle and higher kick energies.

Computed angles represented indicate total

energy andangleassociated withoutactivation

of the chain brake during kickback. Activated

anglerepresentschainstoppingtime relative to

activation angle of chain break and resulting

kick angle of saw. In all cases lower CKA values represent a safer operating environment

for the user.

The following guide bar and chain combinations meet kickback requirements of CSA

Standards Z62.1, Z62.3, & ANSI B175.1

when used on saws listed in this manual.

Use of bar and chain combinations other

than those listed is not recommended and

may not meet the CKA requirements per

standard.

Comp u t ed kickback

Computed kickback angle (CKA) Table

LE SERIES

MODEL

PPB1634

PPB1838

BAR

P/N Length CHAIN P/N

16!

18!

952051547

952051548

952044370

952044418

5

CKA without chain brake

19

_

14

_

NOTE:

r

mercial logging, a chain brake is required

and shall not be removed or otherwise disabledtocomply withFederalOSHA Regulations for Commercial Logging.

SAFETY NOTICE:

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or

abnormal swellings. Prolon ged use in cold

weather has been linked to blood vessel

damage in otherwise healthy people. If

symptoms occur such as numbness, pain,

loss of strength, changeinskin color ortexture,

or loss of feeling in the fingers, hands, or joints,

discontinue th e use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems. Users who operate power tools on

a continual and regular basis must monitor

closely their physical condition and the

condition of this tool.

SPECIALNOTICE:

with atemperaturelimiting muffler andspark

arresting screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon,andWashington require by

law that many internal combustion engines

tobeequippedwitha sparkarrestingscreen.

Ifyou operatea chainsawin astateorlocale

wheresuch regulations exist, you arelegally

responsible for maintaining the operating

condition of these parts. Failure to do so is

aviolation ofthelaw. Refer to the SERVICE

section for maintenance of the spark

arresting screen.

Failuretofollowall SafetyRulesandPrecautionscanresult in serious injury. If situations

occur which are not covered in this manual,

use care and good judgement. If you need

assistance, contact your authorized service

dealer or call 1-800--554--6723.

STANDARDS:

writer’s Laboratories, Inc., in accordance with:

ANSI B175.1--2000

Standards for Gasoline--Powered Chain

Saws -- Safety Requirements

CSA Z62.1--03

Health and Safety

CSA Z62.3--96

pational Health and Safety

If this saw is to be used for com-

Exposure to vibrations

Y oursaw isequipped

Thissaw is listedbyUnder-

American National

Chain Saws -- Occupational

Chain Saw Kickback Occu-

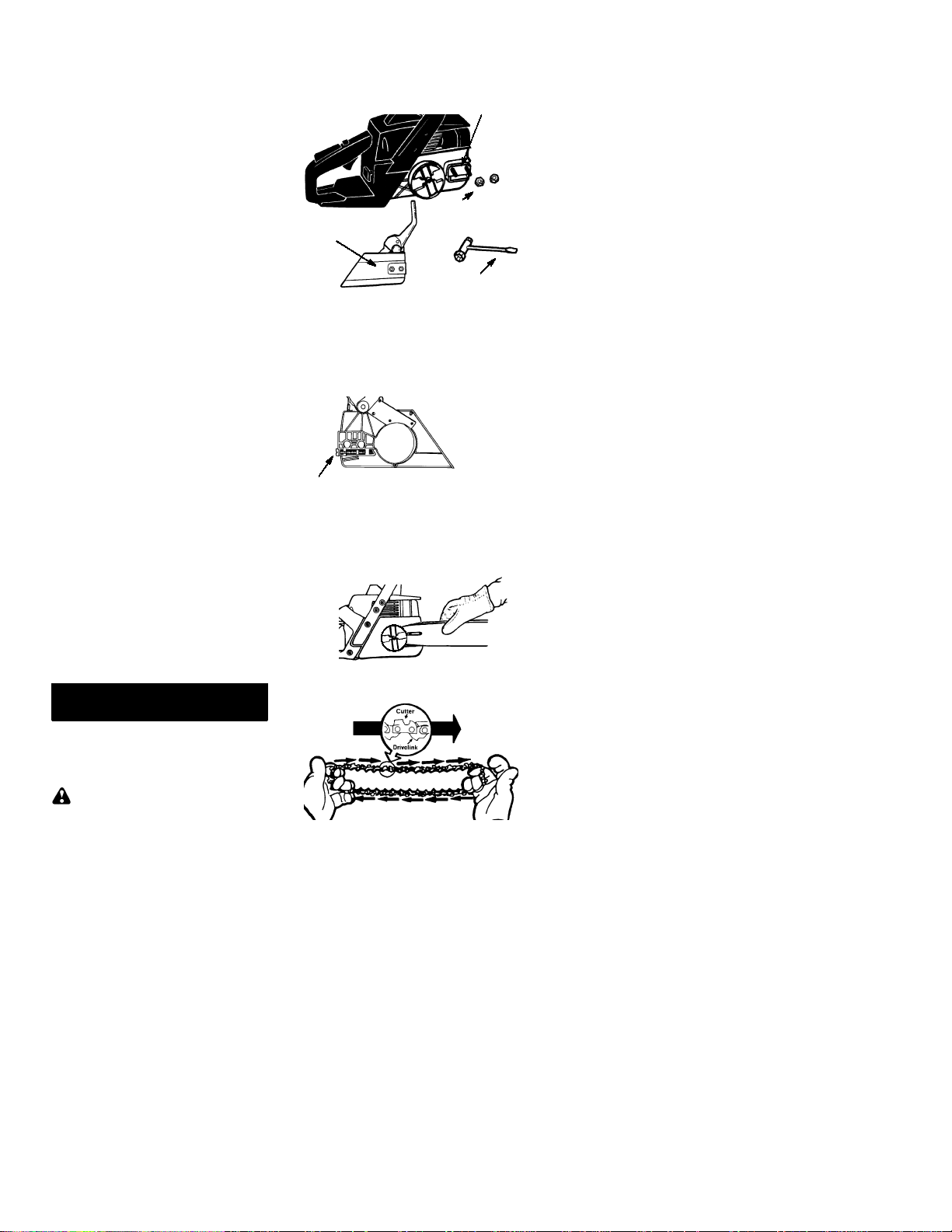

ASSEMBLY

Protective gloves (not provided) should be

wornduringassembly.

ATTACHINGTHEBAR &CHAIN

already attached)

WARNING:

repeat all steps to ensure your saw is properly

assem b led and all fasten ers are secure. Always wear gloves when handling the chain.

If received assembled,

(Ifnot

Thechainis sharp and can cut you even when

it is notmo ving!

1. Loosen and remove the chain brake

nuts and the chain brake from the saw.

2. Remove the plastic shipping spacer (if

present).

Chain Brake

3. An adjusting pin and screw is used to adjust the tension of the chain. It is very important when assembling the bar, that the

pin located on the adjusting screw aligns

into aholein thebar.Turningthe screw will

move the adjustment pin upanddown the

screw. Locate this adjustment before you

begin mounting the bar onto the saw. See

illustration below.

Adjustment located on Chain Brake

4. Turntheadjusting screw by handcounterclockwise until the adjusting pin just

touches the stop. This should allow the

pin to be nearthe correct position.

5. Slide guide bar behindclutch drum until

guide bar stops against clutch drum

sprocket.

6. Carefully removethechain fromthepackage. Hold chain with the drive links as

shown.

Location of shipping space

Chain Brake

Nuts

Bar Tool

Inside view of

Chain Brake

Mount the Bar

CUTTERS MUST FACE IN

DIIRECTION OF ROTATION

Tip of

Bar

6

Loading...

Loading...