Page 1

Please do not return product to retailer.

Por favor, no devuelva el producto al lugar de compra.

Veuillez ne pas retourner le produit au détaillant.

1--800--554--6723

Register your product online at:

Registre su producto en línea en:

Enregistrez votre produit en ligne à l’adresse :

www.poulanpro.com

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

PP258TPC

R

ENGLISH ESPAÑOL

For Occasional Use Only

DANGER:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

PELIGRO:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones graves.

DANGER:

Lire le manueld’instructions et bien respectertous les avertissements et toutes les instructions de sécurité. Tout défaut de le

faire pourrait entraîner des blessures graves.

Poulan PRO

9335 Harris Corners Parkway

Charlotte, NC 28269

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

Poulan PRO

115453627

Rev. 3 4/15/12 BRW

FRANÇAIS

Page 2

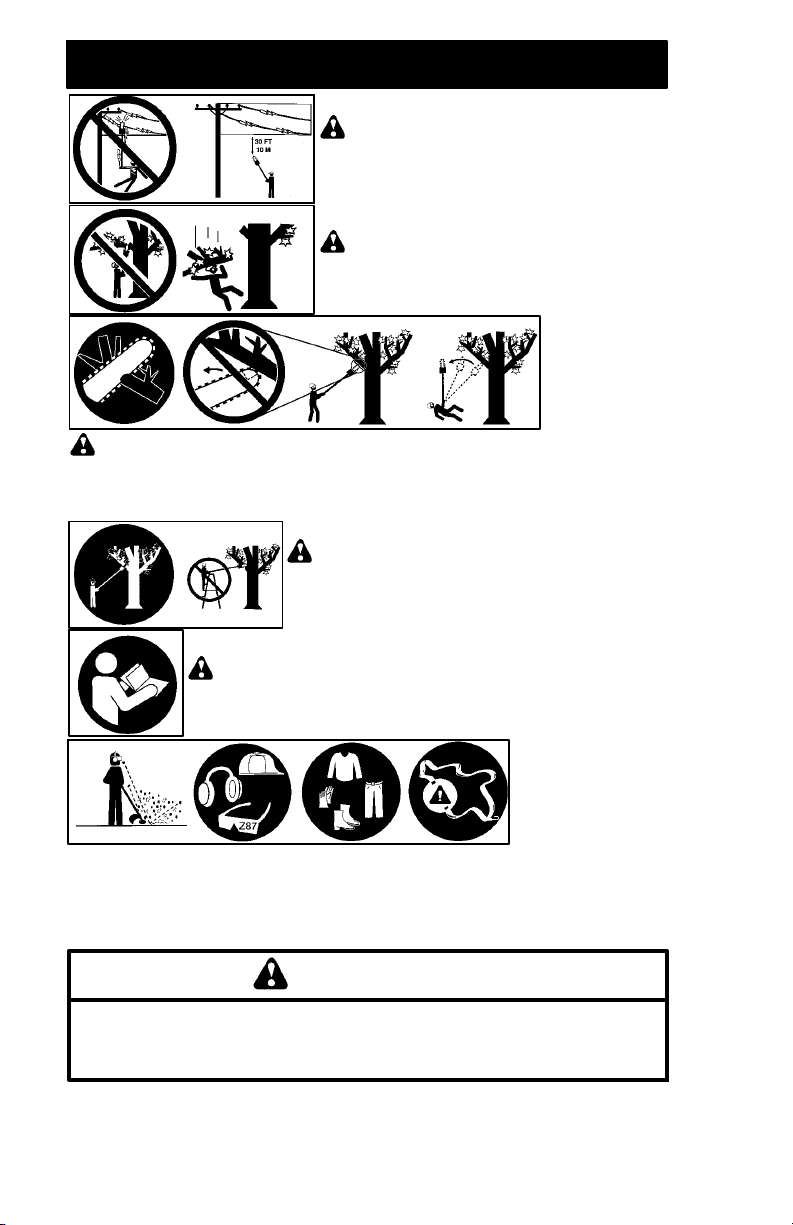

IDENTIFICATION OF SAFETY SYMBOLS

DANGER: To prevent electrocution, do

not use near electrical wires or power lines. Keep

pruner at least 30 feet (10 meters) away from all

power lines.

DANGER: Falling objects can cause severe

head injury. Wear head protection when operating

this unit. Do not stand beneath branch being cut.

WARNING: Avoid kickback which can result in serious injury. Kickback is the back-

ward, upward or sudden forward motion of the guide bar occurring when the chain near the

upper tip of the guide bar contacts any object such as a log or branch, or when the wood

closes in and pinches the chain in the cut. Contacting a foreign object in the wood can also

result in loss of control.

WARNING: Do not operate pruner from a ladder

or unstable support. Always cut with both feet on solid

ground to prevent being pulled off balance.

WARNING: Read the operator’s manual before use. Failure to

follow instructions could result in serious injury to the operator and/or

bystanders. Save operator’s manual.

Trimmer line can throw objects violently. You can be blinded or injured. W ear protective gear.

Always use steel-toed safety footwear with non-slip soles; snug-fitting clothing; heavy, long

pants, and long sleeves; heavy-duty, non-slip gloves; eye protection marked Z87 such as nonfogging, vented goggles or face screen; an approved safety hard hat; and sound barriers (ear

plugs or mufflers) to protect your hearing. Regular users should have hearing checked regularly

as engine noise can damage hearing. Always use shoulder strap when operating unit.

WARNING

The engine exhaust from this product contains

chemicals known to the State o f California to cause

cancer, birth defects or other reproductive harm.

2

Page 3

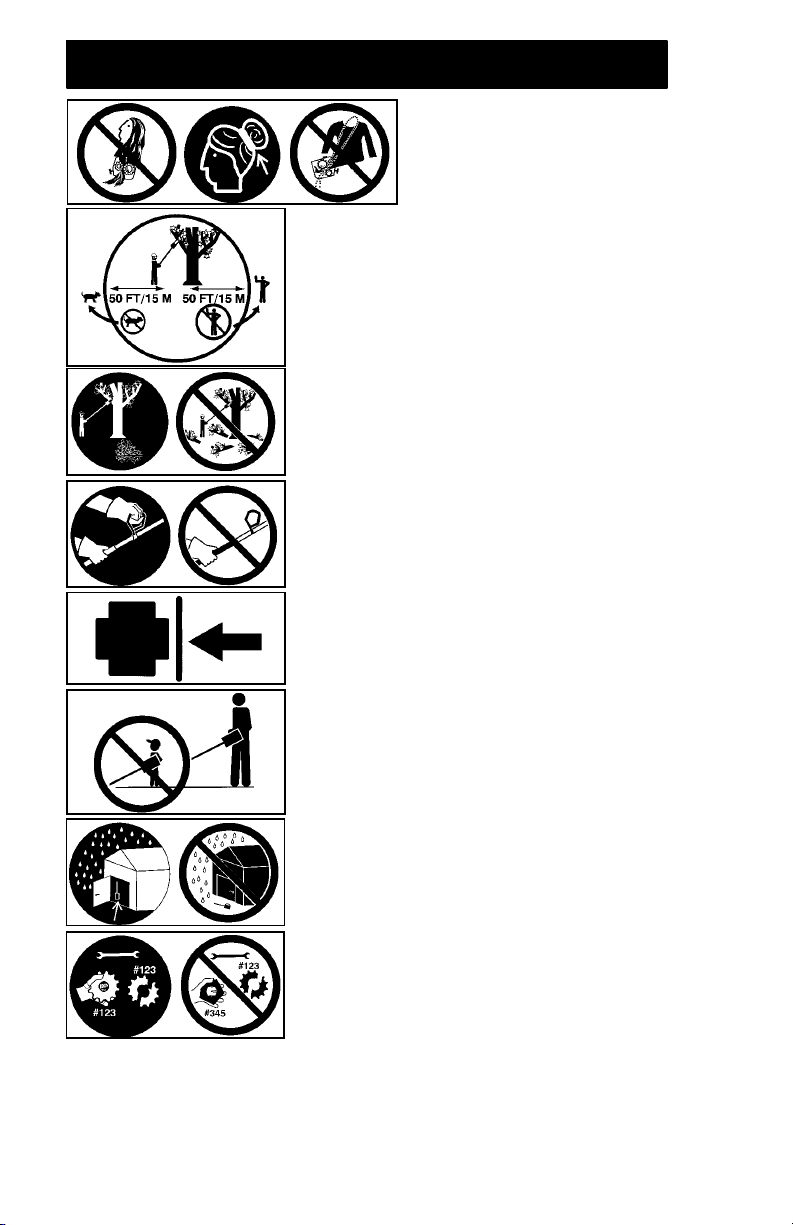

IDENTIFICATION OF SAFETY SYMBOLS

Secure hair above shoulder length. Do

not wear jewelry, loose clothing, or

clothing with loosely hanging straps,

ties, tassels, etc. They can be caught in

moving parts.

Hazard zone. Keep children, bystanders, and animals

a minimum of 50 feet (15 meters) away from the work

area. Do not allow other people or animals to be near

when starting or operating the pruner.

Carefully plan your pruning operation in advance. Do not

start cutting until you have a clear work area, secure

footing, and a planned retreat path.

Do not operate a pruner with one hand. Serious injury to the

operator, helpers, bystanders or any combination of these

persons may result from one-handed operation. A pruner is

intended for two-handed use.

Assist handle to be positioned only below

the arrow.

Never allow children to operate this unit.

Store unit indoors in a high, dry place out of the reach of

children.

When servicing unit, use only identical replacement

parts.

3

Page 4

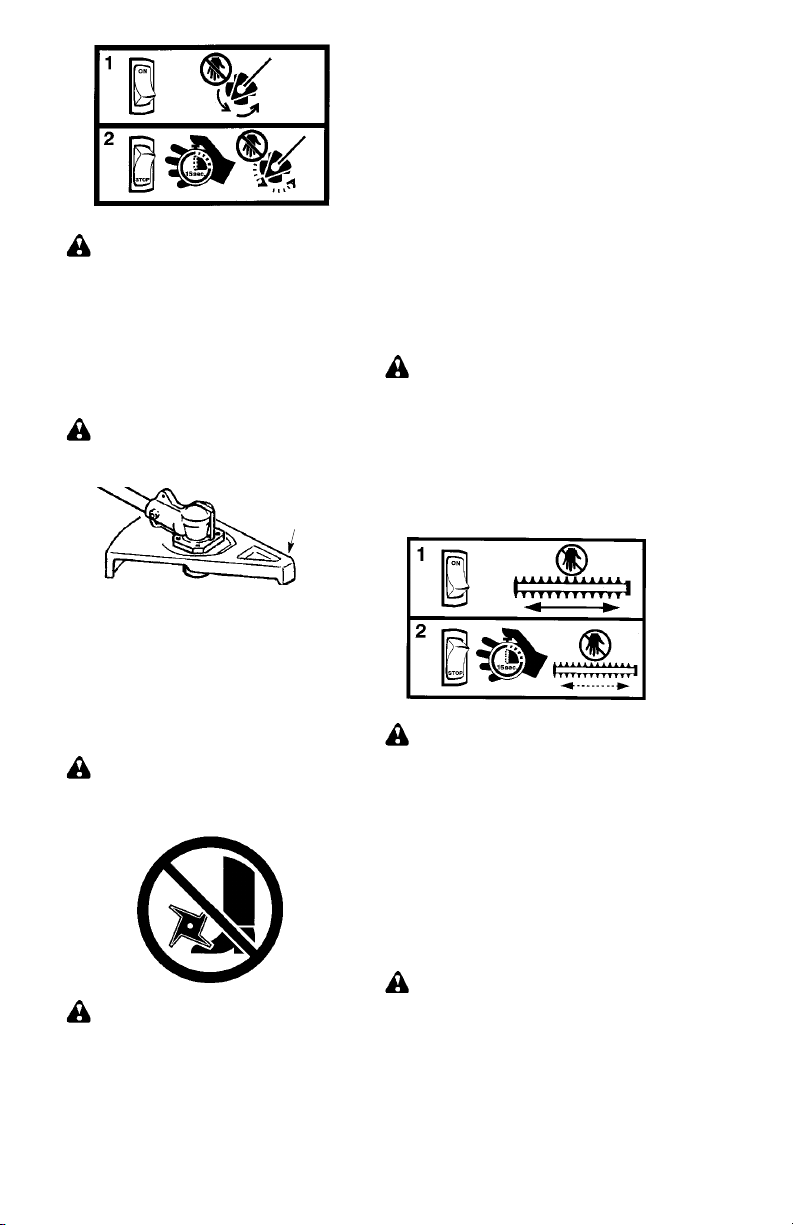

IDENTIFICATION OF SAFETY SYMBOLS

Always stop unit and disconnect spark plug before cleaning or servicing.

WARNING: Fire hazard. Never mix, pour, or store gasoline or

use the unit near a flame or sparks (including smoking, open flames, or

work that can cause sparks).

Use unleaded gasoline and two--stroke oil mixed at a ratio of

40:1 (2.5%).

SAFETY RULES

WARNING: Always disconnect spark

plug wire and place wire where it cannot contact

spark plug to prevent accidental starting when

setting up, transporting, adjusting or making repairs except carburetor adjustments.

Because a pruner is a high-speed wood-cutting

tool, special safety precautions must be observed to reduce therisk of accidents. Careless

or improper use of this tool can cause serious or

even fatal injury.

PLAN AHEAD

S Read this manual carefully until you

completely understand and can follow all

safety rules, precautions, and operating

instructions before attempting to use the unit.

S Restrict the use of your pruner to adult users

who understand and can follow safety rules,

precautions, and operating instructions found

on the unit and in this manual.

INSTRUCTION

MANUAL

S Keep all parts of your body away from the

chain when the engine is running.

S Do not handle or operate a pruner when you

are fatigued, ill, or upset, or if you have taken

alcohol, drugs, or medication. You must be in

good physical condition and mentally alert. If

you have any condition that might be

aggravated by strenuous work, check with

doctor before operating a pruner.

If situations occur which are not covered in

this manual, use care and good judgment. If

you need assistance, contact yourauthorized

service dealer or call 1-800-554-6723.

SAFETY INFORMATION

ON THE UNIT

OPERATE YOUR PRUNER SAFELY

S Operate the pruner only in a well-ventilated

outdoor area.

S Do notuse a prunerto cut down trees or any

portion of the tree trunk.

S Only use for pruning limbs or branches

overhead not greater than 6 inches (15cm)

in diameter.

S Do notcut smallbrush andsaplings withthe

pruner. Slender matter may catch in the

chain and be whipped toward you, pulling

you off balance.

S Make sure the chain will not make contact

with any object while starting the engine.

Never try to start the unit when the guide

bar is in a cut.

S Do notput pressure on the pruner at theend

of the cut. Applying pressure can cause you

to lose control when the cut is completed.

S Do not run the unit at high speed when not

pruning.

S If you strike or become entangled with a

foreign object, stop the engine immediately

and check for damage. Have any damage

repaired by an authorized service dealer

before attempting further operations.

S Do not operate a pruner that is damaged,

improperly adjusted, or not completely and

securely assembled. Always replace bar

and chain immediately if it becomes

damaged, broken or is otherwise removed.

S Always stop the unit when work is delayed

or when walking from onecutting locationto

another. Stop the engine before setting the

unit down.

S Use only in daylight or good artificial light.

S Use only for jobs explained in this manual

(or manuals for optional attachments).

4

Page 5

MAINTAIN YOUR PRUNER IN GOOD

WORKING ORDER

S Have all service performed by a qualified

service dealer with the exception of the

items listed in the maintenance section of

this manual.

S Make certain the chain stops moving when

the throttle trigger is released. For correction,

refer to IDLE SPEED ADJUSTMENT.

S Never modify your unit in any way.

S Keep the handles dry, clean, and free of oil

or fuel mixture.

S Keep fuel and oil caps, screws, and

fasteners securely tightened.

S Make idle speed adjustments with lower

end supported to prevent chain from

contacting any object.

S Keep others away when making idle speed

adjustments.

S Use only Poulan PRO accessories and

replacement parts as recommended.

HANDLE FUEL WITH CAUTION

S Do not smoke while handling fuel or while

operating the pruner.

S Eliminate all sources of sparks or flame in

the areas where fuel is mixed or poured.

There should be no smoking, open flames,

or work that could cause sparks. Allow

engine to cool before refueling.

S Mix andpour fuel inan outdoorarea on bare

ground; store fuel in a cool, dry, well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuelspills before startingengine.

S Move atleast 10 feet(3 meters) from fueling

site before starting engine.

S Turn the engine off and let unit cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

S Store the unit and fuel in an area where fuel

vapors cannot reach sparks or openflames

from water heaters, electric motors or

switches, furnaces, etc.

KICKBACK

WARNING: Avoid kickback which

can result in serious injury. Kickback is the

backward, upward or sudden forward motion

of the guide bar occurring when the chain

near the upper tip of the guide bar contacts

any object such as a log or branch, or when

the wood closes in and pinches the chain in

the cut. Contacting a foreign object in the

wood can also result in loss of control.

S Rotational Kickback can occur when the

moving chain contacts an object at the upper

tip of the guide bar. This contact can cause

the chain to dig into the object, which stops

the chain for an instant. The result is a

lightning fast, reverse reaction which kicks the

guide bar up and back toward the operator.

S Pinch-Kickback can occur when the wood

closes in and pinches the moving chain in

the cut alongthetop ofthe guide barand the

chain is suddenly stopped. This sudden

stopping ofthe chain results ina reversal of

the chain force used to cut wood and

causes the pruner to move in the opposite

direction ofthe chain rotation. The pruner is

driven straight back toward the operator.

S Pull-In can occur when the moving chain

contacts a foreign object inthe wood in the cut

along the bottom of the guide bar and the

chain is suddenly stopped. This sudden

stopping pulls the pruner forward and away

from the operator and could easily cause the

operator to lose control of the pruner.

REDUCE THE CHANCE OF

KICKBACK

S Recognize that kickback can happen. With

a basic understanding of kickback, you can

reduce the element of surprise which

contributes to accidents.

S Never let the moving chain contact any

object at the tip of the guide bar.

S Keep the working area free from

obstructions such as other trees,branches,

rocks, stumps, etc. Eliminate or avoid any

obstruction that your chain could hit while

you are cutting. When cutting a branch, do

not let the guide bar contact branch or other

objects around it.

S Keep your chain sharp and properly

tensioned. A loose or dull chain can

increase the chance of kickback occurring.

Follow manufacturer’s chain sharpening

and maintenance instructions. Check

tension at regular intervals with the engine

stopped, never with the engine running.

Make sure the bar clamp nut is securely

tightened after tensioning the chain.

S Begin and continue cutting at full speed. If

the chainis movingat a slower speed, there

is greater chance of kickback occurring.

S Cut one branch at a time.

S Use extreme caution when re-entering a

previous cut.

S Do not attempt cuts starting with the tip of

the bar (plunge cuts).

S Watch for shifting of wood or other forces that

could close a cut and pinch or fall into chain.

S Use the Reduced--Kickback Guide Bar and

Low- -Kickback Chain specified for your unit.

MAINTAIN CONTROL

S Keep a good, firm grip on the pruner with

both hands when the engine is running and

don’t let go. A firm grip will help you reduce

kickback and maintain control. Keep the

fingers of your left hand encircling and your

5

Page 6

left thumb under the assist handle. Keep

your right hand completely around the

throttle handle whether your are right

handed or left handed.

S Stand with your weight evenly balanced on

both feet.

S Stand slightly tothe leftside ofthe pruner to

keep your body from being in a direct line

with the cutting chain.

KICKBACK SAFETY FEATURES

The following features are included on your

pruner to help reduce the hazard of kickback;

however, such features will not totally eliminate

this danger. As a pruner user, do not rely only

on safety device s. Y o u must follow all saf e t y

precautions, instructions, and maintenance in

this manual to help avoid kickback and other

forces which can result in serious injury.

S Reduced--Kickback Guide Bar, designed with

a small radius tip which reduces the size of

the kickback danger zone on the bar tip.

Reduced Kickback Symmetrical Guide Bar

Small Radius Tip

Symmetrical Guide Bar

SPECIAL NOTICE: This unit is equipped

with a tempe rature limiting muffle r and spark arresting screen which meets the requirements of

California Codes 4442 and 4443. All U.S. forest

land and the states of California, Idaho, Maine,

Minnesota, New Jersey, Oregon, and Washington require by law that many internal combustion engines be equipped with a spark arresting

screen. If you operate in a locale where such

regulations exist, you are legally responsible for

maintaining the operating condition of these

parts.Failuretodosoisaviolationofthelaw.

For normal homeowner use, the muffler and

spark arresting screen will not require any service. After 50 hours of use, we recommend that

your muffler be serviced or replaced by an authorized service dealer.

ADDITIONAL SAFETY RULES

FOR OPTIONAL ATTACHMENTS

WARNING: For each optional at-

tachment used, read entire instruction manual before use and follow all warnings and instructions in manual and on attachment.

WARNING: Ensure handlebar is

installed when using brushcutter attachment.

Attach handlebar above arrow on safety label

on the upper shaft (engine end of unit). If your

brushcutter attachment does not include a handlebar, a handlebar accessory kit (#530071451)

is available from your authorized service dealer.

S Low-- Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter .

Contoured D epth Gauge

L o w --- K i c k b a c k

Chain

N o t a Lo w --- K i ck b a c k Ch a i n

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause bloodvessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or abnormal swellings. Prolonged use in cold

weather has been linked toblood vessel damage in otherwise healthy people. Ifsymptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek medical attention. An anti--vibration system does

not guarantee the avoidance of these problems. Users who operate power tools on a

continual and regular basis must monitor

closely their physical condition and the condition of this tool.

Large Radius Tip

Elongated Guard Link

Deflects

kickback force

and allows wood

to gradually ride

into cutter

Can Obstruct Material

Handlebar

LINE TRIMMER SAFETY

WARNING: Never use blades with

line trimmer attachment. Never use flailing

devices with any attachment. Use of any other accessories with line trimmer attachment

will increase the risk of injury.

WARNING: Trimmer line throws ob-

jects violently. Y ou and others can be blinded/injured. Wear eye and leg protection. Keep body

parts clear of rotating line.

WARNING: Keep children, bystand-

ers, and animals 50 feet (15 meters) away. Bystanders should be encouraged to wear safety

glasses. Stop unit immediately if approach ed.

6

Page 7

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., thatcan

ricochet, be thrown, or otherwise cause injury

or damage during operation.

S Use only for trimming, scalping, mowing and

sweeping. Do not use for edging, pruning or

hedge trimming.

S Cut from your right to your left. Cutting on

left side of the shield will throw debris away

from the operator.

EDGER SAFETY

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., thatcan

ricochet, be thrown, or otherwise cause injury

or damage during operation.

WARNING: Blade rotates momen-

tarily after the trigger is released or engine is

turned off. The blade can seriously cut you or

others. Allow blade to stop before removing it

from the cut.

S Do not set unit on any surface except a

clean, hard area while engine is running.

Debris such as gravel, sand, dust, grass,

etc., could be picked up by the air intake

and thrown out through discharge opening,

damaging unit, property, or causing serious

injury to bystanders or operator.

S Never place objects inside the blower tubes,

vacuum tubes or blower outlet. Always direct

the blowing debris away from people, animals, glass, and solid objects such as trees,

automobiles, walls, etc. The force of air can

cause rocks, dirt, or sticks to be thrown or to

ricochet which can hurt people or animals,

break glass, or cause other damage.

S Never run unit without the proper equip-

ment attached. When using your unit as a

blower, always install blower tubes.

S Check air intake opening, blower tubes or

vacuum tubes frequently, always with engine stopped and spark plug disconnected.

Keep vents and discharge tubes free of debris which can accumulate and restrict

proper air flow.

S Never place any object in air intake opening

as this could restrict proper air flow and

cause damage to the unit.

S Never use for spreading chemicals, fertiliz-

ers, or other substances which may contain

toxic materials.

S Toavoid spreading fire, do not use near leaf

or brush fires, fireplaces, barbecue pits,

ashtrays, etc.

BRUSHCUTTER SAFETY

DANGER: Blade can thrust violently

away from material it does not cut. Blade

thrust can cause amputation of arms or legs.

S Throw away blades that are bent, warped,

cracked, broken or damaged in any other

way. Replace parts that are cracked,

chipped, or damaged before using the unit.

S Do not attempt to remove cut material nor

hold material to be cut when the engine is

running or when cutting blade is moving.

S Always keep the wheel and depth adjusting

skid in contact with the ground.

S Always push the unit slowly over the

ground. Stay alert for uneven sidewalks,

holes in the terrain, large roots, etc.

BLOWER/VACUUM SAFETY

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks,glass, wire, etc. that can

ricochet, be thrown, or otherwise cause injury

or damage during operation.

WARNING: Do not use trimmer head

as a fastening device for the blade.

WARNING: The blade continues to

spin after the trigger is released or engine is

turned off. The coasting blade can throw objects or seriously cut you if accidentally

touched. Stop the blade by contacting the

right hand side of the coasting blade with material already cut.

7

Page 8

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., thatcan

ricochet, be thrown, or otherwise cause injury

or damage during operation.

S Throw away and replace blades that are

bent, warped, cracked, broken or damaged

in any other way.

S Install required shield properly before using

the unit. Use the metal shield for all metal

blade use.

WARNING: Only use brushcutter at-

tachments that provide a metal shield with

proboscis nose.

Proboscis

nose

S Useonly specified bladeand make sure it is

properly installed and securely fastened.

S Cut from your left to your right. Cutting on

the right side of the shield will throw debris

away from the operator.

S Always use the handlebar and a properly

adjusted shoulder strap with blade(see AS-

SEMBLYinstructions in brushcutter attach-

ment instruction manual).

CULTIVATOR SAFETY

WARNING: Rotating tines can cause

serious injury. Keep away from rotating tines.

Stop the engine and disconnect the spark plug

before unclogging tines or making repairs.

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., thatcan

ricochet, be thrown, or otherwise cause injury

or damage during operation.

S Avoid heavy contact with solid objects that

might stop the tines. If heavy contact occurs, stop the engine and inspect the unit

for damage.

S Never operate the cultivator without thetine

cover in place and properly secured.

S Keep the tines and guard clear of debris.

S After striking a foreign object, stop the engine,

disconnect the spark plug andinspect the cultivator for damage. Repair before restarting.

S Disconnect attachment from the drive en-

gine before cleaning the tines with a hose

and water to remove any build--up. Oil the

tines to prevent rust.

S Always wear gloves when servicing or

cleaning the tines. The tines become very

sharp from use.

S Do not run unit at high speed unless culti-

vating.

HEDGE TRIMMER S AF ETY

WARNING: RISK OF CUT; KEEP

HANDS AWAY FROM BLADE -- Blade

moves momentarily after the trigger is released or engine is turned off. Do not attempt

to clear away cut materialwhen the blade isin

motion. Make sure engine is stopped, the

spark plug wire is disconnected, and the

blade has stopped moving before removing

jammed material from the cutting blade. Do

not grab or hold the unit by the cutting blade.

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., that can

ricochet, be thrown, or otherwise cause injury

or damage during operation.

S Do not use a cutting blade that is bent,

warped, cracked, broken or damaged in any

other way. Have worn or damaged parts replaced by your authorized service dealer.

S Always keep unit in front of your body.

Keep all parts of your body away from the

cutting blade.

S Keep the cutting blade and airvents clearof

debris.

SNOW THROWER SAFETY

WARNING: Keep hands and feet

away from the rotor when starting or running

the engine. Never attempt to clear the rotor

with the engine/motor running. Stop engine

and disconnect spark plug before unclogging

snow or debris from discharge chute or when

adjusting vanes.

8

Page 9

WARNING: Never lean over dis-

charge chute. Rocks or debris could be

thrown intothe eyes and face and cause serious injury or blindness.

WARNING: Inspect area before

starting unit. Remove all debris and hard objects such as rocks, glass, wire, etc., thatcan

ricochet, be thrown, or otherwise cause injury

or damage during operation.

S Direct material discharge away from glass

enclosures, automobiles, etc.

S Do not run engine at high speed while not

removing snow.

S Be attentive when using the snowthrower,

and stay alert for holes in the terrain and

other hidden hazards.

S Make sure the rotor will spin freely before at-

taching the snowthrower to the powerhead.

ASSEMBLY

CAUTION: If received assembled, repeat

all steps to ensure your unit is properly assembled and all fasteners are secure.

Examine parts for damage. Do not use damaged parts.

NOTE: If you need assistance or find parts

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fuel or oil residue on muffler is normal

due to carburetor adjustments and testing

done by the manufacturer.

TOOLS REQUIRED

S Hex wrench (provided)

INSTALLING PRUNER ATTACHMENT

CAUTION:

tachments, place the unit on a flat surface for

stability.

NOTE: The pruner attachment connects to

the engine end shaft through use of a coupler

system. For extra reach, the extension shaft

(included) can be used.

1. Loosen the couplers on the extension

When removing or installing at-

shaft andon the engine endshaft by turning the knobs counterclockwise.

S If the rotor will not rotate freely due tofrozen

ice, thaw the unit before thoroughly before

attempting to operate under power.

S Keep the rotor clear of debris.

S Do not throw snow near other people. The

snow thrower could propel small objects at

high speed causing injury.

S After striking a foreign object, stop the en-

gine, disconnect spark plug and inspect the

snowthrower for damage and repair if necessary before restarting unit.

S Never operate the snowthrower near glass

enclosures, automobiles and trucks.

S Never attempt to use the snowthrower ona

roof.

S Never operate the snowthrower near win-

dow wells, dropoffs, etc.

S Never discharge snow onto public roads or

near moving traffic.

S Clear snow from slopes by going up and

down; never across. Use caution when

changing directions. Never clear snow from

steep slopes.

S Let snowthrower run for a few minutes after

clearing snow so moving parts do not freeze.

S Look behind and use care when backing

up. Exercise caution to avoid slippingor falling, especially when operating in reverse.

S Know how to stop quickly.

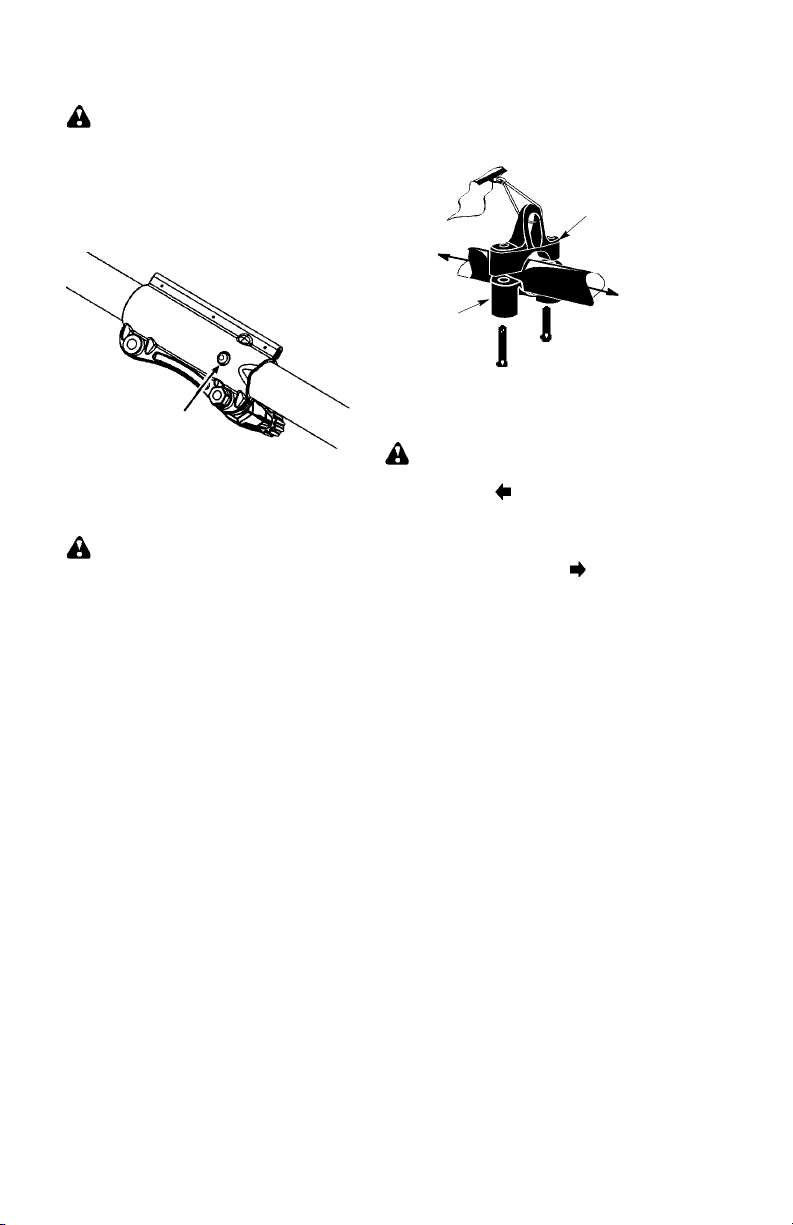

Coupler

Shipping

protector

2. Remove shipping protectors from

couplers.

3. Remove shaft caps from pruner attachment and extension shaft (if present).

4. Position locking/release button ofattachment into guide recess of coupler on

extension shaft.

5. Push the attachment intothe coupler until

the locking/release button snaps into the

primary hole.

Coupler

LOOSEN

Knob

TIGHTEN

Primary Hole

Guide Recess

Upper

Shaft

Locking/

Release

Button

Attachment

9

Page 10

6. Repeat steps to attach extension shaft to

coupler on engine end shaft.

7. Before using the unit, tighten both knobs

securely by turning clockwise.

WARNING: Make sure the locking/

release button is locked in the primary holeof

both couplers and the knobs are securely

tightened before operating the unit. All attachments are designed to be used in the primary

hole unless otherwise stated in the applicable

attachment instruction manual. Using the wrong

hole could lead to serious injury or damage to

the unit.

TO RELOCATE SHOULDER STRAP

CLAMP:

1. Loosen and remove both clamp screws.

2. Place the upper shoulder strap clamp

over the upper shaft.

3. Position the lower shoulder strap clamp

under the upper shaft andalign theupper

and lower clamp screw holes.

Upper Shoulder

Strap Clamp

POWERHEAD

END

Locking/Release

Button in Primary Hole

For assembly of optional attachments (see

list on page 13), refer to the ASSEMBLYsection of the applicable attachment instruction

manual.

SHOULDER STRAP ASSEMBLY

WARNING: Proper shoulder strap

adjustments must be made with the engine

completely stopped before using unit.

1. Try on shoulder strap and adjust for fit

and balance before starting the engine or

beginning a cutting operation.

2. Insert your right arm and head through

the shoulder strap and allow it to rest on

your left shoulder. Make sure the danger

sign is centered on your back and the

hook is to the right side of your waist.

NOTE: A one-half twist is built in the shoul-

der strap to allow the strap to rest flat on the

shoulder.

3. Adjust the strap, allowing the hook to be

about 3 -- 6 inches (8 -- 15 cm) below the

waist.

4. Fasten the strap hook to the clamp located betweenthe throttle handle andthe

assist handle and lift the tool to the operating position.

NOTE: It may be necessary to relocate the

shoulder strap clamp on the shaft for proper

balancing of unit.

Lower Shoulder

Strap Clamp

4. Insert two screws into the screw holes.

5. Secure shoulder strap clamp by tightening screws with a hex wrench.

ATTACHMENT

END

Screws

ADJUSTING THE ASSIST HANDLE

WARNING: When adjusting the as-

sist handle, be sure it remains between the

coupler and the

coupler) on the safety label to ensure proper

balancing of unit. When adjusting the assist

handle or handlebar during use of optional attachments, it must be repositioned between

the throttle trigger and the

(closest to engine) on the safety label.

1. Loosen wing nut on handle.

2. Rotate the handle on the shaft to an upright position; retighten wing nut.

lower arrow (closest to

upper arrow

10

Page 11

OPERATION

f

KNOW YOUR PRUNER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT.

Compare the illustrations with your unit to familiarize yourself with the location of the various controls

and adjustments. Save this manual for future reference.

Pruner

Shaft

Assist Handle

Muf

ler

Attachment

Hanger

Chain

Bar

Extension Shaft

ON/STOP SWITCH

The ON/STOP switch is located on the trigger

handle and is used to stop the engine. To stop

the engine, push and release the engine ON/

STOP switch.

PRIMER BULB

The PRIMER BULBremoves air from thecarburetor and fuel lines and fills them with fuel.

This allows you to start the engine with fewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to return to

its original form.

START LEVER

The START LEVER helps to supply fuel to the

engine to aid in starting. Activate the starting

Bar oil fill cap

Bar nut

ON/STOP

Switch

BEFORE STARTING ENGINE

WARNING: Be sure to read the fuel

information in the safety rules before you begin. If you do not understand the safety rules,

do not attempt to fuel your unit. Call

1-800-554-6723.

FUELING ENGINE

WARNING: Remove fuel cap slowly

when refueling.

HELPFUL TIP

Toobtain the correct oil mix

ratio, pour 3.2 ounces of

2-- cycle synthetic oil into

one gallon of fresh gas.

Coupler

Throttle Trigger

Spark Plug

Starter Handle

system by movin g the sta r t lever to the START

position. DO NOT squeeze the throttle trigger

until the engine has started and runs. After the

engine starts, allow the engine to warm--up 5

seconds, then fully squeeze the throttle trigger

to deactivate the starting system.

COUPLER

The COUPLER enables optional attachments to be installed on the unit.

CHAIN TENSION

It is normal for a new chain to stretch during

first 15 minutes of operation. You should

check your chain tension frequently. See

CHAIN TENSION in the SERVICE AND ADJUSTMENTS section.

IMPORTANT: This equipment is designed to

operate on unleaded gasoline with a minimum

87 octane (R+M/2 method), with ethanol

blended up to 10% maximum by volume (E-10).

Before operation, gasoline must bemixed with a

good quality synthetic 2-cycle air-cooled engine

oil designed to be mixed at a ratio of 40:1.

Poulan/WEED EATER brand synthetic oil is

recommended. Mix gasoline and oil at a ratio of

40:1. A 40:1 ratio is obtained by mixing 3.2 fluid

ounces of oil with 1 gallon of unleaded gasoline.

DO NOT USE automotive oil or marine oil.

These oils will cause engine damage. When

mixing fuel, follow instructions printed on

container. Once oil is added to gasoline, shake

container momentarily to assure that the fuel is

thoroughly mixed. Always read and follow the

safety rules relating to fuel before fueling your

unit. Purchase fuelin quantities thatcan be used

within 30 days to assure fuel freshness.

Primer Bulb

Start Lever

11

Page 12

CAUTION: Never use straight gasoline in

your unit. This will cause permanent engine

damage and void the limited warranty. Do not

use alternate fuels such as ethanol blends

above 10% by volume (E-15, E-85) or any

methanol blended fuel. Use of these fuels can

cause major engine performance and durability

problems.

BAR AND C HAIN LUBRICATION

The bar and chain require lubrication. Thechain

oiler provides continuous lubrication to thechain

and guide bar. Be sure to fill the bar oil tank

when you fill the fuel tank (Capacity = 4.6 fl. oz.).

Lack of oil will quickly ruin the bar and chain.

T oo little oil will cause overheating shown by

smoke coming from the chain and/or discoloration of the bar. The oil output is automatically

metered during operation. Always fill the bar oil

tank when you fill the fuel tank.

Genuine Poulan or Poulan PRO bar and

chain oil is recommended to protect your unit

against excessive wear from heat and friction. Poulan or Poulan PRO oil resists high

temperature thinning. If Poulan or Poulan

PRO bar and chain oil is not available, use a

good grade SAE 30 oil.

S Never use waste oil for bar and chain

lubrication.

S Always stop the engine before removing

the oil cap.

HOW TO STOP YOU R UNIT

S Release the throttle trigger.

S Push and release the engine ON/STOP

switch. The switch will automatically return

to the ON position. W ait 5 seconds before

attempting to restart unit to allow switch to

reset.

ON/STOP

Switch

HOW TO START YOUR UNIT

WARNING: Make sure the chain will

not make contact with any object while starting the engine. Never try to start the unit when

the guide bar is in a cut. Avoid any contact

with the muf fler. A hot muffler can cause serious burns.

Starting position

HELPFUL TIP

If your engine still does not

start after following these

instructions, please call

1--800--554--6723.

STARTINGACOLDENGINE

NOTE:

DO NOT squeeze the throttle trigger

until the engine has started and runs.

1. Set unit on a flat surface.

2. Slowly press the primer bulb 6 times.

3. Move the start lever to the START position.

Primer Bulb

Start Lever

Starter Handle

4. Pull starter rope handle sharply until engine starts and runs.

5. Allow unit to run for 10--15 seconds, then

fully squeeze the throttle trigger to disengage the starting system.

STARTING A WARM ENGINE

1. Squeeze and hold the throttle trigger.

2. Pull starter rope sharply while squeezing

throttle trigger until engine runs.

NOTE: Normally, the warm starting proce-

dure can be used within 5--10 minutes after

the unit is turned off. If the unit sits for more

than 10 minutes without being ran, it will be

necessary to start the unit by following the

steps under STAR TING A COLD ENGINE or

following the starting instruction steps shown

on the unit.

STARTING A FLOODED ENGINE

Flooded engines can be started by placing

the start lever to the RUN position. Fully

squeeze throttle trigger. Pull the starter handle repeatedly while squeezing throttle trigger

until engine starts and runs. This could require pulling the starter handle many times,

depending on how badly the unit is flooded.

If the unit still doesn’t start, refer to

TROUBLESHOOTING TABLE or call

1-800-554-6723.

12

Page 13

OPERATING THE COUPLER

This model is equipped with a coupler which

enables optional attachments to be installed.

The optional attachments are:

Edger PP1000E.......................

Cultivator PP2000T....................

Blower PP3000B......................

Brushcutter PP4000C..................

WARNING: Always stop unitand dis-

connect spark plug before removing or installing attachments.

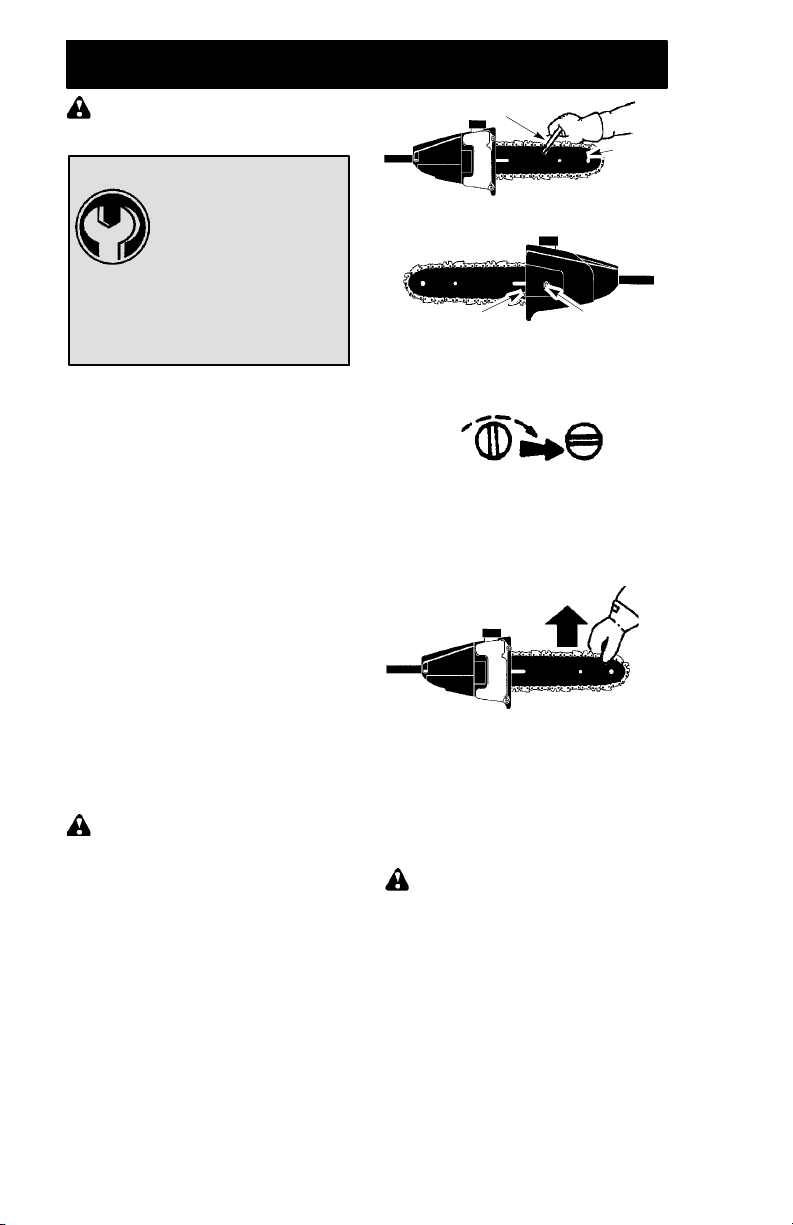

REMOVING PRUNER ATTACHMENT

CAUTION:

tachments, place the unit on a flat surface for

stability.

1. Loosen the coupler by turning the knob

counterclockwise.

When removing or installing at-

Coupler

MODEL:

Upper

Shaft

Primary Hole

Guide Recess

Locking/

Release

Button

Attachment

Coupler

WARNING: Make sure the locking/

release button is locked in the primary hole

and the knob is securely tightened before operating the unit. All attachments are designed

to be used in the primary hole unless otherwise

stated in the applicable attachment instruction

manual. Using the wrong hole couldlead to serious injury or dam age to the unit.

Attachment

2. Press and hold the locking/release button.

Locking/Release

Button

Attachment

3. While securely holding the engine end shaft

and extension shaft, pull the attachment

straight out of the extension shaft coupler.

4. Repeat steps to remove extension shaft

from coupler on engine end shaft.

Coupler

LOOSEN

Knob

TIGHTEN

Upper Shaft

INSTALLING OPTIONAL ATTACHMENTS

CAUTION:

with other optional attachments.

1. Remove the shaft cap from the attachment (if present).

2. Position locking/release button ofattachment into guide recess of coupler on engine end shaft.

3. Push the attachment intothe coupler until

the locking/release button snaps into the

primary hole.

4. Before using the unit, tighten theknob securely by turning clockwise.

DO NOT use extension shaft

Locking/Release

Button in Primary Hole

INSTALLING ATTACHMENT

HANGER

An attachment hanger is provided forstorage

when attachment is not in use.

To install hanger on attachment:

1. Remove the shaft cap from the attachment (if present) and discard.

2. Press and hold the locking/release button.

3. Push hanger onto the attachment until the

locking/release button snaps into the hole.

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operated for longer than 1 minute at full

throttle.

OPERATING POSITION

ALWAYS WEAR:

Head

protection

Eye

protection

Long pants

Heavy

shoes

13

Page 14

DANGER: Do not extend arms above

shoulders while pruning. Do not stand beneath branch being cut.

WARNING: Always wear head, eye,

hearing, foot and body protection to reduce

the risk of injury when operating this unit.

When operating unit, clip shoulder strap onto

clamp, stand as shown and check for the following:

S Extend your leftarm andhold assist handle

with your left hand.

S Hold throttle grip with your right hand with

finger on throttle trigger.

S Keep engine end below waist level.

S Keep shoulder strap pad centered on your

left shoulder and danger sign centered on

your back.

S Maintain full weight of tool on your left

shoulder.

Always release the throttle trigger and allow the

engine to return to idle speed when not pruning.

To stop engine:

S Release the throttle trigger.

S Push and release the engine ON/STOP

switch.

PRUNING

WARNING: Be alert for and guard

against kickback. Do not allow the moving

chain to contact any other branches or objects at the nose of the guide bar when pruning. Allowing such contact can result in serious injury.

IMPORTANT POINTS

S Work slowly, keeping both hands firmly

gripped on the pruner. Maintain secure

footing and balance.

S Plan cut carefully. Check direction branch

will fall.

S Watch out for springpoles. Springpoles are

small size lim bs which can catch the chain

and whip toward you or pull you of f balance.

Use extreme caution when cutting small size

limbs or slender material.

S Watch out for branches immediately behind

the branch being pruned. If the chain hits the

rear branch, damage to the unit may occur.

S Be alert for springback. Watch out for

branches that are bent or under pressure.

Avoid being struck by the branch or the

pruner when the tension in the wood fibers

is released.

S Keep a clear work area. Frequently clear

branches out of the way to avoid tripping

over them.

S Long branches should be removed in

several pieces.

PRUNING TECHNIQUE

When ready to cut, accelerate to full throttle

and apply a light cutting pressure. DO NOT

use back and forth sawing action.

Second cut

Third cut

Collar

First cut

Pruning technique

1. Make the first cut 6 inches (15 cm) from

the tree trunk on the bottom of the limb.

Use topof guidebar to make this cut. Cut

1/3 through the diameter of the limb.

NOTE: When making the second and third

cuts, rest the foot of the pruner against the

tree limb that is being cut to prevent whipping

of the branch.

Foot

2. Next, move 2 -- 4 inches (5 -- 10 cm) farther out on the limb and make a second

cut all the way through the limb.

3. Then,make a finalcut leavinga 1-- 2 inch

(2.5 -- 5 cm) collar from the trunk of the

tree to avoid damage to the tree.

14

Page 15

MAINTENANCE

WARNING: Disconnect the spark

plug before performing maintenance except

for idle speed adjustments.

HELPFUL TIP

IMPORTANT: Have all

repairs other than the recommended maintenance

described in the instruction

manual performed by an

If any dealer other than an authorized

service dealer performs work on the

product, Poulan PRO may not pay for

repairs under warranty. It is your responsibility to maintain and perform

general maintenance.

CHECK FOR LOOSE

FASTENERS AND PARTS

S Spark Plug Boot

S Air Filter

S Housing Screws

S Assist Handle Screw

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

S ON/STOP Switch -- Ensure ON/STOP

switch functions properly by pushing and

releasing the switch. Make sure engine

stops. Wait 5 seconds before attempting to

restart unit to allow switch to reset. Restart

engine and continue.

S Fuel tank -- Discontinue use of unit if fuel

tank shows signs of damage or leaks.

S Oil tank -- Discontinue use of unit if oil tank

shows signs of damage or leaks.

INSPECT AND CLEAN UNIT AND LABELS

S After each use, inspect complete unit for

loose or damaged parts. Cleanthe unit and

labels using a damp cloth with a mild detergent.

S Wipe off unit with a clean dry cloth.

CHECK CHAIN TENSION

WARNING: Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is not moving. Make

chain adjustments with lower end supported.

Chain tension is very important. Chains

stretch duringuse. Thisis especially trueduring the first fewtimes youuse your pruner. Always check chain tension each time you use

and refuel your unit.

1. Use the screwdriver end of the chain adjustment tool (bar tool) to move chain

around guide bar to ensure kinks do not

exist. The chain should rotate freely.

authorized service dealer.

Chain Adjustment Tool

Guide

Bar

2. Loosen bar clamp nut until it is finger tight

against the bar clamp.

Adjusting Screw

3. Turn adjusting screw clockwise until

chain solidly contacts bottomof guide bar

rail. Then, turn adjusting screw an additional 1/4 turn.

Adjusting Screw -- 1/4 Turn

4. Using bar tool, roll chain around guide bar

to ensure all links are in bar groove.

5. Lift up tip of guide bar to check for sag.

Release tip of guide bar,then turnadjustingscrew1/4 turnclockwise. Repeat until

sag does not exist.

6. While lifting tip of guide bar, tighten bar

clamp nut securely with the bar tool.

7. Use the screwdriver end of the bar tool to

move chain around guide bar.

8. If chain does not rotate, it is too tight.

Slightly loosen bar clamp nut and loosen

chain by turning the adjusting screw 1/4

turn counterclockwise. Retighten bar

clamp nut.

9. If chain is too loose, it will sag below the

guide bar and needs to be tightened following above procedure.

WARNING: DO NOT operate the

pruner if the chain is loose. If the pruner is operated with a loose chain, the chain could jump off

the guide bar and result in serious injury.

CHECK CHAIN SHARPNESS

A sharp chain makes wood chips. A dullchain

makes a sawdust powder and cuts slowly.

See CHAIN SHARPENING in the SERVICE

AND ADJUSTMENTS secti o n.

Bar clamp nut

15

Page 16

CLEAN AIR FILTER

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keep dirt from falling into the carburetor

chamber when the cover is removed.

2. Remove parts by pressing button to release air filter cover.

NOTE: To avoid creating a fire hazard or

producing harmful evaporative emissions, do

not clean filter in gasoline or other flammable

solvent.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Replace parts.

Button

Air Filter

Air Filter Cover

BAR MAINTENANCE

If your pruner cuts to one side, has to be

forced throughthe cut, or been run with an improper amount of bar lubrication it may be

necessary to service your bar. Aworn bar will

damage your chain and make cutting difficult.

After each use, clean all sawdust from the

guide bar and sprocket hole.

To maintain guide bar:

S Disconnect spark plug.

S Loosen and remove bar clamp nut and

chain brake. Remove bar and chain from

pruner.

S Clean the oil holes and bar groove after

each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

with a flat file.

S When rail top is uneven, use a flat file to

restore square edges and sides.

File Rail Edges

and Sides

Square

Replace guide bar when the groove is worn,

the guide bar is bent or cracked, or when

excess heatingor burringof the rails occurs. If

replacement is necessary, use only the guide

bar specified for your pruner in the repair

parts list.

Correct GrooveWorn Groove

LUBRICATION

Bar Oil

Fill Cap

S See GUIDE BAR AND CHAIN OIL under

the OPERATION section.

MUFFLER AND SPARK ARR ESTING SCREEN

WARNING: The muffler on this prod-

uct contains chemicals known to the State of

California to cause cancer.

As your unit is used, carbon deposits buildup

on the muffler and spark arresting screen.

For normal homeowner use, however, the

muffler and spark arresting screen will not require any service. After 50 hours of use, we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

REPLACE SPARK PLUG

Replace the spark plug each year to ensure

the engine starts easier and runs better. Inspect spark plug every 25 hours of usage.

Clean and/or replaceas necessary. Setspark

plug gap at 0.025 inch (0.6 mm). Ignition timing is fixed and nonadjustable.

NOTE: This spark igniti on system complies

with the Canadian standard ICES--002.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and

discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench.

4. Reinstall the spark plug boot.

SERVICE AND ADJUSTMENTS

WARNING: Disconnect the spark

plug before performing maintenance, service, or

adjustments except for idle speed adjustments.

CHAIN SHARPENING

WARNING: Improper chain sharpen-

ing techniques and/or depth gauge maintenance will increase the chance of kickback

which can result in serious injury.

WARNING: Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is not moving.

Conditions which indicate the need for chain

sharpening:

S Reduction in size of woodchips. The sizeof

the wood chip will decrease as the chain

gets duller until it becomes more like a

powder thana chip. Note thatdead or rotted

wood will not produce a good chip.

16

Page 17

S Saw cuts to one side or at an angle.

A

f

f

S Saw has to be forced through the cut.

Tools required:

S 3/16 inch (4,5 mm) diameter round file and

file holder

S Flat file

S Depth gauge tool

TO SHARPEN CHAIN:

1. Disconnect spark plug.

2. Check chain for proper tension. Adjust

chain tension if necessary. See CHECK

CHAIN TENSION section.

3. Sharpen cutters.

S To sharpen the cutters, position the

file holder level (90° ) so that it rests on

the top edges of the cutter and depth

gauge.

NOTE: The chain has both left and

right hand cutters.

File Holder

Cutter

S Align the 30° file holder marks parallel

30°

File Holder Line

S Sharpen cutters on one side of the chain

S File on the forward stroke only. Use 2

S Keep all cutters the same length when

S File enough to remove any damageto

Same Length

S File chain to meet the specifications

30°

File

90°

Depth Gauge

with the bar and to the center of the

chain.

Cutter

Cutter

first. File from the inside of each cutter to

the outside. Then, turn the chain saw

around and repeat the process for the

other side of the chain.

or 3 strokes per cutting edge.

filing.

cutting edges(side plate and top plate

of cutter).

ll Cutters

as shown.

Remove Damage

Top Plate

Side Plate

75°

60°

Hook Angle

0.025 inch

(0.65 mm)

Rounded

Right

Too Much HookAngle

Wrong

WARNING: Maintain the proper hook

angle according tothe manufacturer’s specifications for the chain you are using. Improper hook

angle will increase the chance of kickback

which can result in serious injury.

4. Check and lower depth gauges.

Depth Gauge Tool

S Place gauge tool on cutter.

S If the depth gauge is higher than the

depth gauge tool, file it level to the top of

the depth gauge tool.

S Maintain roundedfront corner of depth

gauge with a flat file.

NOTE: The very top of the depth

gauge should be flat with the front half

rounded off with a flat file.

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call our customer

assistance help line at 1- -800--554- -6723.

Corner

Squared O

Corner

File

Depth Gauge

CHAIN REPLACEMENT

WARNING: Wear protective gloves

when handling chain. The chain is sharp and

can cut you even when it is not moving.

It is normal for a new chain to stretch during the

first 15 minutes of operation. You should recheck your chain tension frequently and adjust

the chain tension as required. See CHAIN TENSION section.

Replace the old chain when it becomes worn or

damaged. Use only the Low-Kickback replacement chain specified in the repair parts list.

TO REPLACE CHAIN:

1. Disconnect spark plug.

2. Remove bar clamp nut.

3. Remove bar clamp.

4. Turn adjusting screw by hand counter-

clockwise until adjusting pin just touches

the stop.

5. Slide guide bar behind sprocket until

guide bar stops against sprocket.

6. Remove the old chain.

17

Page 18

7. Carefully remove new chain from package. Hold chain with the drive links as

shown.

Tip of

Bar

CUTTERS MUST FACE IN

DIRECTION OF ROTATION

Cutters

8. Place chain over sprocket, fitting the

drive links in the sprocket.

9. Fit bottom ofdrive links between theteeth

in the sprocket in the nose of the guide

bar.

10. Fit chain drive links into bar groove.

11. Pull guide bar forward until chain is snug

in guide bar groove. Ensureall drive links

are in the bar groove.

12. Now, install bar clamp making sure the

adjusting pin is positioned in the lower

hole in the guide bar.

Cutter

Drivelink

Depth Gauge

Drive Links

13. Install bar clamp nut and finger tighten

only. Do not tighten any further at this

point. Proceed to the CHAIN ADJUSTMENT section.

CHAIN ADJUSTMENT

See CHECK CHAIN TENSION in MAINTENANCE section.

IDLE SPEED ADJUSTMENT

WARNING: Keep others away when

making idle speed adjustments. The chain

will be moving during most of this procedure.

Wear your protective equipmentand observe

all safety precautions. After making adjustments, thechain must not moveat idlespeed.

The carburetor has been carefully set at the

factory. Adjustment of the idle speed may be

necessary if you notice any of the following

conditions:

S Engine will not idle when the throttle is re-

leased.

S The chain moves at idle.

Make adjustments with the unit supported so

the pruner is off the ground and the chain will

not make contact with any object. Hold the

unit by hand while running andmaking adjustments. Keep all parts of your body away from

the chain and muffler.

To adjust idle speed:

Allow engine toidle.Adjust idlespeed until engine runs without chain moving (idle too fast)

or stalling (idle speed too slow).

S Turn idle speed screw clockwise to in-

crease enginespeed if enginestalls ordies.

S Turn idle speed screw counterclockwise to

decrease engine speed if chain moves at idle.

WARNING: Recheck the idle speed

after each adjustment. The chain must not

move at idle speed to avoid serious injury to

the operator or others.

Idle Speed Screw

Guide Bar

Adjusting Pin

Lower

Hole

Air Filter Cover

If you require further assistance or are unsure

about performing this procedure, contact your

authorized service dealer or call

1-- 800- -554- -6723.

18

Page 19

USER REPLACEABLE SERVICE PARTS

REPLACEMENT PART PART NUMBER

Guide bar -- 8″ 952044908

Chain -- 8″ 952051549

Air Filter 530036575

Spark Plug 952030249

Fuel Filter 530095646

Fuel Cap 530057973

STORAGE

CAUTION: Perform the following steps af-

ter each use:

S Allow engine to cool before storing or trans-

porting.

S Store unit and fuel in a well ventilated area

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

S Store unit with all guards in place. Position

unit so that any sharp object cannot accidentally cause injury.

S Store unit and fuel well out of the reach of

children.

SEASONAL STORAGE

Prepare unit for storage at end of season or if

it will not be used for 30 days or more.

If your unit is to be stored for a period of time:

S Clean the entire unit before lengthy

storage.

S Store in a clean dry area.

S Lightly oil external metal surfaces.

FUEL SYSTEM

Under FUELING ENGINE in the OPERATION section of this manual, see messagelabeled IMPORTANT regarding the use of

proper fuel in your engine.

Fuel stabilizer is an acceptable alternative in

minimizing the formation of fuel gum deposits

during storage. Add stabilizer to the gasoline

in the fuel tank or fuel storage container. Follow the mix instructions found on stabilizer

container. Run engine at least 5 minutes after

adding stabilizer.

ENGINE

S Remove spark plugand pour 1 teaspoon of

40:1, 2-cycle engine oil (air cooled) through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

S Replace spark plugwith new one of recom-

mended type and heat range.

S Clean air filter.

S Check entire unit for loose screws, nuts,

and bolts. Replace any damaged, broken,

or worn parts.

S At the beginning of the next season, use

only fresh fuel having the propergasoline to

oil ratio.

OTHER

S Do not store gasoline from one season to

another.

S Replace your gasoline canif itstarts torust.

During storage of your gas/

oil mixture, the oil will separate from the gas.

We recommend that you

shake the gas can weekly

to insure proper blending of

the gas and oil.

HELPFUL TIP

19

Page 20

TROUBLESHOOTING TABLE

WARNING: Always stop unit and disconnect spark plug before performing allof the

recommended remedies below except remedies that require operation of the unit.

TROUBLE CAUSE REMEDY

Engine will not

start.

1. Engine flooded.

2. Fuel tank empty.

3. Spark plug not firing.

4. Fuel not reaching

carburetor.

5. Carburetor requires

adjustment.

1. See “Starting a Flooded Engine” in

Operation Section.

2. Fill tank with correct fuel mixture.

3. Install new spark plug.

4. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

5. Contact an authorized service dealer.

Engine will

not idle

properly.

Engine will not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

Chain moves at

idle speed.

1. Idle speed set too high

or too low.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compression low.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

1. Idle speed requires

adjustment.

2. Clutch requires repair.

LIMITED WARRANTY

Poulan PRO, a division of Husqvarna Consumer Outdoor Products N.A., Inc., warrants to the

original consumer purchaser that each new

Poulan PRO brand gasoline tool or attachment

is free from defects in material and workmanship and agrees to repair or replace under this

warranty any defective gasoline product or attachment as follows from the original date of

purchase.

2YEARS--Parts and Labor, when used for

household purposes.

90 DAYS - - Parts and Labor, when used for

commercial, professional, or income producing

purposes.

1. See “Carburetor Idle Speed Adjustment”

in Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer.

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact an authorized service dealer.

30 DAYS -- Parts and Labor, if used for rental

purposes.

This warranty is not transferable and does not

cover damage or liability caused by improper

handling, improper maintenance or alteration, or

the use of accessories and/or attachments not

specifically recommended by Poulan PRO for

this tool. This warranty does not cover tune--up,

spark plugs, filters, starter ropes, cutting line, or

rotating head parts that will wear and require replacement with reasonable use during the warranty period. This warranty does not cover pre-delivery setup or normal adjustments explained

20

Page 21

in the instruction manual. This warranty does

not cover transportation costs.

In the event you have a claim under this warranty, you must return the product to an authorized

service dealer.

Should you have any unanswered questions

concerning this warranty, please contact:

Poulan PRO, a divisio n of Husqvarna

Consumer Outdoor Products N.A., Inc.

9335 Harris Corners Parkway

Charlotte, NC 28269

1-- 800- -554- -6723

In Canada, contact:

Poulan PRO

850 Matheson Blvd. West

Mississauga, Ontario L5V 0B4

Giving the model number, serial number and

date of purchase of your product and the name

and address of the authorized dealer from

whom it was purchased.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVEOTHER RIGHTS WHICH VARY FROM STATE TO

STATE.

IMPORTANT: This product is compliant with U.S. EPAPhase 3 regulations for exhaust and evaporative emissions. T o ensure EPA Phase 3 compliance, we recommend using only genuine Poulan

PRO brand replacement parts. Use of non-compliant replacement parts is a violation of federal law .

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EXPRESSLY STIPULAT ED HEREIN.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG AN IMPLIED WARRANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDE NTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATIONS OR EXCLUSION MAY NOT APPLY

TO YOU.

This is a limited warranty within the meaning of

that term as defined in the Magnuson--Moss Act

of 1975.

The policy of Poulan PRO is to continuously

improve its products. Therefore, Poulan PRO

reserves the right to change, modify , or discontinue models, designs, specifications,

and accessories of all products at any time

without notice or obligation to any purchaser.

U.S. EPA/CALIFORNIA/ENVIRONMENT CANADA

EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS: The U.S. Environmental

Protection Agency, California Air Resources

Board, Environment Canada and Poulan

PRO are pleased to explain the emissions control system warranty on your year 2012 and later small off--road engine. In California, all small

off--road engines must be designed, built, and

equipped to mee t the Stat e’s stringent anti-smog standards. Poulan PRO must warrant

the emission control system on your small

off--road engine for the periods of time listed

below provided there has been no abuse, neglect, or improper maintenance of your small

off--road engine. Your emission con trol system

includes parts such as the carburetor, the ignition system and the fuel tank. Where a warrantable condition exists, Poulan PRO will repair

your small off-- road engine at no cost to you.

Expenses covered under warranty include

diagnosis, parts and labor. MANUFACTUR-

ER’S WARRANTY COVERAGE: If any

emissions related part on your engine (as

listed underEmissions Control Warranty Parts

List) is defective or a defect in the materials or

workmanship of the engine causes the failure of

such an emission related part, the part will be repaired or replaced by Poulan PRO. OWNER’S

WARRANTY RESPONSIBILITIES: As the

small off--road engine owner,you are responsible for the performance of the required

maintenance listed in your instruction manual. Poulan PRO recommends that you retain

all receipts covering maintenance on your

small off--road engine, but Poulan PRO cannot deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance. As the

small off-- road engine owner, you should be

aware that Poulan PRO may deny you warranty coverage if your small of f--road engine

or a part of it has failed due to abuse, neglect,

improper maintenance, unapproved modifications, or the use of parts not made or approved by the original equipment manufacturer. You are responsible for presenting your

small off--road engine to an Poulan PRO authorized repair center as soon as a problem exists.

Warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and responsibilities, you should

contact your nearest authorized service center,

callPoulan PRO at 1--800--554--6723, or send

e-mail correspondence to emission.warranty

HCOP--emission.com

MENCEMENT DATE: The warranty period

begins on the date the small off--road engine

is purchased. LENGTH OF COVERAGE:

This warranty shall be for a period of two

years from the initial date of purchase, or until

the end of the product warranty (whichever is

longer). WHAT IS CO VERED: REPAIR OR

REPLACEMENT OF PARTS. Repair or replacement of any warranted part will be performed at no charge to the owner at an approved Poulan PRO servicing center. If you

have any questions regarding your warranty

rights and responsibilities, you should contact

your nearest authorized service center, call

Poulan PRO at 1--800--554--6723, or send

e-mail correspondence to

@HCOP-- emission.com

RIOD: Any war ranted p art which is not scheduled for replacement as required maintenance, or which is scheduled only for regular

. WARRANTY COM-

emission.warranty

. WARRANT Y PE-

21

@

Page 22

inspection to the effectof “repair or replace as

necessary” shall be warranted for 2 years.

Any warranted part which is scheduled for replacement as required maintenance shall be

warranted for the period of time up to the first

scheduled replacement point for that part.

DIAGNOSIS: The owner shall not be

charged for diagnostic labor which leads to

the determination that a warranted part is defective if the diagnostic work is performed at

an approved Poulan PRO servicing center.

CONSEQUENTIAL DAMAGES: Poulan

PRO may be liable for damages to other engine components caused by the failure of a

warranted part still under warranty. WHAT IS

NOT COVERED: All failures cause d by

abuse, neglect, or improper maintenance are

not covered. ADD--ON OR MODIFIED

PARTS: The use of add--on or modified parts

can be grounds for disallowing a warranty claim.

Poulan PRO is not liable to cover failures ofwarranted parts caused by the use of add--on or

modified parts. HOW TOFILE A CLAIM: If you

have any questions regarding your warranty

rights and responsibilities, you should contact

your nearest authorized service center, call

Poulan PRO at 1--800- -554--6723, or send

e-mail correspondence to emission.warranty

HCOP--emission. com

The information on the product label indicates which standard your engine is certified.

Example: (Year) EPA and/or CALIFORNIA.

.

WHERE TO GET WARRANTY SERVICE:

Warranty serv ic es or repairs shall be provided at all Poulan PRO servic e centers.

Call: 1--800 --554--6723 or send e-mail correspondence to emiss ion.w arranty @

HCOP--emission.com

PLACEMENT AND REPAIR OF EMISSION

RELATED PARTS: Any Poulan PRO ap-

proved replacement part used in the performance of any warranty maintenance or repair

on emission related parts will be provided

without charge to the owner ifthe part is under

warranty. EMISSIONCONTROL WARRAN-

TY PARTS LIST: Carburetor, air filter (covered up to maintenance schedule), ignition

system: spark plug (covered up to maintenance schedule), ignition module, muffler including catalyst (if equipped), fuel tank, line

and cap. MAINTENANCE STATEMENT:

The owner is responsible for the performance

of all required maintenance as defined in the

instruction manual.

@

. MAINTENANCE, RE-

This engine is certified to be emissions compliant for the following use:

Moderate (50 hours)

Intermediate (125 hours)

Extended (300 hours)

22

Page 23

IDENTIFICACIÓN DE LOS SÍMBOLO S DE SEGURIDAD

PELIGRO! Para protegerse de una posible

electrocución, No la use cerca de los alambres

eléctricos o de las líneas de energía. Mantenga la

cortadora de ramas por lo menos 30 pies (10 metros) lejos de todas las líneas de energía.

PELIGRO! Los objetos al caer pueden cau-

sar lesiones en su cabeza. Use protección en su

cabeza mientras opere este aparato. Nunca se

pare bajo la rama que está podando.

ADVERTENCIA! Evite reculada le pueden causar graves heridas. Reculada es el

movimiento hacia el frente, hacia atrás o rápidamente hacia adelante, esto puede ocurrir

cuando la punta de la barra guía de la cortadora de ramas entra en contacto con cualquier

objeto como puede ser otra rama o tronco, o cuando la madera se cierra y atasca mientras

se hace el corte. El entrar en contacto con algún objeto extraño a la madera le puede causar al usuario la pérdida del control de la cortadora de ramas.

ADVERTENCIA! No use el aparato al estar

en una escalera o en un soporte inestable. Siempre

corte con ambos pies bien apoyados en suelo sólido

para evitar perder el equilibrio.

ADVERTENCIA: Lea el manual de instrucciones antes de usar.

No seguir las instrucciones podía causar graves heridas tanto al operador

como a otras personas. Guarde el manual de instrucciones.

ADVERTENCIA

Los gases de escape del motor de este producto

contienen sustancias químicas conocidas en el

Estado de California como causantes de cáncer,

defectos congénitos y otros daños reproductivos.

23

Page 24

IDENTIFICACIÓN DE LOS SÍMBOLO S DE SEGURIDAD

La línea de corte arroja objetos violentamente. Los objetos arrojados pueden cegarlo o herirlo a

usted y a terceros. Use equipo protector. Siempre use calzado de seguridad con puntas de

acero y suelas anti--deslizantes; ropa ajustada el cuerpo; pantalones pesados y largos y mangas

largas; guantes gruesos de uso industrial anti- -deslizantes; protección de ojos marcado con Z87

tales como gafas de seguridad que no se empañan y con aberturas de ventilación o mascara

protectora para la cara; casco duro aprobado; y barrera de sonido (tapones de oído u orejeras

anti- -sonido) para proteger la audición. Los que usan cortadora de ramas de fuerza deberán

hacerse revisar la audición frecuentemente ya que el ruido de las cortadora de ramas puede

dañar los oídos. Use siempre la correa para el hombro cuando el aparato es en funcionamiento.

Asegúrese de tener el cabello recogido

por encima de los hombros. No use

joyería, ropa suelta ni ropa con corbatas,

tiras, borlas, etc. que cuelgan libremente.

Pueden enredarse en las piezas en movimiento.

Zona de peligro. Mant enga a los niños, es pectadores y

animales a una distancia mínima de 15 metros (50 pies)

del área de trabajo o cuando está hacienco arrancar el

motor.

No ponga en marcha la cortadora de ramas sin tener un

área de trabajo despejada, superficie estable para pararse y

un camino predeterminado de retroceso.

Mantenga las dos manos en las mangos siempre que el

aparato esté en marcha. El uso del aparato con una sola

mano puede causar graves heridas al usuario, a los asistentes, o a los espectadores. Las cortadora de ramas

están diseñadas para que se las use con las dos manos en

todo momento.

El mango auxiliar debe colocarse siempre por debajo de

la flecha.

No permita que los niños usen este aparato.

24

Page 25

IDENTIFICACIÓN DE LOS SÍMBOLO S DE SEGURIDAD

Guarde el aparato al abrigo de la intemperie, desenchufado,

en un lugar alto, seco y fuera del alcance de los niños.

Guarde el aparato y el combustible en un lugar donde los

vapores del combustible no puedan alcanzar chispas ni

llamas provenientes de los termotanques, los motores o

interruptores eléctricos, los calefactores centrales, etc.

Al mantener este aparato, use solamente las piezas

de reemplazo idénticas.

Siempre apague el aparato y desconecte la bujía antes

de dar mantenimiento.

ADVERTENCIA: Riesgo de incendios. Nunca mezcle, vierta, o

almacene el combustible o utilice el aparato cerca de llamas o fuentes

de chispas (inclusive los cigarrillos, las llamas abiertas, y cualquier trabajo que cause chispas).

Utilice gasolina sin plomo y aceite para motores de dos tiempos

mezclado en proporción al 40:1 (2.5%).

REGLAS DE SEGURIDAD

ADVERTENCIA: Desconecte

siempre el cablede la bujíay colóquelodonde

no puede entrar en contacto conel bujía,para

evitar cualquier arranque accidental alpreparar, transportar, ajustar o reparar el aparato,

excepto en el caso de ajustes al carburador.

Debido aque las cortadora de ramas son instrumentos para cortar madera a alta velocidad, deben observarse precauciones de seguridad especiales para reducir el riesgo de accidentes. El

uso descuidado o indebido de esta herramienta

puede causar graves o aún heridas fatales.

PIENSE ANTES DE PROCEDER

S Antes de utilizar lacortadora deramas, lea at-

tentamente este manual hasta estar seguro o

comprenderlo completamente y poder seguir

todas las reglas de seguridad, precaucións e

instrucciones de uso que se dan en él.

S Limite el uso de la cortadora de ramas a

aquellos usuarios adultos que comprendad