Page 1

Sits

Pouton

m

Read Special

SAFETY CENTER SPREAD

each time you use

your MICRO 25

BEAIRD-POULAN/WEED EATER

Division Emerson Electric Co.

5020 Flournoy-Lucas Road

Shreveport, Louisiana 71109

CHAIN SAW

OPERATOR’S MANUAL

Page 2

N

CONTROLLING KICKBACK by Lloyd Tuggl

CONTENTS

Controlling Kickback .

Your Micro 25 Chain Saw ..........................3

Assembly Hand Guard ...........................

Attaching Guide Bar and

Chain. Adjusting Chain...........................5

Fueling Bar & Chain Oil ............................6

Starting - Good Performance

SAFETY CENTER SPREAD

Types of Cutting .................................10-11

Adjusting Carburetor

Air Filter ................................................... 13

Sharpening Chain

& Guide Bar Maint...................................14

Starter Rope

............................................

..............................

....................

...................

.......................

PAGE

.4

8-9

.12-13

15

Read

SAFETY CENTER SPREAD

FREQUENTLY

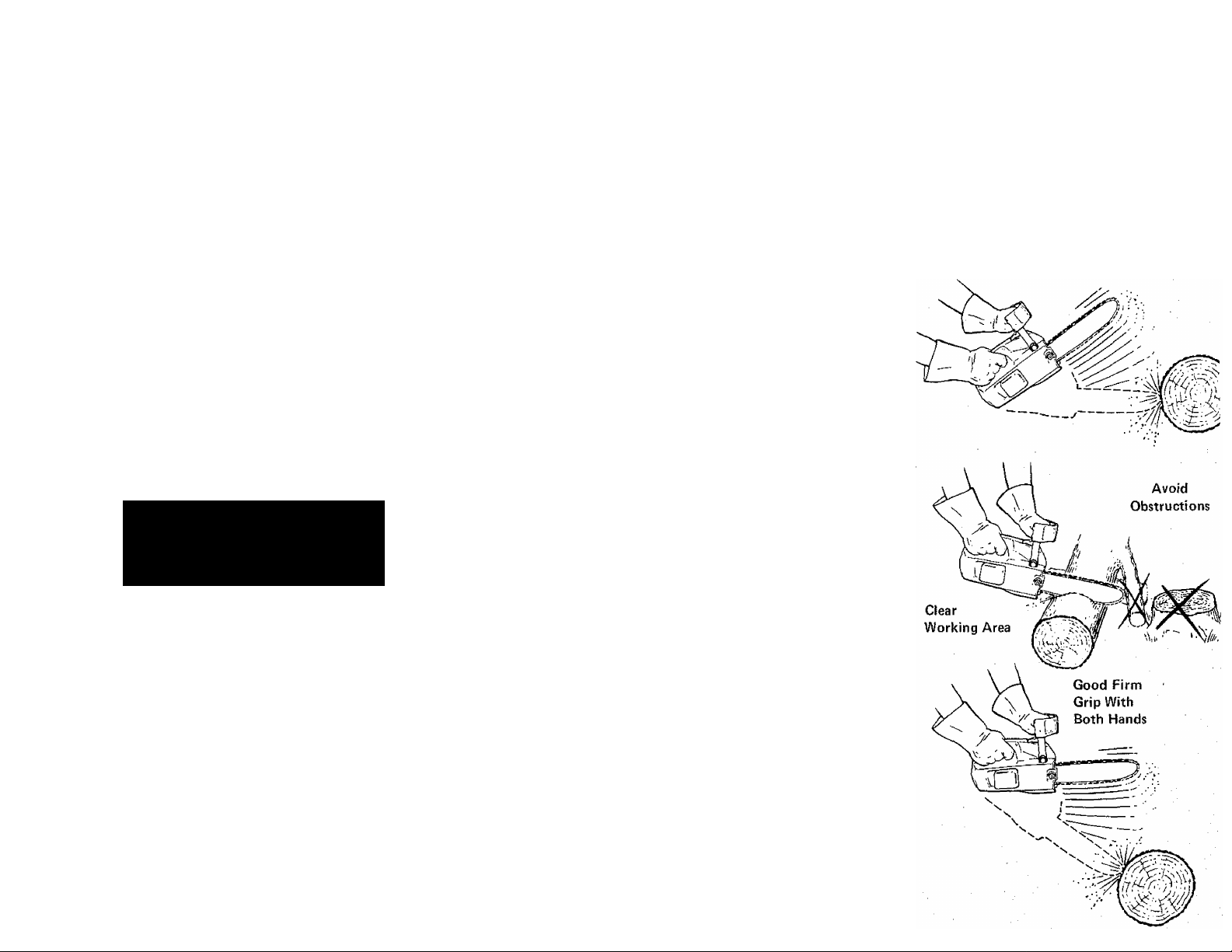

KICKBACK may happen when the nose or tip of the moving chain touches an object while the saw is

2

7

operating. This contact may abruptly STOP the cutting action and in some cases may cause a lightning

fast reverse REACTION, kicking the saw tip up or down and back. KICKBACK has caused some

operators to lose control of the saw. The cutting chain can then cause serious injury if it comes in

contact with any part of the body.

As a chain saw user you can take several steps to avoid an accident or injury due to kickback.

1. By simply UNDERSTANDING and knowing about kickback you take out the element of SURPRISE. It's the

SURPRISE that really contributes to accidents.

2. Make sure your HAND GUARD is securely fastened to the

handlebar AT ALL TIMES.

3. Make sure the area in which you are cutting is FREE

FROM OBSTRUCTIONS such as other trees, branches,

rocks, fences, stumps, etc. Eliminate or’avoid any obstruc

tions that your saw chain could hit while you are cutting

through a particular log or branch.

4. Keep a good firm grip on-the saw with BOTH hands. (Left

hand completely around the front handlebar with thumb

under and the right hand completely around the rear

handle.) A FIRM GRIP can neutralize kickback and help

you maintain control of the saw. DON'T LET GO.

r---------------------------

SAFETY FEATURES:

•Control TIpTMOulde Bar

•Low Kick Chain

•Hand Guard

Your Poulan chain saw is a reliable and powerful cutting toot.

Please use it safely and carefully so that each cutting job is

SUCCESSFUL AND SAFE. Controlling kickback is really a

partnership between you and Poulan. GOOD CUTTING.

Lloyd Tuggle, Senior Vice President

Manufacturing and Engineering, Beaird-Poulan

Page 3

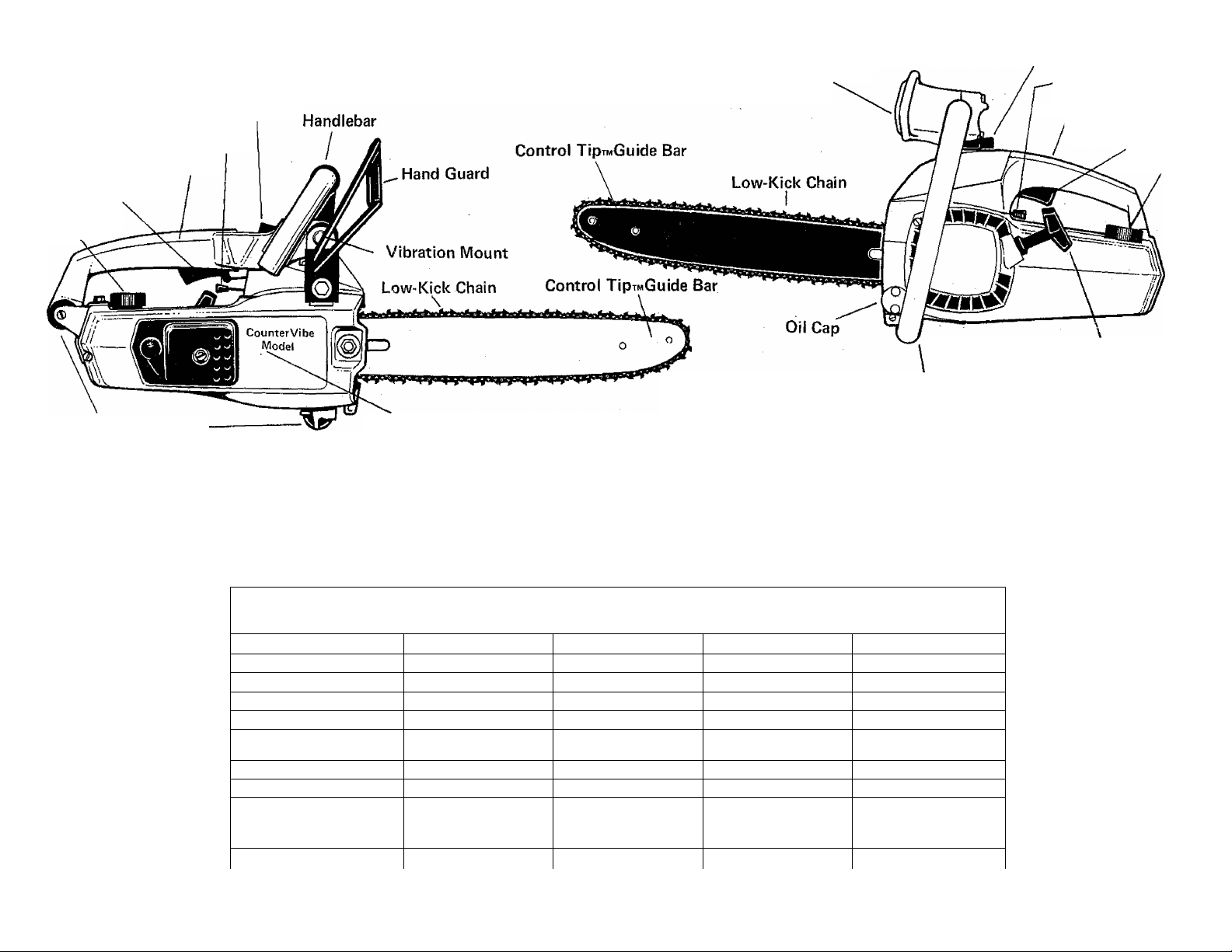

YOUR MICRO 25 CHAIN SAW

THIS SAW INTENDED FOR OCCASIONAL USE ONLY.

Choke Knob

Start/Stop Switch

Control Handle

Throttle Trigger

Fuel Cap

Hand Guard

Choke Knob

Stop Start Switch

Control Handle

Throttle Trigger

Fuel Cap

Starter Handle

Handlebar

Vibration Mounts

WHO SHOULD USE IT

The occasional user of a chain saw.

The non-professional.

SPECIFICATIONS ю saw

ENGINE DISPLACEMENT

SPARK PLUG

SPARKPLUG GAP

IGNITION

MODULE AIR GAP

FUEL MIX

OILER

GUIDE BAR

CHAIN

MUFFLER

Bar Clamp

WHAT IT SHOULD BE USED FOR

Cutting your own firewood.

Clearing wooded sites.

Cleaning up storm damage.

Light pruning at ground level.

12" SAW

2.0 Cu. In. 2.0Cu. in.

Champion CJS

.023 to .027"

Solid State Solid State

.008 to .014" .008 to .014"

(16:1) У2 Pt.Oil to

1 Gat. Reg. Gasoline

Automatic only

10" Control Tip™

Low Profile 3/8 Pitch

40 Drive Links

Spark Arresting

Champion CJS

.023 to ,027"

(16:1) Vz Pt. Oil to

1 Gal. Reg. Gasoline

Automatic only

12" Control Tip™

Low Profile 3/8 Pitch

Chrome Cutters

45 Drive Links

Spark Arresting

WHAT IT SHOULD NOT BE USED FOR

Not for commercial or heavy, continuous

use.

Not for carpentry work.

Not to cut any material other than wood.

14" SAW

2.0 Cu. In. 2.0CU. In.

Champion CJ8 Champion CJS

.023 to ,027"

Solid State Solid State

.008 to .014"

(16:1) % Pt. Oil to

1 Gal. Reg, Gasoline

Automatic only

14" Control TipTM

Low Profile 3/8 Pitch

Chrome Cutters

52 Drive Links

Spark Arresting

16" SAW

.023 to .027"

.008 to .014"

(16:1) Pt. Oil to

1 Gal. Reg, Gasoline

Automatic only

16" Control TipTM

Low Profile 3/8 Pitch

Chrome Cutters

56 Drive Links

Spark Arresting

Page 4

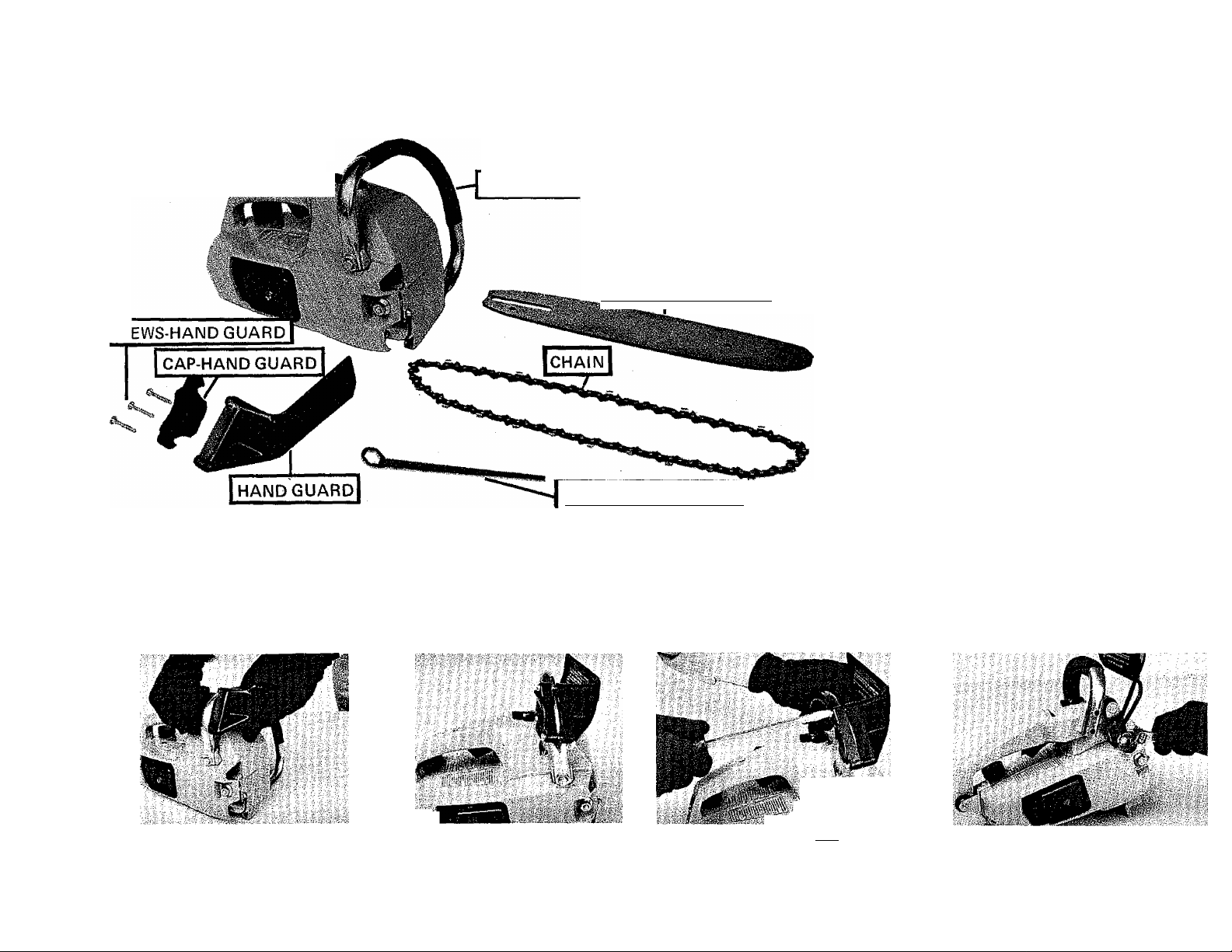

ASSEMBLY - PARTS AND TOOLS

Check the box for each item shown here. If something is

missing, please call place of purchase.

.■-. is- i'

SCP

CHAIN SAW POWER HEAD

rCONTRQL TIRmBAR \

BAR ADJUSTING TOOl]

YOU WILL NEED:

AH of the items shown here plus a large

screwdriver, work gloves, uncluttered work

area, approved mixing container for fuel.

For CounterVibe Model, a small adjustable

wrench.

YOU WILL;

• Attach the hand guard.

• Mount the bar and chain.

• Adjust the chain.

FOR MIXING FUEL AND ADDING CHAIN OIL:

You will need the proper fuel mixture, (see

the fueling section of this manual, page 6),

and, bar and chain lube or clean SAE 30 oil.

ATTACHING THE

HAND GUARD

1. Align 2 parts of hand guard around

handlebar so knob of guard fits the

hole in the handlebar.

The hand guard helps prevent the hand from coming in contact with the cutting chain

should your hand slip off the handlebar. It does not eliminate the possibility of injury

from kickback or loss of control of the saw. Please lift and carry the chain saw by the

handlebar or the control handle, NOT by the hand guard, so it will not come loose.

Retighten, if it ever does come loose. DO NOT USE THE SAW WITHOUT THE HAND

GUARD IN PLACE.

2. Insert the 3 mounting screws into

the 3 holes on hand guard.

3.Turn each screw a little at a time

clockwise to tighten until the two

halves meet and are tight. Move

from 1 screw to the next, a couple

of turns to secure guard evenly.

COUNTERVIBE MODELS

Remove 6-sided hex bolt from

CounterVibe Bracket. Place hand

guard base over the bracket. Tight

en the bolt.

Page 5

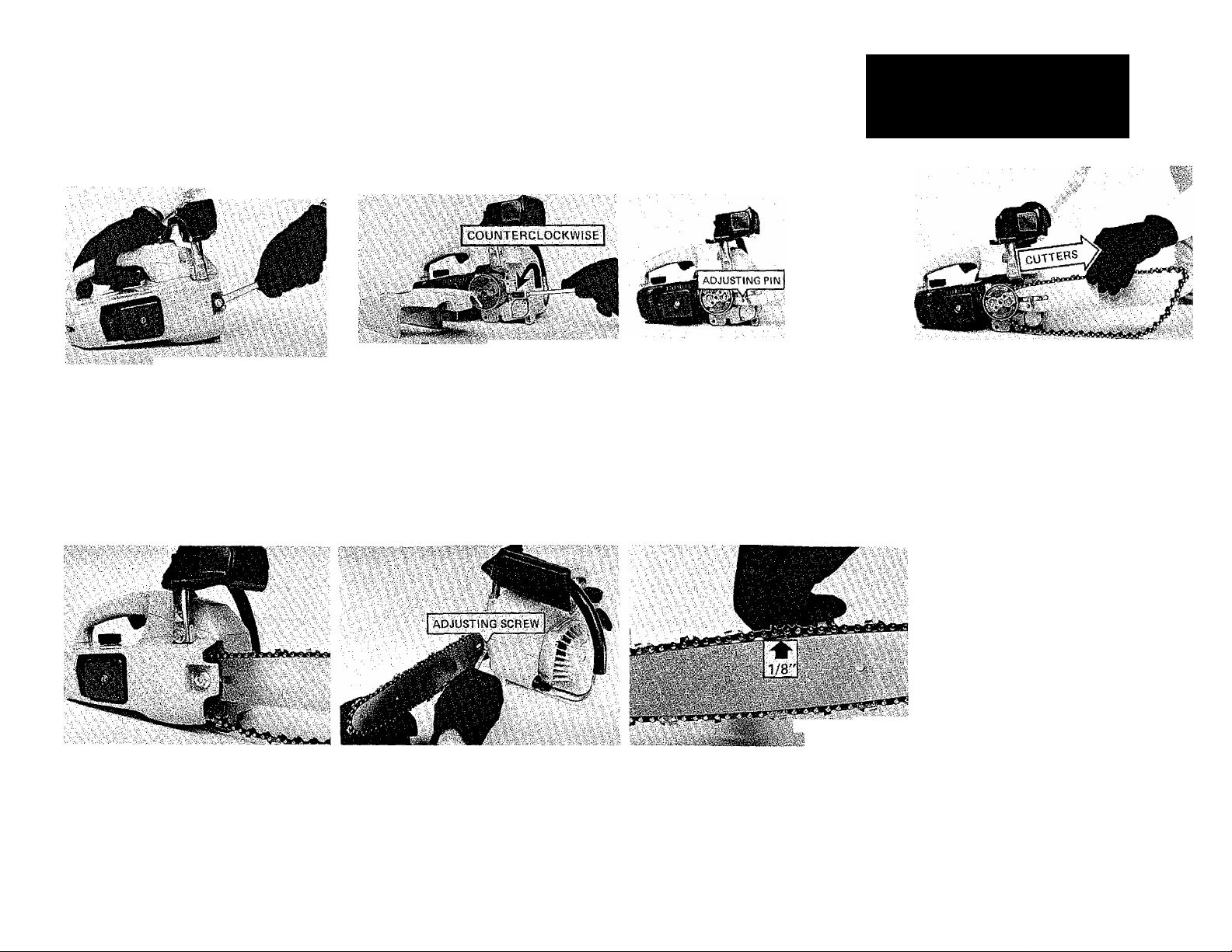

ATTACHING THE BAR AND CHAIN

Always wear your gloves when working on or with your saw. The Top Sharp Chain on your Power Sharp saw is

extremely sharp and can easily cut you even when it is not moving! Your saw is equipped with a Control Tip bar and

a Low-Kick chain to help avoid accidents due to kickback. When replacing these items, always use the Control Tip and

Low-Kick chain designed for your particular chain saw model.

, ■■

Read

SAFETY CENTER SPREAD

FREQUENTLY

1. Remove the 6-sided hex nut near the

front of the saw. Loosen by turning hex

wrench counterclockwise. Remove small

screw in back.

5. Making sure the guide bar is still flat

against the side of the saw and the chain

is still on the sprocket, replace the bar

clamp and finger tighten the hex nut.

Don't tighten it down as you are going

to adjust the chain before you finish

tightening the nut. Replace the small

bar clamp screw in back and tighten.

2. Remove the bar clamp. Find the small

adjusting pin and screw just to the right

and below the bar mounting stud (silver

bolt). Turn the adjusting screw counter

clockwise to position the pin nearly alt

the way to the rear.

6. Holding the tip of the bar up, turn the

adjusting screw clockwise just until the

chain does not sag beneath the bar.

3. To install the guide bar as shown, slide

the guide bar behind the clutch drum

with the large bolt fitting in the slot in

the bar and the small adjusting pin

through the small hole in the bar. Once

the guide bar is in position, keep it flat

against the side of the saw during chain

mounting.

7. When you have the proper tension on

the chain it will move freely around the

bar but only lift about 1/8" from the

bar as shown above. Now while holding

the tip of the bar up, tighten the hex

nut completely and recheck the rear

screw.

4. Pick up the chain so that the top links

have the cutters facing in the direction

shown above. Place the chain behind the

clutch drum on the sprocket. Bring the

chain along the top of the bar, setting it

in the groove. If the chain does not set

in easily at the tip, pull the chain

forward and let the groove guide the

chain around the tip.

NOTE; The chain stretches during use

(especially when new) and it will be neces

sary to adjust and tighten it occasionally.

Check the chain tension each time you use

the saw. A loose chain will wear the bar

and itself, A loose chain can also jump off

the bar while you are cutting. A chain that

is too tight can damage the saw and/or

break. Either situation, too loose or too

tight, could cause injury. Keep the chain

out of the dirt. Cutting into the dirt or cut-

ing a dirty piece of wood will immediately

dull the chain.

Page 6

FUELING

Inhaling gasoline vapors is dangerous so fuel your chain saw only outside or in a

well-ventilated area. Eliminate or stay away from all sources of ignition. No

smoking, no open flames, no tools nor work that could cause sparks.

Your chain saw operates on a mixture of gasoline and oil. CAUTION: Using straight

gasoline will burn out your engine.

POULAN

16n

OIL

+

1

GALLON

REGULAR

GASOLINE

Read

SAFETY CENTER SPREAD

FREQUENTLY

Do not leave fuel in the fuel tank for more than 8 weeks. This will cause hard

starting and can damage the engine. Remove old fuel mixture or allow the saw to

run out of fuel before storing.

BAR AND CHAIN OIL

OR

POULAN

32:1

OIL

+

PINT

Mix 1/2 pt. (8 02.) Poulan 16:1 oil with 1 gallon of regular leaded gasoline; or 1/2

pt. {8 02.) Poulan 32:1 oil with 2 gallons of gasoline. If Poulan oil is not available,

use a good grade of 2 stroke cycle air cooled engine oil and mix 1/2 pt. (8 02.) oil

with 1 gallon of gasoline.Do not use gasohol because it could have harmful effects

on your engine. Pour the oil into an approved container, add the gasoline and shake

mixture well. Do not try to mix the oil and gasoline directly in the saw.

The fuel tank on your chain saw is toward the back and the fuel tank cap is marked

FUEL MIX. Carefully fill the tank, but DO NOT OVERFILL. Wipe up spills.

1

GALLON

REGULAR

GASOLINE GASOLINE

1

GALLON

REGULAR

The bar and chain oil tank is in front of the saw. Keep it full to lubricate the bar

and chain or both can be damaged. Use straight bar and chain tube above 30

Fahrenheit. If bar and chain lube is not available use a good grade SAE 30 oil.

Between 30° F and 0° F use a mixture of 95% bar and chain lube and 5% either

kerosene or # 1 diesel fuel. For below 0 F operation increase the kerosene or

diesel fuel to 10%.

Turn the saw on its side with the oil cap UP. Remove the cap. Fil

Wipe up any spills.

Fill the bar and chain oil tank each time you refuel. As long as you see oil

lubricating the bar and chain during saw operation, your oil supply is adequate. If

you are using less oil and the oil tank is full, the oil hole on the guide bar might be

blocked. Remove the bar clamp and bar and chain. Clear the oil hole in the bar anc

replace the bar, chain, and bar clamp.

After you have turned off the saw, a small amount of oil may appear under the saw

This is normal, oil will drain from the bar and chain after use.

the oil tank

Page 7

STARTING YOUR CHAIN SAW

IMPORTANT; Make sure you have read and understand the entire safety center spread and the infornnation on

kickback (pg. 2) before starting or using your chain saw. Now, move away from the area in which you fueled your saw.

Make sure you are on solid footing. Make sure the saw handles are free of gas and oil, and that you have the proper

chain tension. Don't forget to wear your protective gear.

1. Move the choke lever to your right, to the CHOKE po

sition. Move the START/STOP switch to START. Hold

the control handle in your right hand and squeeze the

throttle trigger. Firmly grip the starter rope handle in

your left hand.

2. Now, push the saw away from you with your right

hand while holding the starter handle stationary. Make

short, 12" to 14" strokes. Hold the saw and the rope

firmly. Do not let the rope snap back into the saw. Let

it rewind slowly. After a few pulls the engine should

fire, when it does, return the choke to its original

position. While again squeezing the throttle trigger, pull

the starter rope until the engine runs, if engine does

not fire after 5 to 6 pulls, it may be flooded. Push

choke off (clockwise) and pull starter several times

while holding trigger at wide open throttle. If saw has

run out of fuel, 8 to 10 pulls with choke on may be

required to restart engine. When restarting a hot

engine, or one which has just been refueled, you may

have to choke the engine for one or two pulls.

3. To stop your chain saw, push the START/STOP switch

to STOP.

Do not run the engine at high speed when not in a cut.

Squeeze the throttle trigger just before entering the cut

and keep the saw at full throttle the entire time you

are cutting.

Page 8

Your Planning and Preparation

Do not handle or operate a chain saw when you

are fatigued, tired, or upset; or if you are under

the influence of alcoholic beverages, medi

cation, or drugs. You must be in good phy

sical condition and mentally alert.

Always wear personal protective gear. Wear safety

footwear, protective gloves, snug-fitting clothing,

and eye, hearing and head protection devices.

Use caution when handling fuel. No smoking

when fueling or operating the saw. Handle fuel

only in open, well-ventilated areas. Wipe up spills.

Keep the handles dry, clean and free of oil or fuel

mixture.

Conditions in Your Work Area

Do not operate a chain saw that is damaged, is

improperly adjusted, or is not completely and

securely assembled. Keep all screws and fasten

ers tight.

Move the chain saw at least 10 feet (3m) from the

fueling point, before starting the engine.

Make sure chain is sharp and at proper tension.

Carry the chain saw with the engine stopped, the

guide bar and chain covered and to the rear, and

the muffler away from your body.

Before you let anyone use your saw, be certain

the person understands and can apply the safety

rules, precautions, and operating instructions

found in this manual.

All chain saw service other than the items listed in the oper

ator’s manual maintenance instructions, should be performed

by competent chain saw service personnel.

Do not attempt to cut if the weather is bad—strong wind,

rain, snowing, or other adverse weather conditions. You

need good visibility, so don’t cut at night.

Operate the chain saw only in well-ventilated areas. Don’t

operate it in an enclosed, confined area because you need

room to perform the cutting and good ventilation.

Do not start cutting until you have a clear work area, secure

footing, and a planned retreat path from the falling tree (if

you are cutting down trees).

Do not allow other persons to be near the chain saw wh

starting or cutting with the chain saw. Keep bystanders a

animals out of the work area.

Operate the chain saw on level, solid ground. DO NOT op

ate the saw from a ladder.

Do not operate the chain saw in a tree unless you have be

specifically trained to do so.

Never carry your saw while climbing. You need both har

for safe climbing.

Page 9

OPERATING YOUR CHAIN SAW

Wear your protective gear.

Before you start the engine, make sure the saw chain is not

contacting anything.

Keep all parts of your body away from the saw chain when

the engine is running.

Hold the chain saw firmly with both hands when the engine

Is running. Use a firm grip with thumbs and fingers encircling

the chain saw handles. Keep your left hand on the front

handle and your right hand on the rear handle.

Do not let the nose of the guide bar contact a log, branch,

the ground, or any other obstruction, to help prevent kick-

back.

Guard against kickback. Kickback is the upward motion of

the guide bar which occurs when the saw chain at the nose

of the guide bar contacts an object. Kickback can lead to

dangerous loss of control of the chain saw.

Do not overreach. You might lose your balance.

Do not cut above shoulder height. Don’t cut overhead, since

you would have poor control of the saw and the saw would

be too close to your face and body.

When cutting a limb that is under tension be alert for spring-

back, so that you will not be struck by the limb when the ten

sion in the wood fibers is released.

Be sure that the saw chain stops moving when the throttle

control trigger is released. If the chain does not stop moving,

refer to the maintenance section and adjust the carburetor

as outlined.

After cutting, shut off the engine before setting the saw

down.

Let the saw cool in a non-combustible area, not on dry

leaves or paper.

Wipe off oil before storing the chain saw. Do not store your

chain saw in any room with any type open flame heater or

stove. Store the saw in a locked area or in an area away from

children.

Follow manufacturer’s sharpening and maintenance in

structions for the saw chain.

Always do your cutting at high engine speed.

Please read message on kickback from Lloyd Tuggle,

Senior Vice President, Engineering, Beaird-Poulan. This il

lustrated message is located on the inside front cover of this

manual.

Page 10

TYPES OF CUTTING for the occasional chain saw user

There are several types of wood cutting you can do successfully and safely. Please read the Safety Center Spread for

safe preparation of your saw and your work area, and for safe operation of the saw. If the weather is bad delay cutting

until it improves.

FELLING A TREE

DON’T PUT YOURSELF IN THESE POSITIONS

Plan or determine the direction the tree will fall by studying its lean, wind

conditions and weight of the branches (to one side or another), and

whether or not the tree is on a hill. Make sure there is enough room for the

tree to fall. Make sure the area you are going to stand and work in is free

from obstacles. Plan a clear retreat path in the opposite direction of the

fall.

If you cannot determine direction of fall, or if you are considering working near electrical

wires, buildings or other structures, leave it to the professional.

Read

SAFETY CENTER SPREAD

FREQUENTLY

SMALL TREES -

WEAR YOUR PROTECTIVE GEAR

Less than 8" across. If you know the direction of fall make a single felling cut on the side away from the direction of

fall. Cut all the way through. When the tree starts to fall, stop the saw, put it down and GET AWAY QUICKLY. If you

are not sure which way the tree will fall, use the NOTCH METHOD shown here.

NOTCH METHOD

Remove the wedge.

through the notch.

BE CAREFUL WHEN IN THE WOODS. DON'T START FOREST FIRES!

Page 11

DEBRANCHING

Bucking is cutting a fallen tree to desired log size. It can be done when a tree section is resting on another log, or when a tree section is placed on a

BUCKING

bucking stand. Use both hands — grip the saw firmly. Stand uphill because a log that is cut loose will roll downhill.

In area "A", come up from the bottom 1/3 of the way.

►U-A-^

Finish by coming down from the top.

In area "B", come down from the top 1/3 of the way.

Finish by coming up from the bottom.

Do not turn the saw upside down to undercut. Position

the guide bar under the log and exert light pressure

upward.

WARNING; When coming up from the bottom using the

top of the bar (undercutting) the saw will push back at

you, hold it firmly.

Never debranch in a tree. It's too dangerous. Once the tree is down debranching can be done properly and safely. Keep chain

out of dirt.

Cut from the side of the tree opposite the branch you are cutting. Do not let

the tip of the cutting bar touch anything that might cause kickback. Keep a

firm grip on the saw, left hand around the handlebar, right hand around the

control handle. Do not cut overhead. Limit your debranching to chest level or

below. Work slowly, watching out for branches that are bent or under

pressure, and for supporting limbs. BE ALERT FOR SPRINGBACK — the

release of tension a branch or even a whole tree might be under. Keep your

body clear of possible springback. Frequently clear branches out of the way

so you won't trip over them.

Using a bucking stand, in area A

come up from bottom 1 /3 of the

way first. Finish by cutting down

from the top. In area B come down

from top 1/3 of the way. Finish by

cutting up from bottom.

If saw becomes wedged in a log,

don't try to force it out. Stop the

saw and drive in a wedge until saw

can be removed easily. Be careful

not to damage the chain with the

wedge.

Second

Cut

B

Second

Cut

PRUNING

Cutting branches off a tree while the tree is still standing can be done safely by the non-professional

when branches are shoulder height or lower. If they are higher, get a professional. Never climb into a

tree to debranch, nor work overhead.

Keep both hands on the saw with firm grips, be sure of your footing and balance. Do not turn saw

upside down to cut, watch out for springback and where the branch will fall. Clear fallen branches

frequently so you don't trip over them.

V'

FIRST CUT

Using iaB side of bar and

chain, make first cut from

bottom. Make finishing cut

from top. Do not turn the saw

upside down.

11

Page 12

ADJUSTING THE CARBURETOR

CAUTION: The chain could be moving during this procedure. Wear your protective gear and observe all of your

safety precautions.

The carburetor has been carefully adjusted at the factory

but due to changes in altitude and operating conditions,

your carburetor may require additional adjustments.

PRELIMINARY ! Stop the engine. Be sure you have fresh fuel mix at the proper gasoline/oii ratio (see mixing

instructions), and a screwdriver.

1. Remove the carburetor cover by loosening and

removing the 2 screws on either side of the choke

knob.

CLOCKWISE

4. Turn the idle speed screw 1/2 turn ciockwise. (The

engine should idle without the chain turning when you

start the engine). Turning the idle speed screw clock

wise increases idle speed. Turning it counterclockwise

decreases idle speed. Run the engine for a few minutes

to bring it up to operating temperature for the best

carburetor adjustment.

2. Find the 3 adjusting screws; idle speed screw (1), low

speed mixture screw (2) and high speed mixture screw

(3). Turn the low speed mixture screw and the high

speed mixture screw clockwise just until they stop.(DO

NOT TIGHTEN. YOU MAY DAMAGE THE NEEDLE

SEATS.)

5. Turn the low speed mixture screw slowJy clockwise

until the RPM starts to drop. Then turn the low speed

mixture screw counterclockwise until the RPM speeds

up and then starts to drop again. Position the low

speed mixture screw at the mid point.

3.Turn both screws — Low speed mixture screw and high

speed mixture screw one full turn counterclockwise.

Start the engine. If the engine stops, when the trigger is

not squeezed (idle position).............

6. If the chain is turning at the best idle setting, turn the

idle speed screw counterclockwise until the chain

stops, it may be necessary to recheck the low speed

mixture screw for the best idle, after the idle speed has

been reduced.

12

Page 13

Read

SAFETY CENTER SPREAD

FREQUENTLY

7, When the idle speed has been adjusted, squeeze the

throttle trigger. If the saw accelerates without

hesitating, make a test cut. Be careful to keep chips

and dirt out of the carburetor. If the saw seems to

smoke or have low power in the cut it is set too rich.

Turn the high speed mixture screw 1/16th of a turn

clockwise and repeat the test cut. Repeat this adjust

ment until the saw runs smoothly.

10, Be sure the idle speed screw is set properly and the

chain is not turning. Before replacing the carburetor

cover, clean the mating surfaces of the housing and

cover. Move the choke knob all the way to the choke

position and move the choke shutter to the choke

position and replace cover. (Refer to Fig, 1, Page 12).

CAUTION: NEVER SET THE HIGH SPEED MIX

TURE LESS THAN 7/8THS TURN OPEN. A LEAN

SETTING WILL RUIN YOUR ENGINE.

8, If the engine does not have power in the test cut, and

quits, it is set too lean. Turn the high speed mixture

screw 1/16th turn counterclockwise. Test cut again.

Repeat adjustment until saw runs smoothly.

CLEANING AIR FILTER

9. When you have completed these adjusments, recheck

for proper idle mixture screw setting per instructions in

views No. 5, 6, and 7. Check for acceleration. If there

is a slight hesitation, turn the low speed mixture screw

1/16 turn counterclockwise at a time until you have

smooth acceleration.

The air filter, located in front of the carburetor, captures

dirt and dust and prevents it from entering the engine. It

is oil coated. The filter should be cleaned after every 10

tanks of fuel or every 5 hours of operation.

Wash the air filter with soap and water. Do not use

gasoline or other flammable liquid. Squeeze dry and add a

small amount of oil to coat, but not to soak the filter.

Squeeze out any excess oil. Replace the filter in housing,

tuck in edges, and smooth it flush with the housing.

Replace carburetor cover.

13

Page 14

SHARPENING THE CHAIN

Remember to wear your gloves!

A sharp chain will make your cutting chores much easier. The wood chips your saw makes should be about the size of

the teeth of the chain. If, instead they are small and powdery, the chain is dull and needs sharpening. When the chain is

cutting well, light pressure should b6 enough. If you have to force the saw through the cut with heavy pressure or if the

saw cuts to one side, the chain is dull or the guide bar worn or both.

To sharpen your chain you will need:

• Your gloves

• 5/32” file

• 6” file holder

• Medium flat file

• Gaugit

Your Poulan dealer has everything listed.

You will also need a vise to hold the

guide bar as you sharpen the chain.

1. Adjust the tension as tightly as you can and still be

able to move the chain around the bar. Place guide bar

in a vise, clamping the center of the bar.

2. Sharpen all the cutting edges on one side first. Then

sharpen the cutting edges on the other side. Mark your

starting point so you will know when you have

finished. File in 1 direction only — 2 or 3 strokes per

cutting edge is sufficient.

GUIDE BAR MAINTENANCE

Wear your gloves. Work in

cutting harder.

Check the underside of the chain for wear which could be causing wear to the guide bar. A lack of OIL in the chain oil

tank can damage both the chain and the bar. Make sure there is oil in the tank and that you have proper tension on the

u

Correct Groove Worn Grooves File Edges Square

14

lUfOt

chain. Improper tension will also cause excessive wear to guide bar.

The figure on the left shows a cross-section of the guide bar groove. Check

the tip and rails of the guide bar often for wear. If the inside groove of the

guide bar rail or nose is worn replace the guide bar.

3. After sharpening the cutting edges, place the gaugit

over the depth gauge. If the depth gauge sticks out, file

it off with the flat file. Do this for each depth gauge.

Your chain should now be sharp.

a lighted area with chain cooled off. A worn guide bar will damage the chain and make

Page 15

STARTER ROPE MAINTENANCE

Repairing the recoil starter rope requires a certain degree of mechanical skill. You may decide to let your dealer handle

this procedure. If you do try the procedure and the pulley spring pops out, take the unit to your dealer.

1, Remove the two screws on the side of the fan housing. 2. Then, remove the large screw at the rear of the control 3. Pull the gas line off the fitting going into the saw

handle and the small screw directly below it.

SAFETY CENTER SFREAP

FREbuENTLY

handle. Pull off the fan housing. Remove the fuel cap,

slide the fuel tank from the fan housing, replace the

cap and set it aside.

4. If the starter rope has broken, the tension on the

starter spring, which is located under the pulley, will be

released. If rope is not broken, release the spring

tension by pulling about 10 inches of rope from the

pulley and catch the rope in the notch as shown. Turn

the pulley counterclockwise until the spring tension is

released. Remove the pulley screw in the center of the

pulley. Carefully lift the pulley while gently twisting it

counterclockwise. Remove the old rope.

5, Move away from the fuel tank and burn the end of the

new rope which is going into the pulley. Pull the burnt

end through a rag while still hot, to smooth it. Feed

the rope through the housing and through the round

starter hole. Put the rope into the pulley groove and up

through the hole. Tie a knot into the end of the rope

and pull it tightly against the pulley. Rewind all the

rope onto the pulley, turning counterclockwise.

6.Set the pulley into the housing, push it down and

engage the spring. Replace and tighten the pulley

screw. Pull out 10" of rope and catch the rope in the

slot in the pulley. Turn the pulley 2 complete turns

clockwise winding up the spring. Holding the pulley,

pull the starter rope to the full extent and then let the

rope rewind slowly. Replace the fuel tank in the fan

housing and replace the housing. Make sure the fuel

line is not pulled loose or pinched. Replace the four

screws and the fuel line over the fitting. -[g

Page 16

PARTS AND SERVICE

Your POULAN Chain Saw has been expertly engineered and carefully manufactured with rigid

quality standards. As with all mechanical products, some adjustment or part replacement may

be necessary during the life of your unit.

FOR SERVICE OR REPLACEMENT PARTS;

1. Consult the yellow pages of your phone directory for the name of the nearest Beaird-Poulan/

Weed Eater Master Service Center {under Saws ) or Skil Service Center (under tools-electric).

2. For replacement parts, have available the following information:

a. Name of the unit

b. Model number

c. Description of part.

NOTE: Beaird-Poulan/Weed Eater provides parts and service through its authorized distributors

and dealers. All requests for parts and service should be directed to your local dealerfs).

Your dealer can keep you informed about improvements in our products as they are

placed on the market also. Parts and repair service are not available directly from BeairdPoulan/Weed Eater, Division Emerson Electric Co.

BEAIRD POULAN/WEED EATER

Division Emerson Electric Co.

Attn: Accessory Manager P.O. Box 9329

Shreveport, Louisiana 71129 ■iii—iiiii- . .■

64567 10/81

Loading...

Loading...