Poulan Pro 2025 LE Series, 2075 LE Series, 2150 LE Series, 2050 LE Series, 2175 LE Series Instruction Manual

...Page 1

Poulan

Please do not return unit to retailer.

Por favor, no devuelva el aparato al lugar de compra.

Veuillez ne pas retourner I'outil au d_taillant.

• 1-800-554-6723

www.poulan.com

Instruction Manual

Manual de Instrucciones

Manuel d'lnstructions

!

&

1950 / 2025 / 2050 / 2075

2150 / 2175 / 2350 / 2375

For Occasional Use Only

WARNING:

Read and follow all Safety Rulesand Operating Instructionsbefore

usingthis product. Failure to do so can resultin serious injury.

LE Series i

C_US

ADVERTENCIA:

Lea el manual de instruccionesy sigatodas las advertencias e en-

struccionesde seguridad. El nohacerlopuede resultaren lesiones

graves.

AVERTISSEMENT:

Life le manuel d'instructions et bien respecter tous les avertisse-

ments et toutes les instructionsde s_curit&. Toutd6faut de le faire

pourraitentraTnerdes blessuresgraves.

ElectroluxHomeProducts,Inc.

250 BobbyJonesExpressway

Augusta, GA30907

[] Ftom the _ Group. The wo,dd's No.l choice.

t.n_,,tr_N,CL_A_IRG,_D otrmooR_ppLout'C_L_4_VB_

Copyright ©2002 Electrolux Home Products, Inc,

53(_66523

4/9/02 !

Page 2

- B

WARNING! This chain Read and understand the

saw can be dangerou!! Care- instruction manual before

lessor improper usecancause usingthe chain saw.

seriousoreven fatal injury.

-_ Always wear appropriate ear protection, eye protectionand headprotection.

@

Always use two hands when operating the chain saw.

WARNING! Contacting the guide bar tipwith any object

should be avoided; tip contact may cause the guide barto

movesuddenly upwardandbackward, whichmay cause se-

riousinjury.

Measured maximum kickbackvalue without chain brakefur the bar

and chain combination on the label.

_k WARNING: Always disconnect

spark plug wireand place wirewhere it can-

notcontact spark plugto prevent accidental

starting when setting up, transporting, ad-

justing or making repairs except carburetor

ad ustments.

Because a chan saw s a high-speed wood-

cu_ing tool, special safety precautions must

be observed to reduce the riskof accidents.

Careless or improper use of this tool can

cause serious injury.

PLAN AHEAD

• Read this manual carefully until you com-

pletelyunderstandand can followall safety

rules, precautions, and operating instruc-

tionsbefore attemptlingto use the unit.

• Restrictthe use of your sawto adult users

who understand and can follow safety

rules, precautions, and operating instruc-

tions found in this manual

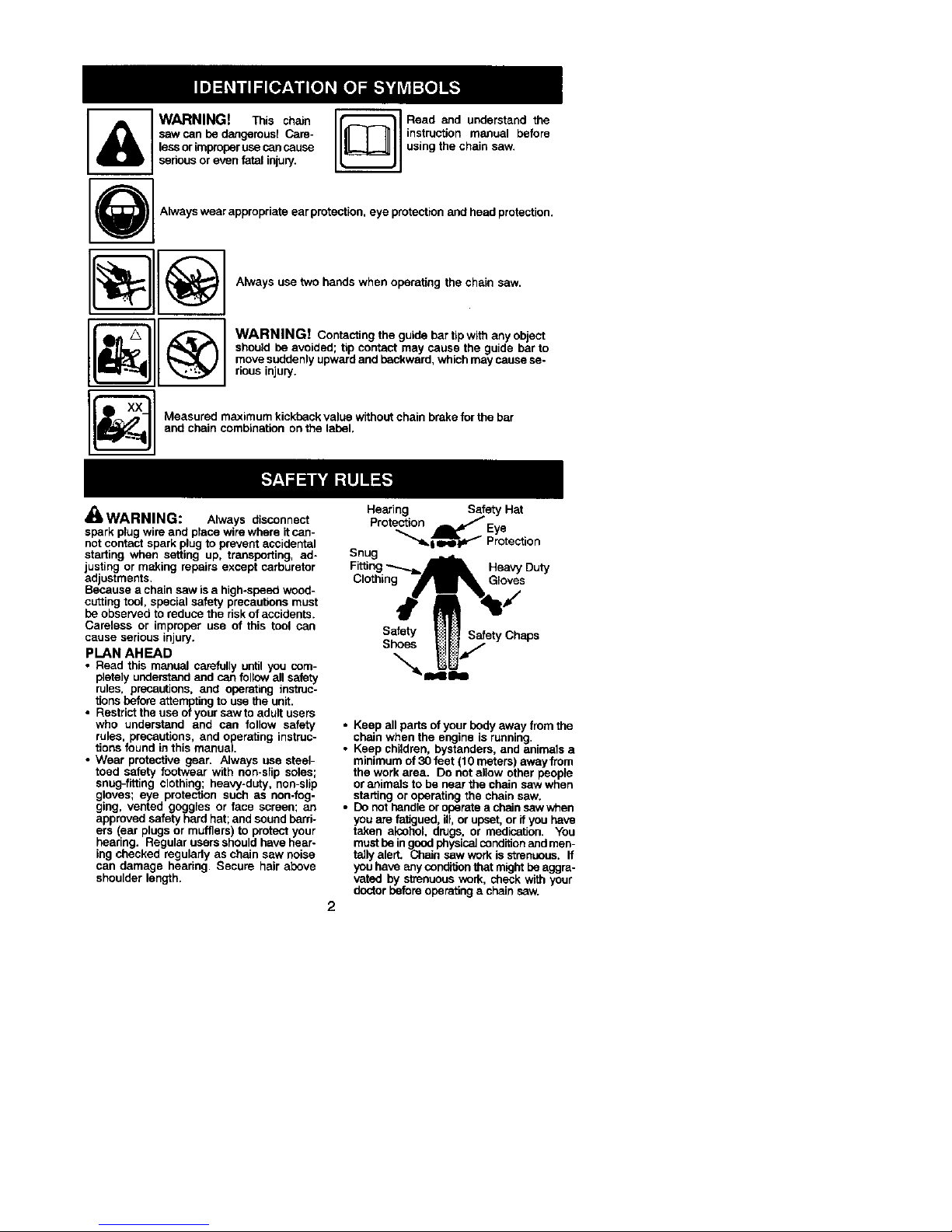

• Wear protective gear. Always use steel-

toed safety footwear with non-sSp soles;

snug-fitting clothing; heavy*duty, non-slip

gloves; eye protection such as non-fog-

ging, vented goggles or face screen; an

approved safety hard hat;andsound barri-

ers (ear plugsor mufflers) to protect your

hearing. Regular usersshouldhave hear-

ing checked regulady as chain saw noise

can damage hearing. Secure hair abeve

shoulder length.

Hearing Saf_y Hat

Protection _ Eye

"_i IMp_AI" Protection

Snug

Heavy Duty

Clothing Gloves

Safety Safety Chaps

Shoes

• Keep allparts of yourbody away from the

chain when the engine is running.

• Keep children, bystanders, and animals a

minimum of30 feet (10 meters) awayfrom

the work area. Do not allow other people

oranimals to benear the chain saw when

startingor operating the chain saw.

• Do not handleor operate a chainsawwhen

youare fatigued, ill, or upset, or if youhave

taken alcohol, drugs, or medication. You

must be ingoodphysicalconditionandmen-

tally alert. Chain saw work isstrenuous. If

youhave any conditionthat migl_ be aggra-

vated by strenuouswork, check with your

doctorbefore operatinga chain saw.

Page 3

• Carefully plan your sawing operation inad*

vance. Do notstartcutting unffiyou have a

clear work area, secure footing, and, ifyou

are felling trees, a planned retreat path.

OPERATE YOUR SAW SAFELY

• Donot operate a chain saw with one hand.

Serious injurytothe operator, helpers, by-

standers orany combination of these per-

sons may result from one-handed opera-

tion. A chain saw is intended for

two-handed use.

• Operate the chain saw only in awerl-venti*

lated outdoor area.

• Do not operate saw from a ladder or in a

tree.

• Make sure the chain will not make contact

with any object while starting the engine.

Never tryto start the saw when the guide

bar is in a cut.

• Do not put pressureon the saw at the end

of the cut. Applying pressure can cause

you to lose control when the cut is com-

pleted.

• Stop the engine before setting the saw

down.

• Do not operate a chain saw that is dam-

aged, irnpropedy ad usted, or not com-

pletely and securely assembled. Always

replace bar, chain, hand guard, or chain

brake immediately ff itbecomes damaged,

broken or is otherwise removed.

• With the engine stopped, hand carry the

chain saw with the muffler away from your

body, and the guide bar and chain to the

rear, prMerably covered with a scabbard.

MAINTAIN YOUR SAW IN GOOD

WORKING ORDER

• Have all chain sawservice performed bya

qualified service dealer with the exception

of the items listed inthe maintenance sec-

tionof thismanual. For example, if improp-

ertools are usedto remove orhold the fly-

wheel when servicingthe clutch,structural

damage to the flywrheel can occur and

cause the flywheel to burst.

• Make certain the saw chain stops moving

when the throttle trigger is released. For

correction, refer to CARBURETOR AD-

JUSTMENTS.

• Never modify your saw in any way.

• Keep the handles dry, clean, and free of oil

or fuel mixture.

• Keep fuel and oil caps, screws, and fas-

teners securely tightened.

• Use only Poulan® accessories and re-

placement paris as recommended.

HANDLE FUEL WITH CAUTION

• Do not smoke while handling fuel or while

operating the saw.

• Eliminate all sources ef sparks orflame in

the areas where fuel is mixed or poured.

There shouldbe no smoking,openflames,

orworkthat could cause sparks. Allowen-

gine to cool before refueling.

• Mix and pour fuel in an outdoor area on

bare ground; store fuel in a cool, dry,well

ventilated place; and use an approved,

marked container for all fuel purposes.

Wipe up all fuel spills before starting saw.

• Move at least 10 feet (3meters) from fuel-

ing site before starting engine.

• Turn the engine off and let saw cool in a

non-combustible area, not on dry leaves,

straw, paper, etc. Slowly remove fuel cap

and refuel unit.

• Store the unitand fuel inan area where fuel

vapors cannot reach sparks or open

flames fromwater heaters, electric motors

or switches, furnaces, etc.

KICKBACK

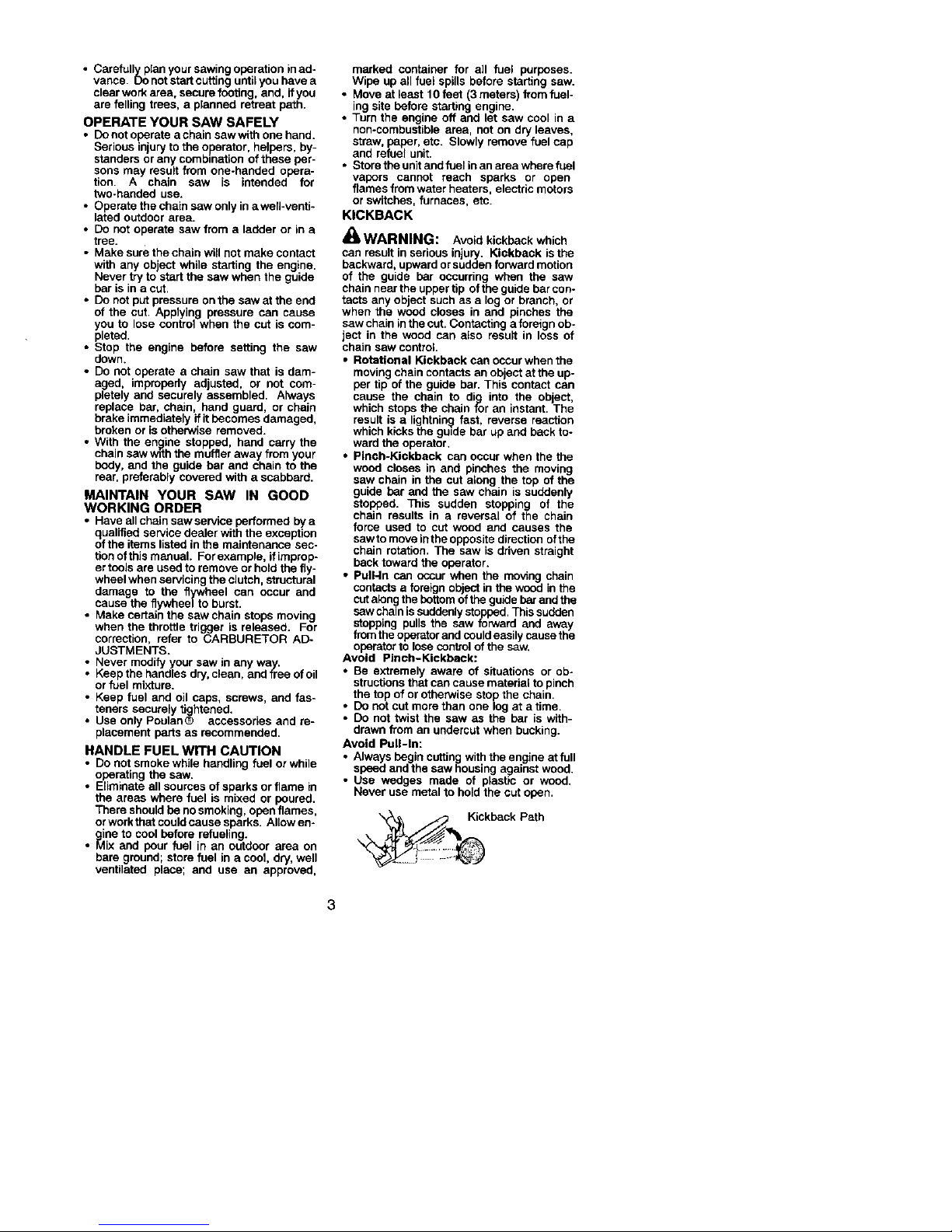

WARNING: Avoidkickbackwhich

can result inserious injury. Kickback isthe

backward, upward orsudden forward motion

of the guide bar occurring when the saw

chain near the uppertip oftheguide barcon*

tacta any object such as a log or branch, or

when the wood closes in and pinches the

saw chain inthe cut. Contacting a foreign ob-

ject in the wood can also result in loss of

chain saw control.

• Rotational Kickback can occur when the

moving chain contacts an ob ect at the up-

per tip of the gu de bar. Th s contact can

cause the chain to di_ into the object,

which stops the chain for an instant. The

result is a lightnin9 fast, reverse reaction

which kicks the guide bar up and back to*

ward the operator,

• Pinch-Kickback can occur when the the

wood closes in and pinches the moving

saw chain in the cut along the top of the

guide bar and the saw chain is suddenly

stopped. This sudden stopping of the

chain results in a reversal of the chain

force used to cut wood and causes the

sawtomove in the opposite direction of the

chain rotation. The saw is driven straight

back toward the operator.

• Pult-tn can occur when the moving chain

contactsa foreignobject in the wcod inthe

cutalongthebottomof theguidebarandthe

sawchainis suddenlysto)pped.This sudden

stopping pulls the saw forward and away

fromthe operatorand couldeasilycause the

operatorto losecontrol of the saw.

Avoid Pinch-Kickback:

• Be extremely aware of situations or oh*

strucfionsthat can cause material topinch

the top of or otherwise stop the chain.

• Do notcut more than one log at a time.

• Do not twist the saw as the bar is with-

drawnfrom an undercutwhen bucking.

Avoid Pug-In:

• Always begincuttingwiththe engine atfull

speed andthe saw housing against wood.

• Use wedges made of plastic or wood.

Never use metal to hold the cutopen.

Kickback Path

Page 4

Avoid Obstructions

Clear The Working Area

REDUCE THE CHANCE OF

KICKBACK

• Recognize that kickback can happen.

With a basic understanding of kickback,

you can reduce the element of surprise

which contributesto accidents.

• Never let the movingchaincontact any ob-

Ject at the tip ofthe guide bar.

• Keep the workingarea free from obstruc-

tions suchasothertrees, branches, rocks,

fences, stumps, etc. Eliminate or avoid

any obstruction that your saw chain could

hit while you are cutting. When cutting a

branch, do not let the guide bar contact

branch or other objects around it.

• Keep your saw chain sharp and properly

tensioned. A loose or dull chain can in-

crease the chance of kickback oocurhng.

Follow manufacturer's chain sharpening

and maintenance instructions. Check ten-

sion at regular intervals with the engine

stopped, never with the engine running.

Make sure the chain brake nuts are se-

• cutely tightened after tensioning the chain.

Begin and continue cuttingat full speed. If

the chain is moving at a slower speed

there s greater chance of kickback occur-

ring.

• Cut one log at a time.

• Use extreme caution when re-entering a

pl

revious cut.

• Do not attempt cuts starting withthe tip of

• the bar (plunge cuts).

Watch forshifting logsorother forces that

could close a cut and pinch or fall into

chain.

• Use the Reduced-Kickback Guide Bar

and Low-Kickback Chain specified for

yoursaw.

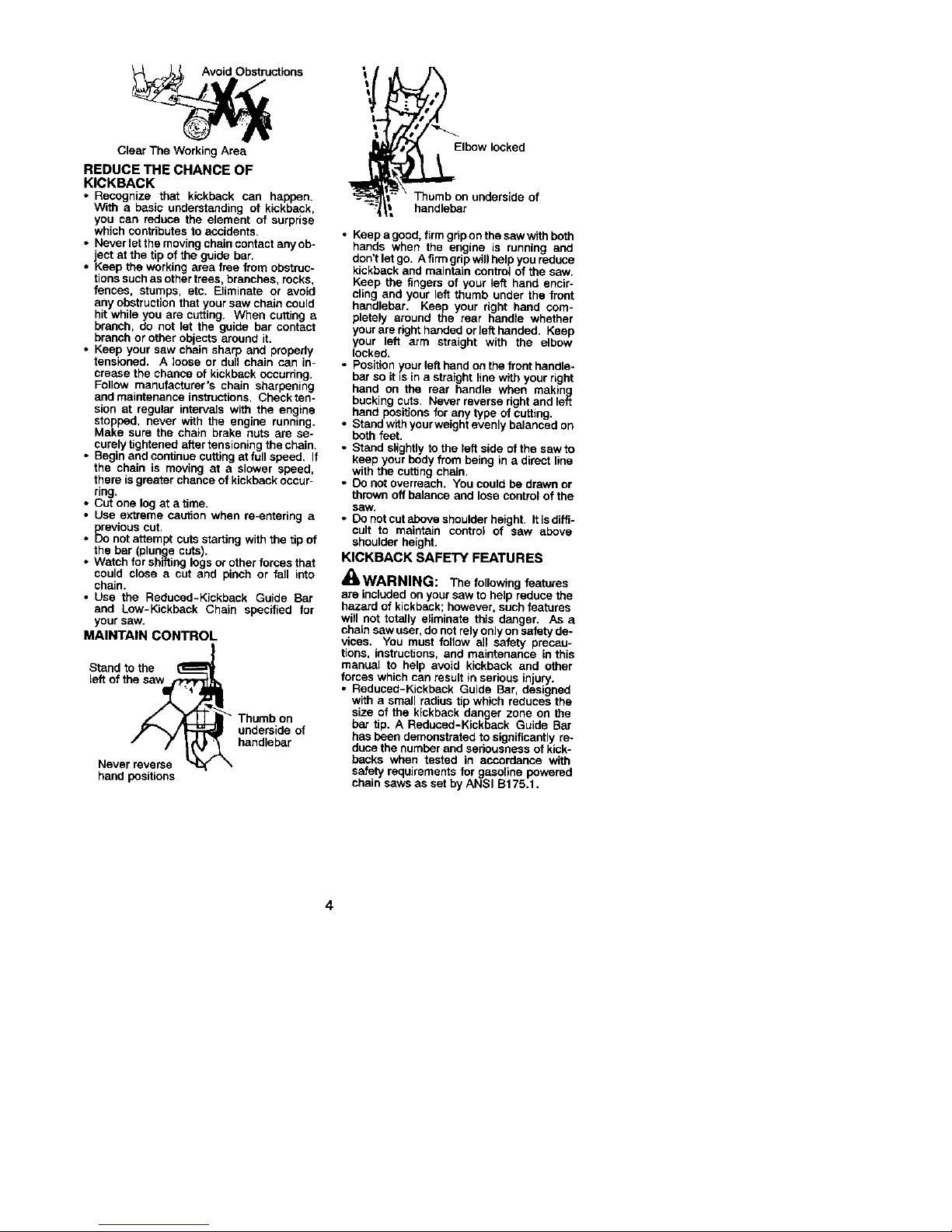

MAINTAIN CONTROL

Stand to the

left of the saw

Thumb on

underside of

handlebar

Never reverse

hand positions

Elbow locked

Thumb on underside of

handlebar

• Keep agood, firm grip on the saw with both

hands when the engine is running and

don't let go. A firmgrip will help you reduce

kickback and maintain controlof the saw.

Keep the fingers of your left hand encir-

cling and your left thumb under the front

handlebar. Keep your right hand com-

pletely around the rear handle whether

your are right handed or left handed. Keep

your left arm straight with the elbow

locked.

• Position your left hand onthe front handle-

bar soit is in a straight line with your right

hand on the rear handle when makin

a

bucking cuts. Never reverse right and le_

hand positions for any type of cutting.

• Stand with yourweight evenly balanced on

bath feet.

• Stand slightly to the left side of the saw to

keep your body from being in a direct line

with the cut_ngchain.

• Do not overreach. You could be drawn or

thrown off balance and lose control of the

saw.

• Donotcutaboveshoulder beight. Itisdiffi-

cult to maintain control of saw above

shoulder height.

KICKBACK SAFETY FEATURES

A_' WARNING: The following features

are included on your saw to help reduce the

hazard of kickback; however, suchfeatures

will not totally eliminate this danger. As a

chain saw user, do notrelyonly onsafety de-

vices. You must follow all safety precau-

tions, instructions, and maintenance in this

manual to help avoid kickback and other

forces which can result in serious in u_y.

• Reduced-Kickback Guide Bar, des gned

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced-Kickback Guide Bar

has been demonstrated to significantly re-

duce the numberandseriousness of kick-

backs when tested in accordance with

safety requirementsfor gasoline powered

chain saws as set by ANSI B175.1.

4

Page 5

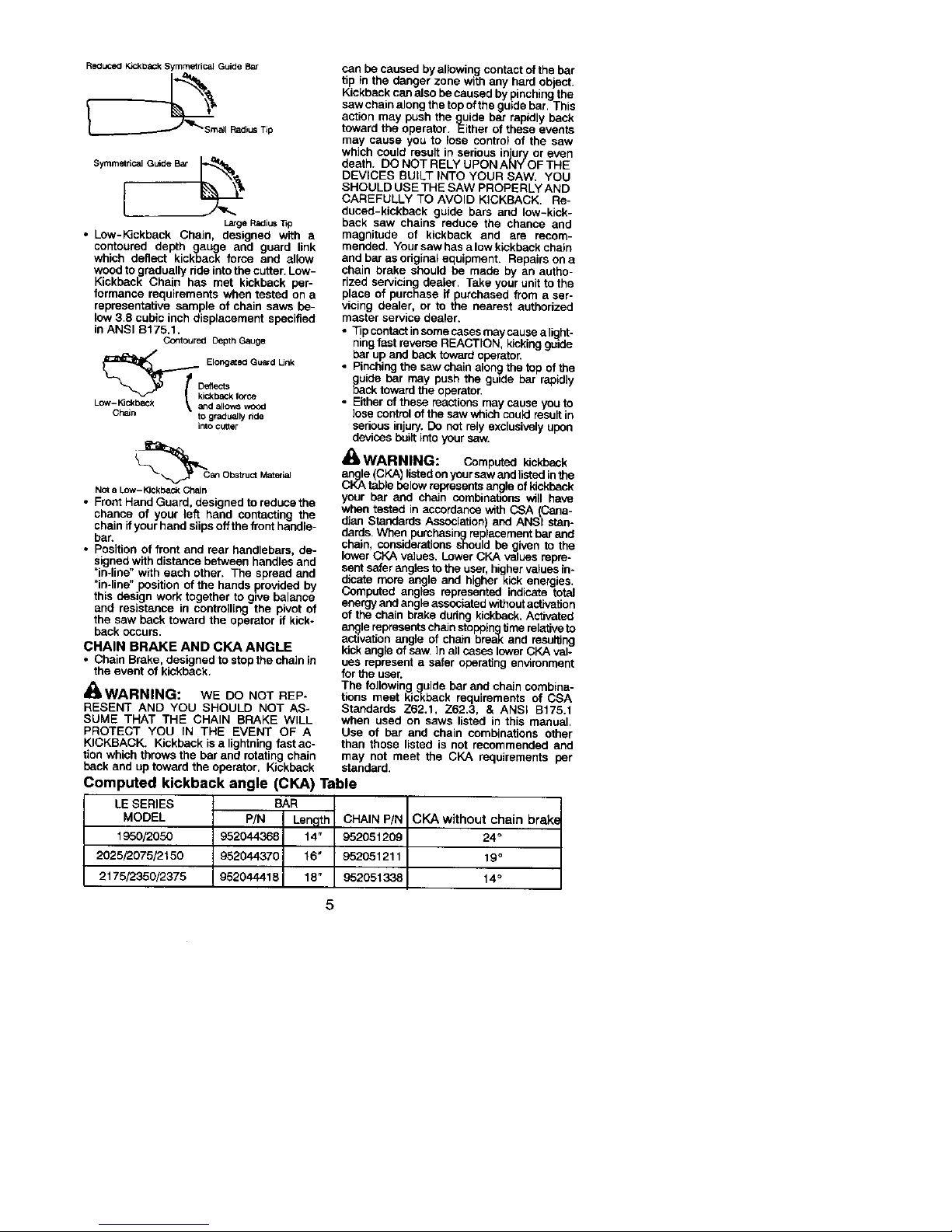

Reduced KickbaCk Symmetrical Guide Bar

aJI Radius T_p

Symmetrical GL_de Bar I,_1_

Large Radius 13p

• Low-Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride intothe cutter.Low-

Kickback Chain has met kickback per-

formance requirements when tested on a

representative sample of chain saws be-

low3.8 cubic inch displacement specified

inANSI B175.1.

Contoured Depth Gauge

__ Elong=ed Guard Unk

Deflects

ic_baCk fc_ce

Low-K3c_back _ and allowS woc_l

Chain to gradually ride

into cu_er

i_Can Obst rue1Material

Not a Low- _0ckback Chain

• Front Hand Guard, designed to reduce the

chance of your left hand contacting the

chain if your hand slipsoff the front handle-

bar.

• Position of front and rear handlebars, de-

signed with distance between handles and

"in-line" with each other. The spread and

"in-line" position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kick-

back occurs.

CHAIN BRAKE AND CKA ANGLE

• Chain Brake, designed to stop the chainin

the event of kickback.

_I=WARNING: WE DO NOT REP-

RESENT AND YOU SHOULD NOT AS-

SUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A

KICKBACK. Kickback is a lightningfast ac-

tion which throws the bar and rotatingchain

back and up toward the operator. Kickback

Computed kickback angle (CKA) Table

LE SERIES BAR

MODEL P/N Length CHAIN P/N

1950/2050 952044368 14" 952051209

2025/2075/2150 952044370 16" 952051211

2175/2350/2375 952044418 18" 952051338

can becaused byallowing contactof the bar

tip in the danger zone with any hard object.

Kickbackcanalso be caused by pinchingthe

saw chainalong thetopofthe guide bar. This

action may pushthe g=uidebar rapidly back

toward the operator. Either of these events

may cause you to lose control of the saw

which could result in serious in'ulurv(oreven

death. DO NOT RELY UPON ANY'OF THE

DEVICES BUILT INTO YOUR SAW. YOU

SHOULD USE THE SAW PROPERLY AND

CAREFULLY TO AVOID KICKBACK. Re-

duced-kickback guide bars and low-kick-

back saw chains reduce the chance and

magnitude of kickback and are recom-

mended. Your saw has a lowkickback chain

and bar as original equipment. Repairs on a

chain brake should be made by an autho-

rized servicing dealer. Take yourunit to the

place of purchase if purchased from a ser-

vicing dealer, or to the nearest authorized

master service dealer.

• 33pcontactinsomecasesmaycause a light-

ningfast reverse REACTION, kickingguide

bar upand backtoward operator.

• Pinchingthe saw chain alon9 thetop ofthe

guide bar may push the guide bar rapidly

back towardthe operator.

• Either of these reactionsmaycause youto

lose control of thesaw which couldresultin

sedous injury.Do notrely exclusivelyupon

devicesbuilt intoyoursaw.

_1' WARNING: Computed kickback

_nK_e(t_bCKA)listed on yoursaw and listedinthe

le below representsangleof kickback

your bar and chain combinations will have

when tested in accordancewith CSA(qCana-

dian Standards Association and ANS_ stan-

dards.When purchasng repacement bar and

chain, considerations should be givento the

lower CKA values. Lower CKA values repre-

sent safer anglesto the user,higlhervalues in-

dicate more angle and higberkick energies.

Domputod angles represented indic_e total

energyand angleassociatedwithoutactivation

of the chain brake duringkickback.Activated

an_le representschainstopeingtime relativeto

astwatlen angle of chain break and resulting

kickangle ofsaw. ]n allcases lowerCKA val-

ues representa safer operating environment

for the user.

The following g=uidebar andchain combina-

tions meet kickback requirements of CSA

Standards Z62.1, Z62.3, & ANSI B175.1

when used on saws listed in this manual.

Use of bar and chain combinations other

than those listed is not recommended and

may not meet the CKA requirements per

standard.

CKA without chain brak_

24°

19°

14°

5

Page 6

NOTE: If this saw is to be used for corn*

mercial logging, a chain brake is required

and shall not be removed or otherwise dis-

abled to complywith Federal OSHA Regula-

tions for Commercial Logging.

SAFETY NOTICE: Exposureto vibrations

throughprelonged use of gasoline powered

handtools couldcause bloodvessel ornerve

damage in the fingers, hands, and ointsof

peope prone to crcuaton dsorders or

abnormal swellings. Prolonged use in cold

v_ather has been linked to blood vessel

damage in othenNise healthy people. If

symptoms occur such as numbness, pain,

lossofstrength,changeinskin colorortexture,

orlossoffeeling inthefingers,hands,orjoints,

discontinue the use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems.Users who operate power tools on

a Continualand regular basis must monitor

closely their physical condition and the

conditionofthistool.

SPEClAL NOTICE: Yoursaw isequipped

witha temperature limitingmufflerand spark

arresting screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey, Oregon, and Washington requireby

law that many internal combustion engines

to be equipped witha sparkarresting screen.

Ifyouoperate a chain saw ina state orlocale

where suchregulationsexist, you are legally

responsible for maintaining the operating

condition of these parts. Failure to do so is

a violationofthe law. R_fer tothe SERVICE

section for maintenance of the spark

arresting screen.

FailuretofollowallSafety Rules andPrecau-

tionscan resultin serious injury. If situations

occur whlch are notcovered in this manual,

use care and goodjudgement. If you need

assistance, contactyour authodzed service

dealer or call t-800-554-6723.

STANDARDS: This saw islistedbyUnder-

writer'sLaboratories,Inc., in accordancewith:

ANSI B175.1-2000 American National

Standards for Gasoline-Powered Chain

Saws - Safety Requirements

CSA Z62.1-1995 Chain Saws - Occupa-

tional Health and Safety

CSA Z62.3-1996 Chain Saw Kickback Oc-

cupational Health and Safety

The chain issharpand cancut youevenwhen

it is notmoving!

• Loosen and remove the chain brake nuts

and the chain brake from the saw.

• Remove the plastic shipping spacer (if

present).

Location of shipping spacer

_O

a_ Chain Brak_e

Ch Nuts

Bar Tool

• An edju_ng pinand screw is usedto adjust

the tensionof the chain. Itisvery important

whenassemblingthepar,thatthepin located

on the adjustingscrew aligns into a hole in

the bar.Turningthe screwwill move the ed-

ustmeot pinup and downthe screw.Locate

ths adjustment before you begin mounting

the baronto the saw. See illustrationbelow.

Inside view of

/'4 C_aln Brake

Adjustment located on Chain Brake

• Turn the adustingscrew by hand counter-

clockwise until the adusting pin just

touches the stop. Th sshould allow thepin

to be near the correct position.

• Slide guide bar behind clutch drum until

guide bar stops against clutch drum

sprocket.

• Carefullyremovethe chain from the pack-

age. Hold chain with the dnve links as

shown.

Protective gloves (not provided) should be

wom duringassembly.

An'ACHING THE BAR & CHAIN (If not

already attached)

_I_WARNING: If received assembled,

repeatallsteps to ensure your saw iswopelty

assembledand all fasteners are secure. Al-

ways wear gloves when handlingthe chain.

6

_p of

Bar

3UTTERS MUST FACE IN I

DIIRECTION OF ROTATION

Page 7

Cutters Depth Gauge

Drive Links

Place chain onto the sprocket

• Place chain over and behind clutch, fitting

the drive links in the crutch drum sprocket.

• Fit bottom of drive links between the teeth

in the sprocket in the nose of the guide bar.

• Fit chain drive links into bar groove.

• Pull guide barforward until chain is snug in

guide bar groove. Ensure all drive links

are in the bar groove.

NOTE: CHAIN BRAKE MUST BE

DISENGAGED BEFORE INSTALLA-

TION ON THE SAW. TO DISENGAGE

CHAIN BRAKE, PULL THE FRONT

HAND GUARD BACK TOWARD THE

REAR OF THE CHAIN BRAKE AS

FAR AS POSSIBLE (SEE ILLUSTRA-

TION),

DISENGAGED _

Front Hand Guard

/

ENGAGED

Chain Brake

• Now, install chain brake making sure the

adjusting pin ispositioned inthe lower hole

in the guide bar. Remember this pin

moves the bar forward and backward as

the screw is tamed.

• Install chain brake nuts and finger tighten

only. Once thechain istensioned, you will

need to tighten chain brake nuts.

CHAIN TENSION

(Including units with chain already installed)

NOTE: When adusting chain tension,

make sure the cha n brake nuts are finger

tight only. Attempting to tension the chain

when the chain brake nuts are tight can

cause damage.

Checking the tension:

Use the screwdriver endof the chainadjust-

menttool (bartool)to movethe chain around

the bar, If the chaJndoes not rotate, it istoo

tight,fftoo loose, the chain willsag belowthe

bar.

Chain Ad ustment

Chain Brake Nuts Too Bar Tool)

Adjusting the tension:

Chain tension is very important. Chain

stretches durin_luse. This isespecially true

duringthe first tew times you use your saw.

Always check chain tension each time you

use and refuel your saw.

You.can ed'ustJthe chain tension byloosen-

ing the cham brake nuts and turningthe ad-

justing screw 1/4 of a turnwhile lifting up on

the bar.

• Ifchainistootight,turnadjusting screw 1/4

turn counterclockwise.

• If chain is too loose, turn adjusting screw

1/4 turn clockwise.

Chain Brake Nuts Guide Bar

Adjusting Screw - 1/4 Turn

• Lift up the tip of the bar and tighten the

chain brake nuts with the bar tool.

• Recheck chain tension.

WARNING: If the saw isoperated

with a loose chain, the chain could ump off

the guide bar and resultin serious injury.

Page 8

KNOWYOURCHAINSAW

READTHISINSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

CHAIN SAW, Compare the illustrations with your unit to familiarize yourself with the location of

the various controls and adjustments. Save this manual for future reference.

Chain Front Hand Guard--=- _ f'%./ Front Handle

Adjustment Tool I I_--

(BarTool) I_l J l\ _ / Starter Rope

I_ k_ LaY-_,_=_ / ON/STOP

(_tt======_ _/_, Switch

Chin Muffler _ _'_/_ Pdmer

Bulb

Bar Oil Fill Cap Housing Fuel Mix Fill Cap

Cylinder Cover

Fast

Throttle Chain

Direction

Rear of Travel

Handle

Throttle Choke Ba0

Trigger Knob Chain Chain Nuts Sprocket

Brake Catcher Hole

ON/STOP SWITCH

The ON!STOP SWITCH is used to stopthe

engine.

THRO'I-I'LE TRIGGER

.me THROTTLE TRIGGER controlsengine

spend.

THROTTLE LOCK-OUT

.me THROTTLE LOCK-OUT must be

pressedbefem you can squeeze the throttle

l_gger. This feature prevents you from acci-

dentally squeezingthe _gger.

FAST IDLE LOCK

.me FAST IDLE LOCK hoidsthe throttletrigger

in the starting position.Activate the fast idle

lock by pressing the throttle lockout and

squeeTJngthe throttletdgger.With the throttle

gger squeezed, press the fast idlelock. Re-

leasethe throttle lockoutandthgger whilehold-

ingthe fast idlelock button.

CHOKE KNOB

.me CHOKE KNOB activates the choke to

provideadditionalfeel to theengine duringcold

starting.

PRIMER BULB

The PRIMER BULB circulatesfuel to the car-

buretorto providequickerstarting.

CHAIN BRAKE

The CHAIN BRAKE is a device designedto

stop the chain if kickback occurs..me chain

Ixake activates automatically in the event of

kickback. The chainbrake activates manually

if the fronthand guard is pushed forward,.me

chain brake isdisengaged by pullingthe front

handguardbeck toward the front handle as far

as possible.

CHAIN TENSION

Itis normalf(x a new chalotostretch dudnqfirst

30 minutes of operation. You shouldc'fheck

your chain tension frequently. See CHAIN

TENSION under the ASSEMBLY section.

_1, WARNING: Muffler isvery hot dur-

ing and after use. Do not touch the muffler or

allow combustible material such as dry

grass or fuel to do so.

Page 9

/1=WARNING: Removefuelcapslow-

lywhen refueling,

FUELING ENGINE

This engine is certified to operate on un-

leaded gasoline. Before operation, gasoline

mustbe mixedwith a _ood quality synthetic

2-cycle air-cooled engine oil desislgnedto be

mixed at a ratio of 40:1, Poulan/Weed Eater

brand synthetic oil isrecommended. A40:1

ratio is obtained by mixing 3.2 ounces of oil

with 1gallon of unleaded gasoline. Included

withthis saw isa 3.2 ouncecontainerof Pou-

lan/Weed Eater brand synthetic oil Pourthe

entirecontentsofthiscontainer intoI gallonof

gasolineto achievethe properfuelmixture,

DO NOT USE automotive or boatoil. These

oilswillcause engine damage, When mixing

fuel follow the instructions printed on the

container, Always read and follow the safety

rules listed under HANDLE FUEL WITH

CAUTION.

BAR AND CHAIN LUBRICATION

The bar and chain require continuous lubri-

cation. Lubrication is provided by the auto-

matic oiler system when the oil tank iskept

filled. Lack of oil willquickly ruin the barand

chain, Too little oil will cause overheating

shownby smoke comingfrom the chain and/

or discolorationof the bar,

In freezing weather oil willthicken, making it

necessary to thin bar and chain oil with a

small amount 5 to 10%) of #1 Diesel Fuel or

kerosene. Bar and chan oil must be free

flowing for the oil system to pump enough oil

for adequate lubrication.

Genuine Poulan ® bar and chainoil is recom-

mended to protect your unit against exces-

sive wear from heat and friction. Poutan®

oil resists high temperature thinning. IfPou-

lan® barandebain oilisnofavailable, usea

good grade SAE 30 oil.

• Never use waste oilfor bar and chain lubd-

cation.

• Always stop the engine before removing

the oHcap.

IMPORTANT

Experience indicates that alcohol-blended

fuels (called gasohol or using ethanol or

methanol) can attract moisturewhich leads

to separation and formation of acids during

storage. Acidic gas can damage the fuel

system of an engine while in storage. To

avoid engine problems, the fuel s,y.'stem

should be emptied before storage for 30

days or longer. Drain the gas tank, start the

engtineand let it run until the fuel lines and

carburetor are empty. Use fresh fuel next

season. See STORAGE section for addi-

tional information.

9

_ WARNING:

The chain must not

move when the engine runsat idle speed. If

the chain moves at idle speed refertoCAR-

BURETOR ADJUSTMENT within this

manual, Avoid contact withthe muffler. A hot

mufflercan cause serious burns.

To stop the enbgine move the ON/STOP

switch tothe STOP position,

To start the engine hold the saw firmly on

the ground as illustrated. Make sure the

chain is free to turn without contacting any

object,

Use only15"-18" of rope per pull.

Hold saw firmly while pulling starter rope

Starair rope handle

Left hand

on front

handle

Right foot through rear handle

IMPORTANT POINTS TO REMEMBER

When pullin_g the starterrope, do not use the

full extent of the rope as this can cause the

rope to break. Do not let starter ropesnap

back. Hold the handle and let the rope re-

wind slowly.

NOTE: Do not attempt to cut material with

the fast idlelock button inthe locked position.

STARTING A COLD ENGINE (or

warm engine after running out of

fuel)

ON/STOP SWITCH

(SIDE VIEW)

sO"op

• Move ON/STO Pswitchto the ON position.

• Pull choke knob out to the furlextent.

• Slowly pressprimer bulb 6 times,

• Squeeze and hold throttle trigger. With

thumb press fast idle lock down; then re-

lease throttle trigger,

Fast idle lock button

Throttle _ •

Iock-ou

Throttle_l_.----J / Cbakeknob

trigger

• Sharply pull the starter rope handle 5times

with your right hand. Then, proceed to the

next step.

NOTE: Ifthe engine sounds as if it is try-

ing to start before the 5th pull, stop pulling

and immediately proceed to the next step.

Page 10

• Push the choke knobin completely (tothe

OFF position);pull the starter ropeun_lthe

engine starts.

CHOKE

Choke knob OFF FULL

• Allow the en_line to run for approximately5

seconds. Then, squeeze and release

throttle trigger'to alk_w engine to returnto

idle speed.

STARTING A WARM ENGINE:

• Move ON/STOP switch tothe ON position.

• Push the choke knob in completety (tothe

OFF position).

• Slowly press primer bulb 6 times.

• Squeeze and hold throttle trigger. With

thumb press fast idle Inck down; then re-

lease throttle trigger.

• Sharply pull thestarter ropewith yourright

hand untilthe engine starts.

• Squeeze and release throttle triOger to al-

lowengine to return to idle speed.

DIFFICULT STARTING (or starting a

flooded engine):

The engine may be flooded with too much

fuel if it has not started after 10 pulls.

Flooded engines can be cleared of excess

fuel by following the warm engine starting

procedure listed above. Insure the ON/

STOP switch is in the ON position.

Starting could require pullingthe starter rope

handle many times depending on how badly

the unit is flooded. If enginefailsto start,refer

to the TROUBLESHOOTING TABLE or call

1-800.554o6723.

CHA|N BRAKE

_WARNING: If the brake band is

worn too thin it may break when the chain

brake Istfiggared. With abroken brake bend,

the chain brake will not stop the chain. The

chain brake shouldbe replaced by an autho-

rized service dealer ifany part is worn to less

than 0.020" {0.5 ram) thick. Repairs on g

chain brake should be made by an autho-

rized service dealer. Take your unit to the

place of purchase if purchased from a sar-

v_cing dealer, or to the nearest authodzed

master service dealer.

• This saw is equipped with a chain brake.

The brake isdesigned to stop the chain if

kickback occurs.

• The inertia-activated chain brake is

activated ifthe front hand guard ispushed

forward, either manually (by hand) or

automatically _bysudden movement).

• If the brake is already activated, it is

disengaged by pullingthe front hand guard

back toward the front handle as far as

possible,

• When cutting with the saw, the chain brake

must be disengaged.

Disengaged

:i_Engaged

,,

Braking function control

CAUTION: The chain brake must be

checked several times daily. The engine

mustbe runningwhen performing this proce-

dure. This istheonly instance when the saw

should be placed on the ground with the en-

gine running.

Place the saw on firm ground. Grip the rear

handle withyour righthand and the frontban-

die with your [efthand. Apply full throttle by

fully depressing the throttle trigger. Activate

the chain brake by turning your left wrist

against the hand guard without releasing

your griparound the front haedle. The chain

shouldstop immediately.

Inertia activating function control

,_WARNING: When performing the

following procedure, the engine must be

turned off.

Grip the rearhandle with yourright hand and

the front handte with your left hand. Hold the

chain saw approximately 14" (35 cm)above

a stump or other wooden surface. Release

your grip on the front handle and use the

weight of the saw to let the top of the guide

bat fall forward and contact the stump.

When the tip of the bar hits the stump, the

brake should activate.

IMPORTANT POINTS

• Check chain tension before first use and

after 1 minute of operation. See CHAIN

TENSION in the ASSEMBLY section.

• Cut wood orgy. Do not cut metal plastics,

masons/ non-,,_od building materials, etc.

• Stop the saw dthe chain str kes a fore gn

object. Inspect the saw and repair or re-

I_e ptirts as p,ecessary.

• Keep the chainoutof dirtand sand. Evena

small amount ofdirtwill quicklydull a chain

and thus increasethe possibilityofkickback.

• practice cutting a few small logs usingthe

followingtechniques toget the "feel" ofus-

Ing your saw before you begin a major

sawing operation.

• Squeeze the throttle trigger and allow

the engine to reach full speed before

cutting.

• Begin cutting with the saw frame

against the log.

Keep the engine at fullspeed the entire

i time are cutting.

you

Allow the chain tocutforyou. Exertonly

light downward pressure, if you force

the cut, dame e tothe bar,chain, oren-

gine can rescue.

10

Page 11

• Release the throttle triggereras soonas

the cut is completed, allowing the en-

the to idle. If you run the saw at full

gi_rottlewithouta cutting load, unneces-

sary wear can occur to the chain, bar,

andengine. It is recommended that

the engine not be operated for lon-

er than 30 seconds at full throttle.

• _ avoid losingcontrol when cut iscom-

plete, do notputpressure onsaw atend

of cut.

• Stop the engine before setting the saw

down after cutting,

TREE FELLING TECHNIQUES

_ikWARNING: Check for broken or

dead branches which can fall while cutting

causing serious injury. Do not cutnear build-

ings or elect ricalwires ifyou do not knowthe

direction of tree fall, norcut at nightsinceyou

will not be ale to see well, nor during bad

weather such as rain,snow,or strongwinds,

etc. Ifthe tree makes contact with any utility

line, the utility company should be notified

immediately.

• Carefully plan yoursawing operation in ed-

vance,

• Clear the workarea. You need a clear area

all aroundthe tree so you can have secure

• footings.

The chain saw operator should keep on

the uphillside ofthe terrain as the tree is

likel=ytorollorslide downhillafter itisfelled.

• Study the naturalconditionsthatcan cause

the treeto fall ina gerticular direction.

Natural conditionsthat can cause a tree to

fall ina particular direction include:

• The wind direction and speed.

• The lean of the b'ee. The lean of a tree

might not be apparent due to uneven or

slopingterrain. Usea plumb orlevel tode-

termine the direction oftree lean.

• Weight and branches on one side.

• Surrounding trees and obstacles.

Lookfor decay and rot Ifthe trunk isrotted,

it can snap and fall toward the operator.

Check for broken or dead branches which

can fall on youwhile cutting.

Make sure there isenough room fur the tree

to fall. Maintain a distance of 2-1/2 tree

lengths from the nearest person or other ob*

ects. Engine noisecan drown out awaming

ca ,

Remove dirt, stones, loose bark, nails, sta-

es, and wire fromthe tree where cuts are to

_:_made.

Plan a clear retreat path to the rear and diag-

onal to the line of fall.

_,_,, Plan a clear retreat path

_--- -_._--""_- Direction of Fail

45 ° _

M0

FELLING LARGE TREES

(6 inches in diameter or larger)

The notch method is used to fell large trees.

Anotch iscut onthe sideof thetree inthede-

sired direction of fall. After a felling cut is

made on the opposite side of tree, the tree

will tend to fall into the notch.

NOTE: If the tree has large buttress

roots, remove them before making the

notch. If using sawto remove buttress

roots, keep saw chainfrom contacting

ground to prevent dulling of the chain.

NOTCH CUT AND FELLING THE

TREE

• Make notch cut by cutting the top of the

notchfirst. Cut through 1/3ofthe diameter

ofthe tree. Nextcomplate the notch bycut-

ting the bottom of the notch. See illuatra-

ben. Once the notch is cut remove the

notch ofwood from the tree.

Final (felling) cut here. 2 in-

ches above center of notch.

Pirsfeut\

Notch _. - 2"

s.ono

• After removing the wood from the notch,

make the felling cut on the oppositeside of

the notch.This isdonebymakinga cutabout

two inches higher than the center of the

notch. This will leave enough uncutwood

between the felling cutand the notchtoform

a hinge. This hinge will help preventthebee

fromfalling in the wrongdirection.

Hinge holds tree on stump and helps

control fall

Opening

of felling

7

Closing of

notch

NOTE: Before felling cut is complete, use

wedges to open the cut if necessaLryto

controlthe directionof fall. Toavoid kickback

and chain damage, use wood or plastic

wedges, but never steel or ironwedges.

• Be alert to signs that the tree is ready to

fall: cracking sounds, widening of the fell-

ing cut, or movement in the upper

branches.

• As tree startstofall, stopsaw, put itdown,

and get away quickly onyour planned re-

treat path.

11

Page 12

• DO NOT cut down a partially fallen tree

withyour saw. Beextremely cautious with

partially fallen trees that may be pooorly

supported. When atree doesn't fall com-

pletely, setthe sawaside and pulldownthe

tree with a cable winch, block and tackle,

or traator,

CUTTING A FALLEN TREE

(BUCKING)

Buckingis the term used for cutting a fallen

tree tothe desired log size.

_ WARNING: Do notstand onthe log

being cut. Any portioncan rollcausing loss

of footing and control. Do not stand downhill

of the log being cut.

IMPORTANT POINTS

• Cut only one log at a time.

• Cut shattered wood very car_uJly; sharp

pieces ofwoodcould beflung towardopera-

to_

• Use a sawhorse to cut small logs. Never

allow another person to holdthe log while

cutting and never hold thelog with your leg

or foot.

• Do not cut in an area where logs, limbs,

and rootsare tangled such as in a blown

downarea, Dragthe logs intoa clear area

before cutting by pulling out exposed and

cleared logs first.

TYPES OF CU'I'rlNG USED FOR

BUCKING

_I_WARNING: if saw becomes

pinched or hung in a log,don't try toforce it

out, You can lose controlof the saw resulting

in injuryand/or damage to the saw. Stopthe

saw, driveawedge ofplasticorwoodinto the

cut until the saw can be removed easily. Re-

startthesaw andcarefullyreenter the cut. To

avoid kickback and chain damage, do not

usea metalwedge. Do notattemptto restart

yoursaw when it is pinchedor hung in a log.

Use a wedge to remove pinched saw

Turn saw OFF and use a plastic or

wooden wedge to force cut open.

Ovemutting begins on the top side of the log

with the bottom of the saw against the log.

When overcutting use light downward pres-

sure.

g

Undercutting involvescuttingonthe under-

side ofthe log withtop of sawagainst the log,

When undercutting use light upward pres-

sure, Hold saw firmly and maintain control,

The saw willtend to push back toward you.

_ WARNING: Never turn saw upside

down to undercut. The saw cannot be con-

trolled inthis position.

Always make your first cuton the compres-

sionside of the log. The compression side of

the log is where the pressure of the log's

weight is concentrated.

First cut on compression side of log

%.

7_ _ =_ .

Second cut

Second cut

First cut on compression side of log

BUCKING WITHOUT A SUPPORT

• Overcut through 1/3of the diameter of the

log.

• Roll the log over and finish with a second

overcut.

• Watch for logswith a compression side to

prevent the saw from pinching. See il-

luatrationsforcuttinglogswith a compres-

sion side,

BUCKING USING A LOG OR

SUPPORT STAND

• Remember your first cut isalways on the

compression side ofthe log..

(Refer to the illustrations below for your

first and secondcut)

• Your first cut should extend 1/3 of the

diameter of the log,

• Finish with your second cut.

Using a log for support

" '_"_" .--_......?_

_lSt CUt

12

Page 13

Using a support stand

2ndCut

LIMBING AND PRUNING

WARNING: Be alert for and guard

against kickback. Do not allow the moving

chaintocontactanyotherbranchesor objects

at the nose of the guide bar when limbingor

pruning.._lowing such contact can result in

senous injury.

_ WARNING: Never dimb into a tr_ to

limb or prune. Do not stand on ladders,plat-

forms, a log,or inanypositionwhichcan cause

you to loseyour balance or control of the saw.

IMPORTANT POINTS

• Work slowly, keeping both hands firmly

grippedon thesaw. Maintainsecurefooting

and balance.

• Watch outfor spriogpoles. Spdngpolesare

small size limbs which can c_ch the saw

cbainandwhiptowardyouor pullyou offbal-

ance. Use extTemecaution when cutting

smallsize limbs or slender material.

• Be alert for spdogback. Watch out for

branches that are bent orunder pressure.

Avoid being struck by the branch or the

saw when the tension inthe woodfibers is

released.

• Keep a clear work area. Frequently clear

branches out of the way to avoid tipping

over them,

UMBING

• Always limbatree after itiscutdown. Only

then can limbingbe donesafely and prep-

edy.

• Leave the largerlimbsundemeaththe felled

tree to supportthe tree as you work.

• Startat the base of the felledtree and work

towardthe top, cutflngbranchesand limbs.

Remove small limbswith one cut.

• Keep the tree between you and the chain.

Cut from the side of the tree oppositethe

branchyou are cutting.

• Remove larger, supportingbranches with

the cuttin techai ues desc_bed in SUCK-

ING WITHOUT A_UPPORT.

• Alwaysuse an overcutto cut smalland free-

lyhanginglimbs. Undercuttingcouldcause

limbs to fall and pinch the saw.

PRUNING

WARNING: Umlt pruningto limbs

shoulder height or below. Be not cut ff

branchesare higherthan yourshoulder.Get a

prefesaionaito dothe job.

• Make yourflrstcut 1/3ofthe waythreughthe

bottomof the limb.

• Next make a 2nd cutall the way through

the limb. Then cuta thirdovercut leaving a

1 to2 inchcollar from the truckofthe tree.

i"i Seoondc '!J

aWARNING: Disconnect the spark

plug before performing maintenance except

for carburetor adjustments,

We recommend all service andadjustments

not listed in this manual be performed byan

authorized or Master Service Dealer.

MAINTENANCE SCHEDULE

Lubricate bar

sprock_ hole ....... After each use

Check:

Fuel mixture level .... Before each use

Barlubrication ....... Before each use

Chain tension ....... Before each use

Chain sharpness .... Before each use

For damaged pa_s .. Before each use

For loose caps ...... Before each use

For loose fasteners... Before each use

For loose parts ...... Before each use

Inspect and Clean:

Bar ................ Before each use

Complete saw ....... After each use

Air filter............. Every 5 hours*

Chain brake ........ Every5 hours*

Spark arresting screen

and muffler ......... Every 25 hours*

Replace spark plug . Yearly

iRep ace fue filter... Yearly

i* Hours of Operation

AIR FILTER

CAUTION: Do not clean filter in gasoline

or otherflammable solvent to avoid creating

a fire hazard or producing harmfutevapora*

tive emissions.

Cleaning the air filter:

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

13

Page 14

harmful emissions. Always clean after every

5 hoursof operation.

• Clean the cover and the area around it to

keep dirtand sawdust from falling into the

carburetor chamber when the cover is re-

moved.

• Remove the parts as illustratedbelow.

• Wash the filter in soap and water. Air dry

• completely before reinstalling.

Lightly oil air filter before installing to im-

prove the efficiency of the air filter. Use

2-cycle engine oil or motor oil (SAE 30).

Squeeze excess oilfrom filter.

• Reinstall parts.

Air Filter

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

_kWARNING: The muffler on this

product contains chemicals known to the

State of California to cause cancer.

As the unit isused, carbon depositsbuild up

on the muffler and ssparkarresting screen,

and must be removed to avoidcreating afire

hazard or affecting engine performance.

Replace the spark arresting screen ifbreaks

occur.

CLEANING THE SPARK ARREST-

ING SCREEN

Cleaning is required every 25 hours of op-

eration or annually, whichever comes first.

Outlet

Guide

Muffler

/

Muffler

Backplate Bolts

Muffler

Gasket

Locknut

• Loosen and remove the Iocknut from the

belt cover.

• Remove the boltcover.

• Loosen and remove the 2 muffler belts.

Remove the muffler, mufflergasket, outlet

guide and beckplata. Notice the orienta-

tion ofthese portsfor reassembling.

• Locate the 2 outlet cover screws on the

muffler. Loosen and remove beth screws.

• Remove the outlet cover.

Outlet Cover BACK VIEW OF

i MUFFLER

Muffler

Screws

Screen

• Remove spark arrestingscreen.

• Clean the sparkarrestingscreen witha wire

brush. Replace screenif anywires are bro-

ken or screen is blockedaftercleaning.

• Reinstallsparkarrestingscreen.

• Reinstall outlet cover and 2 screws. En-

sure outlet coverand both screws are re-

installed correctly (see illustrations)topre-

vent damage to the saw. The exhaust

outlet mustface the chain brake (bar side)

of the saw.

Exhaust _%_ C'_et Cover

Exhaust Outlet must face chain

brake (bar side) of chain saw

• Inspect the muffler gasket and replace if

damaged.

• Reinstall backplate, outlet guide, muffler

gasket, and muffler using muffler belts.

13ghten until secure.

• Reinstall belt cover and Iocknut. ]ighten

securely.

CARBURETOR ADJUSTMENTS

Your carburetor is equipped with limiter

caps. Carburetor adjustment is a compli-

cated task. We recommend that you take

our unit to an authorized service dealer.

I_amage willoccur ifyouturnthe needles be-

yond the limiter stops.

BAR MAINTENANCE

Ifyour saw cuts to oneside, has tobe forced

through the cut,or been runwithan improper

amount of bar lubrication it may be neces-

sary to service yourbar, Awornbarwilldam-

age yourchain and make cuffingdifficult.

After each use, ensure ON/STOP switch is

in theSTOP position, then clean all sawdust

from the guide bar and sprocket hole.

To maintain guide bar:

• Move ON/STOP switchtothe STOP posi-

tion.

• Loosen and remove chain brake nutsand

chain brake. Remove barand chain from

saw.

• Clean the oil holes and bar groove after

each 5 hours ofoperation.

14

Page 15

Remove Sawdust From

Guide Bar Groove

O,Ho,es .

• Add lubricant to sprocket hole after each

use.

• Burring of guide bar rails is a normal

process of rail wear. Remove these burrs

witha flatfile.

• When rail top is uneven, use a flat file to re-

store square edges and sides.

_F_ "_- File Rail Edges_- I"1N

a'_du_ir_eS I''1

Worn Groove Correct Groove

Replace guide bar when the groove is worn,

the guidebar isbent or cracked,orwhenexce-

ss heating or burring of the railsoccurs. If re-

placement is necessary, use onlythe guidebar

specifiedfur your saw mthe repair parts listor

on the decal located on the chainsaw.

CHAIN SHARPENING

Chain sharpening is a complicated task that

requires special tools. We recommended

you refer chain sharpening to a professional

chain sharpener.

IGNITION TIMING

Ignition timing is fixed and nonadjustable.

SPARK PLUG

The spark plug should be replaced each

year to ensure the engine starts easier and

runs better.

• Loosen 3 screws oncylinder cover.

• Remove the cylinder cover.

• Pull offthe spark plug boot.

Remove spark plug fromcylinderand dis-

card.

• Replace with Champion RCJ-7Y spark

plug and tighten securely with a 3/4 inch

socket wrench. Spark plug gap should be

0.025 inches.

• Reinstall the spark plug boot.

• Reinstall the cylindercover and 3 screws.

Tighten securely.

Screws

STORAGE

_kWARNING: Stop engine and allow

to cool, and securethe unit before stodng_or

transporting in a vehicle. Store unitand _uel

in an area where fuel vapors cannot reach

sparks or open flames from water heaters,

electric motors or switches, furnaces, etc.

Store unitwithallguards inplace. Positionso

that any sharp object cannot accidentally

cause injuryto passersby. Storethe unitout

of reach of children.

• Before stodng, drain all fuel from the unit.

Start engine andallow to run until itstops,

• Clean the unitbefore storing. Pay particu-

lar attention to the air intake area, keeping

it free of debds. Use a mild detergent and

sponge to clean the plastic surfaces.

• Do notstore the unit orfuel ina closed area

where fuel vapors can reach sparks or an

open flame from hot water heaters, electric

motors or switches,furnaces, etc.

• Store in a dry area out of the reach of chil-

dren.

CAUTION: It is important to prevent gum

deposits fromformingin essential fuel system

parts such as the carburetor, fuel filter, fuel

hose, or fuel tank dudng storage. Alcohol

blendedfuels called gasohstor usingethanol

or methano) can attractmoisturewhichleads

to fuel mixture separation and formation of

acidsdudng storage.Acidicgas can damage

the engine.

NEED ASSISTANCE?

Call1-800-554-6723.

NEED SERVICE PART?

Contactyourdealerorplaceofpurchase.

Plug

15

Page 16

TROUBLESHOOTING TABLE

_k WARNING: Always stop unitand disconnect spark plugbefore performing all of

the recommended remedies belowexcept remedies that require operation of theunit.

TROUBLE

Engine will not

start orwill run

only a few

seconds after

starting.

I

; CAUSE

I

: • Ignition switch off.

i • Engine flooded.

I

• Fuel tank empty.

• Spark plug not firing.

• Fuel not reaching

carburetor.

Engine will • Carburetor requires

not idle adjustment

properly. • Crankshaft seals worn.

REMEDY

Engine will not ] • Air filter dirty.

accelerate, i ° Spark plug fouled.

lacks power. ; • Chain brake engaged.

or dies under I • Carburetor requires

a load. i adjustment.

i

'' asne_gTC°olimUOho,1 mixed with

• Move ignition switchto ON.

• See "DifficuRStarting" in

Operation Section.

• Fill tank with correct fuel mixture.

• Install new spark plug.

• Check for dirty fuel filter; replace.

Check forkinked or split fuel line;

repair or replace.

Contact an authorized service dealer.

Contact an authodzed service dealer.

• Clean or replace air filter.

• Clean or repiace plug and regap.

• Disengage chain brake.

• Contact an authorized service dealer.

Engine • Empty fuel tank and refillwith

smokes correctfuel mixture.

excessively.

ELECTROLUX HOME PRODUCTS, INC,,

warrants to the original purchaser that each

new Poulan brand gasoline chain saw is

free fromdefects in material and workman-

ship and agrees to repair or replace under

this warranty any defective gasoline chain

saw as followsfrom the original date of pur-

chase.

1 YEAR - Parts and Labor,when used for

Household purposes.

60 DAYS - Parts and Labor, when used for

Commercial, Professional, or Income Pro-

ducinlg purposes.

30 DAYS - Parts and Labor,if usedfor rental

urpuses,

_his warranty is not transferable and does

not cover damage or liability caused by im-

proper handling, improper maintenance, or

the use of accessories and/or attachments

not sbecificail;lyrecommended by ELEC-

TROLUX HOME PRODUCTS, INC,, for this

chain saw. Additionally, this warranty does

not cover damage caused by improper han-

dling,improper maintenance, or if thesaw is

altered inany way whichin ourjudgement af-

fects itsconditionoroperation. This warranty

does not cover tune-up, sparkplugs, filters,

starterropes, starter springs, chain sharpen-

ing, bars, chains, and other partswhichwear

and require replacement with reasonable

use dudngthe warranty period. Thiswarran-

ty does notcover predeliveryset-up, instal-

lationof guide barand chain, and normalad-

justments explained in the instruction

manual such ascarburetor adustmentslu_,and

chain tension adjustments. 'This warranty

does not cover transportation costs.

THIS WARRANTY GIVES YOU SPECIFIC

LEGAL RIGHTS, AND YOU MAY HAVE

OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

NO CLAIMS FOR CONSEQUENTIAL OR

OTHER DAMAGES WILL BE ALLOWED,

AND THERE ARE NO OTHER EXPRESS

WARRANTIES EXCEPT THOSE EX*

PRESSLY STIPULATED HEREIN.

SOME STATES DO NOT ALLOW LIMITA-

TIONS ON HOW LONG AN IMPLIED WAR-

RANTY LASTS OR THE EXCLUSION OR

LIMITATIONS OF INCIDENTAL OR CON-

SEQUENTIAL DAMAGES, SO THE

ABOVE LIMITATIONS OR EXCLUSION

MAY NOT APPLY TO YOU.

The poli_cyof ELECTROLUX HOME PRO-

DUCTS, INC., isto continuously improve its

products.Therefore, ELECTROLUX HOME

PRODUCTS, INC., reserves the right to

change, modify, or discontinue models, de-

signs, specifications, and accessories of all

productsat any time without noticeorobliga-

tionto any purchaser.

16

Page 17

YOUR WARRANTY RIGHTS AND OB-

LIGATIONS: The U.S. Environmental

Protection Agency, California Air Resources

Board, Environment Canada and POULAN/

WEED EATER. DIVISION OF WCI OUT-

DOOR PRODUCTS, INC., are pleased to

explain the emissions control system war-

rantyonyouryear 2000-2003 small off-road

engine. In California, all new small off-road

engines must be designed, built, and

equipped to meet the State's stringent anti-

smog standards. POULAN/WEED EATER

must warrantthe emission controlsystem on

your small off-toed en=gl_ineforthe periodsof

time listed below providedthere has been no

abuse, negFect, or improper maintenance of

your small off-road engine engine. Your

emission control system includes partssuch

as the carburetor and the ignition system.

Where awarrantable condition exists, POU-

LAN/WEED EATER will repair your small

off-road engine engine at no cost toyou. Ex-

penses covered under warranity mclude

dia_,nosis,partsand labor. MANU]FACTUR-

ER S WARRANTY COVERAGE: If any

emissions related part on your engine (as

listed under Emissions Control Warranty

Parts Ust) isdefective ora defect in the ma-

terialsor workmanship ofthe engine causes

the failure of such an emission related pert,

the partwill be repaired orreplaced by POU-

I-AN/WEED EATER. OWNER'S WAR*

RANTY RESPONSIBILITIES: As the small

off-road engine engine owner, you are re-

spensible for the performance of the re-

quired maintenance listedin your instruction

manual. POULAN/WEED EATER recom-

mends that you retain all receipts covering

maintenance on our small off-road en ine,

but POULAN/W_ED EATER cannot _eny

warranty solely for the backof receipts or for

your failure to ensure the performance of all

scheduled maintenance. As the small off-

road engine engine owner, you should be

aware that POULAN/WEED EATER may

deny you warranty coverage if your small

off-road engine engine or a part of it has

failed due to abuse, neglect, improper main-

tenance, unapproved modifications, or the

use of parts not made or approved by the

original equipment manufacturer. You are

responsible for presentin[mgyour small off-

road engine to a POULAN/WEED EATER

authorized repair center as soon as a prob-

lem exists. Warranty repairs should be com-

pleted in a reasonable amountof time, not to

exceed 30 days. If you have any questions

regarding your warranty hghts and responsi-

bilities, you should contact your nearest au-

thorized service center or call POULAN/

WEED EATER at 1-800-554-6723.

WARRANTY COMMENCEMENT DATE:

The warranty period begins onthe date the

small off-road eegme is purchased,

LENGTH OF COVERAGE: This warranty

shall be for a period oftwo years from theini-

tial date of purchase. WHAT IS COVERED:

REPAIR OR REPLACEMENT OF PARTS,

Repair orreplacement of any warrar_ed part

will be performed at no charge to the owner

at an approved POULAN/WEED EATER

servicingcenter. If you have any questions

re_jardiegyourwarranty rightsand raspensi-

bihties, you should contact your nearest au-

thodzed service center or call POULAN/

WEED EATER at 1-800-554-6723.

WARRANTY PERIOD: Any warranted part

which is not scheduled for replacement as

required maintenance, or which is sched-

uled=only for regular inspectionto the effect

of repair or replace as necessary" shall be

warranted for 2 years. Any warranted part

which is scheduled for replacement as re-

uired maintenance shall be warranted for

t_e period oftime uptothefirst scheduled re-

J_lacementpointfor that part. DIAGNOSIS:

he owner shall not be charged fordiagnos-

tic laborwhich leads to the determination that

awarranted part is defective if thediagunostic

work isperformed atan approved POULAN/

WEED EATER servicing center. CONSE-

QUENTIAL DAMAGES: POULAN/WEED

EATER may be liable for damages to other

engine components caused by the failure of

awarranted part stillunder warranty. WHAT

IS NOT COVERED: All failures caused by

abuse, neglect, or improper maintenance

are not covered. ADD-ON OR MODIFIED

PARTS: The useof add-on or modifiedparts

can be grounds for disallowing a warranty

claim. POULAN/WEED EATER is not liable

to cover failures ofwarranted parts caused

bythe use ofadd-on or medified parts. HOW

TO FILE A CLAIM: If you have any ques-

tions re_arding your warranty rights and re-

spensibdities,you shouldcontact your near-

est authorized service center or call

POULAN/WEED EATER at

1-800-554-6723. WHERE TO GET WAR-

RANTY SERVICE: Warranty services or re-

pairs shall be provided at all POULAN/

WEED EATER service centers, call:

1-800-554-6723 MAINTENANCE, RE-

PLACEMENT AND REPAIR OF EMIS-

SION RELATED PARTS: Any POULAN/

WEED EATER approved replacement pert

used in the performance of any warranty

maintenance or repair on emissnonrelated

parts willbe provided without charge to the

owner if thepart is under warranty. EMIS-

SIGN CONTROL WARRANTY PARTS

LIST: Carburetor, Ignition System: Spark

Plug covered upte maintenance schedule,

Ignition Module, Muffler ncedng catalyst.

MAINTENANCE STATEMENT: The owner

is responsible for the performance of all re-

quired maintenance as defined in the in-

structionmanual.

17

Page 18

The information onthe product label indicates which standard your engine is certified.

Example: (Year) EPA Phase 1 or Phase 2 and/or CALIFORNIA.

This engine is certified to be emissionscompliant for the following use:

[] Moderate (50 hours)

[] Intermediate (125 hours)

[] Extended (300 hours)

18

Loading...

Loading...