Page 1

IMPORTANT mmUAL

Do Not Throw Awaf

OPERATOR'S MANUAL

MODEL:

Read this Manual and follow all Warnings and

Safety Instructions. Failure to do so can result

in serious injury.

HDF550

REAR TINE TILLER

ALWAYS WEAR EYE PROTECTION DURING OPERATION

Visit our website:

• Español, p. 18

www.poulan.com

A WARNING:

194793 11.11.04 TR

Printed in U.S.A.

Page 2

SAFETY RULES

A

Safe Operation Practices for Walk-Behind Powered Rotary Tillers A

TRAINING

• Read the Owner’s Manual carefully. Be thoroughly

familiar with the controls and the proper use of the

equipment. Know how to stop the unit and disengage

the controls quickly.

Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

Keep the area of operation clear of all persons, par

ticularly small children, and pets.

PREPARATION

Thoroughly inspect the area where the equipment is

to be used and remove all foreign objects.

Disengage all clutches and shift into neutral before

starting the engine (motor).

Do not operate the equipment without wearing ade

quate outer garments. Wear footwear that 'A'ill improve

footing on slippery surfaces.

Handle fuel with care; it is highly flammable.

Use an approved fuel container.

Never add fuel to a running engine or hot engine.

Fill fuel tank outdoors with extreme care. Never fill fuel

tank indoors.

Replace gasoline cap securely and clean up spilled

fuel before restarting.

Use extension cords and receptacles as specified by

the manufacturer for all units with electric drive motors

or electric starting motors.

Never attempt to make any adjustments while the

engine (motor) is running (except where specifically

recommended by manufacturer).

OPERATION

Do not put hands or feet near or under rotating parts.

Exercise extreme caution when operating on or cross

ing gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic. Do not carry passengers.

After striking a foreign object, stop the engine (motor),

remove the wire from the spark plug, thoroughly inspect

the tillerfor any damage, and repair the damage before

restarting and operating the tiller.

Exercise caution to avoid slipping or falling.

If the unit should start to vibrate abnormally, stop the

engine (motor) and check immediately for the cause.

Vibration is generally a warning of trouble.

Stop the engine (motor) when leaving the operating

position.

Take all possible precautions when leaving the machine

unattended. Disengage the tines, shift into neutral, and

stop the engine.

Before cleaning, repairing, or inspecting, shut off the

engine and make certain all moving parts have stopped.

Disconnect the spark plug wire, and keep the wire away

from the plug to prevent accidental starting. Disconnect

the cord on electric motors.

Do not run the engine indoors; exhaust fumes are

dangerous.

Never operate the tiller without proper guards, plates,

or other safety protective devices in place.

Keep children and pets away.

Do not overload the machine capacity by attempting

to till too deep at too fast a rate.

Never operate the machine at high speeds on slippery

surfaces. Look behind and use care when backing.

Never allow bystanders near the unit.

Use only attachments and accessories approved by

the manufacturer of the tiller.

Never operate the tiller without good visibility or light.

Be careful when tilling in hard ground. The tines may

catch in the ground and propel the tiller forward. If this

occurs, let go of the handlebars and do not restrain the

machine.

MAINTENANCE AND STORAGE

• Keep machine, attachments, and accessories in safe

working condition.

• Check shear pins, engine mounting bolts, and other

bolts at frequent intervals for proper tightness to be

sure the equipment is in safe working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such

as hot water and space heaters, clothes dryers, and

the like. Allow the engine to cool before storing in any

enclosure,

• Always refer to the operator’s guide instructions for

important details if the tiller is to be stored for an ex

tended period.

- IMPORTANT -

CAUTIONS, IMPORTANTS, AND NOTES ARE A MEANS OF

ATTRACTING ATTENTION TO IMPORTANT OR CRITICAL

INFORMATION IN THIS MANUAL.

IMPORTANT: USED TO ALERT YOU THAT THERE IS A

POSSIBILITY OF DAMAGING THIS EQUIPMENT.

NOTE: Gives essential information that will aid you to

better understand, incorporate, or execute a particular set

of instructions.

Look for this symbol to point out im

A

A

portant safety precautions. It means

CAUTION!!! BECOME ALERT!!! YOUR

SAFETY IS INVOLVED.

CAUTION; Always disconnect spark

plug wire and place wire where it can

not contact spark plug in order to pre

vent accidental starting when setting

up, transporting, adjusting or making

repairs.

^ WARNING^

The engine exhaust from this product con

tains chemicals known to the State of Cali

fornia to cause cancer, birth defects, or other

reproductive harm.

Page 3

PRODUCT SPECIFICATIONS

Gasoline Capacity:

Oil (API-SG-SL):

(Capacity: 20 oz./O.OL)

Spark Plug:

(Gap: .03070.76mm)

CONGRATULATIONS on your purchase of a new tiller, it

las been designed, engineered and manufactured to give

iou the best possible dependability and performance.

should you experience any problems you cannot easily

emedy, please contact your nearest authorized service

ienter. We have competent, well-trained technicians and

he proper tools to service or repair this unit.

^lease read and retain this manual. The instructions will

enable you to assemble and maintain your tiller properly.

\lways observe the “SAFETY RULES”.

3 Quarts (2.8L)

Unleaded Regular

SAE 30 (Above 32°F/0°C)

SAE 5w-30(Below 32°F/0°C)

Champion RC12YC

CUSTOMER RESPONSIBILITIES

• Read and observe the safety rules.

• Follow a regular schedule in maintaining, caring for

and using your tiller.

• Follow instructions under“Maintenance" and “Storage”

sections of this Manual.

IMPORTANT: THIS UNIT IS EQUIPPED WITH AN INTERNAL

COMBUSTION ENGINE AND SHOULD NOT BE USED ON

OR NEAR ANY UNIMPROVED FOREST-COVERED, BRUSH-

COVERED OR GRASS COVERED LAND UNLESS THE

ENGINE'S EXHAUST SYSTEM IS EQUIPPED WITH A SPARK

ARRESTER MEETING APPLICABLE LOCAL LAWS (IF ANY).

IF A SPARK ARRESTER IS USED, ITSHOULD BE MAINTAINED

IN EFFECTIVE WORKING ORDER BY THE OPERATOR.

IN THE STATE OF CALIFORNIA, A SPARK ARRESTER IS

REQUIRED BY LAW (SECTION 4442 OF THE CALIFORNIA

PUBLIC RESOURCES CODE). OTHER STATES MAY HAVE

SIMILAR LAWS. FEDERAL LAWS APPLY ON FEDERAL LANDS.

SEE YOUR AUTHORIZED SERVICE CENTER/DEPARTMENT

FOR SPARK ARRESTER.

TABLE OF CONTENTS

SAFETY RULES............................................................ 2

PRODUCT SPECIFICATIONS.....................................

CUSTOMER RESPONSIBILITIES

ASSEMBLY

3PERATION

MAINTENANCE SCHEDULE

.......

........................................................

.............................................................

.................................

...

..................................

3

3

4-5

6-9

10

MAINTENANCE

SERVICE & ADJUSTMENTS

..

................................................ 10-12

................................

12-14

STORAGE............................................................... ..15

TROUBLESHOOTING

WARRANTY

ESPAÑOL

......................................................... 17

..........................................................

..........................................

16

.18

Page 4

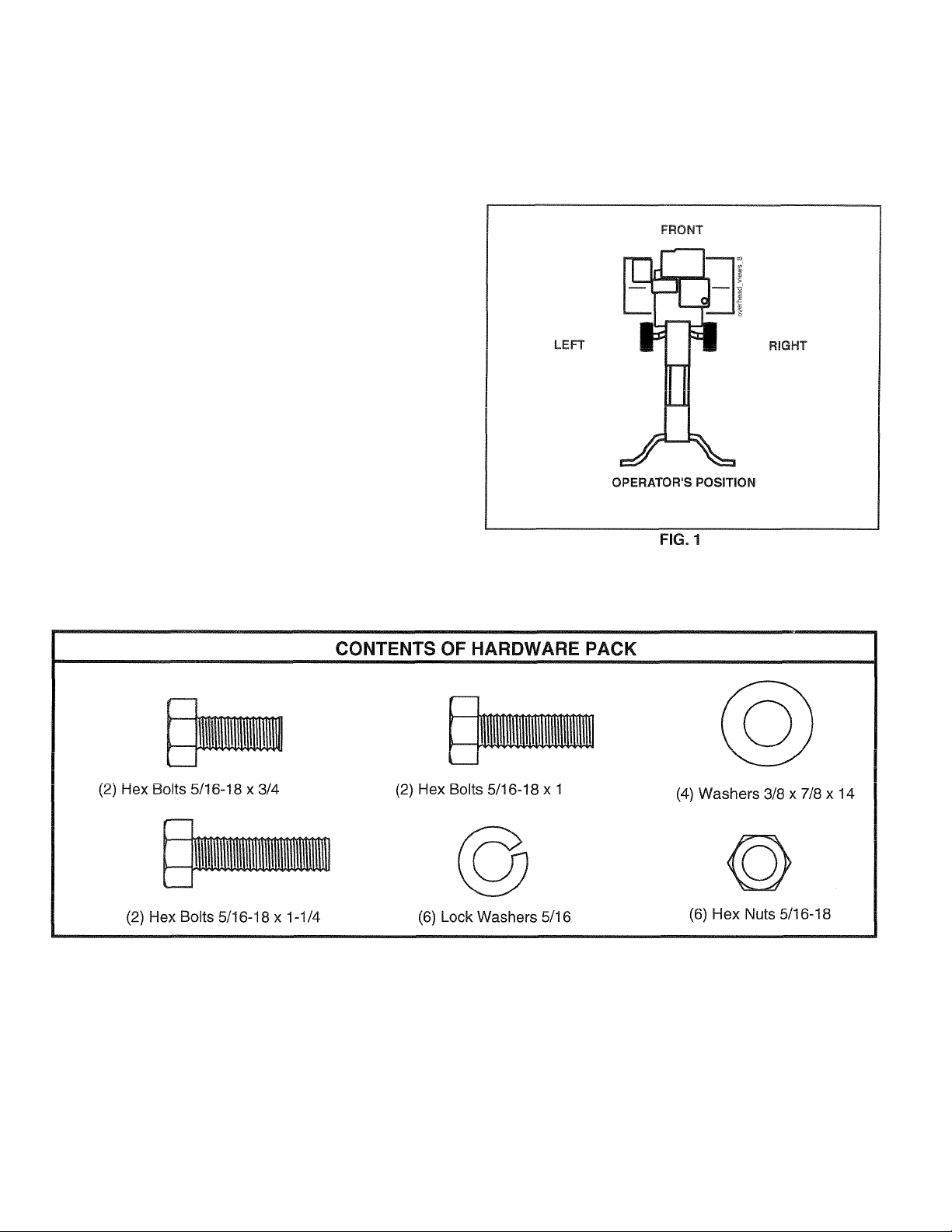

ASSEMBLY

Your new tiller has been assembled at the factory with exception of those parts left unassembled for shipping purposes.

To ensure safe and proper operation of your tiller all parts and hardware you assemble must be tightened securely Use

the correct tools as necessary to insure proper tightness.

TOOLS REQUIRED FOR ASSEMBLY

A socket wrench set will make assembly easier. Standard

wrench sizes are listed.

(1) Utility knife

(1) Screwdriver

(2) 1/2“ wrenches

OPERATOR’S POSITION (See Fig. 1)

When right or left hand is mentioned in this manual, it

means when you are in the operating position (standing

behind tiller handles).

Page 5

ASSEMBLY

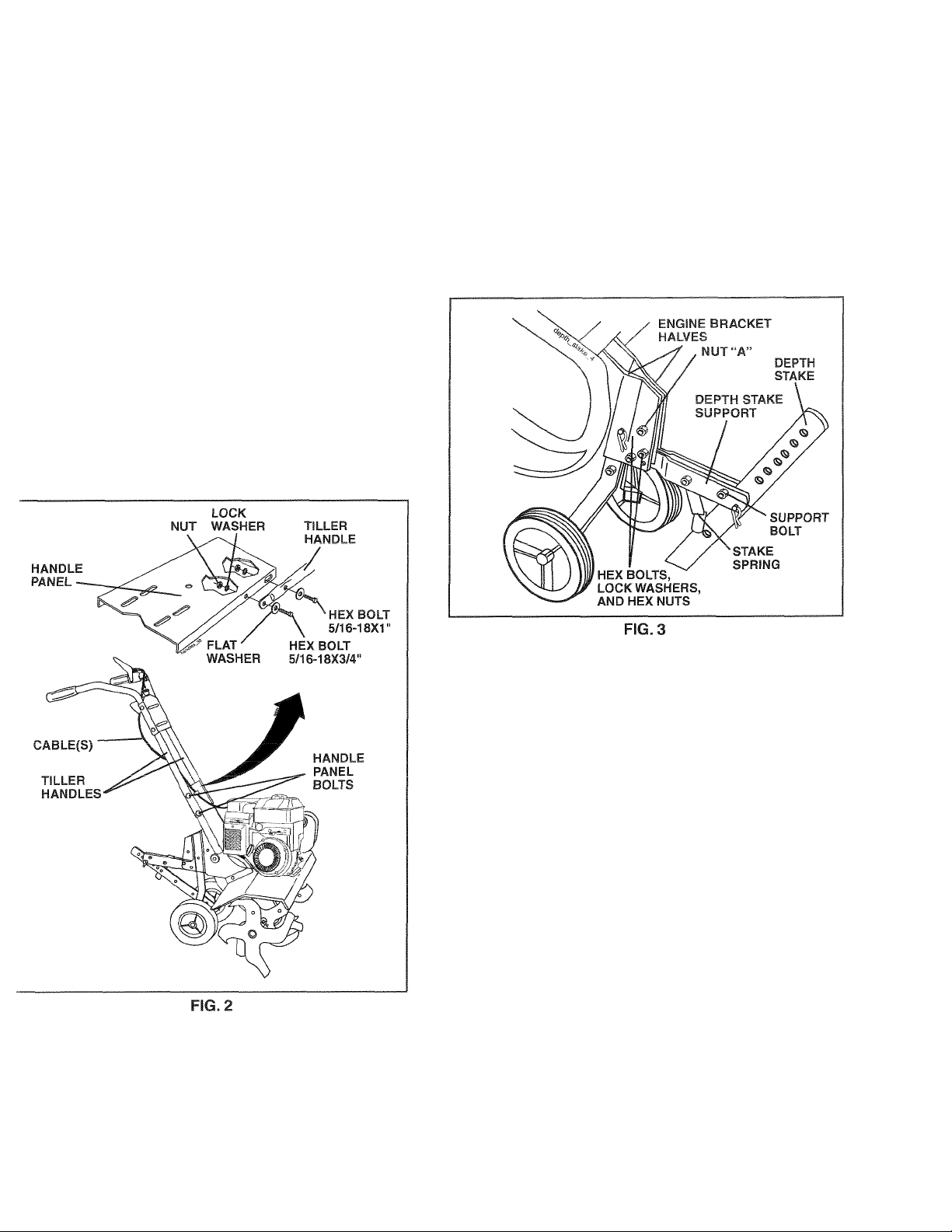

JNPACK CARTON & INSTALL HANDLE 'See Fig. 2)

CAUTION; Be careful of exposed

A

IMPORTANT; WHEN UNPACKING AND ASSEMBLING

TILLER, BE CAREFUL NOT TO STRETCH OR KINK

:ABLE(S).

• Cut cable ties securing handles.

> Slowly lift handle assembly up, route cable(s) as shown

and align handle holes with handle panel hole and

slot.

> Loosely assemble hardware as shown. Be sure the

shorter (3/4" long) hex bolt is assembled in lower

hole of handle. Repeat for opposite side. Tighten all

hardware securely.

> Cut cable ties securing tiller to skid and remove tiller

from skid.

• Remove screws securing depth stake to skid and dis

card the screws.

staples when handling or disposing

of cartoning material.

INSTALL DEPTH STAKE ASSEMBLY

(See Fig. 3)

• Loosen nut “A”.

• Insert stake support between engine bracket halves

with stake spring down.

• Bolt stake support to engine brackets with bolts, lock

washers and nuts. Tighten securely. Tighten nut “A”.

• Depth stake must move freely. If it does not, loosen

support bolt.

HANDLE HEIGHT

• Handle height may be adjusted to better suit operator.

(See “HANDLE HEIGHT” in the Service and Adjust

ments section of this manual).

TILLING WIDTH

• Tilling width may be adjusted to better handle your

tilling conditions (See “TINE ARRANGEMENT” in the

Service and Adjustments section of this manual).

TINE OPERATION

• Check tine operation before first use. (See “TINE OP

ERATION CHECK” in the Service and Adjustments

section of this manual).

Page 6

OPERATION

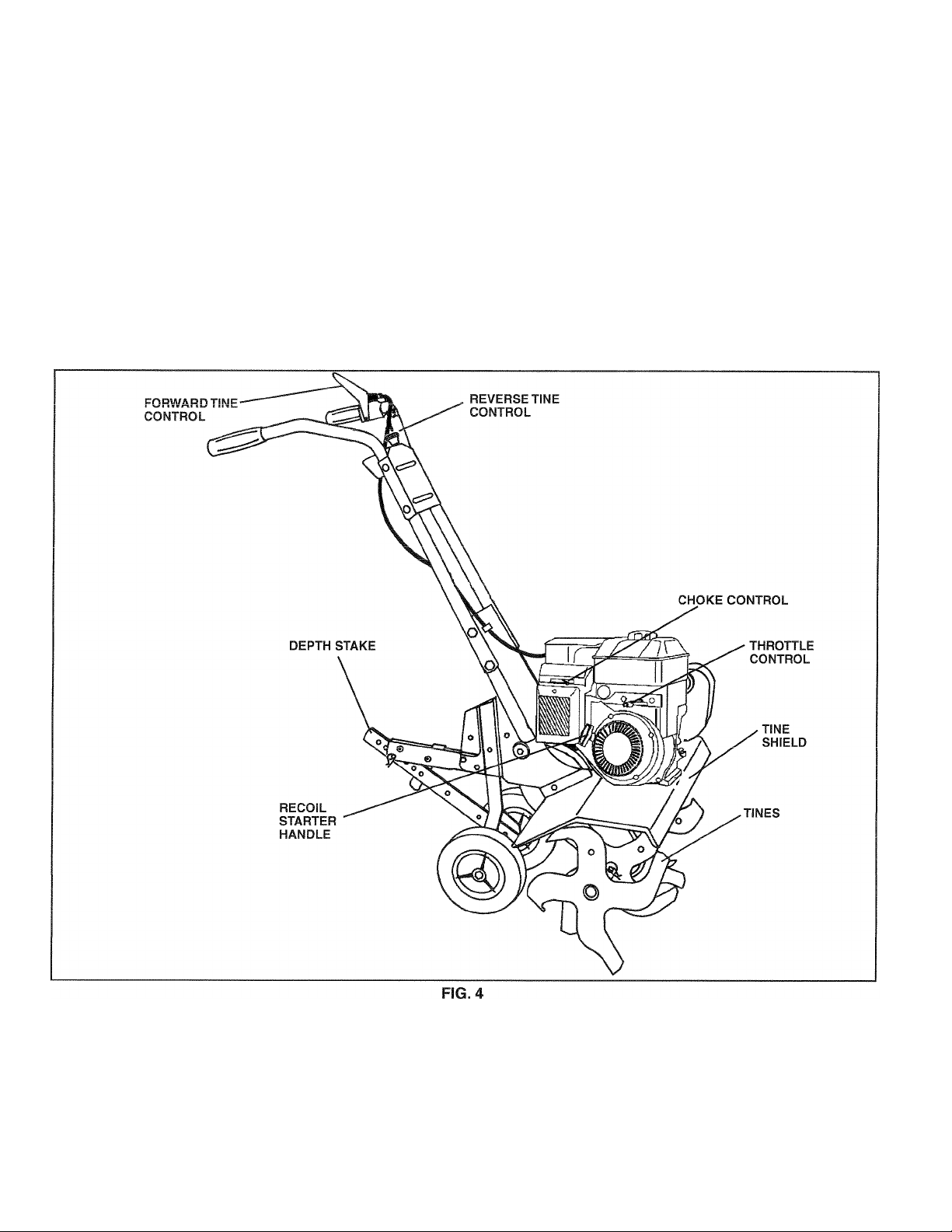

KNOW YOUR TILLER

READ THIS MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your Tiller or in literature supplied with the product. Lsarn and understand their mean

ing.

RUN

I

riLLING FORWARD NEUTRAL REVERSE CAUTION ENGINE ENGINE FAST SLOW CHOKE FUEL OIL

OR WARNING ON OFF

STOP

O

MEETS ANSI SAFETY REQUIREMENTS

Our tillers conform to the safety standards of the American National Standards Institute.

CHOKE CONTROL - Used when starting a cold engine.

DEPTH STAKE - Controls forward speed and the depth at

which the tiller will dig.

FORWARD TINE CONTROL - Engages tines in forward

direction.

REVERSE TINE CONTROL - Engages tines in reverse

RECOIL STARTER HANDLE - Used to start the engine,

direction.

THROTTLE CONTROL - Controls engine speed.

Page 7

OPERATION

SAFETY GUSSa

The operation of any tiller can result in foreign objects thrown into the eyes, which can result

in sewere eye damage. Always weat safety glasses or eye shields before starting your tiller

and while tilling. We recommend a wide ¥ision safety mask for over spectacles or standard

safety glasses.

10WT0 USE YOUR TILLER

(now how to operate all controls before adding fuel and oil

)r attempting to start engine.

STOPPING (See Fig. 5)

FINES

» Release forward tine control to stop forward move

ment.

• Release reverse tine control to stop reverse move

ment.

ENGINE

» Move throttle control to “STOP” position.

• Never use choke to stop engine.

REVERSE “OFF”(UP) POSITION

CONTROL

FORWARD TINE CONTROL IN

TILLING

The speed and depth of tilling is regulated by the position

of the depth stake and wheel height.

The depth stake should always be below the wheels for

digging. It serves as a brake to slow the tiller’s forward

motion to enable the tines to penetrate the ground. Also,

the more the depth stake is lowered into the ground the

deeper the tines will dig.

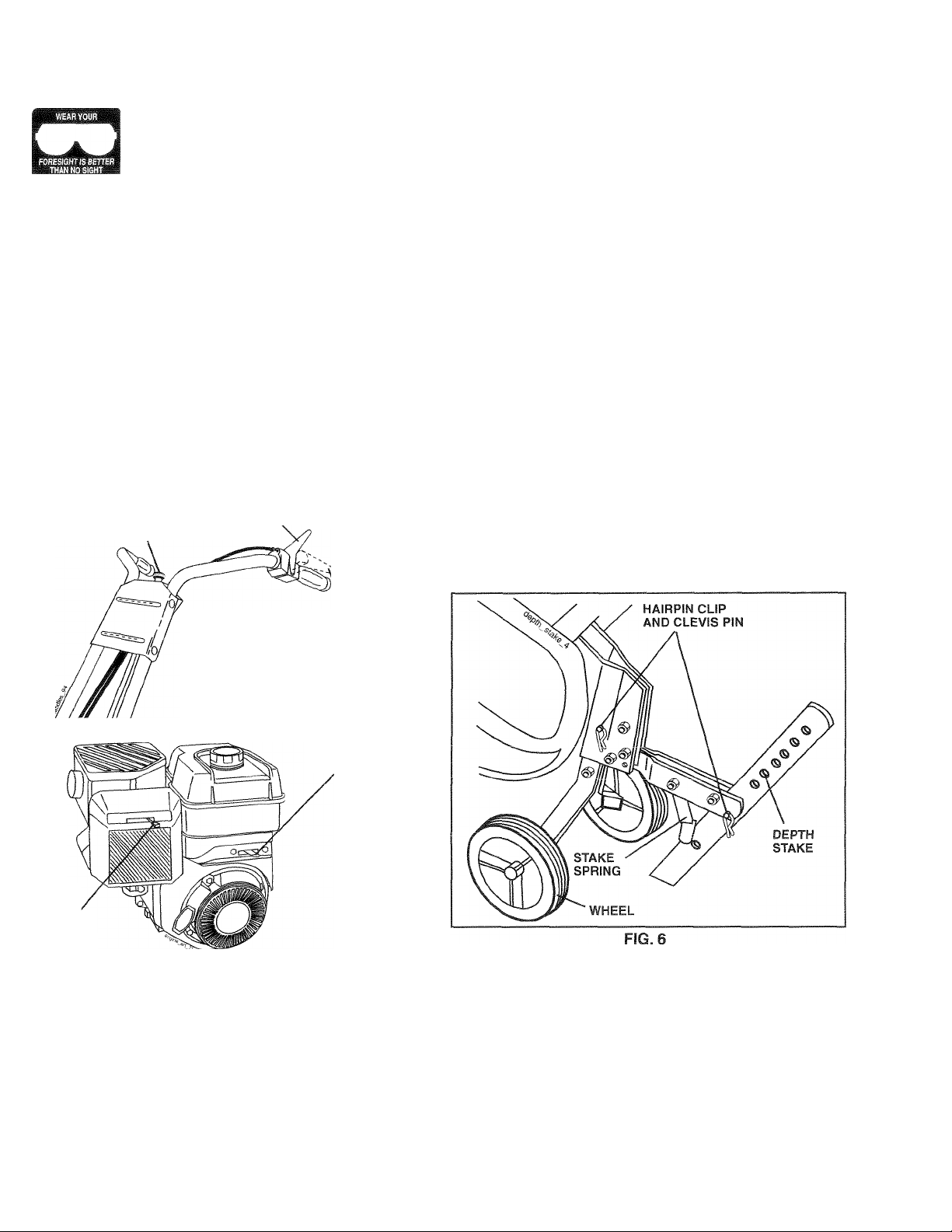

DEPTH STAKE (See Fig. 6)

Adjust depth stake by removing the hairpin clip and clevis

pin. Change depth stake to desired position. Replace the

clevis pin and hairpin clip.

• For normal tilling, set depth stake at the second or third

hole from the top.

WHEELS (See Fig. 6)

Adjust wheels by removing the hairpin clip and clevis pin.

Change wheel position. Replace the hairpin clip and clevis

pin.

• For normal tilling, set wheels at the second or third

hole from the top.

FORWARD TINE CONTROL

IN “ON” (DOWN) POSITION

THROTTLE

CONTROL

CHOKE■

CONTROL

FIG. 5

TINE OPERATION (See Fig. 5)

FORWARD

• Squeeze forward tine control to handle.

REVERSE

• With forward tine control “OFF” (up) position, pull back

and hold reverse tine control.

Page 8

OPERATION

TO TRANSPORT

CAUTION: Before lifting or transporting,

A

AROUNDTHEYARD

• Tip depth stake forward until it is held by the stake

spring.

• Push tiller handles down, raising tines off the ground.

• Push or pull tiller to desired location.

AROUNDTOWN

• Disconnect spark plug wire.

• Drain fuel tank.

• Transport in upright position to prevent oil leakage.

allow tiller engine and muffler to cool.

Disconnect spark plug wire. Drain

gasoline from fuel tank.

BEFORE STARTING ENGINE

IMPORTANT: BE VERY CAREFUL NOT TO ALLOW DIRT

TO ENTER THE ENGINE WHEN CHECKING OR ADDING

OIL OR FUEL. USE CLEAN OIL AND FUEL AND STORE IN

APPROVED, CLEAN, COVERED CONTAINERS. USE CLEAN

FILL FUNNELS.

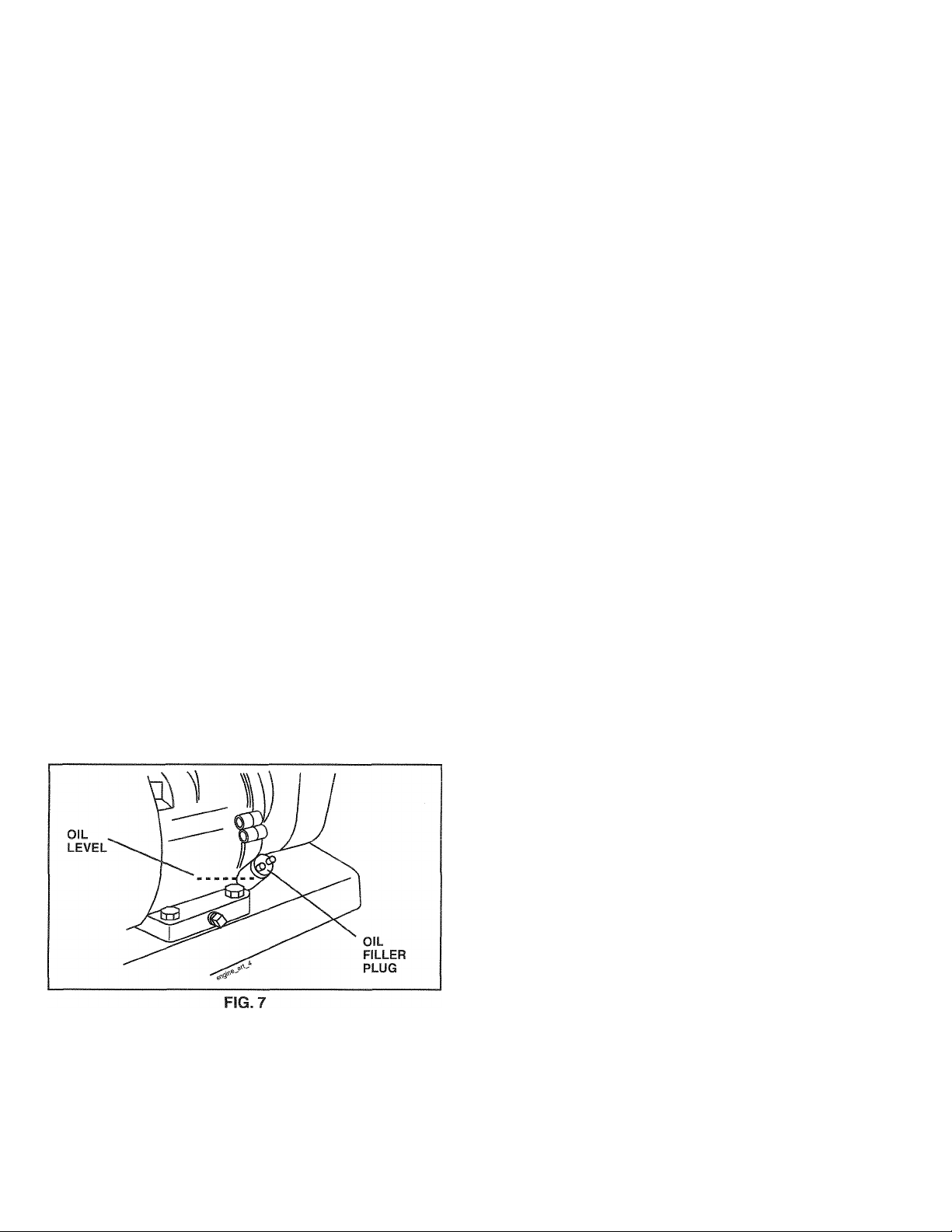

FILL ENGINE WITH OIL (See Fig. 7)

• With engine level, remove engine oil filler plug.

• Fill engine with oil to point of overflowing. For approx

imate capacity see “PRODUCT SPECIFICATIONS” on

page 3 of this manual.

• Tilt tiller back on its wheels and then re-level.

• With engine level, refill to point of overflowing if nec

essary. Replace oil filler plug.

• For cold weather operation you should change oil for

easier starting (See “OIL VISCOSITY CHART” in the

Maintenance section of this manual).

• To change engine oil, see the Maintenance section of

this manual.

ADD GASOLINE

• Fill fuel tank to bottom of filler neck. Do not overfill.

Use fresh, clean, regular unleaded gasoline with a

minimum of 87 octane. (Use of leaded gasoline will

increase carbon and lead oxide deposits and reduce

valve life). Do not mix oil with gasoline. Purchase fuel

in quantities that can be used within 30 days to assure

fuel freshness.

CAUTION: Fill to within 1/2 inch of top

A

IMPORTANT: WHEN OPERATING IN TEMPERATURES

BELOW32°F(0°C), USE FRESH, CLEAN WINTER GRADE

GASOLINE TO HELP INSURE GOOD COLD WEATHER

STARTING.

CAUTION: Alcohol blended fuels (called

gasohol or using ethanol or methanol) can at

tract moisture which leads to separation and

formation of acids during storage. Acidic gas

can damage the fuel system of an engine while

in storage. To avoid engine problems, the fuel

system should be emptied before storage of

30 days or longer. Drain the gas tank, start

the engine and let it run until the fuel lines

and carburetor are empty. Use fresh fuel next

season. See Storage Instructions for additional

information. Never use engine or carburetor

cleaner products in the fuel tank or permanent

damage may occur.

of fuel tank to prevent spills and to allow

for fuel expansion. If gasoline is ac

cidentally spilled, move machine away

from area of spill. Avoid creating any

source of ignition until gasoline vapors

have disappeared.

Wipe off any spilled oil or fuel. Do not

store, spill or use gasoline near an

open flame.

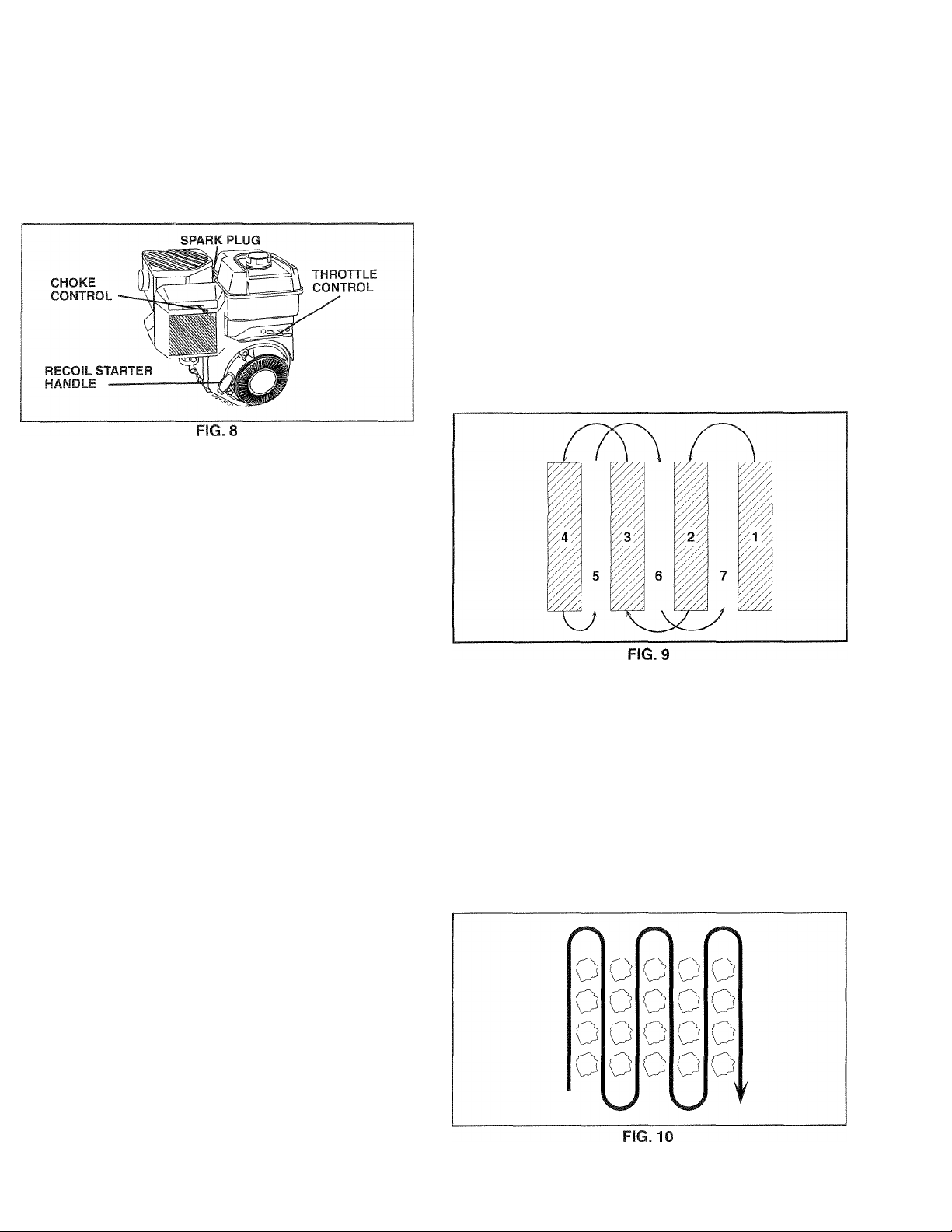

TO START ENGINE (See Fig. 8)

CAUTION: Keep drive control bar in

A

When starting engine for the first time or if engine has run

out of fuel, it will take extra pulls of the recoil starter to

move fuel from the tank to the engine.

• Make sure spark plug wire is properly connected.

• Move shift lever indicator to “N” (neutral) position.

• Place throttle control in “FAST” position.

• Turn fuel shut-off valve 1/4 turn to open position.

• Move choke control to choke position.

• Grasp recoil starter handle with one hand and grasp

tiller handle with other hand. Pull rope out slowly until

engine reaches start of compression cycle (rope will

pull slightly harder at this point).

• Pull recoil starter handle quickly. Do not let starter

handle snap back against starter.

• If engine fires but does not start, move choke control

to half choke position. Pull recoil starter handle until

engine starts.

• When engine starts, slowly move choke control to

"RUN" position as engine warms up.

NOTE: A warm engine requires less choking to start.

• Move throttle control to desired running position.

• Allow engine to warm up for a few minutes before

engaging tines.

“DISENGAGED” position when start

ing engine.

Page 9

OPERATION

NOTE: If at a high altitude (3000 feet) or in cold

temperatures (below 32°F), the carburetor fuel mixture

may need to be adjusted for best engine performance.

See "TO ADJUST CARBURETOR" in the Service and

Adjustments section of this manual.

NOTE: If engine does not start, see troubleshooting

points.

BREAKING IN YOUR TILLER

Break-in your belt(s), pulleys and tine control before you

actually begin tilling.

• Start engine, tip tines off ground by pressing handles

down and engage tine control to start tine rotation.

Allow tines to rotate for five minutes.

• Check tine operation and adjust if necessary. See‘TINE

OPERATION CHECK” in the Service and Adjustments

section of this manual.

Soil conditions are important for proper tilling. Tines will

not readily penetrate dry, hard soil which may contribute

to excessive bounce and difficult handling of your tiller.

Hard soil should be moistened before tilling; however,

extremely wet soil will “ball-up” or clump during tilling.

Wait until the soil is less wet in order to achieve the

best results. When tilling in the fall, remove vines and

long grass to prevent them from wrapping around the

tine shaft and slowing your tilling operation.

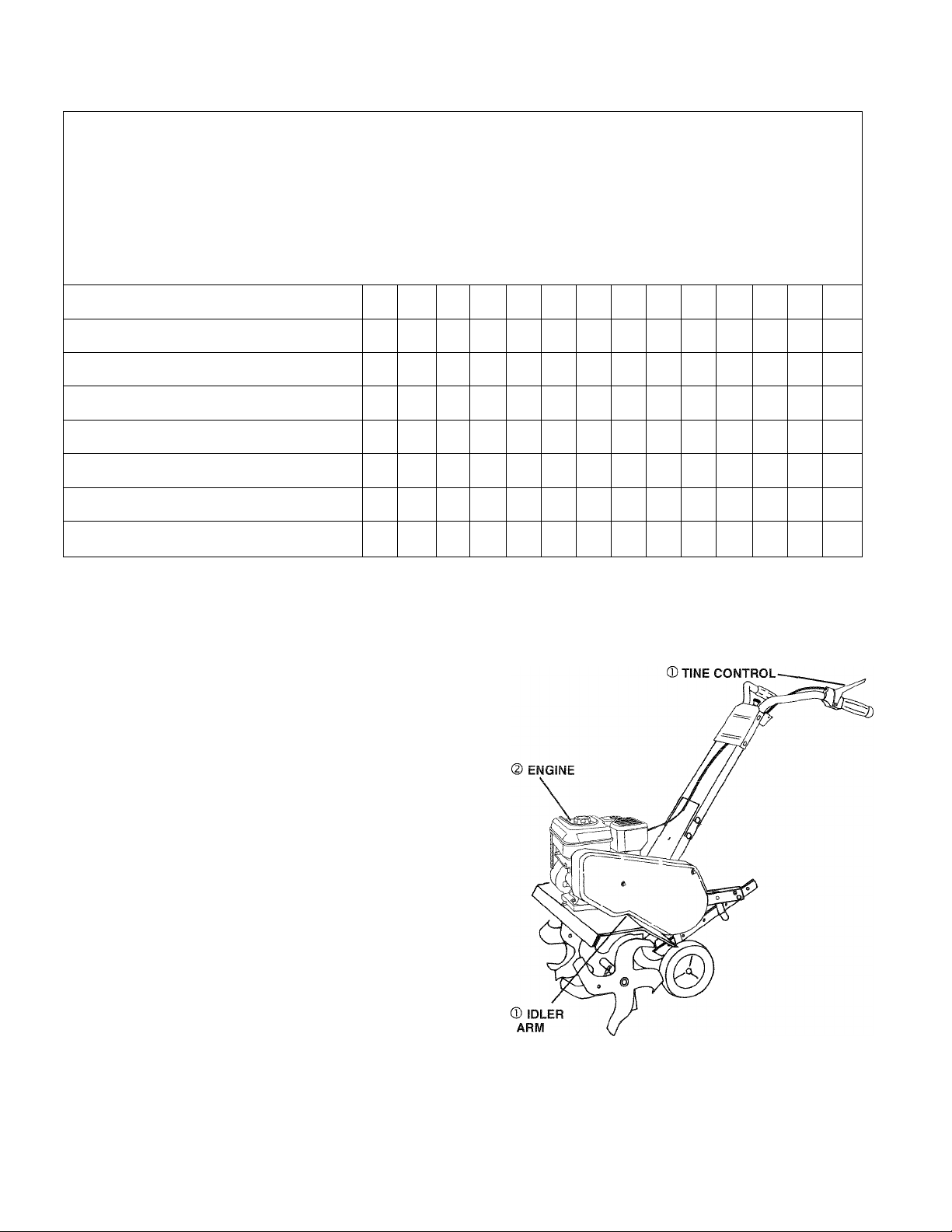

You will find tilling much easier if you leave a row un

tilled between passes. Then go back between tilled

rows. (See Fig. 9) There are two reasons for doing

this. First, wide turns are much easier to negotiate than

about-faces. Second, the tiller won’t be pulling itself,

and you, toward the row next to it.

Set depth stake and wheel height for shallow tilling

when working extremely hard soil or sod. Then work

across the first cuts at normal depth.

TILLING HINTS

CAUTION: Until you are accustomed

A

To help tiller move forward, lift up th_e handles slightly (thus

lifting depth stake out of ground), lo slow down the tiller,

press down on handles.

If you are straining ortiller is shaking, the wheels and depth

stake are not set properly in the soil being tilled.The proper

setting of the wheels and depth stake is through trial and

error and depends upon the soil condition. (The harder or

wetter the ground, the slower the engine and tine speed

needed. Under these poor conditions, at fast speed the

tiller will run and jump over the ground).

A properly adjusted tiller will dig with little effort from the

operator.

• Tilling is digging into, turning over, and breaking up

packed soil before planting. Loose, unpacked soil helps

root growth. Best tilling depth is 4"-6". A tiller will also

clearthe soil of unwanted vegetation.The decomposition

of this vegetable matter enriches the soil. Depending

on the climate (rainfall and wind), it may be advisable

to till the soil at the end of the growing season to further

condition the soil.

to handling your tiller, start actual field

use with throttle in slow position.

CULTIVATING

Cultivating is destroying the weeds between rows to pre

vent them from robbing nourishment and moisture from the

plants. At the same time, breaking up the upper layer of

soil crust will help retain moisture in the soil. Best digging

rifinth if! 1 "-.f?"

• You will probably not need to use the depth stake. Begin

by tipping the depth stake forward until it is held by the

stake spring.

• Cultivate up and down the rows at a speed which will

allow tines to uproot weeds and leave the ground in

rough condition, promoting no further growth of weeds

and grass (See Fig. 10).

Page 10

MAINTENANCE

SCHEDULE

FILL IN DATES

AS YOU COMPLETE

REGULAR SERVICE

MAINTENANCE

'W$/

^ ^ /

w/

%

A

/ Cr, / Co /

0/^/

/ ,0 /

' X /

§/ SERVICE DATES

( s

Check Engine Oil Level

Change Engine Oil

Oil Pivot Points

Inspect Spark Arrester / Muffler

Inspect Air Screen

Clean or Replace Air Cleaner Cartridge

Clean Engine Cylinder Fins

Replace Spark Plug

1 - Change more often when operating under a heavy ioad or in high ambient temperatures.

2 - Service more often when operating in dirty or dusty conditions.

✓

✓

✓

✓

GENERAL RECOMMENDATIONS

The warranty on this tiller does not cover items that have

been subjected to operator abuse or negligence. To receive

full value from the warranty, the operator must maintain tiller

as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your tiller.

At least once a season, check to see if you should make

any of the adjustments described in the Service and Ad

justments section of this manual.

• Once a year you should replace the spark plug, clean

or replace air filter, and check tines and belts for wear.

A new spark plug and clean air filter assure proper

air-fuel mixture and help your engine run better and

last longer.

<2

✓

•/2

•/

✓

LUBRICATION CHART

BEFORE EACH USE

• Check engine oil level.

• Check tine operation.

• Check for loose fasteners.

LUBRICATION

Keep unit well lubricated (See “LUBRICATION CHART”).

©SAE 30 OR 10W-30 MOTOR OIL

©REFER TO MAINTENANCE “ENGINE” SECTION

10

Page 11

A

MAINTENANCE

Disconnect spark plug wire before performing any maintenance (except carburetor adjustment! to

prevent accidental starting of engine.

Prevent fires! Keep the engine free of grass, leaves, spilled oil, or fuel. Remove fuel from tank

before tipping unit for maintenance. Clean muffler area of all grass, dirt, and debris.

Do not touch hot muffler or cylinder fins as contact may cause burns.

ENGINE

LUBRICATION

Use only high quality detergent oil rated with API service

classification SG-SL. Select the oil’s SAE viscosity grade

according to your expected temperature.

SAE VISCOSITY GRADES

F -20 0 30 32 40 60 80 100

C -30

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

NOTE: Although multi-viscosity oils (5W-30,10W-30, etc.)

improve starting in cold weather, these multi viscosity oils

will result in increased oil consumption when used above

32°F (0°C). Check your engine oil level more frequently to

avoid possible engine damage from running low on oil.

Change the oil after every 25 hours of operation or at least

once a year if the tiller is not used for 25 hours in one year.

Check the crankcase oil level before starting the engine

and after each five (5) hours of continuous use. Add SAE

30 motor oil or equivalent. Tighten oil filler plug securely

each time you check the oil level.

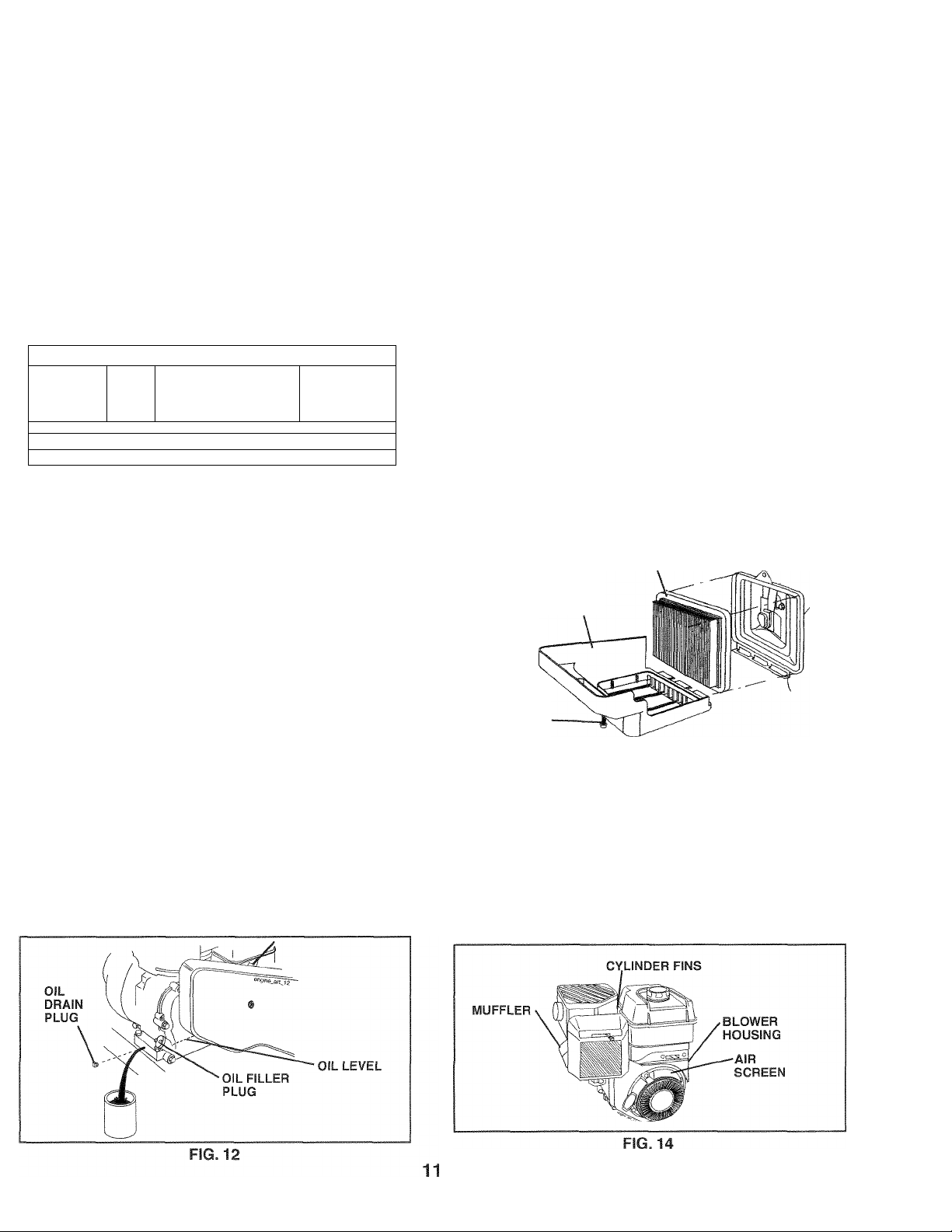

TO CHANGE ENGINE OIL (See Figs. 11 and 12)

Determine temperature range expected before oil change.

All oil must meet API service classification SG-SL.

• Be sure tiller is on level surface.

• Oil will drain more freely when warm.

• Catch oil in a suitable container.

• Remove drain plug.

• Tip tiller forward to drain oil,

• After oil has drained completely, replace oil drain plug

and tighten securely.

• Remove oil filler plug. Be careful not to allow dirt to

enter the engine.

• Refill engine with oil. See “CHECK ENGINEOILLEVEC

in the Operation section of this manual.

20 -10 0 10 20 30 40

FIG. 11

AIR CLEANER (See Fig. 13)

Service air cleaner cartridge every twenty-five hours, more

often if engine is used in very dusty conditions.

• Loosen air cleaner screws, one on each side of

cover.

• Remove air cleaner cover.

• Carefully remove air cleaner cartridge. Be careful. Do

not allow dirt or debris to fall into carburetor.

• Clean by tapping gently on a flat surface.

• If very dirty or damaged, replace cartridge.

• Clean and replace cover. Tighten screws securely.

CAUTION: Petroleum solvents, such as

kerosene, are not to be used to clean

cartridge. They may cause deterioration

of the cartridge. Do not oil cartridge.

Do not use pressurized air to clean or

dry cartridge.

AIR CLEANER CARTRIDGE

COVER

AIR

CLEANER

SCREW -

FIG. 13

COOLING SYSTEM (See Fig. 14)

Your engine is air cooled. For proper engine performance

and long life keep your engine clean.

• Clean air screen frequently using a stiff-bristiedbrush.

• Remove blower housing and clean as necessary.

• Keep cylinder fins free of dirt and chaff.

Page 12

MAINTENANCE

MUFFLER

Do not operate tiller without muffler. Do not tamper with

exhaust system. Damaged mufflers orspark arresters could

create a fire hazard. Inspect periodically and replace if

necessary. If your engine is equipped with a spark arrester

screen assembly, remove every 50 hours for cleaning and

inspection. Replace it damaged.

SPARK PLUG

Replace spark plugs at the beginning of each tilling sea

son or after every 50 hours of use, whichever comes first.

Spark plug type and gap setting are shown in “PRODUCT

SPECIFICATIONS” on page 3 of this manual.

TRANSMISSION

Your transmission is sealed and will not require lubrication

unless serviced.

SERVICE AND ADJUSTMENTS

CAUTION: Disconnect spark plug wire from spark plug and place wire where it cannot come into

A

contact with plug.

CLEANING

Do not clean your tiller when the engine and transmission

are hot. We do not recommend using pressurized water

(garden hose, etc.) to clean your unit unless the gasket

area around the transmission and the engine muffler, air

filter and carburetor are covered to keep water out. Water

in engine will shorten the useful life of your tiller.

• Clean engine, wheels, finish, etc. of all foreign mat

ter.

• Keep finished surfaces and wheels free of all gasoline,

oil, etc.

• Protect painted surfaces with automotive type wax.

TILLER

TO ADJUST HANDLE HEIGHT (See Fig. 15)

Factory assembly has provided lowest handle height. Select

handle height best suited for your tilling conditions. Handle

height will be different when tiller digs into soil.

• If a higher handle height is desired, loosen the four

nuts securing handle panel to engine brackets.

• Slide handle panel to desired location.

• Tighten the four nuts securely.

NORMAL TILLING - 26" PATH (See Fig. 16)

• Assemble holes “A” in tine hubs to holes “B” in tine

shaft.

MID-WIDTH TILLING - 24" PATH (See Fig. 17)

• Assemble holes “A” in tine hubs to holes “C” in tine

shaft.

TINE ARRANGEMENT

Youroutertines can be assembled in several different ways

to suit your tilling or cultivating needs.

CAUTION: Tines are sharp. Wear

A

gloves or other protection when han

dling tines.

12

Page 13

SERVICE AND ADJUSTMENTS

NARROWTILLING/CULTIVATING -12-3/4" PATH

(See Fig. 18)

• Remove outer tines.

FIG. 18

NOTE: When reassembling outer tines, be sure right tine

assembly (marked “R”) and left tine assembly (marked “L’)

are mounted to correct side of tine shaft.

TINE OPERATION CHECK (See Fig. 19)

WARNING: Disconnect spark plug wire

A

For proper tine operation, forward tine control lever must be

against control body and all slack removed from innerwire of

control cable when control is in the “OFF’ (up) position.

If lever and cable are loose, loosen cable clip at lower end of

cable. Pull up on cable to remove slack, without extending

spring on end of cable, and retighten cable clip.

from sparkplug to prevent starting whiie

checking tine operation.

FINAL CHECK “OFF” POSITION

• With tine control “OFF” (up), push down on handle to

raise tines off the ground.

• Slowly pull recoil starter handle while observing tines.

Tines should not rotate.

• If tines rotate, inner wire of control cable is too tight

which is extending lower spring and engaging tines.

Loosen cable clip and push down on cable only enough

to relieve spring tension. Tighten cable clip.

• Recheck in “OFF” position and adjust if necessary.

FINAL CHECK “ON” POSITION

• With tine control “ON” (held down to handle) push down

on handle to raise tines off the ground.

• Slowly pull recoil starter handle while observing tines.

Tines should rotate forward.

• If tines do not rotate, inner wire of control cable is too

loose. Loosen cable clip and pull cable up to remove

slack and retighten clip.

• Recheck in “ON” position and adjust if necessary.

NOTE: If “ON” position check required adjustment, recheck

“OFF” position adjustments insure tines do not rotate when

control is “OFF” (up).

TO REMOVE BELT GUARD (See Fig. 20)

• Remove two (2) cap nuts and washers from side of

belt guard.

• Loosen (do not remove) tine shield nut on underside

of tine shield.

• Pull belt guard out and away from unit.

• Replace belt guard by reversing above procedure. Be

sure slot in bottom of belt guard is under head of tine

shield bolt and all nuts are tightened securely.

TO REPLACE V-BELTS (See Figs. 21 and 22)

Replace V-belts if they have stretched considerably or if

they show cracks or frayed edges. There are two (2) V-belts

- forward (inside) and reverse (outside).

Belt guard must be removed to service belts. See “TO

REMOVE BELT GUARD” in this section of manual.

NOTE: Observe carefully routing of both belts and location

of all belt guides before removing belts.

13

Page 14

SERVICE AND ADJUSTMENTS

BELT REMOVAL

• Remove reverse idler pulley from idler arm.

• Remove reverse (outside) V-belt.

• Remove forward (inside) V-belt from transmission pulley

first and then from engine pulley.

BELT REPLACEMENT

• Install ne'w forward (inside) V-belt to engine pulley first

then to transmission pulley. Be sure belt is positioned

on inside groove of both pulleys, inside all belt guides

and rests on idler pulley.

• Before installing reverse (outside) V-belt, turn belt “inside

out”. Twist so wide, flat surface of belt is to inside.

• Wrap V-belt around reverse idler pulley and reassemble

idler to idler arm. Tighten securely. Be sure belt is

between reverse idler pulley and idler arm pin.

• Install belt to outside groove of transmission pulley. Be

sure belt is inside 3.11 b© It guides and rests on outside

groove of engine pulley.

CHECK TINE OPERATION

• See ‘TINE OPERATION CHEOK” in this section of

manual.

REPLACE BELT GUARD

ENGINE

TO ADJUST CARBURETOR

Thecarburetorhasbeen presetatthefactoryandadjustment

should not be necessary. However, engine performance

can be affected by differences in fuel, temperature, altitude

or load. If the carburetor does need adjustment, contact

your nearest authorized service center/department

IMPORTANT: NEVERTAMPERWITHTHEENGINEGOVERNOR,

WHICH IS FACTORY SET FOR PROPER ENGINE SPEED.

OVERSPEEDING THE ENGINE ABOVE THE FACTORY HIGH

SPEED SETTING CAN BE DANGEROUS. IF YOU THINK THE

ENGINE-GOVERNED HIGH SPEED NEEDS ADJUSTING,

CONTACTYOURNEARESTAUTHORIZEDSERVICECENTER/

DEPARTMENT WHICH HAS THE PROPER EQUIPMENT AND

EXPERIENCE'

14

Page 15

STORAGE

Immediately prepare your tiller for storage at the end of the

season or if the unit will not be used for 30 days or more.

WARNING: Never store the tiller with

gasoline In the tank Inside a building

A

where fumes may reach an open flame

or spark. Allow the engine to cool before

storing in any enclosure.

TILLER

• Clean entire tiller (See“CLEANING”in the Maintenance

section of this manual).

• Inspect and replace belts, if necessary (See belt re

placement instructions in the Service and Adjustments

section of this manual).

• Lubricate as shown in the Maintenance section of this

manual.

• Be sure that all nuts, bolts and screws are securely

fastened. Inspect moving parts for damage, breakage

and wear. Replace if necessary.

• Touch up all rusted or chipped paint surfaces; sand

lightly before painting.

ENGINE

ENGINE OIL

Drain oil (with engine warm) and replace with clean oil. (See

“ENGINE” in the Maintenance section of this manual).

CYLINDER(S)

• Remove spark plug.

• Pour 1 ounce (29 ml) of oil through spark plug hole into

cylinder.

• Pull starter handle slowly several times to distribute

oil.

• Replace with new spark plug.

OTHER

• Do not store gasoline from one season to another.

• Replace your gasoline can if your can starts to rust.

Rust and/or dirt in your gasoline will cause problems.

• If possible, store your unit indoors and cover it to give

protection from dust and dirt.

• Cover your unit with a suitable protective cover that

does not retain moisture. Do not use plastic. Plastic

cannot breathe which allows condensation to form and

will cause your unit to rust.

IMPORTANT: NEVER COVER TILLER WHILE ENGINE AND

EXHAUST AREAS ARE STILL WARM.

FUEL SYSTEM

IMPORTANT: IT IS IMPORTANTTO PREVENTGUM DEPOSITS

FROM FORMING IN ESSENTIAL FUEL SYSTEM PARTS SUCH

AS THE CARBURETOR, FUEL FILTER, FUEL HOSE, OR TANK

DURING STORAGE. ALSO, EXPERIENCE INDICATES THAT

ALCOHOL BLENDED FUELS (CALLED GASOHOL OR USING

ETHANOLOR METHANOL) CAN ATTRACT MOISTUREWHICH

LEADSTO SEPARATION AND FORMATION OF ACIDS DURING

STORAGE. ACIDIC GAS CAN DAMAGE THE FUEL SYSTEM

OF AN ENGINE WHILE IN STORAGE.

• Empty the fuel tank by starting the engine and let it run

until the fuel lines and carburetor are empty.

• Never use engine or carburetor cleaner products in the

fuel tank or permanent.

• Use fresh fuel next season.

NOTE: Fuel stablizer is an acceptable alternative in

minimizing the formation of fuel gum deposits during

storage. Add stabilizer to gasoline in fuel tank or storage

container. Always follow the mix ratio found on stablizer

container. Run engine at least 10 minutes after adding

stablizer to allow the stabilizer to reach the carburetor.

Do not empty the gas tank and carburetor if using fuel

stabilizer.

15

Page 16

TROUBLESHOOTING POINTS

PROBLEM

Will not Start 1.

Hard to start 1.

Loss of power 1.

10. Dirty engine air screen.

11. Dirty/ciogged muffler.

12. Carburetor out of adjustment.

13. Poor compression.

CAUSE

Out of fuel.

2. Engine not “CHOKED” properly.

3. Engine flooded.

4, Dirty air cleaner.

5. Water In fuel.

Clogged fuel tank.

6.

7.

Loose spark plug wire. 7.

8. Bad spark plug or Improper gap.

9. Carburetor out of adjustment.

Throttle control not set properly. 1.

2. Dirty air cleaner.

3.

Bad spark plug or improper gap.

4.

Stale or dirty fuel. 4.

5. Loose spark plug wire.

6. Carburetor out of adjustment.

Engine is overloaded. 1.

2. Dirty air cleaner.

3. Low oil level/dirty oil.

4.

Faulty spark plug. 4.

5. Oil in fuel.

6. Stale or dirty fuel.

7. Water in fuel.

Clogged fuel tank.

8.

9. Spark plug wire loose.

CORRECTION

1,

Fill fuel tank.

2.

See “TO START ENGINE” in the Operation section.

3.

Wait several minutes before attempting to start.

4.

Clean or replace air cleaner cartridge.

5, Empty fuel tank and carburetor, and refill tank with

fresh gasoline.

6. Remove fuel tank and clean.

Make sure spark plug wire is seated properly on

plug.

8.

Replace spark plug or adjust gap.

9.

Make necessary adjustments.

Place throttle control in “FAST’ position.

2.

Clean or replace air cleaner cartridge.

3. Replace spark plug or adjust gap.

Empty fuel tank and refill with fresh gasoline.

5.

Make sure spark plug wire is seated properly on

plug.

6.

Make necessary adjustments.

Set depth stake and wheels for shallower tilling.

2.

Clean or replace air cleaner cartridge.

3. Check oil level/change oil.

Clean and regap or change spark plug.

5.

Empty and clean fuel tank and refill, and clean

carburetor.

6.

Empty fuel tank and refill with fresh gasoline.

7.

Empty fuel tank and carburetor, and refill tank with

fresh gasoline.

8. Remove fuel tank and clean.

9. Connect and tighten spark plug wire.

10. Clean engine air screen.

11.

Clean/replace muffler.

12.

Make necessary adjustments.

13. Contact an authorized service center/department.

Engine overheats

Excessive bounce/

difficult handling

Soil balls up or clumps 1.

Engine runs but tiller 1. Tine control is not engaged.

won’t move 2.

Engine runs but labors 1. Tilling too deep. 1.

when tilling

1. Low oil level/dirty oil. 1.

2. Dirty engine air screen. 2.

3. Dirty engine.

4

Partially plugged muffler.

Improper carburetor adjustment.

5.

1. Ground too dry and hard. 1.

2.

Wheels and depth stake Incorrectly adjusted. 2.

Ground too wet. 1.

V-beit not correctly adjusted. 2.

3. V-belt is off pulley(s). 3.

2. Throttle control not properly adjusted.

3. Carburetor out of adjustment.

16

Check oil level/change oil.

Clean engine air screen.

3. Clean cylinder fins, air screen, muffler area.

4. RernovG and ciGan mufflGr.

5. Adjust carburetor to richer position.

Moisten ground or wait for more favorable soil

conditions.

Adjust wheels and depth stake.

Wait for more favorable soil conditions.

1.

Engage tine control.

Inspect/adjust V-belt.

inspect V-belt.

Set depth stake for shallower tilling.

2. Check throttle control setting.

3.

Make necessary adjustments.

Page 17

LIMITED WARRANTY

The Manufacturer warrants to the original consumer purchaser that this product as manufactured is free from de

fects in materials and workmanship. For a period of two (2) years from date of purchase by the original consumer

purchaser, we will repair or replace, at our option, without charge for parts or labor incurred in replacing parts, any

part which we find to be defective due to materials or workmanship. This Warranty is subject to the following limita

tions and exclusions.

1. This warranty does not apply to the engine or components parts thereof. Please refer to the applicable manu

facturer's warranty on these items.

2. Transportation charges for the movement of any power equipment unit or attachment are the responsibility of

the purchaser. Transportation charges for any parts submitted for replacement under this warranty must be paid

by the purchaser unless such return is requested by Electrolux Home Products.

3. The Warranty period for any products used for rental or commercial purposes is limited to 90 days from the date

of original purchase.

4. This Warranty applies only to products which have been properly assembled, adjusted, operated, and maintained

in accordance with the instructions furnished. This Warranty does not apply to any product which has been

subjected to alteration, misuse, abuse, improper assembly or installation, delivery damage, or to normal wear

of the product.

5. Exclusions: Excluded from this Warranty are belts, tines, tine adapters, normal wear, normal adjustments, stan

dard hardware and normal maintenance.

6. In the event you have a claim under this Warranty, you must return the product to an authorized service deal

er.

Should you have any unanswered questions concerning this Warranty, please contact:

Electrolux Home Products, Inc.

Outdoor Products Customer Service Dept.

1030 Stevens Creek Road

Augusta, GA 30907 USA

giving the model number, serial number and date of purchase of your product and the name and address of the

authorized dealer from whom it was purchased.

THIS WARRANTY DOES NOT APPLY TO INCIDENTAL OR CONSEQUENTIAL DAMAGES AND ANY IMPLIED

WARRANTIES ARE LIMITED TO THE SAME TIME PERIODS STATED HEREIN FOR OUR EXPRESSED WAR

RANTIES. Some areas do not allow the limitation of consequential damages or limitations of how long an implied

Warranty may last, so the above limitations or exclusions may not apply to you. This Warranty gives you specific legal

rights, and you may have other rights which vary from locale to locale.

This is a limited Warranty within the meaning of that term as defined in the Magnuson-Moss Act of 1975.

In Canada contact:

Electrolux Canada Corp.

7075 Ordan Drive

Mississauga, Ontario

L5T1K6

17

Page 18

REGLAS DE SEGURIDAD

Jnlk Prácticas de Operación Seguras para las Cultivadoras Rotatorias Empujables a Motor

ENTRENAMIENTO

• Lea el Manual dei Dueño cuidadosamente. Familiarícese

completamente con los controles y con el uso adecuado

del equipo. Sepa cómo parar la unidad y desenganchar los

controles rápidamente.

• Nunca permita que los niños operen el equipo. Nunca permita

que los adultos operen el equipo sin los conocimientos

adecuados.

• Mantenga el área de operación despejada de personas,

especialmente niños pequeños y animales domésticos.

PREPARACIÓN

• Inspeccione cuidadosamente el área en donde se va usar

el equipo y remueva los objetos extraños.

• Desenganche todos los embragues y cambie a neutro antes

de hacer arrancar el motor.

• No opere el equipo sin usar ropa exterior adecuada.

Use zapatos que mejoren el equilibrio en superficies

resbalosas.

• Maneje el combustible con cuidado pues es muy

inflamable.

• Use un envase de combustible aprobado.

• Nunca añada combustible a un motor en funcionamiento o

caliente.

• Llene el estanque de combustible afuera con mucho cuidado.

Nunca llene el estanque de combustible en un recinto

cerrado.

• Vuelva a colocar la tapa del depósito de gasolina en forma

segura y limpie el combustible derramado antes de volver a

arrancar.

• Use cordones de extensión y receptáculos, según las

especificaciones del fabricante, para todas las unidades con

motores de impulsión o con motores de arranque eléctrico.

• Nunca trate de hacer ningún ajuste mientras que el motor

esté funcionando (excepto en los casos específicamente

recomendados por el fabricante).

OPERACIÓN

• No ponga ni las manos ni los pies cerca o debajo de las

piezas rotatorias.

• Tenga mucho cuidado cuando opere o cruce entradas para

automóviles de ripio, senderos o caminos. Esté alerta en lo

que se refiere a los peligros escondidos o al tráfico. No lleve

pasajeros.

• Después de pegarle a un objeto extraño, pare el motor,

remueva el alambre de la bujía, inspeccione la cultivadora

cuidadosamente, para verificar si hay daños, y repare el

daño antes de volver a arrancar y operar la cultivadora.

• Tenga cuidado para evitar resbalarse o caerse.

• Si la unidad empieza a vibrar anormalmente, pare el motor y

revísela inmediatamente para verificar la causa. La vibración

normalmente es un aviso de problemas.

• Pare el motor cuando abandone la posición de operación.

• Tome todas las precauciones posibles cuando deje la máquina

desatendida. Desenganche los brazos, cambie a neutro y

pare el motor.

• Antes de limpiar, reparar e inspeccionar, apague el motor

y asegúrese que todas las partes en movimiento se han

detenido. Desconecte el alambre de la bujía, y manténgalo

alejado de ésta para evitar el arranque por accidente.

Desconecte el cordón en los motores eléctricos.

• No haga funcionar el motor en recintos cerrados; los gases

de escape son peligrosos.

• Nunca opere lacultivadorasin las protecciones, y las planchas

adecuadas y sin los demás dispositivos de seguridad en su

lugar.

18

• Mantenga a los niños y a los animales domésticos

alejados.

• No sobrecargue la capacidad de la máquina, tratando de

cultivar a mucha profundidad, muy rápido.

• Nunca opere la máquina a altas velocidades en superficies

resbalosas. Mire hacia atrás y tenga cuidado cuando

retroceda.

• Nunca permita la presencia de espectadores cerca de la

unidad.

• Use solamente accesorios y aditamentos para la cultivadora

aprobados por el fabricante.

• Nunca opere la cultivadora sin buena visibilidad o luz.

• Tenga cuidado al cultivar en terreno duro. Los brazos pueden

quedarse agarrados en el suelo e impulsar a la cultivadora

hacia adelante. Si esto sucede, suelte los mangos y no

restrinja la máquina.

MANTENIMIENTO Y ALMACENAMIENTO

• Mantenga ios accesorios y aditamentos de la máquina en

buenas condiciones para el funcionamiento.

• Revise las clavijas de seguro, los pernos de montaje del

motor y otros pernos, a intervalos frecuentes, para verificar

sí están apretados en forma segura y asegurarse que el

equipo esté en buenas condiciones de funcionamiento.

• Nunca guarde la máquina con combustible en el estanque de

combustible dentro de un edificio en donde hay fuentes de

ignición presentes, tales como calentadores de agua o del

ambiente, secadoras de ropa u otros artefactos parecidos.

Permita que se enfríe el motor antes de guardarlo en algún

lugar cerrado.

• Siempre refiérase a las instrucciones en la guía del operador

para ver los detalles de importancia si la cultivadora va a ser

guardada por un período de tiempo largo.

- IMPORTANTE -

LOS PARRAFOS DONDE APARECEN LAS PALABRAS

PRECAUCIÓN, IMPORTANTE Y AVISO SIRVEN COMO UN

MEDIO PARA ATRAER LA ATENCIÓN A INFORMACIÓN

IMPORTANTE O CRITICA EN ESTE MANUAL.

IMPORTANTE: SE USA PARA SEÑALARLE QUE EXISTE LA

POSIBILIDAD DE DAÑAR ESTE EQUIPO.

AVISO: Entrega información esencial que le ayudará a

comprender mejor, incorporar o llevar a cabo un conjunto

de instrucciones en particular.

Busque este símbolo que señala las

A

A

precauciones de seguridad de im,portancia. Quiere decir - ¡¡¡ATENCIÓN!!!

¡¡¡ESTE ALERTO!!! SU SEGURIDAD ESTA

COMPROMETIDA.

PRECAUCIÓN: Siempre desconecte el

alambre de la bujía y póngalo donde no

pueda entrar en contacto con la bujía, para

evitar el arranque por accidente, durante

la preparación, el transporte, el ajuste o

cuando se hacen reparaciones.

A ADVERTENCIA A

Es conocido por el Estado de California que ios

gases de escape del motor de este productor

contienen químicos los cuales a ciertos niveles,

pueden ocasionar, cáncer, defectos de nacimiento,

y otros daños al sistema reproductivo.

Page 19

ESPECIFICACIONES DEL PRODUCTO

Capacidad de gasolina;

Aceite (API-SG-SL): SAE 30 (Sobre 32° F [0° C])

(Capacidad: 20 oz.)

Bujía:

(Abertura 0,030")

FELICITACIONES por la compra de su Cultivadora. Ha

sido diseñada, planificada y fabricada para darle la mejor

confiabiiidad y el mejor rendimiento posible.

En el caso de que se encuentre con cualquier problema

que no pueda solucionar fácilmente, haga el favor de pon

erse en contacto con su centro/departamento de servicio,

autorizado, más cercano. Contamos con técnicos bien

capacitados y competentes con herramientas adecuadas

para darle servicio o para reparar su unidad.

Haga el favor de leer y de guardar este manual. Estas

instrucciones le permitirán montar y mantener su cultiva

dora en forma adecuada. Siempre observe las “REGLAS

DE SEGURIDAD.”

3 cuartos

Sin plomo, regular

SAE 5W-30 (Debajo 32° F [0° C])

Champion

RC12YC

RESPONSABILIDADES DEL CLIENTE

• Lea y observe las reglas de seguridad.

• Siga un programa regular de mantenimiento, cuidado

y uso de su cultivadora.

• Siga las instrucciones descritas en las secciones

“Mantenimiento” y “Almacenamiento” de este Manual

del Dueño.

IMPORTANTE: ESTA UNIDAD VIENE EQUIPADA CON UN

MOTOR DE COMBUSTIÓN INTERNO Y NO SE DEBE USAR

SOBRE, O CERCA, DE UN TERRENO NO DESARROLLADO

CUBIERTO DE BOSQUES, DE ARBUSTOS O DE CÉSPED, A

MENOS QUE EL SISTEMA DE ESCAPE DEL MOTOR VENGA

EQUIPADO CON UN AMORTIGUADOR DE CHISPAS QUE

CUMPLA CON LAS LEYES LOCALES O ESTATALES (SI

EXISTEN). SI SE USA UN AMORTIGUADOR DE CHISPAS,

EL OPERADOR DEBE MANTENERLO EN CONDICIONES DE

TRABAJO EFICIENTES.

EN EL ESTADO DE CALIFORNIA, LA LEY EXIGE LO

ANTERIOR (SECCIÓN 4442 DEL “CALIFORNIA PUBLIC

RESOURCES CODE” (DECRETO DE RECURSOS PÚBLICOS

DE CALIFORNIA)). OTROS ESTADOS PUEDEN CONTAR CON

OTRAS LEYES PARECIDAS. LAS LEYES FEDERALES SE

APLICAN EN LAS TIERRAS FEDERALES. VEA A SU CENTRO

DE SERVICIO AUTORIZADO PARA LOS AMORTIGUADORES

DE CHISPAS.

TABLA DE CONTENIDOS

REGLAS DE SEGURIDAD........................................ 18

RESPONSABILIDADES DEL CLIENTE.........................19

ESPECIFICACIONES DEL PRODUCTO

MONTAJE

OPERACIÓN............................................................. 22-26

PROGRAMA DE MANTENIMIENTO...

...............................................................

........................

...........................27

19

20-21

MANTENIMIENTO.................................................

SERVICIO Y AJUSTES

ALMACENAMIENTO

IDENTIFICACIÓN DE PROBLEMAS

GARANTÍA

................................................................... 35

........................................

.....................................................

............................

19

27-29

....30-32

33

34

Page 20

MONTAJE

Su cultivadora nueva ha sido montada en la fábrica, con la excepción de aquellas partes que se dejaron sin montar por

razones de envío. Para asegurarse que la cultivadora operará en forma segura y adecuada, todas las partes y los artículos

de ferretería que monte tienen que estar apretados en forma segura. Use las herramientas correctas, según sea necesario,

para asegurarse de que queden apretadas en forma segura.

HERRAMIENTAS NECESARIAS PARA EL MONTAJE

Se le facilitará el montaje si cuenta con un juego de llaves

de tubo. Se han enumerado los tamaños estándar de las

llaves.

(1) Cuchillo para todo uso

(1) Destornillador

(2) Llaves de 1/2"

POSICIÓN DEL OPERADOR (Vea la Fig. 1)

Cuando en este manual se mencionan los términos lado

derecho” o “lado izquierdo” se refiere a cuando usted se

encuentra en la posición de operación (parado/a detrás de

los mangos de la cultivadora).

CONTENIDOS DEL CONJUNTO DE FERRETERIA

(2) Pernos hexagonales 5/16-18 x 3/4 (2) Pernos hexagonales 5/16-18 x 1 ^4^ Arandelas de calibre

3/8 X 7/8 X 14

|n

9

(2) Perno hexagonales 5/16-18 x 1-1/4

^ segundad 5/16

(6) Tuercas

hexagonales 5/16-18

20

Page 21

MONTAJE

DESEMPAQUE DE LA CAJA DE CARTÓN

(Vea la Fig. 2)

PRECAUCIÓN: Tenga cuidado con las

A

IMPORTANTE: CUANDO DESEMPAQUE Y MONTE LA

CULTIVADORA, TENGA CUIDADO DE NO ESTIRAR O

ENREDAR EL (LOS) CABLE(S).

® Corte las ligaduras del cable que aseguran los

mangos.

® Levante lentamente el conjunto del mango hacia arriba,

encamine el cable (o los cables) según lo mostrado

y alinee los agujeros del mango con el agujero y la

ranura del panel.

• Afloje el montage de la quincallería como mostrado.

Asegúrese que el perno hexagonal más corto (3/4" de

largo) este montado en el agujero inferior del mango.

Repita este procedimiento en el otro lado. Apriete toda

la quincallería con seguridad.

grampas expuestas cuando maneje o

deseche los materiales de la caja de

cartón.

INSTALACIÓN DELCONJUNTO DE LA ESTACA DE PROFUNDIDAD (Vea la Fig. 3)

• Afloje la tuercas “A”.

• Inserte el soporte de la estaca entre las mitades del

puntal del motor, con el resorte de la estaca hacia

abajo.

• Aperen el soporte de la estaca en los puntales del

motor con los pernos hexagonales, las arandelas de

seguridad y las tuercas. Apriételos en forma segura.

También apriete las tuercas “A”.

• La estaca de profundidad se tiene que mover libremente.

Si no lo hace, suelte el perno de soporte.

MITADES DEL PUNTAL

DEL MOTOR

TUERCAS HEXAGONALES

FIG.3

• Corte las ligaduras del cable que aseguran la cultivadora

al rodillo y remueva la cultivadora del rodillo.

• Quitar el tornillo de fijación del pilote de profundidad

para girar y remover el tornillo.

ALTURA DEL MANGO

• Se puede ajustar la altura del mango en la mejor

forma que le acomode al operador. (Vea “ALTURA

DEL MANGO” en la sección de Servicio y Ajustes de

este manual.)

ANCHO DEL LABRADO

• Se puede ajustar el ancho del labrado para manejar

mejor sus condiciones de labración (vea “ARREGLO

DE LOS BRAZOS” en la sección de Servicio y Ajustes

de este manual).

OPERACIÓN DE LOS BRAZOS

• Revise la operación de los brazos antes del primer

uso (vea “REVISIÓN DE LA OPERACIÓN DE LOS

BRAZOS” en la sección de Servicio y Ajustes de este

manual).

21

Page 22

OPERACION

CONOZCA SU CULTIVADORA

LEA ESTE MANUAL DEL DUEÑO Y LAS REGLAS DE SEGURIDAD ANTES DE OPERAR SU

CUTIVADORA

Compare las ilustraciones con su cultivadora para familiarizarse con la ubicación de los diversos controles y ajustes.

Guarde este manual para referencia en el futuro.

Estos símbolos pueden apareser sobre su cultivadora en la literatura proporcionada con el producto. Aprenda

y comprenda sus significados.

FNRA(S©‘^*^l\ní¡'i&^

-ABOREO MARCHA NEUTRO REVÉS ATTENCIÓM O MOTOR MOTOR RÁPIDO LENTO ESTRANGU COM- ACEITE

HACIA ADVERTENOA ENCENDIDO APAGADO LACIÓN BUSTIBLE

MARCHA

RETÉN

I

O

Nuestras cultivadoras cumplen con los estándares de seguridad del

American National Standards Institute.

CONTROL DE LA ACELERACION - Controla la

velocidad del motor.

CONTROL DE LA ESTRANGULACIÓN - Uselo cuando

se hace arrancar un motor frío.

CONTROL DE LOS BRAZOS MARCHA HACIA

ADELANTE Engancha los brazos en la dirección de

marcha hacia adelante.

CONTROL DE LOS BRAZOS MARCHA ATRAS

- Engancha los brazos en la dirección de marcha hacia

atrás.

ESTACA DE PROFUNDIDAD- Controla la velocidad de la

marcha hacia adelante y la profundidad a la cual excavará

la cultivadora.

MANGO DEL ARRANCADOR DE CULATEO - Se usa

para hacer arrancar el motor.

22

Page 23

OPERACION

La operación de cualquier cultivadora puede hacer que salten objetos extraños dentro de

sus ojos, lo que puede producir daños graves en éstos. Siempre use anteojos de seguridad

o protecciones para los ojos antes de hacer arrancar su cultivadora o mientras esté labrando

con élla. Recoroendainos el uso de la máscara de seguridad de visión amplia, para uso sobre

los espejuelos o anteojos de seguridad estándar.

COMO USAR SU CULTIVADORA

Sepa cómo operar todos los controles antes de agregar

combustible y aceite o antes de tratar de hacer arrancar

el motor.

PARADA (Vea la Fig. 5)

BRAZOS

• Suelte el control del movimiento hacia adelante de los

brazos para parar el movimiento.

• Suelte el control del movimiento hacia atrás de los

brazos para parar el movimiento.

MOTOR

• Mueva el control de la aceleración a la posición de

“PARADA” (STOP).

« Nunca use la estrangulación para parar el motor.

CONTROL DE LOS

BRAZOS MARCHA

ATRÁS

CONTROL DE LOS BRAZOS

MARCHA HACIA ADELANTE EN LA

POSICIÓN DE “APAGADO” (ARRIBA)

CONTROL DE LOS BRAZOS

MARCHA HACIA ADELANTE

EN LA POSICIÓN DE

“ENCENDIDO” (ABAJO)

LABRADO

La velocidad y la profundidad del labrado son reguladas

por medio de la posición de la estaca de profundidad y por

(a altura de la rueda.

La estaca de profundidad siempre tiene que estar por

debajo de las ruedas para excavar. Sirve de freno para

retardar el movimiento de marcha hacia adelante de la

cultivadora, para permitir que los brazos penetren en el

suelo.También, mientras más se baje la estaca de profun

didad dentro del suelo, más profunda será la excavación

realizada con los brazos.

ESTACA DE PROFUNDIDAD (Vea la Fig. 6)

Ajuste la estaca de profundidad removiendo la abrazadera

de horquilla y la clavija de horquilla. Cambie la estaca de

profundidad a la posición deseada. Vuelva a colocar la

clavija de horquilla y la abrazadera de horquilla.

• Para el labrado normal, ajuste la estaca de profundi

dad en el segundo o tercer agujero a partir de la parte

superior.

RUEDAS (Vea la Fig. 6)

Ajuste las ruedas removiendo la abrazadera de horquilla

y la clavija de horquilla. Cambie la posición de la rueda.

Vuelva a colocar la abrazadera de horquilla y la clavija de

horquilla.

• Para el labrado normal, ajuste las ruedas en el segundo

o tercer agujero a partir de la parte superior.

CONTROL DE LA

ACELERACIÓN

CONTROL DE LA

ESTRANGULACIÓN

FIG. 5

OPERACIÓN DE LOS BRAZOS (Vea la Fig. 5)

MARCHA HACIA ADELANTE

• Apriete el control de los brazos de marcha hacia

adelante contra el mango.

MARCHA ATRÁS

• Con el control de los brazos de marcha hacia adelante

en la posición de “APAGADO” (OFF) (arriba), tire hacia

atrás y sujete el control de los brazos marcha atrás.

PARA EL TRANSPORTE

PRECAUCIÓN: Antes de levantarla o

transportarla, permíta que el motor

A

de la cultivadora y el silenciador se

enfríen. Desconecte el alambre de la

bujía. Drene la gasolina del estanque

de combustible.

23

Page 24

OPERACION

EN EL JARDÍN

• incline la estaca de profundidad hacia adelante, hasta

que quede sujeta con el resorte de la estaca.

• Empuje los mangos de la cultivadora hacia abajo,

levantando los brazos por encima del suelo.

® Tire o empuje la cultivadora a la ubicación deseada.

EN LA CIUDAD

® Desonecte el alambre de la bujía.

• Drene el estanque de combustible.

• Transpórtela en la posición derecha hacia arriba para

evitar la fuga del aceite.

ANTES DE HACER ARRANCAR EL

MOTOR

IMPORTANTE: TENGA MUCHO CUIDADO DE NO PERMITIR

QUE ENTRE MUGRE AL MOTOR CUANDO REVISE O AÑADA

ACEITE O COMBUSTIBLE. USE ACEITE Y COMBUSTIBLE

LIMPIOSY GUARDELOS EN ENVASES APROBADOS, LIMPIOS

Y CON TAPA. USE EMBUDOS PARA RELLENO LIMPIOS.

RELLENO DEL ACEITE DEL MOTOR (Vea la Fig. 7)

• Con el motor nivelado, remueva el tapón del depósito

de relleno del aceite del motor.

• Llene el motor con aceite hasta el punto de derramarse.

Para verificar la capacidad aproximada vea “ESPE

CIFICACIONES DEL PRODUCTO” en la página 3 de

este manual.

• Incline la cultivadora hacia atrás en sus ruedas y luego

vuelva a nivelarla.

• Con el motor nivelado, vuelva a llenarlo hasta el punto

de derramarse, si es necesario. Vuelva a colocar el

tapón del depósito de relleno de aceite.

• Para la operación en clima frío, debe cambiarse el

aceite para facilitar el arranque (vea la ‘TABLA DE

VISCOSIDAD DEL ACEITE” en la sección de Man

tenimiento en este manual).

• Para cambiar el aceite del motor, vea la sección de

Mantenimiento en este manual.

AGREGUE GASOLINA

• Llene el estanque de combustible. Llene hasta la parte

inferior del cuello de relleno del estanque de gasolina.

No lo llene demasiado. Use gasolina regular, sin plomo,

nueva y limpia con el mínimo de 87 octanos. (El uso

de gasolina con plomo aumentará los depósitos de

óxido de plomo y carbono y se reducirá la duración de

la válvula). No mezcle el aceite con la gasolina. Para

asegurar que la gasolina utilizada sea fresca compre

estanques los cuales puedan ser utilizados durante

los primeros 30 días.

PRECAUCION: Llene el estanque de

combustible hasta dentro de 1/2 pul

A

IMPORTANTE: CUANDO SE OPERE EN TEMPERATURAS

POR DEBAJO DE 32°F (0“C) USE GASOLINA DE CALIDAD

DE INVIERNO, LIMPIAY NUEVA PARA AYUDAR A ASEGURAR

UN BUEN ARRANQUE EN CLIMA FRÍO.

PRECAUCIÓN: Combustibles mezclados con alcohol

(conocidos como gasohol, o el uso de etanol o metano!)

pueden atraer la humedad, la que conduce a la separa

ción y formación de ácidos durante el almacenamiento. La

gasolina acídica puede dañar el sistema del combustible

de un motor durante el almacenamiento. Para evitar los

problemas con el motor, se debe vaciar el sistema de

combustible antes de guardarlo por un período de 30

días o más. Vacíe el estanque de combustible, haga

arrancar el motor y hágalo funcionar hasta que las

líneas del combustible y el carburador queden vacíos.

La próxima temporada use combustible nuevo. Vea las

Instrucciones para el Almacenamiento para más infor

mación. Nunca use productos de limpieza para el motor

o para el carburador en el estanque del combustible

pues se pueden producir daños permanentes.

gada de la parte superior para evitar

los derrames y para permitir que se

expanda el combustible. Si por casu

alidad se derrama la gasolina, aleje la

máquina del área del derrame. Evite

crear cualquiera fuente de ignición

hasta que se hayan desaparecido ios

gases de la gasolina.

No lo llene demasiado. Limpie el aceite

o el combustible derramado. No guarde,

derrame o use la gasolina cerca de una

llama expuesta.

PARA HACER ARRANCAR EL MOTOR (Vea la Fig. 8)

PRECAUCIÓN: Mantenga la barra de

A

Cuando este empezando un motor por la primera vez o

si el motor se ha quedado sin gasolina, será necesario

varios intentos para mover la gasolina desde el estanque

al motor.

control de la impulsión en ia posición

"DESENGANCHADO" cuando haga

arrancar el motor.

24

Page 25

OPERACION

• Asegúrese que el alambre de la bujía esté conectado

en forma adecuada y que la válvula de cierre de la

gasolina este abierta.

• Ponga la palanca de cambio a la posición de (NEUTRO)

"N".

• Ponga la palanca de cambio a la posición de “RAPIDO"

(FAST).

• Mueva la válvula de cierre del combustible 1/4 turno

para ABRIR.

• Mueva el control de la estrangulación a la posición de

ESTRANGULACIÓN.

• Agarre el mango del arrancador de culateo con una

mano y el mango de la cultivadora con la otra mano.

Tire el cordón hacia afuera, lentamente, hasta que el

motor legue al comienzo del ciclo de la compresión

(el cordón se sentirá un poco mas duro en este mo

mento).

• Tire el mango del arrancador de culateo rápidamente.

No permita que el mango del arrancador se devuelva

abruptamente en contra del arrancador. Vuelva a

repetir, si lo es necessario.

• Si el motor se enciende pero no comienza, mueva el

control de la estrangulación al medio. Tire del mango

del arrancador de retroceso hasta que el motor co

mience.

• Cuando comience el motor y al mismo tiempo que se

caliente, mueva, lentamente, el control de la estran

gulación, a la posición de “MARCHA”.

AVISO: Un motor caliente requiere menos estrangulación

para empezar.

• Mueva el control de la aceleración a la posición de

funcionamiento deseada.

• Permita que se caliente el motor por unos cuantos

minutos antes de enganchar los brazos.

AVISO: A mucha altura (sobre 3000 pies) o en climas

fríos (debajo de 40° F [4° C]) puede que la mezcla del

combustible del carburador necesite ajuste, para obtener

el mejor resultado del motor. Vea “PARA AJUSTAR EL

CARBURADOR” en la sección de Servicio y Ajustes de

este manual.

AVISO: Si el motor no arranca, vea la guía de identificación

de problemas.

RODAJE DE SU CULTIVADORA

Use su(s) correa(s), las poleas y el control de los brazos

antes de empezar a labrar.

• Haga arrancar el motor, saque los brazos fuera dei

suelo presionando los mangos hacia abajo y enganche

el control de los brazos para hacer arrancar la rotación

de los brazos. Permita que los brazos roten por cinco

minutos.

• Revise la operación de los brazos y ajústelos^ si es

necesario. Vea “REVISIÓN DE LA OPERACION DE

LOS BRAZOS” en la sección de Servicio y Ajustes de

este manual.

CONSEJOS PARA LABRAR

PRECAUCIÓN: Antes de acostumbrarse

A

Para ayudarle a la cultivadora a moverse hacia adelante,

levante los mangos un poco (levantando en esta forma la

estaca de profundidad fuera del suelo). Para hacer que

la cultivadora ande más lento presione los mangos hacia

abajo.

Si está forzándola o si la cultivadora está vibrando, quiere

decir que las ruedas y la estaca de profundidad no están

ajustadas en forma adecuada para el terreno que se está

labrando. El ajuste adecuado de las ruedas y de la estaca

de profundidad se logra al probarlas en acción y depende

de las condiciones del suelo. (Mientras más duro o más

mojado esté el suelo, menor es la velocidad necesaria del

motor y de los brazos. La cultivadora va a correr y saltar

sobre el terreno si se usa en estas malas condiciones a

una velocidad rápida.)

Si la cultivadora está bien ajustada, excavará con poco

esfuerzo por parte del operador.

• El labrar quiere decir el excavar, dar vuelta y romper el

suelo duro antes de plantar. El suelo suelto y blando

permite el desarrollo de las raíces. La mejor profun

didad de cultivo es 4" a 6". La cultivadora también

puede despejar el suelo de las malezas indeseables.

La descomposición de estas malezas enriquece el

suelo. Dependiendo del clima (lluvia o viento), puede

ser recomendable labrar el suelo afines de latemporada

de cultivo para acondicionar el suelo aún más.

• Las condiciones del suelo son importantes si se de

sea obtener un labrado adecuado. Los brazos no van

a penetrar fácilmente en el suelo seco y duro, lo que

puede contribuir a un rebote excesivo y a dificultades

en el manejo de su segadora. El terreno duro tiene

que ser humedecido antes de labrarlo, sin embargo,

si el suelo está demasiado mojado se convertirá en

bolas o se amontonará durante el labrado. Espere a

que el suelo esté menos mojado para poder obtener

los mejores resultados. Cuando se hagan labrados en

el otoño, remueva las vides y el césped alto para evitar

que se envuelvan alrededor del eje de los brazos y

retarden su operación para el labrado.

a manejar su cultivadora, empiece el uso

de ésta en el terreno con la aceleración

en la posición de “lento” (slow).

25

Page 26

OPERACION

Va a descrubrir que el labrado se facilita si deja una

fila sin labrar entre las pasadas. Entonces vuelva de

nuevo entre las filas de cultivo(Vea la Fig. 9). Hay dos

razones para hacer ésto. Primero, las vueltas amplias

se pueden realizar con más facilidad que las cerradas.

Segundo, la cultivadora no estará empujándose a sí

misma y a usted hacia la próxima hilera.

Ajuste la estaca de profundidad y la altura de !a rueda

para labrado poco profundo cuando esté trabajando en

suelo o terreno herboso demásiado duro. Luego atra

viese los primeros cortes a la profundidad normal.

FIG. 9

CULTIVO

El cultivo quiere decir la destrucción de las malezas entre

las hileras para evitar que éstas le roben la nutrición y la

humedad a las plantas. Al mismo tiempo, si se rompe la

capa superior de la costra del suelo, éste puede retener

la humedad. La mejor profundidad de excavación es de

1" a 3".

* Probablemente no va a necesitar usar ia estaca

de profundidad. Empiece por inclinar la estaca de

profundidad hacia adelante, hasta que quede sujeta

en el resorte de la estaca.

• Cultive hacia arriba y hacia abajo las hileras a una

velocidad que le permita a los brazos sacar las raíces

de las malezas y dejar el suelo en condiciones ásperas,

para desalentar el desarrollo de las malezas y ei césped

(vea la Fig. 10).

M

LA 0 o

o

0

0 0 0

/-"'X

AL 0

V-/

Cj

0 0 0

0

0 0

KmJ

0

0

0

FIG. 10

26

Page 27

MANTENIMIENTO

PROGRAMA DE

MANTENIMIENTO

/cj/

LLENE LAS FECHAS DE MEDIDA /

QUE COMPLETE SU //

SERVICIO REGULAR

Revisar el nivel del aceite del motor

Cambiar el aceite del motor

Aceitar ios puntos de pivote

Inspeccionar el supresor del silenciador

Inspeccionar la rejilla de aire

Limpiar/cambiar el cartucho del filtro de aire

Limpiar las aletas del cilindro del motor

Cambiar la bujía

1- Cambiar más menudo cuando se opere bajo carga pesada o en ambientes con altas temperaturas.

2- Dar servicio más a menudo cuando se opere en condiciones sucias o polvorosas

/3 / /

^/oV<

/ cT/Ù

✓ ✓

✓

✓

Â

<2

)/

3/ 3/

\ / i

7W

w

/ FECHAS DE SERVICIO

A

✓

1/

✓

RECOMENDACIONES GENERALES

La garantía de esta cultivadora no cubre los artículos que

han estado sujetos al abuso o a la negligencia del opera

dor. Para recibir todo el valor de la garantía, el operador

tiene que mantener la cultivadora según las instrucciones

descritas en este manual.

Hay algunos ajustes que se tienen que hacer en forma

periódica para poder mantener su cultivadora adecuada

mente.

Al menos una vez cada estación comprobar si es necesario

efectuar los adjustes descritos en las secciones de Servicio

y Ajustes de este manual.

• Una vez al año, cambie la bujía, limpie o cambie el

filtro de aire y revise si los brazos y las correas están

desgastadas. Una bujía nueva y un filtro de aire limpio

aseguran una mezcla de aire-combustible adecuada

y le ayuda a que su motor funcione mejor y que dure

más.

ANTES DE CADA USO

• Revise el nivel del aceite del motor.

• Revise la operación de los brazos.

• Revise si hay sujetadores sueltos.

LUBRICACIÓN

Mantenga la unidad bien lubricada (vea la “TABLA DE

LUBRICACIÓN”).

TABLA DE LUBRICACIÓN

©ACEITE DE MOTOR SAE 30 O 10W-30

©REFIÉRASE A LA SECCIÓN DEL MOTOR, “MANTENIMIENTO”

27

Page 28

MANTENIMIENTO

Desconecte el alambre de la bujía antes de dar mantenimiento (excepto por el ajuste del carburador)

A

para ewitar que el motor arranque por accidente.

Evite los incendios! Mantenga el motor sin césped, hojas, aceite o combustible derramado. Remueva

el combustible del estanque antes de inclinar la unidad para darle mantenimiento. Limpie el césped,

la mugre y la basura del área del silenciador.

No toque el silenciador caliente o las aletas del cilindro, pues el contacto puede producir

quemaduras.

MOTOR

LUBRICACIÓN

Use solamente aceite de detergente de afta calidad

clasificado con la ciasificación SG-SL de servicio API.

Seleccione la calidad de viscosidad SAE según su

temperatura de operación esperada.

oi!_v©c_ charíl _,s

FiG. 11

AVISO: A pesar de que los aceites de multiviscosidad

(5W-30, 10W-30, etc.) mejoran el arranque en clima frío,

estos aceites de muftiviscosídad van a aumentarel consumo

de aceite cuando se usan en temperaturas sobre 32°F

(0°C). Revise el nivef del aceite del motor más a menudo,

para evitar un posible daño en el motor, debido a que no

tiene suficiente aceite.

Cambie el acete después de 25 horas de operación o por

lo menos una vez a! año si e! cultivadora se utiliza menos

25 horas el año.

Revise el nivel del aceite del cárter antes de hacer arrancar

el motor y después de cada cinco (5) horas de uso continu

ado. Agregue aceite de motor SAE 30 o su equivalente.

Apriete el tapón del depósito de relleno del aceite en forma

segura cada vez que revise el nivel del aceite.

PARA CAMBIAR EL ACEITE DEL MOTOR

(Vea las Figs. 11 y 12)

Determine la gama de temperatura esperada antes del

cambio del aceite. Todos los aceites deben cumplir con los

requisitos de la clasificación de servicio API SG-SL.

• Asegúrese que la cultivadora esté en una superficie

nivelada.

• El aceite drenará más fácilmente cuando está cali

ente.

• Útilice un embudo para impedir el derrame de aceite

sobre la cultivadora, y recoja el aceite en un envase

adecuado.

• Remueva el tapón del drenaje.

• Incline la cultivadora hacia adelante para drenar el

aceite.

• Después de que el aceite se haya drenado completa

mente, vuelva a colocar el tapón del drenaje del aceite

y apriételo en forma segura.

Remueva el tapón del depósito de relleno de aceite.

Tenga cuidado de no permitir que la mugre entre al

motor.