Page 1

USER MANUAL

Page 2

FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may

not cause harmful interference, and (2) this device must accept any interference received, including interference that may

cause undesired operation.

This equipment may generate, use and/or radiate radio frequency energy. If not installed and used in full accordance with this

instruction manual, interference to radio communications may occur. This equipment complies with the limits for a Class A

Information Technology Equipment pursuant to Part 15 of the FCC Rules, which are designed to provide reasonable protection

against such interference when operated in a commercial environment. Operation of this equipment in a residential area may

also cause interference. In such case the user will be required, at own expense, to correct the interference using whatever

means necessary.

Trademarks

ARM is a registered trademark of Advanced RISC Machines Ltd.

Centronics is a registered trademark of Centronics Data Computer Corporation.

Microsoft, Windows are registered trademarks of Microsoft Corporation.

Copyright

Copyright © POSTEK Electronics Co., Ltd. All rights reserved. Under the copyright laws, this manual cannot be reproduced

in any form without the prior written permission of POSTEK. No patent liability is assumed, with respect to the use of the

information contained herein.

TW Series Thermal Printer User’s Manual

2nd edition November, 2016

Disclaimer

This manual has been validated and reviewed for accuracy. The instructions and descriptions it contains are accurate for the

POSTEK TW Series thermal printer at the time of this manual’s distribution. However, succeeding printers and manuals are

subject to change without notice. POSTEK assumes no liability for damages incurred directly or indirectly from errors,

omissions or discrepancies between the printer and this manual.

Although this manual describes and details many issues which could possibly occur, the manufacturer cannot warrant against

unpredictable conditions during the printing process. For problems such as the printer not working, lost or unclear print content,

etc., the manufacturer and resellers are responsible for correcting these issues (according to POSTEK Printer Warranty

Clauses). In no event shall the manufacturer or the resellers involved be liable for any damages whatsoever (including, without

limitation, damages for loss of business profits, business interruption, loss of business information, or other pecuniary loss)

arising from the use of, the results of use or inability to use this product, even if the manufacturer has been advised of the

possibility of such damages.

Page 3

TW Series User’s Manual

ii

Important Safety Instructions

Only qualified and trained service technicians should attempt to repair the printer.

Do not place the printer on or near a heat source.

Be sure that the output of the power adapter is 24 VDC and your power source matches the rating listed on the power

adapter. Be certain your power source is grounded.

To avoid getting an electric shock, do not use a worn or damaged power cord. If the power cord becomes damaged or

frayed, replace it immediately.

Do not insert anything into the ventilation slots or openings on the printer.

The printer and power adapter should never be operated in a location where either one can get wet. Personal injury may

result.

The printhead becomes hot while printing. To protect from damaging the printhead and risk of personal injury, avoid

touching the printhead.

To get increased printhead longevity and higher quality printouts, always use approved labels, tags and thermal transfer

ribbons. Approved supplies can be ordered from your POSTEK authorized reseller.

Static electricity that accumulates on the surface of the human body or other surfaces can damage or destroy the printhead

or electronic components in this device. DO NOT touch the printhead or the electronic components with bare hands.

Place the printer on a flat, firm, solid surface.

Never operate in a high temperature environment.

Turn off the power when not in use for extended periods.

Follow all recommendations and setup instructions included in this manual.

Warnings:

This is a Class A product. In a domestic environment this product may cause radio interference in which case the user may be

required to take adequate measures (see FCC Notice).

Static electricity that accumulates on the surface of the human body or other objects can damage the print head or electronic

components in the TW Series printer. Observe proper electrostatic safety precautions when handling.

Page 4

TW Series User’s Manual

iii

Content

Preface ............................................................................................................................................................................... 1

Important Notice, Read Me First ......................................................................................................................................... 1

Chapter 1: Introduction ................................................................................................................................................... 2

Printer Specifications .......................................................................................................................................................... 2

Contents of Box .......................................................................................................................................................................... 3

Packing List ................................................................................................................................................................ 3

Chapter 2: Setup and Use ................................................................................................................................................ 4

Setting up the Printer .......................................................................................................................................................... 4

Main Parts and Structures ........................................................................................................................................... 4

Loading Path ............................................................................................................................................................... 8

Connecting the Printer ................................................................................................................................................ 8

Power Connection .............................................................................................................................................................. 8

Interface Connection ................................................................................................................................................... 9

Loading the Ribbon ............................................................................................................................................................ 9

Unloading the Ribbon ....................................................................................................................................................... 14

Loading the Media ................................................................................................................................................................... 15

Standard Mode, Peel-off mode and Manually Tear-off mode ................................................................................... 15

Cutting Mode ............................................................................................................................................................ 20

Changing Media and Ribbon ............................................................................................................................................ 22

Adjusting the Position of Media Sensor ............................................................................................................................ 23

Reflective Media Sensor ........................................................................................................................................... 23

Transmissive Media Sensor ....................................................................................................................................... 25

Chapter 3: Operations and Settings .............................................................................................................................. 26

Basic Operations ............................................................................................................................................................... 26

Power Switch ............................................................................................................................................................................ 26

The Front Panel ......................................................................................................................................................... 26

LCD Display ............................................................................................................................................................. 27

LCD Panel Operation................................................................................................................................................ 27

Tear-off ...................................................................................................................................................................................... 31

Manual Peel-off ................................................................................................................................................................ 31

Cutting Mode ............................................................................................................................................................ 32

Adjusting the Pressure of Printhead.................................................................................................................................. 33

Adjusting the Tension of Ribbon ...................................................................................................................................... 34

Windows Driver and Label Software ................................................................................................................................ 35

Chapter 4: Maintenance ................................................................................................................................................ 36

Cleaning the Printhead ...................................................................................................................................................... 36

Cleaning the Platen Roller ....................................................................................................................................................... 37

Cleaning the Printer Interior .................................................................................................................................................... 37

Chapter 5: Troubleshooting .......................................................................................................................................... 38

LCD Error Messages ................................................................................................................................................................ 38

LED Error Indications .............................................................................................................................................................. 39

Miscellaneous ................................................................................................................................................................... 40

Vertical Blank Lines Appear ..................................................................................................................................... 40

Printer Timeout Error Message........................................................................................................................................ 40

Data Sent but Not Printing ........................................................................................................................................ 40

Poor Printing Quality ................................................................................................................................................ 40

Recovery ........................................................................................................................................................................... 41

Appendix A: Interface Specifications ........................................................................................................................... 42

Appendix B: ASCII Table ........................................................................................................................................................... 43

Page 5

TW Series User’s Manual

Preface, Important Notice

1

Preface

Your POSTEK TW Series high performance industrial barcode thermal printer features innovative state-of-the-art technology

and superior quality workmanship. Boasting an all metal frame and unique core construction, the TW Series printer achieves a

sturdy and durable stationary platform for smooth printing. A powerful control system can easily handle the most complicated

printing requirements, and advanced thermal transfer/direct thermal technology offers optimum printout clarity.

This manual explains how to set up and begin using your TW Series printer. It also provides detailed information on

configuring your printer, basic operations, care and troubleshooting.

Please read this manual carefully before using the POSTEK TW Series printer.

Important Notice, Read Me First

The thermal printhead can be easily damaged due to its precision construction. A printhead damaged by misuse is not covered

under the terms of the warranty. To ensure longevity of the printhead, please note the following:

1. DO NOT scrape or use tools that might damage the printhead surface.

2. To protect from corroding the printhead, DO NOT touch the printhead with bare hands.

3. DO NOT use thermal paper or thermal transfer ribbons which contain Sodium (Na), Potassium (K), Chlorine (Cl).

4. Keep printhead away from any form of liquid or dampness.

5. Only use a cotton swab dipped in anhydrous isopropyl alcohol to clean the printhead.

6. Always use high-quality consumables:

When the printhead module is closed, pressure is placed directly onto the printhead; dirt such as paper scraps, sand,

dust and glue can scrape or damage the printhead.

The thermal printhead is also easily damaged by static electricity, which may be generated by poor quality ribbons.

7. Always purchase high quality consumables.

Note: The TW Series printer functions under Direct Thermal or Thermal Transfer print methods. Thermal Transfer is set

as the factory default (requires ribbon for printing). However, if you need to print on Direct Thermal materials (ribbon is

not required), please contact your printer supplier or service provider to reduce the printhead pressure. This can protect

your printhead from early performance deterioration due to direct contact with the thermal media. Any physical printhead

damage caused by direct thermal printing is not covered under warranty.

Page 6

2

TW Series User’s Manual

Chapter 1: Introduction

Chapter 1: Introduction

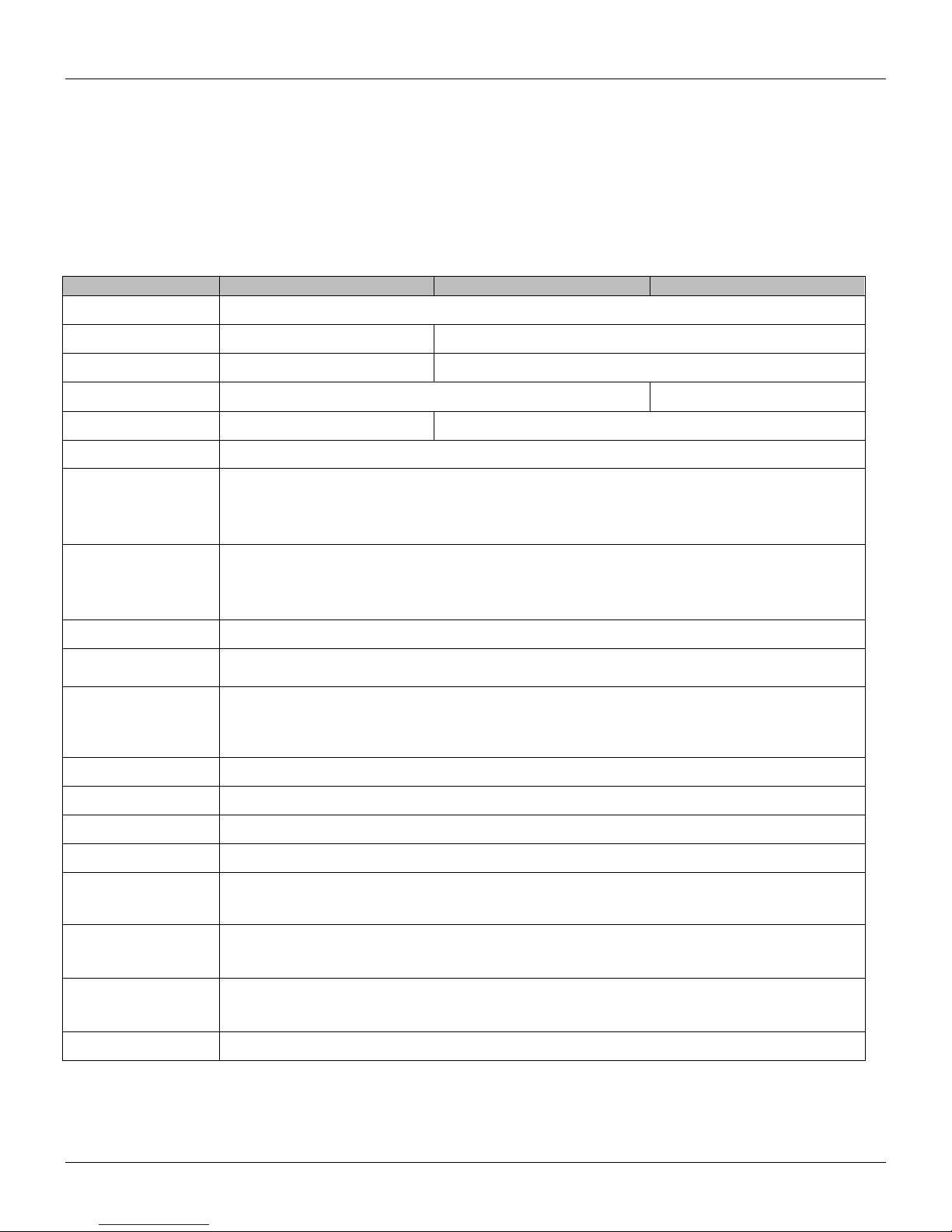

Printer Specifications

Model

TW6 (203dpi)

TW6 (300dpi)

TW8

Printing method

Thermal Transfer

Printing resolution

203 dpi (8 dots/mm)

300 dpi (11.8 dots/mm)

Max printing speed

6 ips (152.4 mm/s)

4 ips (101.8 mm/s)

Max printing width

6.6″ (168 mm)

8.64″ (219.5 mm)

Max printing length

157″ (4000 mm)

79″ (2000 mm)

CPU/Memory

8 MB FLASH ROM, 32 MB SDRAM

Media

Width: 10.23″ (260 mm) max, 3.54" (90 mm) min.

Total thickness (including liner, if any): 0.0024″ (0.06 mm) ~ 0.019″ (0.48 mm).

Supply roll: OD 8.27″ (210 mm) max. ID 3″(76.2 mm) min.

Ribbon

Max width: 8.66″ (220 mm), Max length: 1968' (600 m)

Ink side: Out

Ribbon roll: OD 3.54″ (90 mm) max., ID 1″ (25.4 mm) min.

Media sensor

UP & Down Reflective (Adjustable) / Transmissive (Adjustable)

Fonts

Five built-in dot matrix ASCII fonts, user-downloadable TrueType Fonts

Barcode types

1D Barcode: Code 39, Code 93, Code 128/subset A,B,C, Codabar, Interleave 2 of 5, UPC A/E 2

and 5 add-on, EAN-13/8/128, UCC-128, etc;

2D Barcode: MaxiCode, PDF417, Data Matrix, QR, etc.

Interfaces

RS-232 Serial, USB Device 2.0, USB Host, 10/100 Mb Ethernet.

LCD display

Graphic Dot Matrix

Power rating

100-240 V, 50/60 Hz, 3.5 A

Weight

9 kgs

Dimensions

W 14.8″ (375 mm) x D 17.1″ (435 mm) x H 9.8″ (250 mm) with unfolded Media Stand.

W 14.8″ (375 mm) x D 14.2″ (360 mm) x H 9.8″ (250 mm) with folded Media Stand.

Operation environment

Temperature: 32 F ~ +104 F (0 C ~ 40 C)

Relative humidity: 5% - 85% non condensing

Storage environment

Temperature: -40 F ~ +140 F (-40 C ~ 60 C)

Relative humidity: 5% - 85% non condensing

Optional items

Cutter, Centronics Parallel, WiFi, Bluetooth 4.0

Page 7

3

TW Series User’s Manual

Chapter 1: Introduction

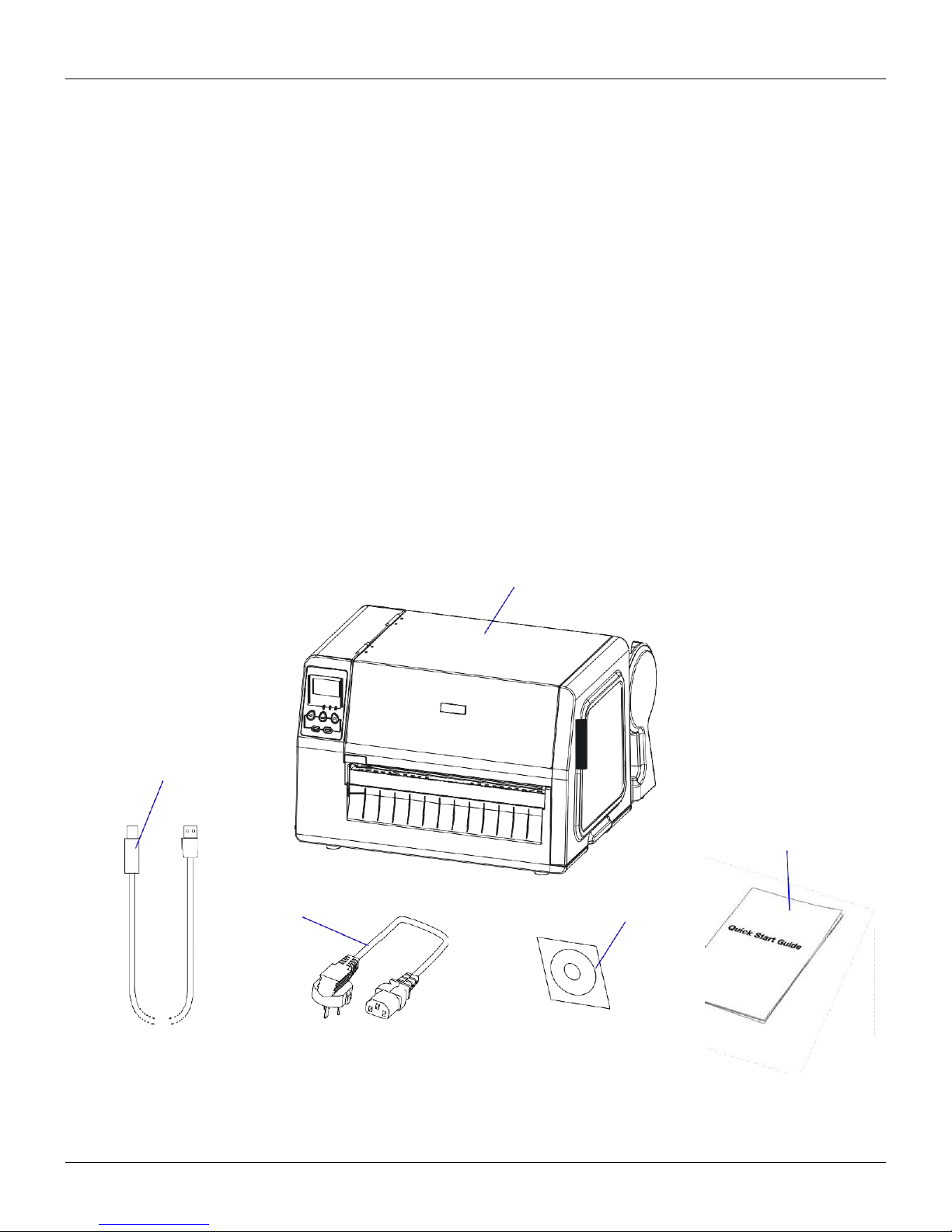

Contents of Box

Inspect the shipping carton(s) for possible shipping damage, if damage is discovered, notify the shipping company to report

the nature and extent of the damage.

Please check the items according to the Packing List. If there are any items missing, notify your authorized reseller.

Packing List

TW Series Printer

1 pc

Power Cord

1 pc

USB interface cable

1 pc

Quick Start Guide

1 pc

*CD-ROM

1 pc

*Note: CD-ROM pack includes TW printer driver, label design software, TW Series User’s Manual and the

Programming Manual.

USB Cable

TW Series Printer

Quick Start Guide

Power Cord

CD-ROM

Page 8

4

TW Series User’s Manual

Chapter 2: Setup and Use

11

1

Chapter 2: Setup and Use

Setting up the Printer

Before setting up the printer consider the following:

1. Make sure there is adequate space around the printer for loading consumables and proper ventilation.

2. Make sure the printer is close to the host so the interface cable is easily accessible at either end.

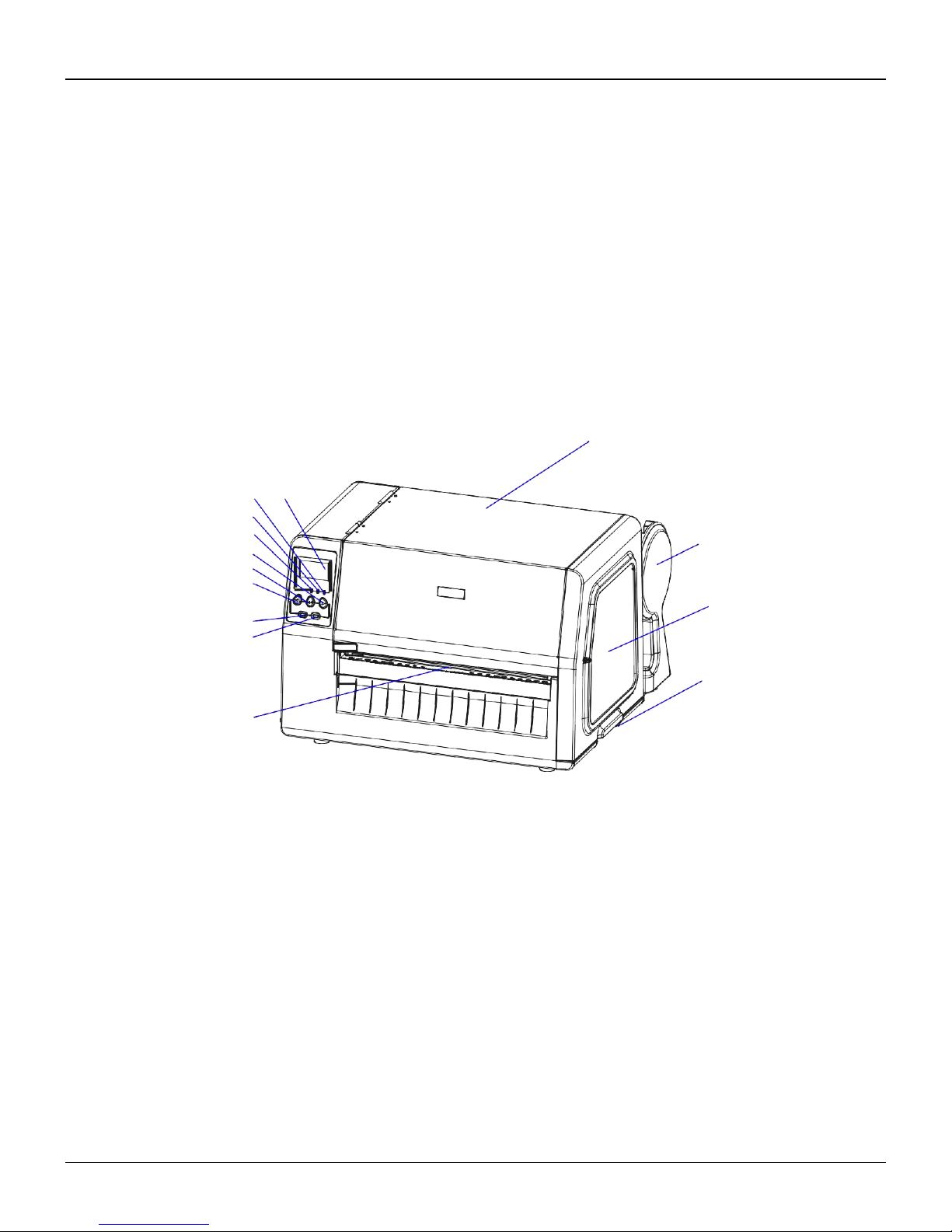

Main Parts and Structures

2

3

4

5

12

6

7

13

8

9

14

10

Figure 2-1

1. LCD

2. READY Indicator

3. MEDIA Indicator

4. RIBBON Indicator

5. CANCEL Button

6. FEED Button

7. PAUSE Button

8. Media Calibration Button

9. MENU Button

10. Media Outlet

11. Right Cover

12. Media Stand

13. viewing window

14. Cover Handle

Page 9

5

TW Series User’s Manual

Chapter 2: Setup and Use

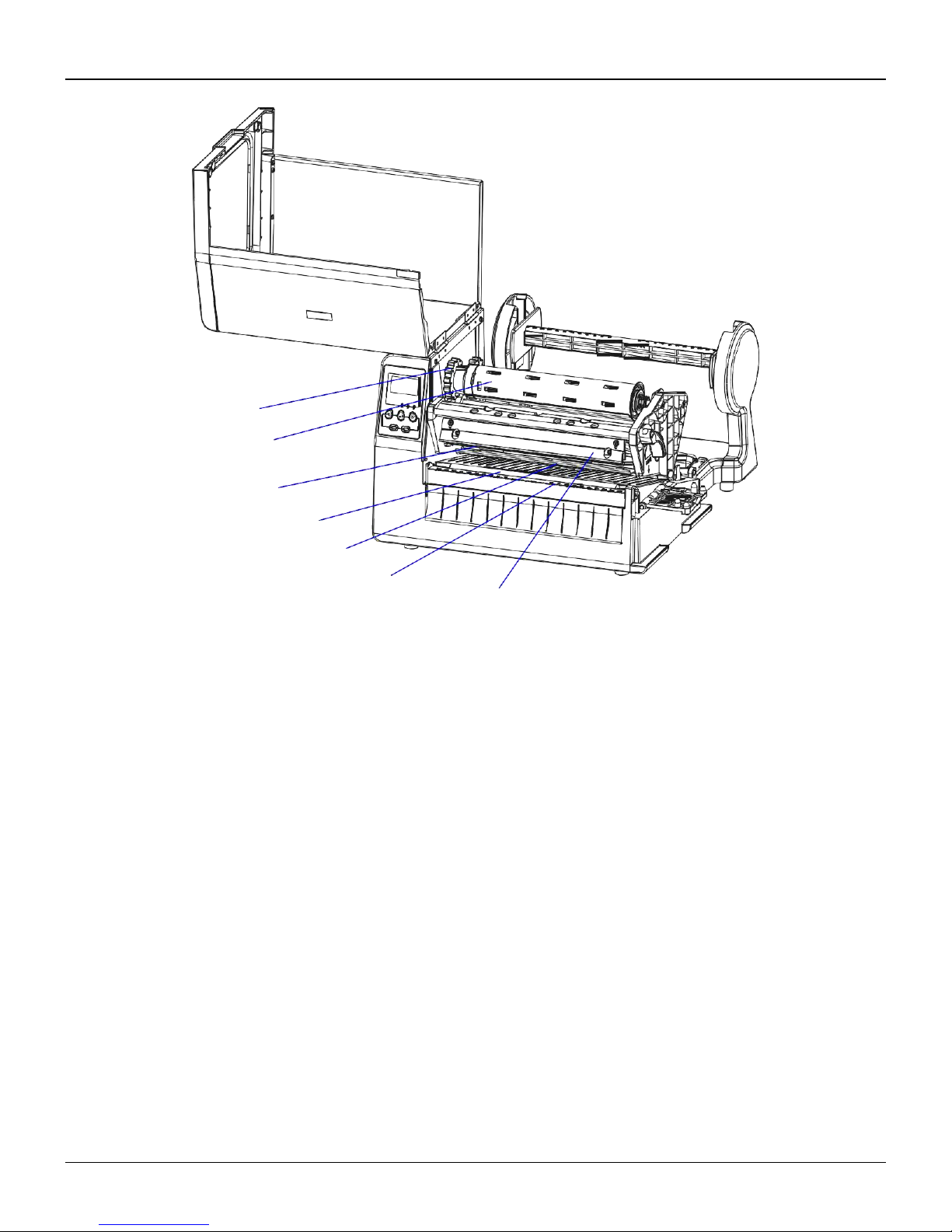

1

2

3

4

5

6

7

Figure 2-2

1. Ribbon Take-up Adjusting

Knob

2. Ribbon Take-up Spindle

3. Printhead

4.

Platen Roller

5.

Media Sensor

6.

Tear Bar

7.

Printhead Bracket

Page 10

6

TW Series User’s Manual

Chapter 2: Setup and Use

8

1

2 3

4

5 6

7

Figure 2-3

1. Printhead Module Plate

2. Handle

3. Printhead Module

4. Media Guide

5. Ribbon Guide Rod

6. Media Sensor

7. Media Guide Rod

8. Media Supply

9. Media Spindle

10. Media Roll Guide

11. Ribbon Sensor

12. Ribbon Supply

12

11

10

9

Page 11

7

TW Series User’s Manual

Chapter 2: Setup and Use

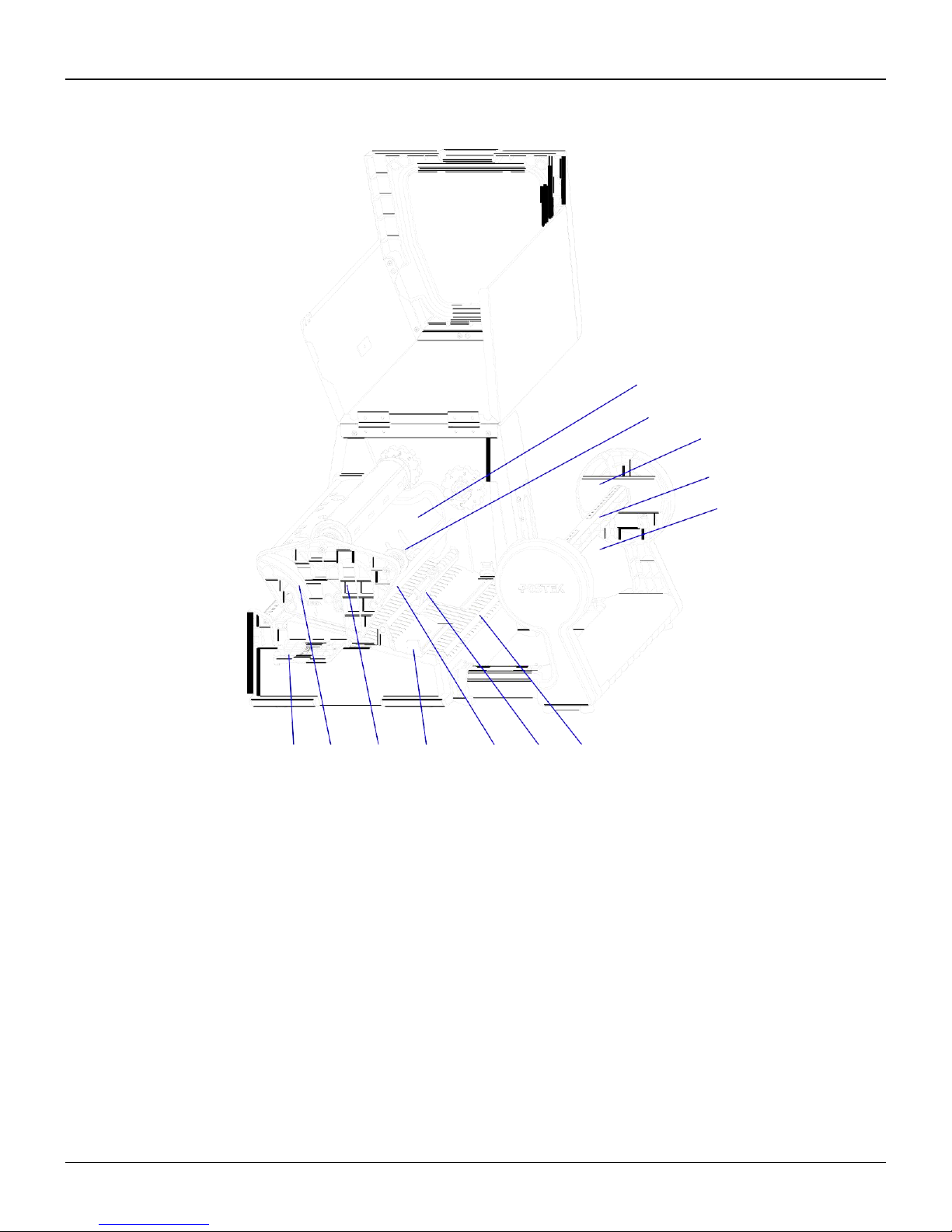

1

2

3

4

5

6

7

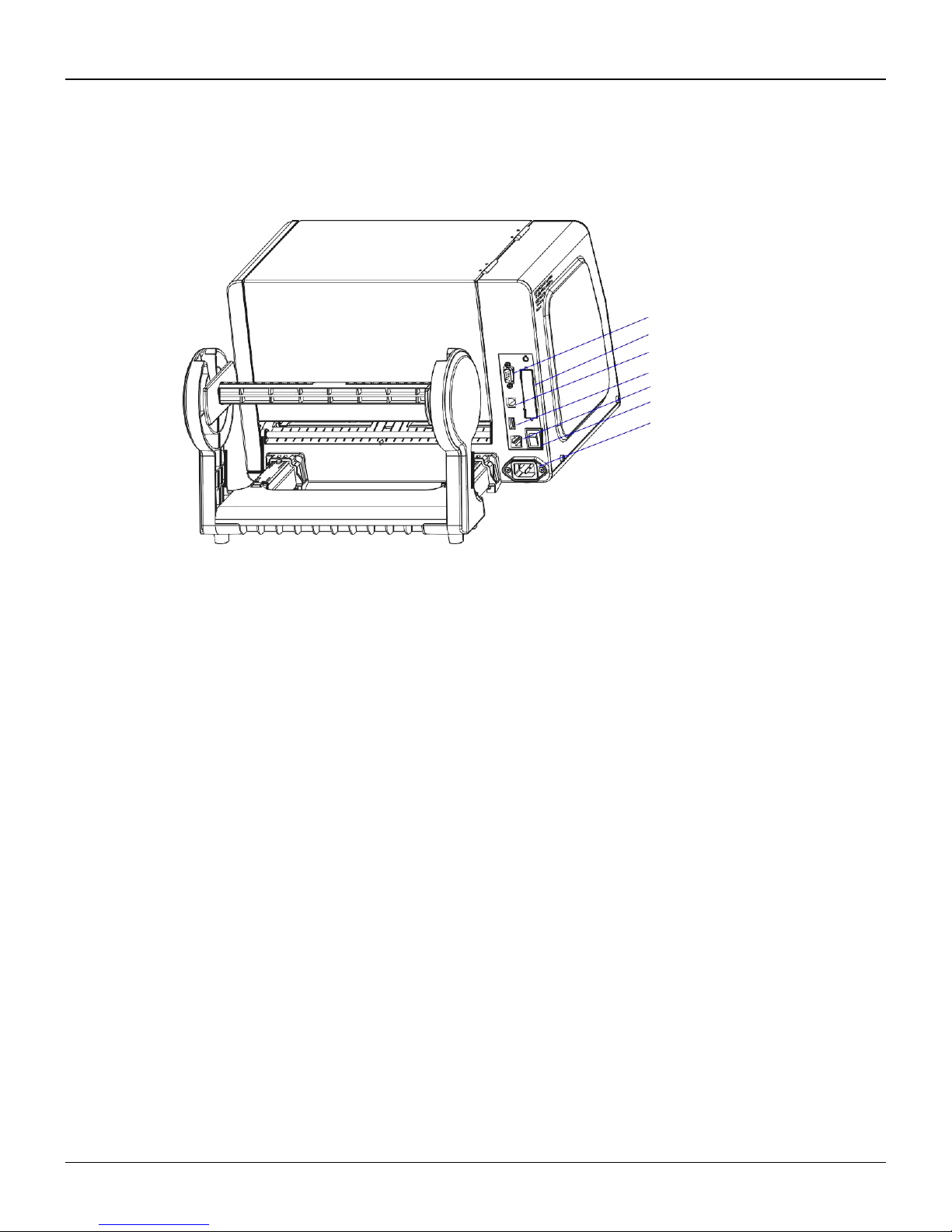

Figure 2-4

1. RS-232 Serial Port

2. Centronics Port

7. USB Device 2.0

4. USB Host

5. Ethernet Port

6. Power Switch

7. AC In Port

Page 12

8

TW Series User’s Manual

Chapter 2: Setup and Use

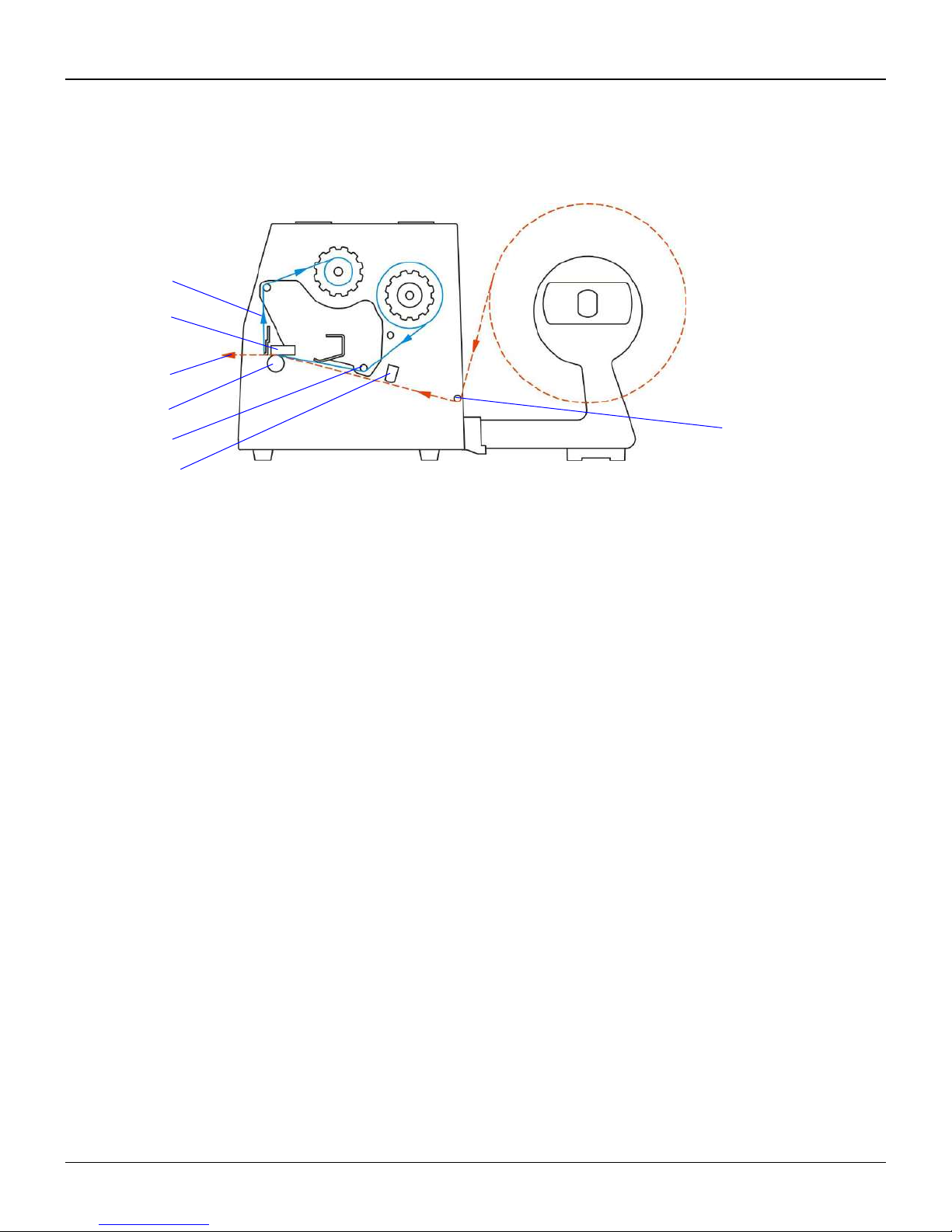

Loading Path

1

2

3

4

7

5

6

Figure 2-5

1. Ribbon Path

2.

Printhead

3.

Media Path

4.

Platen Roller

5. Ribbon Guide Rod

6. Transmissive Media Sensor

7.

Media Guide Rod

Connecting the Printer

Warnings:

(1) Do not use the printer near liquids or corrosive chemicals.

(2) Using the wrong power cord may cause damage to your printer. POSTEK assumes no liability for any damage in such

cases. The rating for the printer is 100-240 V, 50/60 Hz.

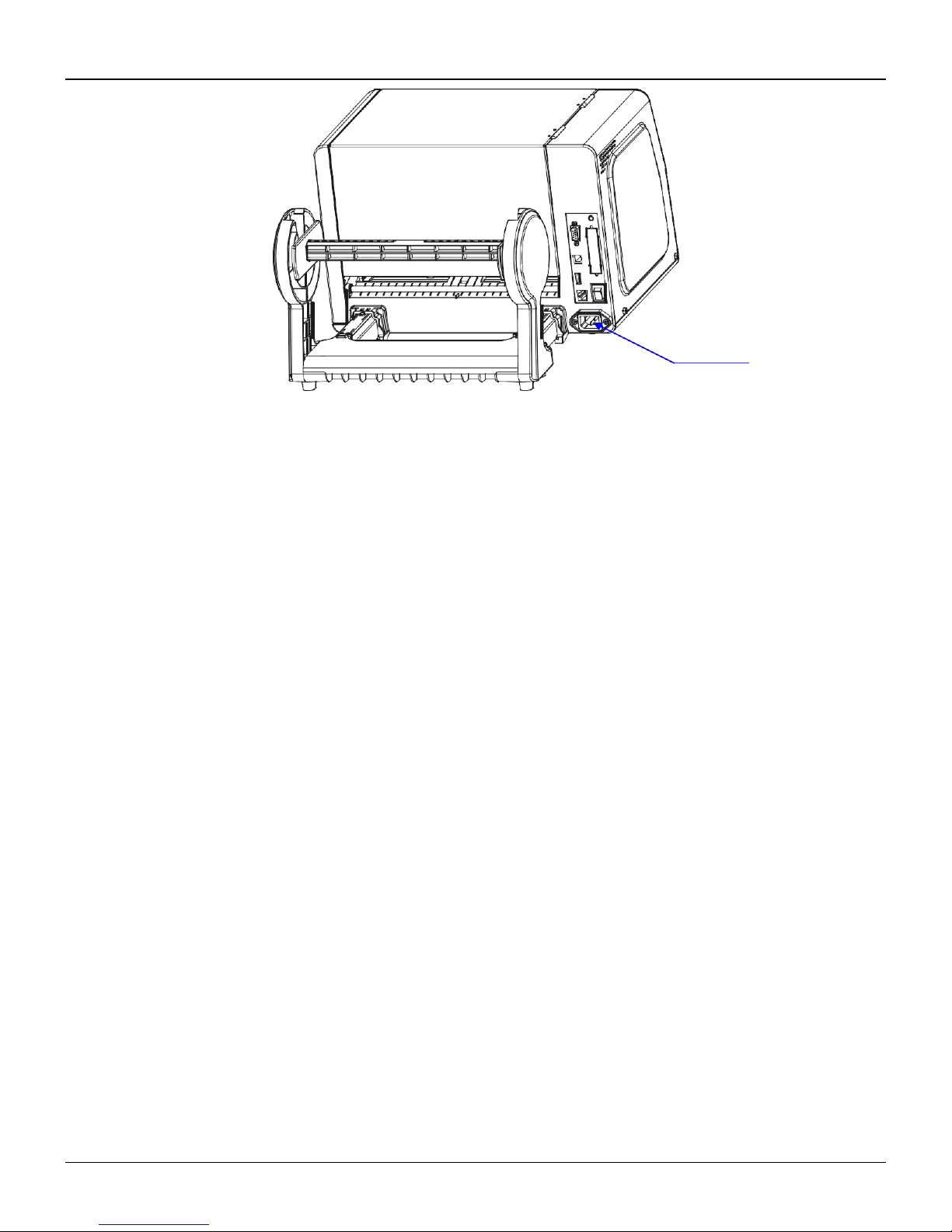

Power Connection

1. Make sure the printer is switched OFF.

2. Connect the power cord to the AC In Port on the back of the printer.

3. Plug the power cord into a live wall outlet.

Page 13

9

TW Series User’s Manual

Chapter 2: Setup and Use

Figure 2-6

Interface Connection

The TW Series printer supports RS-232 Serial, USB, Centronics Parallel, Ethernet and USB Host interface connections.

To connect:

1. Make sure the printer is powered OFF.

2. The printer will identify the communication port automatically.

3. The default values of printer port can be obtained from the self-test report. (See Chapter 2: Operation Basics/

Advanced Functions/ Self Test)

4. Cable configurations for Serial (RS-232C) interface is found in Appendix A of this guide.

5. Please take the following measures to reduce cable noise.

- Restrict the length of the interface cable to less than 6' (1.83 m) if possible.

- Keep the interface cable separate from power cords.

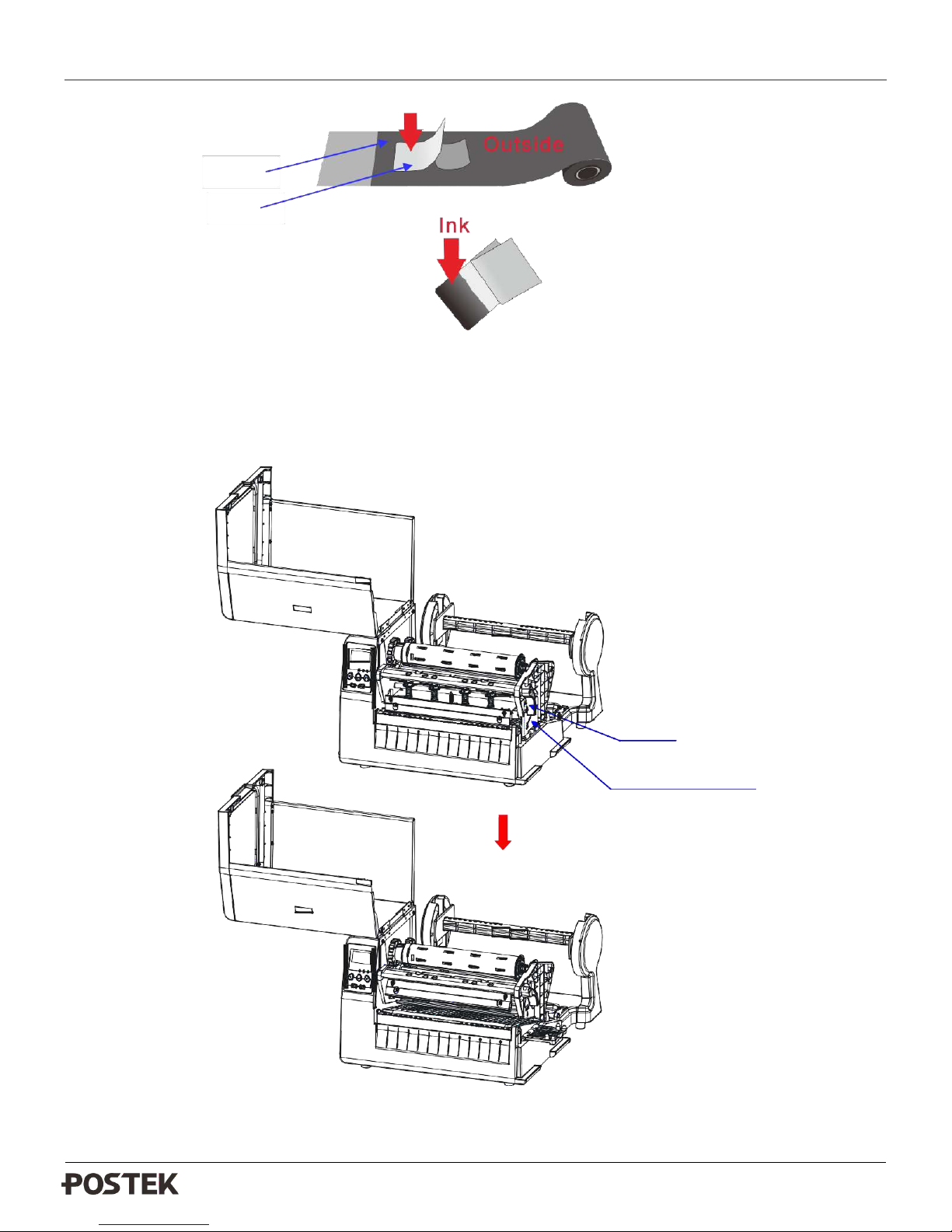

Loading the Ribbon

Note: Load ribbon only when using the thermal transfer printing method, the TW Series printer supports ribbon with ink on

the outside only. Remove any ribbon that may be loaded when using the direct thermal printing method.

To install the ribbon:

1. Method to check if the ribbon is outside ink: Stick a label to the outside of the ribbon and see if the ink is on. See Figure

2-7.

AC In Port

Page 14

10

TW Series User’s Manual

Chapter 2: Setup and Use

Ribbon

Label

Lever

Printhead Module Plate

Figure 2-7

2. Lift to open the right cover of the printer, turn the Lever counter clockwise, and open the Printhead Module Plate (figure

2-8).

Figure 2-8

Page 15

11

TW Series User’s Manual

Chapter 2: Setup and Use

Printhead Module

3. Place the ribbon roll into the ribbon supply area by mounting the roll between the ribbon tension gear and the release knob,

and allow the leading edge of the ribbon to fall underneath the Printhead module and towards the front of the printer;

please ensure the ink side of the ribbon is facing down (see Figure 2-9).

Ribbon Roll

Figure 2-9

Page 16

12

TW Series User’s Manual

Chapter 2: Setup and Use

Ribbon Take-up Spindle

Notch

Arrow

4. Take the ribbon take-up spindle out from the printer, and follow the “TIGHTEN” sign on the right side to twist the rotary

knob counterclockwise, until the arrow is aligned with the notch on the outer roll, then the knob should be tightened and

cannot be twisted anymore (figure 2-10).

Figure 2-10

Page 17

13

TW Series User’s Manual

Chapter 2: Setup and Use

Ribbon Tension

Gear (take-up)

5. Attach the leading edge of the ribbon to the ribbon take-up spindle and wrap a few loops, and mount the spindle back by

inserting it between the release knob and the Ribbon tension gear, make sure the two lumps on the gear panel is aligned

with the two grooves on the rotary knob of the ribbon spindle (figure 2-11), and the ribbon’s ink side is facing outwards.

Adjust the ribbon take-up tension (see “Adjusting Ribbon Tension” on P34) to ensure ribbon is tight and smooth.

Figure 2-11

6. Close the Printhead Module Plate and turn the handle to lock the Printhead Module.

Page 18

14

TW Series User’s Manual

Chapter 2: Setup and Use

Unloading the Ribbon

Note: Please remove the used ribbon roll from the printer each time when loading new ribbon or switching to the direct

thermal printing method.

To uninstall the ribbon:

1. Lift to open the right cover of the printer, turn the Lever counter clockwise, and open the Printhead Module Plate.

2. Take the ribbon supply and ribbon take-up both out from the printer by pushing the rolls to the spring knobs on the right

side and releasing from the adjusting knobs.

3. If you need to remove the used ribbon on the ribbon take-up spindle, please hold the take-up spindle and twist the rotary

knob following the sign of “RELEASE” until the arrow indicator is away from the notch; then the ribbon should be loose

enough to be removed from the spindle (figure 2-12).

Figure 2-12

Notch

Arrow

Page 19

15

TW Series User’s Manual

Chapter 2: Setup and Use

Loading the Media

Note: The term “media” in this manual refers to all the different kinds of paper, label, or tag stock material that can be printed

on by the printer. TW Series printer can print on continuous paper, adhesive backed labels, or non-adhesive tags packaged in

roll.

TW Series printer can be operated in three different modes: Standard mode, Peel-off mode, Manually Tear-off mode and

Cutting mode.

- In Standard mode, each printed label remains on the backing liner.

- In Peel-off mode and Manually Tear-off mode, each printed label is peeled away or tore off from the backing liner

manually.

- In Cutting mode, the printer automatically cuts the label after it is printed.

Standard Mode, Peel-off mode and Manually Tear-off mode

To load media into the TW Series printer while using Standard Mode, Peel-off mode and Tear-off mode:

1. Press the two buttons at the connecting part between the main frame and the media stand at the same time, and then pull

the media stand out, as shown on figure 2-13.

Figure 2-13

Page 20

16

TW Series User’s Manual

Chapter 2: Setup and Use

2. Take out the Media Spindle and remove the two Media Roll Guides.

3. Load a Media Roll onto the Media Spindle with label facing up, using the scale on the spindle to position the roll in the

middle of the spindle.

4. Insert the two Media Roll Guides on each side of the spindle, and push them close to the Media Roll (see figure 2-12).

Media Spindle

Media Roll

Media Roll Guide

Figure 2-12

Page 21

17

TW Series User’s Manual

Chapter 2: Setup and Use

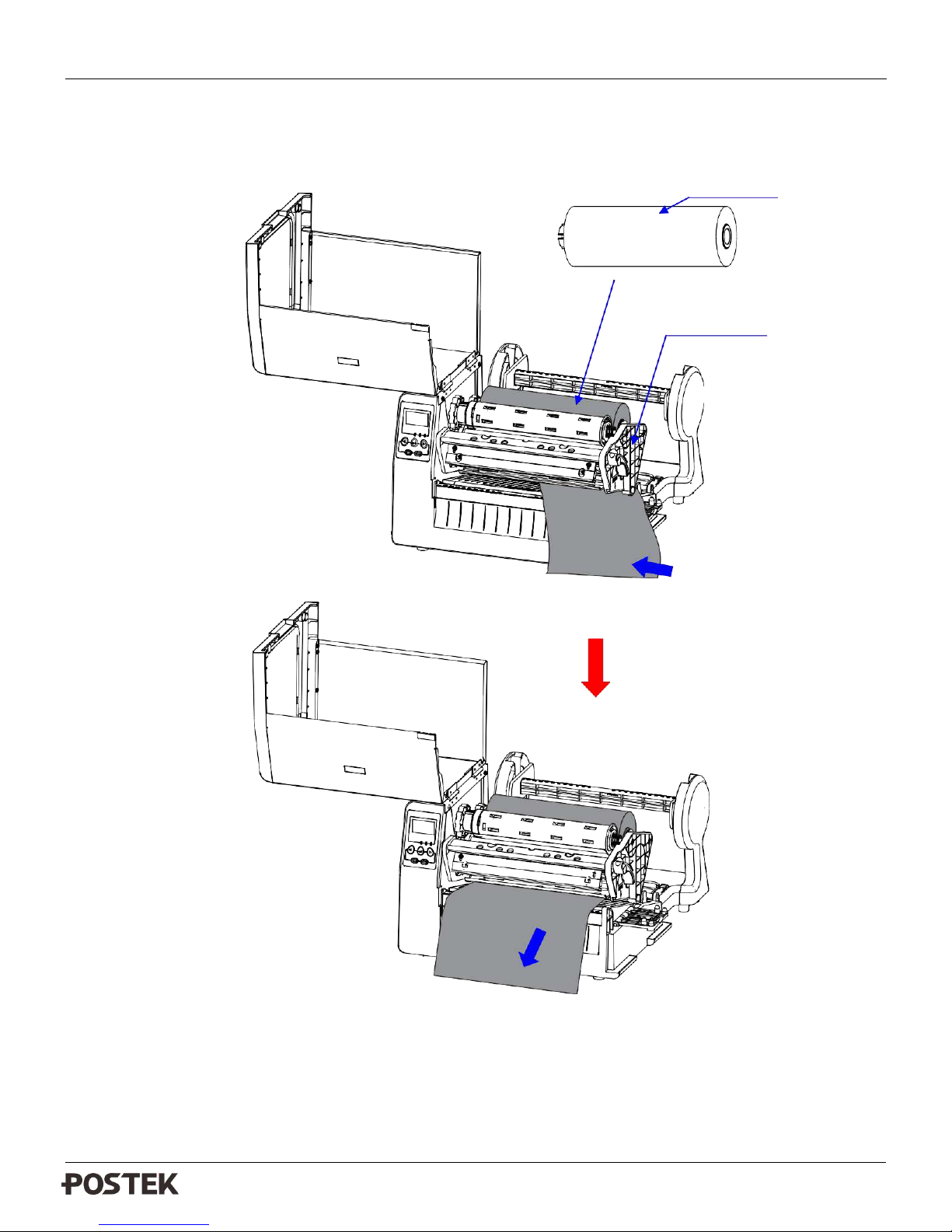

5. Put the unit back into the Media Stand, and lift to open the printer’s right cover, see figure 2-13.

Figure 2-13

Page 22

18

TW Series User’s Manual

Chapter 2: Setup and Use

Transmissive Media Sensor

Media Guide

Media Guide Rod

6. Route the label under and pass the Media Guide Rod, the Transmissive Media Sensorand, and pass over the Platen

Roller to the front of the printer.

7. Slide the Media Guides to the edge of the media properly to ensure the flat and smooth media feeding; please note that

do not squeeze the label paper (see figure 2-14).

Figure 2-14

Page 23

19

TW Series User’s Manual

Chapter 2: Setup and Use

Lever

Printhead Module Plate

8. Pull the media pass and under the Printhead Module and on the tear bar, and use the scale on the tear bar to position the

media in the middle. Then close the printhead module plate and turn the Lever clockwise to lock the Printhead Module.

See Figure 2-15.

Figure 2-15

Page 24

20

TW Series User’s Manual

Chapter 2: Setup and Use

FEED Button

9. Close the right cover and turn on the printer, or press the “FEED” button if the printer is already on (see Figure 2-16).

Figure 2-16

Cutting Mode

Using the TW Series printer in Cutting Mode requires an optional rotary cutter. Please consult an authorized POSTEK

Reseller for additional information.

1. Please follow step 1 ~ 7 in the section above to load the Media Roll correctly.

2. Lead the media pass over the Platen Roller and through the cutter (see figure 2-17); please note to use the scale on the

tear bar to position the media in the middle. If the media cannot pass through the cutter, please see the operation of step

5 (Reset the cutter) of “Cutting Mode” in chapter 3 to solve the problem.

Page 25

21

TW Series User’s Manual

Chapter 2: Setup and Use

Figure 2-17

Page 26

22

TW Series User’s Manual

Chapter 2: Setup and Use

Changing Media and Ribbon

Changing Media

If your printer runs out of media while printing, the LCD will display message “Label Runs Out! Please load new label”, which

means you need to load new media to replace the used one. If you need to cancel the current task and start a new task after a

new media is reloaded, simply turn off the printer and turn on again, then follow step 1 ~ 4 listed below and send new task to

your printer. If your need to complete the current task, please keep your printer switched on and follow all the steps listed

below, your TW Series printer can continue to print the remaining part of the task after reloading.

1. Cut the printed labels off and tidy it up as required.

2. Open the support panel of the printhead module on the right hand side, and turn the lever counter clockwise to

release the printhead module.

3. Take out the used media roll.

4. To load a new media according to the process of Loading the Media.

5. Press FEED button to print the remaining part of the current print task.

Note: If you load a new media with the different size compares to the previous one, please press MEDIA CALIBRATION

button to calibrate the media sensor first, and then press FEED to continue printing.

Changing Ribbon

If your printer runs out of ribbon while printing, the LCD will display message “Ribbon Runs Out! Please load new ribbon”,

which means you need to load new ribbon roll to replace the used one. You can only reload the ribbon roll, or you can reload

the ribbon and media together as required.

If you need to cancel the current task and start a new task after a new ribbon is reloaded, simply turn off the printer and turn on

again, then follow step 1 ~ 3 listed below and send new task to your printer. If your need to complete the current task, please

keep your printer switched on and follow all the steps listed below, your TW Series printer can continue to print the remaining

part of the task after reloading.

1. Open the support panel of the printhead module on the right hand side, and turn the lever counter clockwise to

release the printhead module.

2. Take out the used ribbon roll.

3. To load a new ribbon according to the process of Loading the Ribbon.

4. Press FEED button to print the remaining part of the current print task.

Page 27

23

TW Series User’s Manual

Chapter 2: Setup and Use

Reflective Media Sensor

Adjusting the Position of Media Sensor

There are two sets of media sensors installed on TW series printer, which is to enable the media calibration for different types

of media roll. According to the differences of structure and mode, the sensor located under the printhead module is called

reflective media sensor, and the other is called transmissive media sensor. The following section is to introduce how to adjust

the position of the two sensors.

Reflective Media Sensor

1. Lift the right cover, and twist the handle counterclockwise to release the printhead module.

2. Lift the Printhead Module to expose the reflective media sensor (figure 2-18).

3. Slide the media sensor cap to adjust the position of the media sensor pointer (white arrow), making sure it is pointing to

the label (see figure 2-19 and 2-20 for reference).

Figure 2-18

Page 28

24

TW Series User’s Manual

Chapter 2: Setup and Use

gap

gap

Figure 2-19

gap

Figure 2-20

Page 29

25

TW Series User’s Manual

Chapter 2: Setup and Use

Transmissive Media Sensor

TransmissIve Media Sensor

Figure 2-21

1. The Transmissive Media Sensor is located on a metal bar that under the ribbon supply area (figure 2-21), please note to

load the media correctly according the procedures of “Loading the Media” on P15.

2. The default location of the Transmissive Media Sensor is centred, which is compatible with most of the cases of detecting

media. If the sensor’s position is required to adjust for special cases, then it can be done by loosening the screws on top of

the sensor for sliding the plastic part along the bar.

Page 30

26

TW Series User’s Manual

Chapter 3: Operations and Settings

Chapter 3: Operations and Settings

Basic Operations

Power Switch

The power switch is on the back panel of the printer. The symbols on the switch are defined as follows:

━

— ON

〇 — OFF

The Front Panel

The Front Panel of the TW Series printer consists of:

- Three Indicator Lamps: READY, MEDIA and RIBBON

- Five multi function buttons: PAUSE, FEED, CANCEL, MEDIA CALIBRATION and MENU

Figure 3-1

Page 31

27

TW Series User’s Manual

Chapter 3: Operations and Settings

Indicator Lamps

The three lamps indicate the status of the printer (please refer to Chapter 4: Troubleshooting, for error indicators).

- Solid: Indicates the printer is in the normal state;

- Blinking: Indicates the printer is in the ‘PAUSE’ state.

- Solid: Indicates the printer is in the normal state;

- Blinking simultaneously with READY: Running out of media;

- Solid: Indicates thermal transfer printing;

- Off: Direct thermal printing (no ribbon installed);

- Blinking simultaneously with READY: Running out of ribbon.

Panel Buttons

The five buttons have different functions based on the mode of the operation is performed.

Mode

Function

FEED

Feed one label

PAUSE

- Press once to pause current print job

- Press a second time to resume printing

CANCEL

- Cancel current batch of labels

- Forces the printer to continue working after an error has been corrected

MEDIA CALIBRATION

Performs media sensor calibration

MENU

Enter/exit setup menu

LCD Display

A graphic dot matrix LCD display is affixed to the front panel. Data in the form of characters, letters and numbers are

shown on the LCD display. Please see “LCD Panel Operation” below.

LCD Panel Operation

The LCD can display the printer’s status, total print quantities, error messages, and is also valuable when configuring the

printer. Following are common examples of LCD displays.

RIBBON

MEDIA

READY

Page 32

28

TW Series User’s Manual

Chapter 3: Operations and Settings

Ready Status [Resolution]

Total printed labels (pages) count, will

be reset to 0 if cycle the printer power.

Firmware Version

Current Date. Current Time

The name and version number of the

installed firmware on the printer.

The P/N number of the firmware.

Settings Menu

XXXX is the name of the currently

selected option, icons in the middle

represents different settings options.

Selected/Total (Option Number)

Changing An Option’s Value

XXXX is the name of the

activated option.

Status Bar and Value.

Button functions:

BUTTON

FUNCTION

DESCRIPTION

PAUSE

Item/Parameter

Selection

Descending Item/Parameter selection

FEED

Enter/exit sub-menu

Confirm selection;

Enter/exit sub-menu.

CANCEL

Item/Parameter

Selection

Increasing Item/Parameter selection

MEDIA

CALIBRATION

Media sensor

Calibration

Performs media sensor calibration.

MENU

Enter or exit setup mode

Enter the setup main menu from the ready status or during

printing, the LCD will display menu for printing setup;

Exit from the setup main menu.

XXXX

01/40

XXXX

12

VERSION:

PPLETW8 1.73

FIRMWARE P/N:

00.10088.001

Ready [300DPI]

Total: 888

Version: 1.73

2016-01-01 08:08:08

Page 33

29

TW Series User’s Manual

Chapter 3: Operations and Settings

Advanced Functions

BUTTON

OPERATION

FUNCTION

CANCEL

Press CANCEL and hold it for 4

seconds, the three LED indicators

will blink simultaneously.

To enter the system mode. If no

operations are preformed within 4

seconds, the printer will return to normal

status automatically.

CANCEL + FEED

Press CANCEL and hold it for 4

seconds, and short press FEED.

To perform media calibration.

CANCEL + PAUSE

Press CANCEL and hold it for 4

seconds, and short press PAUSE.

To print out the configuration report.

CANCEL + CANCEL

Press CANCEL and hold it for 4

seconds, and short press it again.

To reset the printer to the factory default.

Items to be set and operating guide:

SUB MENU

DESCRIPTION

Exit

Exit from the menu, with or without saving the changes.

Darkness

Machine’s default setting is as the value set on LCD panel, meanwhile the

command setting will not be valid; but when the value is set as 0 on the LCD

panel, the default setting will be subjected to command setting.

Speed

Language

Options: English, Chinese

Default: English

Tear-off Offset

Media Offset under different modes, range from -99 to +99 mm:

Set positive values to move the media stop position towards out.

Set negative values to move the media stop position towards in.

Feeding Offset

Cutting Offset

Peeling Offset

Print Offset-H

Print Offset-V

Cut Frequency

After the specific copies of labels printing will the cutter cut once.

Default value: 01.

Error Feedback

Allow or forbid the printer to send back error information to the host.

Options: Enable, Disable

Print Mode

Direct Thermal, Thermal Transfer.

Default: Thermal Transfer.

Tear Mode

Options: Enable, Disable.

Default: Disable.

(Note: Cut mode and Peel mode cannot be turned on at the same time; please

enable one if you need to disable the other one.)

Cut Mode

Peel Mode

Page 34

30

TW Series User’s Manual

Chapter 3: Operations and Settings

Media Sensor Type

Options: Down Reflective, Up Reflective, Transmissive.

Default: Transmissive

Baud Rate

Options: 9600, 19200, 38400, 57600.

Default: 38400.

Data Bits

Options: 7 Bit, 8 Bit.

Default: 8 Bit.

Parity

Options: None, Odd, Even

Default: None.

IP Address

The range of XXX is 0-255, press PAUSE to decrease,

CANCEL to increase, FEED to move to next XXX. Upon completion,

pressing FEED will proceed to the “Save/Exit” screen.

(Note: restart the printer to activate the changed settings )

Gateway

Netmask

Port

Set Date

Set system date.

Set Time

Set system time.

Font List

Browse the stored fonts.

Delete Fonts

Delete stored fonts.

Command Type

Options: PPLE, PPLZ

Default: PPLE

DHCP

Options: Enable, Disable

Default: Disable

After DHCP is enabled, the printer will ask for a restart. As the printer being

powered on again, the LCD will prompt “DHCP CONFIGURING, WAIT

ABOUT 2 MINUTES…” Normally it takes 2 minutes to finish the network

settings. If failed, the printer will disable the DHCP and prompt “DHCP

ABORT, CHECK NET, PLS!”

Dump Mode

Options: Enable, Disable

Default: Disable

Detect Length

The Media feed length when perform Media Calibration.

Default 200, Unit mm.

Standalone Printing

Browse the pre-stored label forms, select one to print.

Delete Forms

Clear the forms downloaded to the printer.

Delete Graphics

Clear the graphics downloaded to the printer.

Load Default

Restore factory default settings.

Note: Please read the content in “Important Notice” section before setting your printer to direct thermal mode.

Page 35

31

TW Series User’s Manual

Chapter 3: Operations and Settings

Tear-off

a. Grab printed label

Figure 3-2

b. Tear down

1. Press MENU to enter setup menu: Common Settings → Tear Off, select Enable.

2. Follow the directions shown in Figure 3-2 to tear off the label.

3. If the tear-off position needs to be adjusted, press MENU to enter setup menu: Offset Settings → Tear-off Offset, input

suitable offset value.

Manual Peel-off

a. Press the printed label downwards b. Press the label to printer

c. Remove the label

Figure 3-3

Page 36

32

TW Series User’s Manual

Chapter 3: Operations and Settings

1. Press MENU to enter setup menu: Manual Peel Off, select Enable.

2. Follow the directions shown in Figure 3-3 to peel off the label.

3. Press PAUSE to print next label.

4. If the peeling position needs to be adjusted, press MENU to enter setup menu: Peeling Offset, input suitable offset

value.

Cutting Mode

Note: The Rotary Cutter Kit is an optional accessory.

1. Turn on the printer and enter the Setup Menu by pressing the MENU button on the Front Panel.

2. Enable the cutter under the LCD menu: Common Settings → Cutter, select Enable. Please note that the ‘Manual Peel

Off’ mode and the ‘Cutter’ mode cannot be set as ‘Enable’ simultaneously, so the ‘Manual Peel Off’ should be set as

‘Unable’ before installing the Cutter.

3. Reset the cutter: press and hold the Cancel button for 4 seconds, the three lamps will blink simultaneously. Release

and press the Cancel button again, the three indicators stop blinking and remain lit. The printer is now in its normal

state.

4. Turn the handle counter clockwise to release the Printhead Module, load the media and ribbon on the printer, lead the

label pass and through the cutter. Then close the printhead, the cutter is now ready to use. See Figure 3-4.

Note: Cutter reset is required before loading the media, or the media maybe jammed by blade thus is not able to pass

through.

Figure 3-4

Page 37

33

TW Series User’s Manual

Chapter 3: Operations and Settings

Adjusting Knob

Adjusting Bolt

Pressure Shaft

Adjusting the Pressure of Printhead

Figure 3-5

As shown in Figure 3-5, there are four spring assemblies on the printhead bracket for adjusting the printhead pressure on each

position.

The procedures of adjusting the pressure of printhead: press down the Adjusting Knob below the Adjusting Bolt, and

then twist the knob to align the numbered pressure level with the bolt to apply the different level of pressure; please note that

the bigger the number was, the more pressure the printhead will get from the Pressure Shaft.

Page 38

34

TW Series User’s Manual

Chapter 3: Operations and Settings

Ribbon Tension Gear

Adjusting Ring

Adjusting Knob

Indicating Arrow

Hold the Ribbon Gear

Pull and switch the adjusting ring

Pull the Adjusting Knob

Figure 3-6

Adjusting the Tension of Ribbon

The Ribbon Tension Adjusting modules are installed for both ribbon supply and ribbon take-up, see figure 3-6.

Procedures of adjusting the ribbon tension:

1. Screw the adjusting knob into the gear adjusting ring which located on the ribbon tension gear.

2. Pull the adjusting knob and rotate the adjusting ring to choose the gear level, which is to align the indicator

arrow with the numbers on the gear panel, the higher value means greater tension level; please note that you may

need to hold the gear while pulling the lever, so that the adjusting ring can be rotated smoothly.

3. Unscrew the adjusting knob and keep it in a safe place for future usage.

Page 39

35

TW Series User’s Manual

Chapter 3: Operations and Settings

Windows Driver and Label Software

The TW Series Industrial printer driver is packaged with the printer in the CD-ROM pack, and is compatible with the

following operating systems:

Windows 10

Windows 8

Windows 7

Windows Vista

Windows XP

Windows 98

Windows 2000

Windows 2003

Windows 95

Windows 2008

Windows NT

Windows XP

Page 40

36

TW Series User’s Manual

Chapter 4: Maintenance

Chapter 4: Maintenance

Warnings:

(1) Make sure the printer is powered off before performing maintenance operations.

(2) The Printhead may be hot due to recent printing. Wait until the Printhead cools before performing maintenance.

(3) Use only anhydrous isopropyl alcohol to clean the Printhead.

Cleaning the Printhead

The Printhead is the mechanism that enables the ink to impact the label. Due to the Printheads precision construction and

necessary location in the printer, it comes into contact with consumables and therefore is susceptible to dirt accumulation. If

dirt is not removed, the Printhead may be damaged. To ensure longevity of the Printhead, follow the recommended

maintenance guidelines below:

Note: A Printhead damaged by misuse is not covered under warranty.

Clean the Printhead after every ONE roll of ribbon used or every THREE rolls of label media used. To clean the Printhead:

1. Turn printer power off.

2. Open the top cover of the printer.

3. Turn the handle to open.

4. Remove the ribbon (if applicable) and media.

5. Use a cotton swab dipped in anhydrous isopropyl alcohol. Rub the swab along the Printhead until the swab no longer

accumulates ink.

6. Let the Printhead dry before using the TW Series printer again.

Page 41

37

TW Series User’s Manual

Chapter 4: Maintenance

Cleaning the Platen Roller

The Platen Roller, located at the exit point and underneath labels, supports the labels as they feed out of the printer. The

roller can accumulate debris from consumables, such as dirt, sand, dust or glue. To ensure longevity of the Platen Roller,

follow the recommended maintenance guidelines below:

Clean the Platen Roller after every THREE rolls of label media used. To clean the Platen Roller:

1. Turn off the printer.

2. Open the top cover.

3. Release and lift the Printhead Module

4. Remove the ribbon (if applicable) and media.

5. Use a cotton swab dipped in anhydrous isopropyl alcohol. Rub the swab along the Platen Roller while rotating the roller

until the swab no longer accumulates ink or debris.

Cleaning the Printer Interior

Over time, the printer’s interior may collect dust or debris from the consumables. It is advised to periodically clean the

printer’s interior in order to prevent any accumulated debris from damaging internal parts.

To clean the printer interior, use a cotton swabs dipped with anhydrous isopropyl alcohol to remove any debris.

Page 42

38

TW Series User’s Manual

Chapter 5: Troubleshooting

Chapter 5: Troubleshooting

Occasionally situations occur that require some troubleshooting. Possible issues and potential solutions are listed in this

section. While not every situation is addressed, you may find some of these tips useful.

LCD Error Messages

The LCD displays messages when there is an error. See the table below for LCD errors, the possible causes, and the

recommended solutions.

LCD Display

Possible Cause

Recommended Solution

Memory Error

Problems occurred with printer’s

flash or RAM memory during

printing or executing printing

data/command.

Please restart the printer, and then disable the “Dump

Mode” setting from the main menu. Or contact an

authorized POSTEK service provider for technical

support if problems exist.

Printhead Open

The printhead module is released or

unlocked.

Press down the printhead module to the close

position, and turn the handle to lock it.

Data Error

The labels’ data has been sent to

printer but cannot be identified due

to the invalid format or syntax.

Please follow the command syntax or data format in

the command manual to edit data, and then resend it

to the printer.

Ribbon Error

See LED Error Indications for more information.

Label Error

Cutter Error

The cutter is jammed with paper or

debris; or the cutter is not correctly

installed on the printer.

Turn off the printer and unplug power cord, remove

large pieces of debris as needed; and then inspect the

cutter module for correct installation. Turn on the

printer again and reset the cutter following the step 3

of Cutting Mode. Or contact an authorized POSTEK

service provider for technical support if problems

exist.

System Mode

Press and hold CANCLE for 4

seconds, then the printer will enter

the system mode, and display this

message on LCD.

To perform the advanced functions or the printer will

return to normal state automatically if no operations

are performed within 4 seconds.

Upgrade Interrupted

The firmware upgrade is

interrupted.

Please contact an authorized POSTEK service

provider for technical support.

Page 43

39

TW Series User’s Manual

Chapter 5: Troubleshooting

LED Error Indications

Typically, one or two of the three indicator lamps will begin blinking when the printer is not functioning. The possible

situations addressed by the status of the three indicator lamps are listed below.

READY and MEDIA Lamps blink simultaneously:

Possible Cause

Recommended Solutions

Media sensor cannot detect labels

a) Check and confirm the media has been loaded correctly

b) Check the position of the media sensor and confirm it could detect the

media gap or black line

c) Calibrate the media sensor

d) If using continuous media without any positioner (e.g. gaps or black

lines), ensure correct settings are chosen in the label software

Media ran out

Load a roll of media

Media jammed

Clear the jam

The Media Roll Guides are not firmly

positioned against the Media or have not

been installed.

Install the Media Roll Guides correctly and press them firmly press the

media.

Media sensor is broken

Contact an authorized POSTEK service provider for technical support.

Note: If the printer is switched on during the overall process, the outstanding printing task can be continued by press ‘Feed’

button after the new media is loaded correctly or the issues are solved.

READY and RIBBON Lamps blink simultaneously:

Possible Cause

Recommend Solutions

Ribbon ran out

Load a new roll of ribbon

Ribbon jammed

Clear the jam

Ribbon Sensor error

Contact an authorized POSTEK service provider for technical support.

Note: If the printer is switched on during the overall process, the outstanding printing task can be continued by press ‘Feed’

button after the new ribbon is loaded correctly or the issues are solved.

Only READY Lamp blinks:

Possible Cause

Recommend Solutions

Serial I/O error

Check LCD menu for the baud rate settings

Memory overflow

a) Restart the printer

b) Reset the printer

Page 44

40

TW Series User’s Manual

Chapter 5: Troubleshooting

Miscellaneous

Vertical Blank Lines Appear

If the printer prints vertical blank lines as shown in the below picture, it may be due to a dirty or defective Printhead. See

the table below for possible causes and solutions.

Cause

Corrective Action

The Printhead is dirty.

Clean the Printhead. Follow the recommended maintenance guidelines

for cleaning the Printhead.

Vertical lines still appear after cleaning the

Printhead.

Contact an authorized POSTEK service provider for technical support.

Printer Timeout Error Message

Execute following corrective actions:

1. Check the interface cable for proper connection.

2. Ensure the TW Series printer is powered on.

If the trouble still exists, please contact an authorized POSTEK service provider for technical support.

Data Sent but Not Printing

1. Ensure the correct driver is chosen in the label software.

2. Reset the TW Series printer.

If the trouble still exists, please contact an authorized POSTEK service provider for technical support.

Poor Printing Quality

When experiencing poor print quality, check the following:

1. Adjust print darkness setting value.

2. Adjust print speed setting value.

3. Clean the Printhead and the platen roller.

4. Poor quality printing may be caused from using a low quality ribbon. Change to higher quality ribbon.

5. Poor quality printing may be caused from using low quality media. Change to higher quality media.

Note: The darkness and print speed settings may also be adjusted in printer’s menu. Adjusting functions in the hardware

always overrides functions set in software.

Page 45

41

TW Series User’s Manual

Chapter 5: Troubleshooting

Recovery

After the miscellaneous has been cleared, press the CANCEL button to clear the alarm or restart the printer to resume

the printing automatically.

Note: For errors not listed here, please contact an authorized POSTEK Service Provider for further assistance.

Page 46

42

TW Series User’s Manual

Appendix A: Interface Specifications

Appendix A: Interface Specifications

RS232 Serial

The RS232 connector on the printer is a DB9F:

Pin

Direction

Definition

1 / / 2 Out

TX 3 In

RX

4

In

CTS

5 - Ground

6

Out

RTS

7

In

DSR

8

Out

DTR

9 / /

Connection with host:

Host 25S

Printer 9P

Host 9S

Printer 9P

TX 2

………

3 RX

RX 2

………

2 TX

RX 3

………

2 TX

TX 3

………

3 RX

DSR 6

………

8 DTR

DTR 4

………

7 DSR

DTR 20

………

7 DSR

DSR 6

………

8 DTR

RTS 4

………

4 CTS

RTS 7

………

4 CTS

CTS 5

………

6 RTS

CTS 8

………

6 RTS

GND 7

………

5 GND

GND 5

………

5 GND

Alternately you can just connect the 3 wires as follows:

Host 25S

Printer 9P

Host 9S

Printer 9P

FP 2

………

3 RX

RX 2

………

2 FP

RX 3

………

2 FP

FP 3

………

3 RX

GND 7

………

5 GND

GND 5

………

5 GND

pin 4

pin 4

pin 5

pin 6

pin 6

pin 7

pin 20

pin 8

– Baud rate: 9600, 19200, 38400, 57600

– Data format: always 8 data bits, 1 start bit and 1 stop bit.

– Parity: always non parity.

– Flow control: RTS/CTS (Hardware flow control).

If you are using software or drivers under the Windows environment, the flow control must be set to “hardware.”

– Any communications port can transmit data from the host (RS232, Ethernet, or USB). Preliminary communications

settings are not required since the printer will automatically detect which port is active.

Note: Never send data from 2 ports at the same time. Data cannot be sent to more than one port simultaneously or data

corruption and print errors may occur.

Page 47

43

TW Series User’s Manual

Appendix B: ASCII Table

Appendix B: ASCII Table

0 1 2 3 4 5 6 7 0

NUL

0 @ P ` p

1

SOH

XON

! 1 A Q a

q

2

SFP

“ 2 B R b r 3 XOFF

# 3 C S c s 4

$ 4 D T d

t

5 NAK

% 5 E U e

u

6

ACK

& 6 F V f

v

7

BEL

‘ 7 G W g w 8

BS ( 8 H X h

x

9

) 9 I Y i

y

A

LF * : J Z j z B ESC

+ ; K [ k { C

FF , < L \ l

|

D

CR - = M ] m } E

SO

RS . > N ^ n ~

F

SI

US / ? O _ o DEL

Note: The € sign is included in the embedded table at DEC128 or HEX 80

Loading...

Loading...