Page 1

Page 2

i

FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment may generate, use and/or radiate radio frequency energy. If not

installed and used in full accordance with this instruction manual, interference to

radio communications may occur. This equipment complies with the limits for a

Class A Information Technology Equipment pursuant to Part 15 of the FCC Rules,

which are designed to provide reasonable protection against such interference when

operated in a commercial environment. Operation of this equipment in a residential

area may also cause interference. In such case the user will be required, at his own

expense, to correct the interference using whatever means necessary.

Trademarks

ARM is a registered trademark of Advanced RISC Machines Ltd.

Centronics is a registered trademark of Centronics Data Computer Corporation.

Microsoft, Windows are registered trademarks of Microsoft Corporation.

POSTEK is a registered trademark of Postek Electronics Co., Ltd.

PS/2 is a registered trademark of International Business Machines Corporation.

Copyright

© 2006-2009 by Postek Electronics Co., Ltd. All rights reserved. Under the

copyright laws, this manual cannot be reproduced in any form without the prior

written permission of Postek. No patent liability is assumed, with respect to the use

of the information contained herein.

C168 Label Printer User’s Manual

2nd edition Dec. 2009

Page 3

ii

Disclaimer

This manual has been validated and reviewed for accuracy. The instructions and

descriptions it contains are accurate for the Postek C168 Label Printer at the time of

this manual’s printing. However, succeeding printers and manuals are subject to

change without notice. Postek assumes no liability for damages incurred directly or

indirectly from errors, omissions or discrepancies between the printer and this

manual.

Although this manual describes and details many issues, which could possibly occur,

the manufacturer cannot warrant against unpredictable conditions during the printing

process. For problems such as the printer not working, lost or unclear print content,

etc., the manufacturer and resellers are responsible for correcting these issues

(according to Postek Printer Warranty Clauses). In no event shall the manufacturer or

the resellers involved be liable for any damages whatsoever (including without

limitation; damages for loss of business profits, business interruption, loss of

business information, or other pecuniary loss) arising from the use of, the results of

use or inability to use this product, even if the manufacturer has been advised of the

possibility of such damages.

Page 4

iii

Important Safety Instructions

◆ Only qualified and trained service technicians should attempt to repair the printer.

◆ Do not place the printer on or near a heat source.

◆ Be sure that the output of the power adapter is 24VDC and your power source

matches the rating listed on the power adapter. Be certain your power source is

grounded.

◆ To avoid getting an electric shock, do not use a worn or damaged power cord. If

the power cord becomes damaged or frayed, replace it immediately.

◆ Do not insert anything into the ventilation slots or openings on the printer.

◆ The printer and power adapter should never be operated in a location where either

one can get wet. Personal injury may result.

◆ The printhead becomes hot while printing. To protect from damaging the

printhead and risk of personal injury, avoid touching the printhead.

◆ To get increased printhead longevity and higher quality printouts, always use

approved labels, tags and thermal transfer ribbons. Approved supplies can be

ordered from your dealer.

◆ Static electricity that accumulates on the surface of the human body or other

surfaces can damage or destroy the printhead or electronic components in this

device. DO NOT touch the printhead or the electronic components with bare

hands.

◆ Place the printer on a flat, firm, solid surface.

Possible Corrective Action

◆ Never jam or block the air vents, or operate in a high temperature environment.

◆ Turn off the power when not in use for extended periods.

◆ Follow all recommendations and setup instructions included in this manual.

Page 5

iv

Contents

Preface ....................................................................................... 1

Important Notice, Read Me First! .......................................... 2

Chapter 1 Introduction ........................................................... 3

Specifications ................................................................................... 3

Specifications for Printer.......................................................... 3

Specifications for Power Adapter ............................................. 4

Unpacking and Inspection ................................................................ 4

Chapter 2 Getting Started ....................................................... 7

Setting up ......................................................................................... 7

Main Parts and Features ................................................................... 8

Connecting the Printer ................................................................... 11

Power Connection .................................................................. 11

Interface Connection .............................................................. 11

Loading the Ribbon ........................................................................ 13

Loading the Media ......................................................................... 20

Adjusting the Position of Media Sensor ......................................... 25

Operation Basics ............................................................................ 28

Power Switch ......................................................................... 28

The Front Panel ...................................................................... 29

Advanced Functions ............................................................... 30

DIP Switch at the Back Panel ................................................ 32

Windows Driver and PosLabel Software ....................................... 34

Chapter 3 Maintenance ......................................................... 35

Cleaning the Printhead ................................................................... 35

Cleaning the Platen Roller ............................................................. 36

Cleaning the Printer Interior........................................................... 36

Page 6

v

Chapter 4 Troubleshooting ................................................... 37

Error Indications ............................................................................ 37

Miscellaneous ................................................................................ 38

Others ............................................................................................. 39

Appendix A: Interface Specifications ................................... 40

Appendix B: ASCII Table ..................................................... 43

Page 7

1

Preface

Welcome to POSTEK’s C168 label printer.

This manual explains how to set up and begin using your C168 printer. It

also provides detailed information on configuring your printer, basic

operations, care and troubleshooting.

Please read this manual carefully before using the C168 printer.

Page 8

2

Important Notice, Read Me First!

Thermal printhead can be easily damaged due to its precision

construction. A printhead damaged by misuse is not covered under the

terms of the warranty. To ensure longevity of the printhead, please note

the following:

1. DO NOT scrape or use tools that might damage the printhead

surface.

2. To protect from corroding the printhead, DO NOT touch the

printhead with bare hands.

1. DO NOT use thermal paper or thermal transfer ribbon, which

contains Na, K or Cl.

2. Keep printhead from any form of liquid or dampness.

3. Use a Cotton Swab dipped in anhydrous isopropyl alcohol to

clean the printhead only.

4. Always use high-quality consumables:

(1) When the printhead module is closed, pressure is placed

directly onto the printhead; dirt such as paper scraps, sand,

dust and glue can scrape or damage the printhead.

(2) The TPH is also easily damaged by Static Electricity, which

may be generated by poor quality ribbons.

Always inspect consumables for quality before purchasing.

Page 9

3

Chapter 1 Introduction

Specifications

Specifications for Printer

Model C168/200s C168/300s

Printing method Direct thermal & Thermal transfer

Printing resolution 203 dpi (8 dots/mm) 300 dpi (11.8 dots/mm)

Max printing speed 4 ips /s (101.6 mm) 3 ips (76.2 mm/s)

Max printing width 4.09″(104 mm) 4.25″(108 mm)

Max printing length 157″ (4000 mm) 79″ (2000 mm)

Memory 2 MB FLASH ROM, 8 MB SDRAM

Media

Roll-feed, die-cut, continuous, fan-fold, tags, tickets in plain

paper or thermal paper

Width:110 mm max., 25 mm min.

Supply roll: OD 4″(102 mm) max., ID 1″(25.4 mm) min.

Thickness: 0.003″~0.007″ (0.08~0.18 mm), including liner

Ribbon

Wax, Wax/ Resi n, Resi n

Ribbon roll: OD 3″(76.2 mm) max., ID 1″(25.4 mm) core

Max width: 110 mm; Max length: 360 M

Fonts Five built-in ASCII fonts; Optional multiple language fonts

Bar Code Types

1D Barcode : Code 39, Code 93, Code 128/subset A,B,C,

Codabar, Interleave 2 of 5, UPC A/E 2 and 5 add-on,

EAN-13/8/128, UCC-128, etc.

2D Barcode : MaxiCode, PDF417, Data matrix, etc.

Media sensor Reflective (Adjustable)

Interfaces RS-232 serial, USB

Power rating* 24 VDC, 2.0 A

Weight 2.8 kgs

Page 10

4

Dimensions W 236 x D 291 x H 199 mm

Operation environment

Temperature: 32° F ~ +104° F (0° C ~ 40° C)

Relative humidity: 5% - 85% non condensing

Storage environment

Temperature: -40° F ~ +140° F (-40° C ~ 60° C)

Relative humidity: 5% - 85% non condensing

Optional items Cutter kit, Peeler kit, Internal 100/10 M Ethernet Interface card

* Power for the C168 barcode label printer is provided via an external power

adaptor.

Specifications for Power Adapter

Input

AC 100~240 V, 47~63 Hz

Output

DC 24 V, 2.0 A

Environment

0° C ~ 40° C

Unpacking and Inspection

Inspect the shipping carton(s) for possible shipping damage, if

damage is discovered, notify the shipping company to report the

nature and extent of the damage.

Please check the items according to the Packing List. If there are any

items missing, notify your authorized reseller.

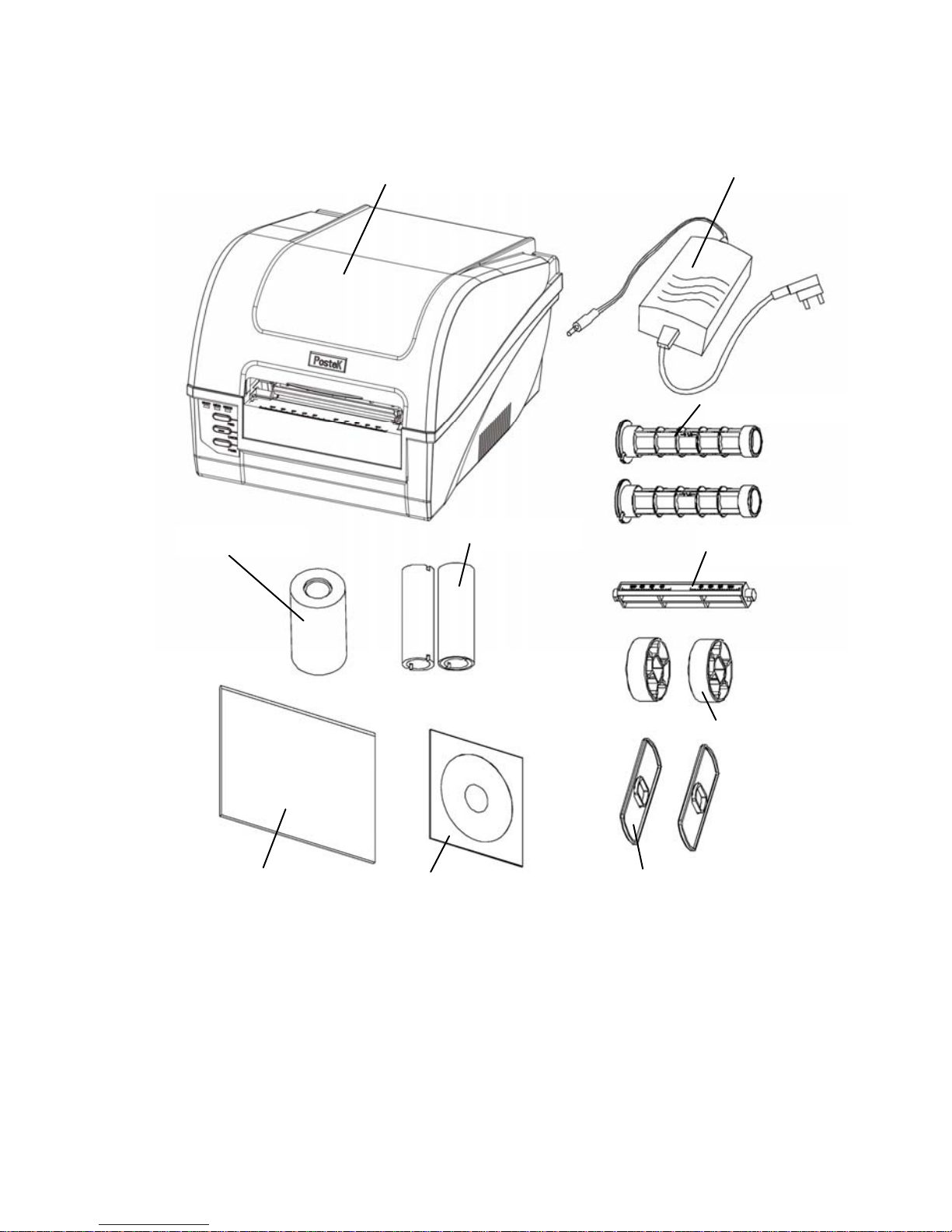

Page 11

5

Packing List(Figure 1):

1. Printer 1 pcs

2. Power Adapter 1 pcs

3. Ribbon Spindle 2 pcs

4. Media Spindle 1 pcs

5. Core Adapter 2 pcs

6. Media Roll Guide 2 pcs

7. Ribbon 1 pcs

8. Sample Media 1 pcs

9. CD Rom 1 pcs

10. Quick Start Guide 1 pcs

Page 12

6

Figure 1 Printer and accessories

Ribbon Spindle

Printe

r

Power Adapte

r

Media Spindle

Core Adapter

Media Roll Guide

Ribbon

Sample Media

CD-Rom User’s Manual

Page 13

7

Chapter 2 Getting Started

Setting up

Before setting up the printer you should consider the following:

1. Make sure there is adequate space around the printer for loading

consumables and proper ventilation.

2. Make sure the printer is close to the host so the interface cable is

easily accessible at either end.

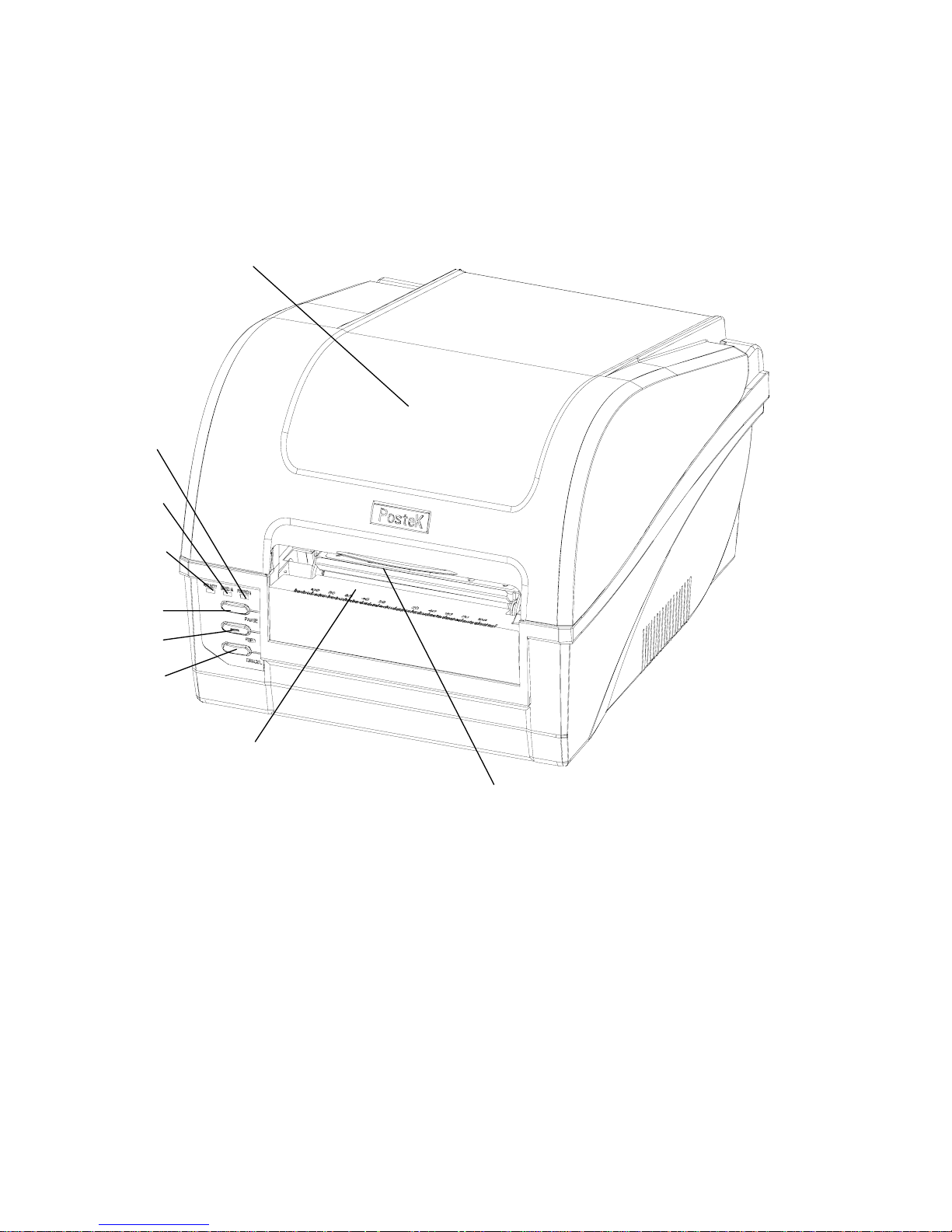

Page 14

8

Main Parts and Features

Figure 2

1. READY Indicator 2. MEDIA Indicator 3. RIBBON Indicator

4. PAUSE Button 5. FEED Button 6. CANCEL Button

7. Media Exit 8. Cover Handle 9. Top Cover

3

1

2

4

5

6

8

7

9

Page 15

9

Figure 3

1. Printhead Module 2. Printhead Bracket 3. Printhead

4. Media Sensor 5. Platen Roller 6. TPH Release Lever

7. Media Guide 8. Ribbon Loading Knob 9. Ribbon Supply Spindle

10. Media Compartment 11.Guide Wheel

1

2

3

4

5

6

7

8

9

10

11

Page 16

10

Figure 4

1. RS232 Serial Port 2. DIP Switches 3. USB Port

4. Ethernet Port 5. DC IN Port 6. Power Switch

7. Centronics Port

Note: The above figure illustrates all possible interface ports on a C168

printer, but some ports may not be available for your printer.

Please check your requirements when purchasing the printer.

1

2

3

4

5

7

6

Page 17

11

Connecting the Printer

Power Connection

Caution:(1) Use of the wrong adapter could damage your printer.

Postek assumes no liability for any damage in such case.

The rating for the printer is 24VDC.

(2) Do not use the printer near liquids or corrosive chemicals.

1. Make sure the printer is switched OFF.

2. Connect the power cord to the Power Adapter.

3. Connect the Power Adapter’s DC output plug to the DC IN port on the

back of the printer.

4. Plug the power cord into a live wall outlet.

Interface Connection

CAUTION: Make sure the printer is switched OFF before connecting

the interface cable.

The interface between the printer and the host will use either a serial or

USB (or parallel) cable. Contact your reseller for Ethernet connection

options.

1. The printer identifies the communication port automatically.

2. The default values of printer port can be obtained from the self-test

report. (See Chapter 2 Operation Basics – Advanced Functions - Self

Test)

3. Cable configurations for serial (RS-232C) and parallel

Page 18

12

(Centronics) interfaces are shown in Appendix A of this guide.

4. Please take the following measures to reduce cable noise.

(1)Reduce the length of the interface cable (keep the cable length

under 1.83 meters / 6 feet) if required.

(2)Keep the communication cable separate from power cords.

Page 19

13

Loading the Ribbon

Caution: (1) Make sure the ink side of your ribbon faces outwards.

Always make sure the ink side of the ribbon faces the

media and NOT the printhead.

(2) The maximum width of the ribbon is 110mm. When

using a ribbon roll with a width less than 110m,

please place the ribbon roll in the middle of the

Ribbon Spindle corresponding to the symmetry

symbol (→|←).

(3) This section is not applicable to direct thermal printing.

1. Lift the top cover (Figure 5-1).

2. Push the TPH release lever to release the Printhead Module.

3. Lift the Printhead Module to expose the ribbon supply spindle (Figure

5-2).

4. Unwrap the ribbon roll pack and separate the ribbon roll and the core

(Figure 5-3).

5. Slide the roll of Ribbon onto one of the Ribbon Spindles and the core

onto the other spindle (Figure5-3).

6. Load the Ribbon Spindle into the printer and route the ribbon through

the Printhead Module as shown in Figure 5-4.

7. Wrap the end of the ribbon around the core (Figure5-5).

8. Load the core into the Ribbon rewinder (Figure5-6).

9. Turn the guide wheel on the left of the core to take up the loose ribbon

and tighten the ribbon.

10. Close the Printhead Module and press down until it locks into place.

Page 20

14

Figure 5-1

Page 21

15

Figure 5-2

Page 22

16

Figure 5-3

Page 23

17

Figure 5-4

Page 24

18

Figure 5-5

Page 25

19

Figure 5-6

Page 26

20

Loading the Media

C168 printers can be operated in three different modes: Standard mode,

Peel-off mode, or Cutting mode.

-- In Standard mode, each printed label remains on the backing

liner.

-- In Peel-off mode, each printed label is peeled away from the

backing liner automatically.

-- In Cutting mode, the printer automatically cuts the label after it is

printed.

Standard Mode

1. Lift up the top cover to expose the media compartment (Figure 6-1).

2. Load a roll of media (labels facing up) on the Media Spindle, then

slide the two Media Roll Guides with their smooth sides toward the

media onto the Media Spindle from each end until snug against the

media. If you are placing a roll of media with a 3″ ID core, please

slide the two Core Adapters onto the Media Spindle first (Figure 6-2).

3. Insert them into the printer.

4. Corresponding to the scale on the Media Spindle, position the media

roll in the middle of the Spindle.

5. Release and lift the Printhead Module.

6. Route the media as shown in Figure 6-3.

7. Slide the Media Guide to the edge of the media.

8. Close the Printhead Module and press down until it locks into place

(Figure 6-4).

9. Close the cover and press the ‘Feed’ button to feed the media and

ensure proper tracking. If the printer does not correctly sense the top

of each label, it may be necessary to perform the Calibration

Procedure in the Operation Basics section.

Page 27

21

Peel-off Mode: The loading guide will be provided with the peeler kit.

Cutting Mode: The loading guide will be provided with the cutter kit.

Figure 6-1

Page 28

22

Figure 6-2

Page 29

23

Figure 6-3

Label

Media Guide

Media Leader

Platen Roller

Page 30

24

Figure 6-4

Page 31

25

Adjusting the Position of Media Sensor

1. Lift the top cover.

2. Push the TPH release lever to release the Printhead Module.

3. Lift the Printhead Module to expose the media sensor cover (Figure

7-1).

4. Remove the media sensor cover and slide the media sensor to the

appropriate position (refer to Figure 7-3, Figure 7-4 and Figure 7-5).

5. Replace the media sensor cover.

Figure 7-1

Media sensor cove

r

Page 32

26

Figure 7-2

Figure 7-3

Media gap

2 – 5mm

Media sensor

Page 33

27

Figure 7-4

Figure 7-5

Media gap

Media gap

Page 34

28

Operation Basics

Power Switch

The power switch is on the back panel of the printer. The symbols on the

switch are defined as follows:

━ —— ON

〇 —— OFF

Page 35

29

The Front Panel

The Front Panel of the printer consists of:

- Three Indicator Lamps: MEDIA, READY and RIBBON

- T

hree multi function buttons: PAUSE, FEED and CANCEL

Indicator Lamps

The three lamps indicate the status of the printer (please refer to Chapter

4 for error indications)

- Solid: Indicates the printer is in the normal state;

- Blinking: Indicates the printer is in the ‘PAUSE’ state.

-

Solid: Indicates the printer is in the normal state;

- Blinking simultaneously with READY: Running out

of media;

- Solid: Indicates thermal transfer printing;

- Off: Direct thermal printing (no ribbon installed);

- Blinking simultaneously with READY: Running out

of ribbon.

READY

MEDIA

RIBBON

Page 36

30

Buttons

The three buttons have different functions based on the mode of the

operation is performed.

Mode Basic Functions

Advanced Functions

(see Advanced Functions below)

Feed/Calibration Feed one label Media Sensor Calibration

Pause/Self Test - Press once to

pause current

print job

- Press a second

time to resume

printing

Self-test:

The Printer performs a

self-test and prints out a

configuration report

Cancel/ Reset - Cancel current

batch of labels

- Forces the printer

to continue

working after an

error has been

corrected

Reset:

Resets the printer to

Factory Default Settings

Advanced Functions

Media Sensor Calibration

It is necessary to accomplish Media Sensor Calibration after a new roll

of media has been loaded.

1. Press and hold the Feed/Calibration button for about 4 seconds.

2. The printer will feed approximately 200mm of media;

Page 37

31

3. The three indicators stop blinking and remain lit, the printer is back to

a normal state.

Self Test

1. Press and hold the Pause/Self Test button for about 4 seconds;

2. The printer will print out a configuration report and the three

indicators will stop blinking and remain lit. The printer is back to a

normal state.

3. The following information will be printed on the self-test report:

- Font list

- Hardware configuration and status

- DIP switch settings

- Label parameters

- Firmware version

Reset – Reset the Printer to the Factory Default Settings

Following the steps listed below allows you to reset the printer to the

factory default settings.

1. Press and hold the Cancel/

Reset button for 4 seconds, the three

lamps will blink simultaneously (the printer will return to normal

state automatically if no operations are performed within 4 seconds);

2. Release and press the Cancel/

Reset button again;

3. The three indicators stop blinking and remain lit. The printer is now in

its normal state.

The following parameters have automatically been reset:

- Label

- Print darkness

- Speed

- Others

Note: The printed label count and printed length may not be reset.

Page 38

32

DIP Switch at the Back Panel

Note: Please turn off the printer before setting the DIP switches.

DIP Bit Functions Remarks

1

ON: Direct thermal print

OFF: Thermal transfer print

Printing type setting

Default: OFF

2

ON: Tear off position

OFF: Edge of next label

Stop position setting

Default: OFF

3

ON: Cutter is installed

OFF: Cutter is not installed

Cutter setting

Default: OFF

1

2

3

4

5

6

7

8

OFF

ON

Page 39

33

4

ON: Peeler is installed

OFF: Peeler is not installed

Peeler settings

Default: OFF

5 Reserved and not available /

6

ON: Enable IP setting

OFF: Disable IP setting

IP address setup

Default: OFF

7

8

7

0 | 0 – 9600,n,8,1

0 | 1 – 19200,n,8,1

1 0 – 38400,n,8,1

1 1 – 57600,n,8,1

RS232 Serial Port

baud rate setting

0: OFF, 1: ON

Default: 00

8

Page 40

34

Windows Driver and PosLabel Software

The printer driver supports Windows 7, Windows Vista, Windows XP,

Windows 2003/2000/NT/ME/98/95 operating systems. Each C168

printer comes with powerful bar code software PosLabel and operating

instructions. Both the Windows driver and PosLabel are available on the

manufacturer’s CD-ROM shipped with the product. If you do not have

the manufacturer’s CD-ROM or wish to upgrade your current software,

it is available for download from:

www.postek.com.cn and www.postektechnologies.com.

Note: If you need to update the driver, please remove any old versions

of the driver before continuing.

Page 41

35

Chapter 3 Maintenance

Warning:

1. Make sure the printer is turned OFF before performing any

maintenance operations.

2. The printhead becomes hot while printing, be careful when

performing maintenance on the printhead.

3. Use only the cleaning agents indicated. Postek Electronics Co.,

Ltd. will not be responsible for damage caused by any other

cleaning materials used on the printer.

4. Anhydrous isopropyl alcohol is a solvent containing no more

than one percent water. Isopropyl alcohol is a flammable

solvent; always take the proper precautions when using this

solvent.

Cleaning the Printhead

The printhead is easily damaged due to its precision construction. A

printhead damaged by misuse is not covered under the terms of the

warranty. To ensure longevity of the printhead, please note the

following:

1. Always use proper cleaning materials and techniques to clean the

printhead. Never use hard materials for scraping the printhead.

2. Always use high-quality consumables. When the TPH module is

closed, pressure is placed directly on the TPH; dirt such as paper

scraps, sand, dust and glue can scrape or damage the printhead.

The TPH is also easily damaged by static electricity, which may be

Page 42

36

generated by poor quality ribbons.

3. After every roll of ribbon or every three rolls of media

, the

printhead should be cleaned with

anhydrous isopropyl alcohol.

a.

Turn off the printer and open the cover.

b. Release and lift the Printhead Module.

c. Remove the ribbon (if applicable).

d.

Using a Cotton Swab dipped in anhydrous isopropyl alcohol, rub

the Swab along the printhead.

Cleaning the Platen Roller

Debris or dirt accumulated on the platen roller should be cleaned

after every three rolls of media.

a. Turn off the printer and open the cover.

b. Release and lift the Printhead Module.

c. Rotate the platen roller and clean it thoroughly with

anhydrous

isopropyl alcohol

and a cotton swab.

Cleaning the Printer Interior

With a brush or a vacuum cleaner, as needed.

Page 43

37

Chapter 4 Troubleshooting

Occasionally situations occur that require some troubleshooting.

Possible issues and potential solutions are listed in this section. While

not every situation is addressed, you may find some of these tips

useful.

Error Indications

Typically, when the printer is not functioning, one or two of the three

indicator lamps will begin blinking. The possible situations addressed by

the status of the three indicator lamps are listed bellow.

READY and MEDIA Lamps blink simultaneously

Possible Cause Recommended

Solutions

Remarks

Cannot detect the

media gap or black

line

(1) Check the media

path

(2) Check the position

of the media sensor

(3) Perform media

sensor calibration

If you are using

continuous media,

be sure you have the

correct settings in

your software

Media run out Load a roll of media

Media jam Clear the jam

The Media Roll

Guides are not

firmly positioned

against the media

Adjust the Media Roll

Guides to firmly press

against the media

Media sensor error Service media sensor

Page 44

38

READY and RIBBON Lamps blink simultaneously

Possible Cause Recommend Solutions Remarks

Run out of ribbon Load a roll ribbon

Ribbon jam Clear the jam

Ribbon Sensor

error

Service Ribbon Sensor To be serviced only

by qualified

personnel

Only READY Lamp blinks

Possible Cause Recommend Solutions Remarks

Serial I/O error Check DIP switches for

the band rate settings

Memory overflow a. Restart the printer

b. Perform Reset

Miscellaneous

Vertical blank lines

Continuous vertical blank lines in printout indicate a dirty or faulty

printhead as shown below:

If the problem cannot be solved by cleaning the printhead, replace the

printhead.

The host shows ‘Printer Timeout’

1. Check if the interface cable is connected.

2. Check if the printer is turned on.

If the situation remains unsolved, please contact your reseller or our

Page 45

39

customer service engineer.

The data has been sent, but not printing

1. Verify you have chosen the correct Windows printer.

2. Reset the printer.

If the situation remains unsolved, please contact your reseller or our

customer service engineer.

Print quality problems

1. Adjust Print Darkness setting.

2. Adjust Print Speed setting.

3. Clean the printhead and platen roller.

4. Make sure the correct media/ribbon is loaded.

5. Use only high-quality Media, replace if necessary.

Recovery

After the corrective action is taken press the CANCEL button to clear

the alarm, the printer will get back to work automatically.

Others

Contact a qualified Service Engineer from your reseller or

Postek for troubles that persist or are not covered in this

section.

Page 46

40

Appendix A: Interface Specifications

RS232 Serial

The RS232 connector on the printer is a DB9F:

Pin Direction Definition

1 / /

2 Out TX

3 In RX

4 In CTS

5 - Ground

6 Out RTS

7 In DSR

8 Out DTR

9 / /

Connection with host:

Host 25S Printer 9P Host 9S Printer 9P

TX 2 ……… 3 RX RX 2 ……… 2 TX

RX 3 ……… 2 TX TX 3 ……… 3 RX

DSR 6 ……… 8 DTR DTR 4 ……… 7 DSR

DTR 20 ……… 7 DSR DSR 6 ……… 8 DTR

RTS 4 ……… 4 CTS RTS 7 ……… 4 CTS

CTS 5 ……… 6 RTS CTS 8 ……… 6 RTS

GND 7 ……… 5 GND GND 5 ……… 5 GND

Page 47

41

Alternately you can just connect the 3 wires as follows:

Host 25S Printer 9P Host 9S Printer 9P

TX 2 ……… 3 RX RX 2 ……… 2 TX

RX 3 ……… 2 TX TX 3 ……… 3 RX

GND 7 ……… 5 GND GND 5 ……… 5 GND

pin 4 pin 4

pin 5 pin 6

pin 6 pin 7

pin 20 pin 8

Baud rate : 9600, 19200, 38400,57600

(Baud Rate set by DIP switches 7–8)

Data format: always 8 data bits, 1 start bit and 1 stop bit.

Parity : always non parity.

Flow control: RTS/CTS (Hardware flow control).

If you are using software or drivers under the Windows environment, the

flow control must be set to “hardware”

Page 48

42

Parallel (Centronics)

The parallel port is a standard 36-pin Centronics interface. Its pin

assignments are as follows:

Pin Direction Definition Pin Direction Definition

1 In /STROBE 13 Out SELECT

2 In Data 1 14,15 NC

3 In Data 2 16 - Ground

4 In Data 3 17 - Ground

5 In Data 4 18 NC

6 In Data 5 19~30 - Ground

7 In Data 6 31 NC

8 In Data 7 32 Out /Fault

9 In Data 8 33~36 - NC

10 Out /ACK

11 Out BUSY

12 Out PE

Any communications port can transmit data from the host (Centronics,

RS232, Ethernet, and USB). Preliminary communications settings are

not required since the printer will automatically detect which port is

active.

Note: Never send data from 2 ports at the same time. Data cannot be sent

to more than one port simultaneously or data corruption and print errors

may occur.

Page 49

43

Appendix B: ASCII Table

0 1 2 3 4 5 6 7

0

NUL 0 @ P ` p

1

SOH XON ! 1 A Q a q

2

STX “ 2 B R b r

3

XOFF # 3 C S c s

4

$ 4 D T d t

5

NAK % 5 E U e u

6

ACK & 6 F V f v

7

BEL ‘ 7 G W g w

8

BS ( 8 H X h x

9

) 9 I Y i y

A

LF * : J Z j z

B

ESC + ; K [ k {

C

FF , < L \ l |

D

CR - = M ] m }

E

SO RS . > N ^ n ~

F

SI US / ? O _ o DEL

Remark: The € sign is included in the embedded table at DEC128

(HEX 80).

Page 50

Loading...

Loading...