Page 1

PP2000 Series

2 Station Printer

User’s Guide

Rev. A

Page 2

Federal Communications Commission Radio Frequency

Interference Statement

This equipment has been tested and found to comply with the limits for a Class A digital

device, pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications.

Operation of this equipment in a residential area is likely to cause harmful interference in which case

the user will be required to correct the interference at his own expense.

For compliance with Federal Noise Interference Standard, this equipment requires a shielded cable.

This statement will be applied only for the printers marketed in U.S.A.

CE manufacturer’s Declaration of Conformity

(EC Council Directive 89/336/EEC of 3 May 1989)

This product has been designed and manufactured in accordance with the International Standards

EN50081-1/01.92 and EN50082-1/01.92 following the provisions of the Electro Magnetic

Compatibility Directive of the European Communities as of May 1989

Warranty Limits

Warranty will terminate automatically when the machine is opened by any person other than

the authorized technicians. The user should consult his/her dealer for the problem happened. Warranty

voids if the user does not follow the instructions in application of this merchandise. The manufacturer is

by no means responsible for any damage or hazard caused by improper application.

About This Manual

This manual is aimed to assist the user to utilize the PP2000 series which is a series of POS

thermal printers delicately designed to work with either serial or parallel interface connection. This

manual covers both operational and technical aspects. This manual is revised to cover also the Epson

emulation commands and some frequently asked questions.

The manufacturer of the PP2000 series heartily apologizes to the user for reserving the right to

change or to modify this manual without notice due to the rapid and constant progress and improvement

on science and technology. The user may always obtain the most up to date information through our

web site: http://www.posiflex.com.tw .

© Copyright Mustek Corp. 1999

All rights are strictly reserved. No part of this documentation may be reproduced, stored in a

retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, or

otherwise, without the prior written consent of Mustek Corp. the publisher of this documentation.

Page 3

Table of Contents

PRODUCT BRIEFING . . . . . . . . . . . . . . . . . . . . . . 1 -- 1

MAIN PARTS ON THE EXTERIOR . . . . . . 2 -- 1

OUTPUT AREAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -- 1

CONTROL PANEL . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 -- 1

INPUT / OUTPUT CONNECTOR . . . . . . . . . . . . . . . .2 -- 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 1

CHECK CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 1

OPEN TOP COVER . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 1

STORE STAMP INSTALLATION . . . . . . . . . . . . . . . 3 -- 2

RIBBON INSTALLATION / REPLACEMENT . . . . . 3 -- 3

CASH DRAWER CONNECTION . . . . . . . . . . . . . . . . 3 -- 4

CONNECT TO HOST COMPUTER . . . . . . . . . . . . . . 3 -- 4

POWER CONNECTION . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 4

POWER ON . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 5

PAPER ROLLS INSTALLATION . . . . . . . . . . . . . . . . 3 -- 5

SELF TEST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 6

REPLACE TOP COVER . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 6

CLEAR BUFFER . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 -- 6

MAINTENANCE NOTICES . . . . . . . . . . . . . . . . 4 -- 1

SOFEWARE COMMANDS . . . . . . . . . . . . . . . . . 5 -- 1

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 1

VALIDATION PRINTING . . . . . . . . . . . . . . . . . . . . . . 6 -- 1

PAPER ROLL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 1

LED INDICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 2

BUTTON FUNCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 2

PRINTER GENERAL SPEC . . . . . . . . . . . . . . . . . . . . . 6 -- 3

PP2000 (E) User’s Manual

i

Page 4

STORE STAMP (OPTION) . . . . . . . . . . . . . . . . . . . . . . 6 -- 4

INTERNAL SWITCHES . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 4

CASH DRAWER CONNECTOR . . . . . . . . . . . . . . . . . 6 -- 5

SERIAL INPUT CONNECTOR (STANDARD 9 PIN RS232

INTERFACE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 5

POWER INPUT CONNECTOR . . . . . . . . . . . . . . . . . . 6 -- 5

PARALLEL INPUT CONNECTOR (STANDARD 25 PIN

SPP INTERFACE) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 5

DIMENSION AND WEIGHT . . . . . . . . . . . . . . . . . . . . 6 -- 5

ENVIRONMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 6

RELIABILITY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 -- 6

POWER ADAPTOR PA-300 . . . . . . . . . . . . . . . . . . . . . 6 -- 6

REGULAR MAINTENANCE PROCEDURE . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7 -- 1

DAILY MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . 7 -- 1

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . 7 -- 2

BASIC TROUBLES SHOOTING . . . . . . . . . . 8 -- 1

NO OPERATION AFTER POWER ON . . . . . . . . . . . 8 -- 1

CAN NOT PRINT WITH A NORMAL POWER ON .8 -- 1

USE SELF TEST CAPABILITY IN CASE OF DOUBT . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 -- 1

PAPER JAMMED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 -- 2

ii

PP2000 (E) User’s Manual

Page 5

I. PRODUCT BRIEFING

This is a high speed 2 - station journal / receipt printer.

l A standard 2 station Journal / Receipt printer: The printing paper

width is 44.5mm. The printer can print both journal and receipt at the

same time or only journal or receipt alone.

l The ability for validation printing.

l The configuration of print head is a 9 Pin impact print head. The

maximum printing speed is about 3 lines / sec and 24 characters /

line. The paper feed speed by command of each journal and receipt is

about 30 lines / sec.

l There are 3 code pages including USA, Multilingual and Portuguese

for use.

l There are 16 sets of international character sets.

l There are two kinds of different interfaces including a 9 pin D

subminiature connector for serial interface and a 25 pin D

subminiature connector for parallel interface and the printer can

automatically detect which one is in use.

l High capacity of printing buffer max. 32 KB can receive data

speedily and store a large quantity of data.

l The ability of controlling two cash drawers.

l Built-in stand-by power to hold data for 1 hour from power off or

power failure so that the printing can be continued after power

resume. (This function can be disabled by jumper.)

l The ability of self-detection on errors like print head overheated.

l Clear LED status indication and easy operating buttons.

l External power supply or +24V DC power from the POS system.

l The PP2000 can be connected to a customer display and work under

pass through commands.

l The life of print head expands considerably

l The style of the model is exquisite and beautiful. The printer itself

takes very little space of the operation site and it is easy to use.

PP2000 (E) User’s Manual

1 - 1

Page 6

l Options include auto stamping ability of the store stamp on receipt

and auto cutting of the receipt.

l The ability of cutting paper in full or in part by software on receipt.

1 - 2

PP2000 (E) User’s Manual

Page 7

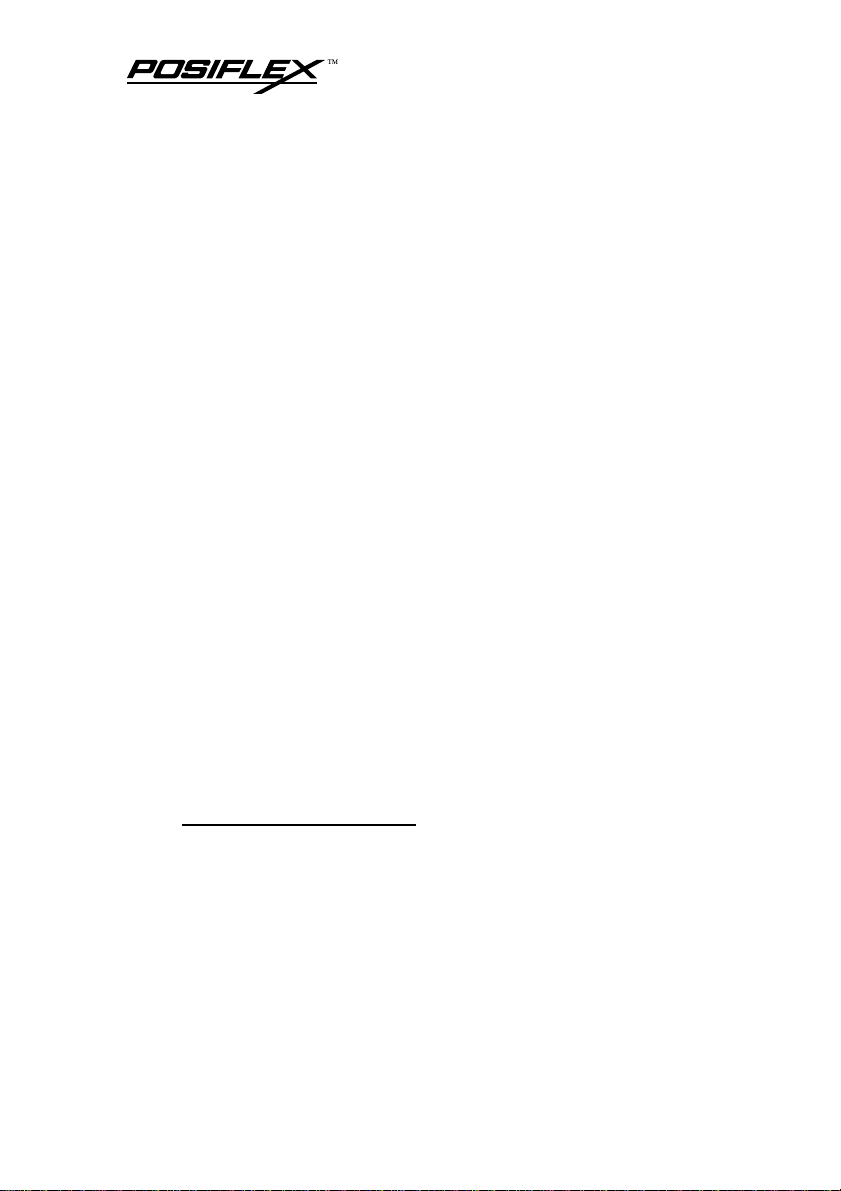

II. MAIN PARTS ON THE EXTERIOR

A. OUTPUT AREAS

Receipt exit slot Journal window

Validation printing

insert slot

B. CONTROL PANEL

Power

On/Off

switch

Power

LED

On line LED

PP2000 (E) User’s Manual

Receipt LED Journal LED On line switch

Manual

stamping

switch

Journal

switch

Receipt switch

2 - 1

Page 8

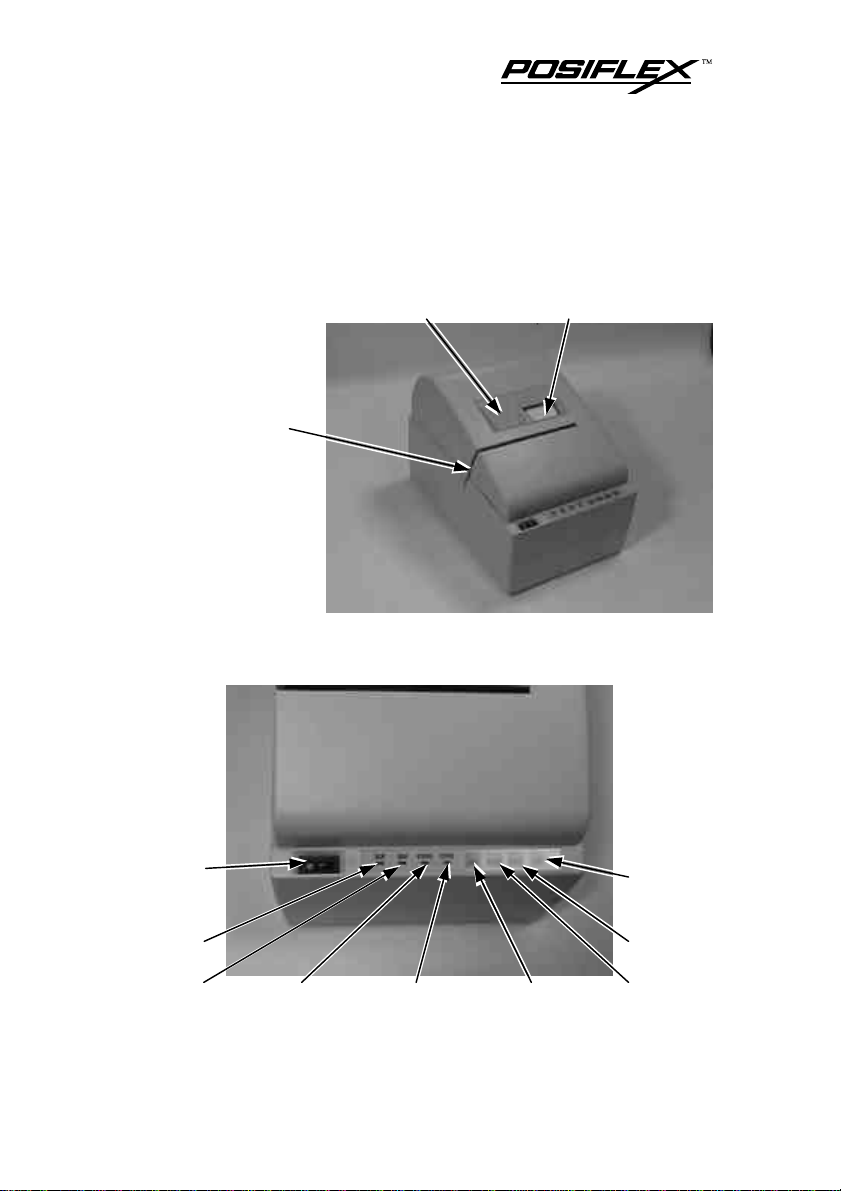

C. INPUT / OUTPUT CONNECTOR

Cash drawer

connector

2 - 2

Serial connector Power connector Parallel connector

PP2000 (E) User’s Manual

Page 9

III. INSTALLATION

A. CHECK CONTENTS

When you unpack carefully the carton that delivers PP2000 series

printer, you will find it contains several items as illustrated below.

ll PP2000 2 - station receipt / journal printer

ll Two rolls of paper roll sample

ll One set of ribbon

ll Power adaptor with power cord (option)

If there is any discrepancy or problem, contact your dealer

immediately. Be sure to save the packing materials in the event that

the printer may need to be shipped at some point in the future.

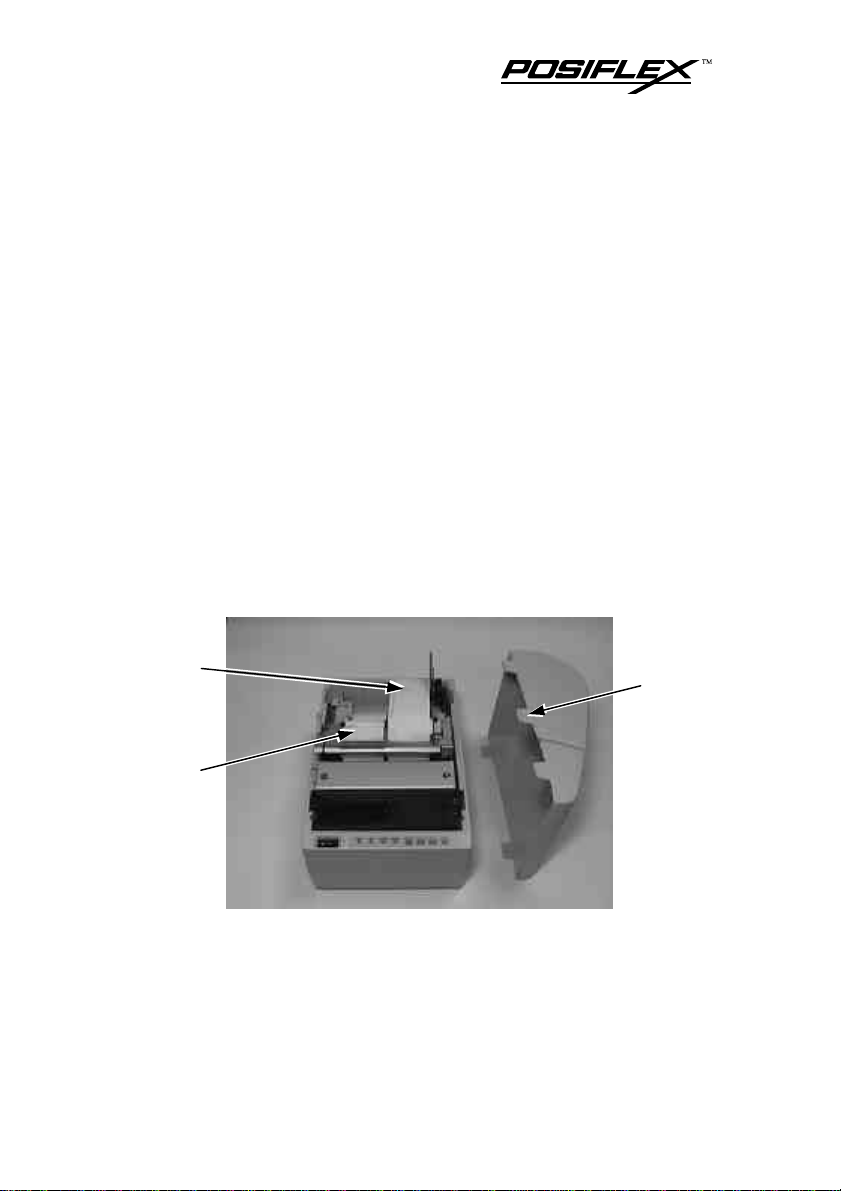

B. OPEN TOP COVER

Journal

Receipt

Please check the Power On / Off switch to be Off. Open top

cover by gently pressing the rear part of top cover inward and lift it up.,

The above figure illustrates the result.

PP2000 (E) User’s Manual

Hook

3 - 1

Page 10

C. STORE STAMP INSTALLATION

Print anvil

assembly

If your printer comes with stamp option, you can find a store

stamp case in the rear of the receipt part of print anvil assembly. You

may take it out gently by holding its handle with your fingers.

Top of

stamp

Print head

assembly

Assembled

sample

Holder Spring piece Store stamp Cushion

Disassemble the holder and the spring piece away from the stamp

case, then install the store stamp, which is engraved with store name or

logo, and cushion and reassemble the spring piece and holder onto the

stamp case as illustrated in the picture above. Please note the direction

3 - 2

PP2000 (E) User’s Manual

Store stamp

case

Page 11

of store stamp. When the printing ink of the stamp is not enough, you

can drip printing ink into the two holes in the rear of the stamp case.

D. RIBBON INSTALLATION / REPLACEMENT

Location of

Handle of

the ribbon

When replacing the ribbon, please take the handle at the center of

the old ribbon case and lift it up. Then the old ribbon can be taken out.

the ribbon

Knob of

the ribbon

When installing a new ribbon, please place the new ribbon to a

suitable position and align the axle hole under the ribbon case to the

driving axletree of the printer. Then push down the ribbon case. Now

PP2000 (E) User’s Manual

3 - 3

Page 12

turn the knob of the ribbon in the marked direction to tighten the ribbon

and to ensure proper operation of the ribbon and to avoid jamming.

E. CASH DRAWER CONNECTION

Using the Posiflex signal cable CCBLA-180 to control a Posiflex

cash drawer (CR3100 or CR3200). However, by using the Posiflex

signal split cable CCBLA-238, PP2000 series can control two Posiflex

cash drawers (CR3100 or CR3200). (CCBLA-180 is a standard

accessory with the Posiflex cash drawer CR3100 or CR3200.)

F. CONNECT TO HOST COMPUTER

The interface from PP2000 to host computer utilizes auto –

detection between serial and parallel. To avoid improper operation,

when one communication interface is in use, the input connector of the

other interface should never be connected with any cable. All the

external connectors are in the recessed area at the rear bottom. The 9 pin

D sub Female connector supports the RS232 series interface and the 25

pin D sub Male connector supports the parallel interface. The protocol

used in serial connection is defaulted: 9,600 bps, parity none, 8 data bits,

1 stop bit. The baud rate is adjustable from 2,400 to 19,200 bps.

G. POWER CONNECTION

If used with Posiflex PST POS system, PP2000 can use DC power

and the power cable from the POS system. If not, user must purchase

PP2000 standard power adaptor. Pull the outer sleeve of the 3 pin plug

of the power adaptor or power cord from the POS system backward to

release the internal latch. Then insert the plug to the power connector

and be sure to hear the click to obtain a firm contact. (Before extraction

of this power cable, be sure to pull the outer sleeve of the plug backward

too. Failure to do this could damage the power plug.) And then connect

the power cord of the power adaptor to the wall outlet or turn on the

POS system. Make sure that the type of power cord and the voltage

requirement of the power adaptor meet the local power conditions. Now

the printer is ready for power on.

3 - 4

PP2000 (E) User’s Manual

Page 13

H. POWER ON

journal

Turn on the On/Off switch at the left to the control panel, there

will be a short buzzing sound and it indicates a normal power on.

I. PAPER ROLLS INSTALLATION

Direction of rolling

Pick up

reel of

Journal

lever

Roll of

journal

Roll of

receipt

Insert slot of journal Insert slot of receipt

1. Please refer to the picture above: Put the receipt roll into the left

paper roll compartment and the journal roll into the right. Please note

that the direction of paper roll is to be pulled up under the roll.

2. Push and hold down the receipt lever and insert the front end of

receipt into the insert slot of receipt. When the front end of receipt is

shown from the front end of the insert slot, release the receipt lever.

3. Push and hold down the journal lever and insert the front end of

journal into the insert slot of journal. When the front end of journal is

shown from the front end of the insert slot, feed the paper enough to

be fixed to the pick up reel of journal and release the journal lever.

Insert the front end of journal into the center slot of the reel and turn

the reel in the indicated direction to fix the journal.

Receipt

lever

PP2000 (E) User’s Manual

3 - 5

Page 14

4. To give an idea about the positioning matter of the receipt, the print

center is 33.3 mm behind the auto-cut position, whilst the stamp

center is 40.0 mm behind the print center.

J. SELF TEST

Please power off the printer for at least three seconds and then

press and hold the receipt button while turning the on / off switch on. A

slip of self test result is printed on both receipt and journal side. Any

signal of the receipt button after the printing of self test result will cause

paper feed of receipt.

K. REPLACE TOP COVER

If there is any difficulty in applying all the five hooks on top cover

into the bottom base of the printer, always align the left three hooks first

and then press down the top cover to the base. In this way, the top cover

will not come in conflict with the receipt lever

L. CLEAR BUFFER

The PP2000E series provides a data preservation function during

power off. This function helps the user to go on printing after an

unexpected power failure. However there can be occasions that the user

wants to restart the printer without printing the unwanted data received

before the printer is turned off. To have the data input buffer cleared, the

user may turn off the printer then press and hold both on line and journal

switches during turning on the printer again.

3 - 6

PP2000 (E) User’s Manual

Page 15

IV. MAINTENANCE NOTICES

l The printer should be put at a well ventilated site and avoid direct

sunshine, also avoid high temperature, high humidity, high

magnetic field. The site should also be free from lots of metal chips

and dust.

l Never place any vessel for water alcohol beverages or any kind of

fluid over the printer. Otherwise it may get turned over and damage

the component inside.

l Use only alcohol or neutral detergent for cleaning of the exterior,

please never use organic solvent like benzene or thinner.

l Maintenance guide:

Ribbon :

Replace for a new one every three months or twenty thousand

pieces of receipt/journal printing. Please do not pour ink into

the ribbon or it is easy to damage the print head.

Print head:

Replace for a new one every seventy thousand pieces of

receipt/journal printing.

Store stamp:

Add ink into store stamp once every three months or twenty

thousand pieces of receipt/journal printed. To avoid illegible

stamping, please replace new store stamp once every twelve

months or eighty thousand pieces of receipt/journal printing.

Auto cutter:

Clean any paper cutting residue and dust in the auto cutting

mechanism regularly to avoid sensor malfunction and paper

jam.

² Use of any ribbon other than the standard supply from the

manufacturer (ERC-32) or refilling of any ink to the ribbon

may cause damage like broken pin in the print head and/or

other consequences. Such damage and consequences are

responsibility of the user and are out of the warranty of the

manufacturer.

PP2000 (E) User’s Manual

4 - 1

Page 16

Page 17

V. SOFTWARE COMMANDS

The commands supported by the PP2000 Printer are listed below.

For detail description of the below listed commands, please visit our

web site http://www.posiflex.com.tw for detail descriptions of each

command.

NAME HEX FUNCTION

LF 0A Print and line feed

CR 0D Print and carriage return

ESC SP 1B 20 Set right side character spacing

ESC ! 1B 21 Select print mode(s)

ESC $ 1B 24 Set absolute print position

ESC % 1B 25 Select/cancel user-defined characters set

ESC & 1B 26 Define user-defined characters

ESC * 1B 2A Select bit-image mode

ESC - 1B 2D Turn underline mode on/off

ESC < 1B 3C Return home

ESC = 1B 3D Select peripheral device

ESC ? 1B 3F Cancel user-defined characters

ESC @ 1B 40 Initialize printer

ESC E 1B 45 Turn emphasized mode on/off

ESC G 1B 47 Turn double-strike mode on/off

ESC R 1B 52 Select an international character set

ESC U 1B 55 Turn unidirectional printing on/off

ESC \ 1B 5C Set relative print position

ESC c 0 1B 63 0 Select paper type for printing

ESC d 1B 64 Print and feed n lines

ESC i 1B 69 Full cut

ESC m 1B 6D Partial cut

5 - 1

PP2000 (E) User’s Manual

Page 18

Software commands continued.

NAME HEX FUNCTION

ESC o 1B 6F Stamp

ESC p 1B 70 Generate pulse

ESC t 1B 74 Select character code table

ESC u 1B 75 Transmit peripheral device status

ESC v 1B 76 Transmit paper sensor status

ESC z 1B 7A

GS * 1D 2A Define download bit image

GS / 1D 2F Print download bit image

Turn parallel printing mode on for receipt and

journal

PP2000 (E) User’s Manual

5 - 2

Page 19

VI. SPECIFICATIONS

A. VALIDATION PRINTING

84.5

Print area

Sensor

Unit: mm

Note: Do not scale

Paper width: 140 mm or above

Paper height: 65 mm or above

Paper thickness: 0.07 ~ 0.14 mm

Validation print: One line

Number of characters: 55

Print area and sensor position: As illustrated in drawing above

10

8

22

2

B. PAPER ROLL

Paper type: High quality paper

Paper roll width: 44.5 +/- 0.5 mm

Paper roll max. O. D.: 83 mm

Paper thickness: 0.06 ~ 0.09 mm

6 - 1

PP2000 (E) User’s Manual

Page 20

C. LED INDICATIONS

Power LED: Green: Printer power is working

On line LED: Green: Printer is at on line state. The printer takes

command from the host system at this state and

takes no command from the buttons.

Receipt LED: Red: Receipt paper is out, or malfunction with receipt

print.

Journal LED: Red: Journal paper is out or malfunction with journal

print.

D. BUTTON FUNCTIONS

On line button: Switches the printer between on line and off line states.

The data in the buffer keep printing out.

Receipt button: Feeds receipt forward one line by each press under off

line state.

Journal button: Feeds journal forward one line by each press under off

line state. Can be used to clear buffer if the printer

switched on while both this button and on line button are

pressed.

Stamp button: Execute one stamp operation by each press under off

line state. (Applicable with stamp option only)

PP2000 (E) User’s Manual

6 - 2

Page 21

E. PRINTER GENERAL SPEC

ITEM SPECIFICATION

Functions Receipt, journal and validation printing

Printing Method

Printing Speed About 3 lines/sec., bi-directional

Printing Capacity

Paper Feed Receipt and journal by separate friction feed

Max.

Paper Feed Speed

Built in Characters 3 code pages with 16 international character sets

Data Buffer 32KB max.

Paper Type

Inked Ribbon EPSON ERC-32(P) purple

Receipt Auto Cut

Pattern

Interface Auto detect between RS232 and Centronics

Sensor Print head over heat protection

Control over

Cash Drawers

Power Used DC 24V

9pin dot matrix impact; synchronized or

separate printing of receipt and/or journal

Receipt: 24 characters/line

Journal: 24 characters/line

Validation: 55 characters in one line

About 30 lines/sec.

Receipt: paper roll (44.5 mm wide x 83 mm

max. O. D.)

Journal: paper roll (44.5 mm wide x 83 mm

max. O. D.)

Validation: single sheet or 2 layers of auto copy

Full cut: 1 point left uncut

Half cut: 3 points left uncut

Can control 2 cash drawers separately

6 - 3

PP2000 (E) User’s Manual

Page 22

F. STORE STAMP (OPTION)

Cushion width: 34.0 mm

Cushion height: 24.0 mm

Cushion thickness: 1.0 mm

Cushion material: PE foam

Stamp total width: 34.0 mm

Stamp total height: 24.0 mm (engraving included)

Stamp total thickness: 5.0 mm

Engraving width: 30.0 mm

Engraving height: 20.0 mm

Engraving thickness: 1.2 mm

Stamp material: porous rubber

Ink type: pre-inked stamp ink (has to match the material of stamp)

G. INTERNAL SWITCHES

Dismount the 4 screws at bottom of the printer and there is a

control board fixed on a steel plate. On this control board, there is a

4PST DIP switch. The functions of each position of this DIP switch are

described below:

P1: For factory setting, should not be changed.

P2: For data preservation. ON – data in input buffer remains when

power off; OFF – data in input buffer are cleared when power

off.

P3 and P4: Setting on serial interface protocols.

P3 OFF P4 OFF 2,400 bps N, 8, 1

P3 OFF P4 ON 4,800 bps N, 8, 1

P3 ON P4 OFF 9,600 bps N, 8, 1 (Default)

P3 ON P4 ON 19,200 bps N, 8, 1

PP2000 (E) User’s Manual

6 - 4

Page 23

H. CASH DRAWER CONNECTOR

PIN DEFINITION

1 Frame ground

2 CR2 kick (by Esc p 0 n1 n2)

3 Drawer open sense

4 +24V DC power

5 CR1 kick (by Esc p 1 n1 n2)

6 Signal ground

I. SERIAL INPUT CONNECTOR

(standard 9 pin RS232 interface)

J. POWER INPUT CONNECTOR

PIN DEFINITION

1 +24 V DC power

2 Power ground

3 N. C.

CASE Frame ground

1

CASE

K. PARALLEL INPUT CONNECTOR

(standard 25 pin SPP interface)

3

2

L. DIMENSION AND WEIGHT

Length Width Height Weight

PRINTER 265 mm 176 mm 193 mm 2.5 Kg

PACKED 315 mm 240 mm 320 mm

6 - 5

3.8 Kg (w/o power adaptor)

4.5 Kg (w/ power adaptor)

PP2000 (E) User’s Manual

Page 24

M. ENVIRONMENT

Temperature: 0°C to 50°C

Humidity: RH 10% to RH 90% without condensation

N. RELIABILITY

Printer mechanism (without print head) life: 8,000,000 lines

Print head life: 150,000,000 characters (2 dots/wire/character average)

O. POWER ADAPTOR PA-300

ITEM SPECIFICATION

INPUT VOLTAGE RANGE 100 V AC to 250 V AC

INPUT FREQUENCY 50 to 60 Hz

OUTPUT VOLTAGE +24 V DC

OUTPUT POWER max. 60 W

CONTINUOUS LOAD max. 2.2 A

OUTPUT STABILITY +/- 5%

RIPPLE AND NOISE max. 240 mV

² Any application of a non Mustek supplied standard power

adaptor may cause damage to the printer, abnormal operation

or noise interference. All such degradations are not covered in

the manufacturer’s warranty.

PP2000 (E) User’s Manual

6 - 6

Page 25

VII. REGULAR MAINTENANCE

PROCEDURE

A. DAILY MAINTENANCE

Perform a basic cleaning and maintenance daily at a suitable

timing as following

Paper exit area

Fig 1 Paper exit area

Insert slot area

Fig 2 Insert slot area

Stamp area

Fig 3 Stamp area

6. Check if the ribbon is still integrated and in good condition. Replace

a new ribbon if any damage found.

1. Turn power off and open the top cover.

Press down the receipt lever and the

journal lever. Take out both the paper

roll of receipt and journal.

2. Use the attached soft brush to clean the

area of the paper exit as indicated in

Fig.1.

3. Pull both the receipt lever and journal

lever forward to raise the print anvil

assembly. Use the attached soft brush

to clean the insert slot area in the

direction as indicated in Fig.2. Brush

gently away the dust and paper

residuals in the direction from the

journal end to the receipt end.

4. Check for dust and paper residuals in

the stamp area. Use the attached soft

brush to clean this area as indicated in

Fig.3.

5. Replace the print anvil assembly. Use

mini-vacuum cleaner if necessary to

remove all the dust and paper residuals

out of the interior of the printer.

7 - 1

PP2000 (E) User’s Manual

Page 26

B. PERIODIC MAINTENANCE

A periodic maintenance and lubrication should take place by a

qualified maintenance specialist in every 6 months.

PP2000 (E) User’s Manual

7 - 2

Page 27

VIII. BASIC TROUBLE SHOOTING

A. NO OPERATION AFTER POWER ON

If the printer does not work, neither does the power on LED lit:

1. Check if the power cord is well connected.

2. Check if the power outlet the printer is connected to is supplied

with power.

3. If the printer does not work, neither does the buzzer beep,

however the power LED does lit, please contact the service

dept. of the manufacturer.

B. CAN NOT PRINT WITH A NORMAL

POWER ON

1. Check if the on line LED is turned on.

2. Check if the interface cable is securely connected. Go on

operation after fixing every joint.

3. Check if the interface cable is incorrectly connected.

C. USE SELF TEST CAPABILITY IN

CASE OF DOUBT

Power off the printer first. Press and hold the receipt button when

turning the power switch on for about 2 second. The printer will print

out the self test data together with the built in fonts.

8 - 1

PP2000 (E) User’s Manual

Page 28

D. PAPER JAMMED

assembly

Receipt lever Journal lever

Raise the

print anvil

In case of serious paper jammed problem, please pull both the

receipt lever and the journal lever forward and push the print anvil

assembly backward (as indicated in the picture) to raise the print anvil

assembly.

PP2000 (E) User’s Manual

8 - 2

Page 29

Once the print anvil assembly is lifted, the paper jam can be

location

dismissed. Please clean the paper residue in the area before putting back

the print anvil assembly if the condition requires.

Pick up reel

moves back

Original

When you are putting back the print anvil, please pay special

attention to the position of the pick up reel for journal. Because the

journal pick up reel moves backward automatically when the print anvil

is raised.

8 - 3

PP2000 (E) User’s Manual

Page 30

to roll

No auto-return

with print anvil

However, the journal pick up reel does not automatically move

forward when the print anvil assembly is put back.

Direction

Please then put the journal pick up reel back to its original

location, and roll the reel so that the journal remains properly tensioned.

PP2000 (E) User’s Manual

8 - 4

Loading...

Loading...