CD-3860 Bar Code Scanner

User’s Manual

Rev. Original

Important Notice

No warranty of any kind is made in regard to this material, including, but not limited to,

implied warranties of merchantability or fitness for any particular purpose. We are not

liable for any errors contained herein nor for incidental or consequential damages in

connection with furnishing, performance or use of this material. We shall be under no

liability in respect of any defect arising from fair wear and tear, willful damage,

negligence, abnormal working conditions, failure to follow the instructions and warnings,

or misuse or alteration or repair of the products without written approval. No part of this

document may be reproduced, transmitted, stored in a retrieval system, transcribed, or

translated into any human or computer or other language in any form or by any means

electronic, mechanical, magnetic, optical, chemical, biological, manual or otherwise,

except for brief passages which may be quoted for purposes of scholastic or literary

review, without express written consent and authorization. We reserve the right to make

changes in product design without reservation and without notification. The material in

this guide is for information only and is subject to change without notice. All trademarks

mentioned herein, registered or otherwise, are the properties of their various, ill,

assorted owners.

General Handling Precautions

Do not dispose of the scanner in fire.

Do not put the scanner directly in the sun or by any heat source.

Do not use or store the scanner in a very humid place.

Do not drop the scanner or allow it to collide violently with other objects.

Do not take the scanner apart without authorization.

Printing Guidance

This programming guide is in A5 size. Please double check your printer setting before

printing it out.

When barcodes are to be printed out for programming, the use of a high-resolution laser

printer is strongly suggested for the best scan result.

Copyright © 2010. All rights reserved.

1

1

For CE-Countries

This scanner is in conformity with CE standards. Please note that an approved, CE-marked

power supply unit should be used in order to maintain CE conformance.

Table of Contents

About This Guide ........................................................................................................3

Introduction to Scanner Configuration.......................................................................3

Default Parameters.....................................................................................................4

Scanner Operation........................................................................4

Interface Communication.............................................................4

Symbologies..................................................................................5

Data Formating.............................................................................6

Programming Procedure.............................................................................................7

Parameter Setting.......................................................................................................8

Scanner Operation........................................................................8

Interface Configuration...............................................................16

The Symbologies.........................................................................24

Data Editing ................................................................................46

Appendix 1: USB Virtual COM Driver Installation ......................49

Appendix 2: Barcode Length Setting ..........................................50

Appendix 3: Full ASCII Code 39 Table.........................................51

2

2

About This Guide

This programming guide applies to various handheld scanners, including

* Advanced Handheld Contact CCD Scanner,

* Advanced Middle-Range Handheld CCD Scanner,

Some settings are not available for certain models. If you are not sure about the

model of your scanner at hand, refer to the device label or contact your distributor.

This document is in A5 size. Please check your printing setting before printing it out.

When barcodes are to be printed out for programming, the use of a high-resolution

laser printer is strongly suggested for the best scan result.

The settings herein shall be updated periodically without prior notice. For the latest

version, please contact your distributor.

Introduction to Scanner Configuration

Scanning a series of programming barcode labels can configure the series scanners.

This allows decoding options and interface protocols to be tailored to a specific

application. The configuration is stored in non-volatile memory and will not be lost by

removing power from the scanner.

The scanner must be properly powered before programming. For RS-232C type

scanners, an external power adapter must be used to supply DC power to the scanner.

If a keyboard emulation type scanner is used with an IBM PC/XT/ AT, PS/2 or any fully

compatible computers, power will be drawn from the keyboard port. No external

power adapter is required. If keyboard emulation type scanner is used with any other

non IBM PC compatible computers, an external power adapter may be needed.

Programmable options are divided into four groups. The second group governs the

operation of different interfaces, RS-232 serial ports, keyboard, and USB. The third

group sets the decoding parameters for each barcode symbology. The last group is

about more advanced data formatting.

3

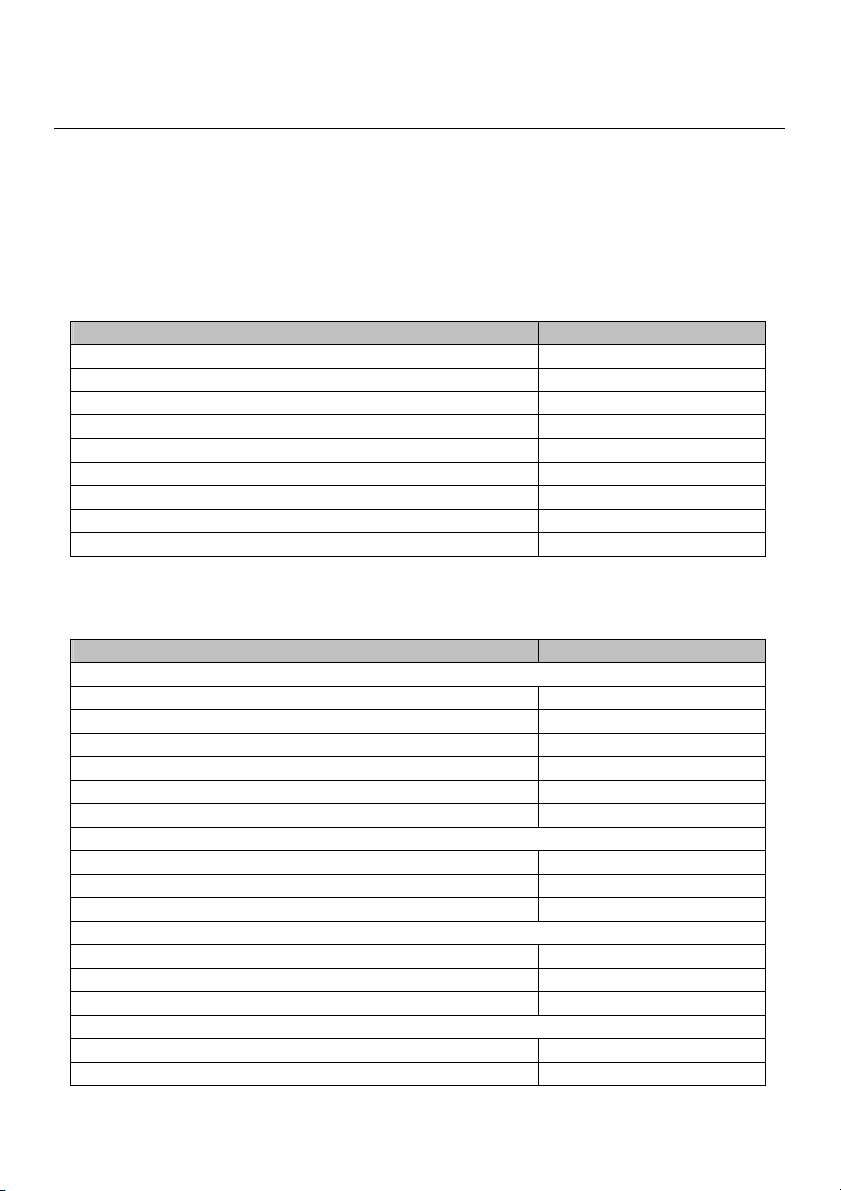

Default Parameters

This table gives the default settings of all the programmable parameters. The default

settings would be restored whenever the scanner reads the "Reset" programming

label in programming mode. If you wish to change any setting, scan the appropriate

barcodes below.

Scanner Operation

Parameter Default

Same code delay 500msec

Beeping frequency Medium

Beeping duration 50msec

LED/Beep before data transmission On

Scan mode Trigger mode

Stand mode (only available for specific models) Enable

Header and trailer None

Inter message delay 0msec

Inter character delay 0msec

Interface Communication

Parameter Default

RS-232 Interface

Baud rate 9600

Parity none

Data Bits 8

Stop Bit 1

RTS/CTS off

Terminator <CR><LF>

Keyboard Wedge Interface

Terminal Type PC/AT

Keyboard US keyboard

Terminator Enter

USB Interface

Terminator type Enter

Code mode Scan code

Keyboard US keyboard

Wand Emulation

Wand emulation speed Normal

Data output Black=high

4

Symbologies

Parameter Default

Decoder Selection

EAN/UPC Enable

Code 39 Enable

Code 32 Disable

Codabar Enable

ITF 2 of 5 Enable

MSI Disable

Chinese Post Code Disable

Code 93 Enable

Code 128 Enable

EAN-128 Disable

Telepen Disable

Code 11 Disable

Standard 2 of 5 Disable

Industrial 2 of 5 Disable

Matrix 2 of 5 Disable

GS1 DataBar Disable

PDF417 Disable

Code Identifiers

Identifier code as factory standard Disable

Identifier code as AIM standard Disable

Code 39 identifier code M

ITF 2 of 5 identifier code I

Chinese post code identifier code H

UPC-A identifier code A

UPC-E identifier code E

EAN-13 identifier code F

EAN-8 identifier code FF

Codabar identifier code N

Code 128 identifier code K

Code 93 identifier code L

MSI identifier code P

Code 11 identifier code O

Standard 2 of 5 identifier code S

Industrial 2 of 5 identifier code D

Matrix 2 of 5 identifier code G

GS1 DataBar identifier code RS

GS1 DataBar Limited identifier code RL

5

GS1 DataBar Expanded identifier code RX

PDF417 identifier code X

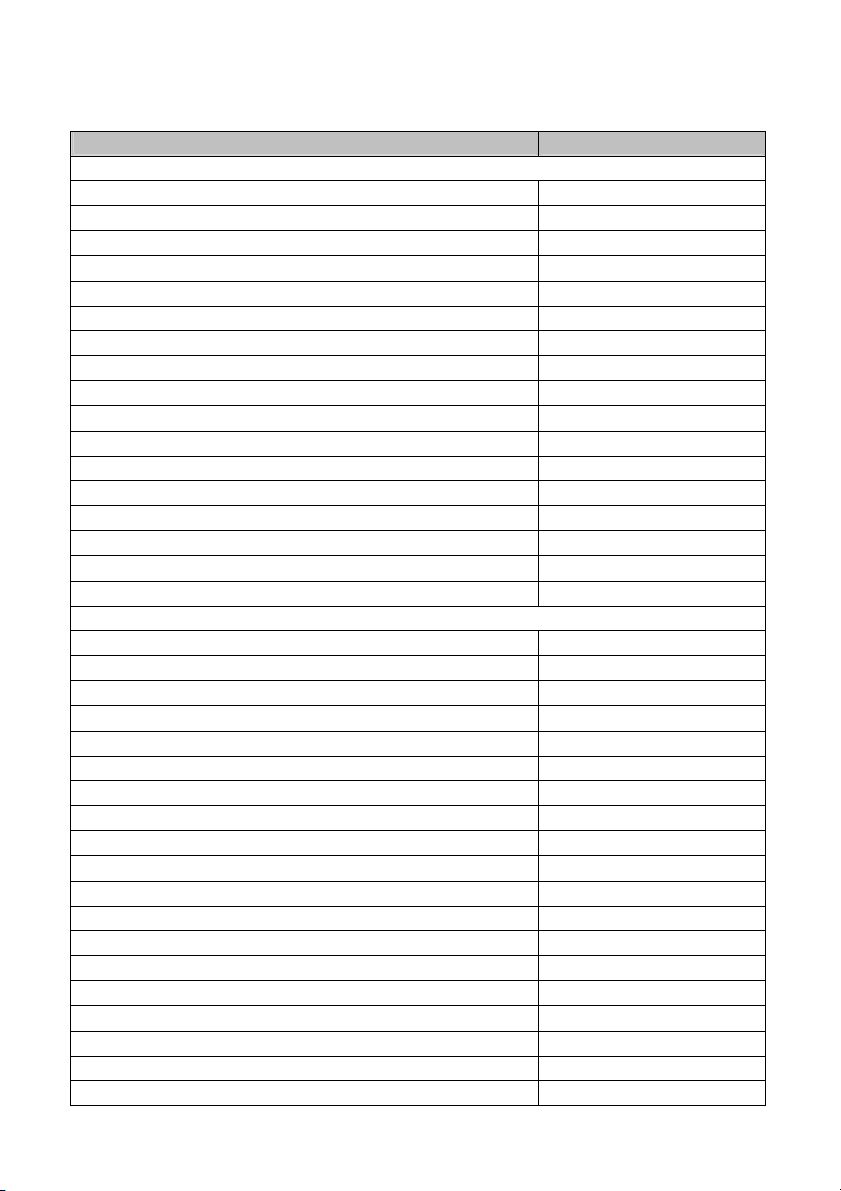

Barcode Length

Codabar

Code 11

Standard 2 of 5

Industrial 2 of 5

Matrix 2 of 5

Code 39

Code 93

Code 128

Chinese Post Code

MSI

ITF 2 of 5

GS1 DataBar Limited

GS1 DataBar Expanded

maximum 32

minimum 6

maximum 62

minimum 3

maximum 16

minimum 10

maximum 32

minimum 4

maximum 14 GS1 DataBar

minimum 14

maximum 48

minimum 6

Data Formating

Code Message Format

EAN-13 D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12 D13

EAN-8 D1 D2 D3 D4 D5 D6 D7 D8

UPC-A D1 D2 D3 D4 D5 D6 D7 D8 D9 D10 D11 D12

UPC-E D1 D2 D3 D4 D5 D6 D7 D8

Code 128 D1-Dx (default 3~62)

EAN-128 C1 D1-Dx (default 3~62)

Code 39 D1-Dx (default 3~62)

Codabar D1-Dx (default 6~32)

ITF 2 of 5 D1-Dx (default 6~32)

Chinese Post Code D1-Dx (default 8~32)

Code 93 D1-Dx (default 3~32)

MSI D1-Dx (default 6~32)

6

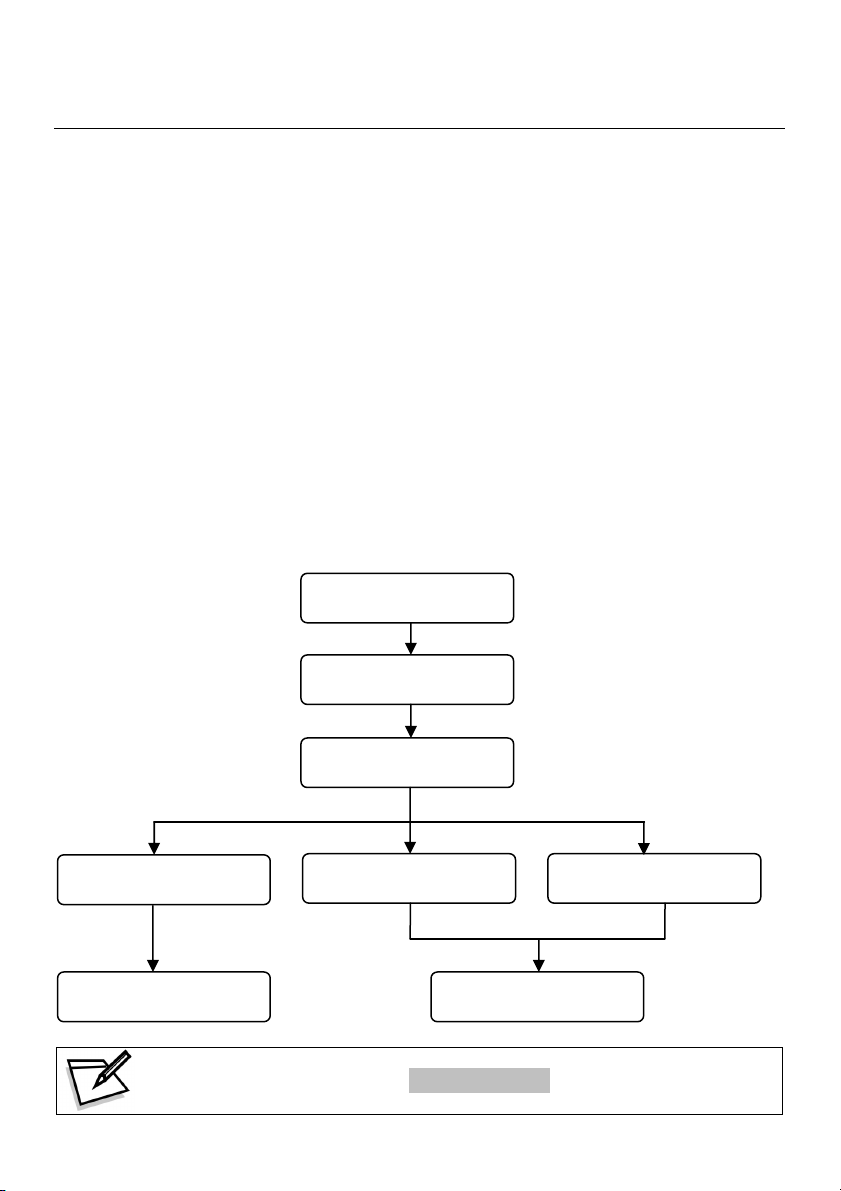

Scan the

“

Start of

Scan the

“

End of

Scan the

“Abort” barcode

Power off the scanner

Finish the configuration

Scan barcode of the

Power up the scanner

Discard the configuration

Programming Procedure

Below is the programming procedure by using barcodes in this guide.

1. Power up the scanner.

2.

Scan the Start of Configuration barcode.

3.

Scan the barcode for the desired feature. Multiple features can be

enabled/disabled before scanning the End of Configuration barcode.

4.

Scan the End of Configuration barcode and save the new configuration.

5.

To give up a configuration change, power off the scanner before scanning the

End of Configuration barcode or scan the Abort barcode.

6.

For some parameter setting, such as barcode length and identifier code, it is

required to scan the Set barcode to save the configuration.

Configuration” barcode

Configuration” barcode

Default values are highlighted in gray background.

desired feature

7

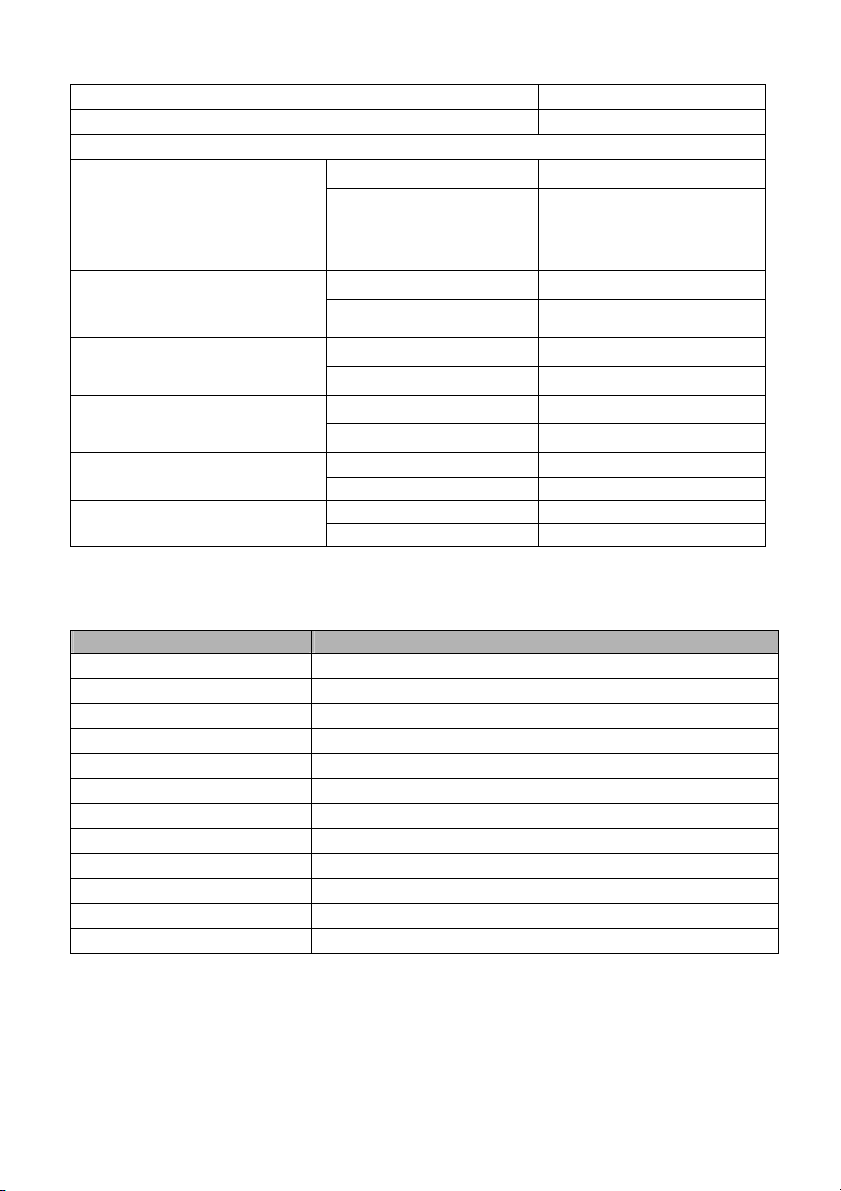

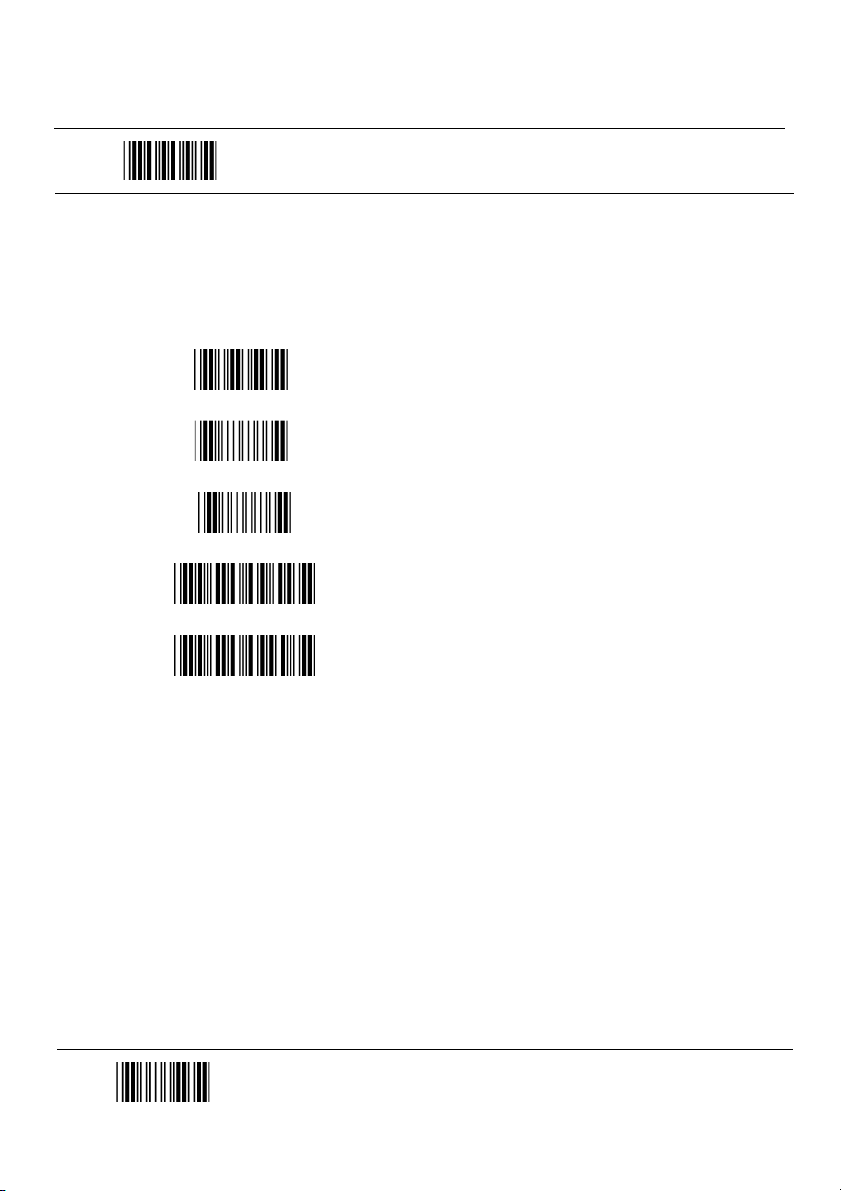

Parameter Setting

Scanner Operation

1. System Function Setting

Barcode

Value

--

%/

++

KE94

KE95

Barcode Label Description

Start Of Configuration

Reset (return to factory default)

Display firmware version

Abort :exit programming mode with no update

Return to customer default

Save as customer default

End Of Configuration

8

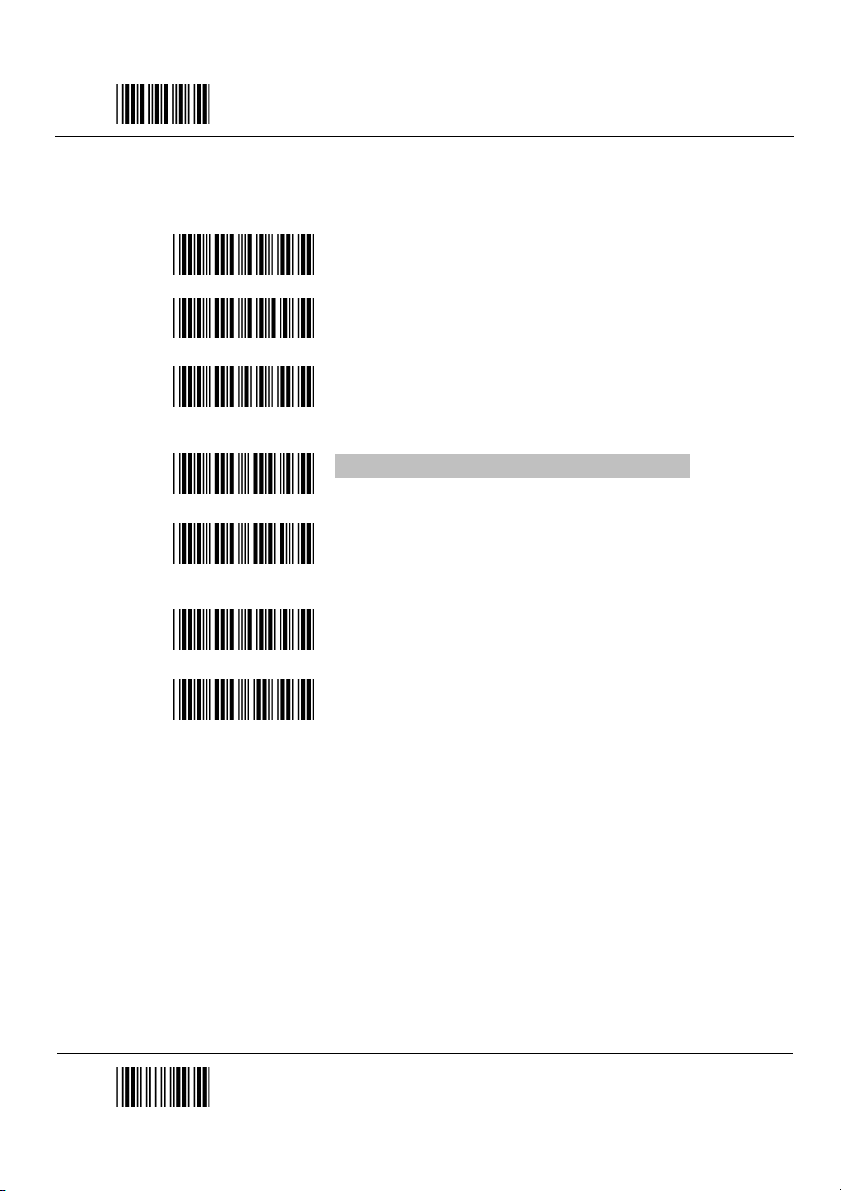

2. Interface Setting

Start Of Configuration

Barcode

Value

KE97

KE99

KE87

KE01

KE05

KE98

KE77

Barcode Label Description

Return to USB default

Return to RS-232 default

Enable USB virtual COM

(Virtual COM driver required. For installation steps refer to

Appendix 1.)

Enable IBM PC/AT/PS/2 Keyboard emulation

Enable stand-alone keyboard

(Required no keyboard or key simulator. Only available for special

firmware version.)

Enable wand emulation

(Only available for special firmware version.)

Enable OPOS/JPOS

(Available for USB interface only and requires driver. For RS-232

interface, the scanner needs reset and identifier code has to be

enabled.)

End Of Configuration

9

Start Of Configuration

3. General Scan Mode Setting

Barcode

Value

SM01

Barcode Label Description

Handheld Operation

Trigger Mode

The scanner becomes inactive as soon as the data

is transmitted. It must be triggered to become

active again.

SM02

SM04

SM05

SM06

Auto Scan Mode

The scanner is still active after the data is

transmitted but the successive transmission of

the same barcode is not allowed when the trigger

switch is pressed again.

Pulse Mode

The scanner will light up and blink when press the

scanner trigger switch once and the scanner will

turn off after next pressing.

Repeat Mode

This mode is similar to Auto Scan Mode, but

double reading for the same barcode is

prohibited if the scanner switch is pressed.

Momentary mode

The scanner will light up only when the trigger

switch is pressed the scanner will turn off when

the trigger switch is release.

10

Barcode

Value

SM20

SM21

Stand Operation

Barcode Label Description

IR On (Auto scan on stand)

The scanner automatically activates scans and

transmits data when detecting object.

IR Off (Scan by manual trigger)

End Of Configuration

Start Of Configuration

4. Operation Function Setting

Good Read Beeper Tone Selection

Barcode

Value

GR02

GR01

GR03

GR05

Barcode

Value

GR13

Barcode Label Description

Barcode Label Description

Low beeper tone

Medium beeper tone

High beeper tone

Speaker disable

Beeper Sound Selection

Very short (5 msec)

GR12

Short (20 msec)

11

GR11

Medium (50 msec)

GR10

GR14

GR15

Barcode

Value

GR20

GR21

GR22

Long (100 msec)

Very Long (200 msec)

Ultra long (500 msec)

End Of Configuration

Start Of Configuration

Beeper Volume Selection

Barcode Label Description

Loud

Medium

Slight

Beeper Timing Selection

Barcode

Value

LB00

Barcode Label Description

LED/Beep after transmission

Use this barcode to indicate a "good read"

after a barcode has been successfully decoded.

12

LB01

LED/Beep before transmission

Use this barcode to indicate a “good read"

before successfully transmitting the barcode

data to the host.

LB03

LB04

Barcode

Value

IM01

IM02

IM03

IM04

Power-on tone enable

Power-on tone disable

End Of Configuration

Start Of Configuration

Inter Message Delay

Barcode Label Description

0 ms

100 ms

500 ms

1000 ms

Inter Character Delay

Barcode

Value

IC01

IC00

IC02

Barcode Label Description

0ms

5ms

10ms

13

IC03

20ms

IC04

IC05

Barcode

Value

SD01

SD02

SD03

SD04

50ms

2ms

End Of Configuration

Start Of Configuration

Same Code Delay

Barcode Label Description

Same code delay time 50msec

Same code delay time 100msec

Same code delay time 200msec

Same code delay time 300msec

SD05

SD06

SD07

SD08

SD09

Same code delay time 400msec

Same code delay time 500msec

Same code delay time 600msec

Same code delay time 700msec

Same code delay time 800msec

14

SD10

Same code delay time 900msec

SD11

SD12

Same code delay time 1000msec

Same code delay time Infinite

End Of Configuration

Start Of Configuration

Connection to an Omnidirectional Scanner

Instead of connecting to a host, sometimes the handheld scanner is to be connected to

the AUX port of an omnidirectional scanner and transmit data to the host system via

this omnidirectional scanner. Such application is not uncommon in places like

hypermarkets and home improvement shops where there are products too heavy or

bulky to be put on the counter and need a handheld scanner to read their barcodes.

In most cases, the auxiliary input port’s data transmission format would follow the

main output format of the omnidirectional scanner, including barcode symbologies and

related parameters. For example, if the handheld scanner can read Codabar while the

omnidirectional scanner can not, the handheld scanner would decode a Codabar

barcode without transmitting the data. To complete the data transmission process, you

have to re-program the omnidirectional scanner and enable Codabar decoding

capability.

The following barcode allows you to enable and disable the AUX port. For more

application and connection instructions, refer to the manual of the omnidirectional

scanner.

Barcode

Value

AUXS

Barcode Label Description

Enable AUX function

15

Not all firmware versions support the AUX function. Please contact your

distributor if you have any questions.

End Of Configuration

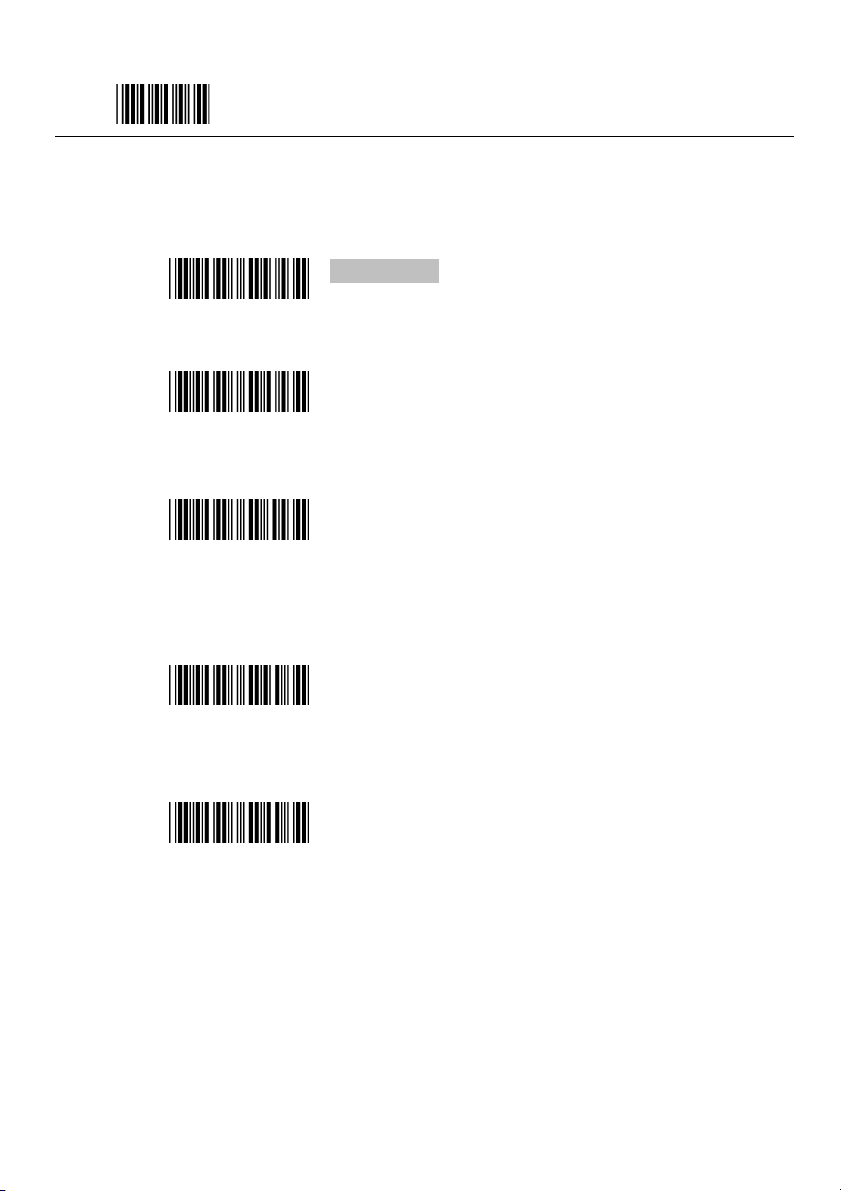

Start Of Configuration

Interface Configuration

1. RS-232C Interface Setting

Barcode

Value

BR09

BR08

BR00

BR01

BR02

Barcode Label Description

Same Code Delay

115200

57600

38400

19200

9600

BR03

BR04

BR05

4800

2400

1200

16

Barcode

Value

PB01

PB02

PB03

PB04

PB05

Barcode

Value

SB01

End Of Configuration

Start Of Configuration

Parity Bit

Barcode Label Description

Even parity

Odd parity

Mark parity

Space parity

None parity

Stop Bit

Barcode Label Description

1 stop bit

SB02

Barcode

Value

Barcode Label Description

2 stop bit

Data Bit

17

Loading...

Loading...