Porter Cable 738, 737 TYPE 2, 737 TYPE 1, 737 Owner’s Manual

_:_!_!_!_!_!i_!!_i_i_ii _!_!ii_ii_ii_i_i_i_iii_i_i_ _iiiii_i_iiiiii_iiiii_i

_i _i_!_!_i_ii_i_i_i_i_i!_iii_i_ii_i!i!_iiii_i_i_iiii_iiiiiii_!_i_i_!i_!!i_!ii_ii_'_

,_ -"-/_ii-t,urpose Saws

Double Insulated Variable

Speed TIGER SAW ®

i i

Patents Pending

IMPORTANT

Please make certain that the person who

is to use this equipment carefully reads

and understands these instructions before

starting operations.

The Model and Serial No. plate is located on the main

housing of the tool. Record these numbers in the

spaces below and retain for future reference.

Model No.

Type

Serial No.

Part No. 899716 - 04-09-03

'f 11 :i i'd

relates to protecting YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recog-

nize this information, we use the symbols below. Please read the manual and pay attention to these

sections.

indicates an imminently hazardous situation which, if not avoided, will result in

death or serious injury.

indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

indicates a potentially hazardous situation which, if not avoided,may result in

minor or moderate injury.

used without the safety alert symbol indicates potentially hazardous situation

which, if not avoided, may result in property damage.

c_or_u_. tone_c_._bY r_w_iM_h_g._ a_ow.g __d_i_l_ Sdrit_ll_g_C_al_ _m) _

cause cancer, birth defects or other reproduc_ve harm. Some example of these chemicals are:

lead from lead-based paints

crystalline silica from bricks and cement and other masonry products

arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To

reduce your exposure to these chemicals: work in a well venUlatsd area, and work with

approved safety equipment, always wear MSHA/NIOSH approved, properly fitfing face mask or

respirator when using such tools.

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUC-

TIONS BEFORE USING THIS EQUIPMENT. Failure to follow all instructions listed

may result in electric shock, fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

WORK AREA

1. Keep your work area clean and well lit. Cluttered benches and dark

areas inviteaccidents.

2. Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases, or dust. Power tools create sparks,

which may ignitethe dust orfumes.

3. Keep bystanders, children, and visitors away while operating a

power tool. Distractions can cause you to lose control.

ELECTRICAL SAFETY

1. Double insulated tools are equipped with a polarized plug (one blade

is wider than the other). This plug will fit in a polarized outlet only one

way. If the plug does not fit fully in the outlet, reverse the plug. If it still

does not fit, contact a qualified electrician to install a polarized outlet. Do

not change the plug in any way. Double Insulated [] eliminatesthe need

for the three wire grounded power cord and grounded power supply system.

2. Avoid body contact with grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric

shock if yourbody isgrounded.

3. Don't expose power tools to rain or wet conditions. Water entering a

power tool willincreasethe riskof electric shock.

below,

2

4. Do not abuse the cord. Never use the cord to carry the tools or pull

the plug from an outlet. Keep cord away from heat, all, sharp edges or

moving parts. Replace damaged cords immediately. Damaged cords

increasethe riskof electricshock.

5. When operating a power tool outside, use an outdoor extension cord

marked "W-A" or "W". These cordsare rated foroutdooruse and reduce the

riskof electricshock.

PERSONAL SAFETY

1. Stay alert, watch what you are doing, and use common sense when

operating a power tool. Do not use tool while tired or under the influence

of drugs, alcohol, or medication. A moment of inattention while operating

power tools may result in seriouspersonal injury.

2. Dress properly, Do not wear loose clothing or jewelry. Contain long

hair. Keep your hair, clothing, and gloves away from moving parts. Loose

clothes, jewelry,or long hair can be caught in movingparts.

3. Avoid accidental starting. Be sure the switch is in the OFF before

plugging in. Carryingtoolswithyour fingeron the switch orplugging intools

that have the switch ON invitesaccidents.

4. Remove adjusting keys or wrenches before turning the tool on. A

wrench ora key that is left attached to a rotating part of the tool may result in

personal injury.

5. Do not overreach. Keep proper footing and balance at all times.

Proper footing and balance enable better control of the tool in unexpected

situations.

6. Use safety equipment. Always wear eye protection. Dust mask, non-

skid safetyshoes, hardhat,or hearingprotectionmustbe usedfor appropriate

conditions.

TOOL USE AND CARE

1. Use clamps or other practical way to secure and support the

workpiece to a stable platform. Holding the work by hand or against your

body is unstableand may lead to lossof control.

2. Do not force tool. Use the correct tool for your application. The

correcttoolwilldo the job betterand safer at the rate for which it isdesigned.

3, Do not use tool ifswitch does not turn it ON or OFF. A tool that cannot

be controlledwiththe switch is dangerous andmust be repaired.

4. Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing the tool. Such preventive

safety measures reduce the riskof startingthe tool accidentally,

5. Store idle tools out of reach of children and other untrained persons.

Toolsare dangerous inthe hands of untrainedusers.

6. Maintain tools with care. Keep cutting tools sharp and clean. Properly

maintainedtools withsharpcutting edge are lesslikelyto bind and are easier

to control,

7. Check for misalignment or binding of moving parts, breakage of

parts, and any other condition that may affect the tool's operation. If

damaged, have the tool serviced before using. Many accidents are caused

by poorlymaintained tools.

8. Use only accessories that are recommended bythe manufacturer for

your model. Accessoriesthat may be suitable for one tool may create a risk

of injurywhen used on anothertool.

SERVICE

1. Toolservice must be performed only by qualified repair personnel.

Service or maintenance performed by unqualifiedpersonnel may result in a

riskof injury.

2. When servicing a tool, use only identical replacement parts. Follow

instructions in the Maintenance Section of this manual. Use of

unauthorizedparts or failure to follow Maintenance Instructionsmay create a

riskof shock or injury.

1. Hold tool by insulated gripping surfaces when performing an

operation where the cutting tool may contact hidden wiring. Contact with

a "live" wire willalso makeexposed metal partsof the tool liveand shock the

operator.

2. Keep blades sharp. Sharp bladeswill dothe job better and safer.

3. Keep hands away from cutting area. When sawing never reach

underneath or behind the material being cut for any reason.

4. When you have finished a cut be careful notto come intocontact with

the blade. Turn offthe motor immediately.

5. EXERCISE EXTREME CAUTION WHEN BLIND CUI-FING TO BE

CERTAIN THATTHERE ARE NO FOREIGNOBJECTS SUCH AS ELECTRICAL

WIRE, CONDUIT, PLUMBING PIPES, ETC., THAT MAY COME INTO

CONTACT WITH THE BLADE.

6. Some wood contains preservatives, which can be toxic. Take extra

careto preventinhalationand skincontact when workingwiththese materials.

Request, and follow, all safety information available from your material

supplier.

7. Stay clear of end pieces that may fall afterbeing cut off.

8. Do not operate the Cordless Reciprocating Saw with guide shoe

removed (Sea PIVOTING GUIDE SHOE sectionof thismanual).

9. Do not attempt to plunge cut metal. Toolis not designed to plunge cut

metal and doing so may resultin riskof injury,

There are certain applications for which this tool was designed. Porter-

Cable strongly recommendsthat this tool NOT be modified and/or used for

any application other than for which it was designed. If you have any

questionsrelativeto itsapplicationDO NOT use the tool untilyou have written

Porter-Cable and we have advisedyou.

TechnicalService Manager

Porter-Cable Corporation

4825 Highway 45 North

Jackson,TN 38305

4

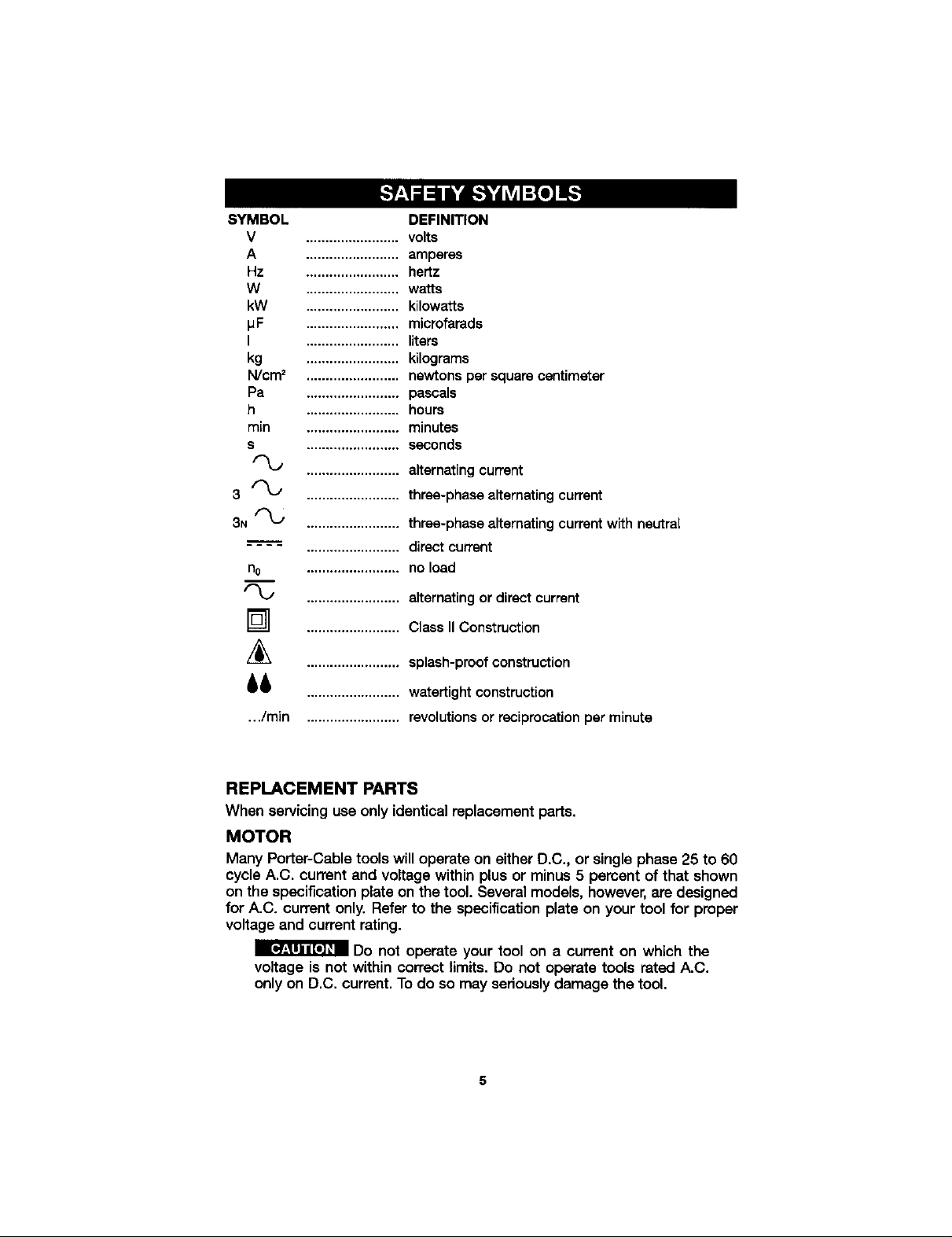

SYMBOL DEFINITION

V ........................ volts

A ........................ amperes

Hz ........................ hertz

W ........................ watts

kW ........................ kilowatts

IJF ........................ microfarads

I ........................ liters

kg ........................ kilograms

N/cm2 ........................ newtons per square centimeter

Pa

h

min

S

3'%,

3N

.... ........................ direct current

no

[]

ii

.../min ........................ revolutions or reciprocation per minute

........................ pascals

........................ hours

........................ minutes

........................ seconds

........................ alternating current

........................ three-phase alternating current

........................ thrae-phase alternating currant with neutral

........................ no load

........................ alternating or direct current

........................ Class II Construction

........................ splash-proof construction

........................ watertight construction

REPLACEMENT PARTS

When servicinguse only identical replacement parts.

MOTOR

Many Porter-Cable tools will operate on either D.C., or single phase 25 to 60

cycle A.C. current and voltage within plus or minus 5 percent of that shown

on the specificationplate on the tool. Several models, however, are designed

for A.C. current only. Refer to the specification plate on your tool for proper

voltage and current rating.

Do not operate your tool on a current on which the

voltage is not within correct limits. Do not operate tools rated A.C.

only on D.C. current. To do so may seriouslydamage the tool.

5

Loading...

Loading...