Porter-Cable 7320, 7319, 7310, 7312 User Manual

Note: Rockler may not carry all products and/or sizes listed in this vendor's publication

RTD10000197AA

ESPAÑOL: PÁGINA 23

FRANÇAISE : PAGE 43

Instruction

manual

73999

MODEL 7310

Trimmer

MODEL 7320

Base

Double Insulated

Laminate Trimmers

MODEL 7312

Offset Trimmer

MODEL 7319

Tilt Base Trimmer

Attachment

For 97311

To learn more about Porter-Cable

visit our website at:

http://www.porter-cable.com

Copyright © 2005 Porter-Cable

IMPORTANT!

Please make certain that the person who is

to use this equipment carefully reads and

understands these instructions before starting

operations.

The Model and Serial No. plate is located on the

main housing of the tool. Record these numbers in

the spaces below and retain for future reference.

®

Model No. __________________________________

T ype _______________________________________

Serial No. __________________________________

Part No. A13635 - 09-23-05 - Rev.A

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . 2

SAFETY GUIDELINES. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . 6

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

WARRANTY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ESPAÑOL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

FRANÇAISE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

IMPORTANT SAFETY INSTRUCTIONS

Read and understand all warnings and operating instructions

before using any tool or equipment. When using tools or equipment, basic

safety precautions should always be followed to reduce the risk of personal

injury. Improper operation, maintenance or modification of tools or equipment

could result in serious injury and property damage. There are certain applications

for which tools and equipment are designed. Porter-Cable strongly recommends

that this product NOT be modified and/or used for any application other than for

which it was designed.

If you have any questions relative to its application DO NOT use the product

until you have written Porter-Cable and we have advised you.

Online contact form at www.porter-cable.com

Postal Mail: Technical Service Manager

Porter-Cable

4825 Highway 45 North

Jackson, TN 38305

Information regarding the safe and proper operation of this tool is available from

the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New

York, NY 10036 www.ansi.org ANSI 01.1Safety Requirements for

Woodworking Machines, and the U.S. Department of Labor regulations www.

SAVE THESE INSTRUCTIONS!

2

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The

information it contains relates to protecting YOUR SAFETY and

PREVENTING PROBLEMS. The symbols below are used to help

you recognize this information.

avoided, will result in death or serious injury.

avoided,could result in death or serious injury.

property damage.

indicates an imminently hazardous situation which, if not

indicates a potentially hazardous situation which, if not

indicates a potentially haz ard ous situation which, if not

avoided,may result in minor or mod erate injury.

used without the safety alert symbol indicates potentially

hazardous situation which, if not avoided, may result in

CALIFORNIA PROPOSITION 65

Some dust created by power sanding, sawing, grinding, drilling,

State of California) to cause cancer, birth defects or other reproductive harm. Some

examples of these chemicals are:

● lead from lead-based paints

● crystalline silica from bricks and cement and other masonry products

● arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type

of work. To reduce your exposure to these chemicals: work in a well ventilated

area, and work with approved safety equipment, al ways wear NIOSH/OSHA

approved, properly fit ting face mask or res pirator when us ing such tools.

and other construction activities contains chemicals known (to the

3

GENERAL SAFETY RULES

instructions listed below may result in electric shock, fire and/or

serious injury. The term "power tool" in all of the warnings listed

below refers to your mains-operated (corded) power tool or

battery-operated (cordless) power tool.

SAVE THESE INSTRUCTIONS

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite

b) Do not operate power tools in explosive atmospheres, such as

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in

b) Avoid body contact with earthed or grounded surfaces such as

c) Do not expose power tools to rain or wet conditions. Water entering

d) Do not abuse the cord. Never use the cord for carrying, pulling or

e) When operating a power tool outdoors, use an extension cord

3) Personal safety

a) Stay alert, watch what you are doing and use common sense

b) Use safety equipment. Always wear eye protection. Safety

c) Avoid accidental starting. Ensure the switch is in the off-position

d) Remove any adjusting key or wrench before turning the power tool

Read all instructions. Failure to follow all

accidents.

in the presence of flammable liquids, gases or dust. Power tools

create sparks which may ignite the dust or fumes.

any way. Do not use any adapter plugs with earthed (grounded)

power tools. Unmodified plugs and matching outlets will reduce risk

of electric shock.

pipes, radiators, ranges and refrigerators. There is an increased risk

of electric shock if your body is earthed or grounded.

a power tool will increase the risk of electric shock.

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts. Damaged or entangled cords increase the

risk of electric shock.

suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

when operating a power tool. Do not use a power tool while you

are tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in

serious personal injury.

equipment such as dust mask, non-skid safety shoes, hard hat, or

hearing protection used for appropriate conditions will reduce personal

injuries.

before plugging in. Carrying power tools with your finger on the switch

or plugging in power tools that have the switch on invites accidents.

4

GENERAL SAFETY RULES

on. A wrench or a key left attached to a rotating part of the power tool

may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times.

This enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your

hair, clothing and gloves away from moving parts. Loose

clothes, jewelry or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly

used. Use of these devices can reduce dust-related hazards.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at

the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off.

Any power tool that cannot be controlled with the switch is dangerous

and must be repaired.

c) Disconnect the plug from the power source before making any

adjustments, changing accessories, or storing power tools. Such

preventive safety measures reduce the risk of starting the power tool

accidentally.

d) Store idle power tools out of the reach of children and do not

allow persons unfamiliar with the power tool or these instructions

to operate the power tool. Power tools are dangerous in the hands of

untrained users.

e) Maintain power tools. Check for misalignment or binding of

moving parts, breakage of parts and any other condition that may

affect the power tools operation. If damaged, have the power tool

repaired before use. Many accidents are caused by poorly maintained

power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting

tools with sharp cutting edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits etc., in accordance

with these instructions and in the manner intended for the

particular type of power tool, taking into account the working

conditions and the work to be performed. Use of the power tool for

operations different from those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified repair person using

only identical replacement parts. This will ensure that the safety of

the power tool is maintained.

continued

5

ADDITIONAL SPECIFIC SAFETY RULES

1. HOLD POWER TOOLS BY INSULATED GRIPPING SURFACES WHEN

PERFORMING AN OPERATION WHERE THE CUTTING TOOL MAY

CONTACT HIDDEN WIRING OR ITS OWN CORD. Contact with a "live"

wire will make exposed metal parts of the tool "live" and shock the operator.

2. USE CLAMPS OR OTHER PRACTICAL WAY TO SECURE AND

SUPPORT THE WORKPIECE TO A STABLE PLATFORM. Holding the

work by hand or against your body is unstable and may lead to loss of

control.

3. DISCONNECT TOOL FROM POWER SOURCE before making

adjustments or changing bits.

4. TIGHTEN COLLET NUT securely to prevent the bit from slipping.

5. USE A CLAMP or some other device to hold the workpiece rigidly in position.

and clear the path of the tool of obstructions.

6. CHECK TO SEE THAT THE CORD will not “hang up” during trimming

operation.

7. CLEAR THE TRIMMER BIT AREA before starting motor.

8. MAINTAIN FIRM GRIP on trimmer to resist starting torque.

9. KEEP HANDS CLEAR OF CUTTER when motor is running to prevent

personal injury.

10. KEEP CUTTING PRESSURE CONSTANT. Do not overload motor.

11. LET THE MOTOR COME TO A COMPLETE STOP before putting the tool

down.

12. NEVER TOUCH router bits after use. They may be extr emely hot.

13. NEVER TIGHTEN COLLET NUT without a bit.

14. DO NOT USE LAMINATE TRIMMER MOTOR WITHOUT THE LAMINATE

TRIMMER BASE INSTALLED. Loss of control could result, causing

personal injury or damage to work.

15. WEAR EYE AND HEARING PROTECTION. ALWAYS USE SAFETY

GLASSES. Everyday eyeglasses are NOT safety glasses. USE CERTIFIED

SAFETY EQUIPMENT. Eye protection equipment should comply with ANSI

Z87.1 standards. Hearing equipment should comply with ANSI S3.19

standards.

16.

DUST OR OTHER AIRBORNE PARTICLES, INCLUDING WOOD DUST,

CRYSTALLINE SILICA DUST AND ASBESTOS DUST. Direct particles

away from face and body. Always operate tool in well ventilated area and

provide for proper dust removal. Use dust collection system wherever

possible. Exposure to the dust may cause serious and permanent

respiratory or other injury, including silicosis (a serious lung disease),

cancer, and death. Avoid breathing the dust, and avoid prolonged contact

with dust. Allowing dust to get into your mouth or eyes, or lay on your skin

may promote absorption of harmful material. Always use properly fitting

NIOSH/OSHA approved respiratory protection appropriate for the dust

exposure, and wash exposed areas with soap and water.

USE OF THIS TOOL CAN GENERATE AND DISBURSE

6

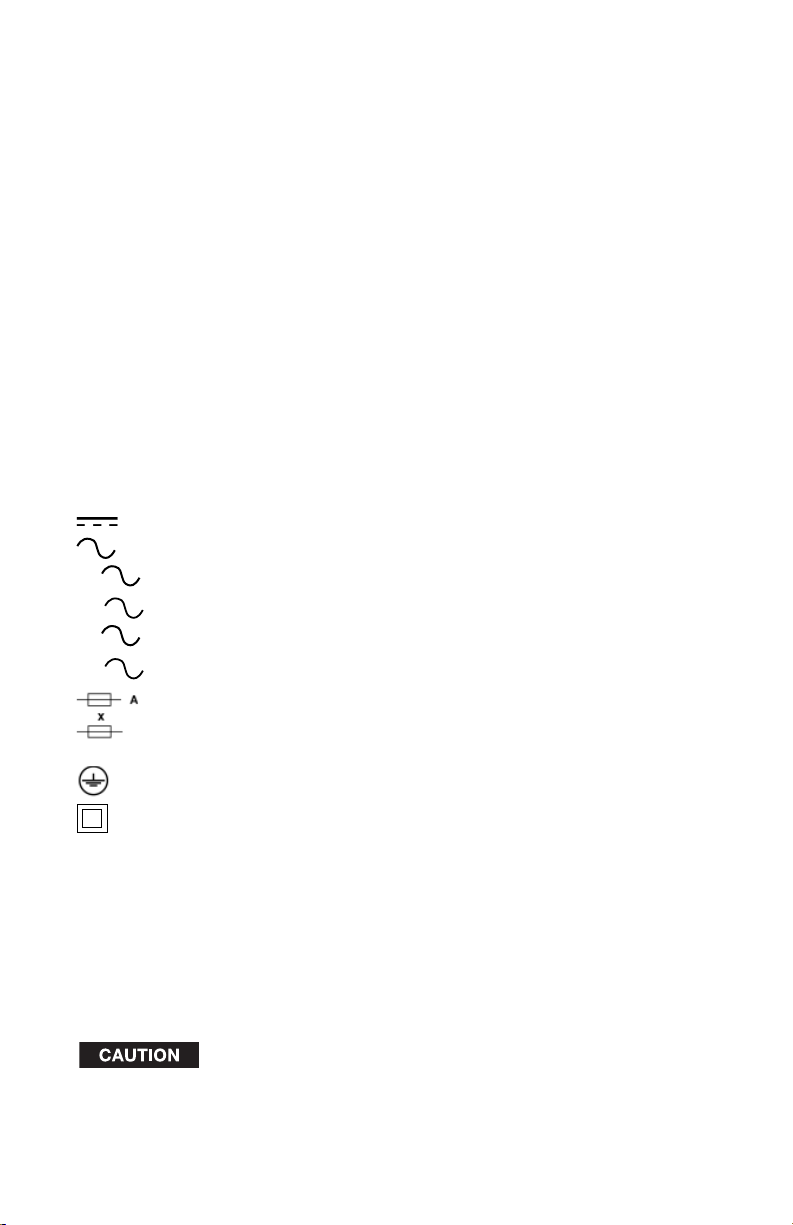

SYMBOL DEFINITION

V ........................................ volts

A ........................................ amperes

Hz ...................................... hertz

W ....................................... watts

kW ..................................... kilowatts

F ........................................ farads

µF ...................................... microfarads

l .......................................... litres

g ........................................ grams

kg....................................... kilograms

bar ..................................... bars

Pa ...................................... pascals

h ........................................ hours

min..................................... minutes

s ......................................... seconds

n

0 .......................................

.../min or …min

1

..............

-

or d.c. .................... direct current

or a.c. ....................... alternating current

2

............................ two-phase alternating current

2N ........................... two-phase alternating current with neutral

3

.............................. three-phase alternating current

3N ............................ three-phase alternating current with neutral

.............................. rated current of the appropriate fuse-link in amperes

................................. time-lag miniature fuse-link where X is the symbol for

................................... protective earth

no-load speed

Revolutions or reciprocations per minute

the time/current characteristic, as given in IEC 60127

.................................... class II tool

IPXX ................................... IP symbol

MOTOR

Many Porter-Cable tools will operate on either D.C., or single phase 25 to 60

cycle A.C. current and voltage within plus or minus 5 percent of that shown on

the specification plate on the tool. Several models, however, are designed for

A.C. current only. Refer to the specification plate on your tool for proper voltage

and current rating.

Do not operate your tool on a current on which the voltage is

not within correct limits. Do not operate tools rated A.C. only

on D.C. current. To do so may seriously damage the tool.

7

Loading...

Loading...