Porter-Cable 33-895X, 33-892, 33-890, 33-891 User Manual

INSTRUCTION MANUAL

12" Radial Arm Saw

(Model 33-890, 33-895X, 33-891, 33-892)

PART NO. 424-02-651-0025 - 03-18-05

Copyright © 2005 Delta Machinery

To learn more about DELTA MACHINERY

visit our website at: www.deltamachinery.com.

For Parts, Service, Warranty or other Assistance,

please call

1-800-223-7278 (In Canada call 1-800-463-3582).

Record this information for future reference.

SERIAL NO.______________________________

DATE OF PURCHASE ____________________

2

TABLE OF CONTENTS

Read and understand all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of personal injury.

Improper operation, maintenance or modification of tools or equipment could result in serious injury and property

damage. There are certain applications for which tools and equipment are designed. Delta Machinery strongly

recommends that this product NOT be modified and/or used for any application other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery

and we have advised you.

Online contact form at www.deltamachinery.com

Postal Mail: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

Information regarding the safe and proper operation of this tool is available from the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSI 01.1Safety Requirements for Woodworking Machines, and

the U.S. Department of Labor regulations www.osha.gov

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

SERVICE CENTER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back cover

3

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may

result in property damage.

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR

SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

SAFETY GUIDELINES - DEFINITIONS

SOME DUST CREATED BY POWER SANDING, SAWING, GRINDING, DRILLING, AND OTHER

CONSTRUCTION ACTIVITIES contains chemicals known to cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

· lead from lead-based paints,

· crystalline silica from bricks and cement and other masonry products, and

· arsenic and chromium from chemically-treated lumber.

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well ventilated area, and work with approved safety equipment, always wear NIOSH/OSHA

approved, properly fitting face mask or respirator when using such tools.

CALIFORNIA PROPOSITION 65

4

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in electric shock,

fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

MANUAL BEFORE OPERATING THE MACHINE.

Learning the machine’s application, limitations, and

specific hazards will greatly minimize the possibility of

accidents and injury.

2. WEAR EYE AND HEARING PROTECTION.

ALWAYS USE SAFETY GLASSES. Everyday

eyeglasses are NOT safety glasses. USE CERTIFIED

SAFETY EQUIPMENT. Eye protection equipment

should comply with ANSI Z87.1 standards. Hearing

equipment should comply with ANSI S3.19

standards.

3. WEAR PROPER APPAREL. Do not wear loose

clothing, gloves, neckties, rings, bracelets, or other

jewelry which may get caught in moving parts. Nonslip

footwear is recommended. Wear protective hair

covering to contain long hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or

wet locations or in rain can cause shock or

electrocution. Keep your work area well-lit to prevent

tripping or placing arms, hands, and fingers in danger.

5. MAINTAIN ALL TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the

machine, check for any damaged parts. Check for

alignment of moving parts, binding of moving parts,

breakage of parts, and any other conditions that may

affect its operation. A guard or any other part that is

damaged should be properly repaired or replaced.

Damaged parts can cause further damage to the

machine and/or injury.

7. KEEP THE WORK AREA CLEAN. Cluttered areas and

benches invite accidents.

8. KEEP CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can

be injured.

9. REDUCE THE RISK OF UNINTENTIONAL STARTING.

Make sure that the switch is in the “OFF” position

before plugging in the power cord. In the event of a

power failure, move the switch to the “OFF” position.

An accidental start-up can cause injury.

10.

USE THE GUARDS. Check to see that all guards are

in place, secured, and working correctly to reduce

the risk of injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools, scrap

pieces, and other debris can be thrown at high speed,

causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not

designed. Damage to the machine and/or injury may

result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by

Delta may cause damage to the machine or injury to the

user.

14. USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using

an extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage, resulting in loss of

power and overheating. See the Extension Cord Chart

for the correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold

the workpiece when practical. Loss of control of a

workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR ABRASIVE

SURFACE. Feeding it from the other direction will cause

the workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you

fall into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNATTENDED.

TURN THE POWER OFF. Don’t leave the machine until it

comes to a complete stop. A child or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, before adjusting or changing

set-ups, or when making repairs. An accidental start-up

can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY

REMOVING STARTER KEYS. The accidental start-up

of a machine by a child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE

MACHINE WHEN YOU ARE TIRED OR UNDER THE

INFLUENCE OF DRUGS, ALCOHOL, OR

MEDICATION. A moment of inattention while operating

power tools may result in injury.

24. USE OF THIS TOOL CAN GENERATE

AND DISBURSE DUST OR OTHER

AIRBORNE PARTICLES, INCLUDING WOOD DUST,

CRYSTALLINE SILICA DUST AND ASBESTOS DUST.

Direct particles away from face and body. Always

operate tool in well ventilated area and provide for

proper dust removal. Use dust collection system

wherever possible. Exposure to the dust may cause

serious and permanent respiratory or other injury,

including silicosis (a serious lung disease), cancer, and

death. Avoid breathing the dust, and avoid prolonged

contact with dust. Allowing dust to get into your mouth

or eyes, or lay on your skin may promote absorption of

harmful material. Always use properly fitting

NIOSH/OSHA approved respiratory protection

appropriate for the dust exposure, and wash exposed

areas with soap and water.

5

1. DO NOT OPERATE THIS MACHINE UNTIL it is

assembled and installed according to the

instructions.

2. OBTAIN ADVICE from your supervisor, instructor,

or another qualified person if you are not familiar

with the operation of this machine.

3. FOLLOW ALL WIRING CODES and recommended

electrical connections.

4. USE THE GUARDS WHENEVER POSSIBLE.

Check to see that they are in place, secured, and

working correctly.

5. ENSURE THAT END PLATES ARE SECURELY

FASTENED TO TRACK ARM prior to use.

6. TIGHTEN ALL CLAMP HANDLES prior to use

except for the motor carriage clamp. Tighten this

clamp only for ripping operations.

7. AVOID KICKBACK BY:

A. keeping blade sharp and free of rust and pitch.

B. keeping blade parallel to the fence when

ripping.

C. using anti-kickback fingers when ripping.

Lower the guard on the infeed end and adjust

the anti-kickback attachment properly.

D. never ripping a workpiece that is twisted or

warped, or does not have a straight edge to

guide along the fence.

E. never sawing a large workpiece that cannot be

controlled.

F. never sawing a workpiece with loose knots or

other flaws.

8. REMOVE CUT-OFF PIECES AND SCRAPS from

the table before starting the saw. The vibration of the

machine may cause them to move into the saw

blade and be thrown out. After cutting, turn the

machine off. When the blade has come to a

complete stop, remove all debris.

9. NEVER perform “free-hand” operations. Use the

fence to position and guide the workpiece.

10. KEEP ARMS, HANDS, AND FINGERS away from

the blade.

11. NEVER REACH around the saw blade.

12. NEVER PERFORM a “crossed arm” operation.

13. PROPERLY SUPPORT LONG OR WIDE

workpieces.

14. NEVER START THE MACHINE with the workpiece

against the blade.

15. FOLLOW ALL RIPPING WARNINGS on machine.

NEVER FEED THE WORKPIECE into the antikickback end of the machine. FEED WORKPIECE

against blade rotation.

16. USE PUSH STICK(S) for ripping a narrow

workpiece.

17. RETURN THE CUTTERHEAD to the full rear

position behind the fence after each crosscut

operation.

18. NEVER PERFORM LAYOUT, ASSEMBLY, or set-

up work on the table/work area when the machine is

running.

19. TURN THE MACHINE “OFF” AND DISCONNECT

THE MACHINE from the power source before

installing or removing accessories, before adjusting

or changing set-ups, or when making repairs.

20. TURN THE MACHINE “OFF”, disconnect the

machine from the power source, and clean the

table/work area before leaving the machine. LOCK

THE SWITCH IN THE “OFF” POSITION to prevent

unauthorized use.

FAILURE TO FOLLOW THESE RULES MAY RESULT IN SERIOUS PERSONAL INJURY.

ADDITIONAL SAFETY RULES FOR RADIAL ARM SAWS

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

66

Fig. A

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of

the same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

2. Grounded, cord-connected machines intended for

use on a supply circuit having a nominal rating

between 150 - 250 volts, inclusive:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. C, the

machine will have a grounding plug that looks like the

plug illustrated in Fig. C. Make sure the machine is

connected to an outlet having the same configuration as

the plug. No adapter is available or should be used with

this machine. If the machine must be re-connected for

use on a different type of electric circuit, the reconnection should be made by qualified service

personnel; and after re-connection, the machine should

comply with all local codes and ordinances.

IN ALL CASES, MAKE CERTAIN THE

RECEPTACLE IN QUESTION IS PROPERLY

GROUNDED. IF YOU ARE NOT SURE HAVE A

QUALIFIED ELECTRICIAN CHECK THE RECEPTACLE.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is

equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must

be plugged into a matching outlet that is properly installed

and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding

conductor can result in risk of electric shock. The

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if

the grounding instructions are not completely

understood, or if in doubt as to whether the machine is

properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-conductor

receptacles that accept the machine’s plug, as shown in

Fig. A.

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

MOTOR SPECIFICATIONS

Your machine either has a 230V, 60 HZ single phase motor (33-890, 33-895X and 33-891) or it has a 230V/460V 60

HZ three phase motor (33-892). Before connecting the machine to the power source, make sure the switch is off.

GROUNDING INSTRUCTIONS

THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE OPERATOR FROM

ELECTRIC SHOCK.

3. Permanently connected machines:

If the machine is intended to be permanently connected,

the machine should be connected to a grounded metal

permanent wiring system, or to a system having an

equipment-grounding conductor.

THREE PHASE OPERATION

Three phase MACHINES are not supplied with a power

cord. They must be permanently connected to the

building electrical system and grounded according to

the National Electrical Code. Since they must be

permanently connected to the building electrical

system, extension cords cannot be used with three

phase MACHINES.

7

EXTENSION CORDS

Use proper extension cords. Make sure

your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type

plug and matching receptacle which will accept the

machine’s plug. When using an extension cord, be sure

to use one heavy enough to carry the current of the

machine. An undersized cord will cause a drop in line

voltage, resulting in loss of power and overheating. Fig.

D-2 shows the correct gauge to use depending on the

cord length. If in doubt, use the next heavier gauge. The

smaller the gauge number, the heavier the cord.

Fig. D-2

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Ampere Total Length Gauge of

Rating Volts of Cord in Feet Extension Cord

0-6 240

up to

50 18 AWG

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

6-10 240

up to

50 18 AWG

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

10-12 240

up to

50 16 AWG

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

12-16 240

up to

50 14 AWG

12-16 240 50-100 12 AWG

12-16 240

GREATER THAN 100 FEET NOT RECOMMENDED

READ AND UNDERSTAND ALL

WARNINGS AND OPERATING INSTRUCTIONS BEFORE USING THIS EQUIPMENT. Failure to follow all

instructions listed at right, may result in electric

shock, fire, and/or serious personal injury or

property damage.

8

FUNCTIONAL DESCRIPTION

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from

all unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone,

gasoline or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household

floor paste wax.

NOTICE: THE PHOTO ON THE MANUAL COVER ILLUSTRATES THE

CURRENT PRODUCTION MODEL. ALL OTHER ILLUSTRATIONS CONTAINED

IN THE MANUAL ARE REPRESENTATIVE ONLY AND MAY NOT DEPICT THE

ACTUAL COLOR, LABELING OR ACCESSORIES AND ARE INTENDED TO

ILLUSTRATE TECHNIQUE ONLY.

CARTON CONTENTS

FOREWORD

Delta’s 12" Radial Arm Saws are built for capacity with versatility. They have a full 3¾" depth of cut at 90°, and 2½" depth

of cut at 45°. The saws can crosscut 14-3/8" in a single pass. They also have a unique turret arm action which permits

the motor assembly to rotate 360° above the work table.

A. Fence

B. Table boards (4)

C. Table

D. Table mounting bracket (2)

E. Track arm end cap and stop

F. Overarm elevating handle

G. Cutting head clamp

H. Wrenches

I. Legs (4)

J. 12" blade

K. Special wrench socket

L.

1

/4"-20x1/2" hex head cap screw

M. 5/

16" lock washer (2)

N. Round head screw (4)

O.

5

/16"-18x3/4" button head screws

P. Sheer pin

Q.

1

/

4" flat washer

R.

5

/16" flat washer

S. 5/16" flat washer

T.

5

/16" hex nut

U. 5/16" carriage head bolt

V. Cuttinghead assembly

W. Base and overarm assembly

C

J

DE

F

G

H

I

K

L

M

N

O

P

Q

R

U

T

S

V

W

A

B

9

ASSEMBLY

ASSEMBLY TOOLS REQUIRED

ASSEMBLY TIME ESTIMATE - 2-3 hrs.

* Blade wrenches (supplied)

*1/2” and 3/8” open end or socket wrenches (not included)

*5/16” hex wrench (not included)

* Flat screwdriver and hammer (not included)

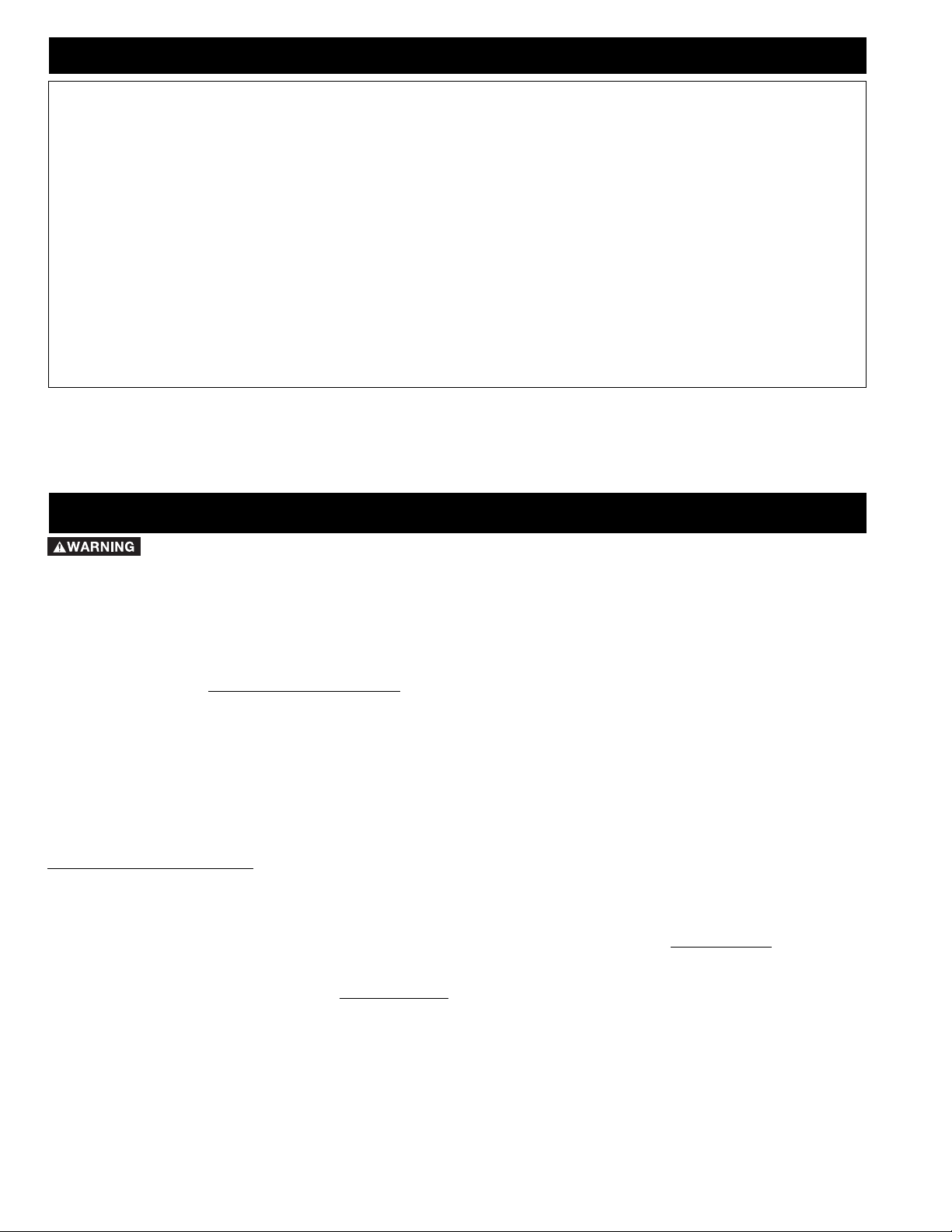

The following is an explanation of the operating controls of the Delta 12” Radial Saw. We suggest you study these

explanations carefully to familiarize yourself with the controls before turning on the power, to avoid damage to the saw

or personal injury.

A – TRACK ARM CLAMP KNOB. Controls swing of track arm

for all miter cutting operations. Locks track arm at any angle for

the full 360º rotation. To rotate track arm loosen clamp knob

and rotate arm. The arm will stop at the 0º and 45º positions

right and left. To move the arm past these points the track arm

index knob (B) must be pulled out. (Fig. 2)

B – TRACK ARM INDEX KNOB. Locates 0º and 45º position,

right and left, of the track arm. (Fig. 2)

C – YOKE INDEX LEVER. Locates each 90º position of the

yoke for ripping or cross-cutting operations. When rotating the

yoke the yoke clamp handle must first be loose. (Fig. 2)

D – YOKE CLAMP HANDLE. The yoke clamp handle must be

loose when rotating the yoke to the rip or cross-cut position.

(Fig. 3)

E – ANTI-KICKBACK DEVICE. When ripping, the yoke is positioned and clamped so that the blade is parallel to the fence.

The infeed side of the blade guard is lowered until it almost

touches the workpiece. The anti-kickback rod is then lowered

so that the fingers catch and hold the workpiece. Never rip

from the anti-kickback end of the blade guard. (Fig. 3)

F – OVERARM ELEVATING HANDLE. Controls the depth of

cut in all operations. Turning the handle raises or lowers the

overarm. (Fig. 2)

G – CUTTINGHEAD CLAMP KNOB. Locks cuttinghead at any

position on the track arm. When ripping the cutting clamp knob

must be tight. (Fig. 3)

H – BEVEL INDEX KNOB. Locates 0º and 45º and 90º

positions of the motor when bevel cutting. When tilting the

motor for bevel cutting, the bevel clamp handle must first be

loose. (Fig. 3)

J – BEVEL CLAMP LEVER. Controls tilt of motor for bevel

cutting operations. Locks motor at any desired angle on the

bevel scale. (Fig. 3)

K – TABLE CLAMP KNOBS. Allows the operator to quickly set

the desired fence position. (Fig. 3)

L – ON-OFF SWITCH. Conveniently placed at eye level; switch

can be turned on or off in an instant for added operator

protection. (Fig. 3)

M – MITER SCALE. Indicates degrees left and right for setting

track arm. (Fig. 2)

N – TRACK ARM STOP. (Located under the track arm.). See

(A) Fig. 58 on Page 24 for illustration. This stop prevents the

blade from contacting column when making straight cut-offs

with the motor tilted for a 45 degree bevel cut.

Fig. 2

Fig. 3

A

C

M

B

F

L

E

H

J

D

G

K

GUIDE TO PARTS

N

THE 12" RADIAL ARM SAW IS VERY HEAVY AND REQUIRES SEVERAL PEOPLE TO LIFT AND

MANUEVER IT DURING ASSEMBLY.

DO NOT OPERATE THIS MACHINE UNTIL YOU READ AND UNDERSTAND THE ENTIRE

INSTRUCTION MANUAL.

DISCONNECT MACHINE FROM POWER SOURCE.

10

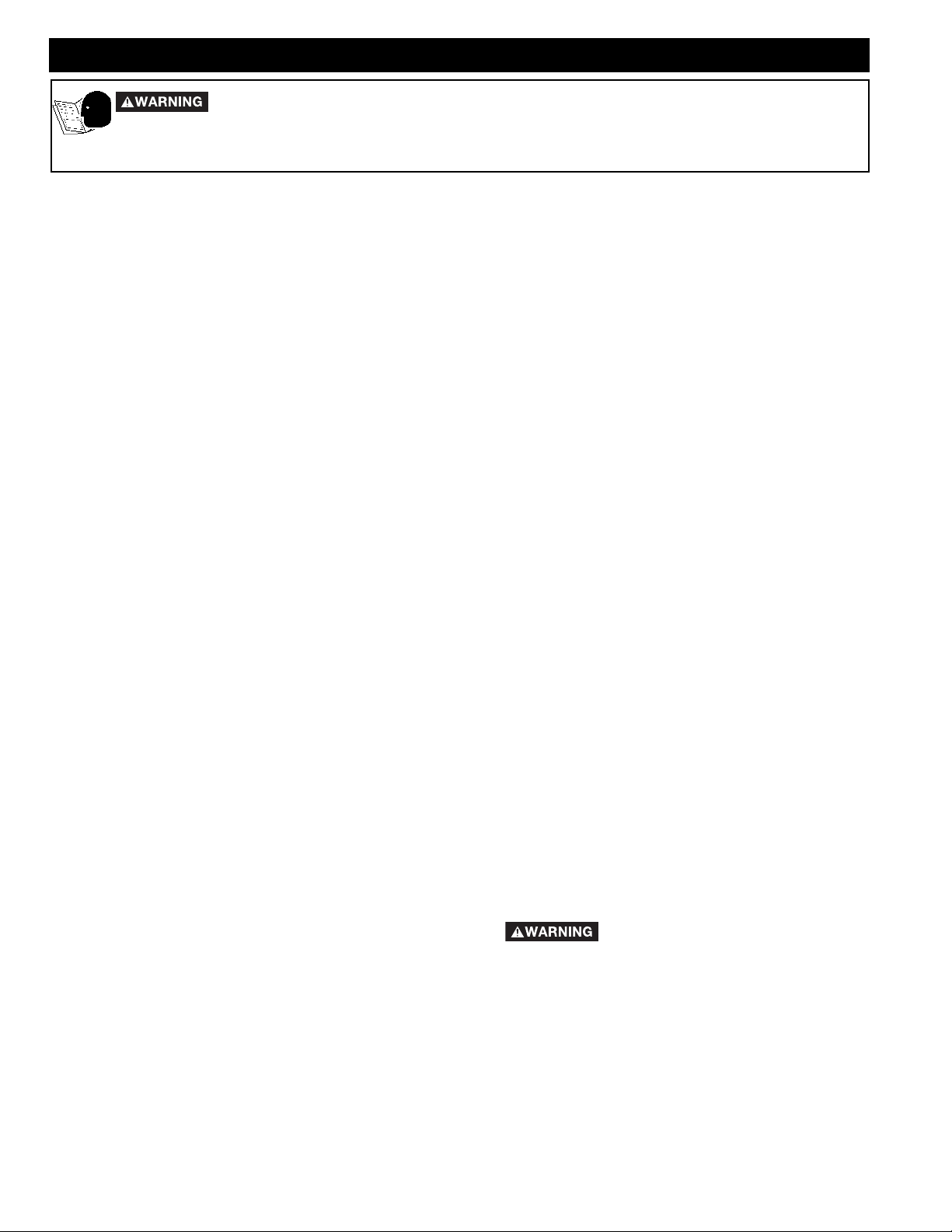

Fig. 4A

ASSEMBLING LEGS TO BASE

Mechanically lift the machine using a forklift and lifting

straps to support the machine. The four steel legs should

be attached to each corner of the base using sixteen

5/16-18 x 5/8" carriage head screws (A) Fig. 4A and Fig.

4B, 5/16" flat washers (B), 5/16" lockwashers (C) and

5/16" hex nuts (D).

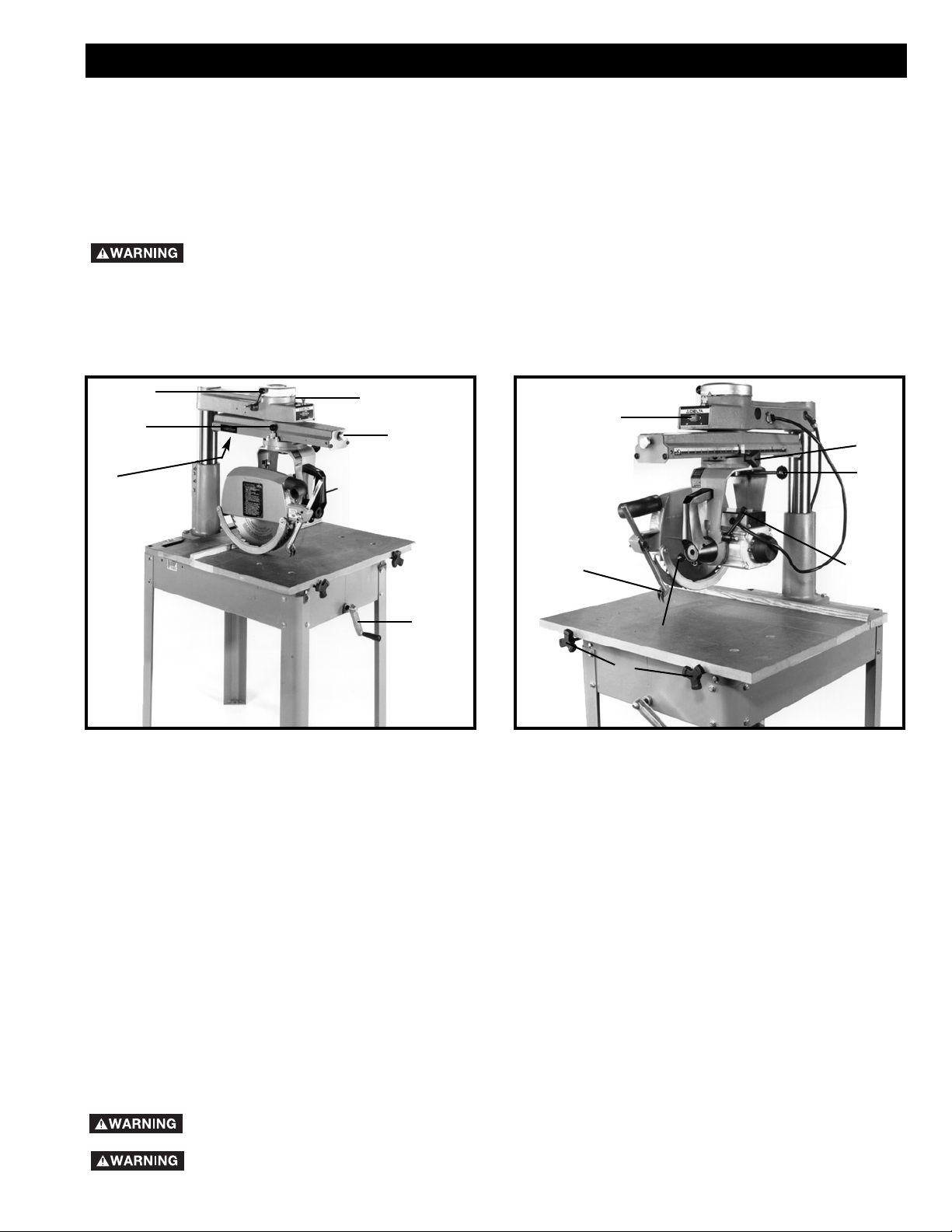

Fig. 5

Fig. 6

ASSEMBLING OVERARM ELEVATING

HANDLE

1. Insert shear pin (A) Fig. 5, into the hole in elevating

shaft (B). Using a hammer, tap this pin in to place as

show in Fig. 5.

2. Line up the slots in elevating handle (C) Fig. 5, with

shear pin (A) and place handle on shaft (B) making

certain the roll pin is engaged in the slots.

3. Fasten elevating handle (C) Fig. 6, to shaft (B) with

a 1/4"-20 x 1/2" hex head screw (D) and 1/4" flat washer

(E).

A

B

C

Fig. 4B

A

B

C

D

A

B

C

D

B

C

D

E

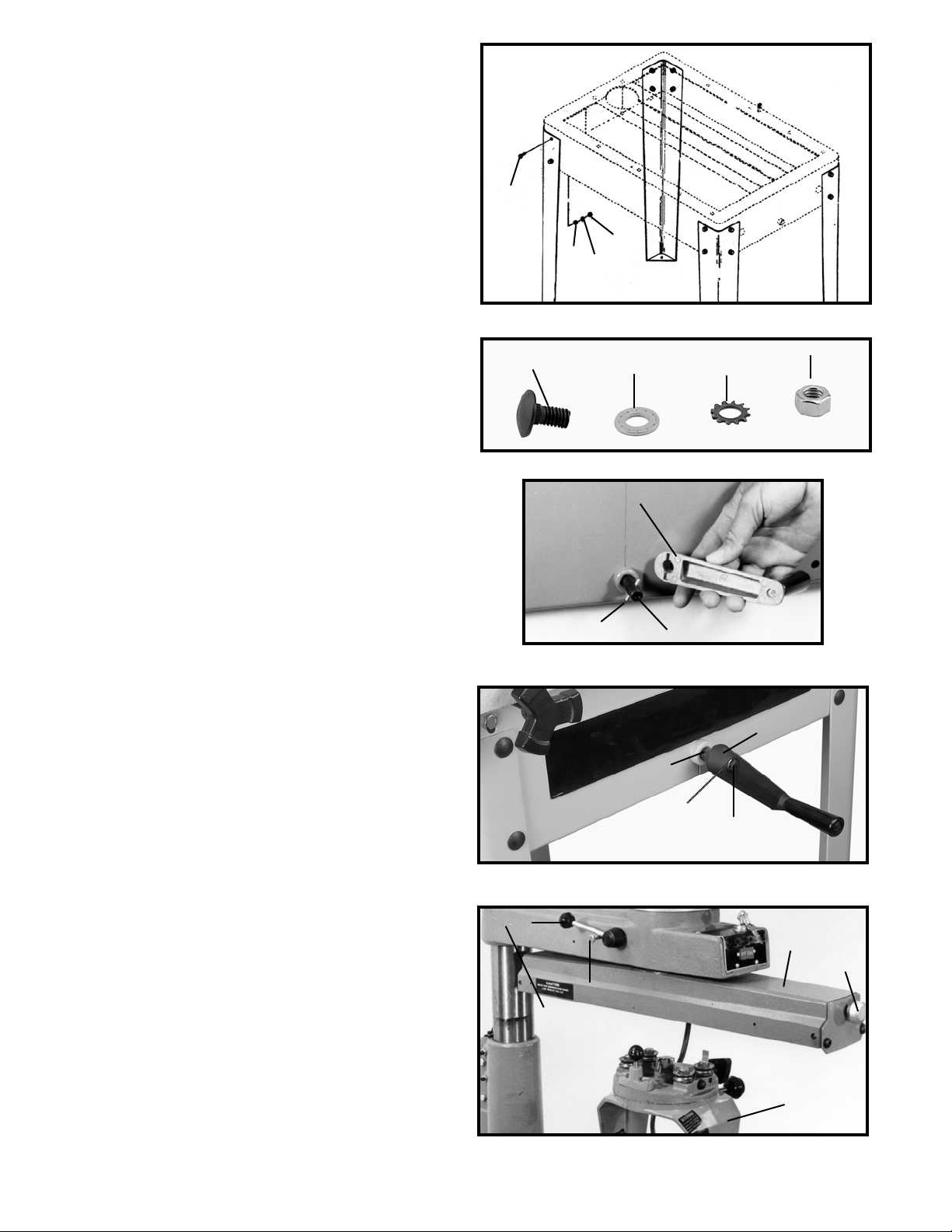

ASSEMBLING CUTTINGHEAD TO

TRACK ARM

1. Raise the track arm assembly (A) Fig. 7, by turning

overarm elevating handle (F) Fig. 2.

2. Remove packing material from around cuttinghead

assembly (B) Fig. 7.

Fig. 7

C

D

A

F

E

B

Loading...

Loading...