Porta-Nails PORTAMATIC 470, PORTAMATIC 472 Owner's Manual

PO Box 1257, Wilmington, NC 28402

910-283-9791 • 800-634-9281 • Fax 910-283-6264

Home Page: www.porta-nails.com E-mail: www.info@porta-nails.com

OWNER’S MANUAL

PORTAMATIC® 470 Hammerhead TL Nailer

PORTAMATIC® 472 Hammerhead S Stapler

For Tongue and Groove Solid Wood

& Hardwood Flooring

CAUTION - Read important safety instruc ons AND opera on

instruc ons BEFORE opera ng your Pneuma c Tool.

Your new Pneuma c Tool is capable of dependable performance throughout

its life me. To take full advantage of these capabili es you should thoroughly

understand the proper method and technique of its opera on. Therefore, we

suggest you read this manual before opera ng, and that you save it for future

reference.

For use with PORTAMATIC® 470 TL Nailers star ng with Serial No. 07042000.

For use with PORTAMATIC® 472 S Staplers star ng with Serial No. 05092000.

FORM P/N 470701 (4/22/2008)

2

INTRODUCTION

This fl ooring tool is a precision-built tool designed for high speed,

high volume fastening. These tools deliver effi cient, dependable

service when used correctly and with care. As with any fi ne power

tool, for best performance the manufacturer’s instruc ons must be

followed. Please study this manual before opera ng the tool and

understand the safety warning and cau ons. The instruc on on

installa on, opera on and maintenance should be read carefully, and

the manual kept for reference. NOTE: Addi onal safety measures

may be required because of your par cular applica on of the

tool. Contact your representa ve or distributor with any ques ons

concerning the tool and its use.

INDEX

INTRODUCTION 2

WARRANTY 3

TOOL SPECIFICATIONS 4

SAFETY INSTRUCTIONS 5

SAFE OPERATION 6

AIR SUPPLY AND CONNECTIONS 8

LUBRICATION 9

LOADING THE TOOL 9

TOOL OPERATION 11

MAINTAINING THE PNEUMATIC TOOL 12

TROUBLE SHOOTING 14

NAIL / STAP LE LENGTH DETERMINATION CHART 15

SERVICING ASSEMBLY / DISASSEMBLY I

NSTRUCTIONS 16

EXPLODED VIEW – 470 HAMMERHEAD TL NAILER 18

470 – PART LISTING 19

EXPLODED VIEW – 472 HAMMERHEAD S STAPLER 21

472 – PART LISTING 22

TL NAILER / S STAP LER ACCESSORIES 24

FASTENERS 25

NOTES: 26

31

“PNI is a proud Member of these Industry Associa ons”

30

NOTES:

3

LIMITED WARRANTY

(U.S. and Canada Only)

Porta-Nails, Inc. (PNI) is proud of the products it manufactures and warrants to the

original retail purchaser that the product purchased is free from defects in material

and workmanship, and agrees to repair or replace, at Porta-Nails’ op on, any

defec ve Porta-Nails branded pneuma c stapler or nailer for a period of one (1)

year from date of purchase. Warranty is not transferable. Proof of purchase date

required. This warranty covers only damage resul ng from defects in material or

workmanship; it does not cover condi ons or malfunc ons resul ng from normal

wear, neglect, abuse, accident or repairs a empted or made by other than our

na onal repair center or authorized warranty service centers. Driver blades,

bumpers, O-rings, pistons and piston rings are considered normally wearing parts.

For op mal performance of your Porta-Nails tool always use genuine Porta-Nails

fasteners and replacement parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. PORTA-NAILS SHALL NOT BE LIABLE FOR

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and countries do not allow limita ons on how long an implied warranty

lasts, or the exclusion or limita on of incidental or consequen al damages, so the

above limita ons or exclusions may not apply to you. This warranty gives you specifi c

legal rights, and you may also have other rights which vary from state to state and

country to country.

Returns for warranty service or repair must be issued an RMA number prior to being

returned. To obtain warranty service in the U.S. call our offi ces at 1-800-634-9281 to

obtain a Returned Merchandise Authoriza on (RMA) and instruc ons for returning

the product, or visit www.porta-nails.com for the loca on of the authorized service

center most convenient for you.

Returns should be sent to:

Porta-Nails, Inc.

A en on: Service Department

4235 US Hwy 421 North

Currie, NC 28435

4

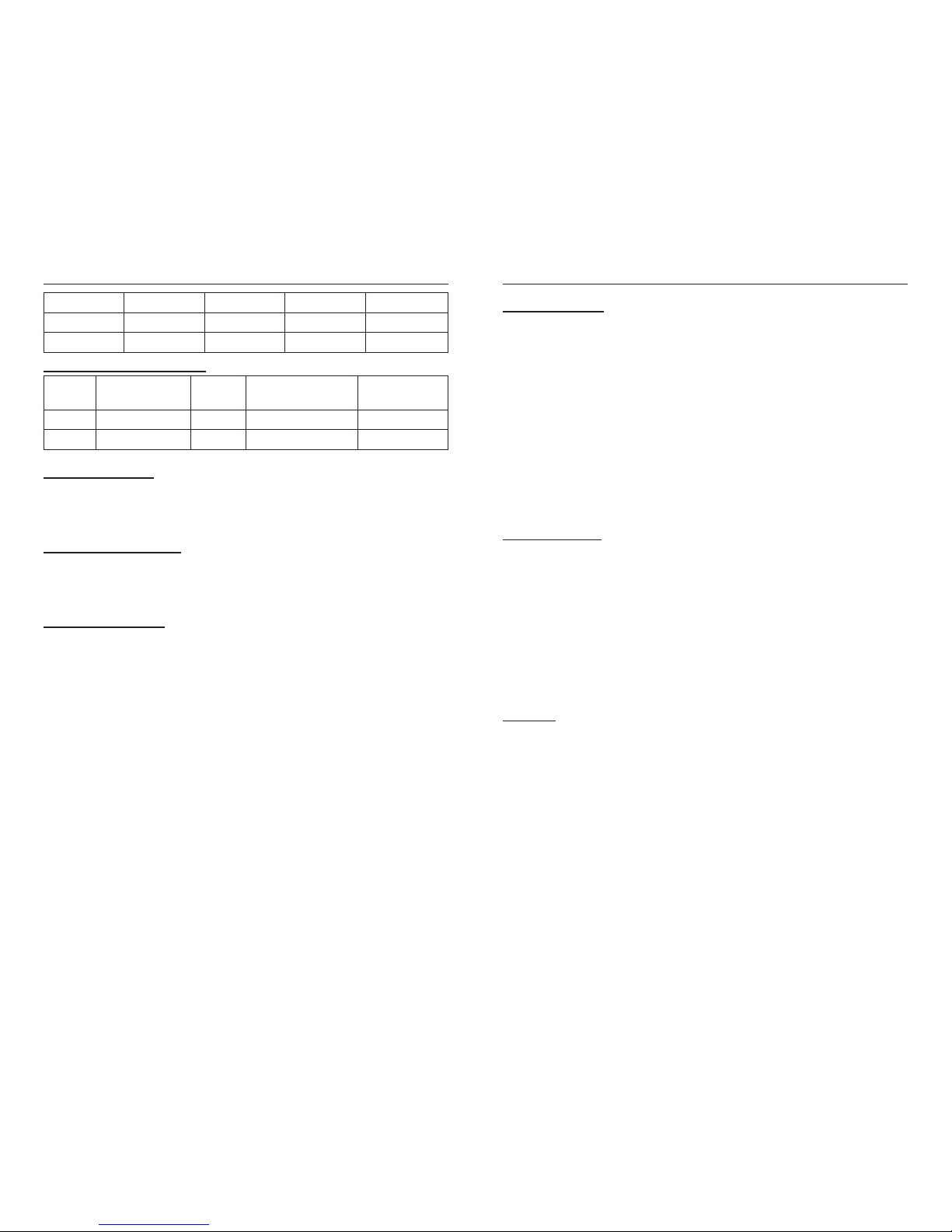

TOOL SPECIFICATIONS

Model Length Height Width Weight

470 18” 18.8” 3-1/8” 9.00 lbs.

472 18” 18.8” 3-1/8” 9.10 lbs.

FASTENER SPECIFICATIONS:

Model

Fastener

Type

Crown

Width Gauge Lengths

470 “T”, “L” Nail 16 Ga. 1-1/2”, 2”

472 Staple 1/2” 15-15-1/2 Ga. 1-1/2”, 2”

TOOL AIR FITTING:

This tool uses a 3/8” NPT male plug. The inside diameter should be

.275” (7mm) or larger. The fi ng must be capable of discharging

tool air pressure when disconnected from the air supply.

OPERATING PRESSURE:

70 to 90 PSI Select the opera ng pressure within this range for

best fastener performance. DO NOT EXCEED THIS RECOMMENDED

OPERATING PRESSURE.

AIR CONSUMPTION:

The Tool requires 4.2 cubic feet per minute (221 liters per minute)

of free air to operate at the rate of 60 fasteners per minute @ 80 PSI

Take the actual rate at which the tool will be run to determine the

amount of air required. For instance, if your fastener usage averages

30 fasteners per minute, you need 50% of the tool’s C.F.M. of free air

which is required to operate the tool at 60 fasteners per minute.

Cau on regarding Use of this Tool to Install Pre-fi nished Flooring

This Flooring Tool was designed for use in installing unfi nished

hardwood fl ooring. It can be used to install pre-fi nished fl ooring

when used with the Pre-Finish fl ooring accessory shoe (P/N 47090);

however, cau on must be used to ensure that the fi nish is not

damaged by the tool. In all fl ooring applica ons, it is recommended

that the tool be tested on a sample sec on to be certain that the

tool and technique of use do not leave marks on the fi nish. This

procedure should be followed before each job due to varia ons in

fl ooring and tool condi on.

29

FASTENERS

PORTA-NAILS “T”:

(For use with Model 470 Portama c TL and Model 421 Portama c Hammerhead 2)

42623 2” T-Nails (10 packages of 1000 Nails).

42629 2” T-Nails (Box of 1000 Nails)

Order in Qtys. of Ten (10).

42660 2” Stainless Steel T-Nails Box of 1000 Nails.

(ACQ Treated Lumber Approved).

42640 1-1/2” T-Nails - Box of 1000 Nails

Order in Qtys. of Five (5).

42646 1-3/16” T-Nails - Box of 1000 Nails

Order in Qtys. of Five (5).

PORTA-NAILS “L”:

(For use with Model 470 Portama c TL)

47020 2” L-Nails (10 packages of 1000 Nails)

4702 2” L-Nails - Box of 1000 Nails

Order in Qtys. of Ten (10).

47040 1-1/2” L-Nails (5 packages of 1000 Nails)

4704 1-1/2” L-Nails - Box of 1000 Nails

Order in Qtys. of Ten (10).

STAPLES:

(For use with Model 472 Portama c S)

47261 2” 15Ga. Staples (1000 Staples)

4722 2” 15Ga. Staples (5000 Staples)

47281 2” 15Ga. Stainless Steel Staples (1000 Staples)

(ACQ Treated Lumber Approved)

4725 2” 15Ga. Stainless Steel Staples (5000 Staples)

(ACQ Treated Lumber Approved)

47271 1-1/2” 15Ga. Staples (1000 Staples)

4724 1-1/2” 15Ga. Staples (7500 Staples)

28

TL NAILER / S STAPLER ACCESSORIES

Part No. Descrip on

47075 Hammer Assy – Graphite

47061 O-ring Kit

47060 Service Parts Kit

47062 Piston Rod Assembly

47065 Extension Handle Assembly – Short

47066 Extension Handle Spacer 4”

47067 Shoe Base Pad – 1/2” Flooring

47068 Oil – Tool

47011 Gasket

47069 Box Wrench

47070 Hex Wrench – 4 MM

47071 Hex Wrench – 5 MM

47072 Hex Wrench – 6 MM

47050 Carrying Case – 470 / 472

50231 Air Hose Kit

50232 Air Dryer Kit

50233 Air Filter / Regulator Kit

50170 Safety Glasses

50525 PortaPro-Air Compressor

47100 PortaJack-Pro Floor Tightening Jack

47090 Pre-Finished Flooring Shoe – 470 / 472

47061 O-ring Kit 47062 Piston Rod Assembly

Part No. Descrip on Part No. Descrip on

47002 O-ring - Cap 47012 Poppet

47007 O-ring – Plunger OD 47009 Piston Rod

47008 O-ring – Piston Rod OD 47016 Piston

47013 O-ring – Poppet ID 47008 O-ring – Piston Rod OD

47015 O-ring – Piston OD 47013 O-ring – Poppet ID

47015 O-ring – Piston OD

47060 Service Parts Kit

Part No. Descrip on

47023 Piston Cushion

47067 Shoe Base Pad – 1/2” Flooring

47068 Oil – Tool

47011 Gasket

47069 Box Wrench

47070 Hex Wrench – 4 MM

47071 Hex Wrench – 5 MM

47072 Hex Wrench – 6 MM

47061 O-ring Kit

5

SAFETY INSTRUCTIONS

Tool Opera on

The employer is responsible for ensuring that the manufacturer’s

tool opera ng/safety instruc ons are available to operators.

The employer and the tool operator are responsible for the safe use

of the tool.

The employer and tool operator are responsible for selec ng an

appropriate tool actua on system from op ons available, taking into

considera on the work applica ons for which the tool is used.

It is the responsibility of the employer and the tool operator to

ensure that the tools are used only when the tool operator and

all other personnel in the work area are wearing eye protec on

equipment and when required, other appropriate protec on

equipment such as head, hearing and foot protec on equipment.

Safety Eye and Face Protec on Equipment

Safety eye and face protec on equipment shall conform to the

requirements of ANSI Z87.1 and shall provide protec on against

fl ying par cles both from the front and side or shall be determined

by the U.S. Department of Labor’s Occupa onal Safety and Health

Administra on (OSHA) to provide protec on equivalent to eye

protec on conforming to the requirements of ANSI Z87.1 and shall

provide protec on against fl ying par cles both from the front and

side.

Head Protec on Equipment

Head protec on shall conform to American Na onal Standards

Ins tute Z89.1, “Protec ve Headwear for Industrial Workers”.

TOOL MAINTENANCE

When working on air tools note the warnings in this manual and use

extra care when evalua ng problem tools.

Responsibility for Proper Tool Maintenance

The employer and tool operator are responsible for assuring that the

tool is kept in safe working order as described in the Tool Opera ng/

Safety Instruc ons. Only qualifi ed personnel shall repair the tool.

The employer is responsible for ensuring that the manufacturer’s

tool maintenance instruc ons are available to personnel performing

maintenance.

Loading...

Loading...