Page 1

PO Box 1257, Wilmington, NC 28402

910-283-9791 • 800-634-9281 • Fax 910-283-6264

Home Page: www.porta-nails.com E-mail: www.info@porta-nails.com

OWNER’S MANUAL

PORTAMATIC® 470 Hammerhead TL Nailer

PORTAMATIC® 472 Hammerhead S Stapler

For Tongue and Groove Solid Wood

& Hardwood Flooring

CAUTION - Read important safety instruc ons AND opera on

instruc ons BEFORE opera ng your Pneuma c Tool.

Your new Pneuma c Tool is capable of dependable performance throughout

its life me. To take full advantage of these capabili es you should thoroughly

understand the proper method and technique of its opera on. Therefore, we

suggest you read this manual before opera ng, and that you save it for future

reference.

For use with PORTAMATIC® 470 TL Nailers star ng with Serial No. 07042000.

For use with PORTAMATIC® 472 S Staplers star ng with Serial No. 05092000.

FORM P/N 470701 (4/22/2008)

Page 2

2

INTRODUCTION

This fl ooring tool is a precision-built tool designed for high speed,

high volume fastening. These tools deliver effi cient, dependable

service when used correctly and with care. As with any fi ne power

tool, for best performance the manufacturer’s instruc ons must be

followed. Please study this manual before opera ng the tool and

understand the safety warning and cau ons. The instruc on on

installa on, opera on and maintenance should be read carefully, and

the manual kept for reference. NOTE: Addi onal safety measures

may be required because of your par cular applica on of the

tool. Contact your representa ve or distributor with any ques ons

concerning the tool and its use.

INDEX

INTRODUCTION 2

WARRANTY 3

TOOL SPECIFICATIONS 4

SAFETY INSTRUCTIONS 5

SAFE OPERATION 6

AIR SUPPLY AND CONNECTIONS 8

LUBRICATION 9

LOADING THE TOOL 9

TOOL OPERATION 11

MAINTAINING THE PNEUMATIC TOOL 12

TROUBLE SHOOTING 14

NAIL / STAP LE LENGTH DETERMINATION CHART 15

SERVICING ASSEMBLY / DISASSEMBLY I

NSTRUCTIONS 16

EXPLODED VIEW – 470 HAMMERHEAD TL NAILER 18

470 – PART LISTING 19

EXPLODED VIEW – 472 HAMMERHEAD S STAPLER 21

472 – PART LISTING 22

TL NAILER / S STAP LER ACCESSORIES 24

FASTENERS 25

NOTES: 26

31

“PNI is a proud Member of these Industry Associa ons”

Page 3

30

NOTES:

3

LIMITED WARRANTY

(U.S. and Canada Only)

Porta-Nails, Inc. (PNI) is proud of the products it manufactures and warrants to the

original retail purchaser that the product purchased is free from defects in material

and workmanship, and agrees to repair or replace, at Porta-Nails’ op on, any

defec ve Porta-Nails branded pneuma c stapler or nailer for a period of one (1)

year from date of purchase. Warranty is not transferable. Proof of purchase date

required. This warranty covers only damage resul ng from defects in material or

workmanship; it does not cover condi ons or malfunc ons resul ng from normal

wear, neglect, abuse, accident or repairs a empted or made by other than our

na onal repair center or authorized warranty service centers. Driver blades,

bumpers, O-rings, pistons and piston rings are considered normally wearing parts.

For op mal performance of your Porta-Nails tool always use genuine Porta-Nails

fasteners and replacement parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING BUT NOT LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE. PORTA-NAILS SHALL NOT BE LIABLE FOR

ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and countries do not allow limita ons on how long an implied warranty

lasts, or the exclusion or limita on of incidental or consequen al damages, so the

above limita ons or exclusions may not apply to you. This warranty gives you specifi c

legal rights, and you may also have other rights which vary from state to state and

country to country.

Returns for warranty service or repair must be issued an RMA number prior to being

returned. To obtain warranty service in the U.S. call our offi ces at 1-800-634-9281 to

obtain a Returned Merchandise Authoriza on (RMA) and instruc ons for returning

the product, or visit www.porta-nails.com for the loca on of the authorized service

center most convenient for you.

Returns should be sent to:

Porta-Nails, Inc.

A en on: Service Department

4235 US Hwy 421 North

Currie, NC 28435

Page 4

4

TOOL SPECIFICATIONS

Model Length Height Width Weight

470 18” 18.8” 3-1/8” 9.00 lbs.

472 18” 18.8” 3-1/8” 9.10 lbs.

FASTENER SPECIFICATIONS:

Model

Fastener

Type

Crown

Width Gauge Lengths

470 “T”, “L” Nail 16 Ga. 1-1/2”, 2”

472 Staple 1/2” 15-15-1/2 Ga. 1-1/2”, 2”

TOOL AIR FITTING:

This tool uses a 3/8” NPT male plug. The inside diameter should be

.275” (7mm) or larger. The fi ng must be capable of discharging

tool air pressure when disconnected from the air supply.

OPERATING PRESSURE:

70 to 90 PSI Select the opera ng pressure within this range for

best fastener performance. DO NOT EXCEED THIS RECOMMENDED

OPERATING PRESSURE.

AIR CONSUMPTION:

The Tool requires 4.2 cubic feet per minute (221 liters per minute)

of free air to operate at the rate of 60 fasteners per minute @ 80 PSI

Take the actual rate at which the tool will be run to determine the

amount of air required. For instance, if your fastener usage averages

30 fasteners per minute, you need 50% of the tool’s C.F.M. of free air

which is required to operate the tool at 60 fasteners per minute.

Cau on regarding Use of this Tool to Install Pre-fi nished Flooring

This Flooring Tool was designed for use in installing unfi nished

hardwood fl ooring. It can be used to install pre-fi nished fl ooring

when used with the Pre-Finish fl ooring accessory shoe (P/N 47090);

however, cau on must be used to ensure that the fi nish is not

damaged by the tool. In all fl ooring applica ons, it is recommended

that the tool be tested on a sample sec on to be certain that the

tool and technique of use do not leave marks on the fi nish. This

procedure should be followed before each job due to varia ons in

fl ooring and tool condi on.

29

FASTENERS

PORTA-NAILS “T”:

(For use with Model 470 Portama c TL and Model 421 Portama c Hammerhead 2)

42623 2” T-Nails (10 packages of 1000 Nails).

42629 2” T-Nails (Box of 1000 Nails)

Order in Qtys. of Ten (10).

42660 2” Stainless Steel T-Nails Box of 1000 Nails.

(ACQ Treated Lumber Approved).

42640 1-1/2” T-Nails - Box of 1000 Nails

Order in Qtys. of Five (5).

42646 1-3/16” T-Nails - Box of 1000 Nails

Order in Qtys. of Five (5).

PORTA-NAILS “L”:

(For use with Model 470 Portama c TL)

47020 2” L-Nails (10 packages of 1000 Nails)

4702 2” L-Nails - Box of 1000 Nails

Order in Qtys. of Ten (10).

47040 1-1/2” L-Nails (5 packages of 1000 Nails)

4704 1-1/2” L-Nails - Box of 1000 Nails

Order in Qtys. of Ten (10).

STAPLES:

(For use with Model 472 Portama c S)

47261 2” 15Ga. Staples (1000 Staples)

4722 2” 15Ga. Staples (5000 Staples)

47281 2” 15Ga. Stainless Steel Staples (1000 Staples)

(ACQ Treated Lumber Approved)

4725 2” 15Ga. Stainless Steel Staples (5000 Staples)

(ACQ Treated Lumber Approved)

47271 1-1/2” 15Ga. Staples (1000 Staples)

4724 1-1/2” 15Ga. Staples (7500 Staples)

Page 5

28

TL NAILER / S STAPLER ACCESSORIES

Part No. Descrip on

47075 Hammer Assy – Graphite

47061 O-ring Kit

47060 Service Parts Kit

47062 Piston Rod Assembly

47065 Extension Handle Assembly – Short

47066 Extension Handle Spacer 4”

47067 Shoe Base Pad – 1/2” Flooring

47068 Oil – Tool

47011 Gasket

47069 Box Wrench

47070 Hex Wrench – 4 MM

47071 Hex Wrench – 5 MM

47072 Hex Wrench – 6 MM

47050 Carrying Case – 470 / 472

50231 Air Hose Kit

50232 Air Dryer Kit

50233 Air Filter / Regulator Kit

50170 Safety Glasses

50525 PortaPro-Air Compressor

47100 PortaJack-Pro Floor Tightening Jack

47090 Pre-Finished Flooring Shoe – 470 / 472

47061 O-ring Kit 47062 Piston Rod Assembly

Part No. Descrip on Part No. Descrip on

47002 O-ring - Cap 47012 Poppet

47007 O-ring – Plunger OD 47009 Piston Rod

47008 O-ring – Piston Rod OD 47016 Piston

47013 O-ring – Poppet ID 47008 O-ring – Piston Rod OD

47015 O-ring – Piston OD 47013 O-ring – Poppet ID

47015 O-ring – Piston OD

47060 Service Parts Kit

Part No. Descrip on

47023 Piston Cushion

47067 Shoe Base Pad – 1/2” Flooring

47068 Oil – Tool

47011 Gasket

47069 Box Wrench

47070 Hex Wrench – 4 MM

47071 Hex Wrench – 5 MM

47072 Hex Wrench – 6 MM

47061 O-ring Kit

5

SAFETY INSTRUCTIONS

Tool Opera on

The employer is responsible for ensuring that the manufacturer’s

tool opera ng/safety instruc ons are available to operators.

The employer and the tool operator are responsible for the safe use

of the tool.

The employer and tool operator are responsible for selec ng an

appropriate tool actua on system from op ons available, taking into

considera on the work applica ons for which the tool is used.

It is the responsibility of the employer and the tool operator to

ensure that the tools are used only when the tool operator and

all other personnel in the work area are wearing eye protec on

equipment and when required, other appropriate protec on

equipment such as head, hearing and foot protec on equipment.

Safety Eye and Face Protec on Equipment

Safety eye and face protec on equipment shall conform to the

requirements of ANSI Z87.1 and shall provide protec on against

fl ying par cles both from the front and side or shall be determined

by the U.S. Department of Labor’s Occupa onal Safety and Health

Administra on (OSHA) to provide protec on equivalent to eye

protec on conforming to the requirements of ANSI Z87.1 and shall

provide protec on against fl ying par cles both from the front and

side.

Head Protec on Equipment

Head protec on shall conform to American Na onal Standards

Ins tute Z89.1, “Protec ve Headwear for Industrial Workers”.

TOOL MAINTENANCE

When working on air tools note the warnings in this manual and use

extra care when evalua ng problem tools.

Responsibility for Proper Tool Maintenance

The employer and tool operator are responsible for assuring that the

tool is kept in safe working order as described in the Tool Opera ng/

Safety Instruc ons. Only qualifi ed personnel shall repair the tool.

The employer is responsible for ensuring that the manufacturer’s

tool maintenance instruc ons are available to personnel performing

maintenance.

Page 6

6

Repair Parts and Accessories

Tools shall be repaired or equipped only with parts or accessories

that are supplied or recommended by the tool manufacturer, or with

parts or accessories which perform equivalently to those supplied or

recommended by the tool manufacturer.

Tools Needing Repair

The employer shall ensure that tools which require repair are

not further used before repair. Tags and physical segrega on are

recommended means of control. OSHA’s General Industry and

Construc on regula ons require the use of tags.

Tool Maintenance Instruc ons

The employer is responsible for ensuring that the tool maintenance

instruc ons are available to the appropriate personnel.

The employer is responsible for the proper maintenance of all tools

in its possession.

Only qualifi ed personnel shall repair the tool and shall use

parts or accessories that are supplied or recommended by the

tool manufacturer, or with parts or accessories which perform

equivalently to those supplied or recommended by the tool

manufacturer.

TOOL OPERATING/SAFETY INSTRUCTIONS

Eye Protec on

WARNING:

!

Eye protec on equipment must be worn by the

operator and other people in the work area.

WARNING:

!

The employer is responsible to enforce the use of

eye protec on equipment by the tool operator

and all other personnel in the work area.

Opera on

Appropriate personal protec ve equipment is to be worn.

Inspect the tool before opera ng to:

Establish use of proper power source as set forth in this •

manual under Power Source.

Determine that the tool is in proper working order.•

An improperly func oning tool must not be used.

Tool Handling

Always assume that the tool contains fasteners.•

27

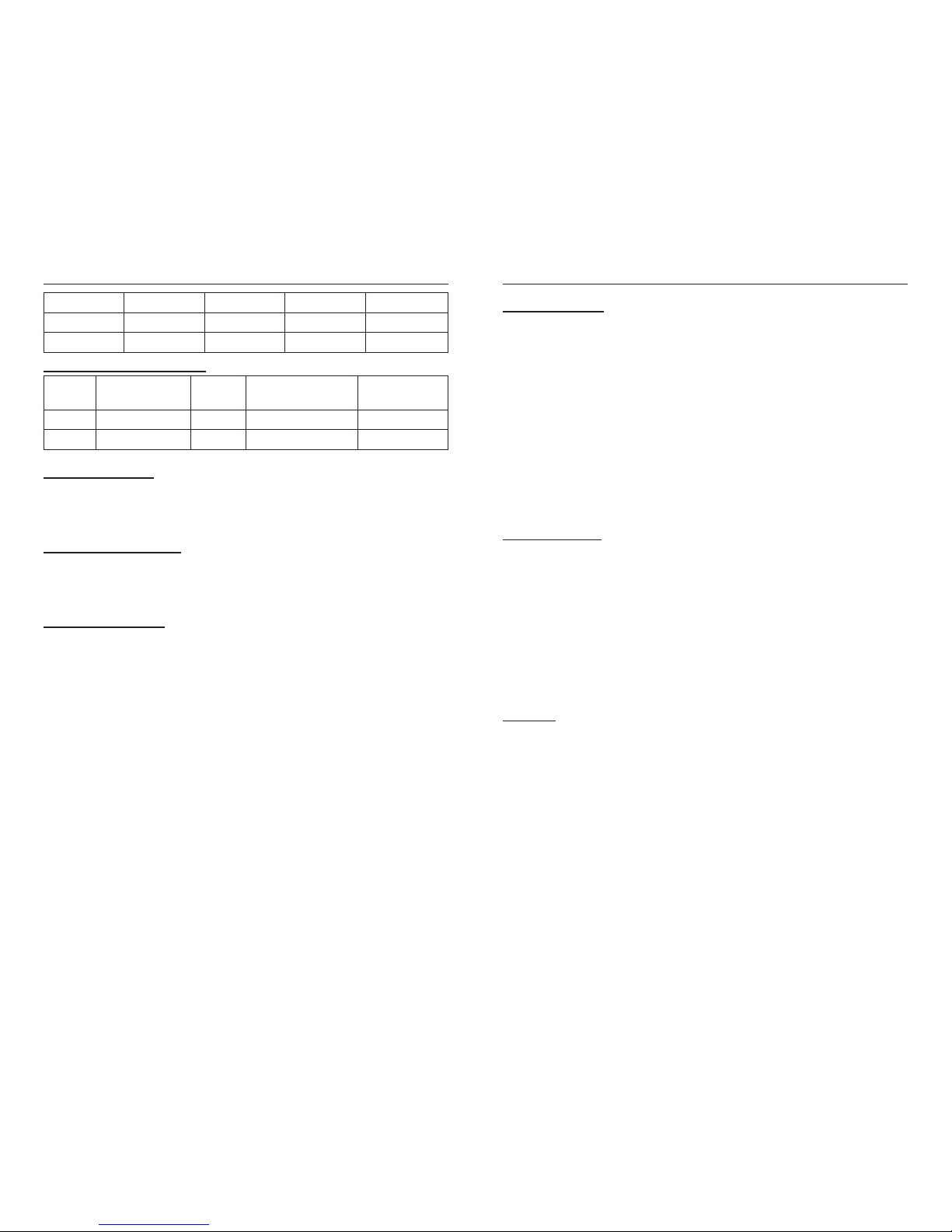

NAIL / STAPLE LENGTH DETERMINATION CHART

This chart will assist you in determining the proper length of NAIL/

STAPLE to use for various thickness of fl ooring when the sub-fl ooring

member varies as to species and thickness and for determina on for

use when installing over concrete. Ver cal penetra on of the NAIL/

STAPLE under the hardwood fl oor is shown for each applica on.

31/32"

19/32"

1 1/8"

25/32"

3/4" FLOO RING

1/2" FLOO RING

2" FASTENER

1-1/2" FASTENER

2" FASTENER

1-1/2" FASTENER

Page 7

26

33 47074 SCREW – HANDLE CAP

34 47236 SCREW – MAGAZINE STAND-OFF

35 47241 SCREW – PUSHER STOP

36 47044 CONSTANT FORCE SPRING

37 47037 MAGAZINE SPACER / STAND-OFF

38 47235 STAPLE GUIDE UNIT

39 47042 SCREW – CONSTANT FORCE SPRING

40 47240 PUSHER FINGER

41 47232 SCREWS – NOSE / MAGAZINE

42 – NOT ASSIGNED

43 – NOT ASSIGNED

44 – NOT ASSIGNED

45, 45A 47028 SCREW – FOOT / MAGAZINE

46 47029 FOOT

47 47032 SPRING PIN – FOOT / DRIVER GUIDE PLATE

48 47244 DRIVER GUIDE PLATE – 472

49 47242 NOSE – 472

50 47234 MAGAZINE – 472

51 47239 SCREWS – MAGAZINE / STAPLE GUIDE

52 47027 SHOE

53 47025 SHOE BASE PAD

54 47024 SCREW – SHOE BASE

55, 55A 47026 SCREWS – SHOE / FOOT / BODY

56* 47047 LOCK NUT – SHOE BASE

57* 47075 HAMMER ASSY – GRAPHITE

*NOT SHOWN IN ILLUSTRATION

7

Do not point the tool toward yourself or anyone whether it •

contains fasteners or not.

Do not actuate the tool unless the tool is placed fi rmly against •

the work piece.

Respect the tool as a working implement.•

Never engage in horseplay.•

Do not hold or carry the tool with a fi nger on the trigger.•

Do not load the tool with fasteners when any one of the •

opera ng controls is ac vated.

Do not operate the tool with any power source other than •

that specifi ed in the tool opera ng/safety instruc ons.

Opera ng Controls

Do not remove, tamper with, or otherwise cause the tool •

opera ng controls to become inoperable.

Do not operate a tool if any por on of the tool opera ng •

controls is inoperable, disconnected, altered, or not working

properly.

Disconnec ng the Tool

Disconnect the tool from the power source when:

Una ended.•

Performing any maintenance or repair.•

Clearing a jam.•

Moving the tool to a new loca on.•

Recommended Fasteners

Use only fasteners made or recommended by the tool manufacturer,

or fastener which perform equivalently to those recommended by

the manufacturer.

Tool Modifi ca on

The wri en approval of the tool manufacturer must be obtained

prior to making any modifi ca ons to the tool.

Other Detailed Informa on

Refer to the tool maintenance instruc ons for detailed informa on

on the proper maintenance of the tool.

Page 8

8

Actua on System

This tool u lizes a dual trigger single sequen al actua on system.

The safety trigger located within the handle must be held depressed

and the ram cap must be struck with the included mallet to

actuate the tool. The ram cap must be struck with the mallet for

each subsequent actua on provided that the safety trigger is held

depressed for subsequent actua ons. The safety trigger is included

to prevent accidental actua on of the tool. Repeated a empts to

actuate the tool while the safety trigger is released may damage the

safety mechanism and the tool.

Power Source

The compressed air power source shall be pressure-regulated. The

regulated pressure must not exceed the maximum air pressure

marked on the tool. If a regulator fails, the pressure delivered to the

tool must not exceed 1.5 mes the maximum air pressure, or 200

PSIG, whichever is greater. The tool normally is not operated at the

maximum air pressure but at a lower pressure determined by the

type of fastener used, the work piece, and other condi ons of use.

Hazardous Power Source

Hazardous power sources shall not be used. Hazardous power

sources include, but are not limited to the following:

Reac ve gases including, but not limited to oxygen and •

combus ble gases.

Pressure sources that can deliver in excess of 1.5 mes the •

maximum air pressure of the tool or 200 PSIG, whichever is

greater, if a regulator fails.

Regulator

Pressure regulators shall be used to limit the air pressure supplied

to the tool. Regulators shall be set at an opera ng pressure which is

lower than or equal to the tool manufacturer’s specifi ed maximum

air pressure.

Hose

Air supply hoses shall have a minimum working pressure ra ng equal

to or greater than the pressure from the power source if a regulator

fails, or 150 PSIG, whichever is greater.

Disconnect

Tools shall be fi ed with a fi ng or hose coupling on or near the tool

25

472 – PART LISTING

472 Part No. Descrip on

1 47001 RAM CAP

2 47002 O-RING – CAP

3, 3A 47003 SCREW – SOCKET HEAD CAP

4 47004 CAP

5, 5A 47005 SCREWS – PLUNGER

6 47006 PLUNGER

7 47007 O-RING - PLUNGER OD

8 47063 RETURN SPRING

9 47011 GASKET

10 47008 O-RING – PISTON ROD OD

11 47009 PISTON ROD

12 47012 POPPET

13 47013 O-RING – POPPET ID

14 47022 SEAL – POPPET OD

15 47016 PISTON

16 47015 O-RING – PISTON OD

17 47010 BALL PIN

18 47243 DRIVER BLADE – 472

19 47017 LOCK NUT – PISTON/DRIVER BLADE

20 47023 PISTON CUSHION

21 47021 PLATE

22 47019 BODY

23 47035 SAFETY PLATE

24 47046 SCREW – SAFETY PLATE

25 47049 SPRING – SAFETY

26 47051 CABLE – SAFETY

27 47058 ELBOW

28 47052 QUICK CONNECT - MALE

29 47045 HANDLE

30 47053 SAFETY TRIGGER

31 47054 PIN – SAFETY TRIGGER

32 47073 CAP – HANDLE

Page 9

24

EXPLODED VIEW – 472 HAMMERHEAD S STAPLER

9

in such a manner that all compressed air in the tool is discharged at

the me the fi ng or hose coupling is disconnected.

TOOL OPERATION

BEFORE HANDLING OR OPERATING THIS TOOL READ AND

UNDERSTAND THE WARNINGS CONTAINED IN THIS MANUAL.

IN ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS MANUAL

OBSERVE THE FOLLOWING FOR SAFE OPERATION.

Use the pneuma c tool only for the purpose for which it was •

designed.

Do not e, tape, or otherwise disable the safety trigger as this •

could result in accidental discharge of the tool causing injury to

yourself and others.

Never use this tool in a manner that could cause a fastener to •

be directed toward the user or others in the work area.

Do not strike the ram/actuator without pulling the safety •

trigger. Hi ng the tool repeatedly with the safety interlock

engaged will severely damage the safety mechanism and the

tool. This abuse and damage is not covered by the warranty.

Do not use the tool as a hammer.•

Always carry the tool by the handle. Never carry the tool by •

the air hose.

Always be aware that misuse and improper handling of this tool •

can cause injury to yourself and others.

Never leave a tool una ended with the air hose a ached.•

Do not operate this tool if it does not contain a legible •

WARNING LABEL.

Do not con nue to use a tool that leaks air or does not func on •

properly. No fy your nearest store representa ve if your tool

con nues to experience func onal problems.

Always handle the tool with care. Never engage in horseplay. •

Never pull the trigger unless nose is directed toward the

work. Keep others a safe distance form the tool while tool is in

opera on as accidental actua on may occur, possibly causing

injury.

The operator must not hold the safety trigger pulled except •

during fastening opera on as serious injury could result if the

ram cap accidentally contacted someone or something with

Page 10

10

enough force to cause the tool to cycle.

Keep hands and body away from the discharge area of the tool. •

The tool may bounce from the recoil of driving a fastener and

an unwanted second fastener may be driven possibly causing

injury.

When loading tool, never place a hand or any part of body in •

fastener discharge area of tool, never point tool at anyone,

do not pull the safety trigger or depress the ram/actuator as

accidental actua on may occur, possibly causing injury.

Always disconnect the air supply before making adjustments, •

when servicing the tool, when clearing a jam, when tool is not

in use, or when moving to a diff erent work area, as accidental

actua on may occur, possibly causing injury.

Check opera on of the safety mechanism frequently. Do not •

use the tool if the safety is not working correctly as accidental

driving of a fastener may result. Do not interfere with the

proper opera on of the safety mechanism.

The safety trigger is a safety device and should only be pulled •

when the tool is in proper posi on on the work surface and

before the ram/actuator is struck with the mallet. Do not e

or tape down the safety trigger as the tool could discharge if

dropped on the plunger. The tool will not fi re unless the trigger

is pulled before striking the ram/actuator with the mallet.

Do not use the safety as a disabling mechanism for the ram/•

actuator in order to use the tool to rack the wood. This will

severely damage the mechanism and the tool. This abuse and

damage is not covered by the warranty. Use the mallet to rack

the fl ooring, not the tool.

Do not strike the ram/actuator without pulling the safety •

trigger! Hi ng the tool repeatedly with the safety engaged will

damage the safety mechanism and the tool.

Do not drive fasteners on top of other fasteners or with the •

tool at an overly steep angle as this may cause defl ec on of

fasteners which could cause injury.

Do not strike the ram/actuator or any part of the tool with the •

metal por on of the mallet. Use the rubber capped end only to

prevent possible injury and/or damage to the tool.

Do not drive fasteners close to the end of the work piece as the •

wood may split, allowing the fastener to be defl ected possibly

23

33 47074 SCREW – HANDLE CAP

34 47036 SCREW – MAGAZINE STAND-OFF

35 47048 ROLLER – SPRING

36 47044 CONSTANT FORCE SPRING

37 47037 MAGAZINE SPACER / STAND-OFF

38 47043 ROLLER WHEEL

39 47042 SCREW – CONSTANT FORCE SPRING

40 47041 PUSHER FINGER

41 47057 SPRING – COMPRESSION

42 47039 PUSHER BRACKET

43 47056 O-RING – PUSHER PIVOT PIN

44 47055 PUSHER PIVOT PIN

45, 45A 47028 SCREWS – FOOT / MAGAZINE

46 47029 FOOT

47 47032 SPRING PIN – FOOT / DRIVER GUIDE PLATE

48 47031 DRIVER GUIDE PLATE

49 47033 NOSE – 470 – T/L

50 47034 MAGAZINE – 470 – T/L

51 47038 NUT – MAGAZINE / STANDOFF SCREWS

52 47027 SHOE

53 47025 SHOE BASE PAD

54 47024 SCREW – SHOE BASE

55, 55A 47026 SCREWS – SHOE / FOOT / BODY

56* 47047 LOCK NUT – SHOE BASE

57* 47075 HAMMER ASSY – GRAPHITE

*NOT SHOWN IN ILLUSTRATION

Page 11

22

470 – PART LISTING

470 Part No. Descrip on

1 47001 RAM CAP

2 47002 O-RING – CAP

3, 3A 47003 SCREW – SOCKET HEAD CAP

4 47004 CAP

5, 5A 47005 SCREWS – PLUNGER

6 47006 PLUNGER

7 47007 O-RING - PLUNGER OD

8 47063 RETURN SPRING

9 47011 GASKET

10 47008 O-RING – PISTON ROD OD

11 47009 PISTON ROD

12 47012 POPPET

13 47013 O-RING – POPPET ID

14 47022 SEAL – POPPET OD

15 47016 PISTON

16 47015 O-RING – PISTON OD

17 47010 BALL PIN

18 47014 DRIVER BLADE

19 47017 LOCK NUT – PISTON/DRIVER BLADE

20 47023 PISTON CUSHION

21 47021 PLATE

22 47019 BODY

23 47035 SAFETY PLATE

24 47046 SCREW – SAFETY PLATE

25 47049 SPRING – SAFETY

26 47051 CABLE – SAFETY

27 47058 ELBOW

28 47052 QUICK CONNECT - MALE

29 47045 HANDLE

30 47053 SAFETY TRIGGER

31 47054 PIN – SAFETY TRIGGER

32 47073 CAP – HANDLE

11

causing an injury.

Do not overdrive fasteners. NOFMA states that one reason for •

split tongues is over driving.

Page 12

12

AIR SUPPLY AND CONNECTIONS

FITTINGS:

Install a male plug on the tool which is free fl owing and which will

release air pressure from the tool when disconnected from the

supply source.

HOSES:

Air hoses should have a minimum of 150 PSI working pressure ra ng

or 150 percent of the maximum pressure that could be produced

in the air system. The supply hose should contain a fi ng that will

provide “quick disconnec ng” from the male plug on the tool.

SUPPLY SOURCE:

Use only clean regulated compressed air as a power source for this

tool. NEVER USE OXYGEN, COMBUSTIBLE GASES, OR BOTTLED

GASES, AS A POWER SOURCE FOR THIS TOOL AS TOOL MAY

EXPLODE.

REGULATOR:

A pressure regulator with an opera ng pressure of 0-125 PSI is

required to control the opera ng pressure for safe opera on of this

tool. Do not connect this tool to air pressure which can poten ally

exceed 200 PSI as tool may fracture or burst, possibly causing injury.

OPERATING PRESSURE:

Do not exceed recommended maximum opera ng pressure as tool

wear will be greatly increased. The air supply must be capable of

maintaining the opera ng pressure at the tool. Pressure drops in

the air supply can reduce the tool’s driving power. Refer to “TOOL

SPECIFICATIONS” for se ng the correct opera ng pressure of tool.

FILTER:

Dirt and water in the air supply are major causes of wear in

pneuma c tools. A fi lter will help to get the best performance and

minimum wear from the tool. The fi lter must have adequate fl ow

capacity for the specifi c installa on. The fi lter has to be kept clean

to be eff ec ve in providing clean compressed air to the tool. Consult

the manufacturer’s instruc ons on proper maintenance of your fi lter.

A dirty and clogged fi lter will cause a pressure drop which will reduce

the tool’s performance.

LOADING THE TOOL

Never place a hand or any other part of the body in nail discharge •

21

EXPLODED VIEW – 470 HAMMERHEAD TL NAILER

Page 13

20

Replace the Cap with four (4) Socket Head Cap Screws and 17.

ghten.

Replace the Ram Cap.18.

Check the tool opera on as explained in the Owner’s Manual and 19.

inspect for leaks.

DETAILS OF 47062 PISTON ROD ASSEMBLY

13

area of tool while the air supply is connected.

Never point the tool at anyone else.•

Never engage in horseplay.•

Never pull the trigger unless nose is directed at the work.•

Always handle the tool with care.•

Do not pull the trigger or depress the trip mechanism while loading •

the tool.

PORTAMATIC® 470 Hammerhead TL Nailer

NAIL LOADING:

Insert “L” or “T” Nails in the end of the Magazine as shown.

Pull Pusher Assembly back to engage Pusher to strip of Nails. The

Tool is now ready to operate.

PORTAMATIC® 472 Hammerhead S Stapler

STAPLE LOADING:

Pull Pusher back. Insert a clip of Staples. Push Pusher forward to

engage the Staple Clip. The Tool is now ready to operate.

LUBRICATION

Page 14

14

Frequent, but not excessive, lubrica on is required for best

performance. Oil added through the air line connec on will lubricate

the internal parts. Use Air Tool Lubricant, Mobil Velocite #10, or

equivalent. Do not use detergent oil or addi ves as these lubricants

will cause accelerated wear to the seals and Piston Cushion in

the tool, resul ng in poor tool performance and frequent tool

maintenance.

If no airline lubricator is used, add oil during use into the air fi ng

on the tool once or twice a day. Only a few drops of oil at a me are

necessary. Too much oil will only collect inside the tool and will be

no ceable in the exhaust cycle.

COLD WEATHER OPERATION:

For cold weather opera on, near and below freezing, the moisture in

the air line may freeze and prevent tool opera on. We recommend

the use of WINTER FORMULA air tool lubricant (NEW-MATIC Winter

Formula or equivalent) or permanent an freeze (ethylene glycol) as a

cold weather lubricant.

CAUTION: Do not store tools in a cold weather environment to

prevent frost or ice forma on on the tools opera ng valves and

mechanisms that could cause tool failure.

NOTE: Some commercial air line drying liquids are harmful to

O-rings and seals – do not use these low temperature air dryers

without checking compa bility.

19

SERVICING ASSEMBLY / DISASSEMBLY INSTRUCTIONS

Remove Ram Cap with Box Wrench.1.

Remove four (4) Socket Head Cap Screws. Take off Cap. Note 2.

presence of O-ring which remains in the Cap.

Remove four (4) Socket Head Cap Screws that connects the 3.

Plunger to the Poppet. Pull the Plunger out of the cylinder and

remove the O-ring.

Remove O-ring and clean ma ng surfaces on the Plunger and 4.

Poppet.

Remove four (4) Socket Head Cap Screws thus detaching the 5.

Shoe/Magazine Assembly from the Body.

Manually pull the rubber Piston Cushion out of the Body. Visually 6.

inspect the Piston Cushion for wear, deforma on and/or cracking.

If defec ve, replace.

Grasp the Driver Blade with thumb and forefi nger and pull out of 7.

cylinder Body. The Piston, Poppet and Piston Rod will follow.

Unscrew the Lock Nut from the Piston Rod. Do not deform the 8.

so aluminum part, use the Box Wrench. Slide the Piston off of

the Piston Rod.

Clean all parts with a clean dry rag.9.

Install new O-rings according to the accompanying drawing. Coat 10.

the O-rings, grooves, and cylinder walls evenly with grease and

install.

Reassemble the Poppet and Piston onto the Piston Rod. Insert 11.

the Driver Blade into the slot and pin into the hole. Thread the

Lock Nut un l it is exactly fl ush with the end of the Piston Rod.

Reinsert the Piston Rod followed by the Poppet, Piston and Driver

Blade in the Body.

Reinstall the Piston Cushion into the Body fl ush with the bo om.12.

Guide the Shoe/Magazine Assembly onto the Driver Blade and 13.

press up against the Body. Insert and ghten the four (4) Socket

Head Cap Screws through the Shoe and into the Body.

Returning to the top por on of the tool, reinstall the new Gasket 14.

onto the Plunger. Insert the Plunger with new O-ring into the

Body cylinder using an alignment tool / rod to align the four (4)

screw holes in the Plunger to the threaded holes in the Poppet.

Using Loc te on the threads, insert the four (4) new screws with 15.

spring washer and ghten the Plunger to the Poppet.

Reinstall new Cap.16.

Page 15

18

TROUBLE SHOOTING (Con nued)

PROBLEM CAUSE CORRECTION

Skipping fasteners;

intermi ent feed

(cont’d)

Broken/chipped driver Replace Driver (check

Piston O-ring)

Dry/dirty magazine Clean/lubricate use Air

Tool Lubricant

Worn magazine Replace magazine

Fasteners jam in tool Driver channel worn Replace nose/check door

Wrong size fasteners Use only recommended

fasteners

Bent fasteners Discon nue using these

fasteners

Loose magazine nose

screws

Tighten all screws

Broken/chipped driver Replace Driver (check

Piston O-ring)

15

MAINTAINING THE PNEUMATIC TOOL

When working on air tools, note the warnings in this manual and use

extra care evalua ng problem tools.

CAUTION: Pusher Spring (constant force spring). Cau on must be

used when working with the spring assembly. The spring is wrapped

around, but not a ached to a roller. If the spring is extended beyond

its length, the end will come off the roller and the spring will roll up

with a snap, with a chance of pinching your hand. Also, the edges

of the spring are very thin and could cut. Care must also be taken to

insure no permanent kinks are put in the spring as this will reduce

the spring’s force.

ASSEMBLY PROCEDURE FOR SEALS:

When repairing a tool, make sure the internal parts are clean and

lubricated. Use LITHIUM grease or equivalent on all O-rings. Coat

each O-ring with “O”-LUBE before assembling. Use a small amount

of oil on all moving surfaces and pivots. A er re-assembly, add a few

drops of Air Tool Lubricant through the air line fi ng before tes ng.

AIR SUPPLY-PRESSURE AND VOLUME:

Air volume is as important as air pressure. The air volume supplied

to the tool may be inadequate because of undersized fi ngs and

hoses or from the eff ects of dirt and water in the system. Restricted

air fl ow will prevent the tool from receiving an adequate volume of

air, even though the pressure reading is high. The results will be slow

opera on, jamming, miss-feeds or reduced driving power. Before

evalua ng tool problems for these symptoms, trace the air supply

from the tool to the supply source for restric ve connectors, swivel

fi ngs, low points containing water and anything else that would

prevent full volume fl ow of air to the tool.

DRIVER BLADE ASSEMBLY / REMOVAL:

Disconnect the air supply.1.

Remove the Ram Cap with box wrench.2.

Unscrew & remove Body Cap.3.

Unscrew the four Cap Screws holding the Plunger to the Poppet.4.

Pull the Plunger up and out of the Body Cavity.5.

Turn the tool over and remove the four Cap Screws that fasten 6.

the Shoe Assembly and the Magazine Assembly to the tool Body.

Remove the assemblies off the body.

Remove the rubber Piston Cushion.7.

Pull the Driver Blade Assembly out of the Body.8.

Page 16

16

Hold the Piston Rod with a box wrench over its Hex End and 9.

opposite the Lock Nut. Do not use Pliers anywhere on the metal

parts as they can damage the sealing surfaces.

Remove the Lock Nut, Pin and the Driver Blade.10.

Unscrew the Piston from the Piston Rod. Separate the Piston, 11.

Piston Rod and the Poppet.

TO REPLACE DRIVER BLADE:

Holding the piston rod with box wrench, remove the lock nut.1.

Push out the pin and remove the driver blade.2.

Install a new driver blade in the slot and replace the pin.3.

Screw on the Retaining Lock Nut using the same tools. If the lock 4.

nut becomes worn and loose a er frequent removals, it should

be replaced.

Check the fi t. There should be some sideways movement 5.

between the Driver Blade and the Lock nut assembly. This is

desirable and helps the Driver Blade to align itself with ma ng

parts.

Reassemble the components and be sure to align the Driver 6.

Blade with the slot in the Adapter Foot Assembly.

TO REPLACE DRIVER GUIDE PLATE AND NOSE:

Separate the Magazine form the Shoe by removing the four 1.

Socket Head Cap Screws.

Remove and replace the Driver Guide Plate and Nose.2.

17

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

Trigger valve housing

leaks air

O-ring cut or cracked Replace O-ring

Trigger valve stem

leaks air

O-ring/seals cut or

cracked

Replace trigger valve

assembly

Frame/nose leaks air Loose nose screws Tighten and recheck

O-ring is cut or cracked Replace O-ring

Piston Cushion is cracked/

worn

Replace Piston Cushion

Frame/cap leaks air Damaged seal Replace Seal

Loose cap screws Tighten and recheck

Failure to cycle Air supply restric on Check air supply

equipment

Tool dry, lack of

lubrica on

Use Air Tool Lubricant

Worn head valve O-rings Replace O-rings

Lack of power; slow to

cycle

Tool dry, lack of

lubrica on

Use Air Tool Lubricant

Broken cylinder cap

spring

Replace cap spring

O-rings/Seals cut or

cracked

Replace O-rings / Seals

Exhaust blocked Check Piston Cushion,

head valve spring, muffl er

Dirt/tar build up on driver Disassemble nose/driver

to clean

Head valve dry Disassemble / lubricate

Air pressure too low Check air supply

equipment

Skipping fasteners;

intermi ent feed

Worn Piston Cushion Replace Piston Cushion

Tar/Dirt in driver channel Disassemble and clean

nose and driver

Air restric on/inadequate

air fl ow through quick

disconnect socket and

plug

Replace quick disconnect

fi ngs

Worn piston O-ring Replace O-ring check

driver

Tool dry, lacks lubrica on Use Air Tool Lubricant

Damaged pusher spring Replace spring

Low air pressure Check air supply system

to tool

Loose magazine nose

screws

Tighten all screws

Fasteners too short for

tool

Use only recommended

fasteners

Bent fasteners Discon nue using these

fasteners

Wrong size fasteners Use only recommended

fasteners

Loading...

Loading...