Porta-Nails PORTAMATIC Owner's Manual

OWNER’S MANUAL

PORTAMATIC

®

Pneumatic Nailer

For Tongue and Groove Solid Wood & Hardwood

Laminate Flooring, Roof Decking and Wood Sub Flooring

CAUTION - Read important safety instructions AND operation instructions

BEFORE operating your PORTAMATIC® Pneumatic Nailer.

Your new PORTAMATIC® Pneumatic Nailer is a quality-built

machine, capable of dependable performance throughout its lifetime.

To take full advantage of these capabilities you should thoroughly

understand the proper method and technique of its operation.

Therefore, we suggest you read this manual before operating, and

PO Box 1257, Wilmington, NC 28402

910-762-6334 • 800-634-9281 • Fax 910-763-8650

that you save it for future reference.

Home Page:

www.porta-nails.com E-mail: www.info@porta-nails.com

For use with PORTAMATIC® Nailers Starting with Serial No. 00004000

FORM P/N 750209 (7/1/2004)

32

1

CAT. NO. 421

2

Specifications / Contents

Model 421 PORTAMATIC®

with Angled Shoe to be used for

installing 3/4”- 33/32” Tongue and

Groove Flooring, a Face Shoe to be

used for face nailing the first four (4)

rows and the last five (5) rows of

Tongue and Groove Flooring.

Package Contents Include:

PORTAMATIC® Nailer, Hammer,

Face Shoe, Owner’s Manual,

Wrenches, Safety Glasses, Carrying

Case.

CAT. NO. 422

Specifications / Contents

Model 421 PORTAMATIC®

with Angled Shoe to be used for

installing 3/4”- 33/32” Tongue and

Groove Flooring

Package Contents Include:

PORTAMATIC® Nailer,

Hammer, Owner’s Manual,

Wrenches, Safety Glasses.

PORTAMATIC® SPECIFICATIONS

ETL Listed: Control Num ber 9801577

US Patent Numbers: 6,095,392 & D419,048

Fastener Type: Use only Porta-Nails*

Operating Pressure: 90 P.S.I. (See Operating Instructions Pg. 8)

Firing Mode: Hammer Actuated

Jam Clearance: Lever Type, Quick Release Gate (See

Clearing a Jam Pgs. 10-11)

Dimensions: 19” High x 20” Long x 3” Wide

Weight: Approximately 13 LBS. (Tool Only)

*Porta-Nails Must Be Purchased Separately

31

30

NOTES:

3

PNI’s LIMITED ONE YEAR WARRANTY

PNI is proud of the products that it manufactures and warrants them to be free of

defects from workmanship and material for a period of 1 year from the date of original

purchase (Exceptions: rubber O-rings, Seals and Driver Blades). In the unlikely

event that a problem occurs, return the product to our plant freight prepaid and allowed,

so that a determination of the fault can be made. If the fault is determined to be

defective materials or workmanship, a no-charge replacement or repair will be made, at

our discretion. The product will be returned to you freight prepaid and allowed.

WARRANTY WILL BE VOID IF OIL IS USED IN TOOL

. This warranty does

not cover accidents, abuse or misuse and in no case will PNI be liable for incidental or

consequential damages. No other warranty written or verbal is authorized.

Returns for warranty service or repair must have a RMA number

prior to returning; contact Customer Service at 800-634-9281.

Returns should be sent to:

Porta-Nails, Inc. 4235 US Hwy. 421 N. Currie, NC 28435

Attention Service Dept.

Safety Instructions

1. KNOW YOUR POWER TOOL

Read the owner's manual

carefully. Learn its applications

and limitations as well as the

potential hazards specific to this

tool.

2. THE OPERATOR AND ALL

OTHER PERSONNEL MUST

WEAR PROPER EYE AND

EAR PROTECTION IN THE

WORK AREA.

Wear safety goggles at all times.

(Must comply with ANSI Z87.1).

Everyday eyeglasses have impact

resistant lenses only. They are

NOT safety glasses. Also, wear

ear protectors (plugs or muffs)

during extended periods of

operation

3. KEEP WORK AREA CLEAN

Cluttered areas and benches invite

accidents. Floor must not be

slippery due to sawdust.

4. KEEP CHILDREN AWAY

All visitors should be kept a safe

distance from work area.

5. WEAR PROPER APPAREL

Do not wear loose clothing, gloves,

neckties or jewelry (rings,

wristwatches) that could get caught

in moving parts. Wear non-slip

footwear. Wear protective hair

covering to contain long hair. Roll

long sleeves above the elbow.

6. SECURE WORK

Be sure the tongue and groove of

the flooring strips are properly

interlocked and secured in place

before nailing.

7. STAY ALERT

Watch what you are doing. Use

common sense. Do not operate

tool when you are tired or while

under the influence of medication,

alcohol or drugs.

4

29

8. ALWAYS INSPECT TOOL

BEFORE OPERATING.

Tool must be inspected prior to

use to insure proper use of power

supply. Tool must be inspected to

insure proper working order. An

improperly functioning tool must

not be used.

9. KEEP HANDS, FEET AND

OTHER BODY PARTS AWAY

FROM NAIL EJECTION

AREA.

Serious injury could occur if body

parts are not kept away from nail

ejection area.

10. ALWAYS ASSUME THE

TOOL CONTAINS

FASTENERS.

Do not activate the tool unless the

tool is placed firmly against the

work piece.

11. NO HORSEPLAY.

Do not point the tool toward

yourself or anyone whether it

contains fasteners or not.

12. NEVER DESENGAGE OR

RENDER THE SAFETY INOPERABLE.

13. NEVER TRANSPORT TOOL

WHILE DEPRESSING THE

TRIGGER.

14. DISCONNECT TOOL FROM

AIR SUPPLY WHEN:

Moving the tool to a new location,

performing any maintenance or

repair, clearing a jam or tool is

unattended.

15. NEVER SERVICE WHILE

ATTACHED TO AIR SUPPLY.

Always disconnect the tool from

the power source when servicing,

or replacing parts.

16. DO NOT USE TOOL IF

OPERATING CONTROLS

ARE INOPERABLE.

Do not remove, tamper with, or

otherwise cause the tool operating

controls or safety controls to

become inoperable.

17. DO NOT OPERATE TOOL IF

SAFETY FEATURES NOT

WORKING PROPERLY.

Disconnect tool from power source

if safety trigger or operating

controls are not working properly.

18. USE ONLY PORTA-NAIL

FASTENERS.

Only use fasteners recommended

by the manufacturer. Use of other

fasteners may cause serious injury,

jamming of tool or improper

operation.

19. USE ONLY PRESSURE-

REGULATED POWER

SOURCE.

Use only a pressure regulated

power source set at 125 PSI

maximum. The power so urce must

have a safety relief valve set at 135

PSI maximum.

20. THE TOOL SHOULD NOT BE

OPERATED AT THE

MAXIMUM AIR PRESSURE.

The tool air-line should be

connected to the power source

through an airline pressure

Regulator and an airline Filter.

The air line Regulator should never

be set higher than 110 PSI as

marked on the tool. Lower

pressures may be used as

recommended by the manufacturer.

21. HAZARDOUS POWER

SOURCES SHALL NOT BE

USED.

Hazardous power sources

including, but not limited to,

Oxygen, Combustible gases,

sources whose pressure can exceed

200 PSI if the pressure Regulator

fails, bottled gases, including air

should never be used.

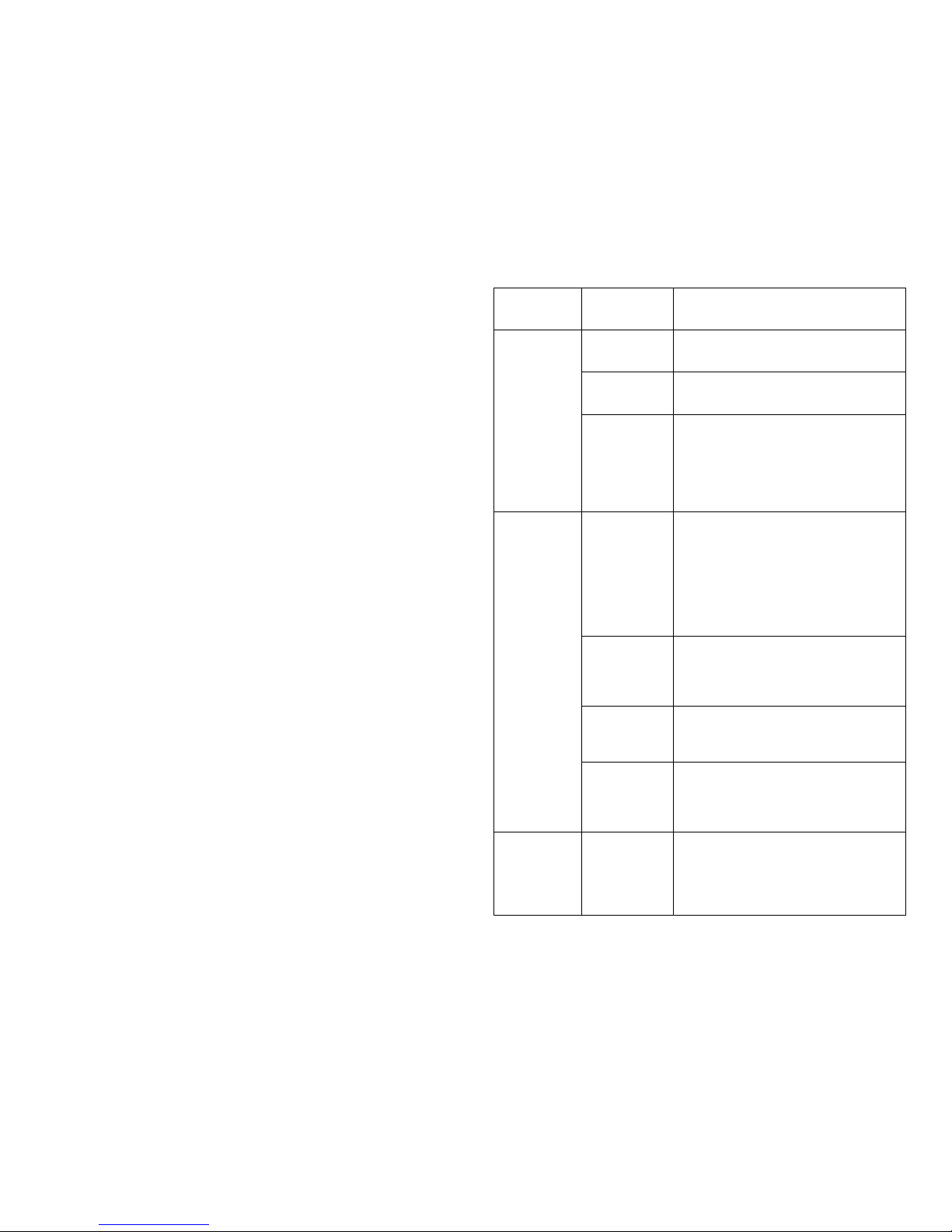

PROBLEM

OR

QUESTION

CAUSE CORRECTIVE ACTION

Ram is stuck

in down

position

Driver Blade

(Ref. #58)

could be bent

Check and replace if needed.

Oil could have

been used in the

tool

Clean, replace O-Rings and grease as

recommended in the Owner’s Manual.

Cylinder

Cushion Ring

(Ref. #5) could

be loose or

damaged or has

been installed

upside down.

Check Cylinder Cushion Ring (Ref. #5) and

replace if loose or damaged. Check for

proper installation. (See Figure 12)

Tool partially

fires when air

hose is

connected

Main Valve

(Ref. #41) is not

seating in Valve

Housing (Ref.

#46).

Check the Return Spring (Ref. #8) under the

Main Valve (Ref. #41) to make sure it is not

damaged and that the Return Spring Washers

(Ref. #3) are not damaged. Replace if

needed.

Check for smoothness and free movement of

the Main Valve (Ref. #41) in the Valve

Housing (Ref. #46). If too tight, replace the

O-Rings on the Main Valve.

O-Rings on the

Discharge

Valve (Ref.

#11) may be

damaged.

Check and replace if needed.

Discharge

Valve Springs

(Ref. #9) not

aligned

Check and re-align if needed.

Cylinder

Exhaust Valve

Screw (Ref.

#50) may be

loose.

Check and tighten if needed. Use

LOCTITE® 242 (Blue) on screw.

Nailer

partially fires

when trigger

is pulled and

before Ram is

struck

Main Valve Lip

Seal (Ref. #41)

is not sealing

Check Lip Seal. If damaged, replace Main

Valve (Ref. #41).

PROBLEM

OR

QUESTION

CAUSE CORRECTIVE ACTION

28

Nailer is

shooting two

nails.

End of Rail

(Ref. #26) is

worn.

Turn Rail (Ref. #26) around to use other

end in Guide if this has not been previously

done. If Rail has already been turned

previously, replace Rail.

Screws holding

Magazine (Ref.

#29) may be

loose

preventing Rail

(Ref. #26) from

being held

properly in

place.

Tighten Screws (Ref. #43, #29) that secure

the Magazine (Ref. #28) to the Guide (Ref.

#21) and the back Magazine Retainer

Bracket (Ref. #27).

Nails are not

being counter

sunk into

wood and are

left sticking

out of wood.

Not driving

Nails into the

tongue area

Always drive Nails into the tongue area, not

the groove.

Tip of Driver

Blade (Ref.

#58) broken

Check Driver Blade (Ref. #58) and replace

if tip is broken.

Air pressure

too low

Set air pressure to 100-110 PSI

Using air

compressor

that is too

small

Follow recommendations in the Owner’s

Manual relative to size and volume of air

compressor

Using an air

line that is too

small

Always use 3/8” ID air line.

The Piston

Cushion (Ref.

#10) could be

damaged

preventing the

Piston (Ref.

#56) from

completing full

stroke.

Check Piston Cushion (Ref. #10) and

replace if needed.

Nailer does

not fire when

trigger is

pulled.

This is a safety

feature

The Nailer is not supposed to fire when the

Trigger is pulled. In order to fire the Nailer,

the Trigger must be pulled and the Ram

Head (Ref. #47) struck with the hammer, in

that order.

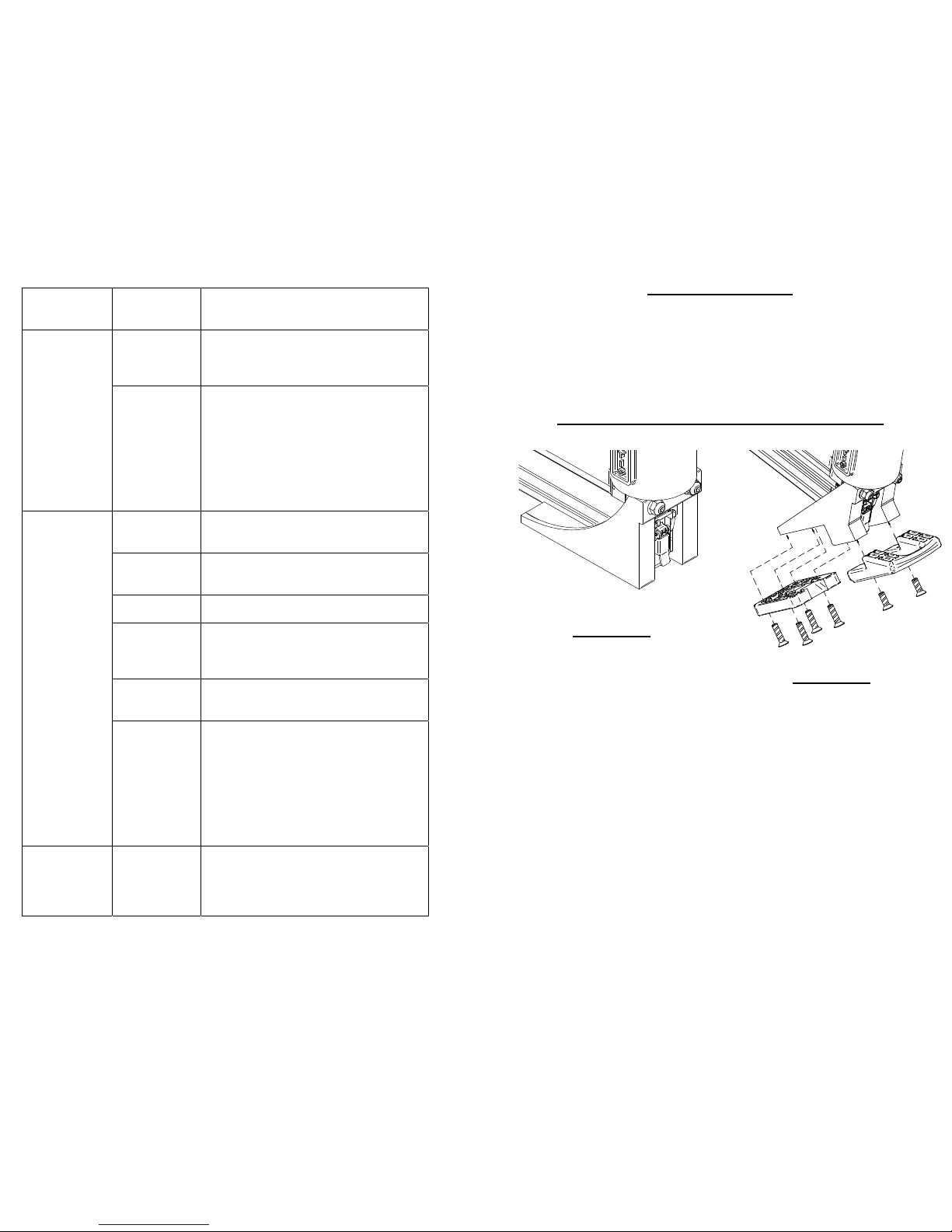

APPLICATIONS

Your model 421 PORTAMATIC® Nailer is designed for Face

Nailing and Angle Nailing 9/16”, 25/32”, and 33/32” Hardwood

Tongue and Groove Flooring. (See Shoe Accessory Applications

section)

PORTAMATIC

®

ACCESSORY SHOE APPLICATIONS

5

FIGURE 1

Face Nailing

Accessory Shoe Cat. No. 50477

FIGURE 2

Tongue Nailing 33/32”

Flooring

Shoe P/N 50125

Shoe Base P/N 50185 (Green)

Shoe Pad P/N 50182 (Green)

Loading...

Loading...