Porta-Nails 418A Operation And Safety Manual

www.porta

-

nails.com

800-634-9281

SAFETY TOPICS:

Tool Application:

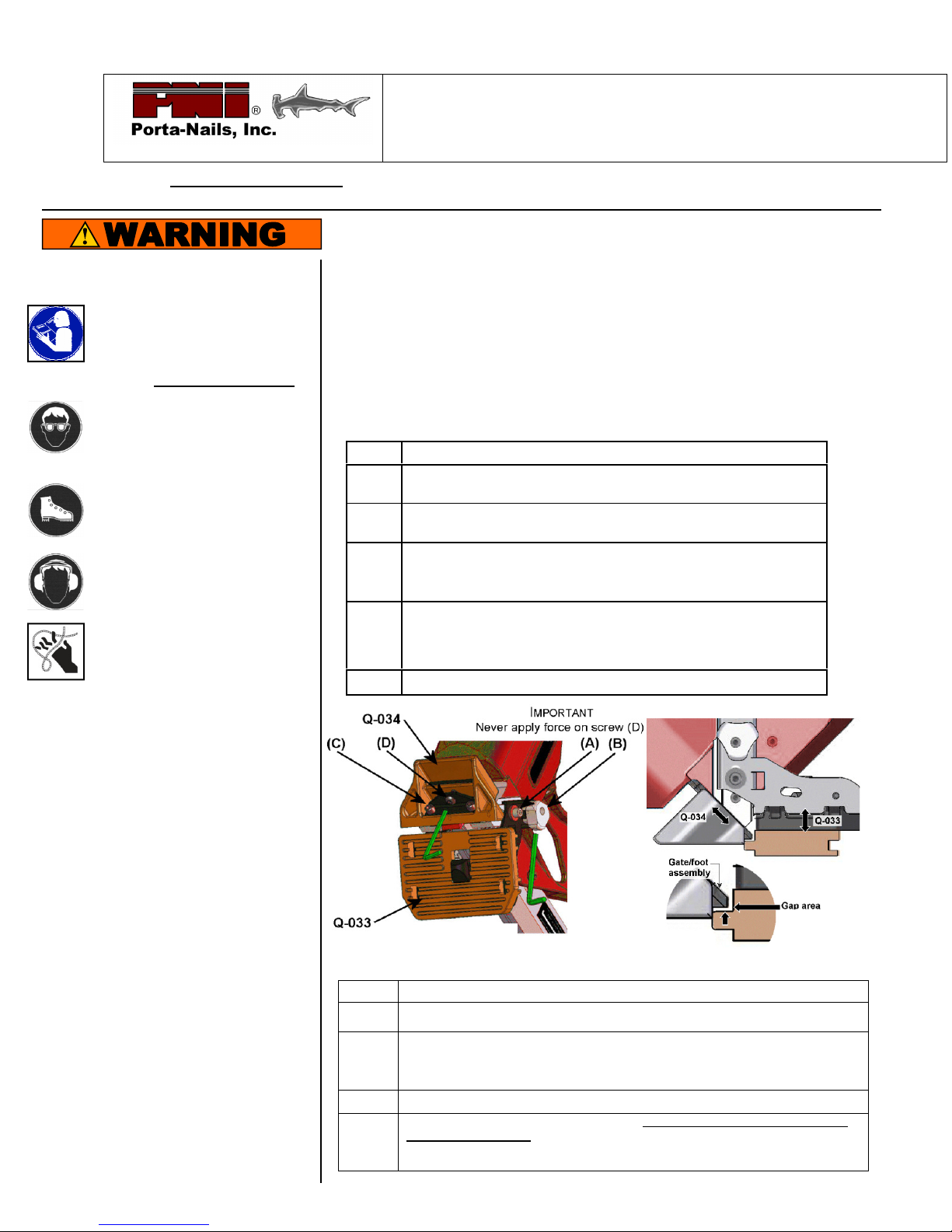

Using the supplied Allen wrench, loosen but do not remove screws (A); one

With the tool in an upside down position, place a short piece of flooring

Adjust the height of the shoe base to obtain a small gap between the

gate/foot assembly and the top side of the tongue of the sample board. A

gap of 1/32”, about half the thickness of the nail, should be adequate for

Operation and Safety Guide

Portamatic Evolution – 18ga. Wood Flooring Cleat Nailer

Model # 418A

Vendor Website:

Support Phone No.

ALWAYS refer to the owners

manual for complete safety and use

instructions. A copy is included with

the product or may be downloaded

by visiting www.porta-nails.com

ALWAYS wear OSHA-required Z-87

safety glasses with side shields

when using this or other pneumatic

and or hand tools

ALWAYS wear proper foot

protection while the air hose is

connected to the pneumatic tool.

ALWAYS wear proper ear

protection while the air supply is

connected to the pneumatic tool.

ALWAYS keep hands and body

away from the nail ejection area as

this may cause serious injury

.

.

SAFETY CHECKLIST:

Tool Operation: This tool is designed for fastening 3/8” – ¾” tongue and

groove flooring using 18ga flooring cleat nails. Operating air pressure is 70 to 85psi – never exceed 100psi.The 418A is fitted with a fully adjustable shoe

base designed to prevent contact with the top edge of the flooring. Because

this tool can be used on varying flooring dimensions it is important to adjust

the nailer to fit the flooring to be installed for proper nail placement prior to

any installation. It is necessary to adjust the Shoe Base Q-033 for the flooring

thickness and the Resting Block Q-034 for the flooring tongue. Follow these

instructions for proper adjustment:

Adjusting the Shoe Base Q-033 for Flooring Thickness

Step Action

1

2

3

4

5

These proper safety guidelines

should always be followed to

work safely with the pneumatic

nailer model 418A.

ALWAYS carry or manipulate the

tool by its handle while the air

supply hose is connected.

ALWAYS disconnect the air supply

when the tool is not in use.

ALWAYS handle the tool with care.

Never engage in horseplay.

ALWAYS make sure that the tool is

properly oriented with the work

surface.

DO NOT strike the head cap of the

actuator if shoe base is not sitting

perfectly on the work surface.

DO NOT service or attempt to repair

the tool, clear obstructions or make

adjustments while the air supply is

connected.

(E)

Adjusting the Resting Block Q-034 for Width of the Tongue

Step

1

2

3

4

Fastening Engineered and Solid Wood Flooring

on each side of the tool.

against the gate/foot assembly (E).

Engage the Allen wrench in knob (B) as shown in (Fig.1); rotate to move the

shoe base up or down. Note that knob (B) has a rotation range of only ½

turn. Do not apply force when a limit is reached.

most situations as shown in (Fig. 2).

Tighten both screws (A) to lock in position.

Fig. 1

Action

Using the Allen wrench, loosen by about ½ turn – do not remove the two screws

(C).

With the Short piece of flooring still against the gate/foot assembly, adjust the gap

between the resting block Q-034 and the flooring tongue with screw (D). A small

gap of 1/32”, about half the thickness of the nail, should be adequate for most

situations as shown in (Fig. 2).

Tighten both screws (C).

Ensure that screw (D) is slightly tightened. Do not apply force on the screw once

screw (C) is tightened.

After completing the adjustments procedure, proceed with the installation of

a few boards. Carefully check for the proper placement of the nail.

Fig. 2

Loading...

Loading...